Molecular and Functional Properties of Protein Fractions and Isolate from Cashew Nut (Anacardium occidentale L.)

Abstract

:1. Introduction

2. Results

2.1. Chemical Compositions

2.2. Molecular Characterization

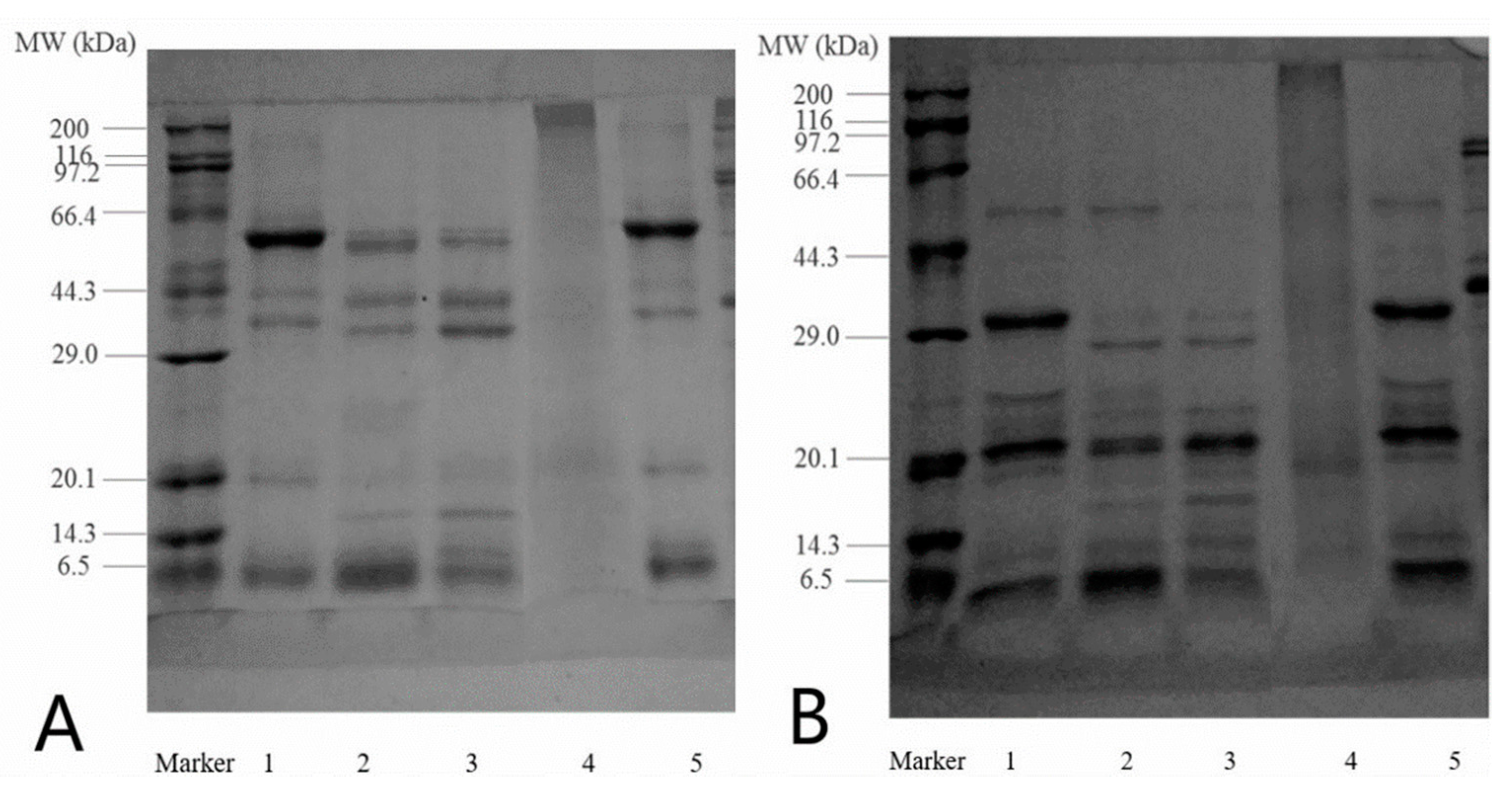

2.2.1. Electrophoresis

2.2.2. Circular Dichroism Spectroscopy

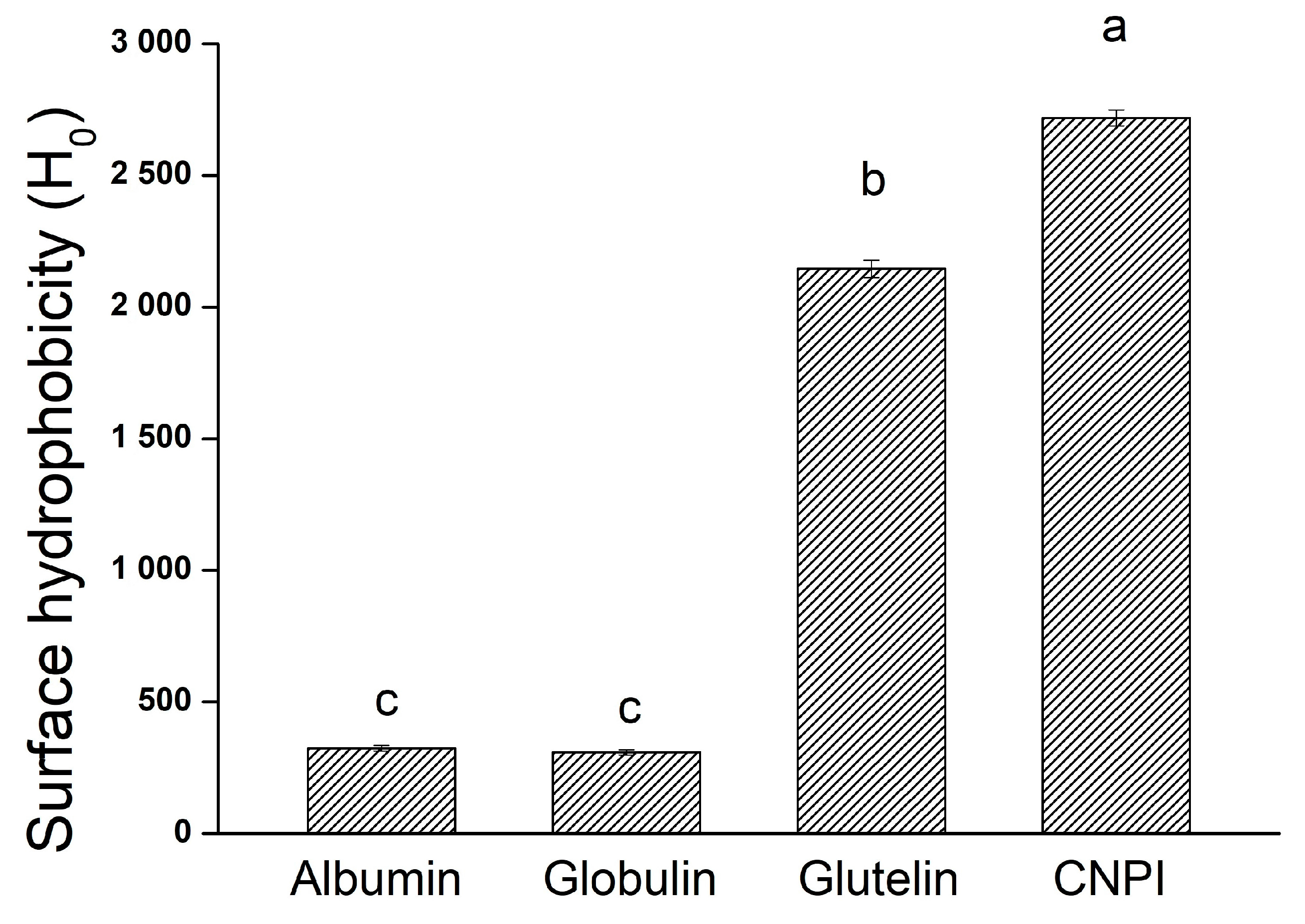

