Entropy Generation Rate Minimization for Methanol Synthesis via a CO2 Hydrogenation Reactor

Abstract

:1. Introduction

2. Reactor Model and System Description

2.1. Reactor Model

2.2. Reaction Kinetic Model

2.3. Conservation Equation

2.4. Entropy Generation Rate of the MSCH Reactor

3. Mathematical Description of the Optimization Problem

3.1. Application of Optimal Control Theory

3.2. Numerical Calculations of Optimization Problem

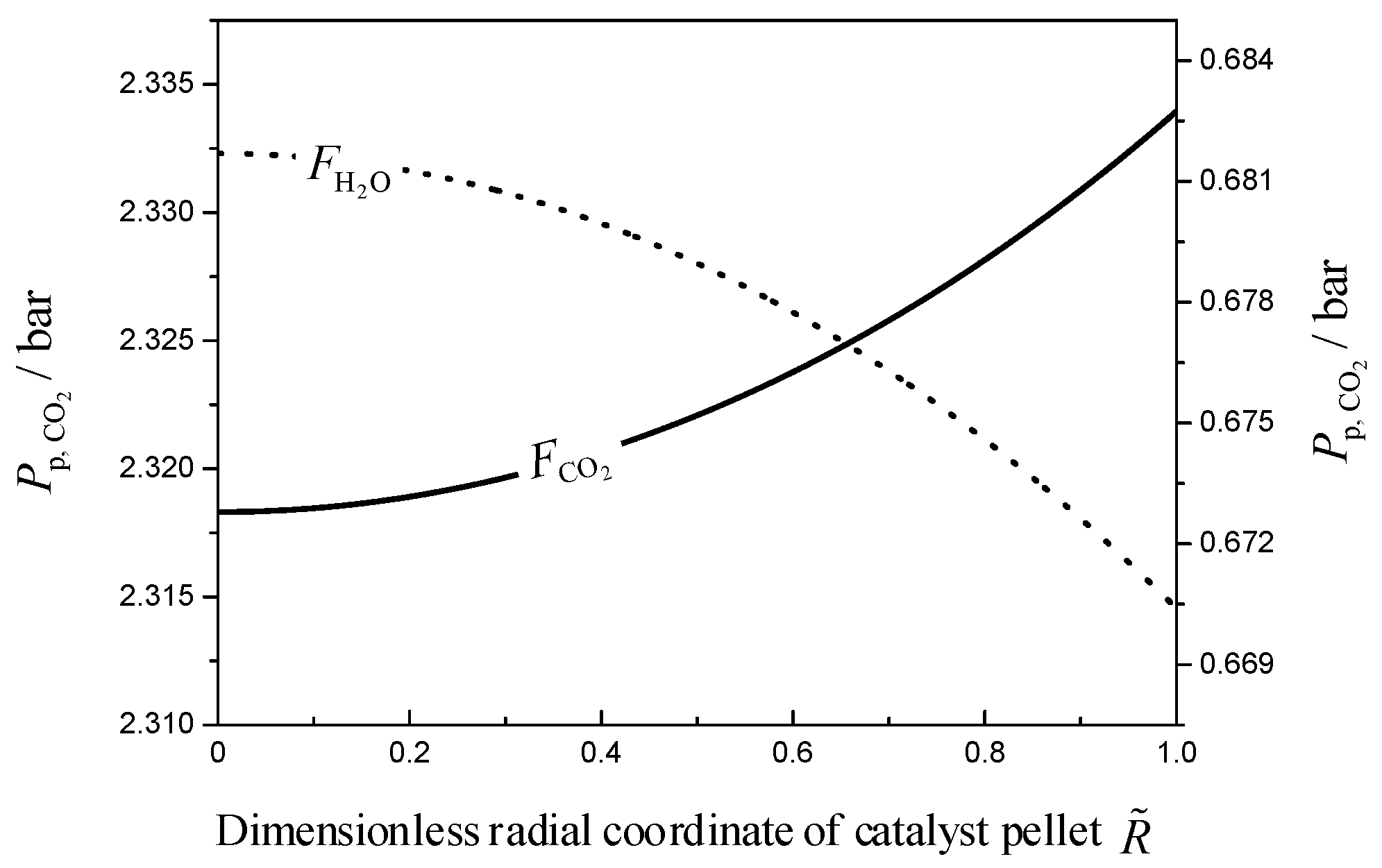

