Thermal Stability, Durability, and Service Life Estimation of Woven Flax-Carbon Hybrid Polyamide Biocomposites

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

2.2. Surface Treatment

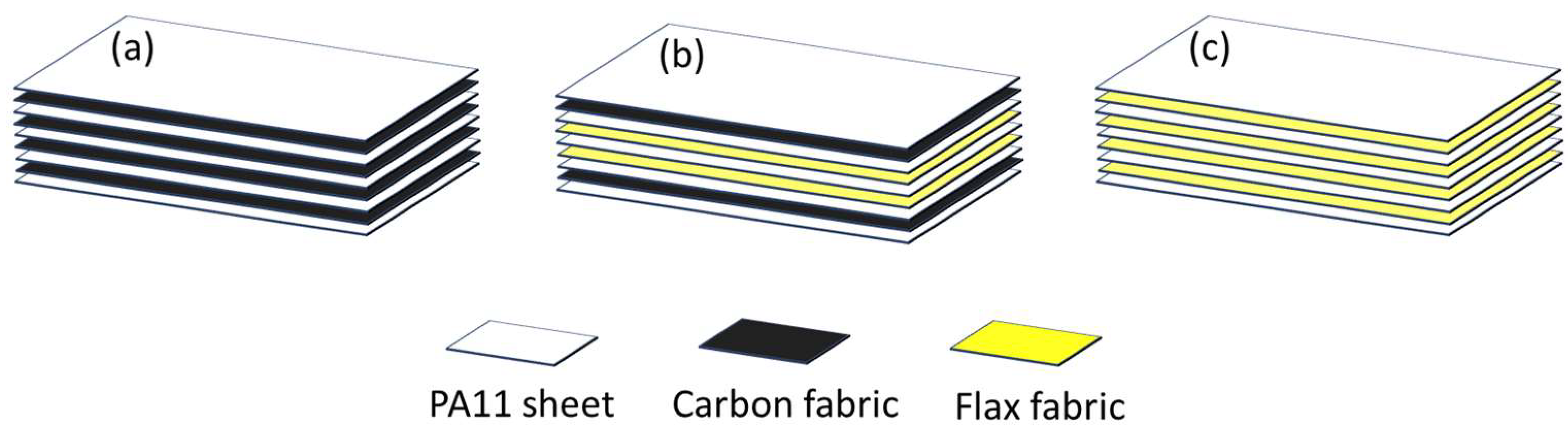

2.3. Composite Manufacturing

2.4. Differential Scanning Calorimetry (DSC)

2.5. Fourier Transform Infrared Spectroscopy (FTIR)

2.6. Thermogravimetric Analysis

2.7. Durability Test

2.8. Thermal Lifetime Estimation

