1. Introduction

Si is the most widely used semiconductor material in integrated optical devices. The use of group IV binary or ternary alloys with Sn and Ge (SiGe [

1], SiSn [

2,

3,

4], SiGeSn [

5]) is one way to apply Si to silicon-based devices because of their promising possibilities for band gap engineering and structural modification. SiSn received widespread attention due to the energy gap (0.75–0.95 eV) being suitable for optical communication [

6]. Several reports have demonstrated that the band gap of SiSn alloys can be adjusted in a wind range by controlling the Sn concentration [

7]. The wide band gap variations of the SiSn thin films means that they can be used in the near-infrared (NIR) to far-infrared region [

8]. Many scientists so far have focused on highly doped Sn to achieve various goals. For example, the SiSn crystallization temperature can be reduced with a substitutional Sn content of around 30% [

2]. In order to make SiSn alloys suitable for optical application, Masato Oda et al. [

9] utilized interacting quasi-band (IQB) theory and found that the indirect–direct gap crossover in Si

1−xSn

x occurs around x = 0.67 with Eg = 0.87 eV. There are also many studies on the optical and electrical properties and surface microstructure of SiSn films with an Sn concentration of 10%–51% [

10,

11,

12].

In recent years, much attention has been paid to the medical applications of the infrared band, especially the near-infrared window of 1000–1700 nm (NIR-II). This band has great application value in NIR brain imaging due to its long tissue penetration depths and ultralow tissue backgrounds [

13,

14]. We attempt to make SiSn films apply in the sensitive layer of near-infrared brain imaging detectors. The variations of the optical bandgap of SiSn films versus Sn concentration are almost a linear relationship [

15] and highly doped Sn will cause the absorption band of the SiSn films to move to the mid–far infrared band. In order to locate the absorption band of the SiSn films in the near-infrared region, the SiSn films with a lower Sn concentration (0–10%) was necessary and the variation of the structure, which is crucial for the design and optimization of NIR brain imaging devices, also needed to be investigated in detail. Raman spectroscopy was chosen as a research method because it is a cheap, easy to operate and nondestructive tool [

16,

17]. The structure of SiSn films with a low Sn concentration, to our best knowledge, has not been reported yet. Here we report the a-Si

1−xSn

x alloy thin films prepared by RF magnetron sputtering at a relatively low concentration of Sn, and a series of Raman parameters versus Sn concentration was mainly studied. X-ray diffraction (XRD) and transmission electron microscopy (TEM) were used to support the Sn nanocrystallization process that may occur during the deposition process. The ratio of photo/dark conductivity and optical bandgap prove it is suitable for NIR-II region sensor.