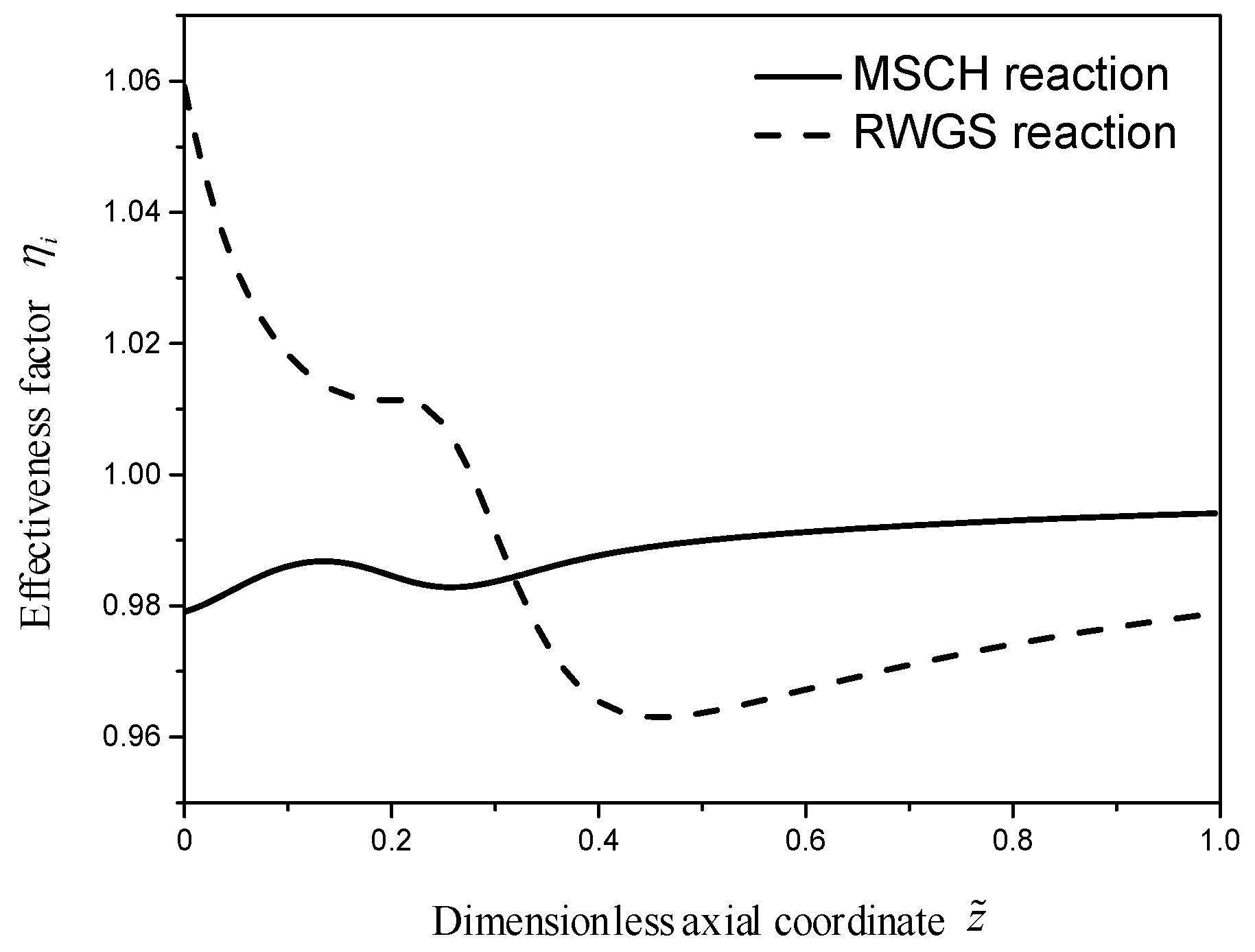

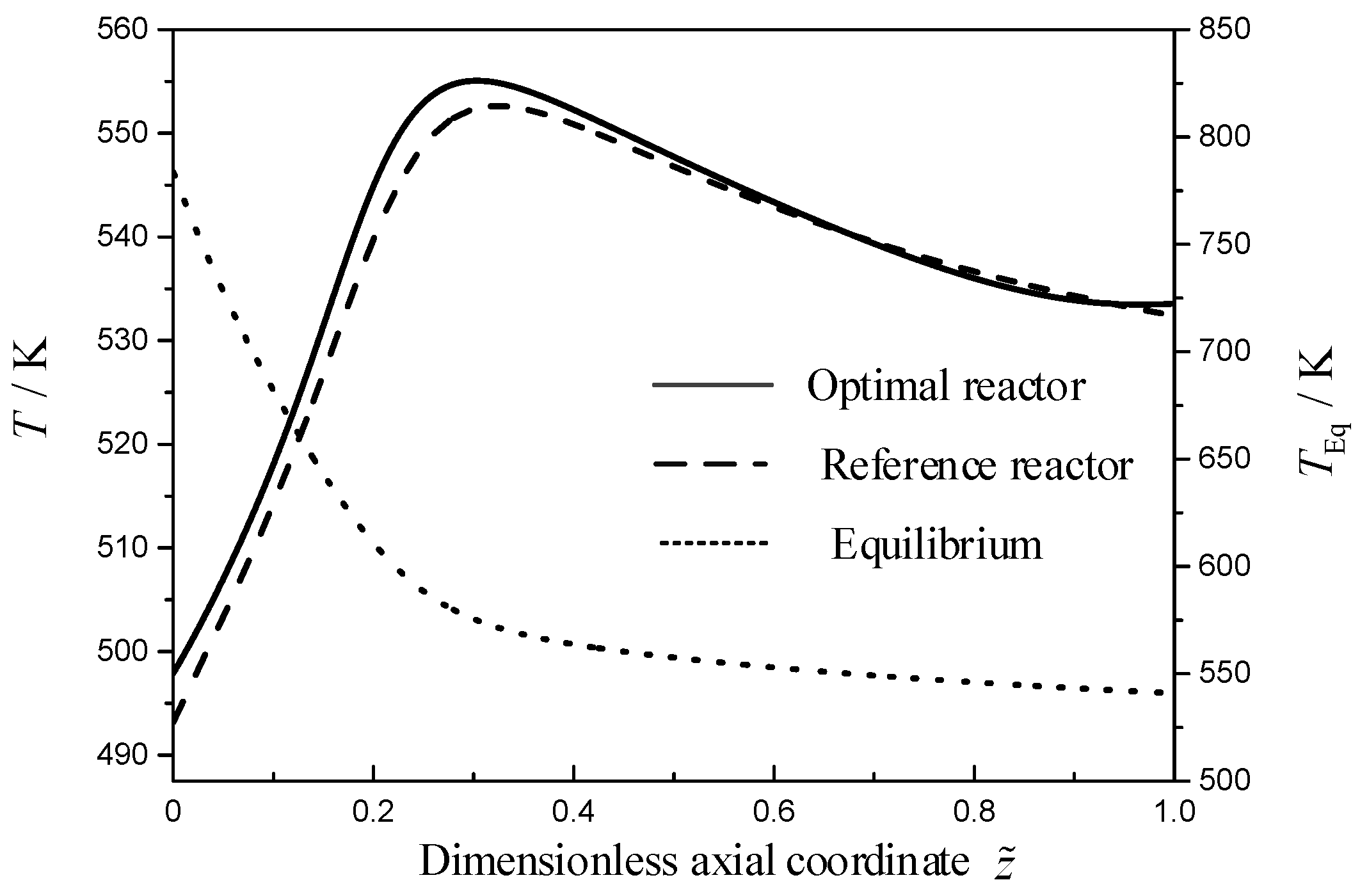

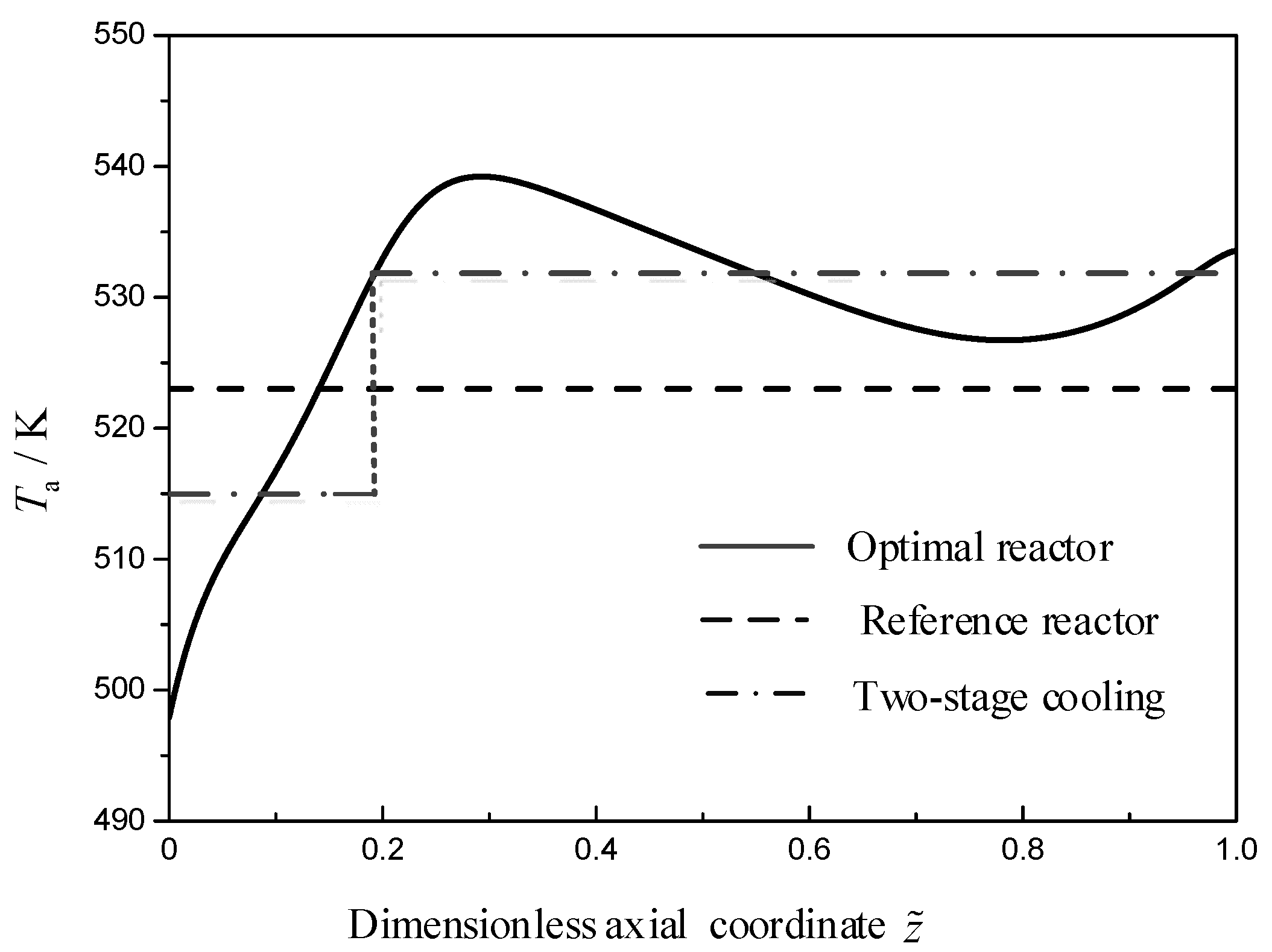

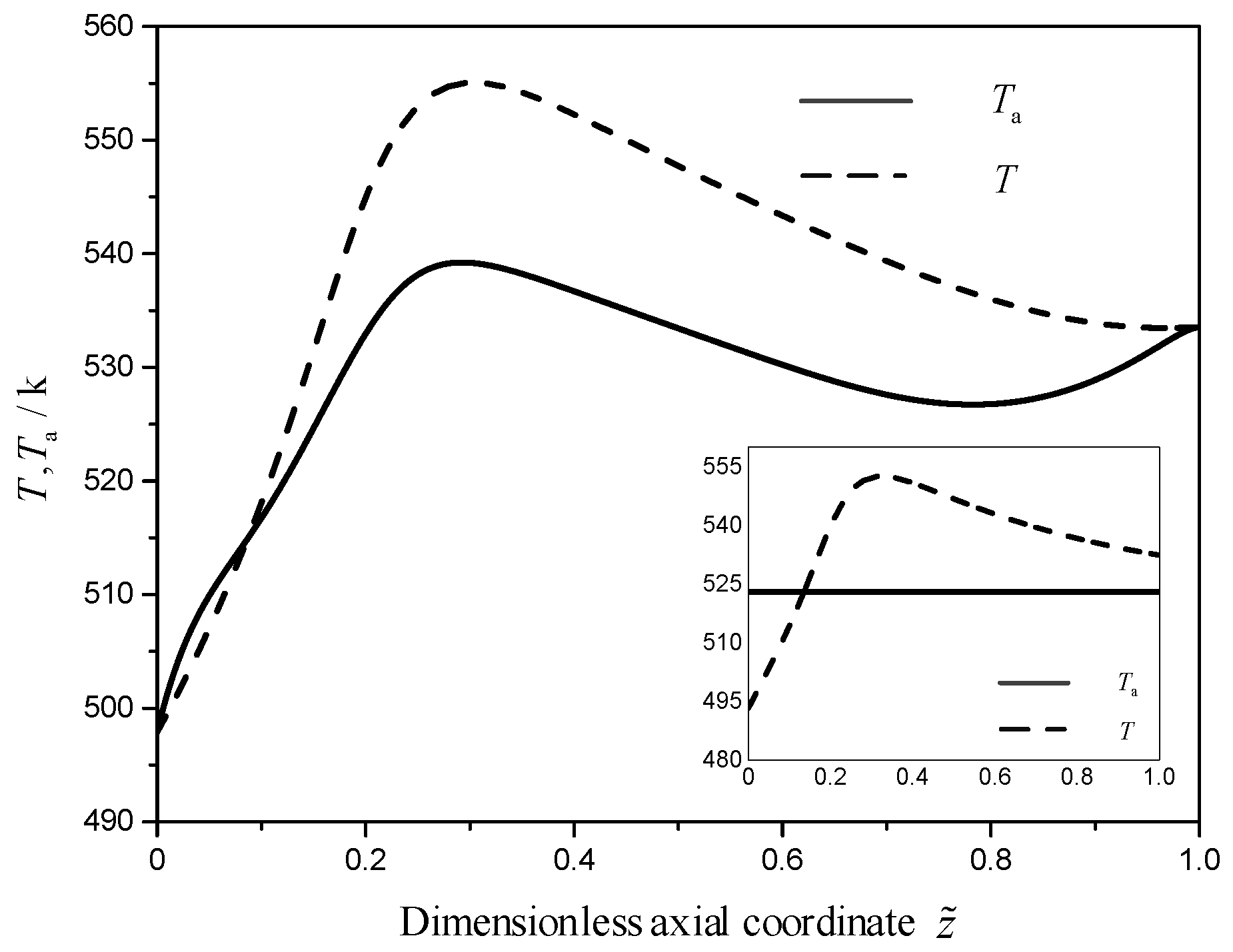

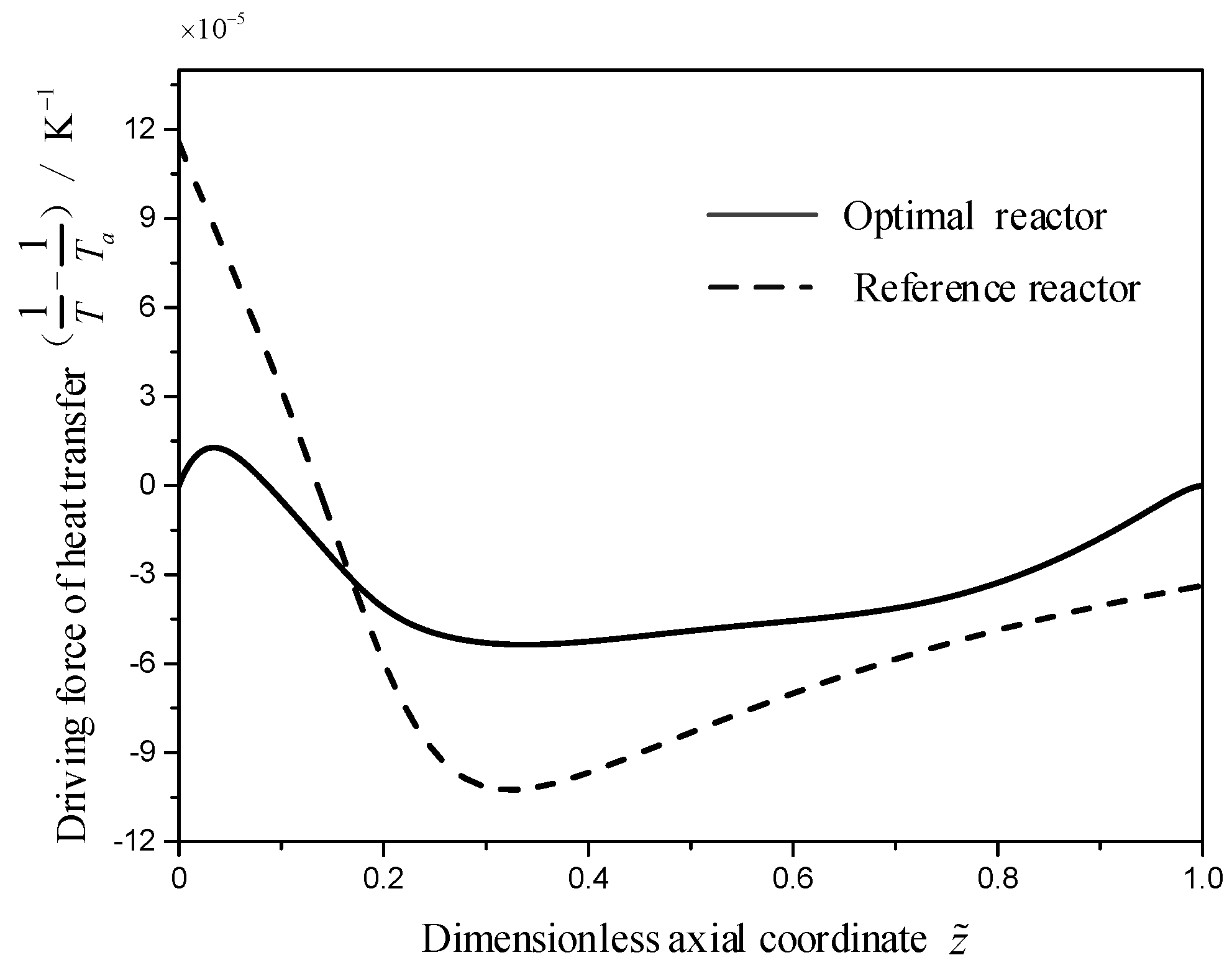

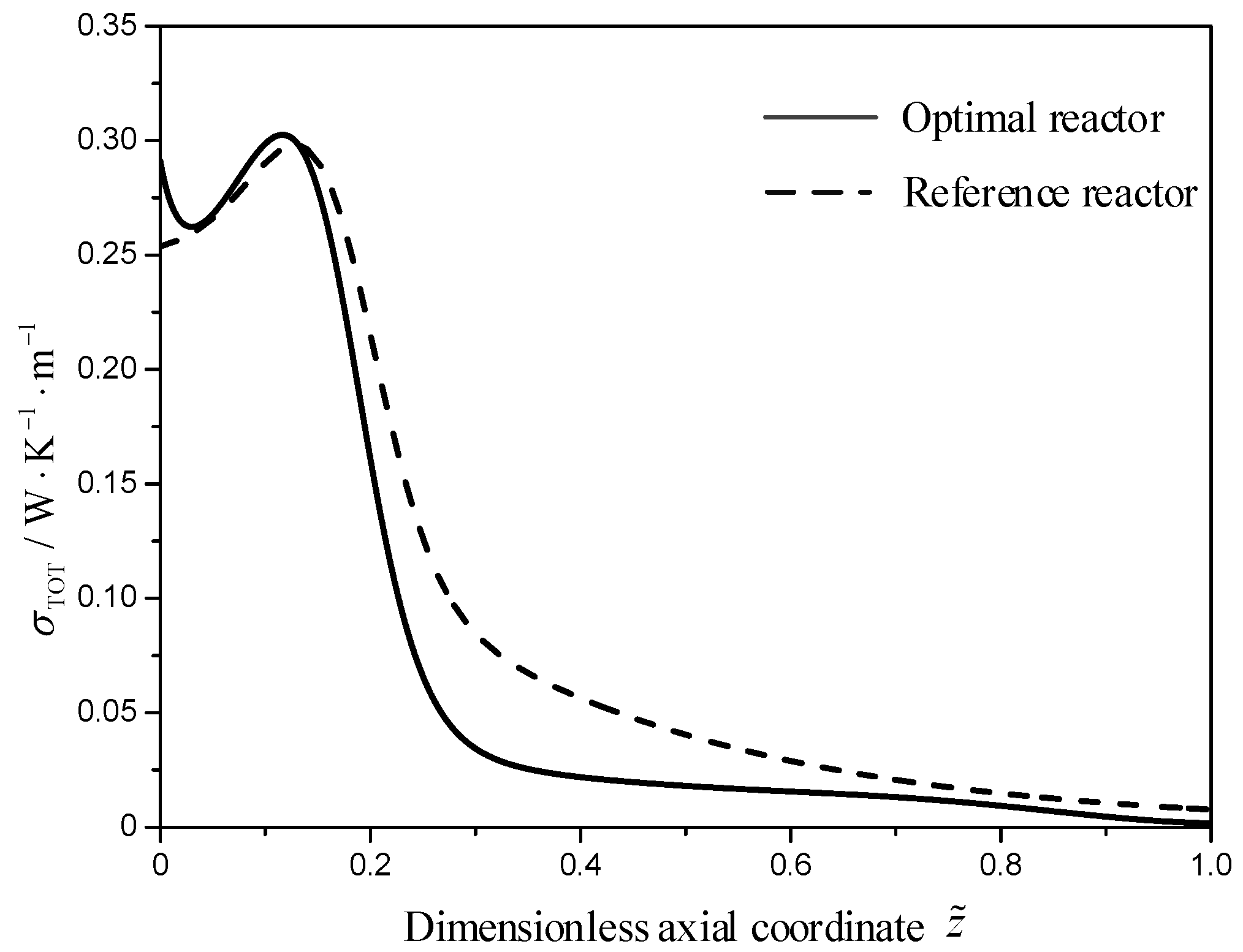