3. Results

3.1. DSC Analysis

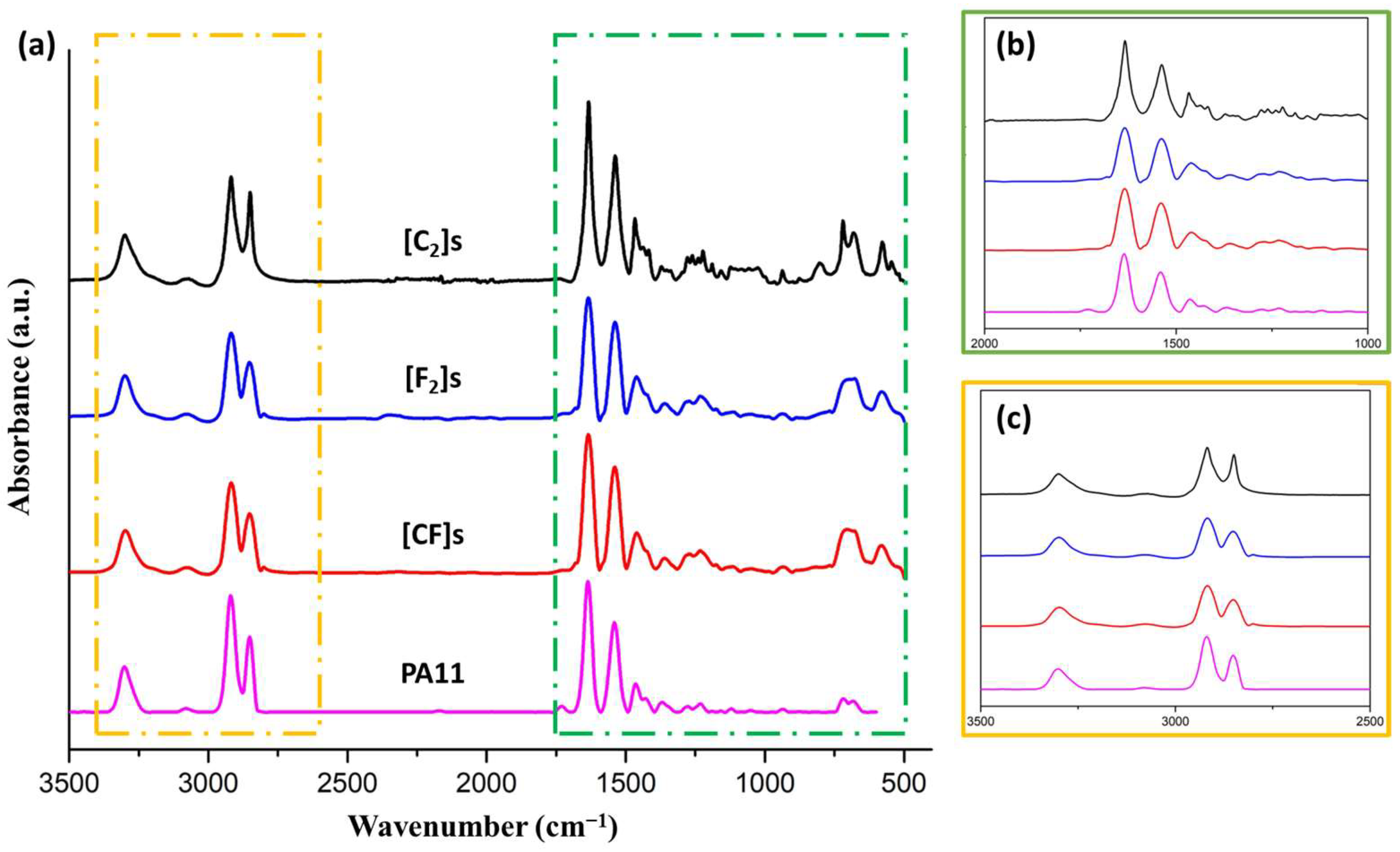

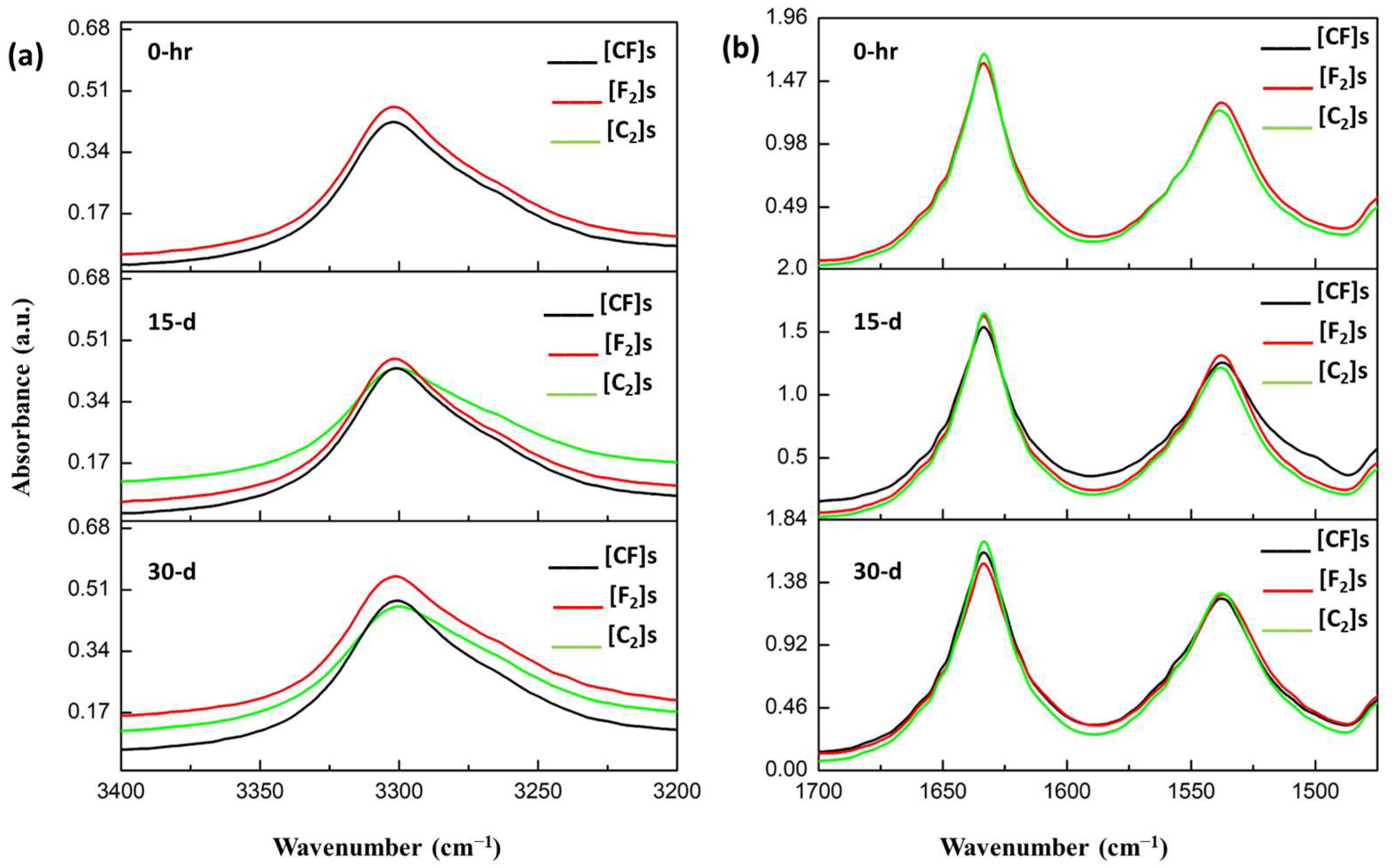

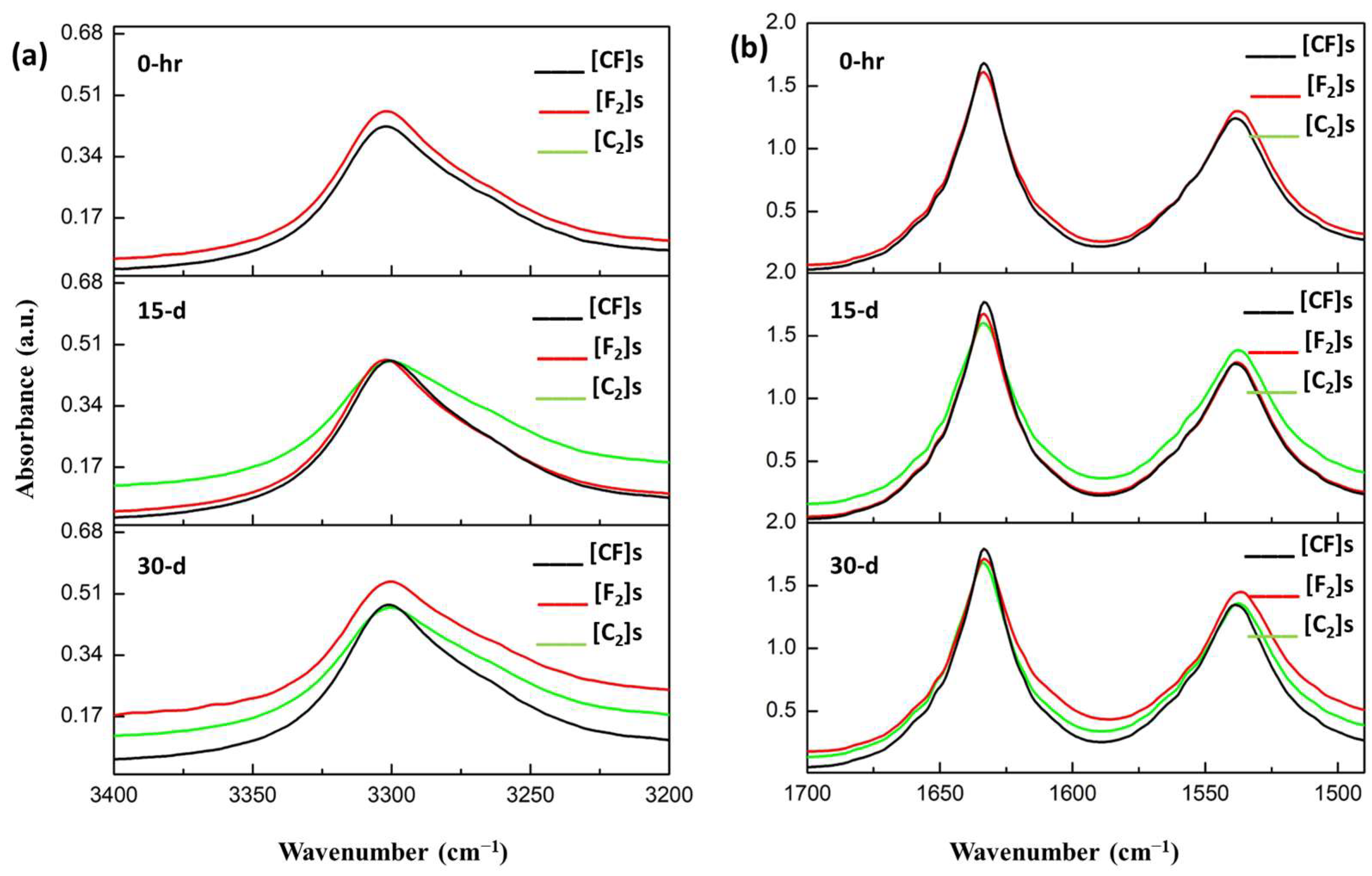

3.2. FTIR Analysis

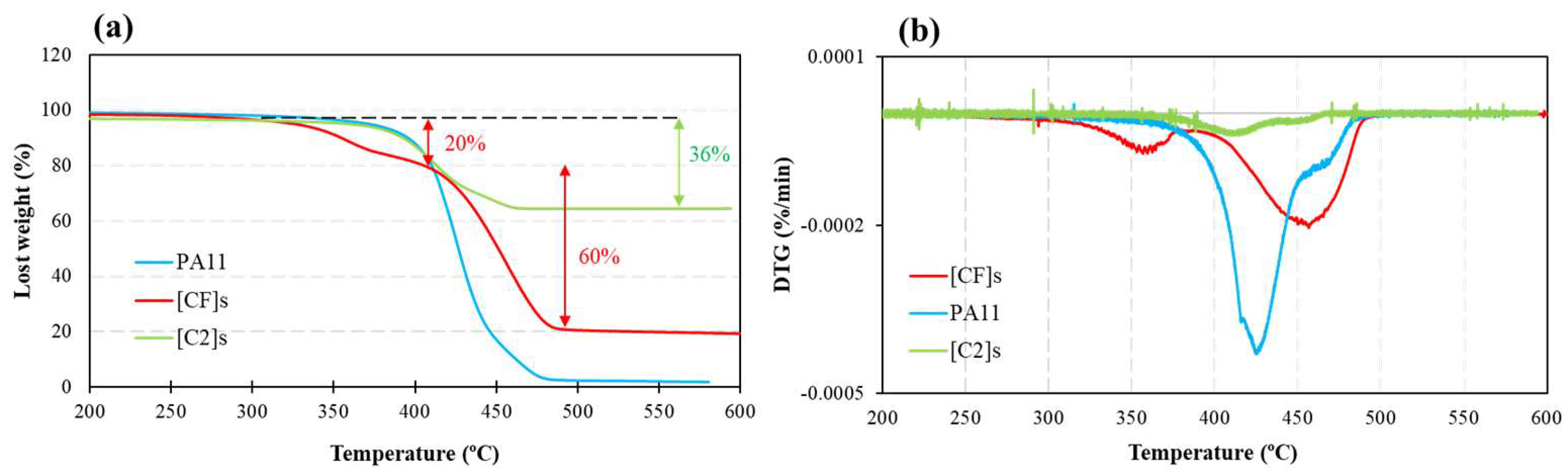

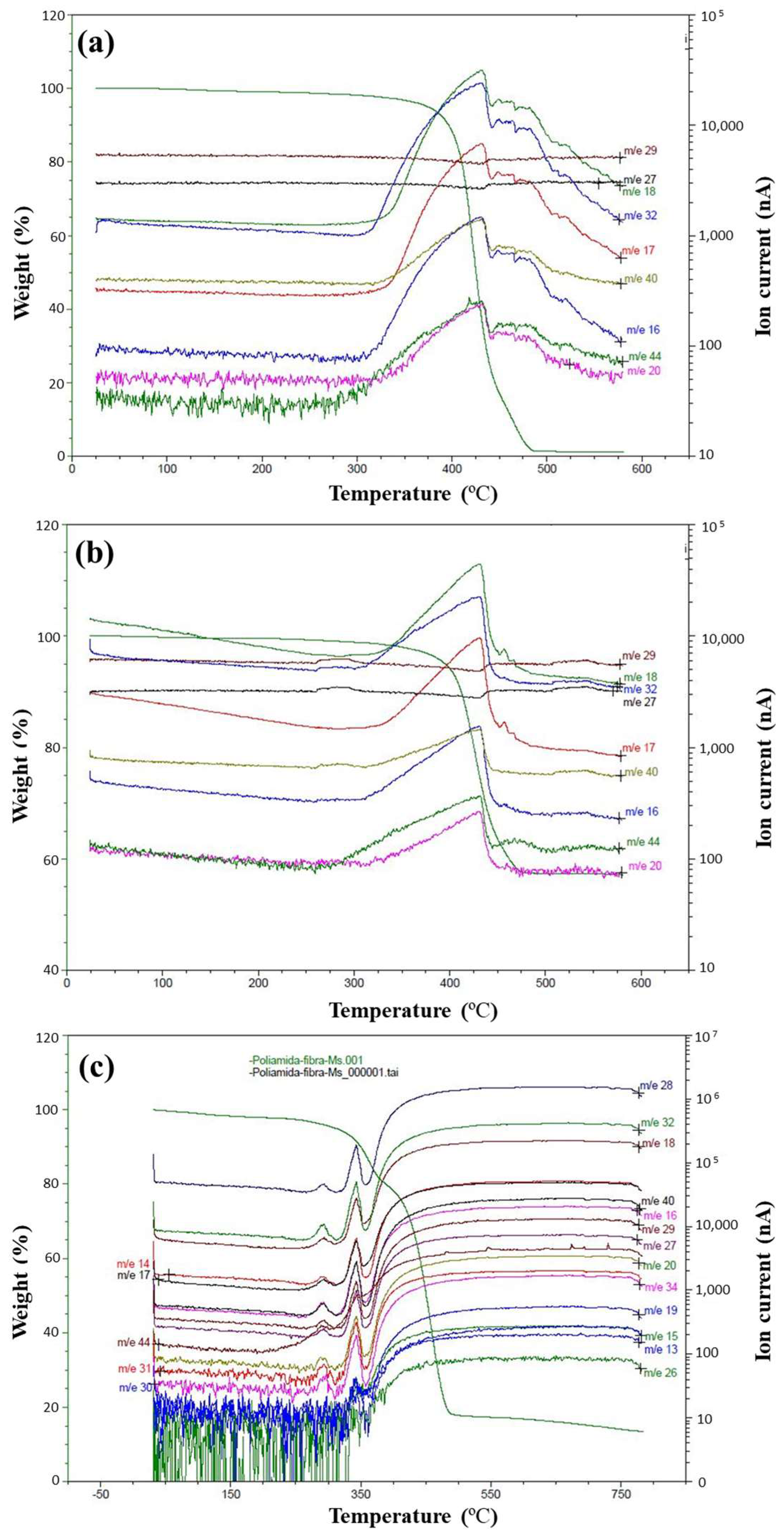

3.3. TGA Analysis

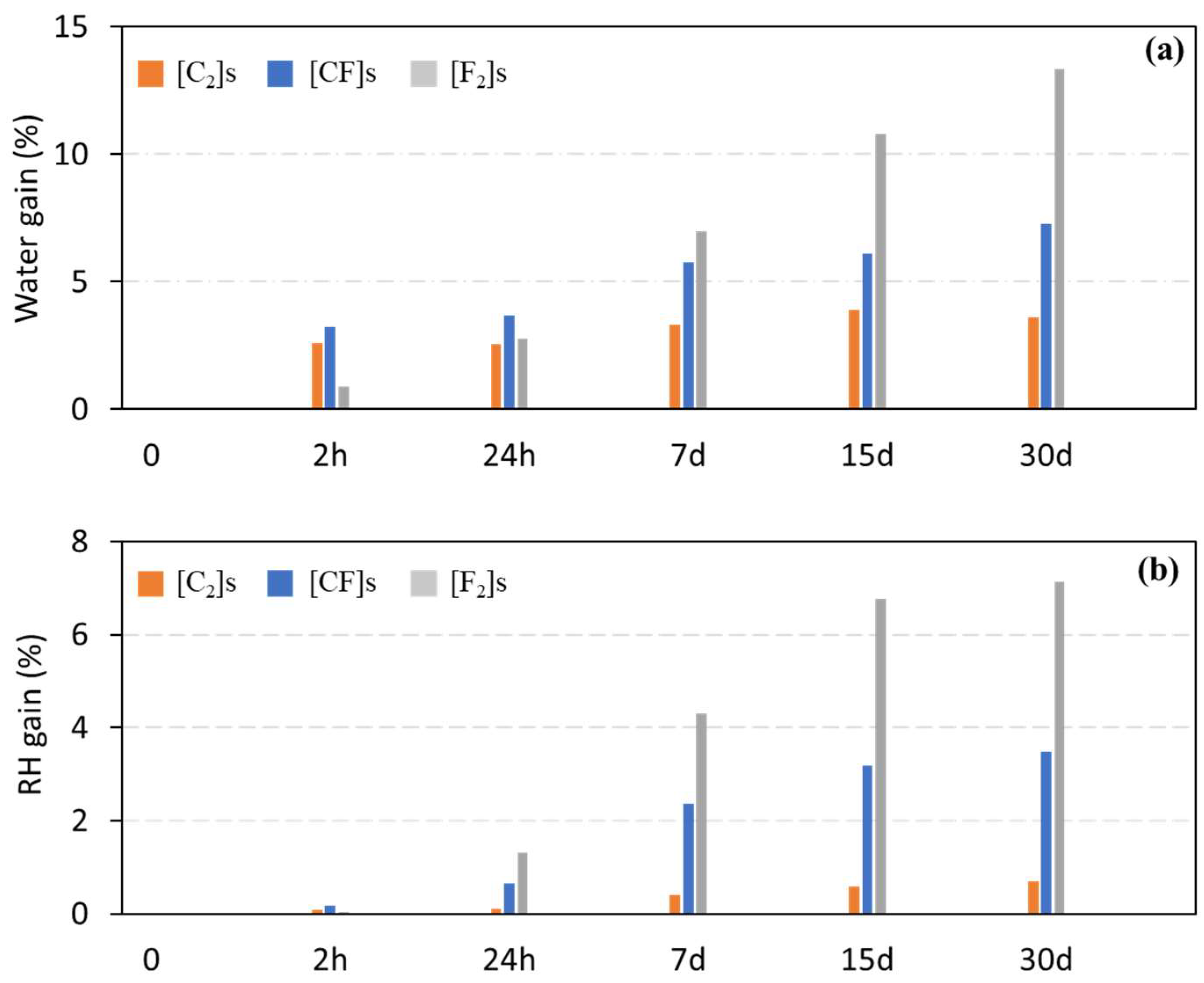

3.4. Durability Test

3.4.1. Post-Durability Test DSC Analysis

3.4.2. Post-Durability Test FTIR Analysis

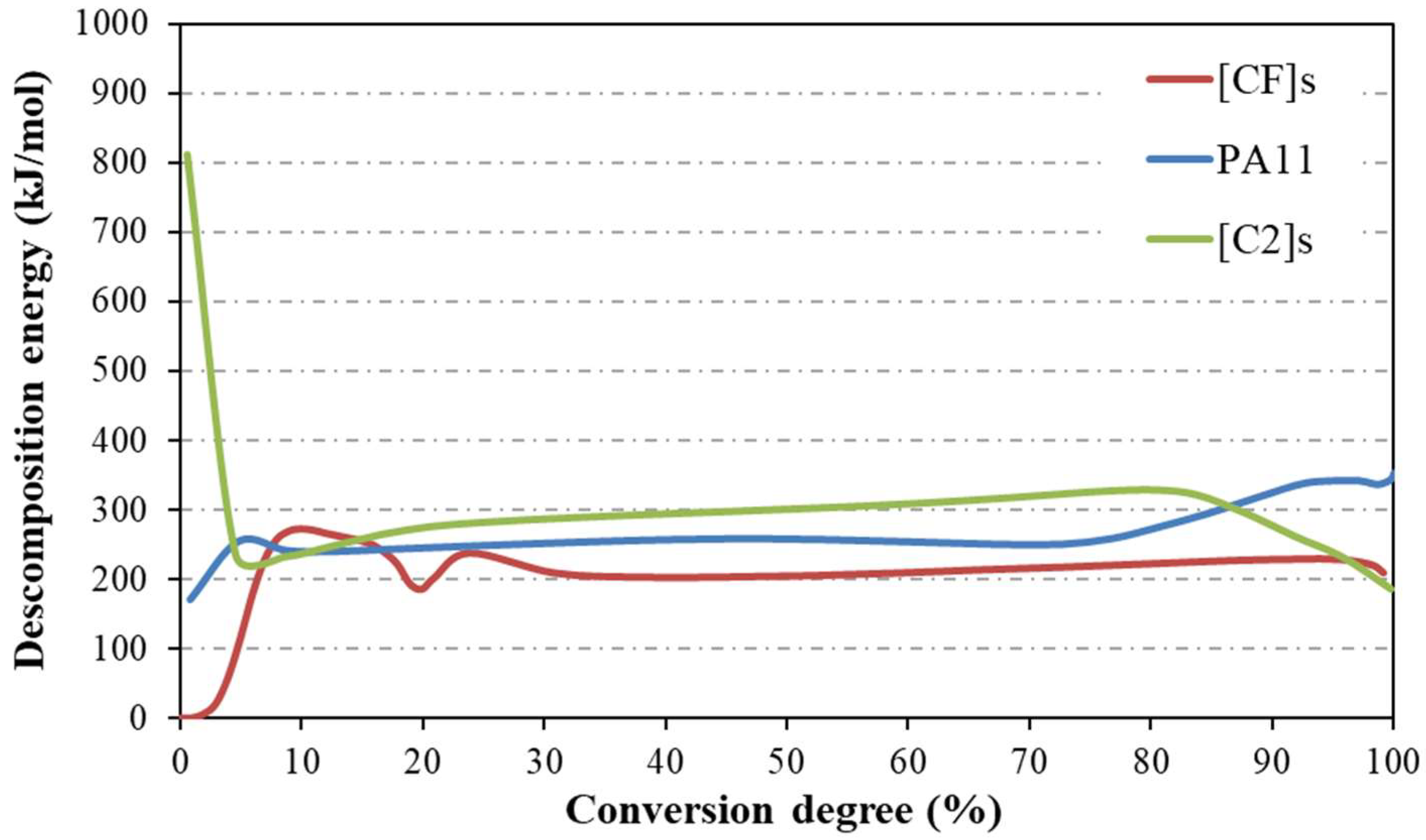

