Journal Description

NDT — Journal of Non-Destructive Testing

NDT

— Journal of Non-Destructive Testing is an international, peer-reviewed, open access journal on non-destructive testing published quarterly online by MDPI. The Faringdon Research Centre for Non-Destructive Testing and Remote Sensing (FCNDT&RS) is affiliated with NDT — Journal of Non-Destructive Testing and its members receive discounts on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 24.8 days after submission; acceptance to publication is undertaken in 5.7 days (median values for papers published in this journal in the first half of 2025).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

- Journal Cluster of Civil Engineering and Built Environment: Architecture, Buildings, CivilEng, Construction Materials, Infrastructures, Intelligent Infrastructure and Construction, NDT and Vibration.

Latest Articles

Elucidation of Electrical Characteristics for Apples (Malus domestica) Using Electrochemical Impedance Spectroscopy

NDT 2025, 3(4), 25; https://doi.org/10.3390/ndt3040025 - 19 Oct 2025

Abstract

Dielectric characterization offers valuable insights into fruit structure, ripening, and storage stability. However, systematic studies on apples are still limited. This work elucidates the electrical and physicochemical properties of a specific variety of apples, Malus domestica, using Electrochemical Impedance Spectroscopy (EIS), a

[...] Read more.

Dielectric characterization offers valuable insights into fruit structure, ripening, and storage stability. However, systematic studies on apples are still limited. This work elucidates the electrical and physicochemical properties of a specific variety of apples, Malus domestica, using Electrochemical Impedance Spectroscopy (EIS), a non-destructive, fast and cost-effective technique, suitable for real-time quality assessments. The apple samples were analyzed over the frequency range of 20 Hz–120 MHz at 25 °C, and impedance data were modeled using equivalent circuits and dielectric relaxation models. Physicochemical analyses confirmed a high moisture content (84%, wwb), pH 4.81, TSS 14.58 °Brix, and acidity 0.64%, which is typical of fresh Red Delicious apples. Impedance spectra revealed semicircular and Warburg elements in Nyquist plots, indicating resistive, capacitive, and diffusive processes. Equivalent circuit fitting with the proposed R-C-Warburg impedance model outperformed (R2 = 0.9946 and RMSE = 6.610) the classical Cole and Double-Shell models. The complex permittivity (ε) represented a frequency-dependent ionic diffusion, space-charge polarization, and dipolar relaxation decay, while electrical modulus analysis highlighted polarization and charge carrier dynamics. The translational hopping of charge carriers was confirmed through AC conductivity following Jonscher’s power law with an exponent of ƞ = 0.627. These findings establish a comprehensive dielectric profile and advanced circuit fitting for biological tissues, highlighting a promising non-invasive approach using EIS for real-time monitoring of fruit quality, with direct applications in post-harvest storage, supply chain management, and non-destructive quality assurance in the food industry.

Full article

(This article belongs to the Special Issue Non-Destructive Testing and Evaluation in Food Engineering)

►

Show Figures

Open AccessArticle

AI-Aided GPR Data Multipath Summation Using x-t Stacking Weights

by

Nikos Economou, Sobhi Nasir, Said Al-Abri, Bader Al-Shaqsi and Hamdan Hamdan

NDT 2025, 3(4), 24; https://doi.org/10.3390/ndt3040024 - 2 Oct 2025

Abstract

►▼

Show Figures

The Ground Penetrating Radar (GPR) method can image dielectric discontinuities in subsurface structures, which cause the reflection of electromagnetic (EM) waves. These discontinuities are imaged as reflectors in GPR sections, often distorted by diffracted energy. To focus the diffracted energy within the GPR

[...] Read more.

The Ground Penetrating Radar (GPR) method can image dielectric discontinuities in subsurface structures, which cause the reflection of electromagnetic (EM) waves. These discontinuities are imaged as reflectors in GPR sections, often distorted by diffracted energy. To focus the diffracted energy within the GPR sections, migration is commonly used. The migration velocity of GPR data is a low-wavenumber attribute crucial for effective migration. Obtaining a migration velocity model, typically close to a Root Mean Square (RMS) model, from zero-offset (ZO) data requires analysis of the available diffractions, whose density and (x, t) coverage are random. Thus, the accuracy and efficiency of such a velocity model, whether for migration or interval velocity model estimation, are not guaranteed. An alternative is the multipath summation method, which involves the weighted stacking of constant velocity migrated sections. Each stacked section contributes to the final stack, weighted by a scalar value dependent on the constant velocity value used and its relation to its estimated mean velocity of the section. This method effectively focuses the GPR diffractions in the presence of low heterogeneity. However, when the EM velocity varies dramatically, 2D weights are needed. In this study, with the aid of an Artificial Intelligence (AI) algorithm that detects diffractions and uses their kinematic information, we generate a diffraction velocity model. This model is then used to assign 2D weights for the weighted multipath summation, aiming to focus the scattered energy within the GPR section. We describe this methodology and demonstrate its application in enhancing the lateral continuity of reflections. We compare it with the 1D multipath summation using simulated data and present its application on marble assessment GPR data for imaging cracks and discontinuities in the subsurface structure.

