A Sensory Shelf-Life Study for the Evaluation of New Eco-Sustainable Packaging of Single-Portion Croissants

Abstract

1. Introduction

2. Materials and Methods

2.1. Standards, Reagents and Solvents

2.2. Croissant Production

2.3. Packaging Material

2.4. Storage Conditions

2.5. Moisture and Water Activity

2.6. Total Titratable Acidity and pH

2.7. Texture Analysis of Croissant

2.8. Sensory Evaluation

2.9. Statistical Analysis

3. Results and Discussion

3.1. Croissant Physiochemical Characterization

3.2. Kinetic Model on Staling of Croissant during Storage

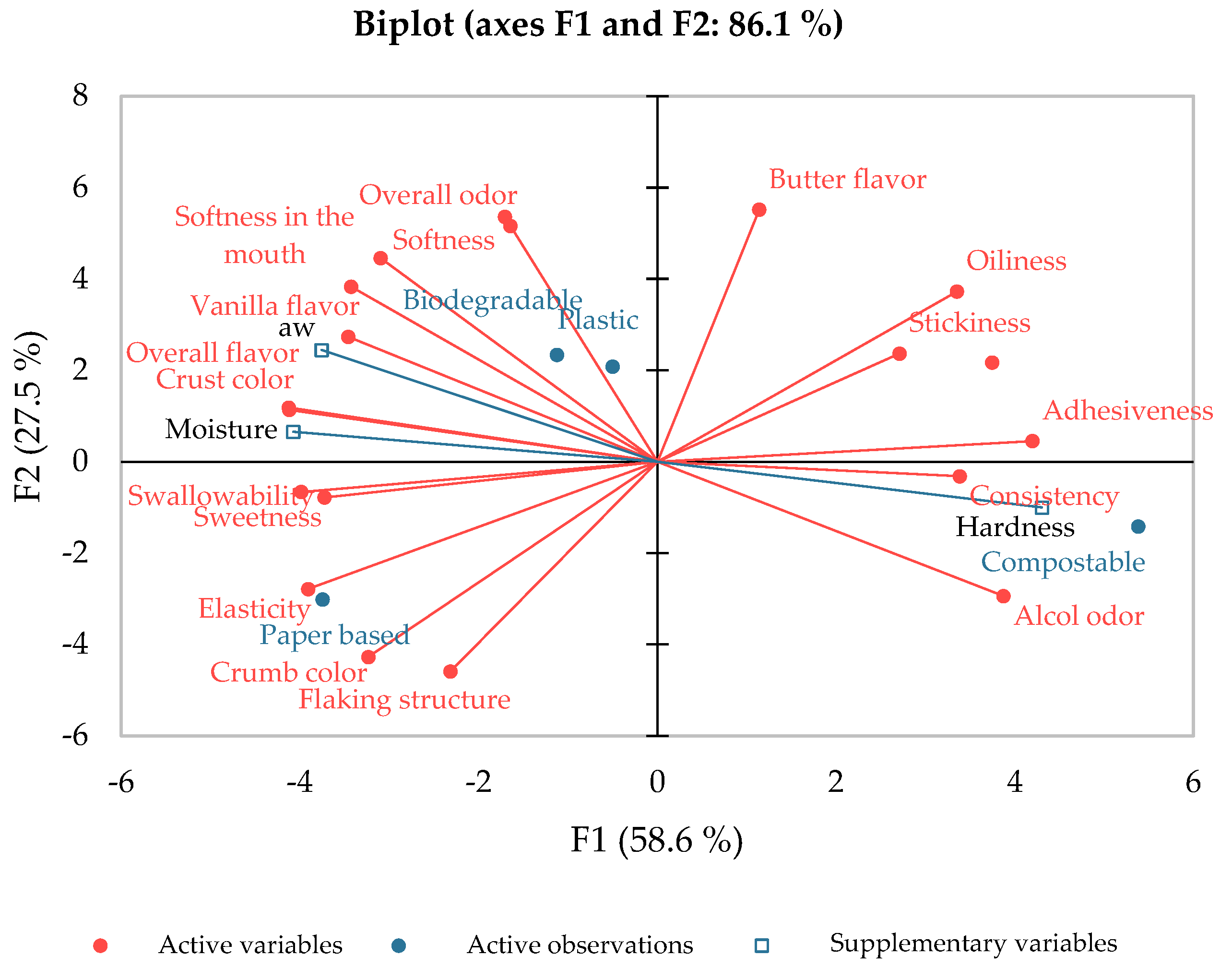

3.3. Sensory Analyses

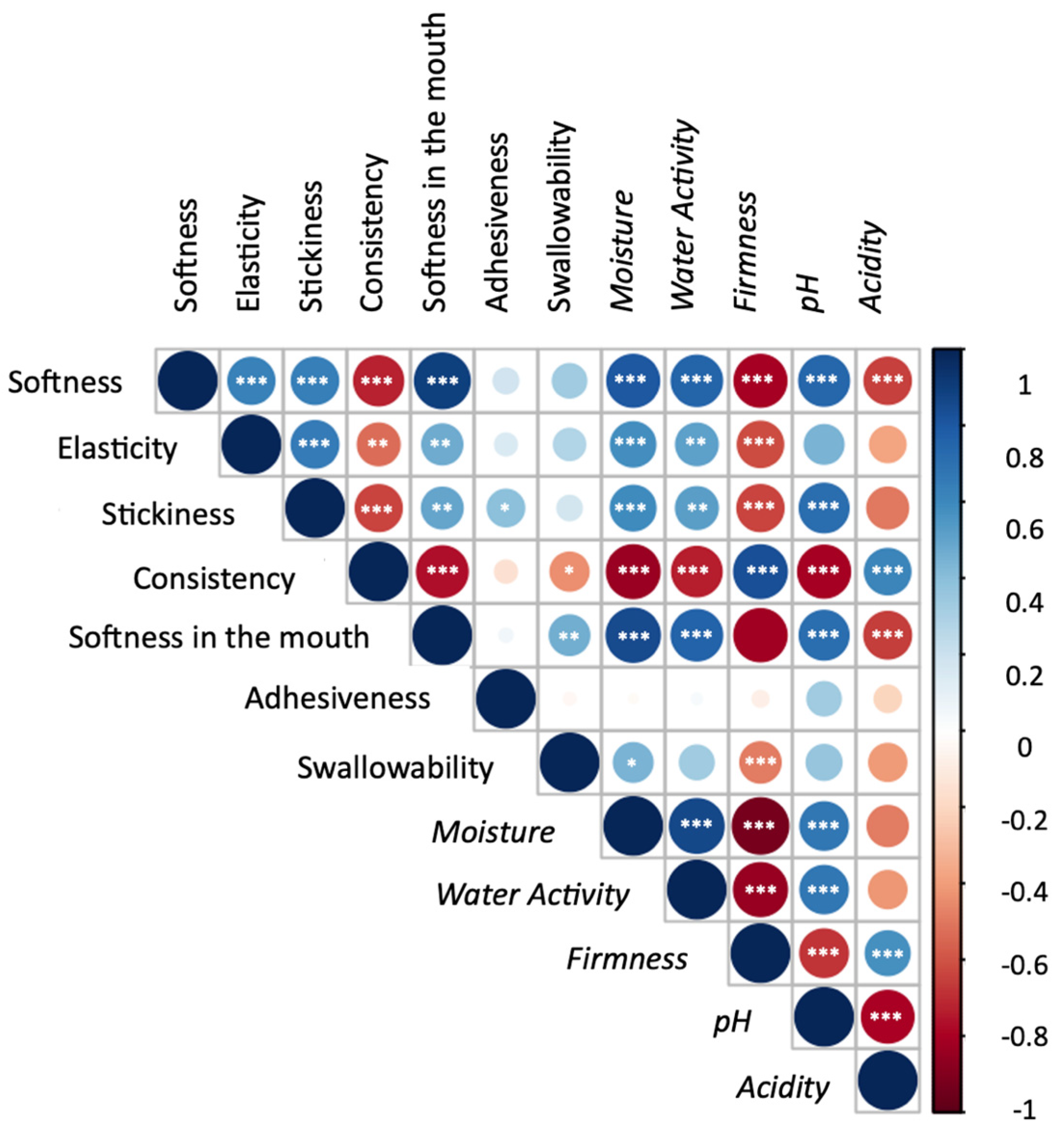

3.4. Correlation Coefficients between Variables

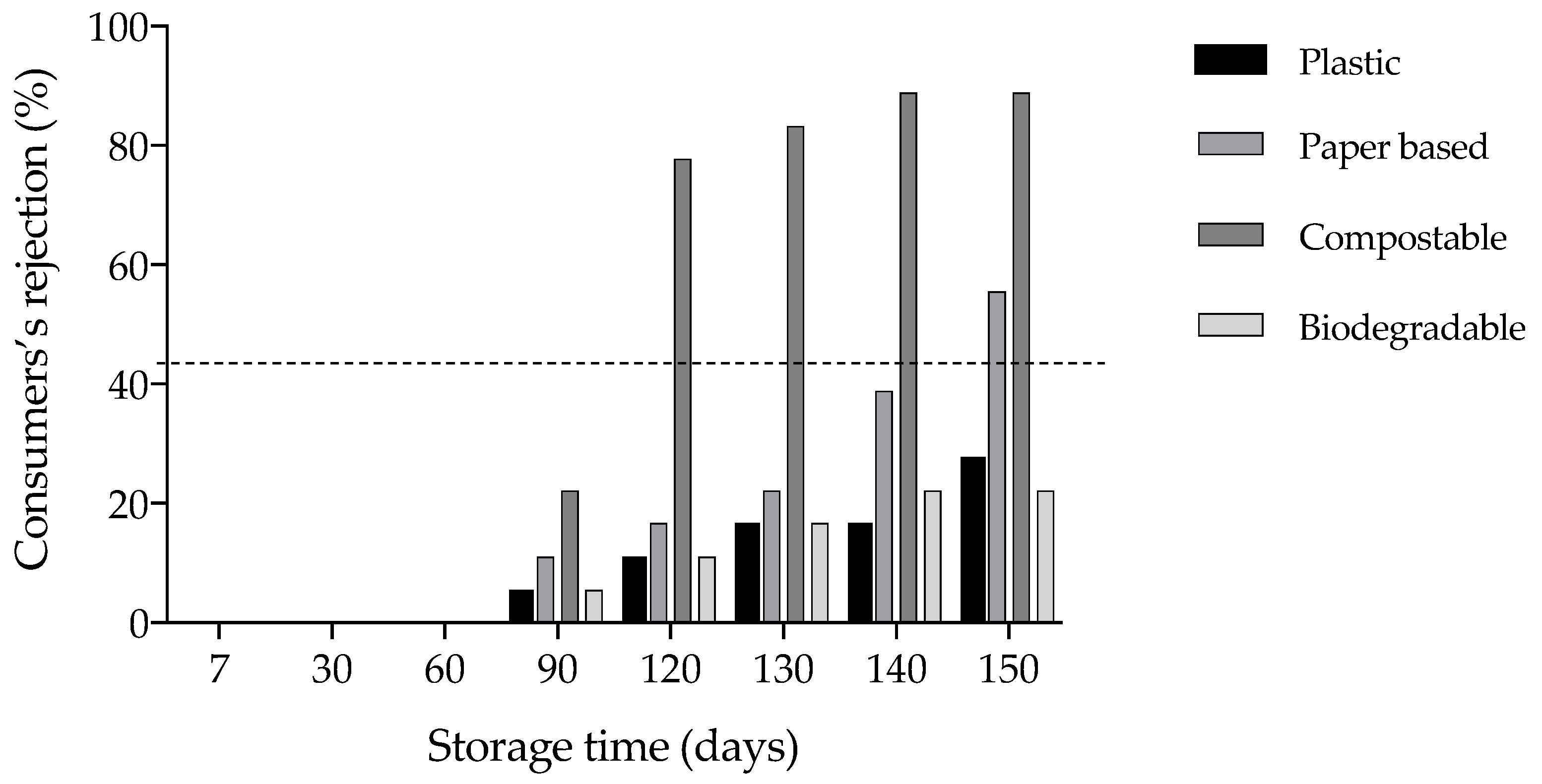

3.5. Survival Analysis and Shelf-Life Prediction

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Di Monaco, R.; Giacalone, D.; Pepe, O.; Masi, P.; Cavella, S. Effect of Social Interaction and Meal Accompaniments on Acceptability of Sourdough Prepared Croissants: An Exploratory Study. Food Res. Int. 2014, 66, 325–331. [Google Scholar] [CrossRef]