3.5. Thermal Lifetime Estimation

4. Conclusions

- DSC analysis exhibited a higher melting enthalpy (∆H) of the hybrid composite than pure flax or carbon composites, indicating improved crystallinity and potentially better mechanical properties due to a more ordered arrangement of polymer chains.

- FTIR analysis revealed that the spectra of the laminated composites closely resembled those of the PA11 matrix, suggesting that detected groups primarily represent the PA11 matrix rather than individual fiber components.

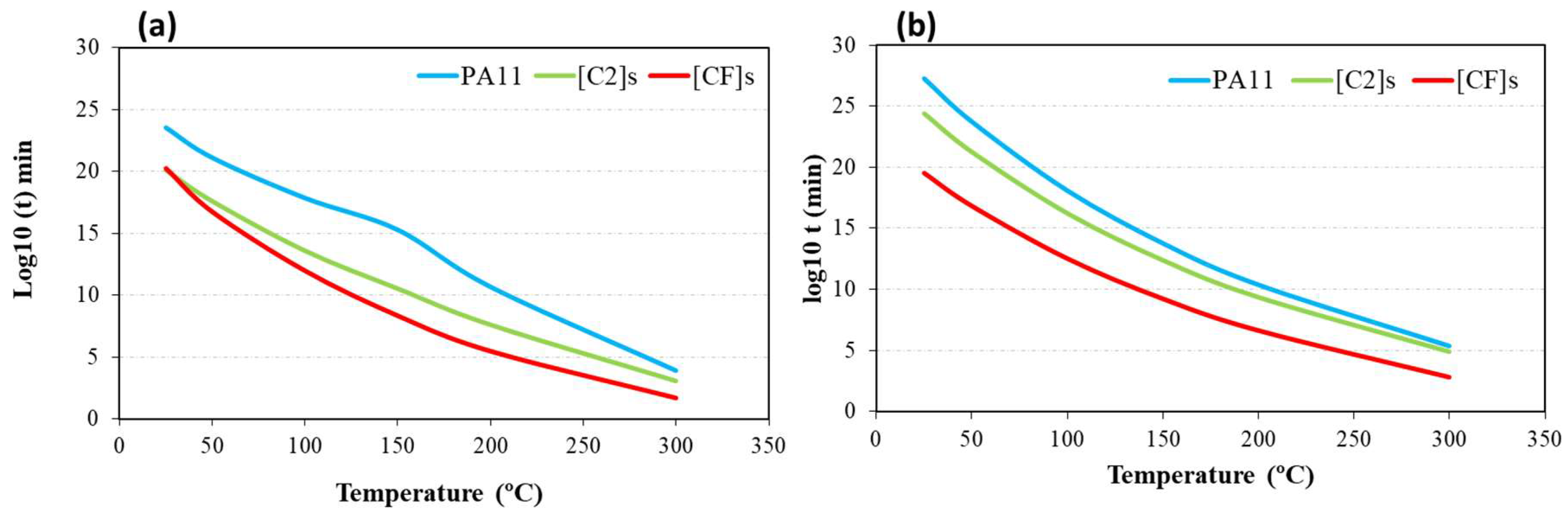

- TGA analysis revealed remarkable thermal stability of the hybrid composite, comparable to the carbon composite, up to 300 °C without any mass loss. This enhanced thermal stability led to a 41% longer estimated service life of the hybrid composite at room temperature compared to the carbon composite, as determined by the MFK model.

