Topology Optimization of Turbulent Flow Cooling Structures Based on the k-ε Model

Abstract

:1. Introduction

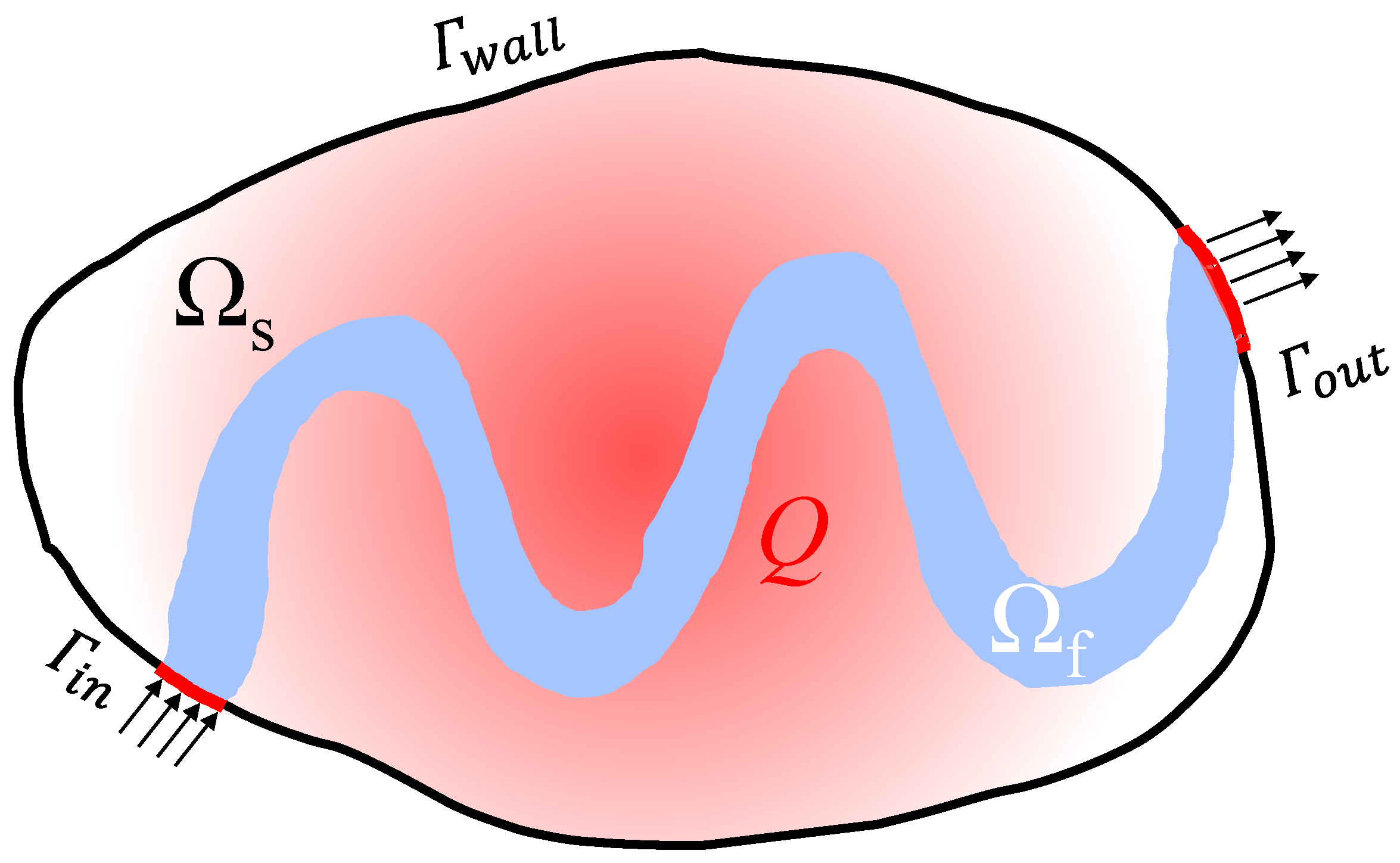

2. Model of the Topology Optimization Problem

2.1. Governing Equations

2.1.1. Turbulent Flow Model

2.1.2. Conjugate Heat Transfer Model

2.2. Topology Optimization Model

2.3. Density Filtering

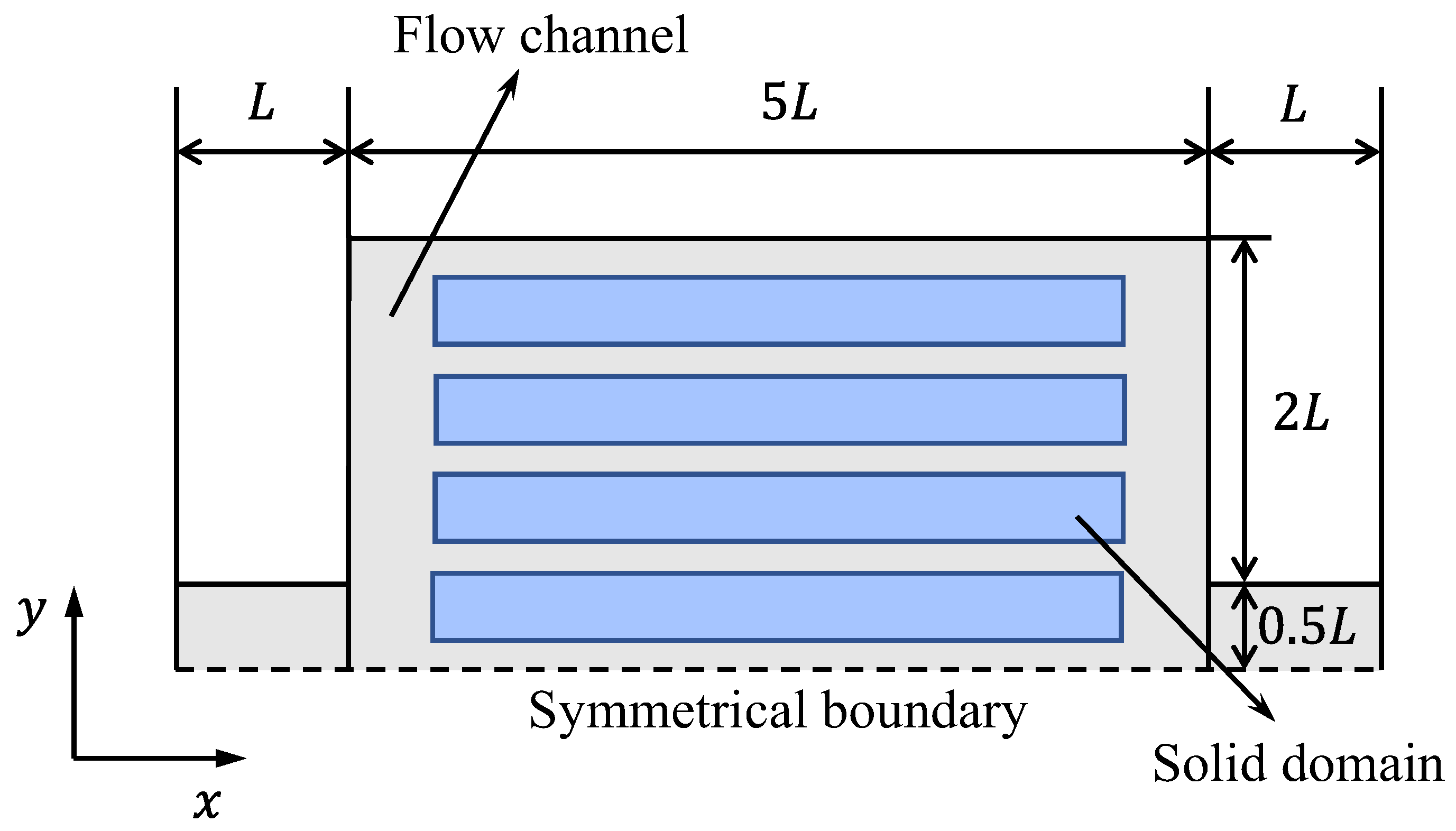

2.4. Numerical Example

3. Results and Discussion

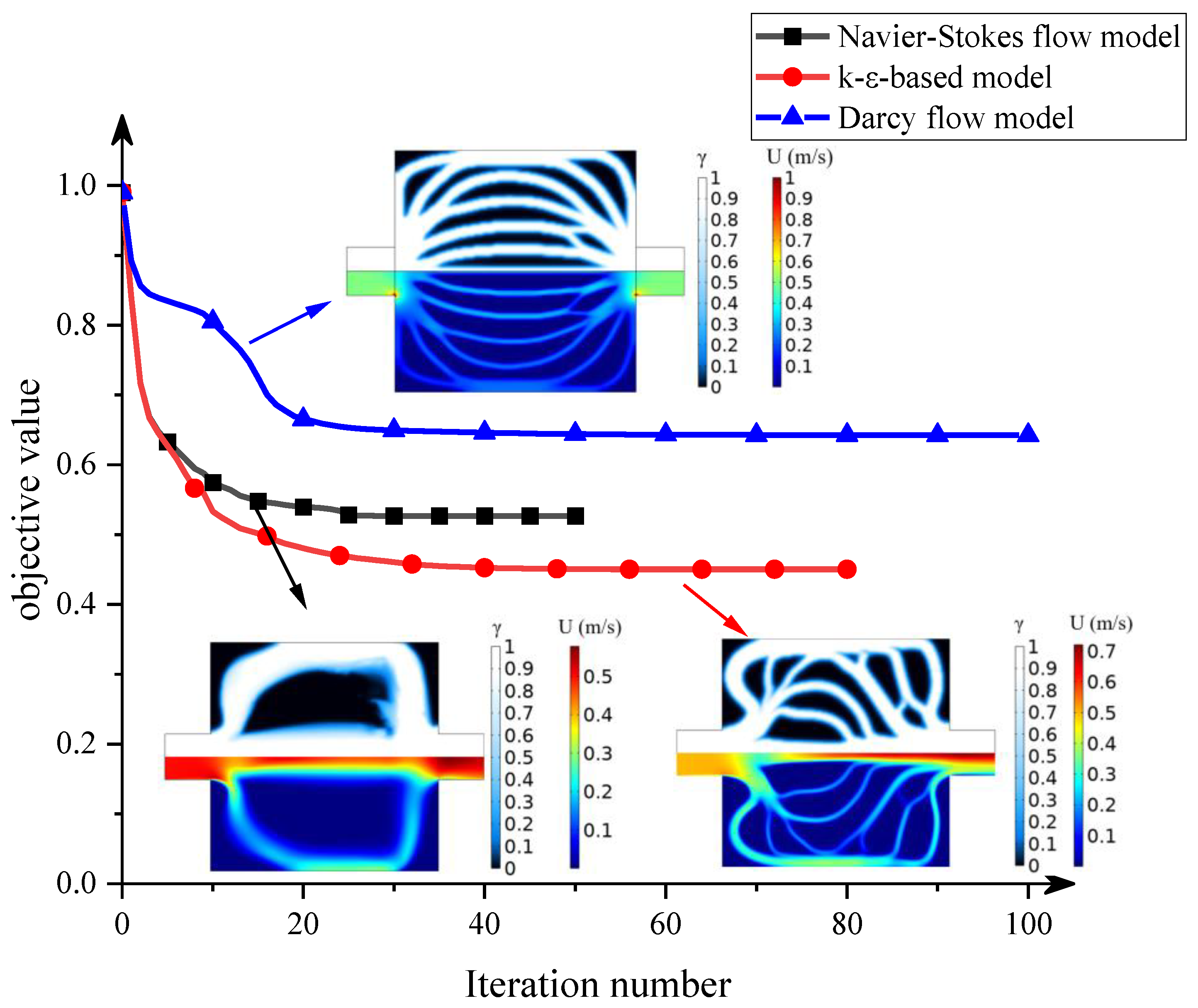

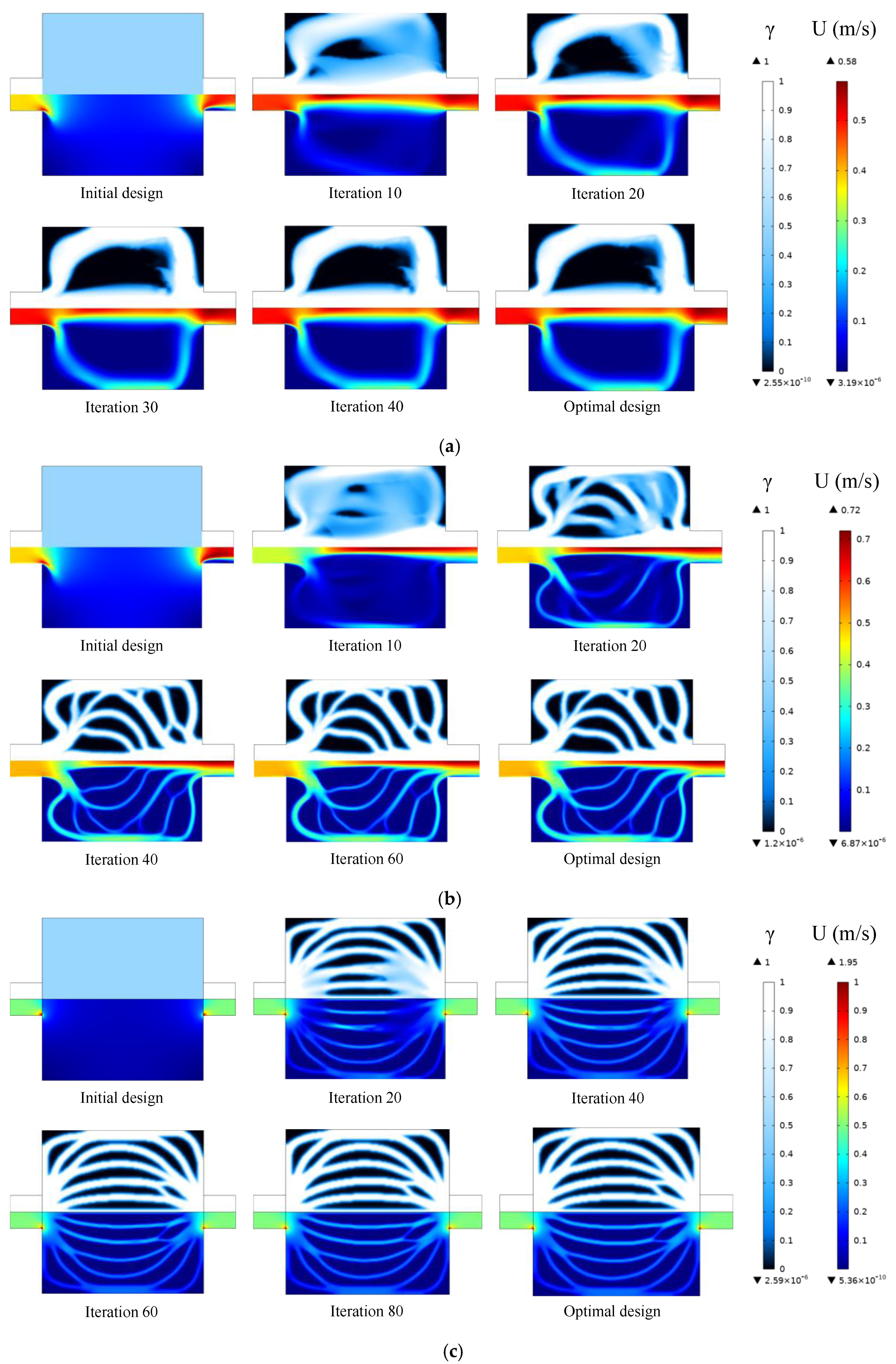

3.1. Comparison of Several Conjugate Heat Transfer Topology Optimization Designs

3.2. Validation of Topology Optimization Results

3.2.1. Grid Independence Test

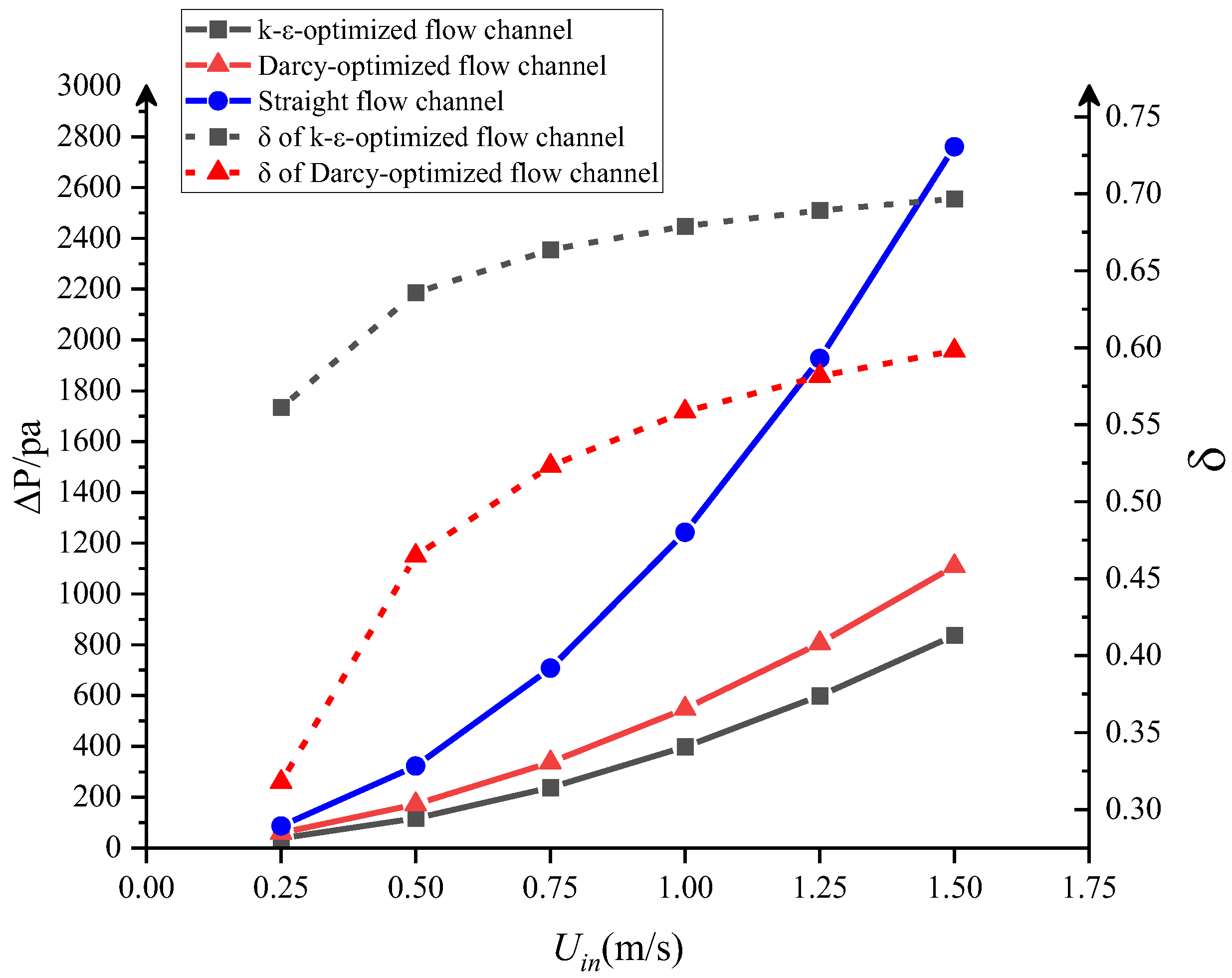

