Lime Pretreatment of Miscanthus: Impact on BMP and Batch Dry Co-Digestion with Cattle Manure

Abstract

1. Introduction

2. Results

2.1. Impact of Lime Pretreatment on BMP

2.2. Mathematical Models to Describe Impact of Concentration and Pretreatment Duration on BMP Values

2.2.1. Experimental Design 1 (CaO Concentration from 7.5 to 17.5% and Duration from 1 to 5 Days)

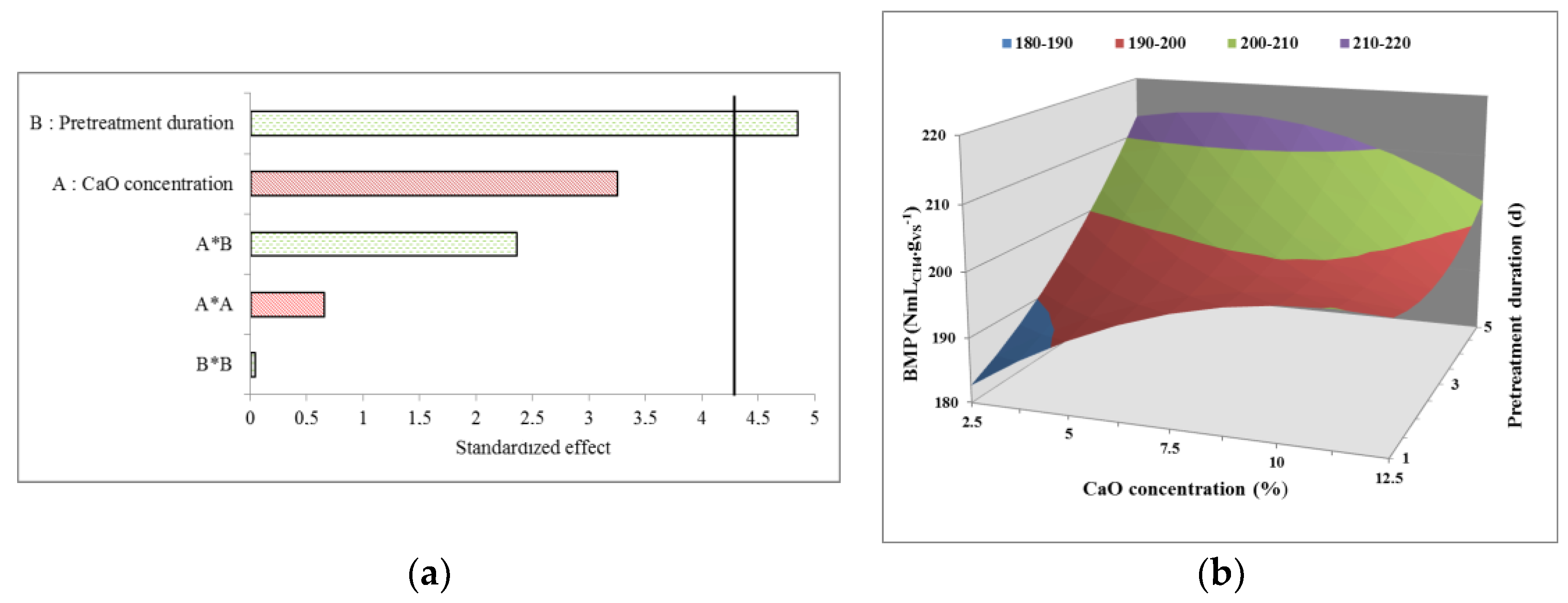

2.2.2. Experimental Design 2 (CaO Concentration from 2.5 to 12.5% and Duration from 1 to 5 Days)

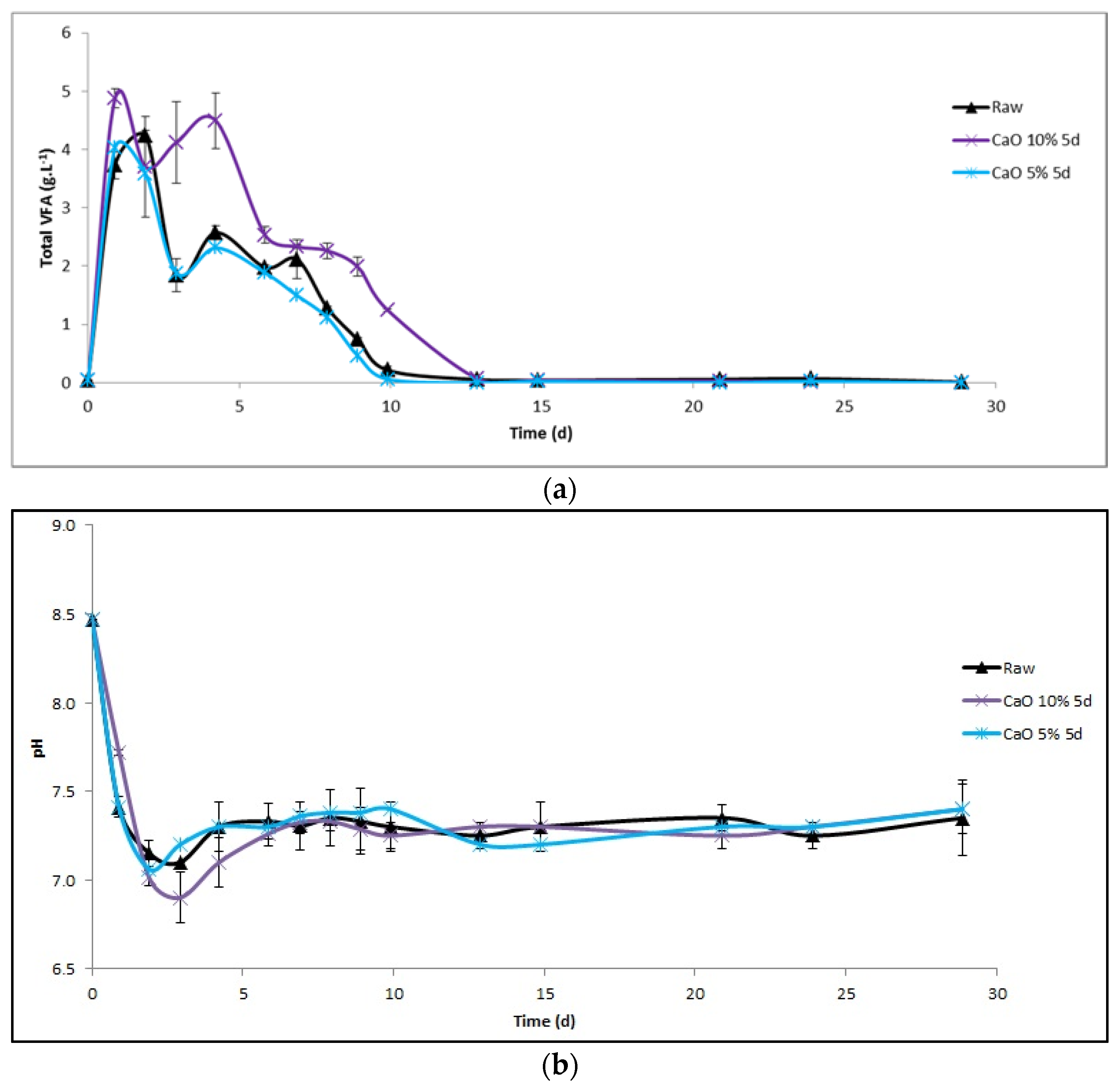

2.3. Co-Digestion

3. Discussion

3.1. BMP and Pretreatment

3.2. Pretreatment and Co-Digestion

4. Materials and Methods

4.1. Miscanthus

4.2. Experimental Design

4.3. Alkaline Pretreatments

4.4. Measure of Methane Potential

4.5. Methane Production Kinetics

4.6. Leach Bed Reactors

4.7. Analysis

4.8. Statistical Analysis

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Torrijos, M. State of Development of Biogas Production in Europe. Procedia Environ. Sci. 2016, 35, 881–889. [Google Scholar] [CrossRef]

- Deguerce, A.; Capdeville, J.; Perrot, C.; Bioteau, T.; Martinez, J.; Peu, P. Fumiers de bovins, une ressource à fort potentiel pour la filière de méthanisation en France? Revue Science Eaux & Territoires. article hors-série. 22 February 2016. Available online: http://www.set-revue.fr/fumiers-de-bovins-une-ressource-fort-potentiel-pour-la-filiere-de-methanisation-en-France (accessed on 30 June 2018).