- Durability testing showed that the hybrid composite had about two times lower water/moisture absorption than the flax composite, suggesting superior performance in high water/humidity environments, although carbon composites still exhibited outstanding water/moisture resistance.

- The thermal lifetime simulation results from MFK and a combination of the Kissinger and Toop methods exhibited a similar trend, with the Kissinger and Toop approaches being more conservative, resulting in slightly higher values for service lives.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Oqla, F.M.; Sapuan, S.; Anwer, T.; Jawaid, M.; Hoque, M. Natural fiber reinforced conductive polymer composites as functional materials: A review. Synth. Met. 2015, 206, 42–54. [Google Scholar] [CrossRef]

- Rohan, T.; Tushar, B.; GT, M. (Eds.) Review of natural fiber composites. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2018, 314, 012020. [Google Scholar] [CrossRef]

- More, A.P. Flax fiber–based polymer composites: A review. Adv. Compos. Hybrid Mater. 2022, 5, 1–20. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Davies, P. Variability of mechanical properties of flax fibres for composite reinforcement. A review. Ind. Crops Prod. 2020, 145, 111984. [Google Scholar] [CrossRef]

- Amroune, S.; Belaadi, A.; Bourchak, M.; Makhlouf, A.; Satha, H. Statistical and experimental analysis of the mechanical properties of flax fibers. J. Nat. Fibers 2022, 19, 1387–1401. [Google Scholar] [CrossRef]

- Le Duigou, A.; Davies, P.; Baley, C. Environmental impact analysis of the production of flax fibres to be used as composite material reinforcement. J. Biobased Mater. Bioenergy 2011, 5, 153–165. [Google Scholar] [CrossRef]

- Dissanayake, N.P.; Summerscales, J.; Grove, S.; Singh, M. Energy use in the production of flax fiber for the reinforcement of composites. J. Nat. Fibers 2009, 6, 331–346. [Google Scholar] [CrossRef]

- Foulk, J.; Akin, D.; Dodd, R.; Ulven, C. Production of flax fibers for biocomposites. In Cellulose Fibers: Bio- and Nano-Polymer Composites—Green Chemistry and Technology; Springer: Berlin/Heidelberg, Germany, 2011; pp. 61–95. [Google Scholar]

- Deng, Y.; Guo, Y.; Wu, P.; Ingarao, G. Optimal design of flax fiber reinforced polymer composite as a lightweight component for automobiles from a life cycle assessment perspective. J. Ind. Ecol. 2019, 23, 986–997. [Google Scholar] [CrossRef]

- Sekar, S.; Suresh Kumar, S.; Vigneshwaran, S.; Velmurugan, G. Evaluation of mechanical and water absorption behavior of natural fiber-reinforced hybrid biocomposites. J. Nat. Fibers 2022, 19, 1772–1782. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal stability of natural fibers and their polymer composites. Iran. Polym. J. 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Joseph, P.; Joseph, K.; Thomas, S.; Pillai, C.; Prasad, V.; Groeninckx, G.; Sarkissova, M. The thermal and crystallisation studies of short sisal fibre reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2003, 34, 253–266. [Google Scholar] [CrossRef]

- Neto, J.S.; de Queiroz, H.F.; Aguiar, R.A.; Banea, M.D. A review on the thermal characterisation of natural and hybrid fiber composites. Polymers 2021, 13, 4425. [Google Scholar] [CrossRef] [PubMed]

- Kumari, Y.R.; Ramanaiah, K.; Prasad, A.R.; Reddy, K.H.; Sanaka, S.P.; Prudhvi, A.K. Experimental investigation of water absorption behaviour of sisal fiber reinforced polyester and sisal fiber reinforced poly lactic acid composites. Mater. Today: Proc. 2021, 44, 935–940. [Google Scholar]

- Sreekumar, P.; Thomas, S.P.; marc Saiter, J.; Joseph, K.; Unnikrishnan, G.; Thomas, S. Effect of fiber surface modification on the mechanical and water absorption characteristics of sisal/polyester composites fabricated by resin transfer molding. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1777–1784. [Google Scholar] [CrossRef]

- Muñoz, E.; García-Manrique, J.A. Water absorption behaviour and its effect on the mechanical properties of flax fibre reinforced bioepoxy composites. Int. J. Polym. Sci. 2015, 2015. [Google Scholar] [CrossRef]

- Moudood, A.; Rahman, A.; Khanlou, H.M.; Hall, W.; Öchsner, A.; Francucci, G. Environmental effects on the durability and the mechanical performance of flax fiber/bio-epoxy composites. Compos. Part B Eng. 2019, 171, 284–293. [Google Scholar] [CrossRef]

- Akil, H.M.; Cheng, L.W.; Ishak, Z.M.; Bakar, A.A.; Abd Rahman, M. Water absorption study on pultruded jute fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2009, 69, 1942–1948. [Google Scholar] [CrossRef]

- Dash, B.; Rana, A.; Mishra, H.; Nayak, S.; Tripathy, S. Novel low-cost jute–polyester composites. III. Weathering and thermal behavior. J. Appl. Polym. Sci. 2000, 78, 1671–1679. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.a.; Richardson, M.O. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Shahzad, A. Effects of water absorption on mechanical properties of hemp fiber composites. Polym. Compos. 2012, 33, 120–128. [Google Scholar] [CrossRef]

- Das, G.; Biswas, S. Effect of fiber parameters on physical, mechanical and water absorption behaviour of coir fiber–epoxy composites. J. Reinf. Plast. Compos. 2016, 35, 628–637. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudharya, R. Effect of Fiber Length and Content on Mechanical and Water Absorption Behavior of Coir Fiber-Epoxy Composite. In Advanced Engineering Research and Applications; Research India Publication: Delhi, India, 2019; pp. 80–100. [Google Scholar]

- Prem Kumar, R.; Muthukrishnan, M.; Felix Sahayaraj, A. Effect of hybridization on natural fiber reinforced polymer composite materials—A review. Polym. Compos. 2023, 44, 4459–4479. [Google Scholar] [CrossRef]

- Gangil, B.; Ranakoti, L.; Verma, S.; Singh, T.; Kumar, S. Natural and synthetic fibers for hybrid composites. In Hybrid Fiber Composites: Materials, Manufacturing, Process Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2020; pp. 1–15. [Google Scholar]

- Gupta, M.; Ramesh, M.; Thomas, S. Effect of hybridization on properties of natural and synthetic fiber-reinforced polymer composites (2001–2020): A review. Polym. Compos. 2021, 42, 4981–5010. [Google Scholar] [CrossRef]

- Bahrami, M.; Abenojar, J.; Martínez, M.Á. Recent progress in hybrid biocomposites: Mechanical properties, water absorption, and flame retardancy. Materials 2020, 13, 5145. [Google Scholar] [CrossRef]

