1. Introduction

A new, high-entropy alloying strategy for the development of high strength and high-temperature alloys has been recently proposed [

1,

2]. In contrast to conventional alloys, which are usually based upon one principal element, high entropy alloys (HEAs) are multi-principal element alloys (e.g., AlCoCrCuFeNi), containing five or more elements at near equiatomic concentrations. High configurational entropy of mixing of the alloying elements is believed to stabilize the more ductile disordered solid-solution phases relative to the brittle intermetallic phases. This strategy is based upon the simple thermodynamic argument that random solid-solutions of multi-principal alloying elements will have higher mixing entropies than intermetallic compounds, and will therefore tend to be more stable (

i.e., they have a lower Gibbs free energy of formation, ΔG = ΔH − TΔS). Since the concept of HEAs was first introduced less than a decade ago, many studies have been carried out to verify this new strategy for alloy design and some HEAs having excellent engineering properties, such as high strength, good ductility, and resistance to corrosion, oxidation, and wear, have been developed [

3,

4,

5,

6,

7,

8].

The design and development of HEAs is built upon the fact that high configuration entropy makes a significant contribution to the phase stability of random mixed disordered solution phases. However, the stability of a phase is determined by its Gibbs energy, which includes contributions from both enthalpy and entropy. The microstructure of an alloy is therefore the result of stability competition among variety of phases in the system. Phase diagrams, which are referred as the road maps for materials design, provide essential information on the phase stability at a given alloy chemistry and temperature. While most of the binary phase diagrams and some ternary sections have been determined via experimental approach, and they can be found in the literatures and handbooks, this is not the case for multi-component systems. Determination of multi-component phase diagrams solely by experimental approaches is obviously not feasible due to the tremendous amount of work involved. In recent years, integration of the calculation of phase diagrams (CALPHAD) approach with key experiments has been used as an effective approach in the determination of complicated multi-component phase diagrams [

9]. The essence of the CALPHAD approach is to develop a thermodynamic database for a multi-component system using experimental data from the constituent binaries and ternaries. This database is then used to calculate the phase stability of the multi-component system. The CALPHAD approach has been successfully applied to the design of traditional alloys based on one key element. In this case, the thermodynamic database needs to be validated only at the corner of the key element. At the same time, to successfully design HEAs that are based on several multiple principal elements, the multi-component thermodynamic database must be developed and validated for the entire composition space, which is a very challenging task.

In this work, a thorough analysis of the microstructure, phase composition and chemical composition of phases in a CrMo0.5NbTa0.5TiZr refractory high entropy alloy was conducted in as-solidified and annealed conditions. The experimental results were compared with the results of solidification and phase equilibrium simulations conducted for this alloy. The purpose of this study was to see if a currently available extensive thermodynamic database can predict the correct topology of phase equilibria in the multi-principal component alloy and to understand the limitations of this database for use in the design of HEAs.

2. Experimental and Modeling Approaches

The CrMo

0.5NbTa

0.5TiZr alloy was prepared by vacuum arc melting of the pure elements. The alloy composition is given in

Table 1. The as-solidified alloy was hot isostatically pressed (HIPd) at 1450 °C for 3 h inside a chamber filled with high purity argon at the pressure of 207 MN/m

2. After HIP, the alloy was cooled to 50 °C at the cooling rate of 20 °C/min with simultaneous pressure release. Details of the alloy preparation and HIP processing are described in [

7]. To study the microstructure/phase stability, the HIPd alloy was annealed at 1000 °C for 100 h. The crystal structure was identified with the use of a Rigaku X-ray diffractometer, using Cu Kα radiation and the 2θ range of 5° to 140°. The microstructure and phases were analyzed with the use of a scanning electron microscope (SEM) Quanta 600F (FEI, North America NanoPort, Hillsboro, OR, USA) equipped with a backscatter electron (BSE), energy-dispersive X-ray spectroscopy (EDS), and electron backscatter diffraction (EBSD) detectors. The quantitative microstructure measurements were conducted using Fovea-Pro software by Reindeer Graphics, Inc. (Asheville, NC, USA).

Solidification simulations and phase equilibrium calculations were performed using the

PandatTM [

10] software and

PanTi [

11] thermodynamic database developed by CompuTherm LLC.

PandatTM is a software package for the calculation of thermodynamic properties and phase equilibria of multi-component, multi-phase systems.

PanTi database is a thermodynamic database for multi-component titanium alloys.

Table 1.

Chemical composition (in at.%) of the CrMo0.5NbTa0.5TiZr alloy produced by vacuum arc melting.

Table 1.

Chemical composition (in at.%) of the CrMo0.5NbTa0.5TiZr alloy produced by vacuum arc melting.

