Atomic Layer Deposited TiO2 and Al2O3 Thin Films as Coatings for Aluminum Food Packaging Application

Abstract

1. Introduction

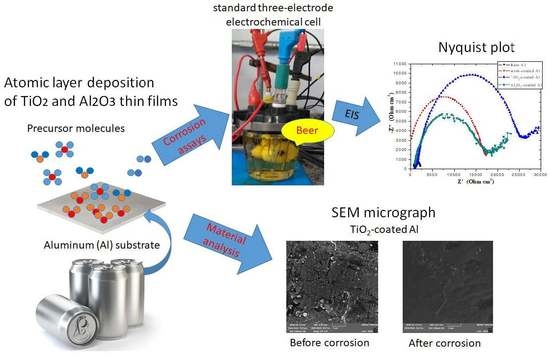

2. Materials and Methods

2.1. Substrate Preparation

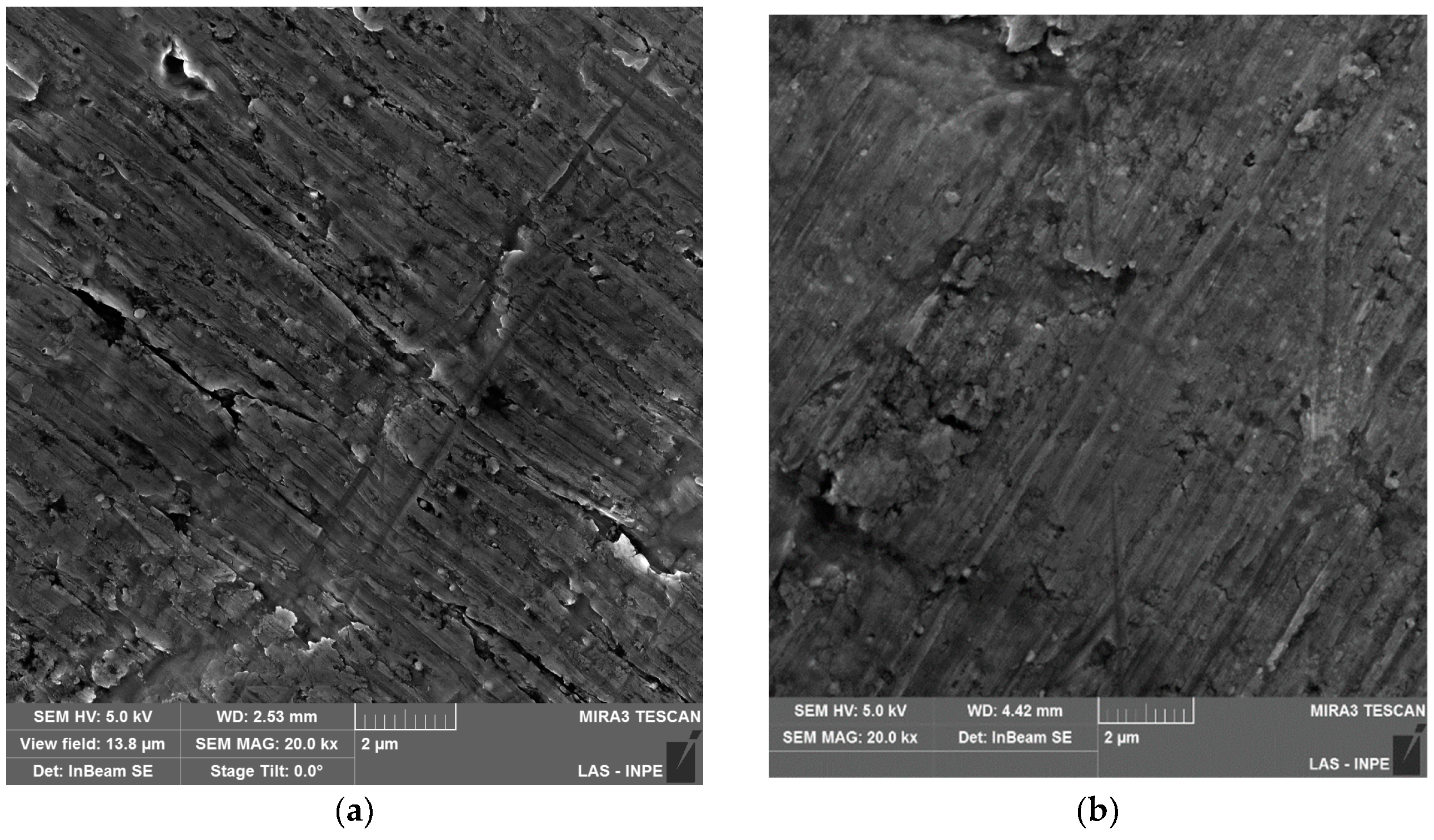

2.2. Film Characterization

2.3. Electrochemical Measurements

3. Results and Discussion

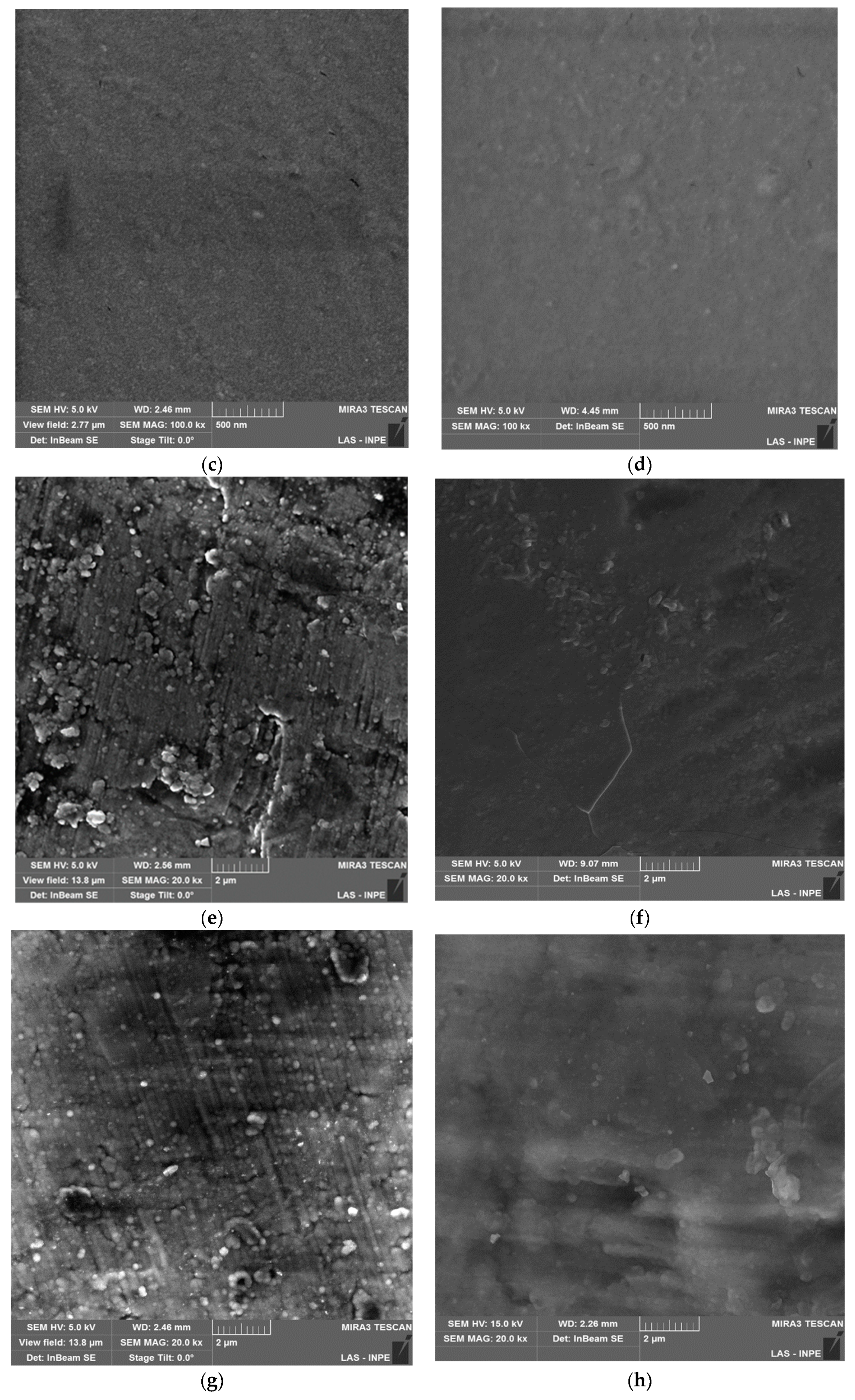

3.1. Material Characterization and Potentiodynamic Polarization

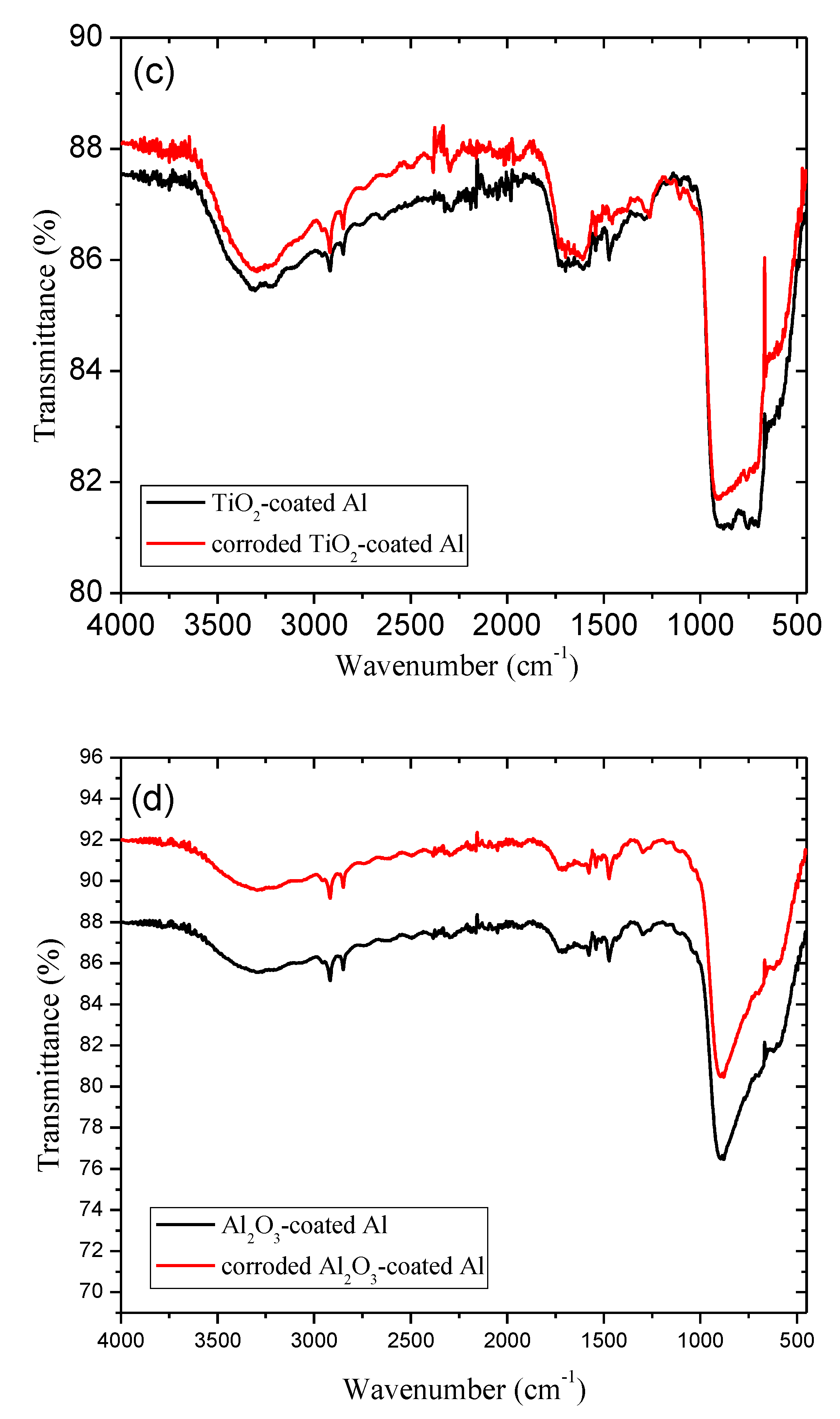

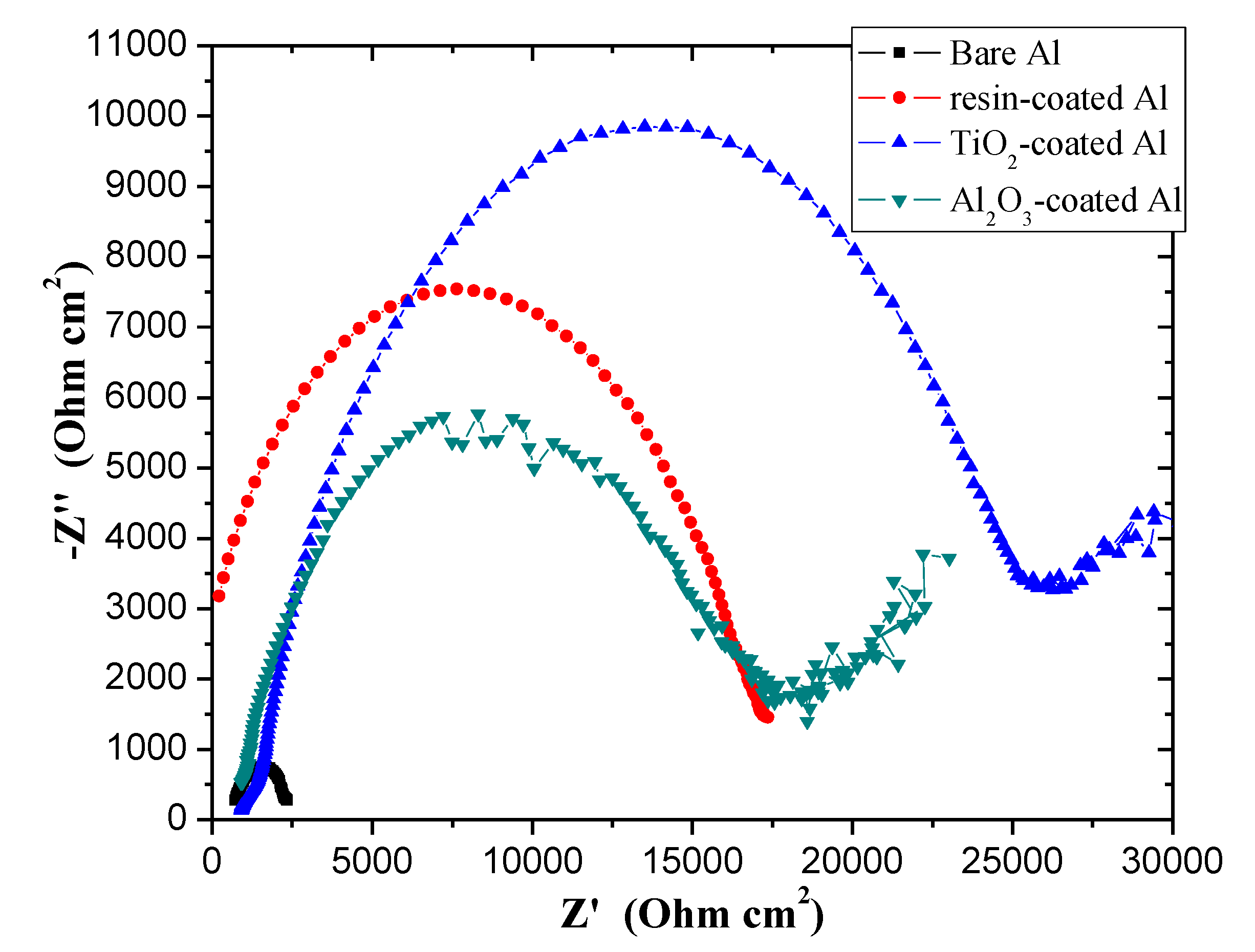

3.2. Electrochemical Impedance Spectroscopy

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Anyadike, N. Aluminium: The Challenges