Full article

Figure 1

Open AccessArticle

Skin Cancer Detection and Classification Through Medical Image Analysis Using EfficientNet

by

Sima Das and Rishabh Kumar Addya

NDT 2025, 3(4), 23; https://doi.org/10.3390/ndt3040023 - 26 Sep 2025

Abstract

►▼

Show Figures

Skin cancer is one of the most prevalent and potentially lethal cancers worldwide, highlighting the need for accurate and timely diagnosis. Convolutional neural networks (CNNs) have demonstrated strong potential in automating skin lesion classification. In this study, we propose a multi-class classification model

[...] Read more.

Skin cancer is one of the most prevalent and potentially lethal cancers worldwide, highlighting the need for accurate and timely diagnosis. Convolutional neural networks (CNNs) have demonstrated strong potential in automating skin lesion classification. In this study, we propose a multi-class classification model using EfficientNet-B0, a lightweight yet powerful CNN architecture, trained on the HAM10000 dermoscopic image dataset. All images were resized to 224 × 224 pixels and normalized using ImageNet statistics to ensure compatibility with the pre-trained network. Data augmentation and preprocessing addressed class imbalance, resulting in a balanced dataset of 7512 images across seven diagnostic categories. The baseline model achieved 77.39% accuracy, which improved to 89.36% with transfer learning by freezing the convolutional base and training only the classification layer. Full network fine-tuning with test-time augmentation increased the accuracy to 96%, and the final model reached 97.15% when combined with Monte Carlo dropout. These results demonstrate EfficientNet-B0’s effectiveness for automated skin lesion classification and its potential as a clinical decision support tool.

Full article

Figure 1

Open AccessArticle

AI-Driven Energy-Efficient Data Aggregation and Routing Protocol Modeling to Maximize Network Lifetime in Wireless Sensor Networks

by

R. Arun Chakravarthy, C. Sureshkumar, M. Arun and M. Bhuvaneswari

NDT 2025, 3(4), 22; https://doi.org/10.3390/ndt3040022 - 25 Sep 2025

Abstract

►▼

Show Figures

The research work presents an artificial intelligence-driven, energy-aware data aggregation and routing protocol for wireless sensor networks (WSNs) with the primary objective of extending overall network lifetime. The proposed scheme leverages reinforcement learning in conjunction with deep Q-networks (DQNs) to adaptively optimize both

[...] Read more.

The research work presents an artificial intelligence-driven, energy-aware data aggregation and routing protocol for wireless sensor networks (WSNs) with the primary objective of extending overall network lifetime. The proposed scheme leverages reinforcement learning in conjunction with deep Q-networks (DQNs) to adaptively optimize both Cluster Head (CH) selection and routing decisions. An adaptive clustering mechanism is introduced wherein factors such as residual node energy, spatial proximity, and traffic load are jointly considered to elect suitable CHs. This approach mitigates premature energy depletion at individual nodes and promotes balanced energy consumption across the network, thereby enhancing node sustainability. For data forwarding, the routing component employs a DQN-based strategy to dynamically identify energy-efficient transmission paths, ensuring reduced communication overhead and reliable sink connectivity. Performance evaluation, conducted through extensive simulations, utilizes key metrics including network lifetime, total energy consumption, packet delivery ratio (PDR), latency, and load distribution. Comparative analysis with baseline protocols such as LEACH, PEGASIS, and HEED demonstrates that the proposed protocol achieves superior energy efficiency, higher packet delivery reliability, and lower packet losses, while adapting effectively to varying network dynamics. The experimental outcomes highlight the scalability and robustness of the protocol, underscoring its suitability for diverse WSN applications including environmental monitoring, surveillance, and Internet of Things (IoT)-oriented deployments.

Full article

Figure 1

Open AccessArticle

Real-Time Industrial Water Pollution Evaluation Using Edge–Cloud IoT Architecture and Multi-Parameter Sensing

by

Anwar Ali Sathio, Vijay Singh, Saeed Anwar and Raja Vavekanand

NDT 2025, 3(3), 21; https://doi.org/10.3390/ndt3030021 - 9 Sep 2025

Abstract

►▼

Show Figures

The escalating concerns regarding environmental pollution, particularly industrial water pollution, have necessitated the development of advanced monitoring systems to ensure water resource safety and sustainability. This paper presents an innovative IoT-based Industrial Water Pollution Evaluation System that integrates sensor networks, communication technologies, and

[...] Read more.

The escalating concerns regarding environmental pollution, particularly industrial water pollution, have necessitated the development of advanced monitoring systems to ensure water resource safety and sustainability. This paper presents an innovative IoT-based Industrial Water Pollution Evaluation System that integrates sensor networks, communication technologies, and data analytics to provide real-time, comprehensive water quality assessment in industrial environments. Our system employs an ESP32 microcontroller connected to four critical sensors (pH, temperature, turbidity, and TDS) to monitor water quality parameters continuously. The collected data is transmitted to a cloud platform and visualized through a dedicated Android application, enabling proactive pollution control measures. Experimental results demonstrate the system’s effectiveness in detecting various pollution scenarios with high accuracy. This solution addresses the limitations of traditional monitoring methods by offering cost-effective, real-time monitoring capabilities that support sustainable water management practices in industrial settings.