| Element | Cr | Mo | Nb | Ta | Ti | Zr |

|---|

| Composition | 18.39 | 10.04 | 21.84 | 11.86 | 19.40 | 18.48 |

4. Discussion

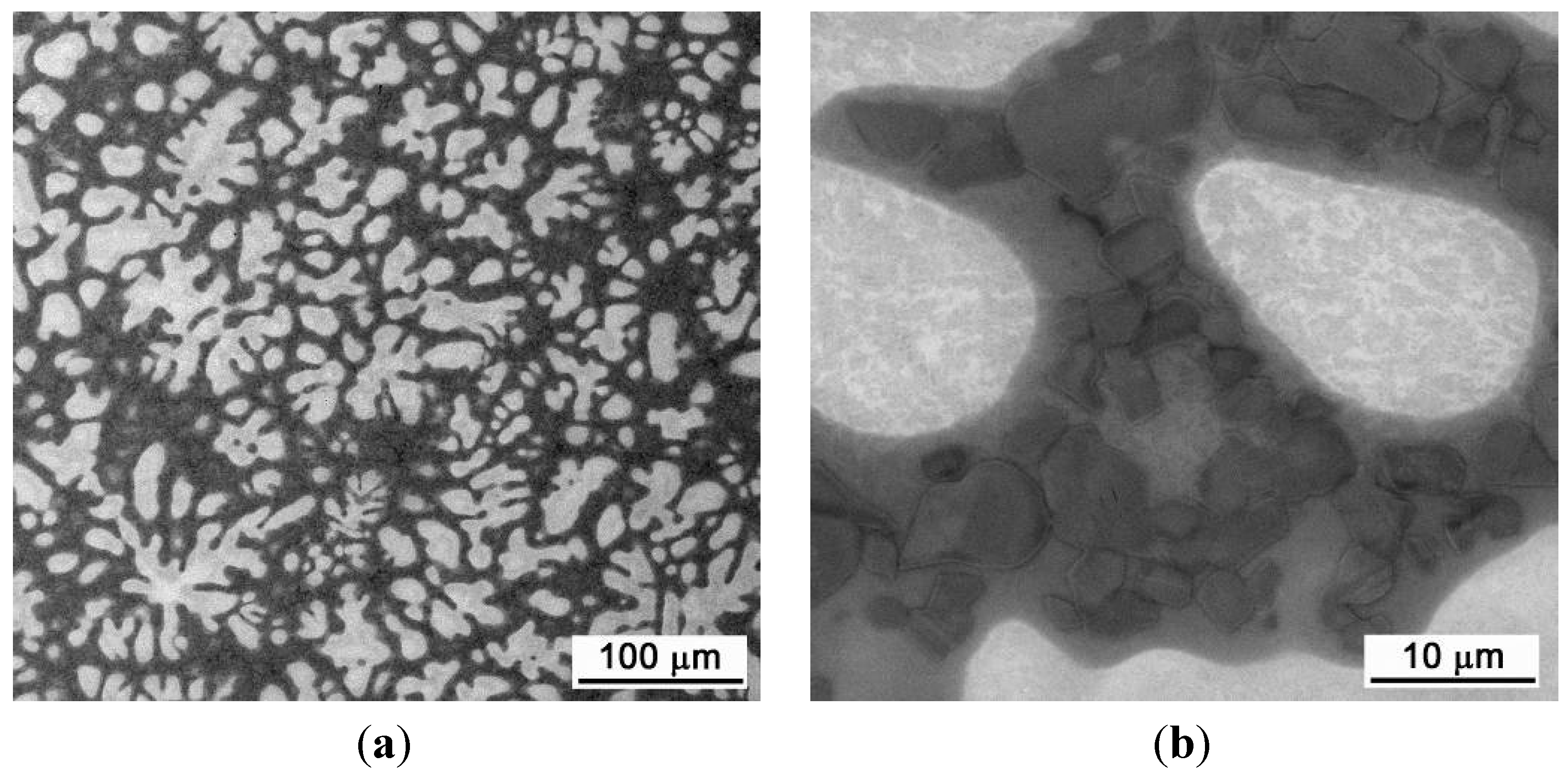