- Bahrami, M.; Enciso, B.; Gaifami, C.M.; Abenojar, J.; Martinez, M.A. Characterization of hybrid biocomposite Poly-Butyl-Succinate/Carbon fibers/Flax fibers. Compos. Part B Eng. 2021, 221, 109033. [Google Scholar] [CrossRef]

- Yuan, W.; Li, Y.; Zhao, J. Mechanical properties of a novel Tri-directional carbon-flax-aramid fiber reinforced composite. Compos. Sci. Technol. 2021, 213, 108923. [Google Scholar] [CrossRef]

- Biricik, G.D.; Celebi, H.; Seyhan, A.T.; Ates, F. Thermal and mechanical properties of flax char/carbon fiber reinforced polyamide 66 hybrid composites. Polym. Compos. 2022, 43, 503–516. [Google Scholar] [CrossRef]

- Dora, K.N.; Mishra, S.S.; Gupta, H.D.; Sahu, D.; Srivatsava, M.; Dalai, N. Enhancement of surface & bulk mechanical properties of Flax reinforced composites with different carbon allotropes. Mater. Today Proc. 2022, 48, 989–993. [Google Scholar]

- Bahrami, M.; Mehdikhani, M.; Swolfs, Y.; Abenojar, J.; Martínez, M.A. Impact properties of flax-carbon hybrid composites under low-velocity impact. In Proceedings of the 20th European Conference on Composite Materials (ECCM20), Lausanne, Switzerland, 26–30 June 2022. [Google Scholar]

- Yashas Gowda, T.G.; Vinod, A.; Madhu, P.; Mavinkere Rangappa, S.; Siengchin, S.; Jawaid, M. Mechanical and thermal properties of flax/carbon/kevlar based epoxy hybrid composites. Polym. Compos. 2022, 43, 5649–5662. [Google Scholar]

- Saha, A.; Kumar, S.; Zindani, D. Investigation of the effect of water absorption on thermomechanical and viscoelastic properties of flax-hemp-reinforced hybrid composite. Polym. Compos. 2021, 42, 4497–4516. [Google Scholar] [CrossRef]

- El-Wazery, M.; El-Kelity, A.; Elsad, R. Effect of water absorption on the tensile characteristics of natural/synthetic fabrics reinforced hybrid composites. Int. J. Eng. 2020, 33, 2339–2346. [Google Scholar]

- Moudood, A.; Rahman, A.; Öchsner, A.; Islam, M.; Francucci, G. Flax fiber and its composites: An overview of water and moisture absorption impact on their performance. J. Reinf. Plast. Compos. 2019, 38, 323–339. [Google Scholar] [CrossRef]

- Tanaka, K.; Mizuno, S.; Honda, H.; Katayama, T.; Enoki, S. Effect of water absorption on the mechanical properties of carbon fiber/polyamide composites. J. Solid Mech. Mater. Eng. 2013, 7, 520–529. [Google Scholar] [CrossRef]

- Nguyen, P.H.; Spoljaric, S.; Seppälä, J. Redefining polyamide property profiles via renewable long-chain aliphatic segments: Towards impact resistance and low water absorption. Eur. Polym. J. 2018, 109, 16–25. [Google Scholar] [CrossRef]

- Pérez-Pacheco, E.; Cauich-Cupul, J.; Valadez-González, A.; Herrera-Franco, P. Effect of moisture absorption on the mechanical behavior of carbon fiber/epoxy matrix composites. J. Mater. Sci. 2013, 48, 1873–1882. [Google Scholar] [CrossRef]

- Meyer, A.; Jones, N.; Lin, Y.; Kranbuehl, D. Characterizing and modeling the hydrolysis of polyamide-11 in a pH 7 water environment. Macromolecules 2002, 35, 2784–2798. [Google Scholar] [CrossRef]

- Paolucci, F.; Peters, G.W.; Govaert, L.E. Plasticity-controlled failure of sintered and molded polyamide 12: Influence of temperature and water absorption. J. Appl. Polym. Sci. 2020, 137, 48525. [Google Scholar] [CrossRef]

- Lu, M.M.; Fuentes, C.A.; Van Vuure, A.W. Moisture sorption and swelling of flax fibre and flax fibre composites. Compos. Part B Eng. 2022, 231, 109538. [Google Scholar] [CrossRef]

- Cheng, M.; Zhong, Y.; Kureemun, U.; Cao, D.; Hu, H.; Lee, H.P.; Li, S. Environmental durability of carbon/flax fiber hybrid composites. Compos. Struct. 2020, 234, 111719. [Google Scholar] [CrossRef]

- Wang, A.; Wang, X.; Xian, G. Mechanical, low-velocity impact, and hydrothermal aging properties of flax/carbon hybrid composite plates. Polym. Test. 2020, 90, 106759. [Google Scholar] [CrossRef]

- Johar, M.; Chong, W.; Wong, K. Moisture Absorption and Tensile Behaviour of Hybrid Carbon/Flax Composites. Fibers Polym. 2023, 24, 1799–1810. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, W.; Wan, B.; Meng, Z.; Han, B. Hygrothermal ageing behavior and mechanism of carbon nanofibers modified flax fiber-reinforced epoxy laminates. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106142. [Google Scholar] [CrossRef]

- Ramesh, M.; Bhoopathi, R.; Deepa, C.; Sasikala, G. Experimental investigation on morphological, physical and shear properties of hybrid composite laminates reinforced with flax and carbon fibers. J. Chin. Adv. Mater. Soc. 2018, 6, 640–654. [Google Scholar] [CrossRef]

- Wang, A.; Liu, X.; Yue, Q.; Xian, G. Hydrothermal durability of unidirectional flax/carbon fiber hybrid composite plates. J. Mater. Res. Technol. 2023, 22, 2043–2061. [Google Scholar] [CrossRef]

- Bahrami, M.; Del Real, J.C.; Mehdikhani, M.; Butenegro, J.A.; Abenojar, J.; Martínez, M.Á. Hybridization effect on interlaminar bond strength, flexural properties, and hardness of carbon–flax fiber thermoplastic bio-composites. Polymers 2023, 15, 4619. [Google Scholar] [CrossRef]

- Bahrami, M.; Butenegro, J.A.; Mehdikhani, M.; Swolfs, Y.; Abenojar, J.; Martinez, M.A. Tensile, impact, and the damping performance of woven flax-carbon hybrid polyamide biocomposites. Polym. Compos. 2023, 45, 3901–3917. [Google Scholar] [CrossRef]

- Bahrami, M.; Abenojar, J.; Martínez, M.A. Comparative characterization of hot-pressed polyamide 11 and 12: Mechanical, thermal and durability properties. Polymers 2021, 13, 3553. [Google Scholar] [CrossRef]

- Kumar, D.; Faisal, N.; Layek, A.; Priyadarshi, G. Enhancement of mechanical properties of carbon and flax fibre hybrid composites for engineering applications. AIP Conf. Proc. 2021, 2341, 040032. [Google Scholar]

- Enciso, B.; Abenojar, J.a.; Martínez, M. Influence of plasma treatment on the adhesion between a polymeric matrix and natural fibres. Cellulose 2017, 24, 1791–1801. [Google Scholar] [CrossRef]

- Enciso, B.; Abenojar, J.; Paz, E.; Martínez, M. Influence of low pressure plasma treatment on the durability of thermoplastic composites LDPE-flax/coconut under thermal and humidity conditions. Fibers Polym. 2018, 19, 1327–1334. [Google Scholar] [CrossRef]

- Tiwari, S.; Bijwe, J. Surface treatment of carbon fibers-a review. Procedia Technol. 2014, 14, 505–512. [Google Scholar] [CrossRef]

- Conrads, H.; Schmidt, M. Plasma generation and plasma sources. Plasma Sources Sci. Technol. 2000, 9, 441. [Google Scholar] [CrossRef]