- Smith, J.P.; Daifas, D.P.; El-Khoury, W.; Koukoutsis, J.; El-Khoury, A. Shelf Life and Safety Concerns of Bakery Products--a Review. Crit. Rev. Food Sci. Nutr. 2004, 44, 19–55. [Google Scholar] [CrossRef]

- Volpe, S.; Di Monaco, R.; Puleo, S.; Torrieri, E. Prediction of secondary shelf-life of croissants: Survival analysis and cata questions methodology. Ital. J. Food Sci. 2017, 30, 126–131. [Google Scholar]

- Jain, P.; Hudnurkar, M. Sustainable Packaging in the FMCG Industry. Clean. Responsible Consum. 2022, 7, 100075. [Google Scholar] [CrossRef]

- Soltani, M.; Alimardani, R.; Mobli, H.; Mohtasebi, S.S. Modified Atmosphere Packaging; A Progressive Technology for Shelf-Life Extension of Fruits and Vegetables. J. Appl. Packag. Res. 2015, 7, 33–59. [Google Scholar]

- Wu, Q.; Ding, M.; Guo, J.; Nie, M.; Wang, Q.; Wu, L. Layer-by-Layer Stacking, Low-Temperature Welding Strategy to Effectively Recycle Biaxially-Oriented Polypropylene Film Waste. Polymer 2022, 253, 125006. [Google Scholar] [CrossRef]

- Qian, M.; Liu, D.; Zhang, X.; Yin, Z.; Ismail, B.B.; Ye, X.; Guo, M. A Review of Active Packaging in Bakery Products: Applications and Future Trends. Trends Food Sci. Technol. 2021, 114, 459–471. [Google Scholar] [CrossRef]

- San, H.; Laorenza, Y.; Behzadfar, E.; Sonchaeng, U.; Wadaugsorn, K.; Sodsai, J.; Kaewpetch, T.; Promhuad, K.; Srisa, A.; Wongphan, P.; et al. Functional Polymer and Packaging Technology for Bakery Products. Polymers 2022, 14, 3793. [Google Scholar] [CrossRef] [PubMed]

- Rüegg, N.; Röcker, B.; Yildirim, S. Application of Palladium-Based Oxygen Scavenger to Extend the Mould Free Shelf Life of Bakery Products. Food Packag. Shelf Life 2022, 31, 100771. [Google Scholar] [CrossRef]

- Commission Regulation (EC) No 2073/2005 of 15 November 2005 on Microbiological Criteria for Foodstuffs (Text with EEA Relevance). Off. J. Eur. Union 2005, 50, 1–26.

- Tolve, R.; Tchuenbou-Magaia, F.L.; Sportiello, L.; Bianchi, F.; Radecka, I.; Favati, F. Shelf-Life Prediction and Thermodynamic Properties of No Added Sugar Chocolate Spread Fortified with Multiple Micronutrients. Foods 2022, 11, 2358. [Google Scholar] [CrossRef] [PubMed]

- ASTM E2454-20; Standard Guide for Sensory Evaluation Methods to Determine Sensory Shelf Life of Consumer Products|GlobalSpec. ASTM International: West Conshohocken, PA, USA, 2020. Available online: https://standards.globalspec.com/std/14182192/astm-e2454-20 (accessed on 19 March 2024).

- Chanadang, S.; Chambers, E. Sensory Shelf Life Estimation of Novel Fortified Blended Foods Under Accelerated and Real-Time Storage Conditions. J. Food Sci. 2019, 84, 2638–2645. [Google Scholar] [CrossRef]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices; Food Science Text Series; Springer: New York, NY, USA, 2010; ISBN 978-1-4419-6487-8. [Google Scholar]

- Cincotta, F.; Tripodi, G.; Merlino, M.; Nalbone, L.; Condurso, C.; Verzera, A. FTIR Spectroscopy vs. Sensory Analyses for the Sensory Shelf-Life Definition of Hamburger Buns. Int. J. Food Sci. Technol. 2023, 58, 795–801. [Google Scholar] [CrossRef]

- Salinas, M.; Puppo, M. Bread Staling: Changes during Storage Caused by the Addition of Calcium Salts and Inulin to Wheat Flour. Food Bioprocess Technol. 2018, 11, 2067–2078. [Google Scholar] [CrossRef]

- No 679/2016; Regulation (EU) No 679/2016 of the European Parliament and of the Council Regulation. European Union: Luxembourg, 2016. Available online: https://eur-lex.europa.eu/eli/reg/2016/679/oj (accessed on 23 April 2024).