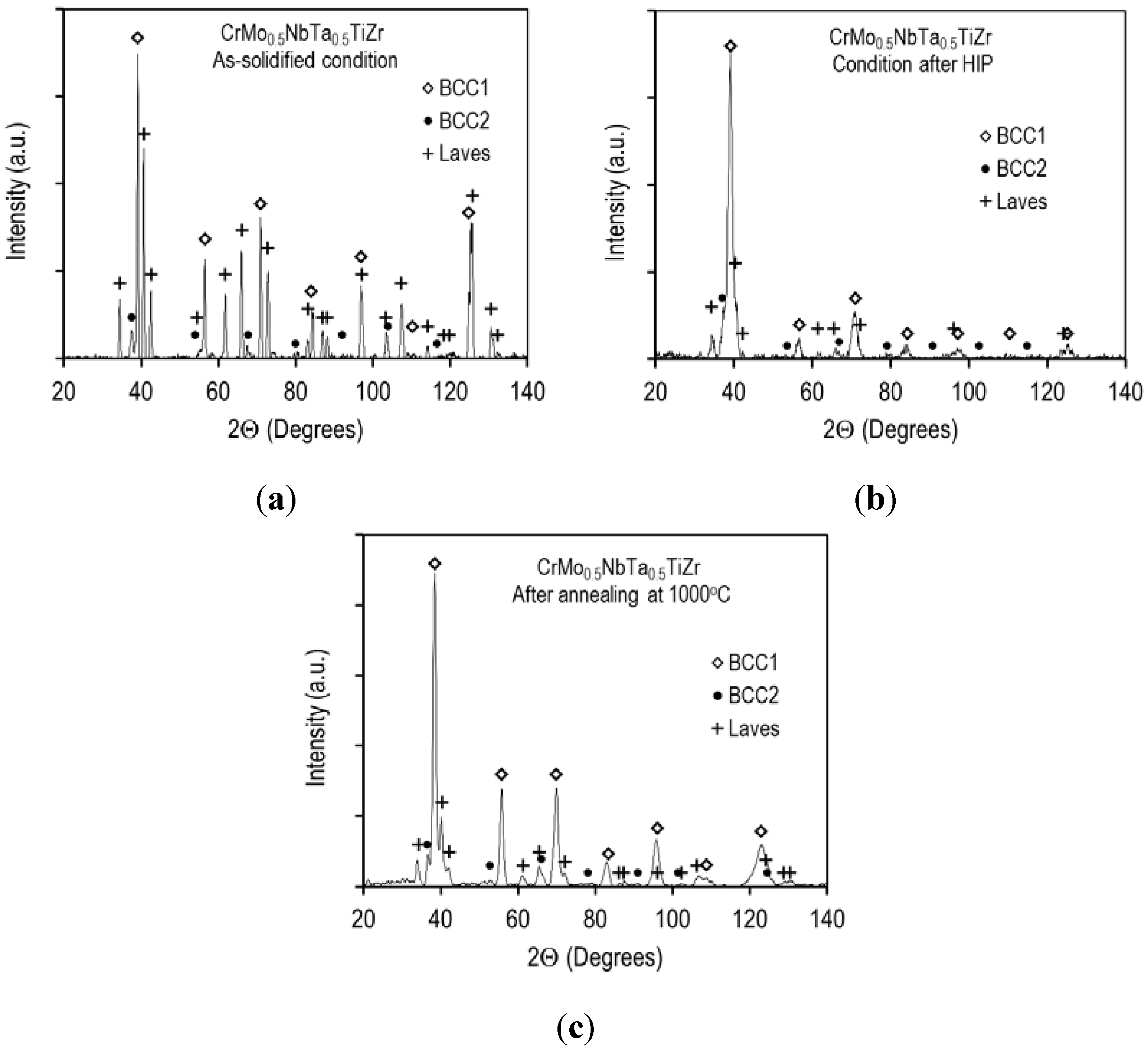

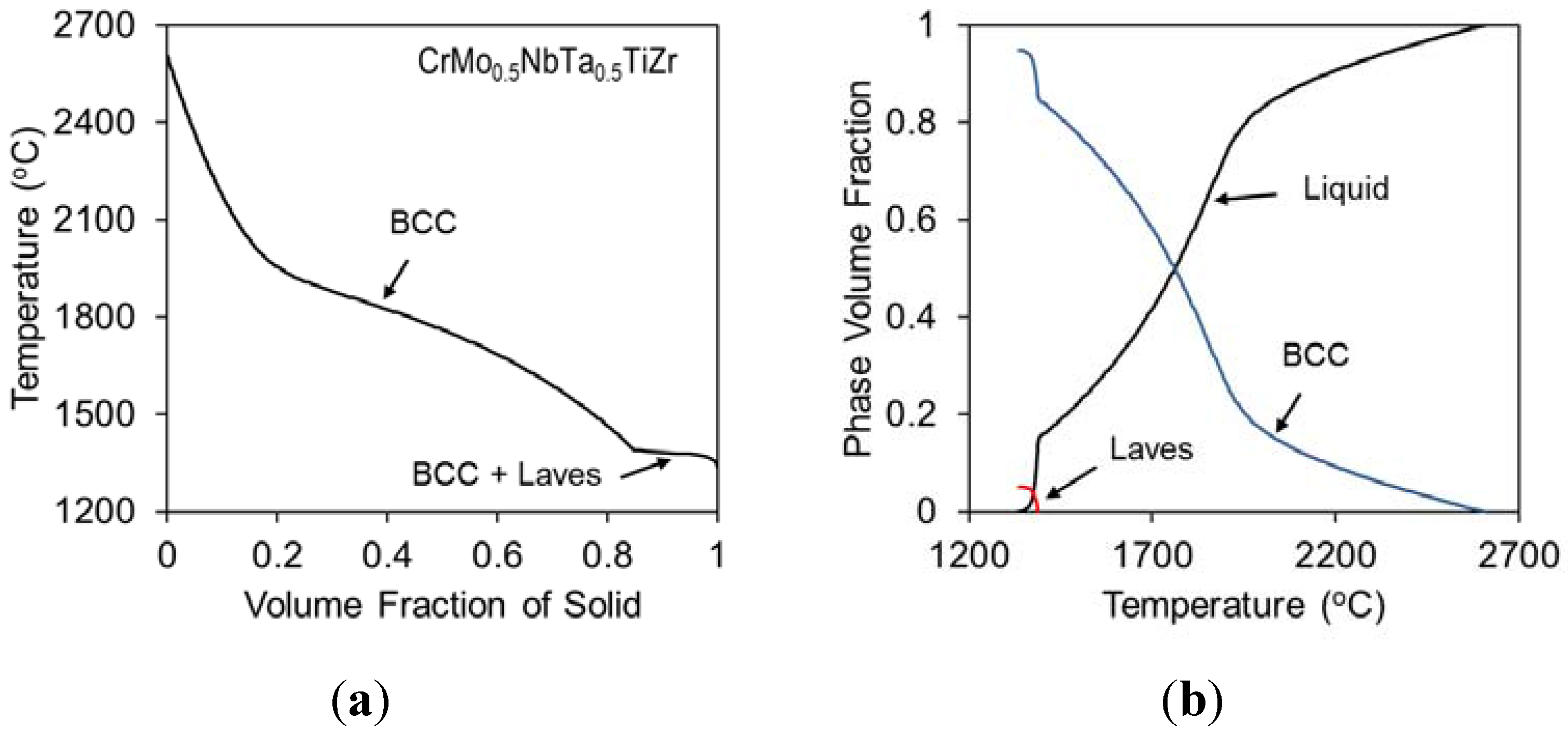

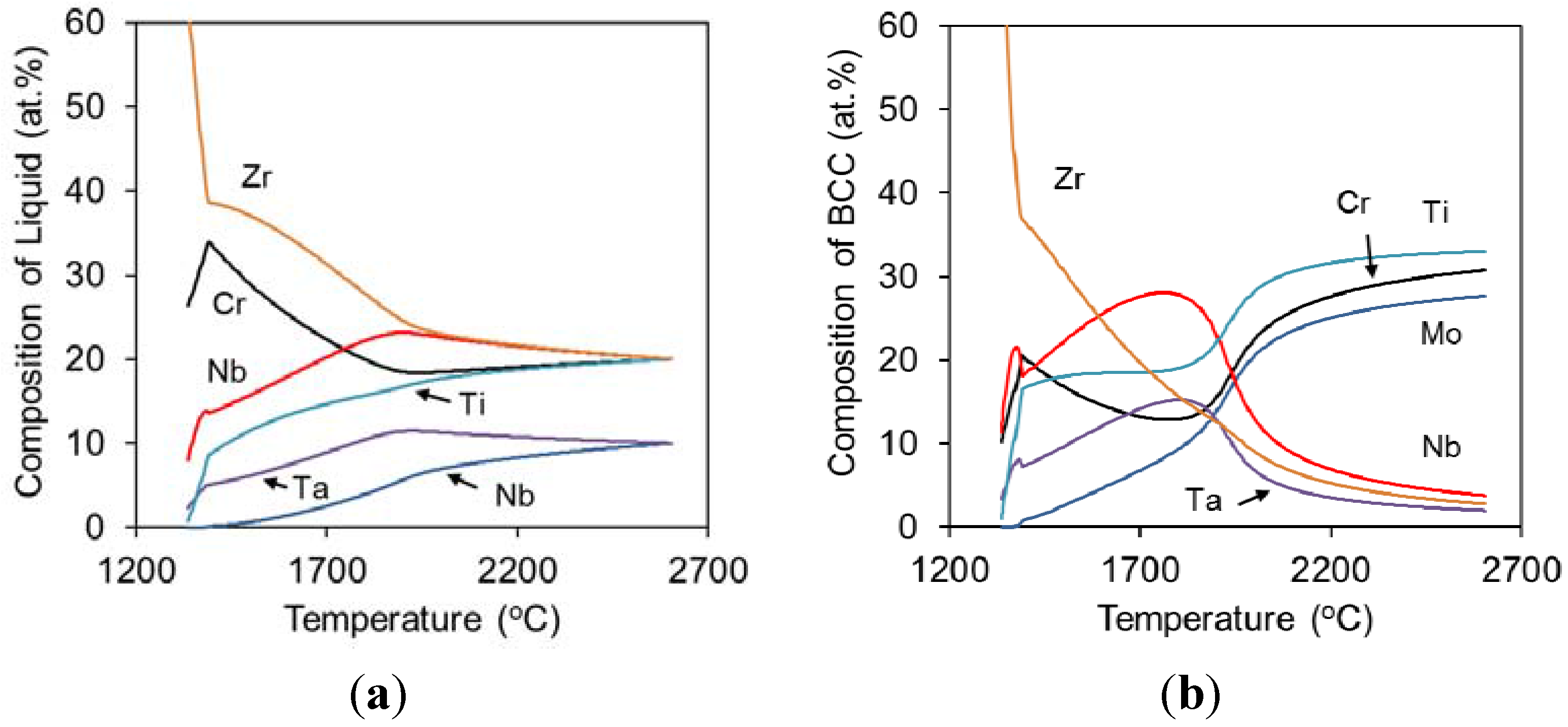

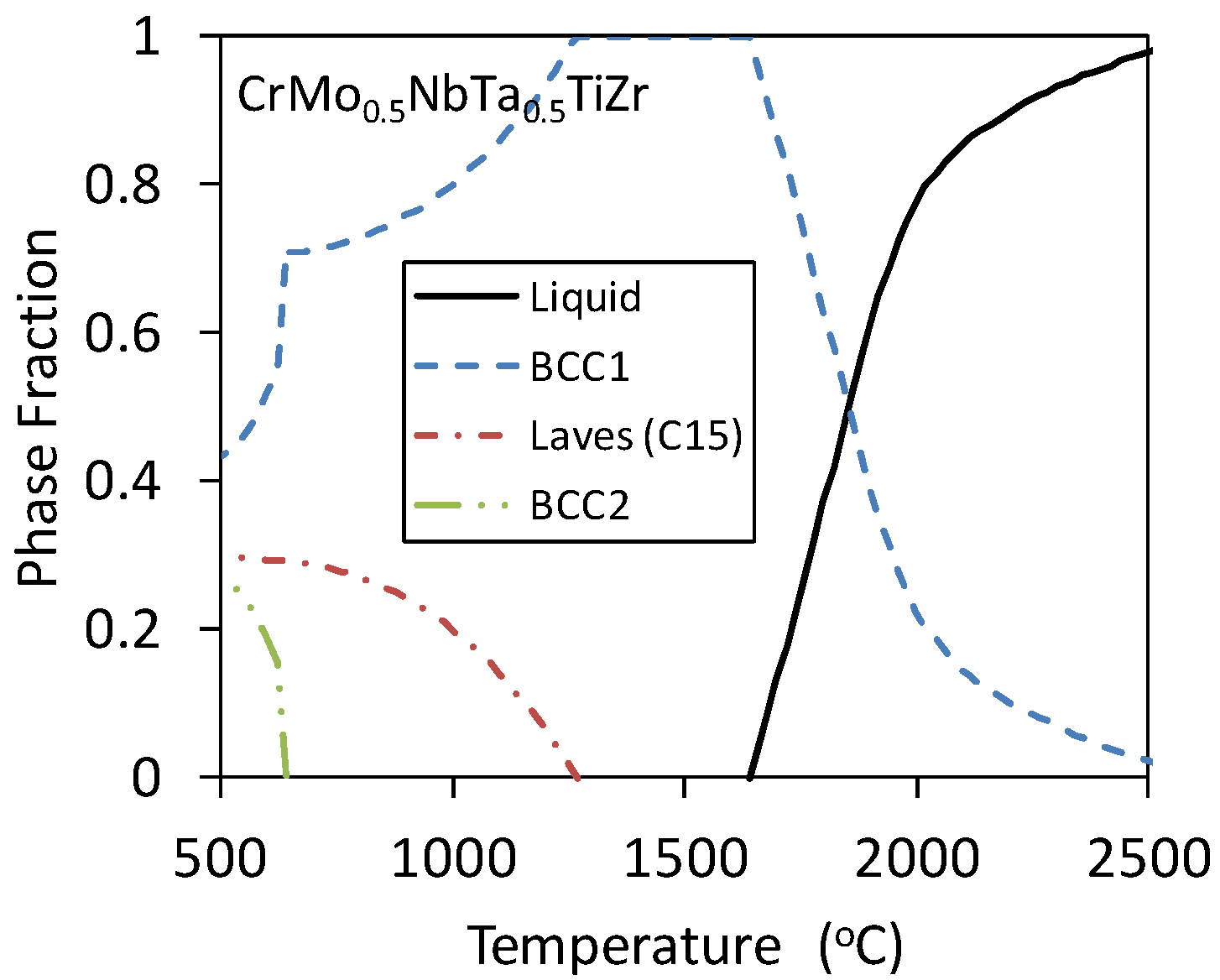

Solidification simulation (Scheil model) results showing the presence of the eutectic reaction with the formation of the BCC2 and Laves phases in the CrMo

