Motion of Adsorbed Nano-Particles on Azobenzene Containing Polymer Films

Abstract

:1. Introduction

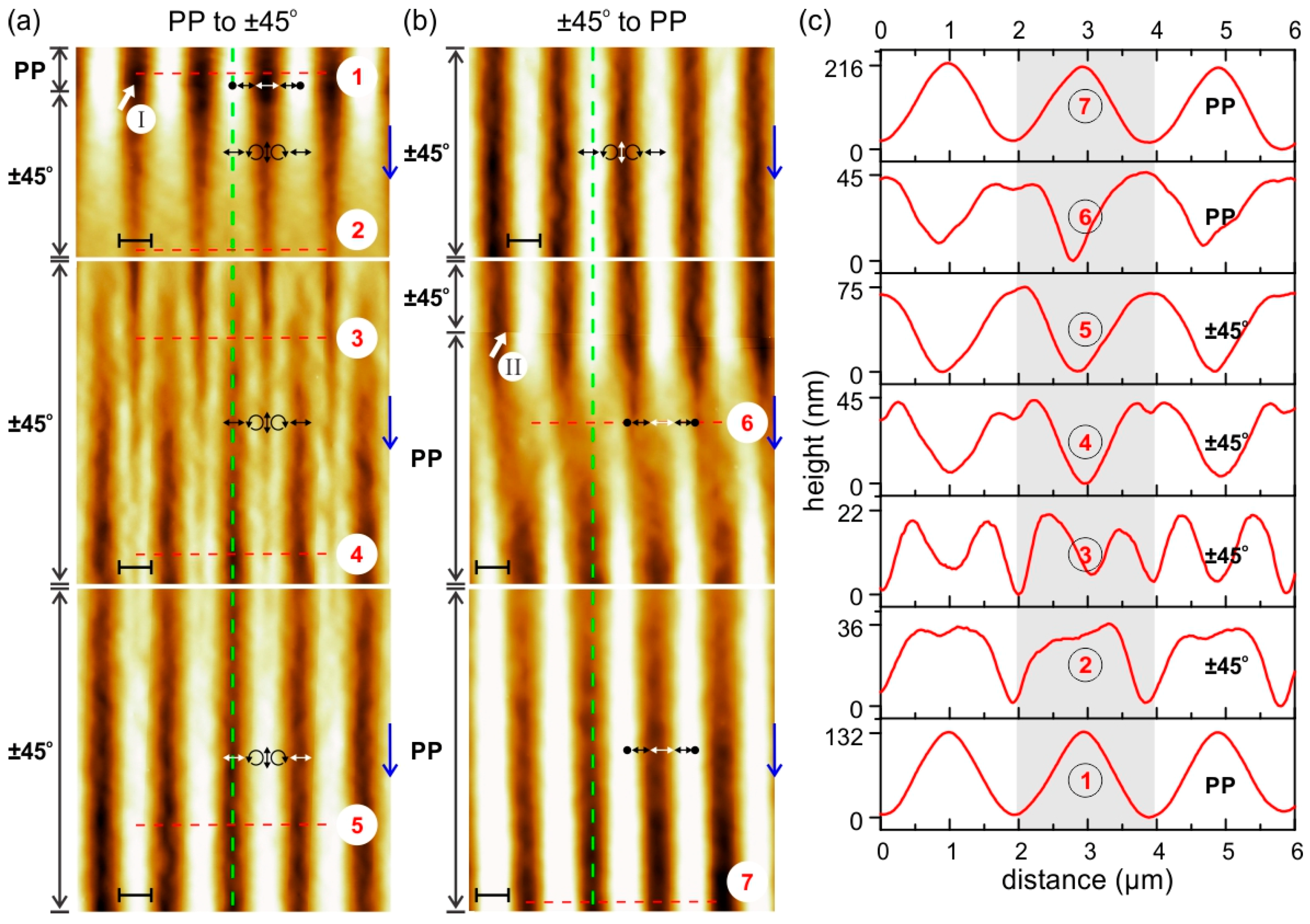

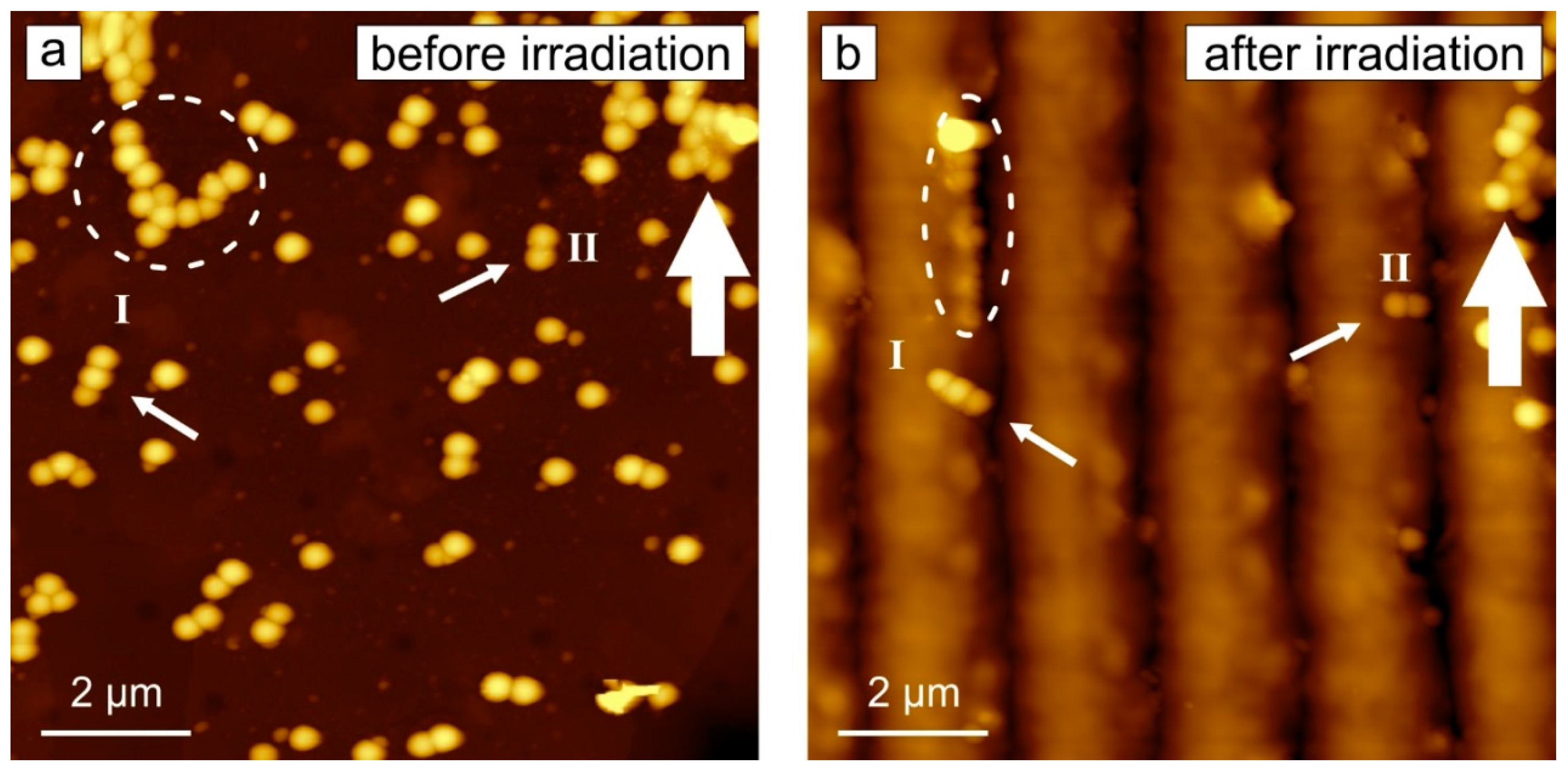

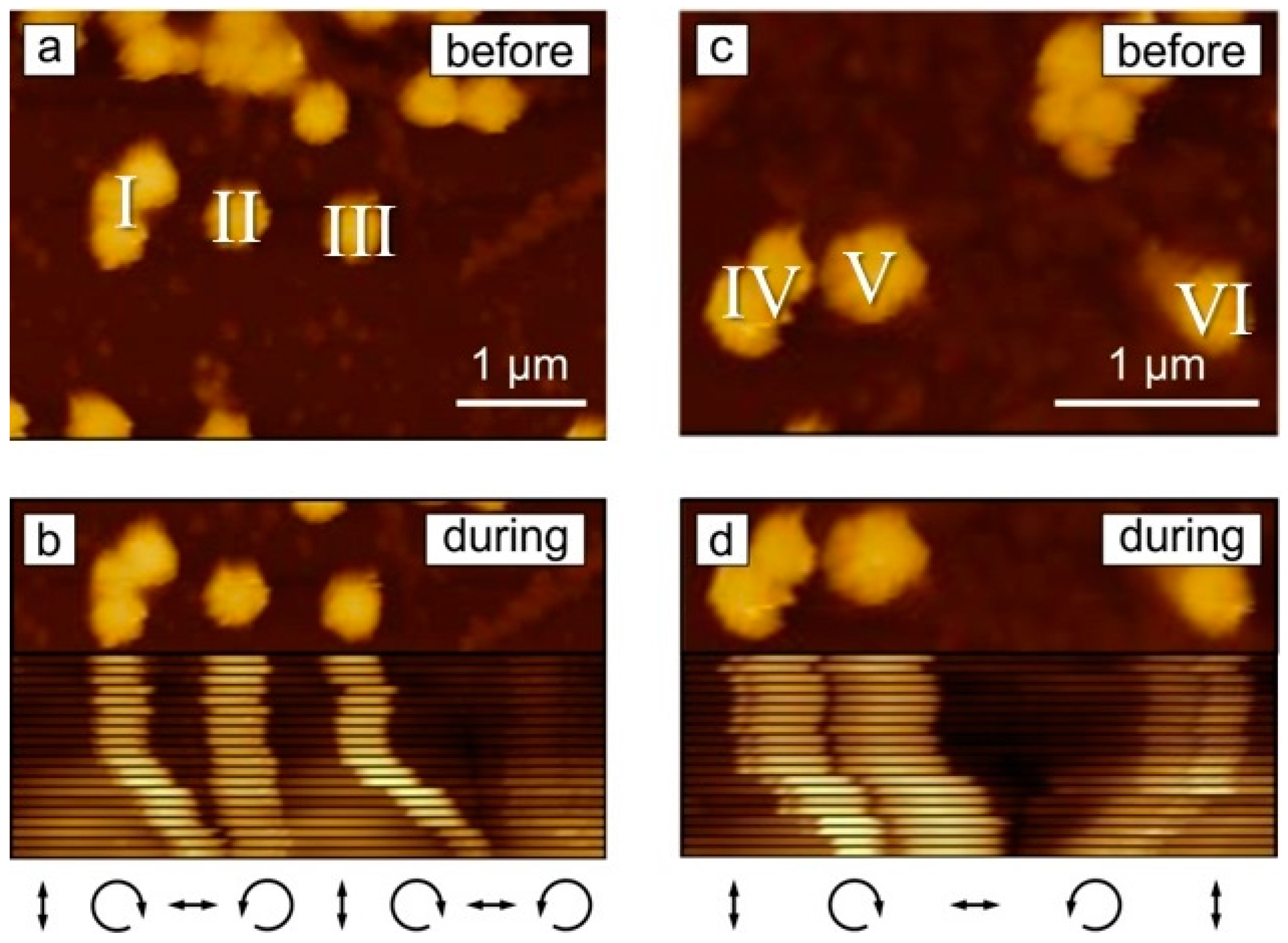

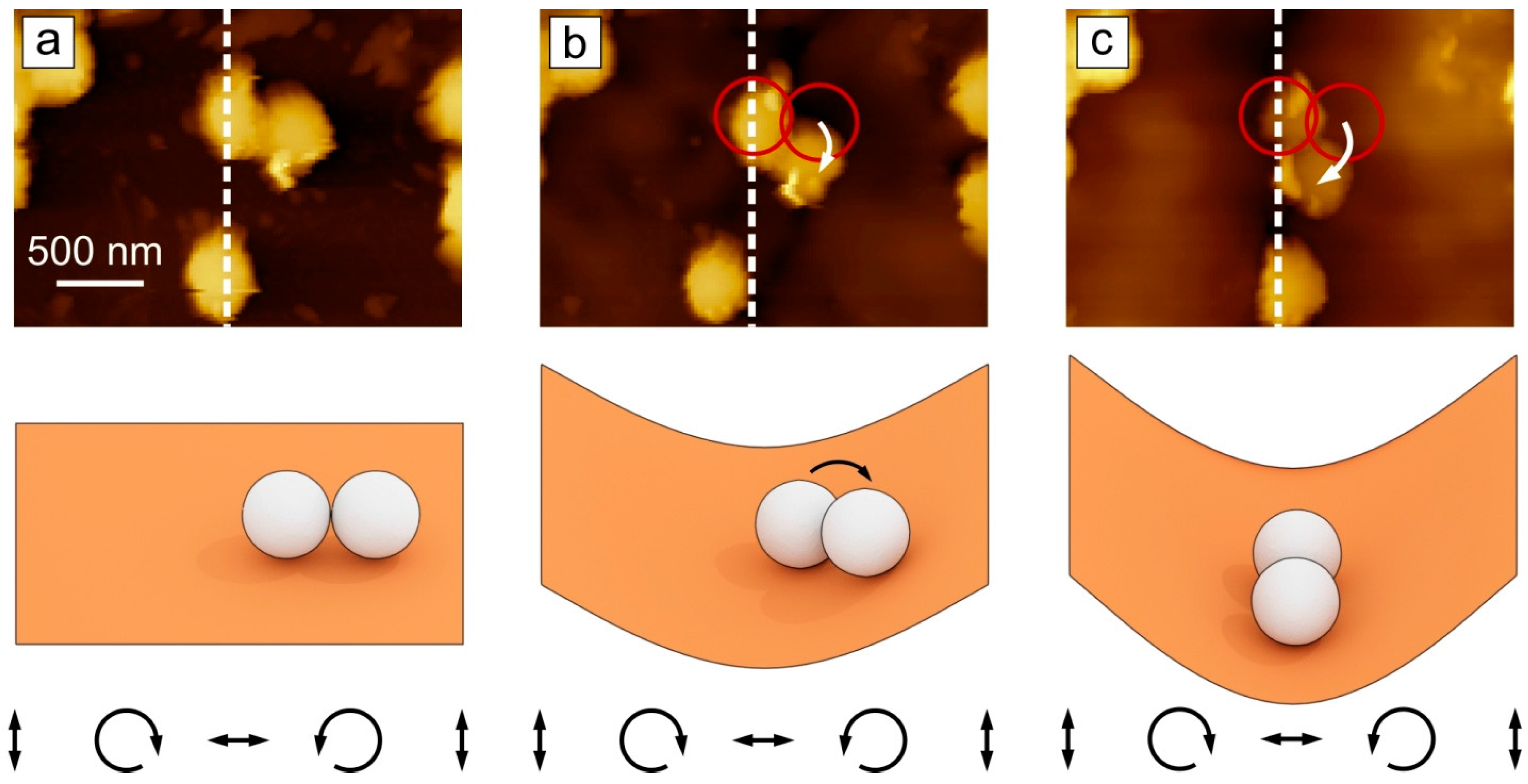

