Simulation of Entropy Generation under Stall Conditions in a Centrifugal Fan

Abstract

:1. Introduction

2. Numerical Model

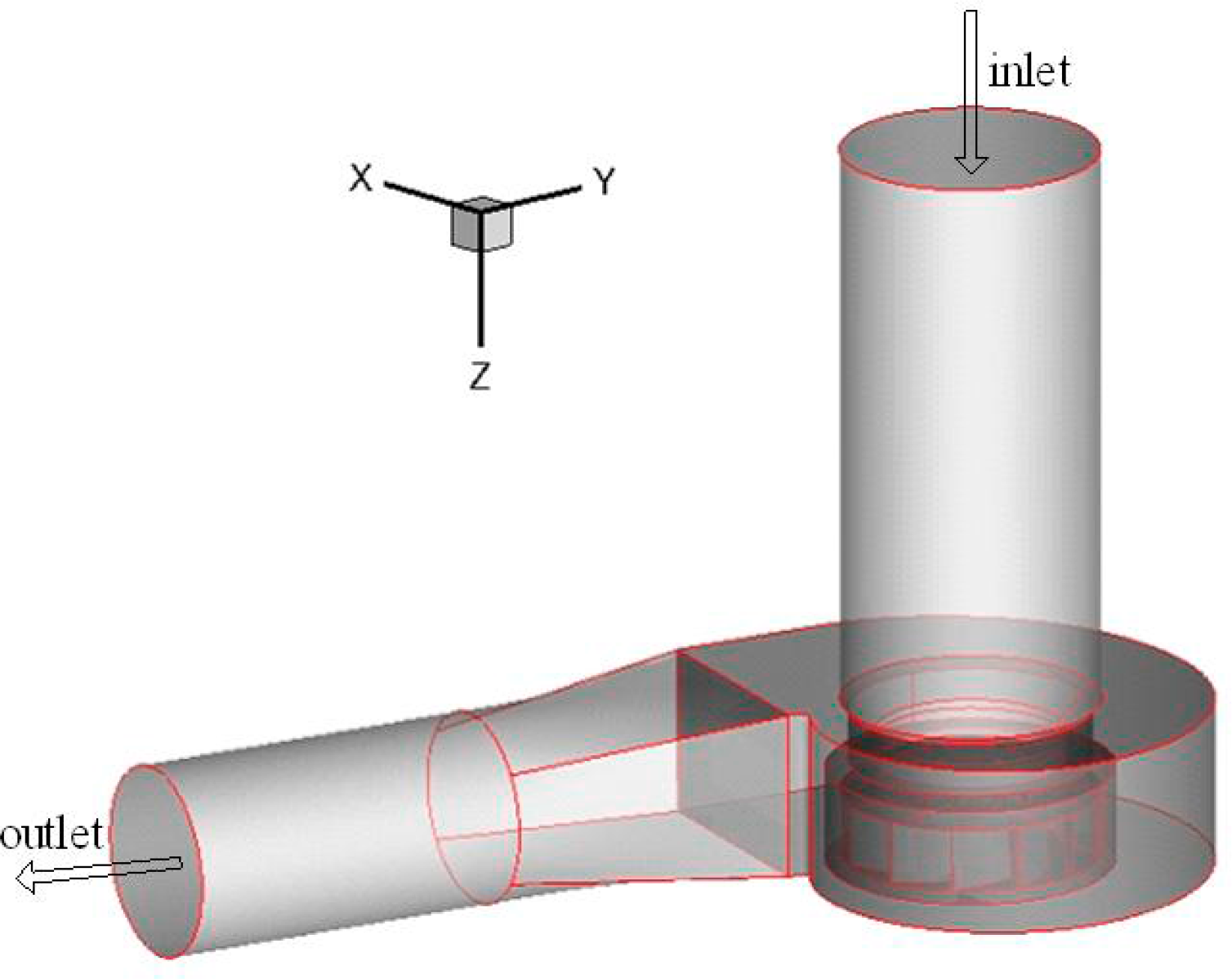

2.1. Geometry Model

2.2. Throttle Model

2.3. Governing Equations

2.4. Meshing Strategy

2.5. Entropy Generation Calculation

3. Results and Discussion

3.1. Entropy Generation Characteristics on Five Typical Conditions

3.2. Entropy Generation Characteristics on Design Condition

3.3. Entropy Generation Characteristics on Stall Inception Condition

3.4. Entropy Generation Characteristics during Rotating Stall Conditions

3.5. Entropy Generation Characteristics During the Circumference Propagation of Stall Cell

4. Conclusions

- (1)

- The entropy generation is concentrated on the impeller and volute for boundary layer separation, turbulence, secondary flow formation, etc. The turbulent dissipation is more significant than viscous dissipation on the entropy generation. With the decrease of the flow rate, the entropy generation becomes larger due to the increase of the incidence angle.