0.5NbTa

0.5TiZr high entropy alloy seem to support the experimental observations and explain the morphology of the microstructure, with the mixture of the BCC2 and Laves phases forming a continuous network between the BCC1 (dendrite) particles (see

Figure 4). However, the observed and predicted volume fractions of the phases are quite different. The experimental data shows 42% of BCC1, 27% of BCC2 and 31% of Laves phases in the as-solidified alloy, while Scheil simulation predicts 83% BCC1, 12% BCC2 and 5% Laves. The Scheil model satisfactorily predicts an increased concentration of Zr in the BCC2 phase, however it fails to predict enrichment of the BCC1 phase with Mo, Nb and Ta (compare

Table 2 and

Table 5). The model also incorrectly predicts considerably higher amounts of Zr in BCC1 and Cr in the BCC1 and BCC2 phases. The simulated Laves phase is essentially binary Cr

2Zr phase containing very small amount (~0.8%) Ti. The experimental results however indicate that this phase is multicomponent and it contains other alloying elements at rather large concentrations, varying from 8.1% for Mo to 13.5% for Nb, which partially replace Cr and Zr in the binary Laves phase. It is likely that the lack of predicting high solubility of the alloying elements in the Cr

2Zr Laves phase is the main reason that the solidification simulation calculates considerably smaller amount of the Laves phase.

The experimental results seem to largely disagree with the simulated equilibrium phase diagram. In accord to this diagram, the alloy must have a single-phase BCC1 structure at T = 1450 °C and two-phase, BCC1 and Laves, structure at T = 1000 °C. However, all three phases BCC1, BCC2 and Laves are present both after HIP at 1450 °C for 3 h and after annealing at 1000 °C for 100 h. The main difference between the HIPd and annealed samples is a higher volume fraction of the Laves phase, at the same volume fraction of the BCC2 phase, in the annealed sample, due to additional precipitation of fine Laves phase particles inside the BBC1 phase. This observation indicates that the volume fraction of the Laves phase in the alloy increases with a decrease in temperature due to partial decomposition of the BCC1 phase, which is supported by the simulated data. Due to this decomposition, the BCC1 phase becomes more depleted with Cr. The modeling of equilibrium phases however predicts 80% of the BCC1 phase and 20% of the Laves phase at T = 1000 °C, while the experimental results show 52% BCC1, 16% BCC2 and 32% Laves phases after annealing at 1000 °C for 100 h. The main difference is again in incorrect prediction of the composition of the Laves phase.

The discrepancies found between the calculated results and the experimental data suggest that the current

PanTi thermodynamic database, which was developed for titanium-based alloys and validated at the Ti-rich corner, is not valid in the entire composition space of the Cr-Mo-Nb-Ta-Ti-Zr system and cannot be used to predict the phase stability of alloys with near equiatomic concentrations. This thermodynamic database was developed by the CALPHAD approach [

12,

13,

14]. Thermodynamic descriptions for all the key binaries and some key ternaries were developed in this database. On the basis of these descriptions, a reliable account of a higher order system at the Ti-corner was obtained via the extrapolation method [

15]. Model parameters for the subsystems higher than ternaries are usually not considered in the construction of a conventional multi-component database. This is because although interactions between binary components are strong, they are weaker among ternary components, and the interactions in higher order subsystems become negligibly weak [

14,

16]. The

PanTi thermodynamic database developed by this way enables calculation of the phase diagrams for multi-component Ti-based systems that are experimentally unavailable.

In spite of only constituent binaries and ternaries are considered, the number of subsystems need to be assessed is still large. There are

constituent binaries and

constituent ternaries in an

n components system, which represent 10 binaries and 10 ternaries in a five-component system, and 45 binaries and 120 ternaries in a ten-component system. The large number of subsystems and the lack of experimental data make the development of “complete” thermodynamic database that can be applied to the entire composition space for a system with more than 10 components extremely difficult. It is due to this reason that most of currently available databases were developed and validated at the key component corner. Although they are quite useful for correct prediction and understanding of the phase equilibria and microstructures in the key-component based alloys, the currently available databases require additional adjustments before they can be successfully applied to multi-principle component alloys. How to apply the CALPHAD approach in aiding the design of HEAs was discussed by Zhang

et al. [

17]. In particular, in order to develop a thermodynamic database that is valid in the entire composition region for the Cr-Mo-Nb-Ta-Ti-Zr system, 15 constituent binaries and 20 constituent ternaries need to be assessed. These constituent binaries and ternaries are listed in

Table 8 and

Table 9. In the current

PanTi database, all the constituent binaries listed in

Table 8 were assessed, while only the Ti-X-Y ternaries (X and Y represent other elements in the system) at the Ti-corner were assessed. In order to have a complete database for this six-component system, thermodynamic descriptions for all the 20 ternaries listed in

Table 9 need to be developed.

Table 8.

Constituent binaries in the Cr-Mo-Nb-Ta-Ti-Zr system.

Table 8.

Constituent binaries in the Cr-Mo-Nb-Ta-Ti-Zr system.

| Cr-Mo | Cr-Nb | Cr-Ta | Cr-Ti | Cr-Zr |

|---|

| Mo-Nb | Mo-Ta | Mo-Ti | Mo-Zr | Nb-Ta |

| Nb-Ti | Nb-Zr | Ta-Ti | Ta-Zr | Ti-Zr |

Table 9.

Constituent ternaries in the Cr-Mo-Nb-Ta-Ti-Zr system.