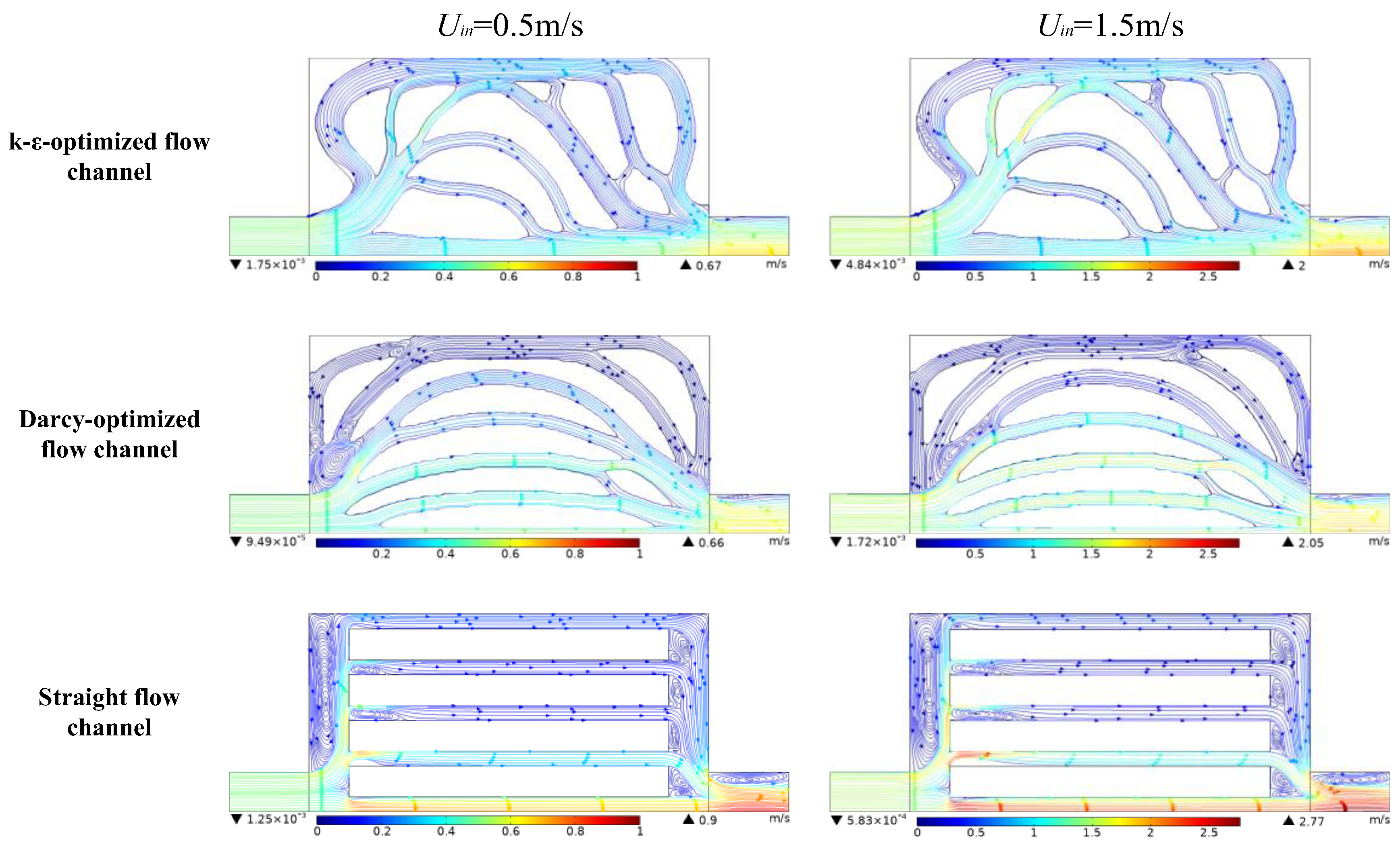

3.2.2. Flow Characteristics Analysis

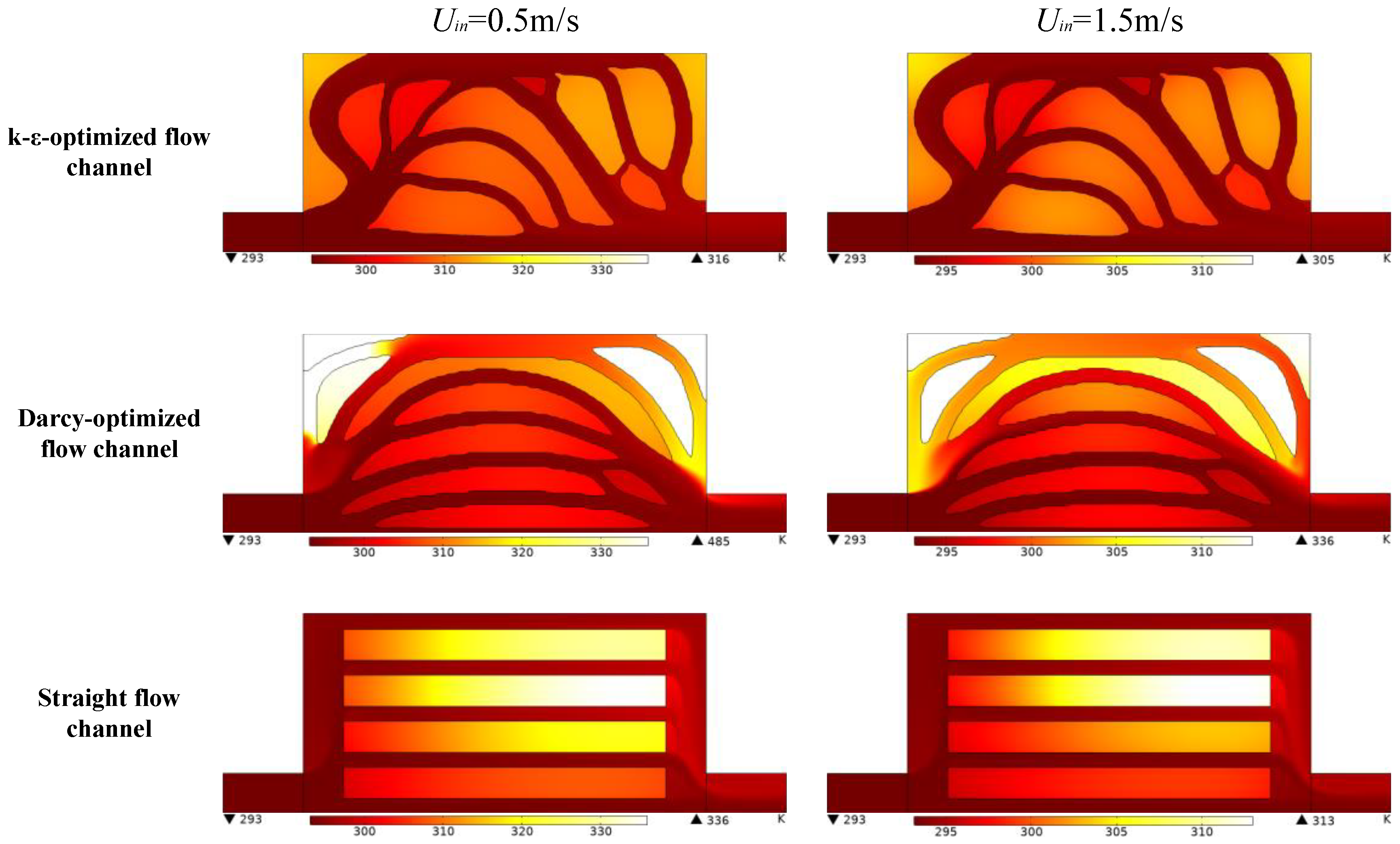

3.2.3. Heat Transfer Characteristics Analysis

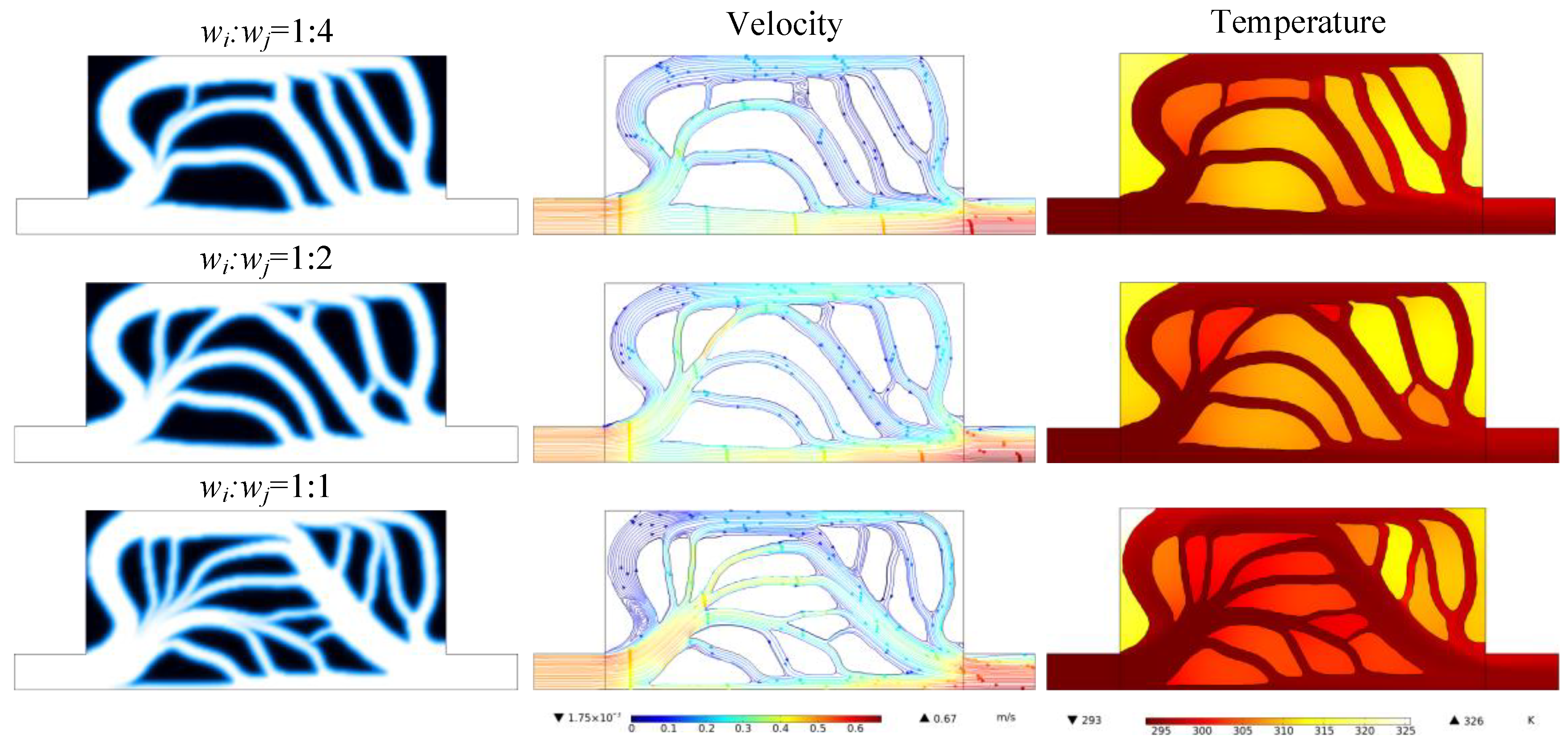

3.3. Weighting Factor Ratio wi:wj Analysis

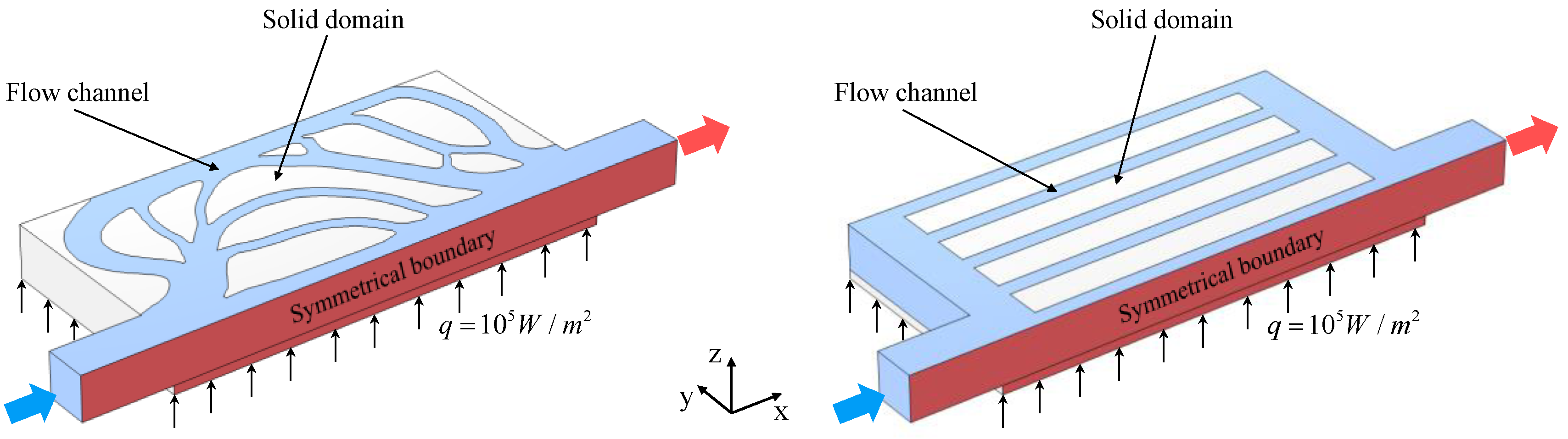

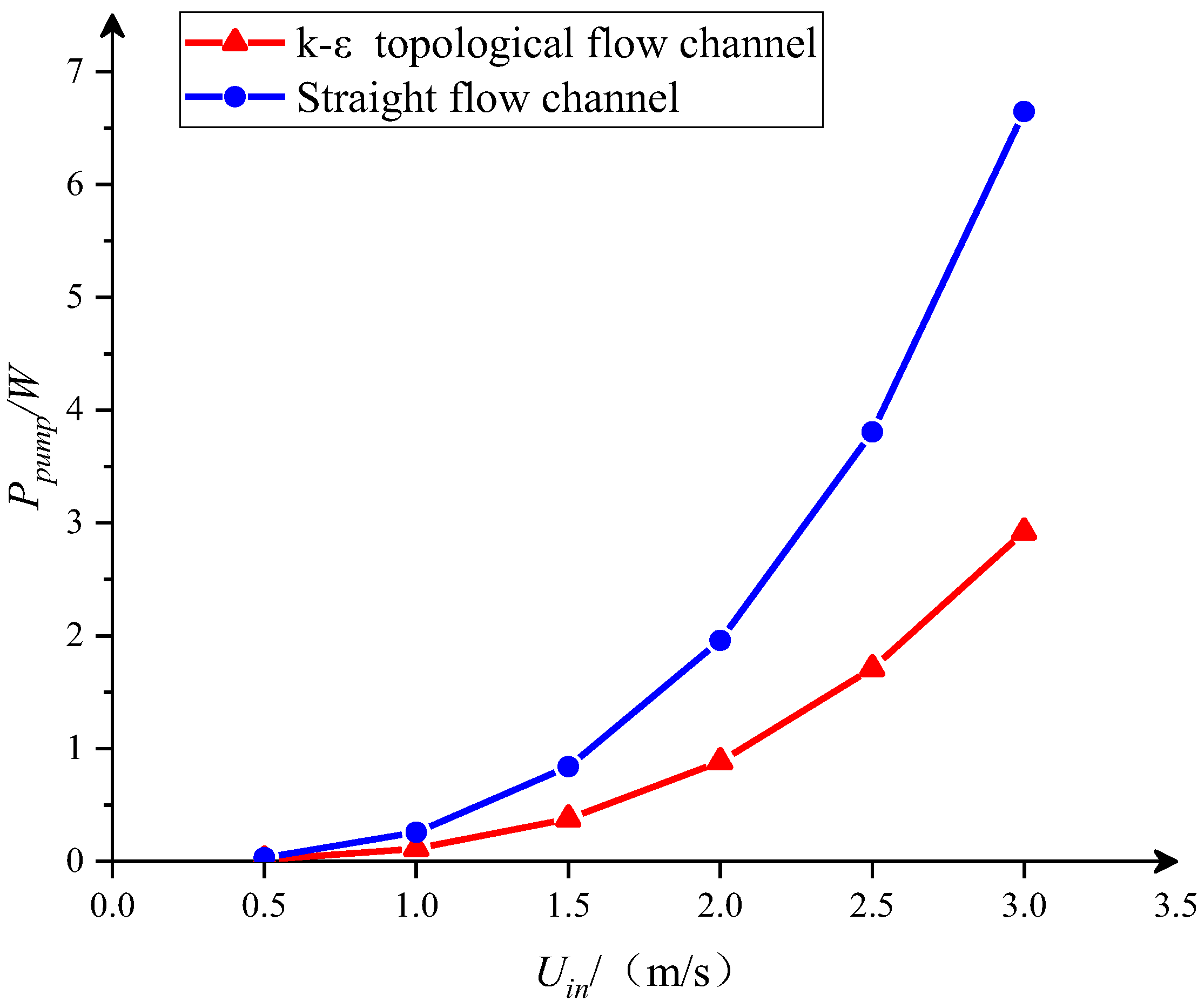

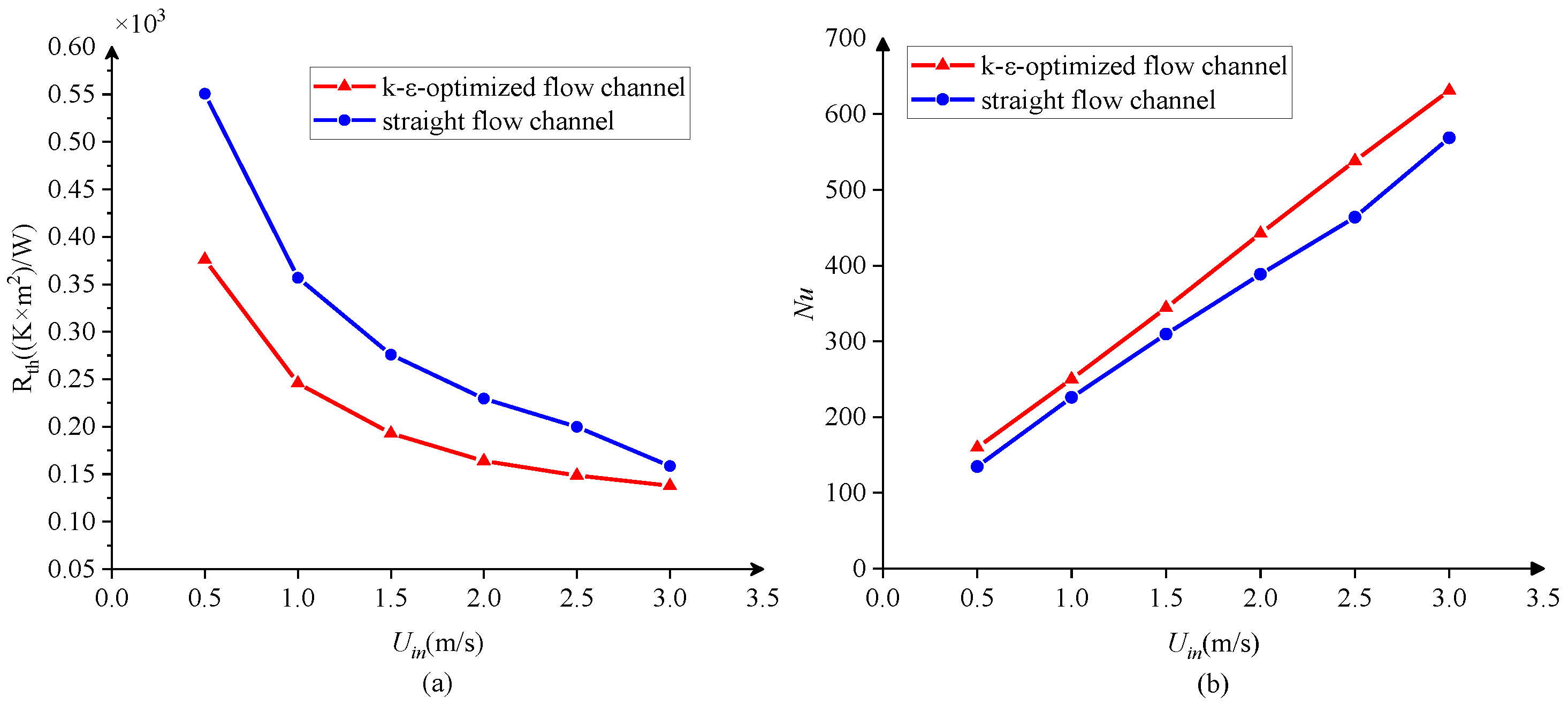

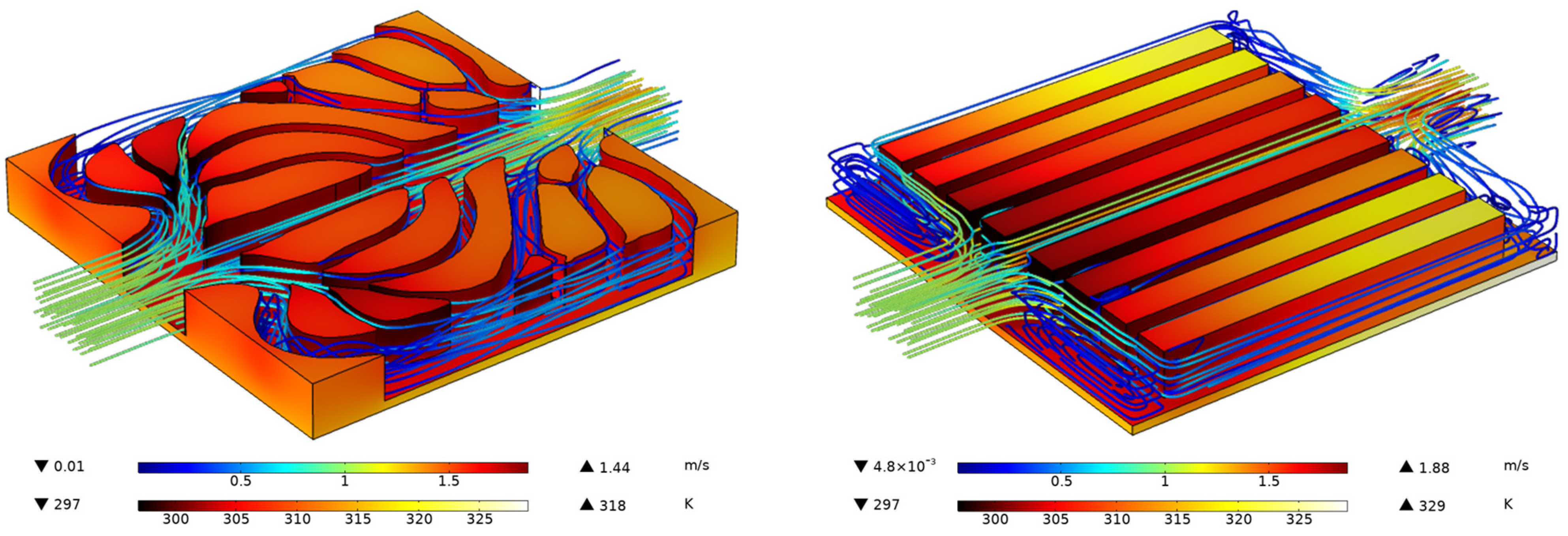

3.4. Three-Dimensional Flow Channel Model Analysis

4. Conclusions

- It is crucial to add appropriate penalty terms to the turbulent kinetic energy equation and turbulent energy dissipation equation of the k-ε model, respectively. Compared with the Navier–Stokes flow channel and Darcy-optimized