- (2)

- At the stall inception stage, the high entropy generation areas become larger compared to the design condition. There are two high entropy areas and one of them is near the volute tongue. During the maturation of stall cell stage, the number of high entropy generation areas turn into one and the entropy generation is less in the passages away from stall cell. The high entropy generation areas move along the circumferential and axial directions.

- (3)

- During the circumferential propagation of stall cell, the volute tongue has great influence on entropy generation. The entropy generation curves of the impeller and that of volute are similar to sine curves, and their oscillation periods are both 1.6 revolutions. With the decrease of flow rate, the stall cell has greater influence on entropy generation and the amplitude of the curves become larger.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- An, L.S. The structure and performance of fan. In Pumps and Fans; China Electric Power Press: Beijing, China, 2001; pp. 31–36. (in Chinese) [Google Scholar]

- Bejan, A. Entropy minimization: The new thermodynamics of finite-size devices and finite-time processes. Appl. Phys 1996, 79, 1191–1218. [Google Scholar]

- Makinde, O.D.; Chinyoka, T.; Adetayo, S. Numerical investigation of entropy generation in an unsteady flow through a porous pipe with suction. Exergy 2013, 12, 279–297. [Google Scholar]

- Herpe, J.; Bougeard, D.; Russeil, S.; Stanciu, M. Numerical investigation of local entropy production rate of a finned oval tube with vortex generators. Int. J. Thermal Sci 2009, 48, 922–935. [Google Scholar]

- Hassan, M.; Sadri, R.; Ahmadi, G.; Dahari, M.B.; Kazi, S.N.; Safaei, M.R.; Sadeghinezhad, E. Numerical study of entropy generation in a flowing nanofluid used in micro- and minichannels. Entropy 2013, 15, 144–155. [Google Scholar]

- Ohta, Y.; Fujita, Y.; Morita, D. Unsteady Behavior of Surge and Rotating Stall in an Axial Flow Compressor. J. Therm. Sci 2012, 21, 302–310. [Google Scholar]

- Wang, S.L.; Hou, J.H.; An, L.S.; Ai, J.C. Experiment study and feature extraction on rotating stall of centrifugal fan in power plant. Compress. Blower Fan Tech 2003, 6, 15–19. (in Chinese). [Google Scholar]

- Gourdain, N.; Burguburu, S.; Leboeuf, S.; Miton, H. Numerical simulation of rotating stall in a subsonic compressor. Aerosp. Sci. Tech 2006, 10, 9–18. [Google Scholar]

- Gourdain, N.; Burguburu, S.; Leboeuf, S.; Michon, G.J. Simulation of Rotating Stall in a Whole Stage of an Axial Compressor. Comput. Fluid 2010, 39, 1644–1655. [Google Scholar]

- Choi, M.; Vahdati, M.; Imregun, M. Effects of Fan Speed on Rotating Stall Inception and Recovery. J. Turbomach 2011, 133, 041013. [Google Scholar]

- Zhang, L.; Wang, S.L.; Zhang, Q.; Wu, Z.R. Fluid dynamics characteristics of rotating stall in a centrifugal fan. Proc. CSEE 2012, 32, 95–101. (in Chinese). [Google Scholar]

- Li, J.C.; Tong, Z.T.; Lin, F.; Nie, C.Q. Experimental investigation of tip air injection base on detection mechanism of early stall warning. J. Eng. Thermophys 2012, 33, 573–577. (in Chinese). [Google Scholar]

- Wu, Y.H.; Zhao, K.; Tian, J.T.; Chu, W.L. Analysis of near-tip unsteady flow field in a transonic compressor rotor at near stall condition. J. Eng. Thermophys 2012, 33, 401–404. (in Chinese). [Google Scholar]