Full article

Figure 1

Open AccessArticle

Contrast-Enhanced OCT for Damage Detection in Polymeric Resins Embedded with Metallic Nanoparticles via Surface Plasmon Resonance

by

Maha Hadded, Thiago Luiz Lara Oliveira, Olivier Debono, Emilien Bourdon and Alan Jean-Marie

NDT 2025, 3(3), 20; https://doi.org/10.3390/ndt3030020 - 25 Aug 2025

Abstract

►▼

Show Figures

Nanoparticle-embedded polymeric materials are an important subject in advanced structural applications due to their advantageous combination of low weight and high mechanical performance. Optical coherence tomography (OCT) is a high-resolution imaging technique that enables subsurface defect visualization, which can be used as one

[...] Read more.

Nanoparticle-embedded polymeric materials are an important subject in advanced structural applications due to their advantageous combination of low weight and high mechanical performance. Optical coherence tomography (OCT) is a high-resolution imaging technique that enables subsurface defect visualization, which can be used as one of the methods to reveal defects resulting from decomposition pathways or mechanisms of polymers. Nevertheless, the low contrast of polymeric materials, particularly PEEK-based polymers, does not allow for automatic geometry extraction for analytical input. To address the constraint of weak contrast, localized surface plasmon resonance (LSPR) of plasmonic nanoparticle-reinforced polymer materials has been used as an OCT contrast agent to provide the necessary contrast. The backscattering efficiency of light was also theoretically investigated, based on the Lorenz–Mie theory, with a single spherical nanoparticle embedded in a PEEK matrix as a non-absorptive, isotropic and homogeneous medium. In this study, the cases of a single homogeneous

Figure 1

Open AccessArticle

Terrain-Integrated Soil Mapping Units (SMUs) for Precision Nutrient Management: A Case Study from Semi-Arid Tropics of India

by

Gopal Tiwari, Ram Prasad Sharma, Sudipta Chattaraj, Abhishek Jangir, Benukantha Dash, Lal Chand Malav, Brijesh Yadav and Amrita Daripa

NDT 2025, 3(3), 19; https://doi.org/10.3390/ndt3030019 - 7 Aug 2025

Abstract

►▼

Show Figures

This study presents a terrain-integrated Soil Management Unit (SMU) framework for precision agriculture in semi-arid tropical basaltic soils. Using high resolution (10-ha grid) sampling across 4627 geo-referenced locations and machine learning-enhanced integration of terrain attributes with legacy soil maps, and (3) quantitative validation

[...] Read more.

This study presents a terrain-integrated Soil Management Unit (SMU) framework for precision agriculture in semi-arid tropical basaltic soils. Using high resolution (10-ha grid) sampling across 4627 geo-referenced locations and machine learning-enhanced integration of terrain attributes with legacy soil maps, and (3) quantitative validation of intra-SMU homogeneity, 15 SMUs were delineated based on landform, soil depth, texture, and slope. Principal Component Analysis (PCA) revealed SMU11 as the most heterogeneous (68.8%). Geo-statistical analysis revealed structured variability in soil pH (range = 1173 m) and nutrients availability with micronutrient sufficiency following Mn > Fe > Cu > Zn, (Zn deficient in SMU13). Organic carbon strongly correlated with key nutrients (AvK, r = 0.83 and Zn, r = 0.86). This represents the first systematic implementation of terrain-integrated SMU delineation in India’s basaltic landscapes, demonstrating a potential for 20–25% input savings. The spatially explicit fertility-integrated SMU framework provides a robust basis for developing decision support systems aimed at optimizing location-specific nutrient and land management strategies.

Full article

Figure 1

Open AccessArticle

Effect of Graphene Oxide on the Durability Properties of Poor-Quality Concrete Through Integrated Non-Destructive Testing

by

Jose A. Cabello-Mendez, Abraham Lopez-Miguel, Jose T. Perez-Quiroz, Alejandro Moreno-Valdes, Jose M. Machorro-Lopez and Ilse C. Castillo-Arteaga

NDT 2025, 3(3), 18; https://doi.org/10.3390/ndt3030018 - 19 Jul 2025

Abstract

►▼

Show Figures

Concrete is the most important construction material, and improving its durability properties is a topic in constant development owing to the economic costs that the degradation of concrete implies. Different nanoparticles have been reported to improve concrete durability, although the positive results are

[...] Read more.