- Mata-Alvarez, J.; Macé, S.; Llabrés, P. Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour. Technol. 2000, 74, 3–16. [Google Scholar] [CrossRef]

- Riggio, S.; Torrijos, M.; Debord, R.; Esposito, G.; van Hullebusch, E.D.; Steyer, J.P.; Escudié, R. Mesophilic anaerobic digestion of farmyard manure of different origins in a batch leach-bed reactor: Substrate characterization and process performance. Waste Manag. 2016, 59, 129–139. [Google Scholar] [CrossRef] [PubMed]

- Tufaner, F.; Avsar, Y. Effects of co-substrate on biogas production from cattle manure: A review. Environ. Sci. Technol. 2016, 13, 2303–2312. [Google Scholar] [CrossRef]

- Botji, T.; Kovàcs, K.L.; Kakuk, B.; Wirth, R.; Ràkhely, G.; Bagi, Z. Pretreatment of poultry manure for efficient biogas production as monosubstrate or co-fermentation with maize silage and corn stover. Anaerobe 2017, 46, 138–145. [Google Scholar] [CrossRef]

- Assemblée Nationale. Décret n° 2016-929 du 7 Juillet 2016 pris pour L’application de L’article L. 541-39 du code de L’environnement; Journal officiel de la République Française du 8 juillet 2016 texte n°8; Journal officiel de la République Française: Paris, France, 2016. [Google Scholar]

- Perrin, A.; Wohlfahrt, J.; Morandi, F.; Østergård, H.; Flatberg, T.; De La Rua, C.; Bjørkvoll, T.; Gabrielle, B. Integrated design and sustainable assessment of innovative biomass supply chains: A case-study on miscanthus in France. Appl. Energy 2017, 204, 66–77. [Google Scholar] [CrossRef]

- Morandi, F.; Perrin, A.; Østergård, H. Miscanthus as energy crop: Environmental assessment of a miscanthus biomass production case study in France. J. Clean. Prod. 2016, 137, 313–321. [Google Scholar] [CrossRef]

- Muller-Stover, D.S.; Sun, G.; Kroff, P.; Thomsen, S.T.; Hauggaard-Nielsen, H. Anaerobic co-digestion of perennials: Methane potential and digestate nitrogen fertilizer value. J. Plant Nutr. Soil Sci. 2016, 179, 696–704. [Google Scholar] [CrossRef]

- Kiesel, A.; Wagner, M.; Lewandowski, I. Environmental Performance of Miscanthus, Switchgrass and Maize: Can C4 Perennials Increase the Sustainability of Biogas Production? Sustainability 2016, 9, 5. [Google Scholar] [CrossRef]

- Moiceanu, G.; Voicu, G.; Ferdes, M.; Paraschiv, G.; Dincà, M.N.; Vlàdut, V.; Gageanu, I.; Chitoiu, M. Comparative study on biogas production using cow and swine manure mixed with Miscanthus x giganteus as substrate. Rom. Biotechnol. Lett. 2016, 21, 11968–11973. [Google Scholar]

- Monlau, F.; Barakat, A.; Trably, E.; Dumas, C.; Steyer, J.P.; Carrère, H. Lignocellulosic Materials into Biohydrogen and Biomethane: Impact of Structural Features and Pretreatment. Crit. Rev. Environ. Sci. Technol. 2013, 43, 260–322. [Google Scholar] [CrossRef]

- Zhou, X.; Li, Q.; Zhang, Y.; Gu, Y. Effect of hydrothermal pretreatment on Miscanthus anaerobic digestion. Bioresour. Technol. 2017, 224, 721–726. [Google Scholar] [CrossRef] [PubMed]