3. Results and Discussion

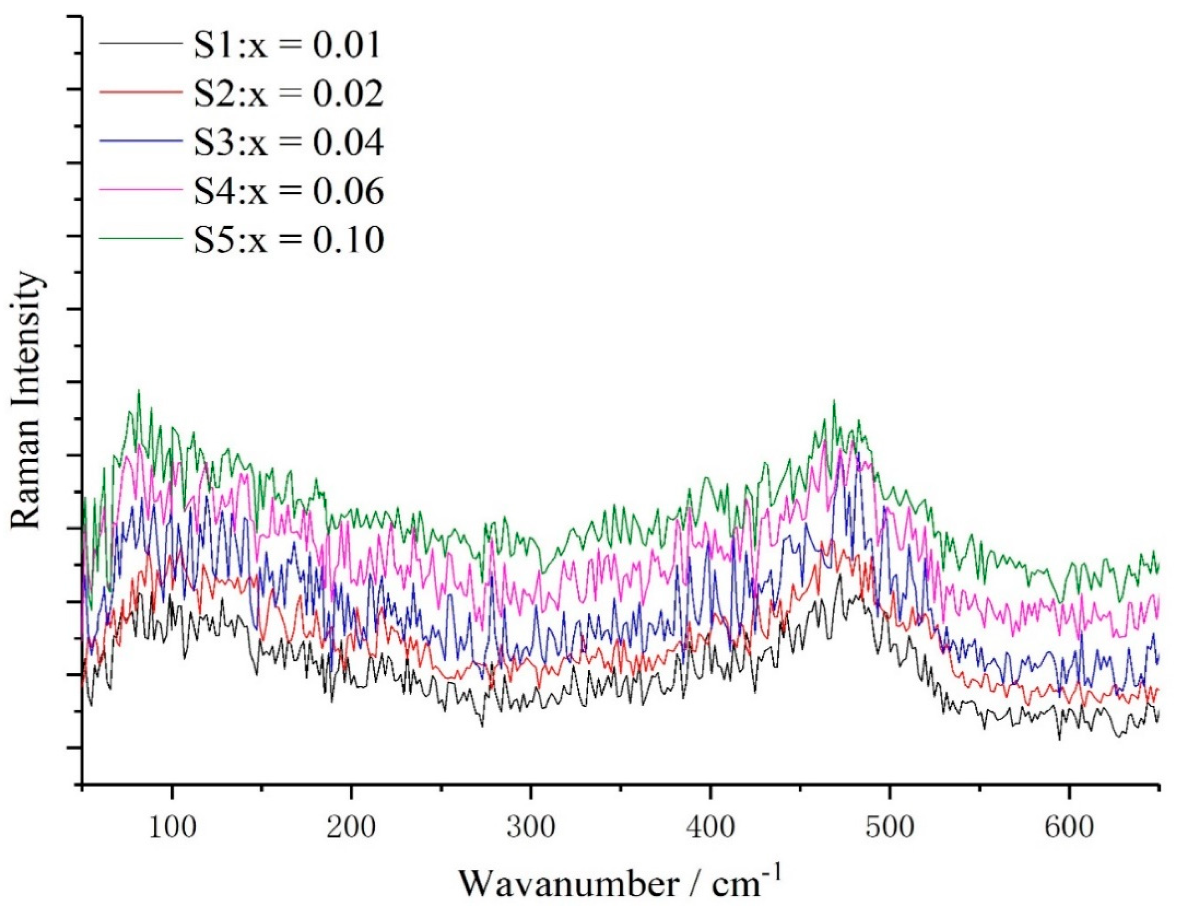

In order to understand the influence of Sn-doped concentrations on lattice vibrations of a-Si

1−xSn

x alloy thin films, their Raman spectra (

Figure 1) were recorded. A typical Raman spectrum of a-Si contains a total of four phonon modes, namely, one longitudinal acoustic (LA), one transverse acoustic (TA), one longitudinal optical (LO) and one transverse optical (TO) branch. The location of TO peak (W

TO), which is proportional to the tetrahedral network (sp3 hybridization) and sensitive to the short-range order [

18], are shifted toward lower wavenumbers in the case of S5 compared to S1 (with the Sn concentration increasing from 0% to 10%). The width of the TO peak (Γ

TO), as shown in

Figure 2b, is broader by 21.26 cm

−1 with Sn concentration variation. Both the shift of W

TO to a low wavenumber and the broadening of the TO peak with increasing concentration of Sn indicate a greater disorder in a short range. The value of ∆θ is increased from 12.21° to 15.72° (

Figure 2c) according to the linear formula Γ

TO = 15 + 6∆θ. A plausible rationale for this behavior is that both W

TO and Γ

TO are related to the Si–Si bond-angle variation ∆θ [

19], and the doped Sn of a-Si

1−xSn

x alloy thin films increases the distortion of the a-Si network due to the difference in size between the Sn atoms and Si atoms. The intensity of LA (I

TA), TA (I

TA), LO (I

LO) and TO (I

TO) are all related to the a-Si network. Zotov et al. [

20] have reported that the Raman characteristic parameters I

LA+LO/I

TO and I

TA/I

TO are related to defect and medium range in a-Si thin films, respectively. The increases in I

LA+LO/I

TO and I

TA/I

TO (

Figure 2d,e) indicate a generation of more defects and a decrease in medium-range order, respectively.