2.2.3. Surface Hydrophobicity (H0)

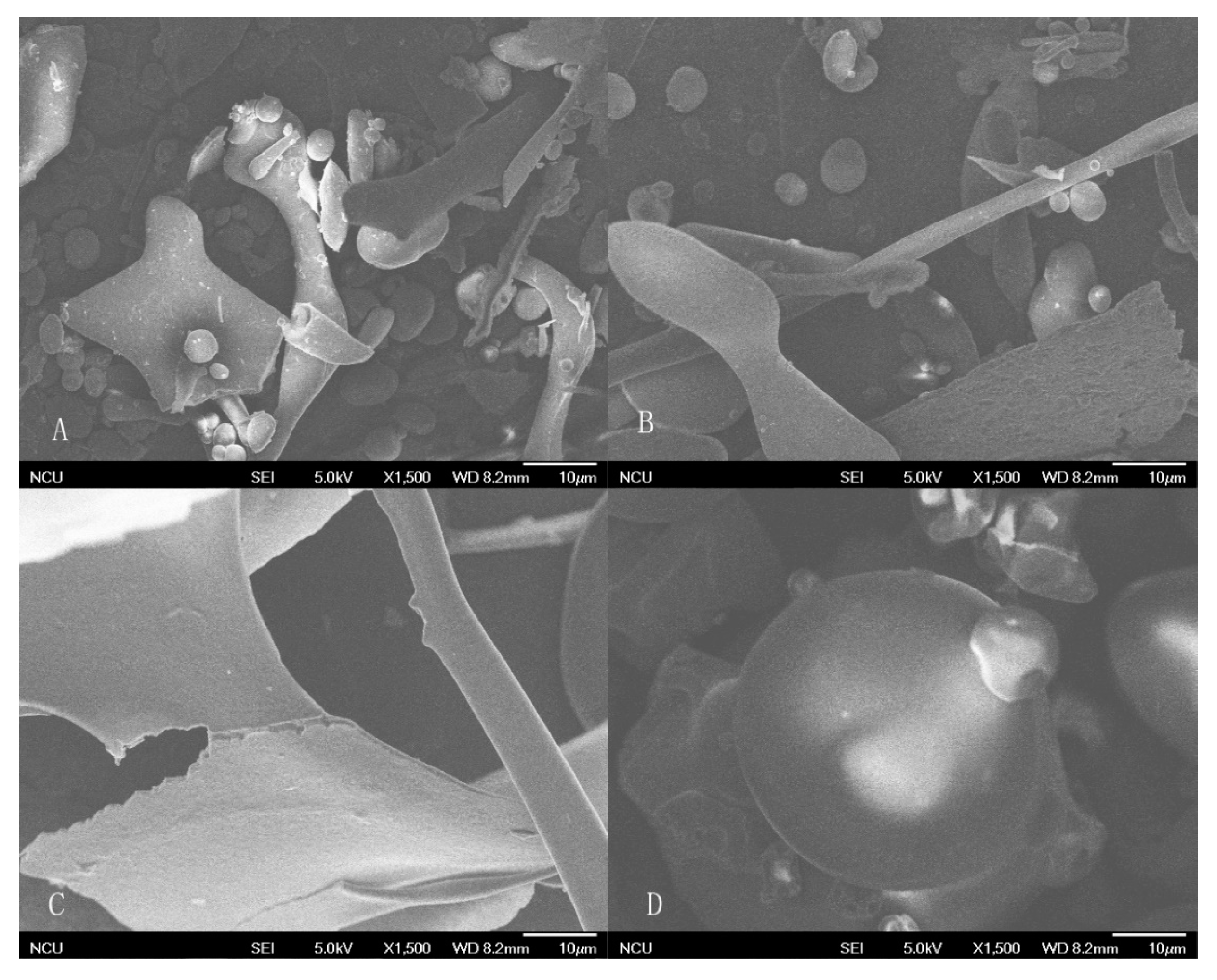

2.2.4. Scanning Electron Microscopy

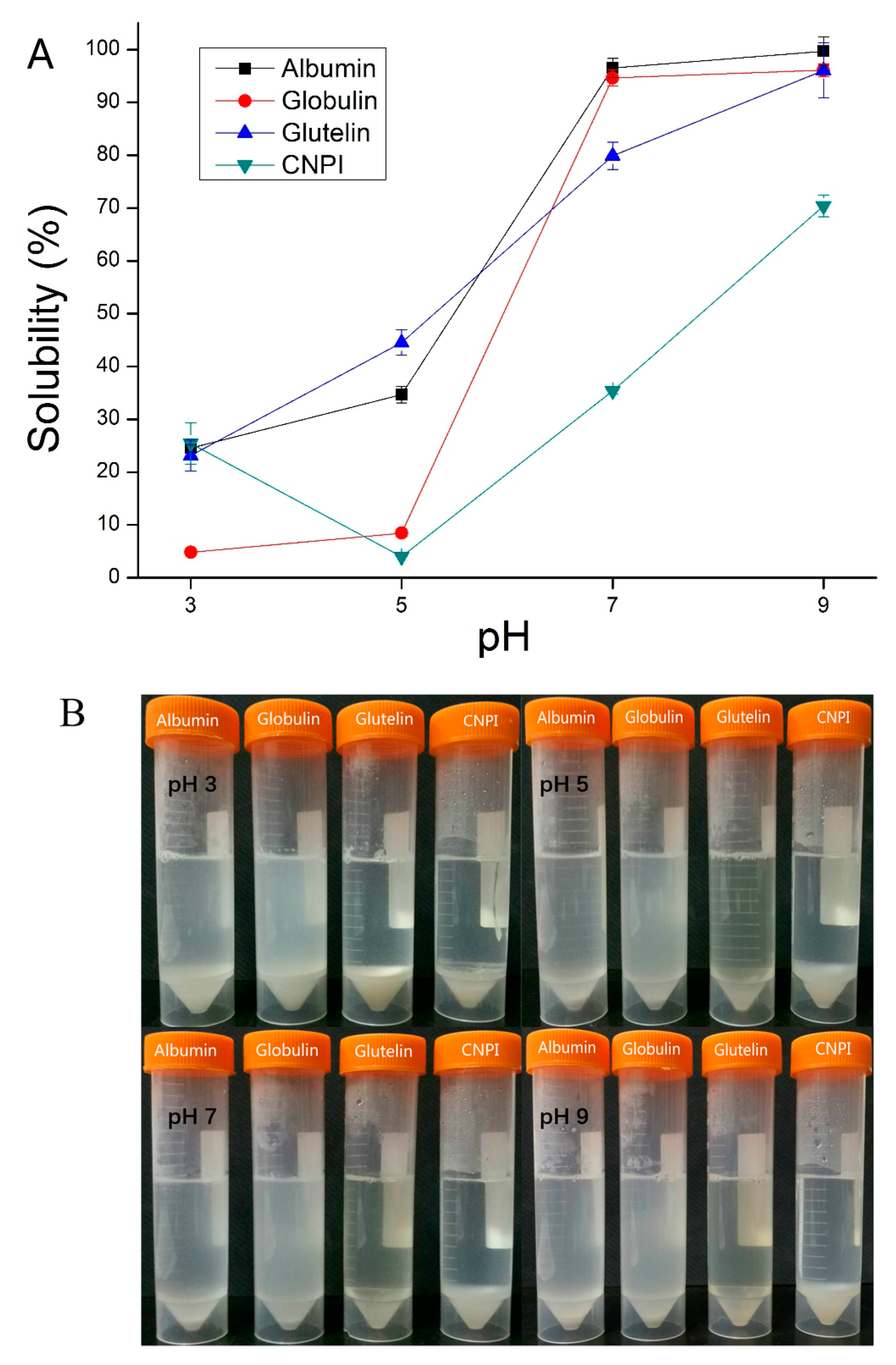

2.3. Protein Solubility (PS)

2.4. Water and Oil Holding Capacity

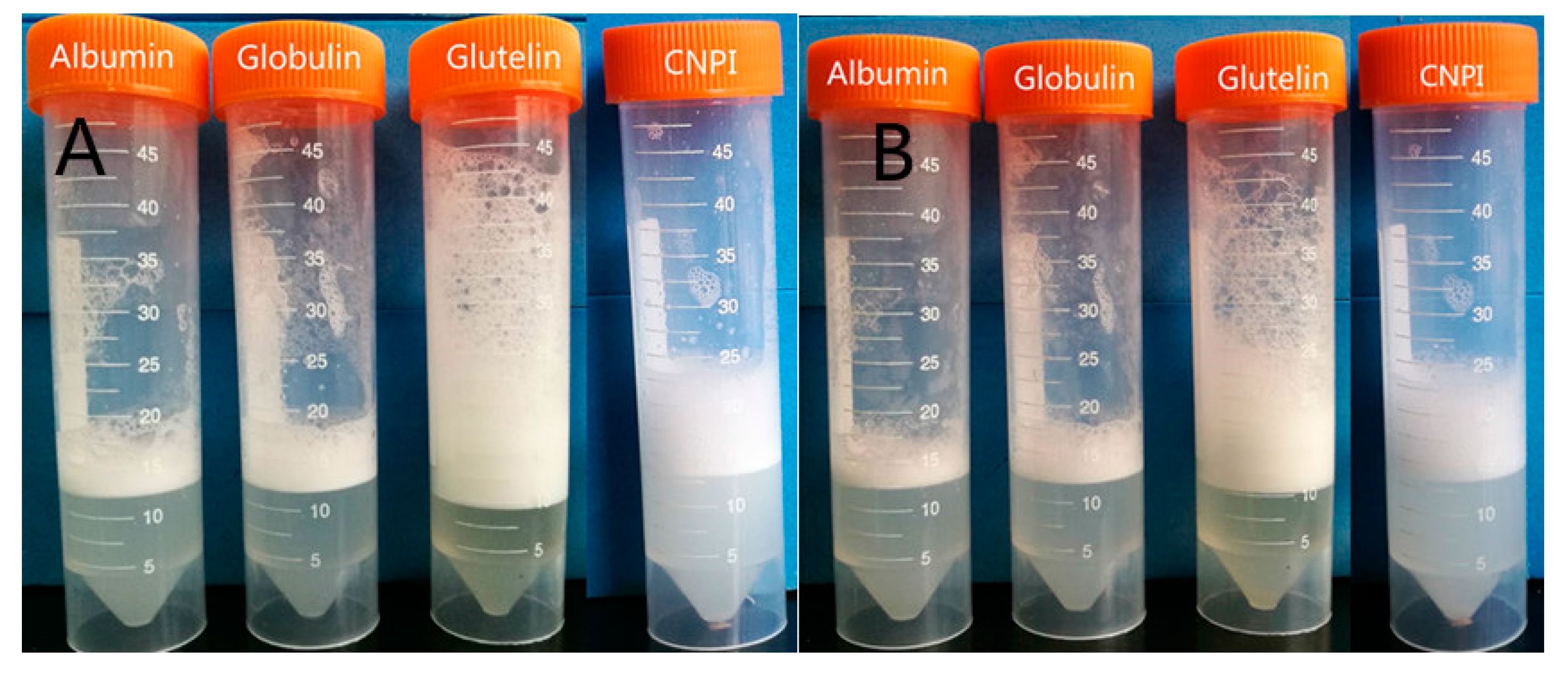

2.5. Emulsifying and Foaming Properties

3. Materials and Methods

3.1. Materials

3.2. Preparation of Defatted Cashew Nut Flour, Protein Isolate and Fractions

3.3. Chemical Analysis

3.3.1. Protein Solubility (PS)

3.3.2. Oil and Water Holding Capacity

3.3.3. Foaming Capacity and Foam Stability

3.3.4. Emulsifying Activity Index (EAI) and Emulsion Stability (ES)

3.3.5. Surface Hydrophobicity (H0)

3.3.6. Amino Acid Composition

3.3.7. Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis (SDS-PAGE)

3.3.8. Far-UV Circular Dichroism (CD) Spectroscopy

3.3.9. Scanning Electron Microscopy

4. Statistical Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rico, R.; Bulló, M.; Salas-Salvadó, J. Nutritional composition of raw fresh cashew (Anacardium occidentale L.) kernels from different origin. Food Sci. Nutr. 2016, 4, 329–338. [Google Scholar] [CrossRef] [PubMed]