Concrete is the most important construction material, and improving its durability properties is a topic in constant development owing to the economic costs that the degradation of concrete implies. Different nanoparticles have been reported to improve concrete durability, although the positive results are not a generality. Among these nanomaterials, graphene oxide stands out as an option for improving concrete properties, such as its compressive strength, which could increase the useful life of concrete infrastructure. This study addresses the effects of graphene oxide on the durability properties of concrete, with the aim of obtaining data on the viability of graphene oxide as an additive in concrete. The incorporation of graphene oxide into concrete was carried out through graphene oxide suspensions that were incorporated into concrete mixtures with a high water/cement ratio. The characterization of concrete was done using non-destructive testing such as ultrasonic pulse velocity, electrical resistivity, porosity, capillary absorption, chloride ion permeability, and other characterization methods such as compressive strength, XPS, SEM, and EDS. Together, these tests provided an overview of the concrete durability properties that are improved, affected, or unchanged by the presence of graphene oxide. In this study, a chemical analysis was also carried out on concrete modified with graphene oxide. The results show that graphene oxide improves the compressive strength of concrete, but the effect on durability properties is negligible; however, there are indications that, in combination with other additives, improvements can be achieved, so it is advisable to continue with these studies.

Full article

Figure 1

Open AccessArticle

Bridging NDT and Laboratory Testing in an Airfield Pavement Structural Evaluation

by

Angeliki Armeni

NDT 2025, 3(3), 17; https://doi.org/10.3390/ndt3030017 - 10 Jul 2025

Abstract

►▼

Show Figures

The accurate assessment of the structural condition of airfield pavements is of paramount importance to airport authorities as it determines the planning of maintenance activities. On this basis, Non-Destructive Testing (NDT) techniques provide a powerful tool to assess the mechanical properties of the

[...] Read more.

The accurate assessment of the structural condition of airfield pavements is of paramount importance to airport authorities as it determines the planning of maintenance activities. On this basis, Non-Destructive Testing (NDT) techniques provide a powerful tool to assess the mechanical properties of the individual layers of the pavement. However, information from laboratory testing of cores taken from the pavement is expected to provide a more accurate assessment of material properties. Against this background, the present research aims to investigate the accuracy of the mechanical properties of in-situ layers derived from NDT data and the associated back-calculation procedures for airfield pavements, where higher pavement thicknesses are usually required due to the high aircraft loads, while few similar studies have been conducted compared to road pavements. For this reason, the assessment of the structural condition of a flexible runway pavement is presented. The analysis shows that there is a strong correlation between the moduli estimated in the laboratory and the moduli estimated by back-calculation. Furthermore, the back-calculated moduli appear to lead to a conservative approach in assessing the structural condition of the pavement. This conservatism promotes a more proactive pavement management by airport authorities.

Full article

Figure 1

Open AccessArticle

Artificial Intelligence for Forensic Image Analysis in Bullet Hole Comparison: A Preliminary Study

by

Guilherme Pina Cardim, Thiago de Souza Duarte, Henrique Pina Cardim, Wallace Casaca, Rogério Galante Negri, Flávio Camargo Cabrera, Renivaldo José dos Santos, Erivaldo Antônio da Silva and Mauricio Araujo Dias

NDT 2025, 3(3), 16; https://doi.org/10.3390/ndt3030016 - 8 Jul 2025

Cited by 1

Abstract

►▼

Show Figures

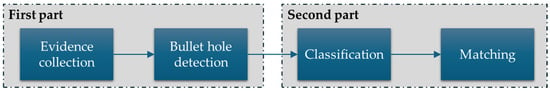

The application of artificial intelligence within forensic image analysis marks a significant step forward for the non-destructive examination of evidence, a crucial practice for maintaining the integrity of a crime scene. While non-destructive testing (NDT) methods are established, the integration of AI, particularly

[...] Read more.

The application of artificial intelligence within forensic image analysis marks a significant step forward for the non-destructive examination of evidence, a crucial practice for maintaining the integrity of a crime scene. While non-destructive testing (NDT) methods are established, the integration of AI, particularly for analyzing ballistic evidence, requires further exploration. This preliminary study directly addresses this gap by focusing on the use of deep learning to automate the analysis of bullet holes. This work investigated the performance of two state-of-the-art convolutional neural networks (CNNs), YOLOv8 and R-CNN, for detecting ballistic markings in digital images. The approach treats digital image analysis itself as a form of non-destructive testing, thereby preserving the original evidence. The findings demonstrate the potential of AI to augment forensic investigations by providing an objective, data-driven alternative to traditional assessments and increasing the efficiency of evidence processing. This research confirms the feasibility and relevance of leveraging advanced AI models to develop powerful new tools for Forensic Science. It is expected that this study will contribute worldwide to help (1) the police indict criminals and prove innocence; (2) the justice system judges and proves people guilty of their crimes.

Full article

Figure 1

Open AccessArticle

An Investigation of GNSS Radio Occultation Data Pattern for Temperature Monitoring and Analysis over Africa

by

Usman Sa’i Ibrahim, Kamorudeen Aleem, Tajul Ariffin Musa, Terwase Tosin Youngu, Yusuf Yakubu Obadaki, Wan Anom Wan Aris and Kelvin Tang Kang Wee

NDT 2025, 3(2), 15; https://doi.org/10.3390/ndt3020015 - 18 Jun 2025

Abstract

►▼

Show Figures

Climate change monitoring and analysis is a critical task that involves the consideration of both spatial and temporal dimensions. Theimproved spatial distribution of the global navigation satellite system (GNSS) ground-based Continuous Operating Reference (COR) stations can lead to enhanced results when coupled with

[...] Read more.