An interesting phenomenon was observed after further analysis of

Figure 2. The three parameters Γ

TO, W

TO and ∆θ related to the TO mode are almost linear with the variations of Sn concentration, while the intensity ratios I

LA+LO/I

TO and I

TA/I

TO are non-linear with the variations of Sn concentration. Referring to the introduction of hydrogen (H) atoms into the a-Si:H thin films, we propose a hypothesis to explain the non-linear relationship. As depicted in

Figure 3a, a silicon ring exists locally in amorphous silicon networks and all Si atoms have four bonds. Hence an H atom contains only one valence electron, the entry of H atoms into amorphous silicon grids breaks the Si rings in the a-Si network as shown in

Figure 3b. Unlike how H atoms break the Si rings, we believe that the Sn atom will form four SiSn bonds with the surrounding four Si atoms, thus the Si ring can still hold a ring configuration as shown in

Figure 3c. Of course, the introduction of the Sn atom will break four Si–Si bonds. This hypothesis could be the reason for the non-linear relationship. The intensity of TO mode I

TO is strongly related to the tetrahedral network, so I

TO will decrease with the decreasing amount of Si–Si bonds. While the I

LA and I

LO are associated with the presence of closed silicon rings in the amorphous network, the reduction of I

LA and I

LO is limited. In general, the effect of the introduction of the Sn atom on I

TO is greater than that on I

LA and I

LO, resulting in the non-linear relation.

Another interesting phenomenon can be also found in

Figure 2, that I

LA+LO/I

TO and I

TA/I

TO increase sharply in the range of a low Sn concentration but increase slowly in a relatively high Sn concentration. The solubility limitation of Sn atoms in a-Si networks may be responsible for this non-linear relationship. Before the Sn concentration reaches the solubility limitation of Sn atoms in a-Si networks, the intensity of the TO mode decreases sharply, resulting in a rapidly increasing rate of I

LA+LO/I

TO and I

TA/I

TO. The concentration of Sn is further increased to reach the solubility limitation, so the concentration of substitutional Sn atoms no longer increases, which suppresses the TO mode rather than the TA, LA and LO modes. Therefore, in the range of a higher Sn concentration, the increase rate of I

LA+LO/I

TO and I

TA/I

TO will also slow down. This non-liner also indicates the formation of the SiSn bonds that were discussed in the previous discussion.

Figure 4 shows the Raman spectra of a-Si

1−xSn

x alloy thin films at different deposition temperatures with an Sn concentration of 6%. Significant variations are not observed in the Raman spectra of the films at a deposition temperature of room temperature, 150 °C and 200 °C. The Raman spectra of the a-Si

1−xSn

x alloy thin films do not show any characteristic peaks for crystalline Si, indicating the presence of amorphous Si. The presence of c-Si is first observed at a higher deposition temperature of 300 °C. W

TO moves to a wavenumber of 511 cm

−1, which is a major Raman peak in c-Si.

More details of the a-Si

1−xSn

x alloy thin films Raman characteristic parameters are given in

Figure 5. W

TO is slightly shifted toward a higher wavenumber and the reduction in ∆θ and Γ

TO both indicate an improvement in the a-Si network. One thing that should be noted is that there is a big variation in W

TO, Γ

TO and ∆θ between a deposition temperature of room temperature and 150 °C, but little variation between deposition temperatures of 150 °C, 200 °C and 300 °C. Therefore, we believe that the amorphous silicon network has been fully ordered at a deposition temperature of 150 °C. This means that the Raman parameters W

TO, Γ

TO, ∆θ, I

LA+LO/I

TO and I

TA/I

TO should be relatively stable between 200 °C and 300 °C. However, I

LA+LO/I

TO and I

TA/I

TO continue to decrease. This anomaly contradicts the previous analysis.