Ahead; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Lamberti, M.; Escher, F. Aluminium Foil as a Food Packaging Material in Comparison with Other Materials. Food Rev. Int. 2007, 23, 407–433. [Google Scholar] [CrossRef]

- Ojha, A.; Sharma, A.; Sihag, M.; Ojha, S. Food packaging–materials and sustainability-A review. Agric. Rev. 2015, 36, 241–245. [Google Scholar] [CrossRef]

- Simal-Gándara, J. Selection of can coatings for different applications. Food Rev. Int. 1999, 15, 121–137. [Google Scholar] [CrossRef]

- Lazarevic, Z.Z.; Miškovic-Stankovic, V.B.; Kacarevic-Popovic, Z.; Drazic, D.M. The study of corrosion stability of organic epoxy protective coatings on aluminium and modified aluminium surfaces. J. Braz. Chem. Soc. 2005, 16, 98–102. [Google Scholar] [CrossRef]

- Salas, B.V.; Wiener, M.S.; Stoytcheva, M.; Zlatev, R.; Beltran, M.C. Corrosion in the food industry and its control. In Food Industrial Processes-Methods and Equipment; InTech: London, UK, 2012. [Google Scholar]

- Qian, Y.; Li, Y.; Jungwirth, S.; Seely, N.; Fang, Y.; Shi, X. The Application of Anti-Corrosion Coating for Preserving the Value of Equipment Asset in Chloride-Laden Environments: A. Int. J. Electrochem. Sci. 2015, 10, 10756–10780. [Google Scholar]

- Lazur, I. Effect of pH on Coatings Used to Protect Aluminum Beverage Cans. Ph.D. Thesis, Carleton University Ottawa, Ottawa, ON, Canada, 2014. [Google Scholar]