flow channel, the k-ε-optimized channel can better balance the relationship between calculation time and design requirements.

- The heat transfer structure with the k-ε-optimized flow channel has superior hydraulic and heat transfer performance compared to conventional straight channels and Darcy-based TO designs. Elimination of undesirable flow vortices is believed to be an important factor for this performance.

- A multi-objective function considering the flow resistance as well as the thermal performance is used, and different weight factors are tested. As the objective function puts more weight on heat transfer, the optimized flow channels become narrower and more branched.

- The k-ε-optimized flow channel has better hydraulic and heat transfer performance in the practical application of the 3D heat sink, which reduces the pumping power and thermal resistance during the heat transfer process and effectively increases the Nusselt number.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, W.H. Investigation on Convective and Conjugate Heat Transfer Characteristics of Cooling Structures in Gas Turbine Thin-Wall Blade. Ph.D. Thesis, Tsinghua University, Beijing, China, 2018. [Google Scholar] [CrossRef]

- Wu, W.; Yao, R.; Wang, J.; Su, H.; Wu, X. Leading edge impingement cooling analysis with separators of a real gas turbine blade. Appl. Therm. Eng. 2022, 208, 118275. [Google Scholar] [CrossRef]

- Hassan, H.; Shafey, N.A. 3D study of convection-radiation heat transfer of electronic chip inside enclosure cooled by heat sink. Int. J. Therm. Sci. 2021, 159, 106585. [Google Scholar] [CrossRef]

- Mukesh Kumar, P.C.; Arun Kumar, C.M. Numerical study on heat transfer performance using Al2O3/water nanofluids in six circular channel heat sink for electronic chip. Mater. Today Proc. 2020, 21 (Pt. 1), 194–201. [Google Scholar] [CrossRef]

- Hao, X.; Peng, B.; Xie, G.; Chen, Y. Efficient on-chip hotspot removal combined solution of thermoelectric cooler and mini-channel heat sink. Appl. Therm. Eng. 2016, 100, 170–178. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S. A review of power battery thermal energy management. Renew. Sustain. Energy Rev. 2011, 15, 4554–4571. [Google Scholar] [CrossRef]