- Venkatachalam, M.; Sathe, S.K. Chemical composition of selected edible nut seeds. J. Agric. Food Chem. 2006, 54, 4705–4714. [Google Scholar] [CrossRef] [PubMed]

- Lima, J.R.; Garruti, D.S.; Bruno, L.M. Physicochemical, microbiological and sensory characteristics of cashew nut butter made from different kernel grades-quality. LWT Food Sci. Technol. 2012, 45, 180–185. [Google Scholar] [CrossRef]

- Yang, J.; Liu, R.H.; Halim, L. Antioxidant and antiproliferative activities of common edible nut seeds. LWT Food Sci. Technol. 2009, 42, 1–8. [Google Scholar] [CrossRef]

- Aremu, M.; Ogunlade, I.; Olonisakin, A. Fatty acid and amino acid composition of protein concentrate from cashew nut (Anarcadium occidentale) grown in nasarawa state, nigeria. Pak. J. Nutr. 2007, 6, 419–423. [Google Scholar] [CrossRef]

- Alobo, A.P.; Agbo, B.N.; Ilesanmi, S.A. Physicochemical and functional properties of full fat and defatted cashew kernel flours. Int. J. Food Sci. Technol. 2009, 44, 581–585. [Google Scholar] [CrossRef]

- Sathe, S.K.; Sze-Tao, K.C.; Wolf, W.J.; Hamaker, B.R. Biochemical characterization and in vitro digestibility of the major globulin in cashew nut (Anacardium occidentale). J. Agric. Food Chem. 1997, 45, 2854–2860. [Google Scholar] [CrossRef]

- Ogunwolu, S.O.; Henshaw, F.O.; Mock, H.-P.; Santros, A.; Awonorin, S.O. Functional properties of protein concentrates and isolates produced from cashew (Anacardium occidentale L.) nut. Food Chem. 2009, 115, 852–858. [Google Scholar] [CrossRef]

- Neto, V.; Narain, N.; Silva, J.; Bora, P. Functional properties of raw and heat processed cashew nut (Anacardium occidentale L.) kernel protein isolates. Mol. Nutr. Food Res. 2001, 45, 258–262. [Google Scholar] [CrossRef]

- Bora, P.S.; Neto, V.Q. Functionality of native and denatured cashew nut kernel protein isolates at isoelectric ph as a function of salt concentration. J. Sci. Food Agric. 2004, 84, 2022–2027. [Google Scholar] [CrossRef]

- Yin, S.-W.; Chen, J.-C.; Sun, S.-D.; Tang, C.-H.; Yang, X.-Q.; Wen, Q.-B.; Qi, J.-R. Physicochemical and structural characterisation of protein isolate, globulin and albumin from soapnut seeds (Sapindus mukorossi Gaertn.). Food Chem. 2011, 128, 420–426. [Google Scholar] [CrossRef] [PubMed]

- Rezig, L.; Riaublanc, A.; Chouaibi, M.; Guéguen, J.; Hamdi, S. Functional properties of protein fractions obtained from pumpkin (Cucurbita maxima) seed. Int. J. Food Prop. 2015, 19, 172–186. [Google Scholar] [CrossRef]

- Du, M.; Xie, J.; Gong, B.; Xu, X.; Tang, W.; Li, X.; Li, C.; Xie, M. Extraction, physicochemical characteristics and functional properties of mung bean protein. Food Hydrocoll. 2017, 76, 131–140. [Google Scholar] [CrossRef]

- Horax, R.; Hettiarachchy, N.; Kannan, A.; Chen, P. Protein extraction optimisation, characterisation, and functionalities of protein isolate from bitter melon (Momordica charantia) seed. Food Chem. 2011, 124, 545–550. [Google Scholar] [CrossRef]

- Tang, C.-H.; Wang, X.-Y. Physicochemical and structural characterisation of globulin and albumin from common buckwheat (Fagopyrum esculentum Moench) seeds. Food Chem. 2010, 121, 119–126. [Google Scholar] [CrossRef]

- Yu, M.; Zeng, M.; Qin, F.; He, Z.; Chen, J. Physicochemical and functional properties of protein extracts from torreya grandis seeds. Food Chem. 2017, 227, 453–460. [Google Scholar] [CrossRef] [PubMed]

- Mundi, S.; Aluko, R.E. Physicochemical and functional properties of kidney bean albumin and globulin protein fractions. Food Res. Int. 2012, 48, 299–306. [Google Scholar] [CrossRef]

- Giroux, I.; Kurowska, E.; Freeman, D.J.; Carroll, K. Addition of arginine but not glycine to lysine plus methionine-enriched diets modulates serum cholesterol and liver phospholipids in rabbits. J. Nutr. 1999, 129, 1807–1813. [Google Scholar] [PubMed]

- Sathe, S.K.; Venkatachalam, M.; Sharma, G.M.; Kshirsagar, H.H.; Teuber, S.S.; Roux, K.H. Solubilization and electrophoretic characterization of select edible nut seed proteins. J. Agric. Food Chem. 2009, 57, 7846–7856. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Jiang, Y.; Zhu, X.; Xiong, H.; Shi, S.; Hu, J.; Peng, H.; Zhou, Q.; Sun, W. Physicochemical and functional properties of the protein isolate and major fractions prepared from akebia trifoliata var. Australis seed. Food Chem. 2012, 133, 923–929. [Google Scholar] [CrossRef]