- Nges, I.A.; Chao, L.; Wang, B.; Xiao, L.; Yi, Z.; Liu, J. Physio-chemical pretreatments for improved methane potential of Miscanthus lutarioriparius. Fuel 2016, 166, 29–35. [Google Scholar] [CrossRef]

- Monlau, F.; Sambusiti, C.; Barakat, A.; Guo, X.M.; Latrille, E.; Trably, E.; Steyer, J.P.; Carrère, H. Predictive models of biohydrogen and biomethane production based on the compositional and structural features of lignocellulosic materials. Environ. Sci. Technol. 2012, 46, 12217–12225. [Google Scholar] [CrossRef] [PubMed]

- Agbor, V.B.; Cicek, N.; Sparling, R.; Berlin, A.; Levin, D.B. Biomass pretreatment: Fundamentals toward application. Biotechnol. Adv. 2011, 29, 675–685. [Google Scholar] [CrossRef] [PubMed]

- Monlau, F.; Barakat, A.; Steyer, J.P.; Carrere, H. Comparison of seven types of thermo-chemical pretreatments on the structural features and anaerobic digestion of sunflower stalks. Bioresour. Technol. 2012. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef] [PubMed]

- Barakat, A.; de Vries, H.; Rouau, X. Dry fractionation process as an important step in current and future lignocellulose biorefineries: A review. Bioresour. Technol. 2013, 134, 362–373. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, J.V.; Alves, M.M.; Costa, J.C. Optimization of biogas production from Sargassum sp. using a design of experiments to assess the co-digestion with glycerol and waste frying oil. Bioresour. Technol. 2015, 175, 480–485. [Google Scholar] [CrossRef] [PubMed]

- Joglekar, A.; May, A. Product excellence through design of experiments. Cereal Foods World 1987, 32, 857–868. [Google Scholar]

- Carlsson, M.; Lagerkvist, A.; Morgan-sagastume, F. The effects of substrate pre-treatment on anaerobic digestion systems: A review. Waste Manag. 2012, 32, 1634–1650. [Google Scholar] [CrossRef] [PubMed]

- Sole-Bundo, M.; Carrere, H.; Garfi, M.; Ferrer, I. Enhancement of microalgae anaerobic digestion by thermo-alkaline pretreatment with lime (CaO). Algal Res. 2017, 24, 199–206. [Google Scholar] [CrossRef]

- Rouches, E. Fungal Pretreatment for Lignocellulosic Biomass Anaerobic Digestion; Université de Montpellier: Montpellier, France, 2015. [Google Scholar]

- Fu, S.; Chen, K.; Zhu, R.; Sun, W.; Zou, H.; Guo, R. Improved anaerobic digestion performance of Miscanthus floridulus by different pretreatment methods and preliminary economic analysis. Energy Convers. Manag. 2018, 159, 121–128. [Google Scholar] [CrossRef]

- Arnoult, S.; Obeuf, A.; Béthencourt, L.; Mansard, M.C.; Brancourt-Hulmel, M. Miscanthus clones for cellulosic bioethanol production: Relationships between biomass production, biomass production components, and biomass chemical composition. Ind. Crops Prod. 2015, 63, 316–328. [Google Scholar] [CrossRef]

- Jiang, D.; Ge, X.; Zhang, Q.; Zhou, X.; Chan, Z.; Keener, H.; Li, Y. Comparison of sodium hydroxide and calcium hydroxide pretreatments of giant reed for enhanced enzymatic digestibility and methane production. Bioresour. Technol. 2017, 244, 1150–1157. [Google Scholar] [CrossRef] [PubMed]

- Peces, M.; Astals, S.; Mata-alvarez, J. Effect of moisture on pretreatment efficiency for anaerobic digestion of lignocellulosic substrates. Waste Manag. 2015, 46, 189–196. [Google Scholar] [CrossRef] [PubMed]