Table 9.

Constituent ternaries in the Cr-Mo-Nb-Ta-Ti-Zr system.

| Cr-Mo-Nb | Cr-Mo-Ta | Cr-Mo-Ti | Cr-Mo-Zr | Cr-Nb-Ta |

|---|

| Cr-Nb-Ti | Cr-Nb-Zr | Cr-Ta-Ti | Cr-Ta-Zr | Cr-Ti-Zr |

| Mo-Nb-Ta | Mo-Nb-Ti | Mo-Nb-Zr | Mo-Ta-Ti | Mo-Ta-Zr |

| Mo-Ti-Zr | Nb-Ta-Ti | Nb-Ta-Zr | Nb-Ti-Zr | Ta-Ti-Zr |

5. Conclusions

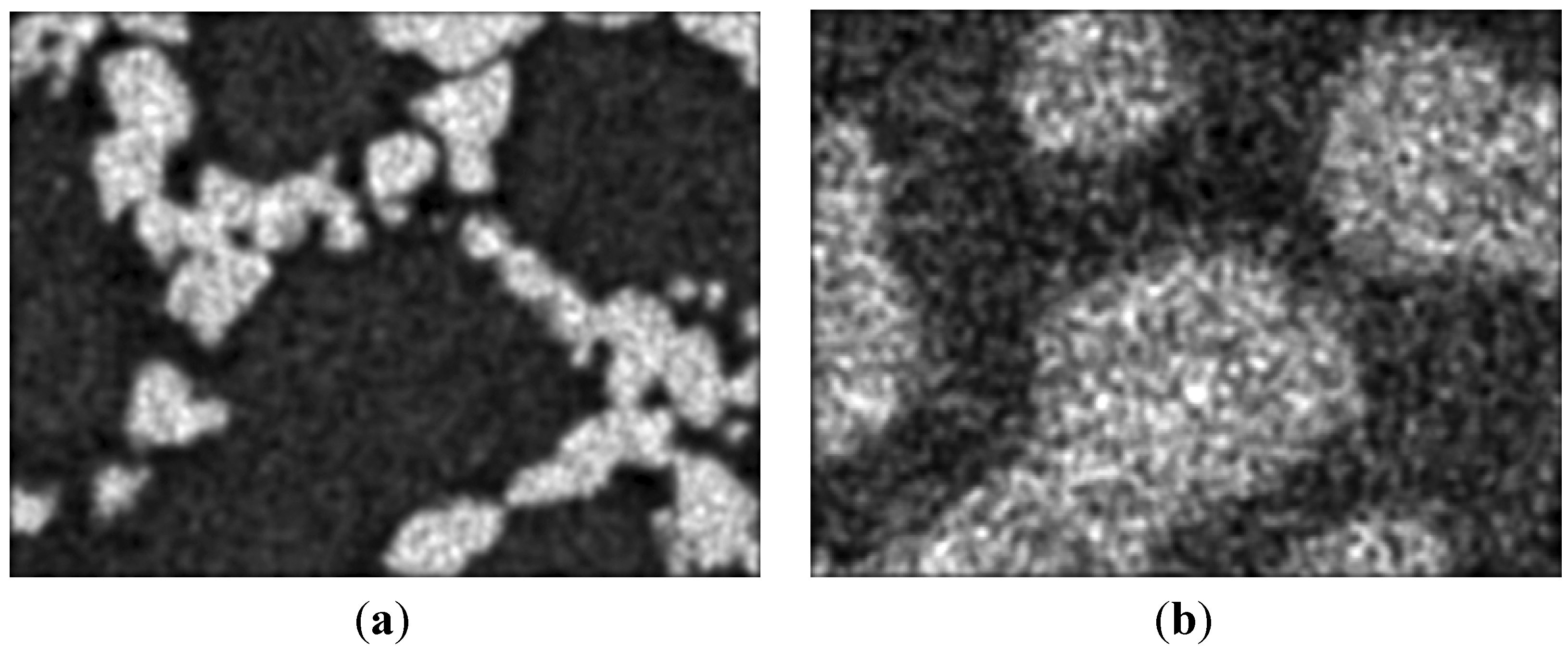

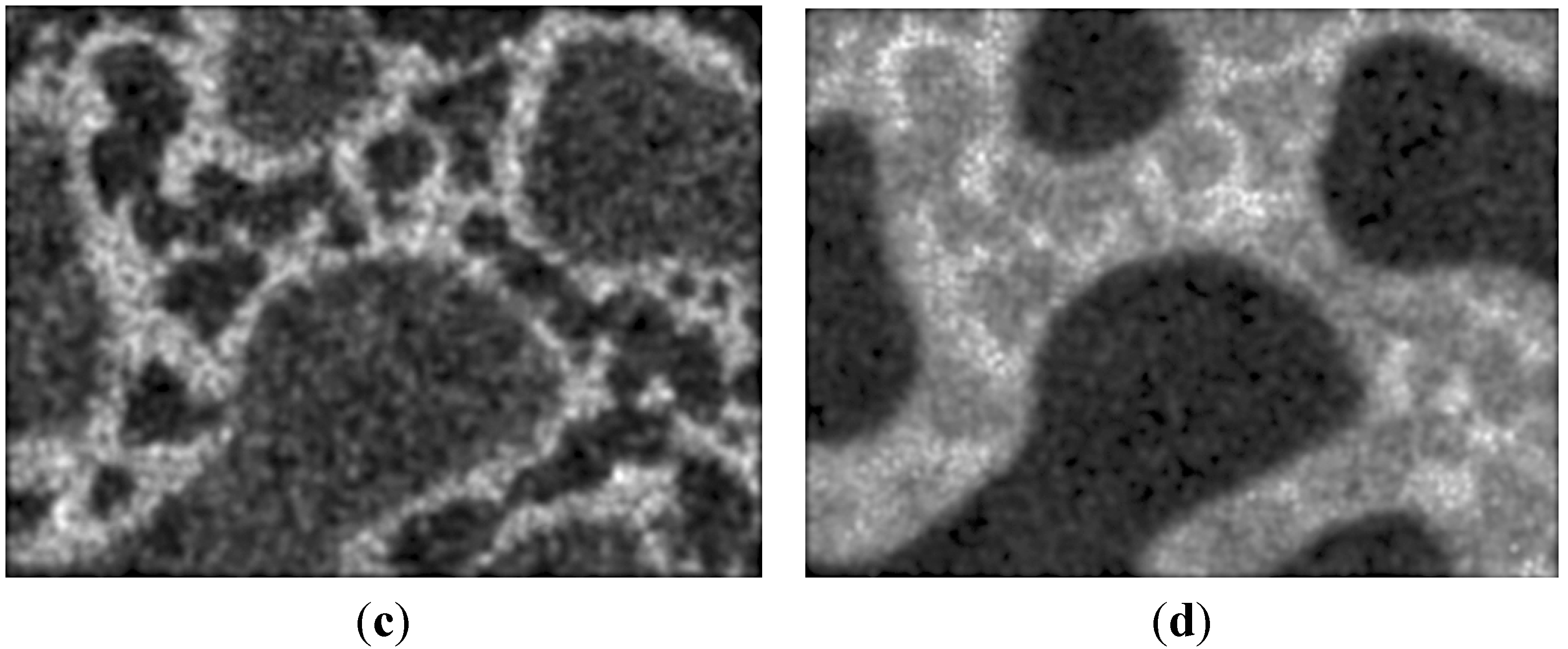

Microstructure and phase composition of a CrMo0.5NbTa0.5TiZr high entropy alloy were studied in the as-solidified condition and after heat treatment at 1450 °C for 3 h and 1000 °C for 100 h.