Climate change monitoring and analysis is a critical task that involves the consideration of both spatial and temporal dimensions. Theimproved spatial distribution of the global navigation satellite system (GNSS) ground-based Continuous Operating Reference (COR) stations can lead to enhanced results when coupled with a continuous flow of data over time. In Africa, a significant number of COR stations do not operate continuously and lack collocation with meteorological sensors essential for climate studies. Consequently, Africa faces challenges related to inadequate spatial distribution and temporal data flow from GNSS ground-based stations, impacting climate change monitoring and analysis. This research delves into the pattern of GNSS radio occultation (RO) data across Africa, addressing the limitations of the GNSS ground-based data for climate change research. The spatial analysis employed Ripley’s F-, G-, K-, and L-functions, along with calculations of nearest neighbour and Kernel density. The analysis yielded a Moran’s p-value of 0.001 and a Moran’s I-value approaching 1.0. For temporal analysis, the study investigated the data availability period of selected GNSS RO missions. Additionally, it examined seasonal temperature variations from May 2001 to May 2023, showcasing alignment with findings from other researchers worldwide. Hence, this study suggests the utilisation of GNSS RO missions/campaigns like METOP and COSMIC owing to their superior spatial and temporal resolution.

Full article

Figure 1

Open AccessArticle

Evaluation of Cold Rolling and Annealing Behavior of Extra-Low-Carbon Steel by Magnetic NDE Parameters

by

Siuli Dutta, Ashis K. Panda and Rajat K. Roy

NDT 2025, 3(2), 14; https://doi.org/10.3390/ndt3020014 - 11 Jun 2025

Cited by 1

Abstract

►▼

Show Figures

This study intends to understand the effect of annealing behavior on the microstructure and mechanical and magnetic properties of cold-rolled extra-low-carbon steel. Deformed steel samples are annealed at temperature ranges of 200–690 °C followed by air-cooling. As part of this study, Magnetic Hysteresis

[...] Read more.

This study intends to understand the effect of annealing behavior on the microstructure and mechanical and magnetic properties of cold-rolled extra-low-carbon steel. Deformed steel samples are annealed at temperature ranges of 200–690 °C followed by air-cooling. As part of this study, Magnetic Hysteresis loop (MHL) and Barkhausen emission (MBE) measurements are carried out for non-destructive evaluation (NDE) of the mechanical properties that are altered during annealing, viz. recovery and recrystallization. At low annealing temperature ranges 200 < T < 550 °C, the recovery causes no substantial variations in microstructure, hardness value from 191–185 HV, and tensile strength 456–452 MPa, while magnetic coercivity decreases from 293–275 A/m for cold-rolled annealed steels. The microstructural changes due to recovery and recrystallization are examined using transmission electron microscopy and orientation imaging microscopy (OIM) through electron backscattered diffraction (EBSD). Recrystallization is found after annealing at T > 550 °C, confirmed by the lowering of the microstructural KAM value from 0.81° to 0.65° and a hardness drop from 190.02 to 98 HV for cold-rolled extra-low-carbon steel.

Full article

Figure 1

Open AccessCommunication

Preliminary Assessment of Quantitative Phase Analysis from Focal Construct Tomography

by

Varsha Samuel, Daniel Spence, Liam Farmer, Simon Godber, Keith Rogers and Anthony Dicken

NDT 2025, 3(2), 13; https://doi.org/10.3390/ndt3020013 - 11 Jun 2025

Abstract

►▼

Show Figures

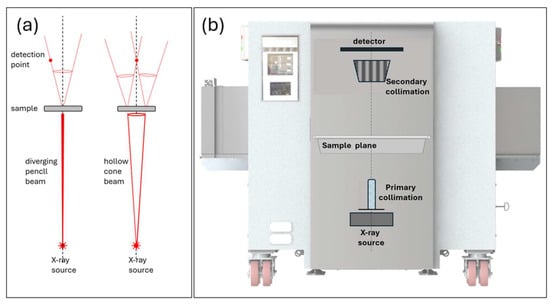

New methods for real-time materials phase identification based upon focal construct tomography (FCT) have been examined. Such quantitative assessment has significant potential in sectors where in-line analysis is required, including screening within aviation security. As a recent component of work programs developing FCT,

[...] Read more.

New methods for real-time materials phase identification based upon focal construct tomography (FCT) have been examined. Such quantitative assessment has significant potential in sectors where in-line analysis is required, including screening within aviation security. As a recent component of work programs developing FCT, its capability for accurate, quantitative analysis has been assessed for the first time. Diffraction signatures from mixed-phase materials were acquired from an energy-dispersive FCT system running under normal operational conditions. A calibration curve was constructed from the spectra and subsequently employed to assess the composition of ‘blind’ samples. The results demonstrated that this approach was able to precisely predict the polymorphic phase composition of samples to ±5 wt%. Conclusions: The potential impact of these findings is significant and will enable applications of FCT beyond those requiring a phase identification to those necessitating quantification, such as counterfeit medicines, pharmaceutical quality assurance, aging of explosives, and cement production.