We propose a reasonable mechanism to explain this phenomenon. Alexander et al. [

21] have reported the presence of SiSn nanocrystals in Si

1−xSn

x alloy thin films, so we believe that our samples also produce SiSn nanocrystals. Once the deposition process is completed, the total number of Sn atoms in the film is constant. On the one hand, the increase in temperature will promote the growth of SiSn nanocrystals. The formation of SiSn nanocrystals consumes Sn atoms, so the substitutional Sn atoms in the a-Si network are reduced. On the other hand, there is an increase in the amount of Si–Si bonds, so the intensity of the TO mode, which is related to the vibration of Si–Si bond, is increased. Therefore, I

LA+LO/I

TO and I

TA/I

TO maintain a tendency to decrease as temperature increases.

To further confirm the formation of nanocrystals, we use XRD and TEM as an auxiliary method.

Figure 6 shows the XRD spectra of a-Si

1−xSn

x alloy thin films at a deposition temperature of room temperature (RT) and 150 °C with an Sn concentration of 0.06%. No characteristic diffraction peaks are observed in the sample with a deposition temperature of RT. The diffraction peaks of Sn deposition at 150 °C were sharp and intense, indicating their highly crystalline nature. Characteristic diffraction peaks of Si and SiSn alloys were not observed. Actually, there was no significant difference in the XRD patterns of Sn and SiSn films, indicating the presence of amorphous Si [

22]; this result can be a proof of our speculation. According to the Scherrer formula, we calculated that the mean size of SiSn nanocrystals is about 10–15 nm. TEM images of a-Si

1−xSn

x alloy thin films at a deposition temperature of 150 °C, as presented in

Figure 7a,b, indicate the coexistence of the amorphous matrix and nanocrystals. It can be clearly seen in

Figure 7a that there are nanoparticles dispersed in the films, and these should be SiSn nanocrystals. The size of nanocrystals (about 10 nm) in TEM images is very close to the result of XRD, which could further confirm the size of the SiSn nanocrystals. Next we use Digital Micrograph to calibrate the interplanar crystal spacing and a crystal face (200) of Sn was determined. Through the literature and analysis mentioned above, this could indicate the formation of SiSn nanocrystals. The diffraction pattern, as shown in the inset of

Figure 7b, consist of a series of poly-crystal rings belonging to Sn nanocrystals. The diffraction ring is relatively wide, probably because the nanoparticle size is too small. Both the width of the diffraction ring and the TEM images show that the nanocrystals are small, which is consistent with the XRD calculation results. Every single result of Raman, XRD or TEM does not seem to be sufficient to prove the formation of SiSn nanocrystals, but the combination of the three analytical results is considered sufficient to demonstrate the formation of SiSn nanocrystals.

In addition, we also studied the ratio of photo/dark conductivity variation of the a-Si

1−xSn

x alloy thin films prepared at different Sn concentrations. The ratio of photo/dark conductivity of the films first increases and then decreases as shown in

Figure 8. The reason for this is because when the concentration of Sn in the films is at a low level, the Sn atoms replace the Si atoms in the a-Si lattice to increase the bright conductance of the films, resulting in an increase in the ratio of photo/dark conductivity. When the Sn concentration of the films increases to a relatively high value, the Sn atoms cannot replace the Si atoms in the a-Si lattice, thereby providing a large amount of free electrons, resulting in an increase in the dark conductivity of the a-Si

1−xSn

x alloy thin films. Finally, we got the optical band gap of the SiSn film at different Sn concentrations as shown in

Figure 9. The absorption wavelength corresponding to the band gap falls just in the near-infrared II region. We believed that both the ratio of photo/dark conductivity and optical bandgap of a-Si

1−xSn

x alloy thin films indicate it can be used in a sensitive layer of the NIR-II sensor.