- Sathe, S. Solubilization and electrophoretic characterization of cashew nut (Anacardium occidentale) proteins. Food Chem. 1994, 51, 319–324. [Google Scholar] [CrossRef]

- Malomo, S.A.; Aluko, R.E. A comparative study of the structural and functional properties of isolated hemp seed (Cannabis sativa L.) albumin and globulin fractions. Food Hydrocoll. 2015, 43, 743–752. [Google Scholar] [CrossRef]

- Choi, S.-M.; Ma, C.-Y. Structural characterization of globulin from common buckwheat (Fagopyrum esculentum Moench) using circular dichroism and raman spectroscopy. Food Chem. 2007, 102, 150–160. [Google Scholar] [CrossRef]

- Yong, Y.H.; Yamaguchi, S.; Matsumura, Y. Effects of enzymatic deamidation by protein-glutaminase on structure and functional properties of wheat gluten. J. Agric. Food Chem. 2006, 54, 6034–6040. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Chen, Z.; Han, D.; Li, Y.; Sun, X.; Wang, Z.; Jin, H. Structural and functional properties changes of beta-conglycinin exposed to hydroxyl radical-generating systems. Molecules 2017, 22, 1893. [Google Scholar] [CrossRef] [PubMed]

- Marcone, M.F.; Kakuda, Y.; Yada, R.Y. Salt-soluble seed globulins of various dicotyledonous and monocotyledonous plants—I. Isolation/purification and characterization. Food Chem. 1998, 62, 27–47. [Google Scholar] [CrossRef]

- Kinsella, J.E. Functional properties of soy proteins. J. Am. Oil Chem. Soc. 1979, 56, 242–258. [Google Scholar] [CrossRef]

- Ma, T.; Zhu, H.; Wang, J.; Wang, Q.; Yu, L.; Sun, B. Influence of extraction and solubilizing treatments on the molecular structure and functional properties of peanut protein. LWT Food Sci. Technol. 2017, 79, 197–204. [Google Scholar] [CrossRef]

- Shilpashree, B.G.; Arora, S.; Chawla, P.; Tomar, S.K. Effect of succinylation on physicochemical and functional properties of milk protein concentrate. Food Res. Int. 2015, 72, 223–230. [Google Scholar] [CrossRef]

- Horax, R.; Hettiarachchy, N.S.; Chen, P.; Jalaluddin, M. Functional properties of protein isolate from cowpea (Vigna unguiculata L. Walp.). J. Food Sci. 2004, 69. [Google Scholar] [CrossRef]

- Ajibola, C.F.; Malomo, S.A.; Fagbemi, T.N.; Aluko, R.E. Polypeptide composition and functional properties of african yam bean seed (Sphenostylis stenocarpa) albumin, globulin and protein concentrate. Food Hydrocoll. 2016, 56, 189–200. [Google Scholar] [CrossRef]

- Moure, A.; Sineiro, J.; Dominguez, H.; Parajo, J.C. Functionality of oilseed protein products: A review. Food Res. Int. 2006, 39, 945–963. [Google Scholar] [CrossRef]

- Moure, A.; Rua, M.; Sineiro, J.; Dominguez, H. Aqueous extraction and membrane isolation of protein from defatted gevuina avellana. J. Food Sci. 2002, 67, 688–696. [Google Scholar] [CrossRef]

- Deng, Q.; Wang, L.; Wei, F.; Xie, B.; Huang, F.; Huang, W.; Shi, J.; Huang, Q.; Tian, B.; Xue, S. Functional properties of protein isolates, globulin and albumin extracted from ginkgo biloba seeds. Food Chem. 2011, 124, 1458–1465. [Google Scholar] [CrossRef]

- Aletor, O.; Oshodi, A.A.; Ipinmoroti, K. Chemical composition of common leafy vegetables and functional properties of their leaf protein concentrates. Food Chem. 2002, 78, 63–68. [Google Scholar] [CrossRef]

- Paredeslopez, O.; Ordoricafalomir, C.; Olivaresvazquez, M.R. Chickpea protein isolates: Physicochemical, functional and nutritional characterization. J. Food Sci. 2006, 56, 726–729. [Google Scholar] [CrossRef]

- Kabirullah, M.; Wills, R.B.H. Functional properties of acetylated and succinylated sunflower protein isolate. Int. J. Food Sci. Technol. 2007, 17, 235–249. [Google Scholar] [CrossRef]

- Foh, M.B.K.; Amadou, I.; Kamara, M.T.; Foh, B.M.; Xia, W. Effect of enzymatic hydrolysis on the nutritional and functional properties of nile tilapia (Oreochromis niloticus) proteins. Am. J. Biochem. Mol. Biol. 2011, 1, 54–67. [Google Scholar] [CrossRef]

- Karaca, A.C.; Low, N.; Nickerson, M. Emulsifying properties of canola and flaxseed protein isolates produced by isoelectric precipitation and salt extraction. Food Res. Int. 2011, 44, 2991–2998. [Google Scholar] [CrossRef]