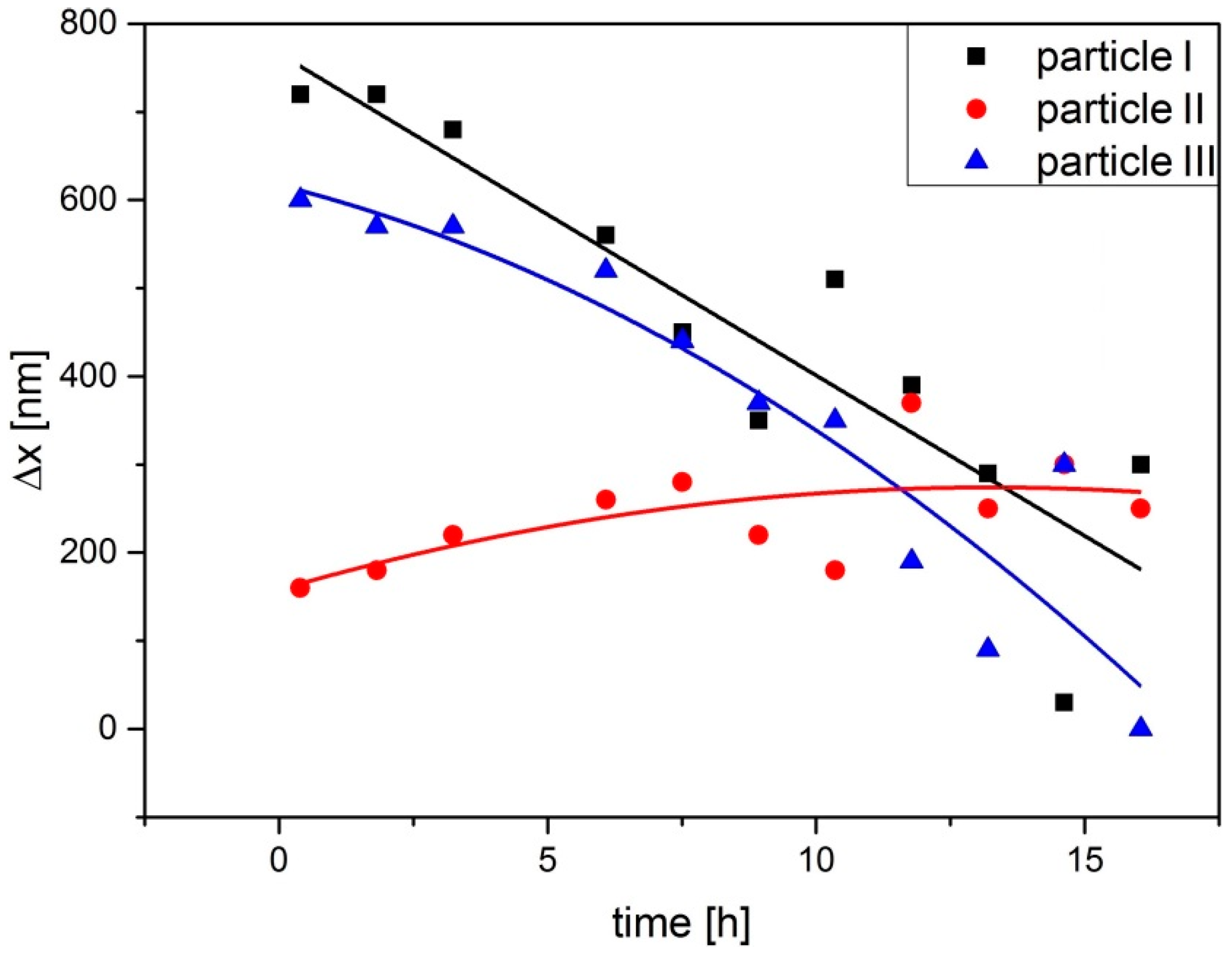

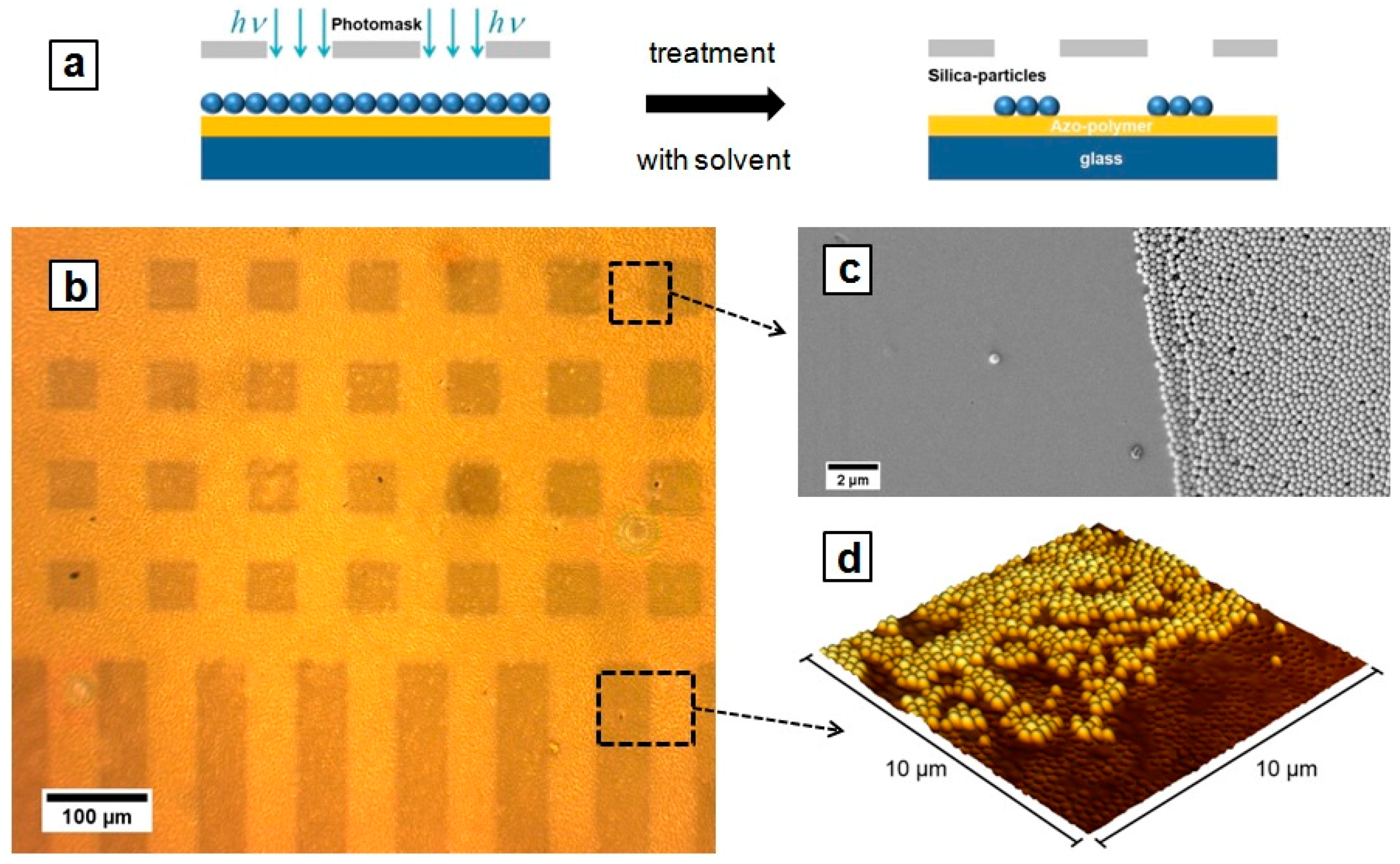

2. Results and Discussion

3. Materials and Methods

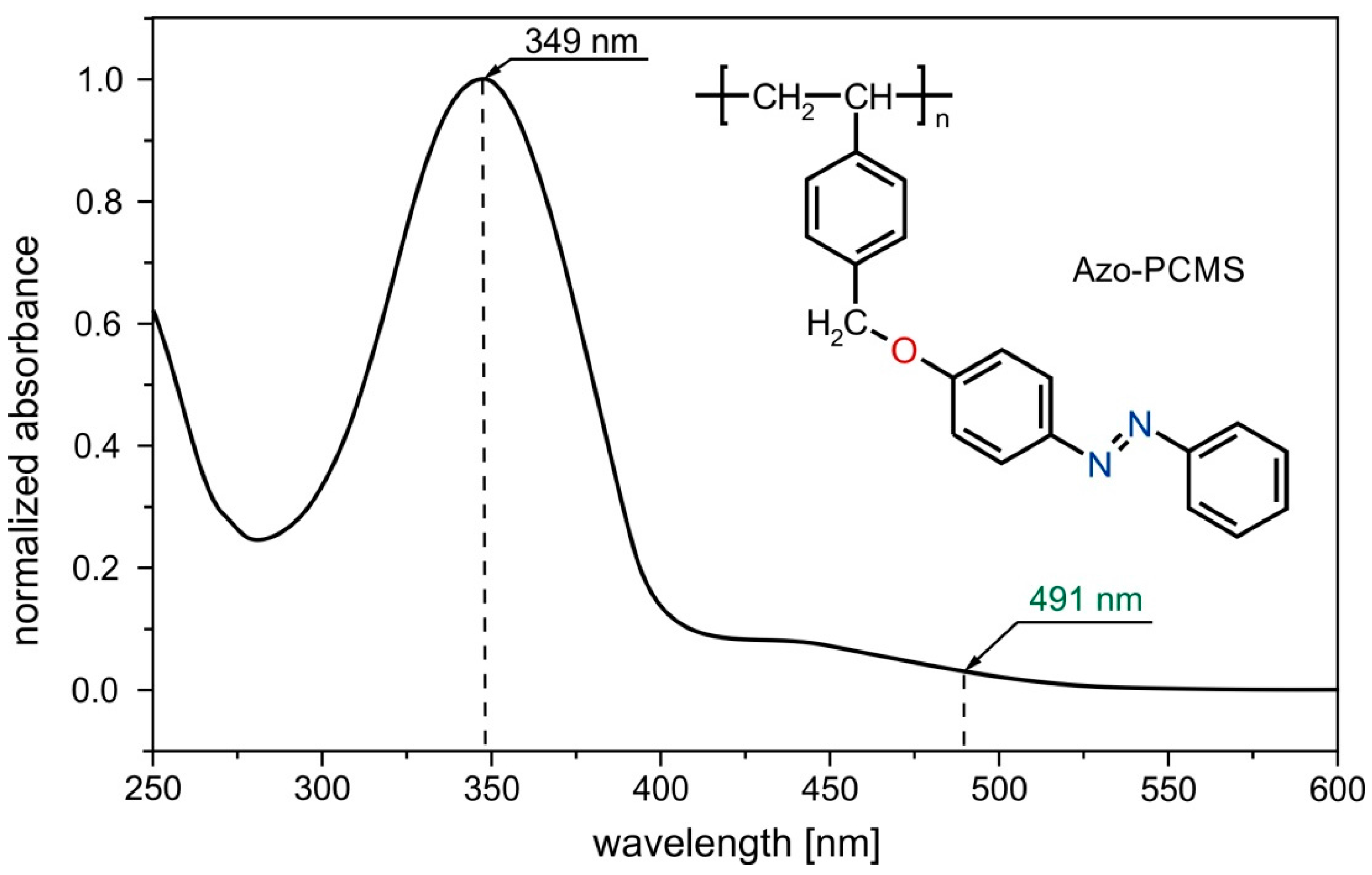

3.1. Photosensitive Materials

3.2. Silica Particles

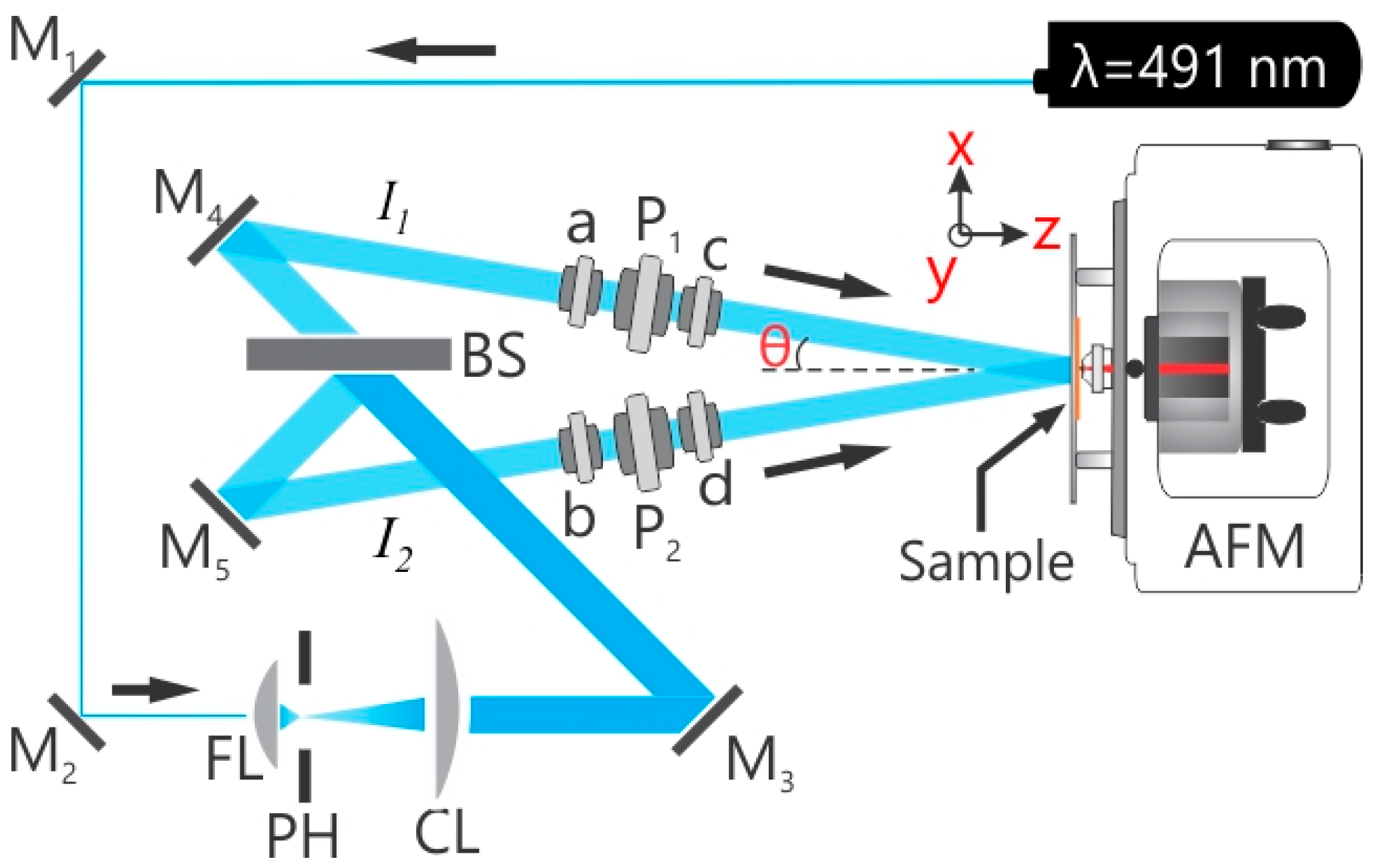