- Wang, Z.-C.; Yin, Y.-X.; Ao, H.-P.; Yin, H.; Ren, D.-F.; Lu, J. The Shelf-Life of Chestnut Rose Beverage Packaged in PEN/PET Bottles under Long Term Storage: A Comparison to Packaging in Ordinary PET Bottles. Food Chem. 2022, 370, 131044. [Google Scholar] [CrossRef] [PubMed]

- Patel, B.K.; Waniska, R.D.; Seetharaman, K. Impact of Different Baking Processes on Bread Firmness and Starch Properties in Breadcrumb. J. Cereal Sci. 2005, 42, 173–184. [Google Scholar] [CrossRef]

- Le-Bail, A.; Boumali, K.; Jury, V.; Ben-Aissa, F.; Zuniga, R. Impact of the Baking Kinetics on Staling Rate and Mechanical Properties of Bread Crumb and Degassed Bread Crumb. J. Cereal Sci. 2009, 50, 235–240. [Google Scholar] [CrossRef]

- Kwaśniewska-Karolak, I.; Mostowski, R. The Influence of Storage Conditions on the Staling Rate and Starch Retrogradation in Wheat Rolls Packaged in a Modified Atmosphere. J. Microbiol. Biotechnol. Food Sci. 2021, 8, 1188–1193. [Google Scholar] [CrossRef]

- Lebesi, D.M.; Tzia, C. Staling of Cereal Bran Enriched Cakes and the Effect of an Endoxylanase Enzyme on the Physicochemical and Sensorial Characteristics. J. Food Sci. 2011, 76, S380–S387. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, X.; Xie, Q.; Chen, L.; Chang, C.; Wu, W.; Xiao, S.; Wang, X. Effects of Laminaria Japonica Polysaccharides on the Texture, Retrogradation, and Structure Performances in Frozen Dough Bread. LWT 2021, 151, 112239. [Google Scholar] [CrossRef]

- Yeşil, S.; Levent, H. The Effects of Emulsifiers on Quality and Staling Characteristics of Gluten-Free Bread Containing Fermented Buckwheat, Quinoa, and Amaranth. J. Food Process. Preserv. 2022, 46, e16668. [Google Scholar] [CrossRef]

- McIver, R.G.; Axford, D.W.E.; Colwell, K.H.; Elton, G.A.H. Kinetic Study of the Retrogradation of Gelatinised Starch. J. Sci. Food Agric. 1968, 19, 560–563. [Google Scholar] [CrossRef]

- Licciardello, F.; Giannone, V.; Del Nobile, M.A.; Muratore, G.; Summo, C.; Giarnetti, M.; Caponio, F.; Paradiso, V.M.; Pasqualone, A. Shelf Life Assessment of Industrial Durum Wheat Bread as a Function of Packaging System. Food Chem. 2017, 224, 181–190. [Google Scholar] [CrossRef] [PubMed]

- Plessas, S.; Alexopoulos, A.; Bekatorou, A.; Mantzourani, I.; Koutinas, A.A.; Bezirtzoglou, E. Examination of Freshness Degradation of Sourdough Bread Made with Kefir through Monitoring the Aroma Volatile Composition during Storage. Food Chem. 2011, 124, 627–633. [Google Scholar] [CrossRef]