- Kato, A.; Nakai, S. Hydrophobicity determined by a fluorescence probe method and its correlation with surface properties of proteins. Biochim. Biophys. Acta Protein Struct. 1980, 624, 13–20. [Google Scholar] [CrossRef]

- Tirgar, M.; Silcock, P.; Carne, A.; Birch, E.J. Effect of extraction method on functional properties of flaxseed protein concentrates. Food Chem. 2017, 215, 417–424. [Google Scholar] [CrossRef] [PubMed]

- Karaca, A.C.; Low, N.; Nickerson, M. Emulsifying properties of chickpea, faba bean, lentil and pea proteins produced by isoelectric precipitation and salt extraction. Food Res. Int. 2011, 44, 2742–2750. [Google Scholar] [CrossRef]

- Mun, S.; Cho, Y.; Decker, E.A.; McClements, D.J. Utilization of polysaccharide coatings to improve freeze–thaw and freeze–dry stability of protein-coated lipid droplets. J. Food Eng. 2008, 86, 508–518. [Google Scholar] [CrossRef]

- Malomo, S.A.; He, R.; Aluko, R.E. Structural and functional properties of hemp seed protein products. J. Food Sci. 2014, 79. [Google Scholar] [CrossRef] [PubMed]

- Lin, M.J.Y.; Humbert, E.S.; Sosulski, F.W. Functional properties of sunflower meal products. J. Food Sci. 2006, 39, 368–370. [Google Scholar] [CrossRef]

- Shevkani, K.; Singh, N.; Rana, J.C.; Kaur, A. Relationship between physicochemical and functional properties of amaranth (Amaranthus hypochondriacus) protein isolates. Int. J. Food Sci. Technol. 2014, 49, 541–550. [Google Scholar] [CrossRef]

- Lowry, O.H.N.G.; Rosebrough, N.J.J.; Farr, A.L.; Randall, R.J.R. Protein measurement with folin fenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [PubMed]

- Sze-Tao, K.W.C.; Sathe, S.K. Functional properties and in vitro digestibility of almond (Prunus dulcis L.) protein isolate. Food Chem. 2000, 69, 153–160. [Google Scholar] [CrossRef]

- Lassissi, T.A.; Hettiarachchy, N.S.; Rayaprolu, S.J.; Kannan, A.; Davis, M. Functional properties and angiotensin-i converting enzyme inhibitory activity of soy–whey proteins and fractions. Food Res. Int. 2014, 64, 598–602. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, G.; Zhao, M.; Ren, J.; Yang, B. Improvement of functional properties of peanut protein isolate by conjugation with dextran through maillard reaction. Food Chem. 2012, 131, 901–906. [Google Scholar] [CrossRef]

- Pearce, K.N.; Kinsella, J.E. Emulsifying properties of proteins: Evaluation of a turbidimetric technique. J. Agric. Food Chem. 1978, 26, 716–723. [Google Scholar] [CrossRef]

- And, C.A.H.; Lichan, E.C.Y. Hydrophobicity of bovine serum albumin and ovalbumin determined using uncharged (PRODAN) and anionic (ANS-) fluorescent probes. J. Agric. Food Chem. 1998, 46, 2671–2677. [Google Scholar]

- Zhang, Q.T.; Tu, Z.C.; Xiao, H.; Wang, H.; Huang, X.Q.; Liu, G.X.; Liu, C.M.; Shi, Y.; Fan, L.L.; Lin, D.R. Influence of ultrasonic treatment on the structure and emulsifying properties of peanut protein isolate. Food Bioprod. Process. 2014, 92, 30–37. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are available from the authors. |

| Chemical Component (%) | Albumin | Globulin | Glutelin | Prolamin | CNPI | DCNF |

|---|---|---|---|---|---|---|

| Protein content | 83.6 ± 0.8 b | 95.5 ± 1.1 a | 81.3 ± 3.8 b | 20.5 ± 2.3 d | 80.7 ± 1.3 b | 31.9 ± 2.1 c |

| Crude fat | 2.80 ± 0.39 a | 0.84 ± 0.38 b | 0.23 ± 0.04 b | -- | 0.36 ± 0.13 b | 0.50 ± 0.36 b |

| Moisture | 4.55 ± 0.01 c | 2.18 ± 0.10 d | 4.49 ± 0.46 c | -- | 8.87 ± 0.04 b | 9.24 ± 0.01 a |

| Soluble sugar | 2.03 ± 0.09 bc | 0.83 ± 0.13 c | 3.05 ± 0.32 b | -- | 3.25 ± 0.24 b | 19.15 ± 1.21 a |

| Ash | 5.70 ± 0.20 a | 3.91 ± 0.80 b | 4.06 ± 0.69 ab | -- | 4.61 ± 0.72 ab | 4.46 ± 0.16 ab |