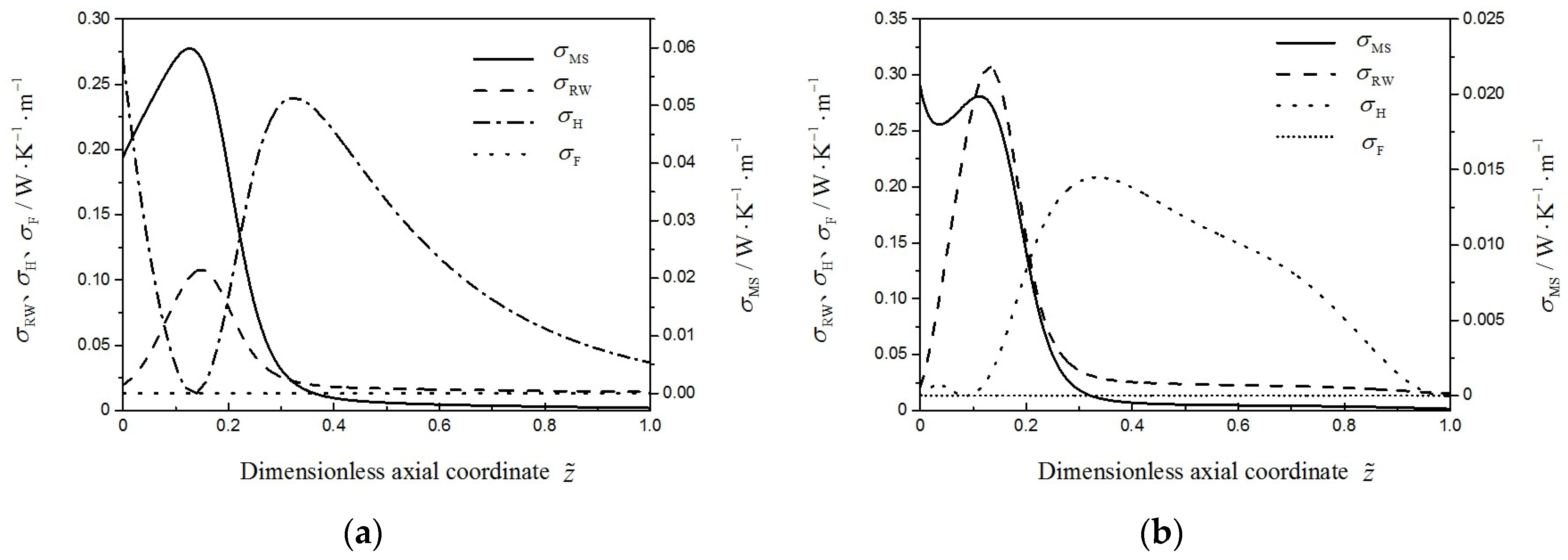

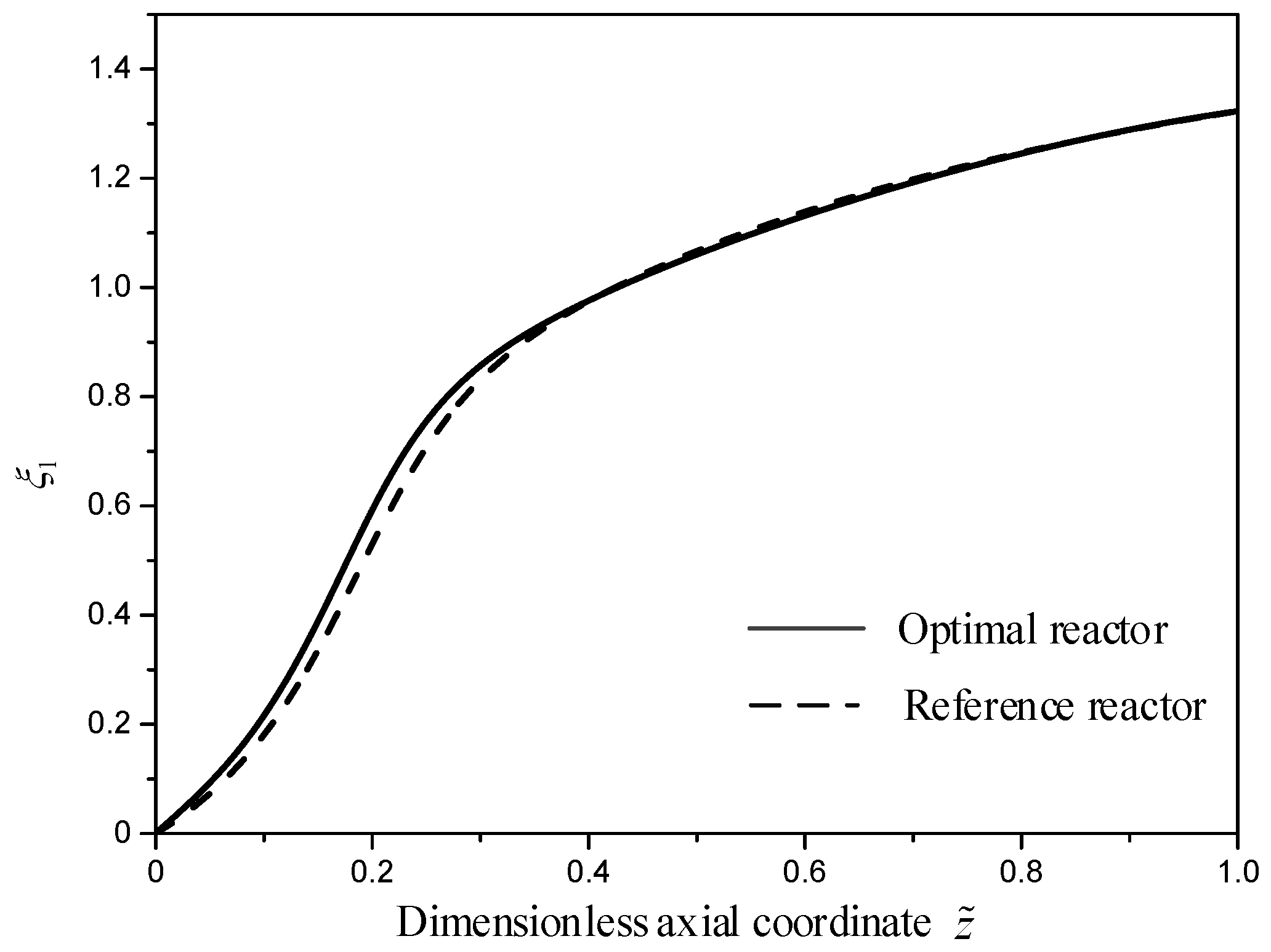

4. Numerical Results and Discussions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Key Parameter | |||

|---|---|---|---|

| Methanol yield | 1.3139 | 1.318 | 0.3 |

| Outlet TRM | 533 | 532 | 0.19 |

| 2.44 | 2.42 | 0.82 |

Appendix C

References

- Lange, J. Methanol synthesis: A short review of technology improvements. Catal. Today 2001, 64, 3–8. [Google Scholar] [CrossRef]