- Giménez, A.; Gagliardi, A.; Ares, G. Estimation of Failure Criteria in Multivariate Sensory Shelf Life Testing Using Survival Analysis. Food Res. Int. 2017, 99, 542–549. [Google Scholar] [CrossRef]

| Packaging | Plastic | Paper Based | Compostable | Biodegradable |

|---|---|---|---|---|

| Film stratigraphy | BOPP | PAPER + PPcoex met | PLA Met + MaterBi | BOPP |

| Film thickness | 25 μm | 25 g/m2 +8 μm | 20 μm + 18 μm | 25 μm |

| WVTR at 23 °C—85%rh g m−2 d−1 | 1.17 | 0.03 | 1.55 | 1.22 |

| WVTR at 38 °C—90%rh g m−2 d−1 | 4.85 | 0.17 | 4.31 | 4.38 |

| OTR at 25 °C—50%rh cm3/m−2 d−1 | 1340 | 14.2 | 3.09 | 1150 |

| Attribute | Definition |

|---|---|

| Appearance | |

| Crust colour | Degree of brown colour by visual evaluation |

| Crumb colour | Degree of yellow colour by visual evaluation |

| Flaking structure | Attribute refers to the flaking of the internal structure due to the lamination process |

| Odour | |

| Overall odour | Overall odour intensity after full sample assessment |

| Alcohol odour | Alcohol odour by orthonasal evaluation |

| Flavour | |

| Overall flavour | Overall flavour intensity after full sample assessment |

| Butter flavour | Butter flavour intensity of the inner part of the croissant |

| Vanilla flavour | Vanilla flavour intensity of the inner part of the croissant |

| Taste | |

| Sweetness | Sweetness intensity by taste evaluation |

| Texture | |

| Elasticity | Ability to return to the initial shape after a compression between the forefinger and thumb |

| Softness | Compressive strength using the forefinger |

| Oiliness | Oiliness released by the sample to the touch |

| Stickiness | Stickiness released by the sample to the touch |

| Mouthfeel | |

| Consistency | Attribute related to the texture that indicates the force required to cut the product with the teeth |

| Softness in the mouth | Mechanical attribute relating to the texture that indicates the ease with which the product compresses between the tongue and the palate according to its alveolation |

| Adhesiveness | Mechanical attribute related to the work necessary with the tongue to detach a food glued to the palate and teeth |

| Swallowability | Attribute related to the number of needed chewies to swallow the sample in the mouth and evaluate |

| Parameter | Packaging | Storage Time (Days) | p-Value | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 30 | 60 | 90 | 120 | 130 | 140 | 150 | Packaging (P) | Storage (S) | P × S | ||

| Moisture | Plastic | 19.47 ± 0.18 A,b | 18.98 ± 0.35 B,b | 18.37 ± 0.18 C,b | 18.63 ± 0.39 D,b | 18.41 ± 0.23 D,E,b | 18.20 ± 0.11 E,F,b | 18.23 ± 0.13 E,F,b | 18.15 ± 0.07 F,b | <0.001 | <0.001 | <0.001 |

| Paper based | 19.47 ± 0.18 d | 19.09 ± 0.09 c | 18.78 ± 0.09 c | 17.62 ± 0.03 c | 17.79 ± 0.29 c | 17.43 ± 0.52 c | 17.32 ± 0.60 c | 17.57 ± 0.04 c | ||||

| Compostable | 19.47 ± 0.18 c | 19.15 ± 0.03 d | 18.73 ± 0.07 d | 17.69 ± 0.33 d | 17.20 ± 0.07 d | 17.01 ± 0.35 d | 16.99 ± 0.17 d | 16.39 ± 0.38 d | ||||

| Biodegradable | 19.47 ± 0.18 a | 19.33 ± 0.07 a | 19.27 ± 0.44 a | 18.96 ± 0.10 a | 18.35 ± 0.20 a | 18.31 ± 0.09 a | 18.37 ± 0.23 a | 18.29 ± 0.16 a | ||||

| aw | Plastic | 0.838 ± 0.01 A,a | 0.840 ± 0.01 B,a | 0.832 ± 0.00 C,a | 0.824 ± 0.00 D,a | 0.823 ± 0.01 D,E,a | 0.819 ± 0.00 E,a | 0.813 ± 0.00 F,a | 0.815 ± 0.00 F,a | <0.001 | <0.001 | <0.001 |

| Paper-based | 0.838 ± 0.01 b | 0.832 ± 0.00 b | 0.832 ± 0.00 b | 0.816 ± 0.00 b | 0.809 ± 0.01 b | 0.803 ± 0.00 b | 0.804 ± 0.00 b | 0.799 ± 0.00 b | ||||