Full article

Figure 1

Open AccessArticle

Identifying Ultrasonic Testing Based Nondestructive Qualification Parameters for Laser DED Processed IN718

by

Guillermo Huanes-Alvan, Himanshu Sahasrabudhe and Sunil Kishore Chakrapani

NDT 2025, 3(2), 12; https://doi.org/10.3390/ndt3020012 - 5 Jun 2025

Abstract

►▼

Show Figures

This article explores the use of ultrasonic nondestructive evaluation for qualification of laser-DED IN718 samples. The main goal of this article is to identify potential ultrasonic parameters which have highest sensitivity to microstructral changes that result from fabrication of DED samples. The ultrasonic

[...] Read more.

This article explores the use of ultrasonic nondestructive evaluation for qualification of laser-DED IN718 samples. The main goal of this article is to identify potential ultrasonic parameters which have highest sensitivity to microstructral changes that result from fabrication of DED samples. The ultrasonic qualification parameters were extracted from ultrasonic testing including velocity and attenuation measurement, and C-Scan imaging. These measurements were further used to extract parameters that quantify the anisotropy, microstructural heterogeneity, and grain scattering. Two laser-DED IN718 samples fabricated with slightly different processing parameters were evaluated to observe the influence of the laser power and scan speed on the qualification parameters. The identified qualification parameters were compared for these two samples, along with a hot-rolled sample that was also used as reference. The results suggest that the anisotropy, attenuation, and heterogeneity were highest in the DED samples compared to the reference sample. The identified qualification parameters seem to capture these changes, suggesting they could be potentially used for qualification of AM parts.

Full article

Figure 1

Open AccessArticle

Enhancing Dermatological Diagnosis Through Medical Image Analysis: How Effective Is YOLO11 Compared to Leading CNN Models?

by

Rakib Ahammed Diptho and Sarnali Basak

NDT 2025, 3(2), 11; https://doi.org/10.3390/ndt3020011 - 21 May 2025

Cited by 1

Abstract

►▼

Show Figures

Skin diseases represent a major worldwide health hazard affecting millions of people yearly and substantially compromising healthcare systems. Particularly in areas where dermatologists are scarce, standard diagnostic techniques, which mostly rely on visual inspection and clinical experience, are frequently subjective, time-consuming, and prone

[...] Read more.

Skin diseases represent a major worldwide health hazard affecting millions of people yearly and substantially compromising healthcare systems. Particularly in areas where dermatologists are scarce, standard diagnostic techniques, which mostly rely on visual inspection and clinical experience, are frequently subjective, time-consuming, and prone to mistakes. This investigation undertakes a comparative analysis of four state-of-the-art deep learning architectures, YOLO11, YOLOv8, VGG16, and ResNet50, in the context of skin disease identification. This study evaluates the performance of these models using pivotal metrics, building upon the foundation of the YOLO paradigm, which revolutionized spatial attention and multi-scale representation. A properly selected collection of 900 high-quality dermatological images with nine disease categories was used for investigation. Robustness and generalizability were guaranteed by using data augmentation and hyperparameter adjustment. By varying benchmark models in balancing accuracy and recall while limiting false positives and false negatives, YOLO11 obtained a test accuracy of 80.72%, precision of 88.7%, recall of 86.7%, and an F1 score of 87.0%. The expedition performance of YOLO11 signifies a promising trajectory in the development of highly accurate skin disease detection models. Our analysis not only highlights the strengths and weaknesses of the model but also underscores the rapid development of deep learning techniques in medical imaging.

Full article

Figure 1

Open AccessReview

Precision Weed Control Using Unmanned Aerial Vehicles and Robots: Assessing Feasibility, Bottlenecks, and Recommendations for Scaling

by

Shanmugam Vijayakumar, Palanisamy Shanmugapriya, Pasoubady Saravanane, Thanakkan Ramesh, Varunseelan Murugaiyan and Selvaraj Ilakkiya

NDT 2025, 3(2), 10; https://doi.org/10.3390/ndt3020010 - 16 May 2025

Cited by 2

Abstract

Weeds cause significant yield and economic losses by competing with crops and increasing production costs. Compounding these challenges are labor shortages, herbicide resistance, and environmental pollution, making weed management increasingly difficult. In response, precision weed control (PWC) technologies, such as robots and unmanned

[...] Read more.