- Wu, K.; Zhang, Y.; Zeng, Y.Q.; Yang, J. Study on the safety performance of lithium-ion batteries. Adv. Chem. 2011, 23, 401–409. [Google Scholar]

- Chen, S.; Zhang, G.; Zhu, J.; Feng, X.; Wei, X.; Ouyang, M.; Dai, H. Multi-objective optimization design and experimental investigation for a parallel liquid cooling-based Lithium-ion battery module under fast charging. Appl. Therm. Eng. 2022, 211, 118503. [Google Scholar] [CrossRef]

- Zhuang, D.; Yang, Y.; Ding, G.; Du, X.; Hu, Z. Optimization of Microchannel Heat Sink with Rhombus Fractal-like Units for Electronic Chip Cooling. Int. J. Refrig. 2020, 116, 108–118. [Google Scholar] [CrossRef]

- Kose, H.A.; Yildizeli, A.; Cadirci, S. Parametric study and optimization of microchannel heat sinks with various shapes. Appl. Therm. Eng. 2022, 211, 118368. [Google Scholar] [CrossRef]

- Guo, R.; Li, L. Heat dissipation analysis and optimization of lithium-ion batteries with a novel parallel-spiral serpentine channel liquid cooling plate. Int. J. Heat Mass Transf. 2022, 189, 122706. [Google Scholar] [CrossRef]

- Tan, H.; Du, P.; Zong, K.; Meng, G.; Gao, X.; Li, Y. Investigation on the temperature distribution in the two-phase spider netted microchannel network heat sink with non-uniform heat flux. Int. J. Therm. Sci. 2021, 169, 107079. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 1988, 71, 197–224. [Google Scholar] [CrossRef]