- Inês, C.; Rodrigues, S.; Ph, C.; Jackson, J.J.; Montross, M.D. A molar basis comparison of calcium hydroxide, sodium hydroxide, and potassium hydroxide on the pretreatment of switchgrass and miscanthus under high solids conditions. Ind. Crops Prod. 2016, 92, 165–173. [Google Scholar] [CrossRef]

- Valle, I.C.; Kandula, D.; Littlejohn, C.; Hill, R.; Walker, M.; Shields, M.; Cummings, N.; Hettiarachchi, D.; Wratten, S. Potential of the beneficial fungus Trichoderma to enhance ecosystem-service provision in the biofuel grass Miscanthus x giganteus in agriculture. Sci. Rep. 2016, 6, 25109. [Google Scholar] [CrossRef]

- Boix, E.; Georgi, F.; Navard, P. Influence of alkali and Si-based treatments on the physical and chemical characteristics of miscanthus stem fragments. Ind. Crops Prod. 2016, 91, 6–14. [Google Scholar] [CrossRef]

- Goupy, J. Modelisation Par Les Plans D’Expériences; Techniques de L’ingénieur: Paris, France, 2014; Volume 33, pp. 1–23. [Google Scholar]

- Witek-krowiak, A.; Chojnacka, K.; Podstawczyk, D.; Dawiec, A.; Pokomeda, K. Application of response surface methodology and artificial neural network methods in modelling and optimization of biosorption process. Bioresour. Technol. 2014, 160, 150–160. [Google Scholar] [CrossRef] [PubMed]

- Rossi, C.; Haupt, K. Application of the Doehlert experimental design to molecularly imprinted polymers: Surface response optimization of specific template recognition as a function of the type and degree of cross-linking. Anal. Bioanal. Chem. 2007, 389, 455–460. [Google Scholar] [CrossRef] [PubMed]

- Thomas, H.L.; Pot, D.; Latrille, E.; Trouche, G.; Bonnal, L.; Bastianelli, D.; Carrère, H. Sorghum Biomethane Potential Varies with the Genotype and the Cultivation Site. Waste Biomass Valoriz. 2017, 1–6. [Google Scholar] [CrossRef]

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 1998. [Google Scholar]

- Cazier, E.A.; Trably, E.; Steyer, J.P.; Escudie, R. Biomass hydrolysis inhibition at high hydrogen partial pressure in solid-state anaerobic digestion. Bioresour. Technol. 2015, 190, 106–113. [Google Scholar] [CrossRef] [PubMed]

- Sambusiti, C.; Ficara, E.; Malpei, F.; Steyer, J.P.; Carrère, H. Influence of alkaline pre-treatment conditions on structural features and methane production from ensiled sorghum forage. Chem. Eng. J. 2012, 211–212, 488–492. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are not available from the authors. |

| Design 1 | Variable A: [CaO] | Variable B: Duration | BMP | k | ||||

| Run | Coded | % | Coded | d | NmLCH4·gVS−1 | Improvement * | d−1 | Improvement * |