| Compostable | 0.838 ± 0.01 b | 0.824 ± 0.00 c | 0.816 ± 0.00 c | 0.800 ± 0.01 c | 0.805 ± 0.00 c | 0.796 ± 0.00 c | 0.760 ± 0.00 c | 0.755 ± 0.01 c | ||||

| Biodegradable | 0.838 ± 0.01 b | 0.830 ± 0.00 b | 0.823 ± 0.00 b | 0.817 ± 0.00 b | 0.809 ± 0.00 b | 0.810 ± 0.00 b | 0.806 ± 0.00 b | 0.804 ± 0.00 b | ||||

| Firmness | Plastic | 425.34 ± 12.76 G,b | 606.26 ± 18.19 F,b | 805.31 ± 24.16 E,b | 897.55 ± 26.93 D,b | 1047.50 ± 31.43 b | 1047.99 ± 31.44 b | 1059.02 ± 31.77 B,b | 1092.16 ± 32.76 A,b | <0.001 | <0.001 | <0.001 |

| Paper-based | 425.34 ± 12.76 b | 690.08 ± 20.70 b | 876.46 ± 26.29 b | 986.26 ± 25.59 b | 1010.35 ± 30.31 b | 1000.47 ± 30.01 b | 1028.08 ± 30.84 b | 1061.88 ± 31.86 b | ||||

| Compostable | 425.34 ± 12.76 a | 704.43 ± 21.13 a | 820.20 ± 24.61 a | 1419.66 ± 42.59 a | 1390.67 ± 41.72 a | 1442.56 ± 43.28 a | 1451.49 ± 43.54 a | 1516.37 ± 45.49 a | ||||

| Biodegradable | 425.34 ± 12.76 c | 518.36 ± 15.55 c | 702.76 ± 21.08 c | 733.36 ± 22.00 c | 844.57 ± 25.34 c | 877.59 ± 26.33 c | 913.51 ± 27.41 c | 916.78 ± 27.50 c | ||||

| pH | Plastic | 4.93 ± 0.15 A | 4.86 ± 0.15 A | 4.80 ± 0.14 A,B | 4.69 ± 0.14 BC | 4.61 ± 0.14 C | 4.59 ± 0.14 C | 4.56 ± 0.14 C | 4.54 ± 0.14 C | n.s. | <0.001 | n.s. |

| Paper-based | 4.94 ± 0.15 | 4.95 ± 0.15 | 4.91 ± 0.15 | 4.78 ± 0.14 | 4.67 ± 0.14 | 4.66 ± 0.14 | 4.63 ± 0.14 | 4.59 ± 0.14 | ||||

| Compostable | 4.95 ± 0.15 | 4.84 ± 0.15 | 4.89 ± 0.15 | 4.69 ± 0.14 | 4.70 ± 0.14 | 4.65 ± 0.14 | 4.63 ± 0.14 | 4.56 ± 0.14 | ||||

| Biodegradable | 4.93 ± 0.15 | 4.91 ± 0.15 | 4.88 ± 0.15 | 4.62 ± 0.14 | 4.60 ± 0.14 | 4.56 ± 0.14 | 4.52 ± 0.14 | 4.51 ± 0.14 | ||||

| Acidity | Plastic | 3.68 ± 0.11 D,a | 3.87 ± 0.12 C,D,a | 3.80 ± 0.11 C,D,a | 4.03 ± 0.12 C,a | 4.23 ± 0.13 B,a | 4.30 ± 0.13 A,B,a | 4.33 ± 0.13 A,B,a | 4.40 ± 0.13 A,a | <0.001 | <0.001 | n.s. |

| Paper-based | 3.67 ± 0.11 b | 3.60 ± 0.11 b | 3.70 ± 0.11 b | 3.70 ± 0.11 b | 3.80 ± 0.11 b | 3.81 ± 0.11 b | 3.99 ± 0.12 b | 4.00 ± 0.12 b | ||||

| Compostable | 3.63 ± 0.11 b | 3.72 ± 0.11 b | 3.80 ± 0.11 b | 3.79 ± 0.11 b | 3.95 ± 0.12 b | 3.99 ± 0.12 b | 4.03 ± 0.12 b | 3.99 ± 0.12 b | ||||