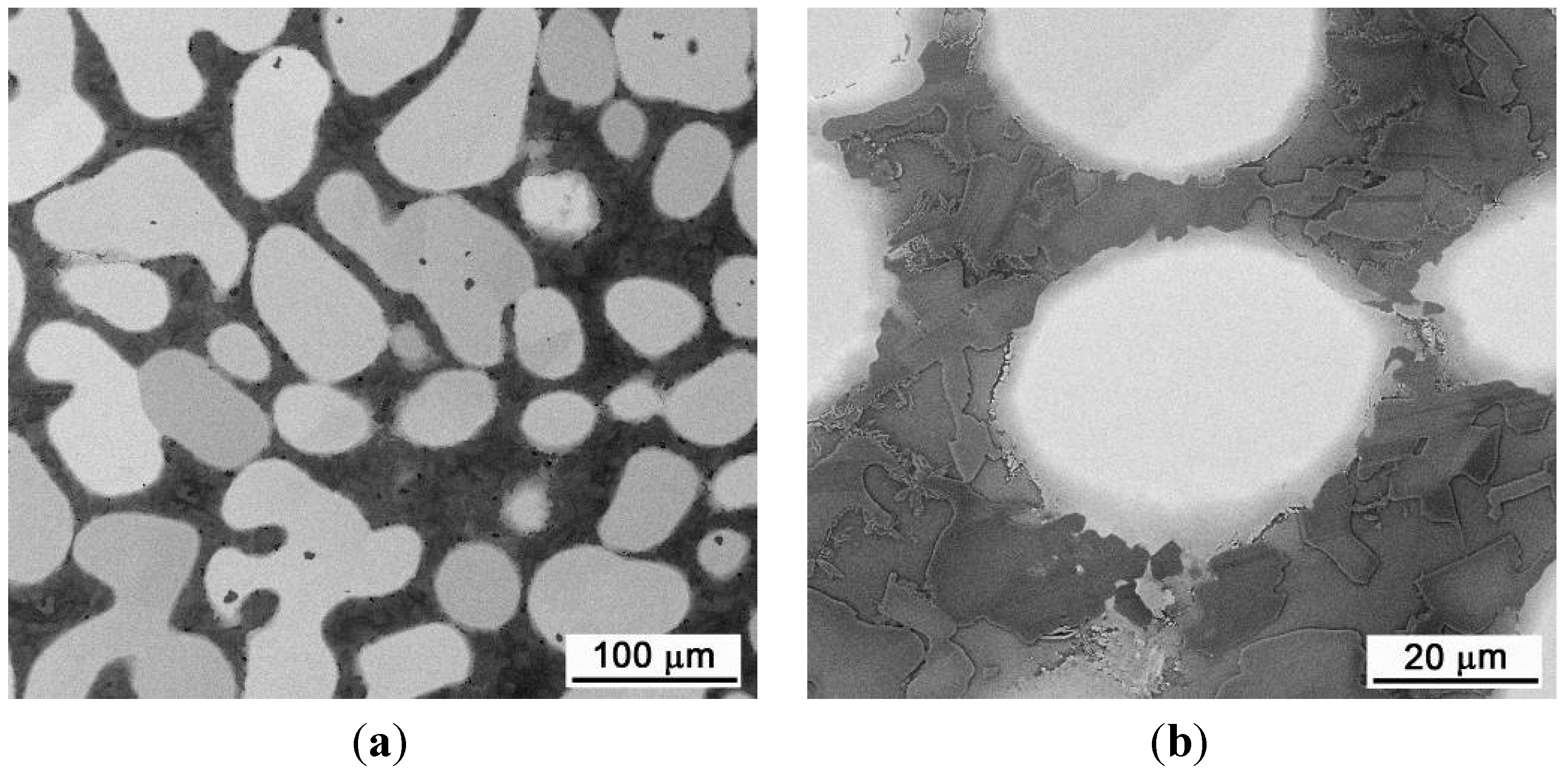

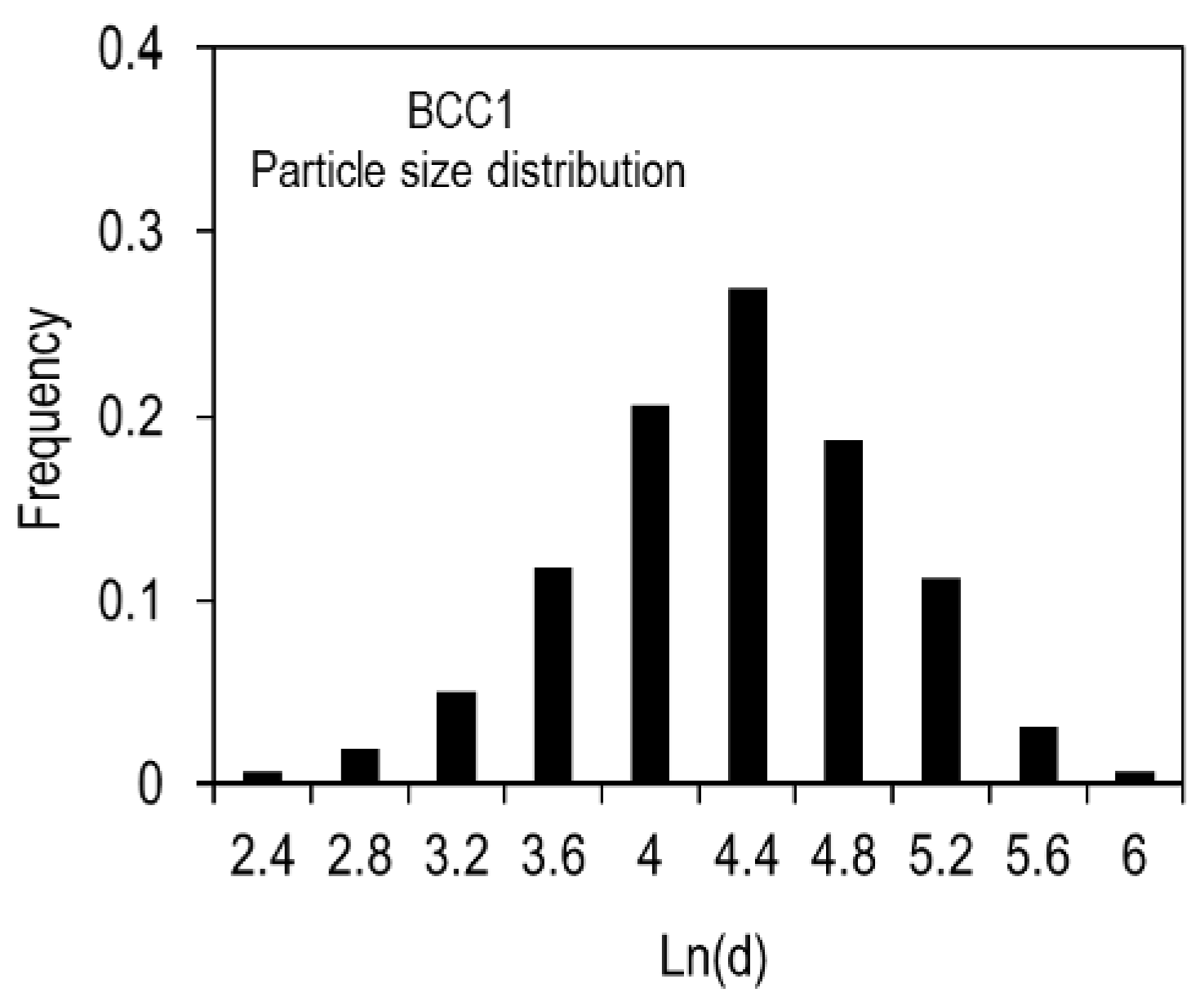

In the as-solidified condition, the alloy consists of three phases, two of which have disordered BCC crystal structures and the third has an ordered cubic Laves phase. The BCC1 phase solidifies first in the form of dendrites enriched with high-melting-temperature elements, Mo, Ta and Nb, and its volume fraction is 42%. The BCC2 and Laves phases likely solidify by eutectic-type reaction filling inter-dendritic regions. The volume fractions of these phases are 27% and 31%, respectively. The BCC2 phase is enriched with Ti and Zr and the Laves phase is heavily enriched with Cr and slightly with Zr. In addition to Cr and Zr, the Laves phase also contains other alloying elements, with the total amount of 37.1%

HIP at 1450 °C for 3 h results in coagulation of the BCC1 dendrites into round-shaped particles and in an increase in the volume fraction of the BCC1 phase to 67%. The volume fractions of the BCC2 and Laves phases decrease to 16% and 17%, respectively. These volume fraction changes cause re-distributions of the alloying elements between the phases. For example, the concentration of Cr in the BCC1 phase increases and in the BCC2 phase decreases. However the main tendency observed for the as-solidified condition remains: the BCC1 phase retains enriched with Mo, Nb and Ta, BCC2 phase is enriched with Ti and Zr and the Laves phase is enriched with Cr.

Annealing at 1000 °C for 100 h, conducted after the HIP processing, results in precipitation of fine, submicron-sized Laves particles inside the BCC1 phase, which causes a decrease in the concentration of Cr and Ta in the BCC1 phase and a decrease in the volume fraction of this phase. After annealing the alloy consists of 52% BCC1, 16% BCC2 and 32% Laves phases.

Thermodynamic analyses of the solidification process and phase equilibria in the CrMo0.5NbTa0.5TiZr alloy were carried out using the thermodynamic database developed by the CALPHAD approach. Discrepancies were found between the calculated results and the experimental data. It was concluded that the current PanTi database, that was initially developed for the Ti-rich alloys, cannot be applied to the multi-principal alloy compositions, far away from the Ti-rich corner. A complete thermodynamic database for the Cr-Mo-Nb-Ta-Ti-Zr six-component system needs to be developed to understand the phase equilibria in this system and guide the design of refractory HEAs based on this system.