| Raw | - | - | - | - | 158 ± 2 | - | 0.024 ± 0.002 | - |

| 1 | 0 | 12.5 | 0 | 3 | 196 | +24% | 0.047 ± 0.001 | +96% |

| 1′ | 0 | 12.5 | 0 | 3 | 201 | +27% | 0.048 ± 0.001 | +100% |

| 2 | 1 | 17.5 | 0 | 3 | 191 ± 2 | +21% | 0.077 ± 0.005 | +221% |

| 3 | 0.5 | 15 | 0.866 | 5 | 207 ± 1 | +31% | 0.075 ± 0.004 | +213% |

| 4 | −0.5 | 10 | 0.866 | 5 | 208 ± 4 | +32% | 0.051 ± 0.004 | +113% |

| 5 | −1 | 7.5 | 0 | 3 | 202 ± 4 | +28% | 0.042 ± 0.001 | +75% |

| 6 | −0.5 | 10 | −0.866 | 1 | 199 ± 2 | +26% | 0.039 ± 0.002 | +63% |

| 7 | 0.5 | 15 | −0.866 | 1 | 179 ± 13 | +14% | 0.050 ± 0.002 | +108% |

| Design 2 | ||||||||

| Raw | - | - | - | - | 158 ± 2 | - | 0.024 ± 0.002 | - |

| 1 | 0 | 7.5 | 0 | 3 | 204 | +29% | 0.041 ± 0.001 | +71% |

| 1′ | 0 | 7.5 | 0 | 3 | 199 | +26% | 0.043 ± 0.001 | +79% |

| 2 | 1 | 12.5 | 0 | 3 | 199 ± 4 | +26% | 0.047 ± 0.001 | +96% |

| 3 | 0.5 | 10 | 0.866 | 5 | 208 ± 4 | +32% | 0.051 ± 0.004 | +113% |

| 4 | −0.5 | 5 | 0.866 | 5 | 216 ± 1 | +37% | 0.050 ± 0.001 | +108% |

| 5 | −1 | 2.5 | 0 | 3 | 193 ± 3 | +22% | 0.040 ± 0.003 | +67% |

| 6 | −0.5 | 5 | −0.866 | 1 | 193 ± 1 | +22% | 0.048 ± 0.003 | +100% |

| 7 | 0.5 | 10 | −0.866 | 1 | 199 ± 2 | +26% | 0.042 ± 0.004 | +75% |

| Coefficient | Design 1 | Design 2 | |

|---|---|---|---|

| YBMP | Yk | YBMP | |

| a0 | 198.5 (±2.7) | 0.0474 (±0.0006) | 201.5 (±2.3) |

| a1 | −7.2 (±2.2) | 0.0173 (±0.0005) | 1.5 (±1.9) |

| a2 | 10.7 (±2.2) | 0.0107 (±0.0005) | 9.5 (±1.9) |

| a12 | 10.4 (±4.4) | 0.0076 (±0.0010) | −8.1 (±3.8) |

| a11 | −2.5 (±3.8) | 0.0122 (±0.0009) | −5.8 (±3.3) |

| a22 | 0.2 (±3.8) | 0.0043 (±0.0009) | 4.9 (±3.3) |

| F-value | 1.33 | 0.22 | 0.75 |

| R² | 0.952 | 0.999 | 0.950 |

| VFA/Alkalinity (gHAceq·gCaCO3−1) 1 | Methane Production (NmLCH4·gVS−1) | k (d−1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| day | 3 | 6 | 10 | 15 | 24 | 38 | 59 | Expected 2 | - |

| raw | 0.35 ± 0.07 | 36 ± 1 | 59 ± 4 | 78 ± 7 | 109 ± 3 | 135 ± 4 | 158 ± 4 | 181 | 0.040 ± 0.004 |

| 10 % 5 days | 0.8 ± 0.14 | 43 ± 2 | 69 ± 3 | 92 ± 3 | 119 ± 2 | 145 ± 2 | 167 ± 2 | 208 | 0.049 ± 0.002 |

| 5 % 5 days | 0.4 | 43 | 67 | 84 | 109 | 131 | 150 | 207 | 0.054 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thomas, H.L.; Seira, J.; Escudié, R.; Carrère, H. Lime Pretreatment of Miscanthus: Impact on BMP and Batch Dry Co-Digestion with Cattle Manure. Molecules 2018, 23, 1608. https://doi.org/10.3390/molecules23071608

Thomas HL, Seira J, Escudié R, Carrère H. Lime Pretreatment of Miscanthus: Impact on BMP and Batch Dry Co-Digestion with Cattle Manure. Molecules. 2018; 23(7):1608. https://doi.org/10.3390/molecules23071608

Chicago/Turabian StyleThomas, Hélène Laurence, Jordan Seira, Renaud Escudié, and Hélène Carrère. 2018. "Lime Pretreatment of Miscanthus: Impact on BMP and Batch Dry Co-Digestion with Cattle Manure" Molecules 23, no. 7: 1608. https://doi.org/10.3390/molecules23071608

APA StyleThomas, H. L., Seira, J., Escudié, R., & Carrère, H. (2018). Lime Pretreatment of Miscanthus: Impact on BMP and Batch Dry Co-Digestion with Cattle Manure. Molecules, 23(7), 1608. https://doi.org/10.3390/molecules23071608