3.3. In Situ AFM Connected Optical Setup

3.4. Mask Irradiation

4. Conclusions

Supplementary Materials

Acknowledgments

Conflicts of Interest

References

- Wong, T.-S.; Kang, S.H.; Tang, S.K.Y.; Smythe, E.J.; Hatton, B.D.; Grinthal, A.; Aizenberg, J. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 2011, 477, 443–447. [Google Scholar] [CrossRef] [PubMed]

- Grier, D.G. A revolution in optical manipulation. Nature 2003, 424, 810–816. [Google Scholar] [CrossRef] [PubMed]

- Chiou, P.Y.; Ohta, A.T.; Wu, M.C. Massively parallel manipulation of single cells and microparticles using optical images. Nature 2005, 436, 370–372. [Google Scholar] [CrossRef] [PubMed]

- Yang, A.H.J.; Moore, S.D.; Schmidt, B.S.; Klug, M.; Lipson, M.; Erickson, D. Optical manipulation of nanoparticles and biomolecules in sub-wavelength slot waveguides. Nature 2009, 457, 71–75. [Google Scholar] [CrossRef] [PubMed]

- Fennimore, A.M.; Yuzvinsky, T.D.; Han, W.-Q.; Fuhrer, M.S.; Cumings, J.; Zettl, A. Rotational actuators based on carbon nanotubes. Nature 2003, 424, 408–410. [Google Scholar] [CrossRef] [PubMed]