- Moghaddam, J.J.; Farahani, M.H.; Amanifard, N. A neural network-based sliding-mode control for rotating stall and surge in axial compressors. Appl. Soft Comput 2011, 11, 1036–1043. [Google Scholar]

- Lucius, A.; Brenner, G. Numerical Simulation and Evaluation of Velocity Fluctuations During Rotating Stall of a Centrifugal Pump. J. Fluids Eng 2011, 133, 081102. [Google Scholar]

- Zhang, L.; Wang, S.; Hu, C.; Zhang, Q. Multi-objective optimization design and experimental investigation of centrifugal fan performance. Chin. J. Mech. Eng 2013, 26, 1267–1276. [Google Scholar]

- Kock, F.; Herwig, H. Local Entropy Production in Turbulent Shear Flows: A High-Reynolds Number Model with Wall Functions. Heat Mass Transf 2004, 47, 2205–2215. [Google Scholar]

- Zhang, L.; Liang, S.; Hu, C. Flow and noise characteristics of centrifugal fan under different stall conditions. Math. Probl. Eng 2014, 2014, 403541. [Google Scholar]

| Parameter | Value |

|---|---|

| Inlet diameter of impeller D (cm) | 56.8 |

| Outlet width of impeller H (cm) | 80 |

| Number of blades Zb | 12 |

| Exit stagger angle β (deg) | 45 |

| Rotation speed (r/min) | 1450 |

| Number | Condition | Remark |

|---|---|---|

| 1 | k1=2 | Close to the design condition. |

| 2 | k1 = 0.89 (the 150th revolution) | The throttle coefficient is 0.89. The stall hasn’t occurred. |

| 3 | k1 = 0.89 (the 185th revolution) | The throttle coefficient is 0.89. The stall inception has occurred. |

| 4 | k1 = 0.89 (the 240th revolution) | The throttle coefficient is 0.89. The stall cell is established in impeller. |

| 5 | k1 = 0.7 | The throttle coefficient is 0.7. The flow rate is smaller the condition 4. The stall cell is established in the impeller. |

Nomenclature

| psout | outlet static pressure | Pa |

| piin | ambient pressure | Pa |

| k0 | constant | - |

| k1 | throttle coefficient | - |

| T | temperature of the fluid | k |

| U | velocity component of the z axial | m·s−1 |

| Φ̅/T | entropy generation | w·m−3·k−1 |

| SD | entropy generation due to viscous dissipation | w·m−3·k−1 |

| SD′ | entropy generation due to turbulent dissipation | w·m−3·k−1 |

| fi | mass force at i axis (i=x,y,z) | N·kg−1 |

| υi | velocity component of the i axis (i=x,y,z) | m·s−1 |

| υτ | friction velocity of wall | m·s−1 |

| y+ | non dimensional distance to the wall (=yυτ/ν) | - |

| Greek symbols | ||

| ρ | density of the fluid | kg·m−3 |

| μ | dynamic viscosity of the fluid | Pa·s |

| ν | kinematic viscosity of the fluid | m2·s−1 |

| ε | Turbulent dissipation rate | - |

| a̅ | time averaged a | - |

| a′ | impulse value of a | - |

© 2014 by the authors; licensee MDPI, Basel, Switzerland This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Zhang, L.; Lang, J.; Jiang, K.; Wang, S. Simulation of Entropy Generation under Stall Conditions in a Centrifugal Fan. Entropy 2014, 16, 3573-3589. https://doi.org/10.3390/e16073573

Zhang L, Lang J, Jiang K, Wang S. Simulation of Entropy Generation under Stall Conditions in a Centrifugal Fan. Entropy. 2014; 16(7):3573-3589. https://doi.org/10.3390/e16073573

Chicago/Turabian StyleZhang, Lei, Jinhua Lang, Kuan Jiang, and Songling Wang. 2014. "Simulation of Entropy Generation under Stall Conditions in a Centrifugal Fan" Entropy 16, no. 7: 3573-3589. https://doi.org/10.3390/e16073573

APA StyleZhang, L., Lang, J., Jiang, K., & Wang, S. (2014). Simulation of Entropy Generation under Stall Conditions in a Centrifugal Fan. Entropy, 16(7), 3573-3589. https://doi.org/10.3390/e16073573