- Marsh, K.; Bugusu, B. Food packaging—roles, materials, and environmental issues. J. food sci. 2007, 72, 39–55. [Google Scholar] [CrossRef] [PubMed]

- Grandle, J.; Taylor, S. Electrochemical impedance spectroscopy of coated aluminum beverage containers: Part 1—Determination of an optimal parameter for large sample evaluation. Corrosion 1994, 50, 792–803. [Google Scholar] [CrossRef]

- Ray, C.J. The Impact of VOC and Waste Disposal Regulations on Protective Coating Product Development. Corrosion/92. In Proceedings of the NACE Annual Conference, Houston, TX, USA, 27 April 1992; p. 492. [Google Scholar]

- LaKind, J.S. Can coatings for foods and beverages: issues and options, International Journal of Technology. Policy Manag. 2013, 13, 80–95. [Google Scholar]

- Nocuń, M.; Burcon, D.; Siwulski, S. Sodium diffusion barrier coatings prepared by sol-gel method. Opt. Appl. 2008, 38, 171–179. [Google Scholar]

- Jadav, S.; Kumar, A. Ceramic coating [TiO2-ZrO2] on aluminium 6061T6 for anti wear properties. IJRET 2014, 3, 43–49. [Google Scholar]

- Lampke, T.; Leopold, A.; Dietrich, D.; Alisch, G.; Wielage, B. Correlation between structure and corrosion behaviour of nickel dispersion coatings containing ceramic particles of different sizes. Surf. Coat. Technol. 2006, 201, 3510–3517. [Google Scholar] [CrossRef]

- Koli, D.K.; Agnihotri, G.; Purohit, R. A review on properties, behaviour and processing methods for Al-nano Al2O3 composites. Procedia Mater. Sci. 2014, 6, 567–589. [Google Scholar] [CrossRef]