- Olah, G.A.; Prakash, G.K.; Goeppert, A. Anthropogenic chemical carbon cycle for a sustainable future. J. Am. Chem. Soc. 2011, 133, 12881–12898. [Google Scholar] [CrossRef] [PubMed]

- Jadhav, S.G.; Vaidya, P.D.; Bhanage, B.M.; Joshi, J.B. Catalytic carbon dioxide hydrogenation to methanol: A review of recent studies. Chem. Eng. Res. Des. 2014, 92, 2557–2567. [Google Scholar] [CrossRef]

- Morgan, E.R.; Acker, T.L. Practical experience with a mobile methanol synthesis device. J. Sol. Energy Eng. Trans. ASME 2015, 137, 064506. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, D.F.; Chen, Q.Q.; Shen, G.F.; Tang, Z.Y. Thermodynamic analysis of CO2 hydrogenation to methanol. Nat. Gas Tech. Econ. 2015, 40, 21–25. (In Chinese) [Google Scholar]

- Huš, M.; Dasireddy, V.D.B.C.; Štefančič, N.S.; Likozar, B. Mechanism, kinetics and thermodynamics of carbon dioxide hydrogenation to methanol on Cu/ZnAl2O4 spinel-type heterogeneous catalysts. Appl. Catal. B Environ. 2017, 207, 267–278. [Google Scholar] [CrossRef]

- Choi, E.; Song, K.; An, S.; Lee, K.Y.; Youn, M.; Park, K.; Jeong, S.; Kim, H.J. Cu/ZnO/AlOOH catalyst for methanol synthesis through CO2 hydrogenation. Korean J. Chem. Eng. 2018, 35, 73–81. [Google Scholar] [CrossRef]

- Schneidewind, J.; Adam, R.; Baumann, W.; Jackstell, R.; Beller, M. Low-temperature hydrogenation of carbon dioxide to methanol with a homogeneous cobalt catalyst. Angew. Chem. Int. Edit. 2017, 129, 1916–1919. [Google Scholar] [CrossRef]

- Chen, L.; Jiang, Q.Z.; Song, Z.Z.; Chen, L. Optimization of inlet temperature of methanol synthesis reactor of LURGI type. Adv. Mater. Res. 2012, 443–444, 671–677. [Google Scholar] [CrossRef]

- Atsonios, K.; Panopoulos, K.D.; Kakaras, E. Thermocatalytic CO2 hydrogenation for methanol and ethanol production: Process improvements. Int. J. Hydrog. Energy 2016, 41, 792–806. [Google Scholar] [CrossRef]

- Nimkar, S.C.; Mewada, R.K.; Rosen, M.A. Exergy and exergoeconomic analyses of thermally coupled reactors for methanol synthesis. Int. J. Hydrog. Energy 2017, 42, 28113–28127. [Google Scholar] [CrossRef]

- Zachopoulos, A.; Heracleous, E. Overcoming the equilibrium barriers of CO2 hydrogenation to methanol via water sorption: A thermodynamic analysis. J. CO2 Util. 2017, 21, 360–367. [Google Scholar] [CrossRef]

- Fornero, E.L.; Chiavassa, D.L.; Bonivardi, A.L.; Baltanás, M.A. CO2 Capture via catalytic hydrogenation to methanol: Thermodynamic limit vs. ‘kinetic limit’. Catal. Today 2011, 172, 158–165. [Google Scholar] [CrossRef]

- Gaikwad, R.; Bansode, A.; Urakawa, A. High-pressure advantages in stoichiometric hydrogenation of carbon dioxide to methanol. J. Catal. 2016, 343, 127–132. [Google Scholar] [CrossRef] [Green Version]

- Johannessen, E.; Kjelstrup, S. A highway in state space for reactors with minimum entropy production. Chem. Eng. Sci. 2005, 60, 3347–3361. [Google Scholar] [CrossRef]

- Andresen, B.; Berry, R.S.; Ondrechen, M.J.; Salamon, P. Thermodynamics for processes in finite time. Acc. Chem. Res. 1984, 17, 266–271. [Google Scholar] [CrossRef]

- Chen, L.G.; Wu, C.; Sun, F.R. Finite time thermodynamic optimization or entropy generation minimization of energy system. J. Non-Equilib. Thermodyn. 1999, 24, 327–359. [Google Scholar] [CrossRef]

- Hoffman, K.H.; Burzler, J.M.; Fischer, A.; Schaller, M.; Schubert, S. Optimal process paths for endoreversible systems. J. Non Equilib. Thermodyn. 2003, 28, 233–268. [Google Scholar] [CrossRef]

- Chen, L.G. Finite-Time Thermodynamic Analysis of Irreversible Processes and Cycles; Higher Education Press: Beijing, China, 2005. (In Chinese) [Google Scholar]

- Andresen, B. Current trends in finite-time thermodynamics. Angew. Chem. Int. Edit. 2011, 50, 2690–2704. [Google Scholar] [CrossRef]

- Kosloff, R. Quantum thermodynamics: A dynamical viewpoit. Entropy 2013, 15, 2100–2128. [Google Scholar] [CrossRef]

- Ge, Y.L.; Chen, L.G.; Sun, F.R. Progress in finite time thermodynamic studies for internal combustion engine cycles. Entropy 2016, 18, 139. [Google Scholar] [CrossRef]

- Bi, Y.H.; Chen, L.G. Finite Time Thermodynamic Optimization for Air Heat Pumps; Science Press: Beijing, China, 2017. (In Chinese) [Google Scholar]

- Chen, L.G.; Xia, S.J. Generalized Thermodynamic Dynamic-Optimization for Irreversible Processes; Science Press: Beijing, China, 2017. (In Chinese) [Google Scholar]

- Badescu, V. Optimal Control in Thermal Engineering; Springer: New York, NY, USA, 2017. [Google Scholar]

- Feidt, M. The history and perspectives of efficiency at maximum power of the carnot engine. Entropy 2017, 19, 369. [Google Scholar] [CrossRef]

- Chen, L.G.; Xia, S.J. Generalized Thermodynamic Dynamic-Optimization for Irreversible Cycles–Thermodynamic and Chemical Theoretical Cycles; Science Press: Beijing, China, 2018. (In Chinese) [Google Scholar]

- Chen, L.G.; Xia, S.J. Generalized Thermodynamic Dynamic-Optimization for Irreversible Cycles–Engineering Thermodynamic Plants and Generalized Engine Cycles; Science Press: Beijing, China, 2018. (In Chinese) [Google Scholar]