| Gross yield | 7.69 | 17.30 | 7.80 | 2.5 | 19.67 | -- |

| Amino Acid | Albumin | Globulin | Glutelin | CNPI | FAO/WHO | |

|---|---|---|---|---|---|---|

| Child | Adult | |||||

| Aspartic acid (Asp) | 6.52 | 8.31 | 7.65 | 8.10 | ||

| Threonine (Thr) a | 2.37 | 2.97 | 3.83 | 2.81 | 3.40 | 0.90 |

| Serine (Ser) | 4.15 | 5.04 | 4.37 | 4.16 | ||

| Glutamic acid (Glu) | 22.51 | 22.55 | 12.57 | 21.54 | ||

| Glycine (Gly) | 3.55 | 4.15 | 4.10 | 3.63 | ||

| Alanine (Ala) | 2.37 | 2.97 | 4.37 | 2.90 | ||

| Cysteine (Cys) | 2.37 | 1.78 | 0.82 | 0.75 | ||

| Valine (Val) a | 4.15 | 5.04 | 4.92 | 4.27 | 3.50 | 1.30 |

| Methionine (Met) a | 1.78 | 1.19 | 1.64 | 1.15 | ||

| Isoleucine (Ile) a | 2.96 | 3.56 | 3.28 | 3.17 | 2.80 | 1.30 |

| Leucine (Leu) a | 5.33 | 6.23 | 6.56 | 5.55 | 6.60 | 1.90 |

| Tyrosine (Tyr) | 2.96 | 2.97 | 3.28 | 2.26 | ||

| Phenylalanine (Phe) a | 3.55 | 3.56 | 3.83 | 3.42 | ||

| Histidine (His) a | 2.96 | 3.26 | 3.28 | 1.67 | 5.80 | 1.60 |

| Lysine (Lys) a | 3.55 | 3.56 | 5.47 | 3.14 | 1.90 | 1.60 |

| Arginine (Arg) | 10.66 | 12.17 | 6.01 | 9.07 | ||

| Proline (Pro) | 2.66 | 2.37 | 3.83 | 3.96 | ||

| sulphur amino acids | 4.15 | 2.97 | 2.46 | 1.90 | 2.50 | 1.70 |

| aromatic amino acid | 6.51 | 6.53 | 7.11 | 5.68 | 5.68 | 1.90 |

| hydrophobic amino acid | 26.35 | 29.07 | 32.53 | 28.05 | ||

| EAA/TAA (%) | 31.58 | 32.04 | 41.11 | 30.88 | ||

| Protein Sample | α-Helix (%) | β-Sheet (%) | Turns (%) | Random Coil (%) |

|---|---|---|---|---|

| Albumin | 9.5 ± 0.15 b | 36.4 ± 0.24 b | 18.6 ± 0.16 b | 35.5 ± 0.24 a |

| Globulin | 6.8 ± 0.13 c | 41.1 ± 0.31 a | 22.5 ± 0.17 a | 29.5 ± 0.28 c |

| Glutelin | 11.7 ± 0.19 a | 36.1 ± 0.28 b | 18.3 ± 0.14 b | 33.9 ± 0.31 b |

| CNPI | 11.9 ± 0.43 a | 35.0 ± 0.24 b | 23.8 ± 0.17 a | 29.3 ± 0.11 c |

| W/O Holding Capacity | Albumin | Globulin | Glutelin | CNPI |

|---|---|---|---|---|

| WHC (g/g) | 1.22 ± 0.02 b | 0.93 ± 0.13 b | 15.85 ± 1.67 a | 1.75 ± 0.05 b |

| OHC (g/g) | 5.94 ± 0.69 c | 9.34 ± 0.58 b | 27.47 ± 2.97 a | 1.05 ± 0.05 d |

| Properties | Albumin | Globulin | Glutelin | CNPI |

|---|---|---|---|---|

| EAI (m2/g) | 10.46 ± 0.27 b | 7.98 ± 0.75 c | 7.03 ± 0.33 c | 20.21 ± 1.53 a |

| ES (min) | 41.84 ± 1.97 b | 28.08 ± 1.16 c | 21.57 ± 2.20 d | 61.78 ± 4.44 a |

| FC (%) | 20.48 ± 2.02 c | 54.05 ± 3.67 b | 101.93 ± 16.39 a | 92.00 ± 1.15 a |

| FS (%) | 19.50 ± 0.93 c | 46.00 ± 9.63 b | 79.18 ± 5.82 a | 76.70 ± 5.77 a |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.-m.; Peng, Q.; Zhong, J.-z.; Liu, W.; Zhong, Y.-j.; Wang, F. Molecular and Functional Properties of Protein Fractions and Isolate from Cashew Nut (Anacardium occidentale L.). Molecules 2018, 23, 393. https://doi.org/10.3390/molecules23020393

Liu C-m, Peng Q, Zhong J-z, Liu W, Zhong Y-j, Wang F. Molecular and Functional Properties of Protein Fractions and Isolate from Cashew Nut (Anacardium occidentale L.). Molecules. 2018; 23(2):393. https://doi.org/10.3390/molecules23020393

Chicago/Turabian StyleLiu, Cheng-mei, Qian Peng, Jun-zhen Zhong, Wei Liu, Ye-jun Zhong, and Fang Wang. 2018. "Molecular and Functional Properties of Protein Fractions and Isolate from Cashew Nut (Anacardium occidentale L.)" Molecules 23, no. 2: 393. https://doi.org/10.3390/molecules23020393