- Pessoa, R.S.; Fraga, M.A.; Santos, L.V.; Massi, M.; Maciel, H.S. Nanostructured thin films based on TiO2 and/or SiC for use in photoelectrochemical cells: A review of the material characteristics, synthesis and recent applications. Mater. Sci. Semicond. Process. 2015, 29, 56–68. [Google Scholar] [CrossRef]

- Daubert, J.S.; Hill, G.T.; Gotsch, H.N.; Gremaud, A.P.; Ovental, J.S.; Williams, P.S.; Oldham, C.J.; Parsons, G.N. Corrosion Protection of Copper Using Al2O3, TiO2, ZnO, HfO2, and ZrO2 Atomic Layer Deposition. ACS Appl. Mater. interfaces 2017, 9, 4192–4201. [Google Scholar] [CrossRef] [PubMed]

- Shen, G.; Chen, Y.; Lin, C. Corrosion protection of 316 L stainless steel by a TiO2 nanoparticle coating prepared by sol–gel method. Thin Solid Films 2005, 489, 130–136. [Google Scholar] [CrossRef]

- Shan, C.; Hou, X.; Choy, K.-L. Corrosion resistance of TiO2 films grown on stainless steel by atomic layer deposition. Surf. Coat. Technol. 2008, 202, 2399–2402. [Google Scholar] [CrossRef]

- Abdulagatov, A.; Yan, Y.; Cooper, J.; Zhang, Y.; Gibbs, Z.; Cavanagh, A.; Yang, R.; Lee, Y.; George, S. Al2O3 and TiO2 atomic layer deposition on copper for water corrosion resistance. ACS appl. mater. interfaces 2011, 3, 4593–4601. [Google Scholar] [CrossRef] [PubMed]

- Matero, R.; Ritala, M.; Leskelä, M.; Salo, T.; Aromaa, J.; Forsén, O. Atomic layer deposited thin films for corrosion protection. Journal Phys. IV 1999, 9, 493–499. [Google Scholar] [CrossRef]

- Shan, C.; Hou, X.; Choy, K.-L.; Choquet, P. Improvement in corrosion resistance of CrN coated stainless steel by conformal TiO2 deposition. Surf. Coat. Technol. 2008, 202, 2147–2151. [Google Scholar] [CrossRef]

- Marin, E.; Lanzutti, A.; Paussa, L.; Guzman, L.; Fedrizzi, L. Long term performance of atomic layer deposition coatings for corrosion protection of stainless steel. Mater. Corros. 2015, 66, 907–914. [Google Scholar] [CrossRef]

- Du, X.; Zhang, K.; Holland, K.; Tombler, T.; Moskovits, M. Chemical corrosion protection of optical components using atomic layer deposition. Appl. Opt. 2009, 48, 6470–6474. [Google Scholar] [CrossRef] [PubMed]

- Hirvikorpi, T.; Vähä-Nissi, M.; Mustonen, T.; Iiskola, E.; Karppinen, M. Atomic layer deposited aluminum oxide barrier coatings for packaging materials. Thin Solid Films 2010, 518, 2654–2658. [Google Scholar] [CrossRef]

- Hirvikorpi, T.; Vähä-Nissi, M.; Nikkola, J.; Harlin, A.; Karppinen, M. Thin Al2O3 barrier coatings onto temperature-sensitive packaging materials by atomic layer deposition. Surf. Coat. Technol. 2011, 205, 5088–5092. [Google Scholar] [CrossRef]

- Sammelselg, V.; Netšipailo, I.; Aidla, A.; Tarre, A.; Aarik, L.; Asari, J.; Ritslaid, P.; Aarik, J. Chemical resistance of thin film materials based on metal oxides grown by atomic layer deposition. Thin Solid Films 2013, 542, 219–224. [Google Scholar] [CrossRef]

- Chiappim, W.; Testoni, G.; de Lima, J.; Medeiros, H.; Pessoa, R.S.; Grigorov, K.; Vieira, L.; Maciel, H. Effect of process temperature and reaction cycle number on atomic layer deposition of TiO2 thin films using TiCl4 and H2O precursors: correlation between material properties and process environment. Braz. J. Phys. 2016, 46, 56–69. [Google Scholar] [CrossRef]