- Xie, Y.M.; Steven, G.P. Evolutionary Structural Optimization; Springer: London, UK, 1997; ISBN 9781447109853. [Google Scholar]

- Bendsøe, M.P.; Sigmund, O. Topology Optimization—Theory, Methods and Applications; Springer: Berlin/Heidelberg, Germany, 2004; ISBN 9783662050866. [Google Scholar]

- Wang, M.Y.; Wang, X.; Guo, D. A level set method for structural topology optimization. Comput. Methods Appl. Mech. Eng. 2003, 192, 227–246. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, W.; Zhang, J.; Yuan, J. Explicit structural topology optimization based on moving morphable components (MMC) with curved skeletons. Comput. Methods Appl. Mech. Eng. 2016, 310, 711–748. [Google Scholar] [CrossRef]

- Borrvall, T.; Petersson, J. Topology optimization of fluids in stokes flow. Int. J. Numer. Methods Fluids 2003, 41, 77–107. [Google Scholar] [CrossRef]

- Gersborg-Hansen, A.; Sigmund, O.; Haber, R.B. Topology optimization of channel flow problems. Struct. Multidiscip. Optimiz. 2005, 30, 181–192. [Google Scholar] [CrossRef]

- Pietropaoli, M.; Ahlfeld, R.; Montomoli, F.; D’Ercole, M. Design for Additive Manufacturing: Internal Channel Optimization. J. Eng. Gas Turbines Power 2017, 139, 102101. [Google Scholar] [CrossRef]

- Han, X.-H.; Liu, H.-L.; Xie, G.; Sang, L.; Zhou, J. Topology optimization for spider web heat sinks for electronic cooling. Appl. Therm. Eng. 2021, 195, 117154. [Google Scholar] [CrossRef]

- Chen, F.; Wang, J.; Yang, X. Topology optimization design and numerical analysis on cold plates for lithium-ion battery thermal management. Int. J. Heat Mass Transf. 2022, 183 (Pt. A), 122087. [Google Scholar] [CrossRef]

- Hu, D.; Zhang, Z.; Li, Q. Numerical study on flow and heat transfer characteristics of microchannel designed using topological optimizations method. Sci. China Technol. Sci. 2020, 63, 105–115. [Google Scholar] [CrossRef]

- Yoon, G.H. Topology optimization for turbulent flow with Spalart–Allmaras model. Comput. Methods Appl. Mech. Eng. 2016, 303, 288–311. [Google Scholar] [CrossRef]

- Sá, L.F.; Yamabe, P.V.; Souza, B.C.; Silva, E.C. Topology optimization of turbulent rotating flows using Spalart–Allmaras model. Comput. Methods Appl. Mech. Eng. 2021, 373, 113551. [Google Scholar] [CrossRef]

- Yoon, G.H. Topology optimization method with finite elements based on the k-εturbulence model. Comput. Methods Appl. Mech. Eng. 2020, 361, 112784. [Google Scholar] [CrossRef]

- Dilgen, C.B.; Dilgen, S.B.; Fuhrman, D.R.; Sigmund, O.; Lazarov, B.S. Topology optimization of turbulent flows. Comput. Methods Appl. Mech. Eng. 2018, 331, 363–393. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, M.; Sigmund, O.; Andreasen, C.S. A “poor man’s approach” to topology optimization of cooling channels based on a Darcy flow model. Int. J. Heat Mass Transf. 2018, 116, 1108–1123. [Google Scholar] [CrossRef]

- Li, A. Topology Optimization of Fluid-Solid Conjugate Heat Transfer Structure. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2020. [Google Scholar] [CrossRef]

- Li, B.; Xie, C.; Yin, X.; Lu, R.; Ma, Y.; Liu, H.; Hong, J. Multidisciplinary optimization of liquid cooled heat sinks with compound jet/channel structures arranged in a multipass configuration. Appl. Therm. Eng. 2021, 195, 117159. [Google Scholar] [CrossRef]

- Dilgen, S.B.; Dilgen, C.B.; Fuhrman, D.R.; Sigmund, O.; Lazarov, B.S. Density based topology optimization of turbulent flow heat transfer systems. Struct. Multidiscip. Optim. 2018, 57, 1905–1918. [Google Scholar] [CrossRef]

- Zou, A.; Chuan, R.; Qian, F.; Zhang, W.; Wang, Q.; Zhao, C. Topology optimization for a water-cooled heat sink in micro-electronics based on Pareto frontier. Appl. Therm. Eng. 2022, 207, 118128. [Google Scholar] [CrossRef]

- Lazarov, B.S.; Sigmund, O. Filters in topology optimization based on Helmholtz-type differential equations. Int. J. Numer. Methods Eng. 2011, 86, 765–781. [Google Scholar] [CrossRef]

- Li, H.; Ding, X.H.; Meng, F.Z.; Jing, D.L.; Xiong, M. Optimal design and thermal modelling for liquid-cooled heat sink based on multi-objective topology optimization: An experimental and numerical study. Int. J. Heat Mass Transf. 2019, 144, 118638. [Google Scholar] [CrossRef]

| 0.6 W/(m·K) | |

| 202 W/(m·K) | |

| 1000 kg/m3 | |

| 2713 kg/m3 | |

| 4200 J/(kg·K) | |

| 871 J/(kg·K) |

| Number of Iterations | Computation Time | Average Time of Each Iteration | The Objective Function | |

|---|---|---|---|---|

| Navier–Stokes flow model | 50 | 18,710 s (5 h 11 min 50 s) | 374.2 s | 0.52705 |

| Darcy flow model | 100 | 202 s (3 min 22 s) | 2.02 s | 0.64244 |

| k-ε turbulent flow model | 80 | 2590 s (43 min 10 s) | 32.375 s | 0.45046 |

| Grid 1 | Grid 2 | Grid 3 | Deviation: 2–1 | Deviation: 2–3 | |

|---|---|---|---|---|---|

| The number of grids | 120,780 | 304,914 | 516,940 | ||

| Average temperature (K) | 301.633 | 301.703 | 301.711 | 0.818% | 0.094% |

| Pressure drop (Pa) | 119.338 | 117.551 | 118.998 | 1.52% | 1.23% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Hao, M.; Wang, Z. Topology Optimization of Turbulent Flow Cooling Structures Based on the k-ε Model. Entropy 2023, 25, 1299. https://doi.org/10.3390/e25091299

Sun Y, Hao M, Wang Z. Topology Optimization of Turbulent Flow Cooling Structures Based on the k-ε Model. Entropy. 2023; 25(9):1299. https://doi.org/10.3390/e25091299

Chicago/Turabian StyleSun, Yiwei, Menglong Hao, and Zexu Wang. 2023. "Topology Optimization of Turbulent Flow Cooling Structures Based on the k-ε Model" Entropy 25, no. 9: 1299. https://doi.org/10.3390/e25091299