| Biodegradable | 3.60 ± 0.11 b | 3.53 ± 0.11 b | 3.68 ± 0.11 b | 3.75 ± 0.11 b | 3.93 ± 0.12 b | 3.88 ± 0.12 b | 3.99 ± 0.12 b | 4.13 ± 0.12 b | ||||

| Packaging | F∞ | t1/2 | n | k | R2 |

|---|---|---|---|---|---|

| Plastic | 1092.16 | 0.36 | 1.50 | 3.21 | 0.96 |

| Paper-based | 1061.88 | 0.35 | 1.44 | 3.07 | 0.90 |

| Compostable | 1516.37 | 0.42 | 1.93 | 3.64 | 0.97 |

| Biodegradable | 916.78 | 0.33 | 1.39 | 3.19 | 0.98 |

| Sensory Attributes | Packaging | Storage Time | Packaging × Storage Time |

|---|---|---|---|

| Crust colour | n.s. | n.s. | n.s. |

| Crumb colour | n.s. | ≤0.0001 | n.s. |

| Flaking structure | n.s. | n.s. | n.s. |

| Overall odour | ≤0.0001 | ≤0.0001 | n.s. |

| Alcohol odour | ≤0.0001 | ≤0.0001 | n.s. |

| Softness | ≤0.0001 | ≤0.0001 | ≤0.0001 |

| Elasticity | ≤0.0001 | ≤0.0001 | ≤0.01 |

| Oiliness | n.s. | ≤0.0001 | n.s. |

| Stickiness | n.s. | ≤0.0001 | ≤0.05 |

| Sweetness | ≤0.001 | ≤0.0001 | n.s. |

| Overall flavour | ≤0.001 | ≤0.0001 | n.s. |

| Butter flavour | ≤0.05 | ≤0.0001 | n.s. |

| Vanilla flavour | ≤0.001 | ≤0.0001 | n.s. |

| Consistency | ≤0.0001 | ≤0.0001 | ≤0.001 |

| Softness in the mouth | ≤0.0001 | ≤0.0001 | ≤0.0001 |

| Adhesiveness | ≤0.01 | n.s. | ≤0.05 |

| Swallowability | ≤0.0001 | n.s. | ≤0.05 |

| Packaging | Shelf-Life (Days) | Moisture (%) | Water Activity | Firmness (N) | pH | Acidity |

|---|---|---|---|---|---|---|

| Plastic | 169 | 17.96 | 0.809 | 1224.04 | 4.48 | 4.47 |

| Paper-based | 142 | 17.37 | 0.800 | 1079.95 | 4.62 | 3.91 |

| Compostable | 109 | 17.44 | 0.789 | 1284.91 | 4.69 | 3.91 |

| Biodegradable | 185 | 17.91 | 0.801 | 1063.93 | 4.38 | 4.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tolve, R.; Sportiello, L.; Rainero, G.; Pelattieri, A.; Trezzi, M.; Favati, F. A Sensory Shelf-Life Study for the Evaluation of New Eco-Sustainable Packaging of Single-Portion Croissants. Foods 2024, 13, 1390. https://doi.org/10.3390/foods13091390

Tolve R, Sportiello L, Rainero G, Pelattieri A, Trezzi M, Favati F. A Sensory Shelf-Life Study for the Evaluation of New Eco-Sustainable Packaging of Single-Portion Croissants. Foods. 2024; 13(9):1390. https://doi.org/10.3390/foods13091390

Chicago/Turabian StyleTolve, Roberta, Lucia Sportiello, Giada Rainero, Andrea Pelattieri, Marco Trezzi, and Fabio Favati. 2024. "A Sensory Shelf-Life Study for the Evaluation of New Eco-Sustainable Packaging of Single-Portion Croissants" Foods 13, no. 9: 1390. https://doi.org/10.3390/foods13091390

APA StyleTolve, R., Sportiello, L., Rainero, G., Pelattieri, A., Trezzi, M., & Favati, F. (2024). A Sensory Shelf-Life Study for the Evaluation of New Eco-Sustainable Packaging of Single-Portion Croissants. Foods, 13(9), 1390. https://doi.org/10.3390/foods13091390