- Chiappim, W.; Testoni, G.; Moraes, R.; Pessoa, R.; Sagás, J.; Origo, F.; Vieira, L.; Maciel, H. Structural, morphological, and optical properties of TiO2 thin films grown by atomic layer deposition on fluorine doped tin oxide conductive glass. Vacuum 2016, 123, 91–102. [Google Scholar] [CrossRef]

- Chiappim, W.; Testoni, G.; Doria, A.; Pessoa, R.; Fraga, M.; Galvão, N.; Grigorov, K.; Vieira, L.; Maciel, H. Relationships among growth mechanism, structure and morphology of PEALD TiO2 films: the influence of O2 plasma power, precursor chemistry and plasma exposure mode. Nanotechnology 2016, 27, 305701. [Google Scholar] [CrossRef] [PubMed]

- Testoni, G.; Chiappim, W.; Pessoa, R.; Fraga, M.; Miyakawa, W.; Sakane, K.; Galvão, N.; Vieira, L.; Maciel, H. Influence of the Al2O3 partial-monolayer number on the crystallization mechanism of TiO2 in ALD TiO2/Al2O3 nanolaminates and its impact on the material properties. J. Phys. D Appl. Phys. 2016, 49, 375301. [Google Scholar] [CrossRef]

- Pessoa, R.; dos Santos, V.; Cardoso, S.; Doria, A.; Figueira, F.; Rodrigues, B.; Testoni, G.; Fraga, M.; Marciano, F.; Lobo, A. TiO2 coatings via atomic layer deposition on polyurethane and polydimethylsiloxane substrates: Properties and effects on C. albicans growth and inactivation process. Appl. Surf. Sci. 2017, 422, 73–84. [Google Scholar] [CrossRef]

- Pessoa, R.; Pereira, F.; Testoni, G.; Chiappim, W.; Maciel, H.; Santos, L. Effect of substrate type on structure of TiO2 thin film deposited by atomic layer deposition technique. J. Integr. Circuits Syst. 2015, 10, 38–42. [Google Scholar]

- Zanin, H.; May, P.; Fermin, D.; Plana, D.; Vieira, S.; Milne, W.; Corat, E. Porous boron-doped diamond/carbon nanotube electrodes. ACS Appl. Mater. Interfaces 2014, 6, 990–995. [Google Scholar] [CrossRef] [PubMed]

- Torknezhad, Y.; Khosravi, M.; Assefi, M. Corrosion protection performance of nanoparticle incorporated epoxy paint assessed by linear polarization and electrochemical impedance spectroscopy. Materi. Corros. 2018, 69, 472–480. [Google Scholar] [CrossRef]

- Kim, H.-G.; Ahn, S.-H.; Kim, J.-G.; Park, S.J.; Lee, K.-R. Electrochemical behavior of diamond-like carbon films for biomedical applications. Thin Solid Films 2005, 475, 291–297. [Google Scholar] [CrossRef]

- Oliveira, C.; Stein, M.; Saito, E.; Zanin, H.; Vieira, L.; Raniero, L.; Trava-Airoldi, V.; Lobo, A.; Marciano, F. Effect of gold oxide incorporation on electrochemical corrosion resistance of diamond-like carbon. Diam. Relat. Mater. 2015, 53, 40–44. [Google Scholar] [CrossRef]

- Ylivaara, O.M.E.; Liu, X.; Kilpi, L.; Lyytinen, J.; Schneider, D.; Laitinen, M.; Julin, J.; Ali, S.; Sintonen, S.; Berdova, M.; et al. Aluminum oxide from trimethylaluminum and water by atomic layer deposition: The temperature dependence of residual stress, elastic modulus, hardness and adhesion. Thin Solid Films 2014, 552, 124–135. [Google Scholar] [CrossRef]

- Miikkulainen, V.; Leskelä, M.; Ritala, M.; Puurunen, R.L. Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends. J. Appl. Phys. 2013, 113, 2. [Google Scholar] [CrossRef]