Weeds cause significant yield and economic losses by competing with crops and increasing production costs. Compounding these challenges are labor shortages, herbicide resistance, and environmental pollution, making weed management increasingly difficult. In response, precision weed control (PWC) technologies, such as robots and unmanned aerial vehicles (UAVs), have emerged as innovative solutions. These tools offer farmers high precision (±1 cm spatial accuracy), enabling efficient and sustainable weed management. Herbicide spraying robots, mechanical weeding robots, and laser-based weeders are deployed on large-scale farms in developed countries. Similarly, UAVs are gaining popularity in many countries, particularly in Asia, for weed monitoring and herbicide application. Despite advancements in robotic and UAV weed control, their large-scale adoption remains limited. The reasons for this slow uptake and the barriers to widespread implementation are not fully understood. To address this knowledge gap, our review analyzes 155 articles and provides a comprehensive understanding of PWC challenges and needed interventions for scaling. This review revealed that AI-driven weed mapping in robots and UAVs struggles with data (quality, diversity, bias) and technical (computation, deployment, cost) barriers. Improved data (collection, processing, synthesis, bias mitigation) and efficient, affordable technology (edge/hybrid computing, lightweight algorithms, centralized computing resources, energy-efficient hardware) are required to improve AI-driven weed mapping adoption. Specifically, robotic weed control adoption is hindered by challenges in weed recognition, navigation complexity, limited battery life, data management (connectivity), fragmented farms, high costs, and limited digital literacy. Scaling requires advancements in weed detection and energy efficiency, development of affordable robots with shared service models, enhanced farmer training, improved rural connectivity, and precise engineering solutions. Similarly, UAV adoption in agriculture faces hurdles such as regulations (permits), limited payload and battery life, weather dependency, spray drift, sensor accuracy, lack of skilled operators, high initial and operational costs, and absence of standardized protocol. Scaling requires financing (subsidies, loans), favorable regulations (streamlined permits, online training), infrastructure development (service providers, hiring centers), technological innovation (interchangeable sensors, multipurpose UAVs), and capacity building (farmer training programs, awareness initiatives).

Full article

(This article belongs to the Special Issue Remote Sensing and Non-Destructive Testing Solutions for Sustainable Development and Urban Resilience)

►▼

Show Figures

Figure 1

Open AccessArticle

Modal Passport Concept for Enhanced Non-Destructive Monitoring and Diagnostics of Wind Turbine Blades

by

Aleksey Mironov, Pavel Doronkin and Aleksejs Safonovs

NDT 2025, 3(2), 9; https://doi.org/10.3390/ndt3020009 - 30 Apr 2025

Abstract

One of the most sensitive parts of a wind turbine to environmental influences are the rotating blades. Today, there are many technologies available to assess blade condition, but they all need to be developed to become more cost-effective and more sensitive to fault

[...] Read more.

One of the most sensitive parts of a wind turbine to environmental influences are the rotating blades. Today, there are many technologies available to assess blade condition, but they all need to be developed to become more cost-effective and more sensitive to fault detection. The algorithms and methods of the modal passport discussed in this paper propose a non-destructive technique already used for helicopter blade condition monitoring and diagnostics. This technique requires adaptation to wind turbine blades because they have larger dimensions, other materials and design, and operate under other conditions. To provide this adaptation, computational and experimental data on the modal properties of the blades must be obtained. The first stage of the study is planned to be performed on a scale model on stationary and rotating test rigs. At this stage of the study, algorithms and methods for the formation of a roadmap to develop a modal passport for a series of composite models of a wind turbine blade are considered. The initial stage of modal passport development included FE modeling of the blade model, calculation of modal parameters, fabricating the blades, and preparing the test equipment. Quantitative assessment of modal tests volume made it possible to plan the step-by-step execution of the roadmap for development and experimental application of the modal passport of wind turbine blade models.

Full article

(This article belongs to the Topic Nondestructive Testing and Evaluation)

►▼

Show Figures

Figure 1

Open AccessArticle

Development of an Integrated Software Framework for Enhanced Hybrid Simulation in Structural Testing

by

Gidewon G. Tekeste, António A. Correia and Aníbal G. Costa

NDT 2025, 3(2), 8; https://doi.org/10.3390/ndt3020008 - 15 Apr 2025

Abstract

►▼

Show Figures

Hybrid simulation integrates numerical and experimental techniques to analyze structural responses under static and dynamic loads. It physically tests components that are not fully characterized while modeling the rest of the structure numerically. Over the past two decades, hybrid testing platforms have become

[...] Read more.

Hybrid simulation integrates numerical and experimental techniques to analyze structural responses under static and dynamic loads. It physically tests components that are not fully characterized while modeling the rest of the structure numerically. Over the past two decades, hybrid testing platforms have become increasingly modular and versatile. This paper presents the development of a robust hybrid testing software framework at the National Laboratory for Civil Engineering (LNEC), Portugal, and evaluates the efficiency of its algorithms. The framework features a LabVIEW-based control and interface application that exchanges data with OpenSees via the OpenFresco middleware using a TCP/IP protocol. Designed for slow to real-time hybrid testing, it employs a predictor–corrector algorithm for motion control, enhanced by an adaptive time series (ATS)-based error tracking and delay compensation algorithm. Its modular design facilitates the integration of new simulation tools. The framework was first assessed through simulated hybrid tests, followed by validation via a hybrid test on a two-bay, one-story steel moment-resisting frame, where one exterior column was physically tested. The results emphasized the importance of the accurate system identification of the physical substructure and the precise calibration of the actuator control and delay compensation algorithms.