- Jang, B.Z. Control of interfacial adhesion in continuous carbon and Kevlar fiber reinforced polymer composites. Compos. Sci. Technol. 1992, 44, 333–349. [Google Scholar] [CrossRef]

- Sánchez, M.L.; Patino, W.; Cardenas, J. Physical-mechanical properties of bamboo fibers-reinforced biocomposites: Influence of surface treatment of fibers. J. Build. Eng. 2020, 28, 101058. [Google Scholar] [CrossRef]

- Gleissner, C.; Landsiedel, J.; Bechtold, T.; Pham, T. Surface activation of high performance polymer fibers: A review. Polym. Rev. 2022, 62, 757–788. [Google Scholar] [CrossRef]

- Bahrami, M.; Butenegro, J.A.; Abenojar, J.; Martinez, M.A. Adhesion characteristics of plasma-treated flax fabrics and elastoplastic properties of their biocomposites. J. Adhes. 2024, 1–26. [Google Scholar] [CrossRef]

- Campoy, I.; Gomez, M.; Marco, C. Structure and thermal properties of blends of nylon 6 and a liquid crystal copolyester. Polymer 1998, 39, 6279–6288. [Google Scholar] [CrossRef]

- Wunderlich, B. Thermal Analysis of Polymeric Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Acierno, S.; Van Puyvelde, P. Rheological behavior of polyamide 11 with varying initial moisture content. J. Appl. Polym. Sci. 2005, 97, 666–670. [Google Scholar] [CrossRef]

- Huner, U. Effect of water absorption on the mechanical properties of flax fiber reinforced epoxy composites. Adv. Sci. Technol. Res. J. 2015, 9, 1–6. [Google Scholar] [CrossRef]

- ASTM D570-98; Standard Test Method for Water Absorption of Plastics. ASTM Standard: West Conshohocken, PA, USA, 1985.

- Collings, T. Moisture absorption–Fickian diffusion kinetics and moisture profiles. In Handbook of Polymer Fibre Composites UK: Longman Scientific and Technical; Longman Pub Group: London, UK, 1994; pp. 366–371. [Google Scholar]

- Correlo, V.M.; Pinho, E.D.; Pashkuleva, I.; Bhattacharya, M.; Neves, N.M.; Reis, R.L. Water absorption and degradation characteristics of chitosan-based polyesters and hydroxyapatite composites. Macromol. Biosci. 2007, 7, 354–363. [Google Scholar] [CrossRef] [PubMed]

- Abot, J.; Yasmin, A.; Daniel, I. Hygroscopic behavior of woven fabric carbon-epoxy composites. J. Reinf. Plast. Compos. 2005, 24, 195–207. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Wight, C.A. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim. Acta 1999, 340, 53–68. [Google Scholar] [CrossRef]

- Blaine, R.L.; Kissinger, H.E. Homer Kissinger and the Kissinger equation. Thermochim. Acta 2012, 540, 1–6. [Google Scholar] [CrossRef]

- Toop, D.J. Theory of life testing and use of thermogravimetric analysis to predict the thermal life of wire enamels. IEEE Trans. Electr. Insul. 1971, 6, 2–14. [Google Scholar] [CrossRef]

- Florez, T.A.; Aparicio, G.M. Thermal characterization and lifetime estimation of the humus lombricospt. Am. J. Anal. Chem. 2014, 5, 45–49. [Google Scholar] [CrossRef]

- Van de Velde, K.; Baetens, E. Thermal and mechanical properties of flax fibres as potential composite reinforcement. Macromol. Mater. Eng. 2001, 286, 342–349. [Google Scholar] [CrossRef]

- Khalfallah, M.; Abbès, B.; Abbès, F.; Guo, Y.; Marcel, V.; Duval, A.; Vanfleteren, F.; Rousseau, F. Innovative flax tapes reinforced Acrodur biocomposites: A new alternative for automotive applications. Mater. Des. 2014, 64, 116–126. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Frone, A.N.; Nicolae, C. Micro-and nano-mechanical characterization of polyamide 11 and its composites containing cellulose nanofibers. Eur. Polym. J. 2013, 49, 3857–3866. [Google Scholar] [CrossRef]

- Ardanuy, M.; Antunes, M.; Velasco, J.I. Vegetable fibres from agricultural residues as thermo-mechanical reinforcement in recycled polypropylene-based green foams. Waste Manag. 2012, 32, 256–263. [Google Scholar] [CrossRef] [PubMed]

- Oliver-Ortega, H.; Méndez, J.A.; Mutjé, P.; Tarrés, Q.; Espinach, F.X.; Ardanuy, M. Evaluation of thermal and thermomechanical behaviour of bio-based polyamide 11 based composites reinforced with lignocellulosic fibres. Polymers 2017, 9, 522. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, M.; Tamil Selvan, M.; Niranjana, K. Hygrothermal Aging, Kinetics of Moisture Absorption, Degradation Mechanism and Their Influence on Performance of the Natural Fibre Reinforced Composites. In Aging Effects on Natural Fiber-Reinforced Polymer Composites: Durability and Life Prediction; Springer: Berlin/Heidelberg, Germany, 2022; pp. 257–277. [Google Scholar]

- Jean, J.Y.; Mallon, P.E.; Schrader, D.M. Principles and Applications of Positron and Positronium Chemistry; World Scientific: Singapore, 2003. [Google Scholar]

- Bourmaud, A.; Morvan, C.; Baley, C. Importance of fiber preparation to optimize the surface and mechanical properties of unitary flax fiber. Ind. Crops Prod. 2010, 32, 662–667. [Google Scholar] [CrossRef]

- Le Duigou, A.; Davies, P.; Baley, C. Exploring durability of interfaces in flax fibre/epoxy micro-composites. Compos. Part A Appl. Sci. Manuf. 2013, 48, 121–128. [Google Scholar] [CrossRef]

- Qian, S.; Wang, H.; Zarei, E.; Sheng, K. Effect of hydrothermal pretreatment on the properties of moso bamboo particles reinforced polyvinyl chloride composites. Compos. Part B Eng. 2015, 82, 23–29. [Google Scholar] [CrossRef]

- Masoodi, R.; Pillai, K.M. A study on moisture absorption and swelling in bio-based jute-epoxy composites. J. Reinf. Plast. Compos. 2012, 31, 285–294. [Google Scholar] [CrossRef]

- Daramola, O.O.; Adediran, A.A.; Adewuyi, B.O.; Adewole, O. Mechanical properties and water absorption behaviour of treated pineapple leaf fibre reinforced polyester matrix composites. Leonardo J. Sci. 2017, 30, 15–30. [Google Scholar]

- Hamdan, M.H.M.; Siregar, J.P.; Cionita, T.; Jaafar, J.; Efriyohadi, A.; Junid, R.; Kholil, A. Water absorption behaviour on the mechanical properties of woven hybrid reinforced polyester composites. Int. J. Adv. Manuf. Technol. 2019, 104, 1075–1086. [Google Scholar] [CrossRef]

- Venoor, V.; Park, J.H.; Kazmer, D.O.; Sobkowicz, M.J. Understanding the effect of water in polyamides: A review. Polym. Rev. 2021, 61, 598–645. [Google Scholar] [CrossRef]

- Marcovich, N.E.; Reboredo, M.M.; Aranguren, M.I. Modified woodflour as thermoset fillers: II. Thermal degradation of woodflours and composites. Thermochim. Acta 2001, 372, 45–57. [Google Scholar] [CrossRef]

- Batista, N.L.; Costa, M.L.; Iha, K.; Botelho, E.C. Thermal degradation and lifetime estimation of poly (ether imide)/carbon fiber composites. J. Thermoplast. Compos. Mater. 2015, 28, 265–274. [Google Scholar] [CrossRef]