- Cimalla, V.; Baeumler, M.; Kirste, L.; Prescher, M.; Christian, B.; Passow, T.; Benkhelifa, F.; Bernhardt, F.; Eichapfel, G.; Himmerlich, M. Densification of thin aluminum oxide films by thermal treatments. Mater. Sci. Appl. 2014, 5, 628. [Google Scholar] [CrossRef]

- Contreras, C.; Sugita, S.; Ramos, E. Preparation of sodium aluminate from basic aluminum sulfate. Adv. Technol. Mater. Mater. Process. J. 2006, 8, 122. [Google Scholar]

- Sahoo, S.K.; Mohanty, S.; Nayak, S.K. Toughened bio-based epoxy blend network modified with transesterified epoxidized soybean oil: synthesis and characterization. RSC Adv. 2015, 5, 13674–13691. [Google Scholar] [CrossRef]

- Maddala, J.; Sambath, K.; Kumar, V.; Ramanathan, S. Identification of reaction mechanism for anodic dissolution of metals using Electrochemical Impedance Spectroscopy. J. Electroanal. Chem. Interfacial. Electrochem. 2010, 638, 183–188. [Google Scholar] [CrossRef]

- Shi, X.; Nguyen, T.A.; Suo, Z.; Liu, Y.; Avci, R. Effect of nanoparticles on the anticorrosion and mechanical properties of epoxy coating. Surf. Coat. Technol. 2009, 204, 237–245. [Google Scholar] [CrossRef]

| Samples | Vcorr (V vs. Ag/AgCl) | jcorr (10−6 A.cm2) | Rp (104 Ω/cm2) | EP (%) | Peff (%) |

|---|---|---|---|---|---|

| Al | −0.40 | 9.06 | 2.77 | 100.0 | - |

| Al + resin | −0.46 | 7.56 | 2.20 | 96.0 | 7.1 |

| Al + TiO2 | −0.50 | 1.24 | 2.19 | 11.4 | 86.3 |

| Al + Al2O3 | −0.55 | 1.79 | 2.27 | 20.4 | 80.0 |

| Sample | CPE (F) | Rs (Ω) | Rp (Ω) | n (%) |

|---|---|---|---|---|

| Al | 7.37 × 10−9 | 1056.3 | 2.841.8 | 99.8 |

| Al + V | 4.66 × 10−9 | 979.7 | 17.905.0 | 99.8 |

| Al + TiO2 | 3.52 × 10−7 | 1682.8 | 32.619.0 | 99.7 |

| Al + Al2O3 | 7.52 × 10−9 | 1220.2 | 27.442.0 | 99.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dias, V.; Maciel, H.; Fraga, M.; Lobo, A.O.; Pessoa, R.; Marciano, F.R. Atomic Layer Deposited TiO2 and Al2O3 Thin Films as Coatings for Aluminum Food Packaging Application. Materials 2019, 12, 682. https://doi.org/10.3390/ma12040682

Dias V, Maciel H, Fraga M, Lobo AO, Pessoa R, Marciano FR. Atomic Layer Deposited TiO2 and Al2O3 Thin Films as Coatings for Aluminum Food Packaging Application. Materials. 2019; 12(4):682. https://doi.org/10.3390/ma12040682

Chicago/Turabian StyleDias, Vanessa, Homero Maciel, Mariana Fraga, Anderson O. Lobo, Rodrigo Pessoa, and Fernanda R. Marciano. 2019. "Atomic Layer Deposited TiO2 and Al2O3 Thin Films as Coatings for Aluminum Food Packaging Application" Materials 12, no. 4: 682. https://doi.org/10.3390/ma12040682

APA StyleDias, V., Maciel, H., Fraga, M., Lobo, A. O., Pessoa, R., & Marciano, F. R. (2019). Atomic Layer Deposited TiO2 and Al2O3 Thin Films as Coatings for Aluminum Food Packaging Application. Materials, 12(4), 682. https://doi.org/10.3390/ma12040682