Full article

Figure 1

Open AccessTechnical Note

Leveraging Variable Frequency Drive Data for Nondestructive Testing and Predictive Maintenance in Industrial Systems

by

Carl Lee Tolbert

NDT 2025, 3(2), 7; https://doi.org/10.3390/ndt3020007 - 24 Mar 2025

Cited by 2

Abstract

►▼

Show Figures

Nondestructive testing (NDT) has a crucial role in ensuring the reliability and safety of industrial systems. However, traditional methods typically rely on external sensors, which can lead to increased costs and added complexity. The current study examined an alternative approach using variable-frequency drive

[...] Read more.

Nondestructive testing (NDT) has a crucial role in ensuring the reliability and safety of industrial systems. However, traditional methods typically rely on external sensors, which can lead to increased costs and added complexity. The current study examined an alternative approach using variable-frequency drive (VFD) data for real-time fault detection and predictive maintenance. Most VFDs continuously monitor essential parameters such as motor speed, torque, efficiency, and power consumption, facilitating sensorless condition monitoring that helps detect early-stage motor and apparatus faults without additional hardware. To improve diagnostic capabilities, calculated metrics such as apparent power, efficiency, torque, and energy consumption can deliver more profound insights into system performance, assisting in identifying potential failure patterns. A Python-based data acquisition and visualization system was developed and implemented as an example of a potential solution, enabling centralized monitoring, anomaly detection, and historical data analysis. Future advancements in artificial intelligence and machine learning could further refine automated fault detection by utilizing historical VFD data to predict system failures accurately. By integrating VFD-based diagnostics into NDT, industries can develop scalable, cost-effective, intelligent testing and maintenance solutions that improve reliability and asset management in modern systems.

Full article

Figure 1

Open AccessArticle

Integrated Non-Destructive Testing for Assessing Manufacturing Defects in Melt-Fusion Bonded Thermoplastic Composite Pipes

by

Obinna Okolie, Nadimul Haque Faisal, Harvey Jamieson, Arindam Mukherji and James Njuguna

NDT 2025, 3(1), 6; https://doi.org/10.3390/ndt3010006 - 19 Mar 2025

Abstract

►▼

Show Figures

The thermoplastic composite pipe (TCP) manufacturing process introduces defects that impact performance, such as voids, misalignment, and delamination. Consequently, there is an increasing demand for effective non-destructive testing (NDT) techniques to assess the influence of these manufacturing defects on TCP. The objective is

[...] Read more.

The thermoplastic composite pipe (TCP) manufacturing process introduces defects that impact performance, such as voids, misalignment, and delamination. Consequently, there is an increasing demand for effective non-destructive testing (NDT) techniques to assess the influence of these manufacturing defects on TCP. The objective is to identify and quantify internal defects at a microscale, thereby improving quality control. A combination of methods, including NDT, has been employed to achieve this goal. The density method is used to determine the void volume fraction. Microscopy and void analysis are performed on pristine samples using optical micrography and scanning electron microscopy (SEM), while advanced techniques like X-ray computer tomography (XCT) and ultrasonic inspections are also applied. The interlayer between the reinforced and inner layers showed good consolidation, though a discontinuity was noted. Microscopy results confirmed solid wall construction, with SEM aligning with the XY axis slice, showing predominant fibre orientation around ±45° and ±90°, and deducing the placement orientation to be ±60°. Comparing immersion, 2D microscopy, and XCT methods provided a comparative approach, even though they could not yield precise void content values. The analysis revealed a void content range of 0–2.2%, with good agreement between microscopy and Archimedes’ methods. Based on XCT and microscopy results, an increase in void diameter at constant volume increases elongation and reduces sphericity. Both methods also indicated that most voids constitute a minority of the total void fraction. To mitigate manufacturing defects, understanding the material’s processing window is essential, which can be achieved through comprehensive material characterization of TCP materials.

Full article

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Drones, Geomatics, Land, NDT, Remote Sensing

Advancing Global Sustainability Through Remote Sensing Technologies

Topic Editors: Fabio Tosti, Andrea Benedetto, Luis A. RuizDeadline: 30 November 2025

Topic in

Applied Sciences, Geomatics, NDT, Remote Sensing

Geographic Information and Remote Sensing Technology (GIRST)

Topic Editors: Francesco Benedetto, Fabio TostiDeadline: 31 December 2025

Topic in

J. Imaging, JNE, NDT, Radiation, Buildings, Applied Sciences

Nondestructive Testing and Evaluation

Topic Editors: Youngseok Lee, Ho Kyung Kim, Zheng TongDeadline: 31 May 2026

Topic in

Applied Sciences, Designs, Energies, Materials, Sensors, NDT

Advances in Non-Destructive Testing Methods, 3rd Edition

Topic Editors: Grzegorz Peruń, Bogusław ŁazarzDeadline: 30 June 2026

Conferences

Special Issues

Special Issue in

NDT

Remote Sensing and Non-Destructive Testing Solutions for Sustainable Development and Urban Resilience

Guest Editors: Livia Lantini, Atiyeh Ardakanian, Enzo RizzoDeadline: 31 October 2025

Special Issue in

NDT

Non-Destructive Testing and Evaluation in Food Engineering

Guest Editors: Phil Cox, Fideline Tchuenbou-MagaiaDeadline: 30 December 2025