- Israelachvili, J.N. Intermolecular and Surface Forces; Academic Press: Cambridge, MA, USA, 2011. [Google Scholar]

- Grobelny, J.; Tsai, D.-H.; Kim, D.-I.; Pradeep, N.; Cook, R.F.; Zachariah, M.R. Mechanism of nanoparticle manipulation by scanning tunnelling microscopy. Nanotechnology 2006, 17, 5519–5524. [Google Scholar] [CrossRef]

- Kim, S.; Ratchford, D.C.; Li, X. Atomic force microscope nanomanipulation with simultaneous visual guidance. ACS Nano 2009, 3, 2989–2994. [Google Scholar] [CrossRef] [PubMed]

- Santer, S.; Rühe, J. Motion of nano-objects on polymer brushes. Polymer 2004, 45, 8279–8297. [Google Scholar] [CrossRef]

- Santer, S.; Kopyshev, A.; Donges, J.; Yang, H.-K.; Rühe, J. Dynamically Reconfigurable Polymer Films: Impact on Nanomotion. Adv. Mater. 2006, 18, 2359–2362. [Google Scholar] [CrossRef]

- Yadavalli, N.S.; König, T.; Santer, S. Selective mass transport of azobenzene-containing photosensitive films towards or away from the light intensity. J. Soc. Inf. Disp. 2015, 23, 154–162. [Google Scholar] [CrossRef]

- Galvin, C.J.; Genzer, J. Applications of surface-grafted macromolecules derived from post-polymerization modification reactions. Prog. Polym. Sci. 2012, 37, 871–906. [Google Scholar] [CrossRef]

- Santer, S.; Kopyshev, A.; Donges, J.; Rühe, J.; Jiang, X.; Zhao, B.; Müller, M. Memory of surface patterns in mixed polymer brushes: Simulation and experiment. Langmuir 2007, 23, 279–285. [Google Scholar] [CrossRef] [PubMed]

- Santer, S.; Kopyshev, A.; Donges, J.; Yang, H.-K.; Rühe, J. Domain memory of mixed polymer brushes. Langmuir 2006, 22, 4660–4667. [Google Scholar] [CrossRef] [PubMed]

- Minko, S.; Müller, M.; Usov, D.; Scholl, A.; Froeck, C.; Stamm, M. Lateral versus Perpendicular Segregation in Mixed Polymer Brushes. Phys. Rev. Lett. 2002, 88, 35502. [Google Scholar] [CrossRef] [PubMed]

- Zhulina, E.B.; Singh, C.; Balazs, A.C. Forming Patterned Films with Tethered Diblock Copolymers. Macromolecules 1996, 29, 6338–6348. [Google Scholar] [CrossRef]

- Tomlinson, M.R.; Genzer, J. Evolution of surface morphologies in multivariant assemblies of surface-tethered diblock copolymers after selective solvent treatment. Langmuir 2005, 21, 11552–11555. [Google Scholar] [CrossRef] [PubMed]

- Müller, M. Phase diagram of a mixed polymer brush. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2002, 65, 30802. [Google Scholar] [CrossRef] [PubMed]

- Mansky, P. Controlling Polymer-Surface Interactions with Random Copolymer Brushes. Science 1997, 275, 1458–1460. [Google Scholar] [CrossRef]

- Rau, H. Photoisomerization of azobenzenes. In Photochemistry and Photophysics; Rabek, J., Ed.; CRC Press: Boca Raton, FL, USA, 1990; pp. 119–142. [Google Scholar]

- Kim, D.Y.; Tripathy, S.K.; Li, L.; Kumar, J. Laser-induced holographic surface relief gratings on nonlinear optical polymer films. Appl. Phys. Lett. 1995, 66, 1166–1168. [Google Scholar] [CrossRef]

- Rochon, P.; Batalla, E.; Natansohn, A. Optically induced surface gratings on azoaromatic polymer films. Appl. Phys. Lett. 1995, 66, 136–138. [Google Scholar] [CrossRef]

- Toshchevikov, V.; Saphiannikova, M. Theory of light-induced deformation of azobenzene elastomers: Effects of the liquid-crystalline interactions and biaxiality. J. Phys. Chem. B 2014, 118, 12297–12309. [Google Scholar] [CrossRef] [PubMed]

- Singleton, T.A.; Ramsay, K.S.; Barsan, M.M.; Butler, I.S.; Barrett, C.J. Azobenzene photoisomerization under high external pressures: Testing the strength of a light-activated molecular muscle. J. Phys. Chem. B 2012, 116, 9860–9865. [Google Scholar] [CrossRef] [PubMed]

- Yadavalli, N.S.; Korolkov, D.; Moulin, J.-F.; Krutyeva, M.; Santer, S. Probing opto-mechanical stresses within azobenzene-containing photosensitive polymer films by a thin metal film placed above. ACS Appl. Mater. Interfaces 2014, 6, 11333–11340. [Google Scholar] [CrossRef] [PubMed]

- Di Florio, G.; Bründermann, E.; Yadavalli, N.S.; Santer, S.; Havenith, M. Polarized 3D Raman and nanoscale near-field optical microscopy of optically inscribed surface relief gratings: Chromophore orientation in azo-doped polymer films. Soft Matter 2014, 10, 1544–1554. [Google Scholar] [CrossRef] [PubMed]