- Enciso, B.; Abenojar, J.; Aparicio, G.; Martínez, M. Decomposition kinetics and lifetime estimation of natural fiber reinforced composites: Influence of plasma treatment and fiber type. J. Ind. Text. 2021, 51, 594–610. [Google Scholar] [CrossRef]

- Paik, P.; Kar, K.K. Kinetics of thermal degradation and estimation of lifetime for polypropylene particles: Effects of particle size. Polym. Degrad. Stab. 2008, 93, 24–35. [Google Scholar] [CrossRef]

| Natural Fiber Composites | Water Absorption (%) | Reference |

|---|---|---|

| Sisal/polyester | 7–22 | [16,17] |

| Flax/bio-epoxy | 6–12 | [18,19] |

| Jute/polyester | 8–20 | [20,21] |

| Hemp/polyester | 10–16 | [22,23] |

| Coir/epoxy | 2–15 | [24,25] |

| Layup | Average Thickness (mm) | Fiber Volume Fraction (%) | ||

|---|---|---|---|---|

| Flax Vf | Carbon Vc | Vf + Vc | ||

| [C2]S | 1.60 ± 0.06 | 0 | 30 | 30 |

| [CF]S | 2.06 ± 0.03 | 30 | 10 | 40 |

| [F2]S | 2.32 ± 0.04 | 42 | 0 | 42 |

| [C2]S | [CF]S | [F2]S | |

|---|---|---|---|

| Tg (°C) | 40.5 | 39.3 | 39.2 |

| Tm (°C) | 193.5 | 193.5 | 193.7 |

| ∆H (J/g) | 23.9 | 36.1 | 33.3 |

| Xc (%) | 16.7 | 29.7 | 28.0 |

| Frequency (cm−1) | Vibration |

|---|---|

| 3301 | N-H stretching strong band/OH |

| 3082 | NH groups weak band |

| 2918 | CH2 asymmetric stretching |

| 2850 | CH2 symmetric stretching |

| 1732 | O-C=O |

| 1635 | Amide I, C=O stretching |

| 1550 | Amide II, C- stretching + C=O in-plane bending |

| 1465 | CH2 bending asym |

| 1367 | CH2 bending sym |

| 1275 | Amide III, NH-O stretching |

| 1226 | C-O-C streching sym/CH2 bending |

| 1111 | CH3 rocking |

| 934 | C-C(O) stretching mode (amide IV) |

| 721 | CH2 rocking/C=O deformation |

| 678 | NH out-of-plane mode (amide V) |

| Materials | PA11 | [C2]S | [CF]S |

|---|---|---|---|

| Td (°C) | 426 ± 8 | 431 ± 8 | 350 ± 6 |

| 463 ± 8 |

| Materials | PA11 | [C2]S | [CF]S |

|---|---|---|---|

| Ed (kJ/mol) | 290.3 | 288.5 | 268.0 |

| Materials | PM (g/mol) | 16 | 17 | 18 | 32 | 44 | 28 | 40 |

|---|---|---|---|---|---|---|---|---|

| Gas | CH4 | OH− | H2O | O2 | CO2 | CO | -CH-CH-CH2 | |

| PA11 | Temperature (°C) | 430 | 430 | 430 | 432 | 430 | - | 430 |

| [C2]S | 430 | 430 | 430 | 432 | 430 | - | 430 | |

| [CF]S | 264 310 | 264 310 | 264 310 | 264 310 | 264 310 | 264 310 | 264 310 |

| D × 10−8 (m2/s) | |

|---|---|

| Moisture Absorption | |

| [C2]S | 1.66 |

| [CF]S | 1.86 |

| [F2]S | 1.94 |

| Property | Sample | 0 h | 2 h | 24 h | 7 d | 15 d | 30 d |

|---|---|---|---|---|---|---|---|

| Tg (°C) | [C2]S –W 1 | 40 | 40 | 38 | 31 | 38 | 32 |

| Tm (°C) | 193 | 194 | 193 | 194 | 193 | 194 | |

| ∆H (J/g) | 24 | 25 | 26 | 25 | 29 | 31 | |

| χc (%) | 17 | 17 | 18 | 17 | 20 | 21 | |

| Tg (°C) | [CF]S –W | 39 | 41 | 37 | 31 | 32 | 32 |

| Tm (°C) | 193 | 194 | 195 | 195 | 191 | 194 | |

| ∆H (J/g) | 36 | 34 | 28 | 28 | 32 | 33 | |

| χc (%) | 29 | 27 | 23 | 23 | 24 | 27 | |

| Tg (°C) | [F2]S –W | 39 | 39 | 38 | 37 | 36 | 36 |

| Tm (°C) | 193 | 194 | 194 | 192 | 192 | 193 | |

| ∆H (J/g) | 33 | 32 | 33 | 34 | 40 | 34 | |

| χc (%) | 28 | 27 | 25 | 28 | 33 | 29 | |

| Tg (°C | [C2]S –RH 2 | 40 | 39 | 40 | 40 | 38 | 39 |

| Tm (°C) | 193 | 197 | 192 | 195 | 195 | 192 | |

| ∆H (J/g) | 23 | 21 | 29 | 22 | 28 | 24 | |

| χc (%) | 16 | 14 | 20 | 15 | 19 | 17 | |

| Tg (°C | [CF]S –RH | 39 | 40 | 40 | 40 | 39 | 40 |

| Tm (°C) | 193 | 195 | 196 | 194 | 197 | 199 | |

| ∆H (J/g) | 36 | 33 | 27 | 29 | 24 | 25 | |

| χc (%) | 29 | 27 | 22 | 24 | 19 | 20 | |

| Tg (°C | [F2]S –RH | 39 | 39 | 41 | 39 | 40 | 39 |

| Tm (°C) | 193 | 194 | 194 | 192 | 192 | 193 | |

| ∆H (J/g) | 33 | 36 | 33 | 36 | 36 | 36 | |

| χc (%) | 28 | 30 | 27 | 30 | 29 | 30 |

| Materials | (α) | Thermal Lifetime Estimation (Minute) | |||||

|---|---|---|---|---|---|---|---|

| 25 °C | 50 °C | 100 °C | 150 °C | 200 °C | 300 °C | ||

| PA11 | 5% | 3.5 × 1023 | 1.3 × 1021 | 6.9 × 1017 | 1.9 × 1015 | 4.5 × 1010 | 7255.1 |

| [C2]S | 1.2 × 1020 | 3.7 × 1017 | 3.6 × 1013 | 3.2 × 1010 | 3.8 × 107 | 1089.8 | |

| [CF]S | 1.7 × 1020 | 5.2 × 1016 | 8.9 × 1011 | 2.1 × 108 | 2.9 × 105 | 47.1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahrami, M.; Abenojar, J.; Aparicio, G.M.; Martínez, M.A. Thermal Stability, Durability, and Service Life Estimation of Woven Flax-Carbon Hybrid Polyamide Biocomposites. Materials 2024, 17, 2020. https://doi.org/10.3390/ma17092020

Bahrami M, Abenojar J, Aparicio GM, Martínez MA. Thermal Stability, Durability, and Service Life Estimation of Woven Flax-Carbon Hybrid Polyamide Biocomposites. Materials. 2024; 17(9):2020. https://doi.org/10.3390/ma17092020

Chicago/Turabian StyleBahrami, Mohsen, Juana Abenojar, Gladis M. Aparicio, and Miguel Angel Martínez. 2024. "Thermal Stability, Durability, and Service Life Estimation of Woven Flax-Carbon Hybrid Polyamide Biocomposites" Materials 17, no. 9: 2020. https://doi.org/10.3390/ma17092020