- Kaushik, S.C.; Tyagi, S.K.; Kumar, P. Finite Time Thermodynamics of Power and Refrigeration Cycles; Springer: New York, NY, USA, 2018. [Google Scholar]

- Bejan, A. Entropy Generation through Heat and Fluid Flow; Wiley: New York, NY, USA, 1982. [Google Scholar]

- Bejan, A. Entropy generation minimization: The new thermodynamics of finite-size devices and finite-time processes. J. Appl. Phys. 1996, 79, 1191–1218. [Google Scholar] [CrossRef]

- Bejan, A. Notes on the history of the method of entropy generation minimization (finite time thermodynamics). J. Non Equilib. Thermodyn. 1996, 21, 239–242. [Google Scholar]

- Bejan, A. Entropy Generation Minimization; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- Bejan, A. Entropy generation minimization, exergy analysis, and the constructal law. Arab. J. Sci. Eng. 2013, 38, 329–340. [Google Scholar] [CrossRef]

- Månsson, B.; Andresen, B. Optimal temperature profile for an ammonia reactor. Ind. Eng. Chem. Proc. Des. Dev. 1986, 25, 59–65. [Google Scholar] [CrossRef]

- Jahanmiri, A.; Eslamloueyan, R. Optimal temperature profile in methanol synthesis reactor. Chem. Eng. Commun. 2002, 189, 713–741. [Google Scholar] [CrossRef]

- Farsi, M.; Jahanmiri, A. Methanol production in an optimized dual-membrane fixed-bed reactor. Chem. Eng. Process. 2011, 50, 1177–1185. [Google Scholar] [CrossRef]

- Farsi, M.; Jahanmiri, A. Application of water vapor and hydrogen-permselective membranes in an industrial fixed-bed reactor for large scale methanol production. Chem. Eng. Res. Des. 2011, 89, 2728–2735. [Google Scholar] [CrossRef]

- Farsi, M.; Jahanmiri, A. Dynamic modeling of a H2O-permselective membrane reactor to enhance methanol synthesis from syngas considering catalyst deactivation. J. Nat. Gas Chem. 2012, 21, 407–414. [Google Scholar] [CrossRef]

- Farsi, M.; Jahanmiri, A. Dynamic modeling and operability analysis of a dual-membrane fixed bed reactor to produce methanol considering catalyst deactivation. J. Ind. Eng. Chem. 2014, 20, 2927–2933. [Google Scholar] [CrossRef]

- Wang, C.; Chen, L.G.; Xia, S.J.; Sun, F.R. Maximum production rate optimization for sulphuric acid decomposition process in tubular plug-flow reactor. Energy 2016, 99, 152–158. [Google Scholar] [CrossRef]

- Van der Ham, L.V.; Gross, J.; Verkooijen, A.; Kjelstrup, S. Efficient conversion of thermal energy into hydrogen: Comparing two methods to reduce exergy losses in a sulfuric acid decomposition reactor. Ind. Eng. Chem. Res. 2009, 48, 8500–8507. [Google Scholar] [CrossRef]

- Kjelstrup, S.; Johannessen, E.; Røsjorde, A.; Nummedal, L.; Bedeaux, D. Minimizing the entropy production of the methanol producing reaction in a methanol reactor. Int. J. Appl. Thermodyn. 2000, 3, 147–153. [Google Scholar]

- Bussche, K.M.V.; Froment, G.F. A steady-state kinetic model for methanol synthesis and the water gas shift reaction on a commercial Cu/ZnO/Al2O3 catalyst. J. Catal. 1996, 161, 1–10. [Google Scholar] [CrossRef]

- Johannessen, E.; Kjelstrup, S. Minimum entropy production rate in plug flow reactors: An optimal control problem solved for SO2 oxidation. Energy 2004, 29, 2403–2423. [Google Scholar] [CrossRef]

- Nummeda, L.; Rosjorde, A.; Johannessen, E.; Kjelstrup, S. Second law optimization of a tubular steam reformer. Chem. Eng. Proc. 2005, 44, 429–440. [Google Scholar] [CrossRef]

- Ao, C.Y.; Xia, S.J.; Song, H.J.; Chen, L.G. Entropy generation minimization of steam methane reforming reactor with linear phenomenological heat transfer law. Sci. Sin. Tech. 2018, 48, 25–38. (In Chinese) [Google Scholar] [CrossRef]

- Chen, Q.X.; Xia, S.J.; Wang, W.H.; Chen, L.G. Entropy generation rate minimization of steam methane reforming reactor with Dulong-Petit heat transfer law. Energy Conserv. 2018, 38, 31–40. (In Chinese) [Google Scholar]

- Kingston, D.; Razzitte, A.C. Entropy production in chemical reactors. J. Non Equilib. Thermodyn. 2017, 42, 265–275. [Google Scholar] [CrossRef]

- Kingston, D.; Razzitte, A.C. Entropy generation minimization in dimethyl ether synthesis: A case study. J. Non Equilib. Thermodyn. 2018, 43, 111–120. [Google Scholar] [CrossRef]

- Chen, L.G.; Zhang, L.; Xia, S.J.; Sun, F.R. Entropy generation minimization for CO2 hydrogenation to light olefins. Energy 2018, 147, 187–196. [Google Scholar] [CrossRef]

- Chen, L.G.; Wang, C.; Xia, S.J.; Sun, F.R. Thermodynamic analysis and optimization of extraction process of CO2 from acid seawater by using hollow fiber membrane contactor. Int. J. Heat Mass Transf. 2018, 124, 1310–1320. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L.G.; Xia, S.J.; Sun, F.R. Entropy generation minimization for reverse water gas shift (RWGS) reactors. Entropy 2018, 20, 415. [Google Scholar] [CrossRef]

- Skrzypek, J.; Lachowska, M.; Moroz, H. Kinetics of methanol synthesis over commercial copper/zinc oxide/alumina catalysts. Chem. Eng. Sci. 1991, 46, 2809–2813. [Google Scholar] [CrossRef]

- Bussche, K.M.V.; Froment, G.F. Nature of formate in methanol synthesis on Cu/ZnO/A2O3. Appl. Catal. A Gen. 1994, 112, 37–55. [Google Scholar] [CrossRef]

- Froment, G.F.; Bischoff, K.B.; De Wilde, J. Chemical Reactor Analysis and Design, 2nd ed.; Wiley: New York, NY, USA, 1990. [Google Scholar]

- Niven, R.K. Steady state of a dissipative flow-controlled system and the maximum entropy production principle. Phys. Rev. E 2009, 80, 283–289. [Google Scholar] [CrossRef] [PubMed]

- England, J.L. Statistical physics of self-replication. J. Chem. Phys. 2013, 139, 121923. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ritchie, M.E. Reaction and diffusion thermodynamics explain optimal temperatures of biochemical reactions. Sci. Rep. 2018, 8, 11105. [Google Scholar] [CrossRef] [PubMed]