- Yadavalli, N.S.; Linde, F.; Kopyshev, A.; Santer, S. Soft Matter Beats Hard Matter: Rupturing of Thin Metallic Films Induced by Mass Transport in Photosensitive Polymer Films. ACS Appl. Mater. Interfaces 2013, 5, 7743–7747. [Google Scholar] [CrossRef] [PubMed]

- Schuh, C.; Lomadze, N.; Rühe, J.; Kopyshev, A.; Santer, S. Photomechanical degrafting of azo-functionalized poly(methacrylic acid) (PMAA) brushes. J. Phys. Chem. B 2011, 115, 10431–10438. [Google Scholar] [CrossRef] [PubMed]

- Lomadze, N.; Kopyshev, A.; Rühe, J.; Santer, S. Light-Induced Chain Scission in Photosensitive Polymer Brushes. Macromolecules 2011, 44, 7372–7377. [Google Scholar] [CrossRef]

- Kopyshev, A.; Galvin, C.J.; Genzer, J.; Lomadze, N.; Santer, S. Opto-mechanical scission of polymer chains in photosensitive diblock-copolymer brushes. Langmuir 2013, 29, 13967–13974. [Google Scholar] [CrossRef] [PubMed]

- Kopyshev, A.; Galvin, C.J.; Genzer, J.; Lomadze, N.; Santer, S. Polymer brushes modified by photosensitive azobenzene containing polyamines. Polymer 2016, 98, 421–428. [Google Scholar] [CrossRef]

- Kopyshev, A.; Lomadze, N.; Feldmann, D.; Genzer, J.; Santer, S. Making polymer brush photosensitive with azobenzene containing surfactants. Polymer 2015, 79, 65–72. [Google Scholar] [CrossRef]

- Yadavalli, N.S.; Loebner, S.; Papke, T.; Sava, E.; Hurduc, N.; Santer, S. A comparative study of photoinduced deformation in azobenzene containing polymer films. Soft Matter 2016, 12, 2593–2603. [Google Scholar] [CrossRef] [PubMed]

- Yadavalli, N.S.; Saphiannikova, M.; Santer, S. Photosensitive response of azobenzene containing films towards pure intensity or polarization interference patterns. Appl. Phys. Lett. 2014, 105, 51601. [Google Scholar] [CrossRef]

- Yadavalli, N.S.; Santer, S. In-situ atomic force microscopy study of the mechanism of surface relief grating formation in photosensitive polymer films. J. Appl. Phys. 2013, 113, 224304. [Google Scholar] [CrossRef]

- König, T. Reversible Strukturierung von Photosensitiven Polymerfilmen. PhD. Thesis, Freiburg University, Freiburg im Breisgau, Germany, 26 October 2011. [Google Scholar]

- Papke, T.; Yadavalli, N.S.; Henkel, C.; Santer, S. Mapping a plasmonic hologram with photosensitive polymer films: Standing versus propagating waves. ACS Appl. Mater. Interfaces 2014, 6, 14174–14180. [Google Scholar] [CrossRef] [PubMed]

- König, T.; Goldenberg, L.M.; Kulikovska, O.; Kulikovsky, L.; Stumpe, J.; Santer, S. Reversible structuring of photosensitive polymer films by surface plasmon near field radiation. Soft Matter 2011, 7, 4174–4178. [Google Scholar] [CrossRef]

- König, T.; Yadavalli, N.S.; Santer, S. Surface plasmon nanolithography: Impact of dynamically varying near-field boundary conditions at the air–polymer interface. J. Mater. Chem. 2012, 22, 5945–5950. [Google Scholar] [CrossRef]

- Watanabe, O.; Ikawa, T.; Kato, T.; Tawata, M.; Shimoyama, H. Area-selective photoimmobilization of a two-dimensional array of colloidal spheres on a photodeformed template formed in photoresponsive azopolymer film. Appl. Phys. Lett. 2006, 88, 204107. [Google Scholar] [CrossRef]

- Kazmierski, K.; Hurduc, N.; Sauvet, G.; Chojnowski, J. Polysiloxanes with chlorobenzyl groups as precursors of new organic-silicone materials. J. Polym. Sci. A Polym. Chem. 2004, 42, 1682–1692. [Google Scholar] [CrossRef]

- Yadavalli, N.S.; Saphiannikova, M.; Lomadze, N.; Goldenberg, L.M.; Santer, S. Structuring of photosensitive material below diffraction limit using far field irradiation. Appl. Phys. A 2013, 113, 263–272. [Google Scholar] [CrossRef]

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loebner, S.; Jelken, J.; Yadavalli, N.S.; Sava, E.; Hurduc, N.; Santer, S. Motion of Adsorbed Nano-Particles on Azobenzene Containing Polymer Films. Molecules 2016, 21, 1663. https://doi.org/10.3390/molecules21121663

Loebner S, Jelken J, Yadavalli NS, Sava E, Hurduc N, Santer S. Motion of Adsorbed Nano-Particles on Azobenzene Containing Polymer Films. Molecules. 2016; 21(12):1663. https://doi.org/10.3390/molecules21121663

Chicago/Turabian StyleLoebner, Sarah, Joachim Jelken, Nataraja Sekhar Yadavalli, Elena Sava, Nicolae Hurduc, and Svetlana Santer. 2016. "Motion of Adsorbed Nano-Particles on Azobenzene Containing Polymer Films" Molecules 21, no. 12: 1663. https://doi.org/10.3390/molecules21121663