- Dixon, A.G. An improved equation for the overall heat transfer coefficient in packed beds. Chem. Eng. Process. 1996, 35, 323–331. [Google Scholar] [CrossRef]

- De falco, M.; Dipaola, L.; Marrelli, L. Heat transfer and hydrogen permeability in modelling industrial membrane reactors for methane steam reforming. Int. J. Hydrog. Energy 2007, 32, 2902–2913. [Google Scholar] [CrossRef]

- Waugh, K.C. Methanol synthesis. Catal. Today 1992, 15, 51–75. [Google Scholar] [CrossRef]

- Graaf, G.H.; Sijtsema, P.; Stamhuis, E.J.; Joosten, G.E.H. Chemical equilibria in methanol synthesis. Chem. Eng. Sci. 1986, 41, 2883–2890. [Google Scholar] [CrossRef]

- Chen, H.F.; Du, J.H. Advanced Engineering Thermodynamics; Tsinghua University Press: Beijing, China, 2003. [Google Scholar]

- Yaws, C.L. Chemical Properties Handbook; McGraw-Hill: New York, NY, USA, 1999. [Google Scholar]

- Hicks, R.E. Pressure drop in packed beds of spheres. Ind. Eng. Chem. Res. 1970, 9, 500–502. [Google Scholar] [CrossRef]

- Kjelstrup, S.; Bedeaux, D.; Johannessen, E.; Gross, J. Non-Equilibrium Thermodynamics of Heterogeneous Systems; World Scientific: Singapore, 2008. [Google Scholar]

- Kjelstrup, S.; Bedeaux, D.; Johannessen, E.; Gross, J. Non-Equilibrium Thermodynamics for Engineers; World Scientific: Singapore, 2010. [Google Scholar]

- Sciacovelli, A.; Verda, V.; Sciubba, E. Entropy generation analysis as a design tool—A review. Renew. Sust. Energy Rev. 2015, 43, 1167–1181. [Google Scholar] [CrossRef]

- Bryson, A.; Ho, Y. Applied Optimal Control: Optimization, Estimation and Control; Hemisphere Publishing Corporation: Washington, NY, USA, 1975. [Google Scholar]

- Wilhelmsen, Ø.; Johannessen, E.; Kjelstrup, S. Energy efficient reactor design simplified by second law analysis. Int. J. Hydrog. Energy 2010, 35, 13219–13231. [Google Scholar] [CrossRef]

- Tondeur, D.; Kvaalen, E. Equipartition of entropy production: An optimality criterion for transfer and separation processes. Ind. Eng. Chem. Res. 1987, 26, 50–56. [Google Scholar] [CrossRef]

- Sauar, E.; Kjelstrup, S.; Lien, K. Equipartition of forces: A new principle for process design and optimization. Ind. Eng. Chem. Res. 1996, 35, 4147–4153. [Google Scholar] [CrossRef]

- Kjelstrup, S.; Island, T.V. The driving force distribution for minimum lost work in a chemical reactor close to and far from equilibrium. 2. oxidation of SO2. Ind. Eng. Chem. Res. 1999, 38, 3051–3055. [Google Scholar] [CrossRef]

- Pantoleontos, G.; Kikkinides, E.S.; Georgiadis, M.C. A heterogeneous dynamic model for the simulation and optimisation of the steam methane reforming reactor. Int. J. Hydrog. Energy 2012, 37, 16346–16358. [Google Scholar] [CrossRef]

- Poling, B.E.; Prausnitz, J.M.; O’Connell, J.P. The Properties of Gases and Liquids, 5th ed.; McGraw Hill: New York, NY, USA, 2001. [Google Scholar]

- Lindsay, A.L.; Bromley, L.A. Thermal conductivity of gas mixtures. Ind. Eng. Chem. 1950, 42, 1508–1511. [Google Scholar] [CrossRef]

- Fuller, E.N.; Schettler, P.D.; Giddings, J.C. A new method for prediction of binary gas-phase diffusion coefficients. Ind. Eng. Chem. 1966, 58, 18–27. [Google Scholar] [CrossRef]

| Parameter | Sign | Value |

|---|---|---|

| Inlet temperature of reaction mixture | 493.2 K | |

| Overall heat transfer coefficient | ||

| Inlet total pressure | ||

| Catalyst density | ||

| Catalyst void fraction | 0.5 | |

| Catalyst pellet diameter | ||

| Total catalyst weight | 0.0267 kg | |

| Reactor length | 0.15 m | |

| Reactor diameter | 0.016 m | |

| Inlet total mole flow rate | 0.0033 mol/s | |

| Inlet mole fraction of CO2 | 0.03 | |

| Inlet mole fraction of H2 | 0.82 | |

| Inlet mole fraction of CO | 0.04 | |

| Inlet mole fraction of H2O | 0.005 | |

| Inlet mole fraction of CH3OH | 0.005 | |

| Inlet mole fraction of N2 | 0.10 |

| Value | Value | ||||

|---|---|---|---|---|---|

| A | 1.07 | A | |||

| B | 36,696 | B | −94,765 | ||

| A | 3453.38 | A | 0.499 | ||

| B | - | B | 17,197 | ||

| A | - | - | - | ||

| B | 124,119 | - | - | - |

| 27.4370 | 25.3990 | 29.5560 | 40.0460 | 33.9330 | 29.3420 | |

| 42.3150 | 20.1780 | −6.5807 | −3.8287 | −8.4186 | −3.5395 | |

| −1.9555 | −3.8549 | 2.0130 | 24.5290 | 2.9906 | 1.0076 | |

| 3.9968 | 31.8800 | −12.2270 | −216.7900 | −17.8250 | −4.3116 | |

| −2.9872 | −87.5850 | 22.6170 | 599.0900 | 36.9340 | 2.5935 | |

| −393.50 | 0 | −110.50 | −201.17 | −241.80 | 191.6 | |

| 44.01 | 2.016 | 28.01 | 32.042 | 18.015 | 28.013 |

| - | 85 bar | 0 | 0 | |

| 0 | - | - | - | |

| - | - | 1.323 | - | |

| 0 | 0 | - | 0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Chen, L.; Xia, S.; Zhang, L. Entropy Generation Rate Minimization for Methanol Synthesis via a CO2 Hydrogenation Reactor. Entropy 2019, 21, 174. https://doi.org/10.3390/e21020174

Li P, Chen L, Xia S, Zhang L. Entropy Generation Rate Minimization for Methanol Synthesis via a CO2 Hydrogenation Reactor. Entropy. 2019; 21(2):174. https://doi.org/10.3390/e21020174

Chicago/Turabian StyleLi, Penglei, Lingen Chen, Shaojun Xia, and Lei Zhang. 2019. "Entropy Generation Rate Minimization for Methanol Synthesis via a CO2 Hydrogenation Reactor" Entropy 21, no. 2: 174. https://doi.org/10.3390/e21020174