Long-Term Effect of Ultraviolet Irradiation on Poly(vinyl chloride) Films Containing Naproxen Diorganotin(IV) Complexes

Abstract

1. Introduction

2. Results and Discussion

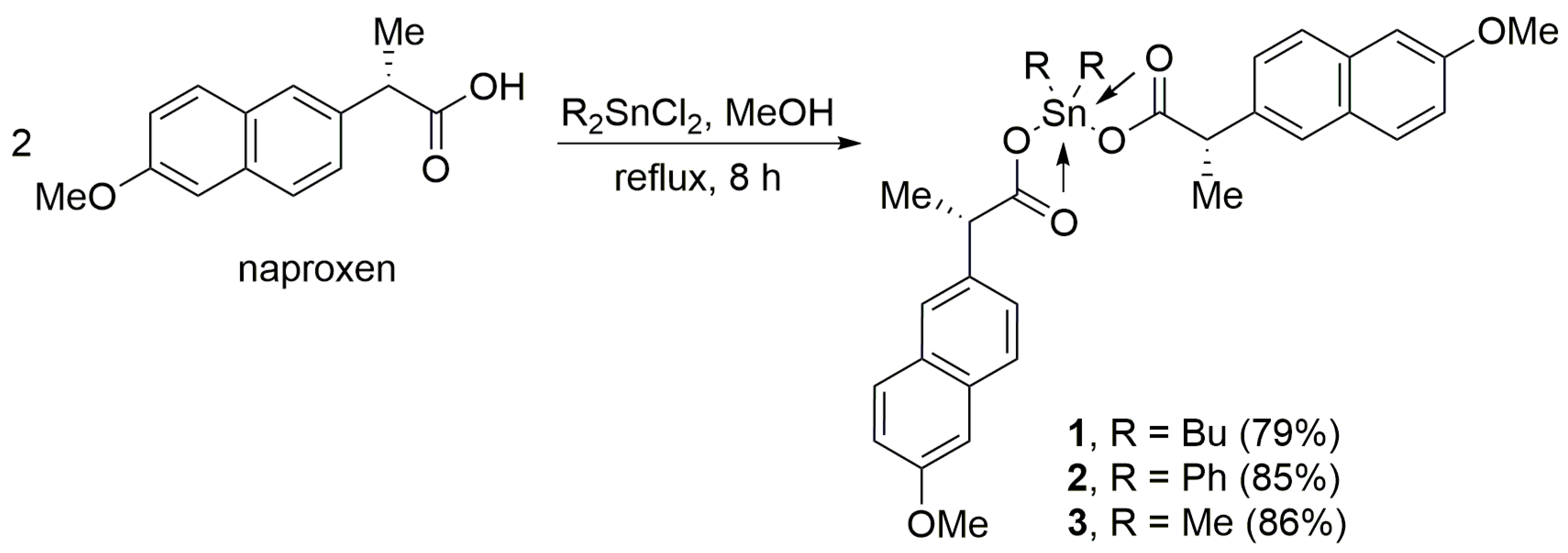

2.1. Synthesis of Sn(IV) Complexes 1–3

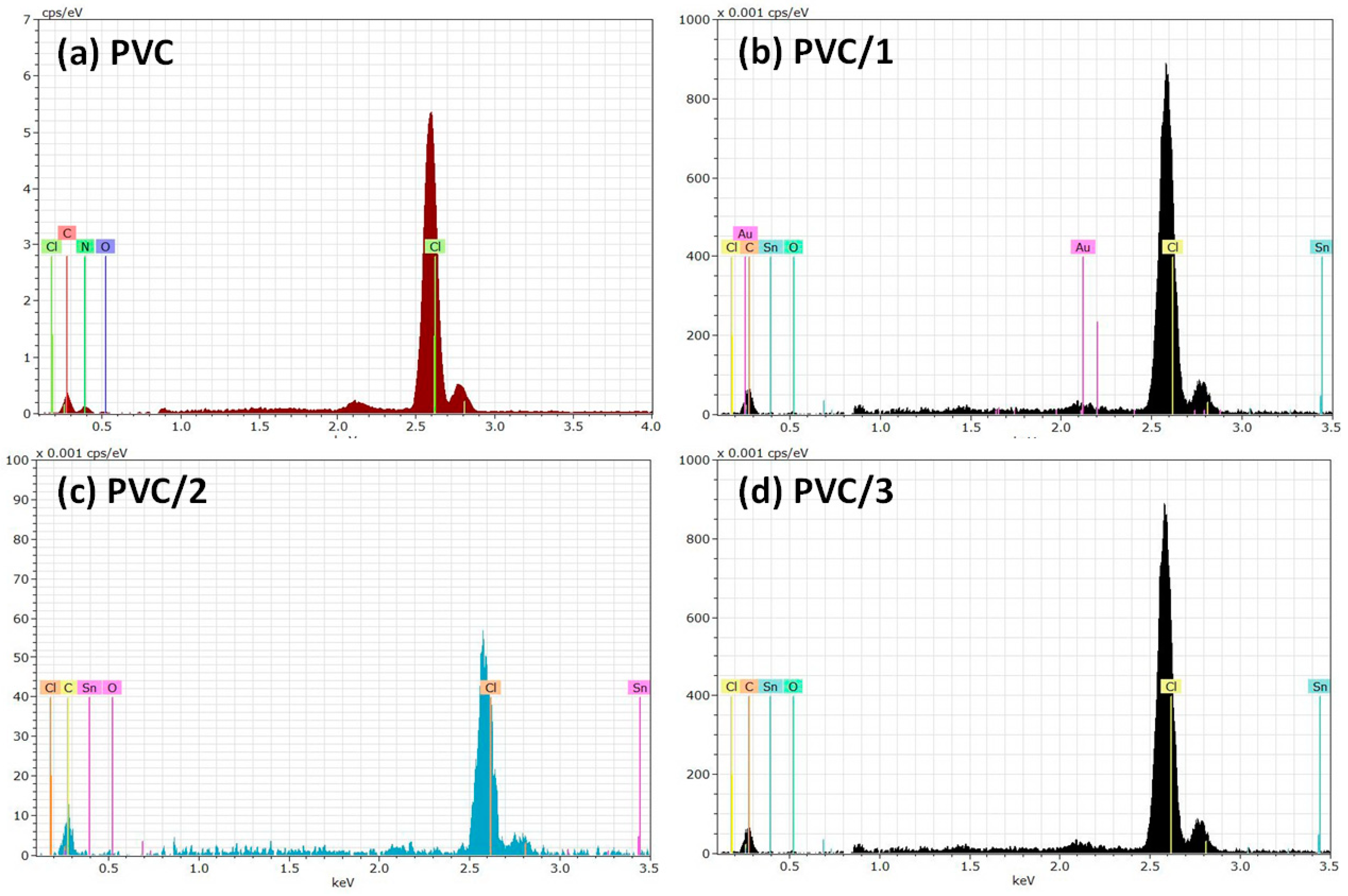

2.2. Weight Loss of PVC Films

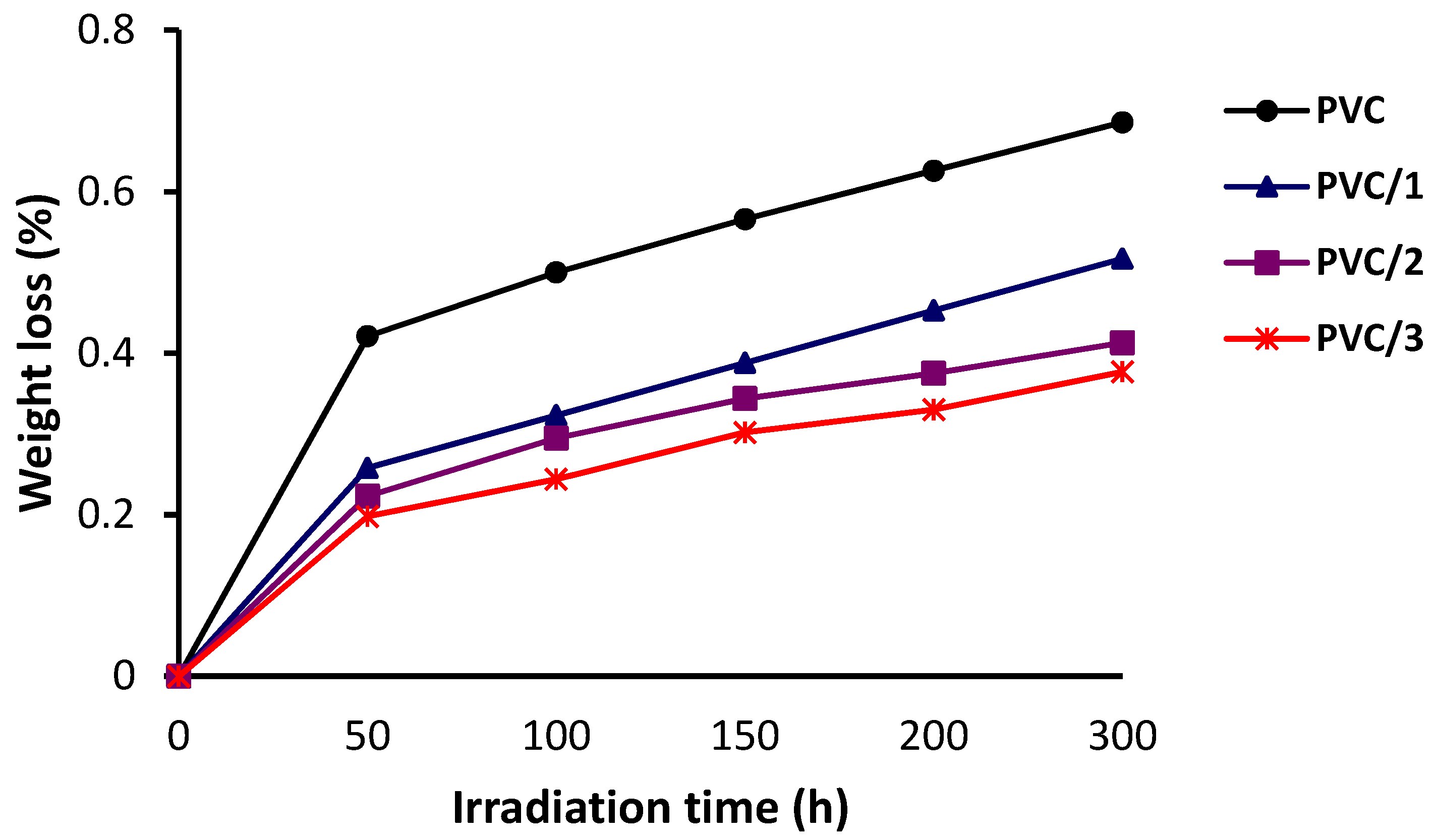

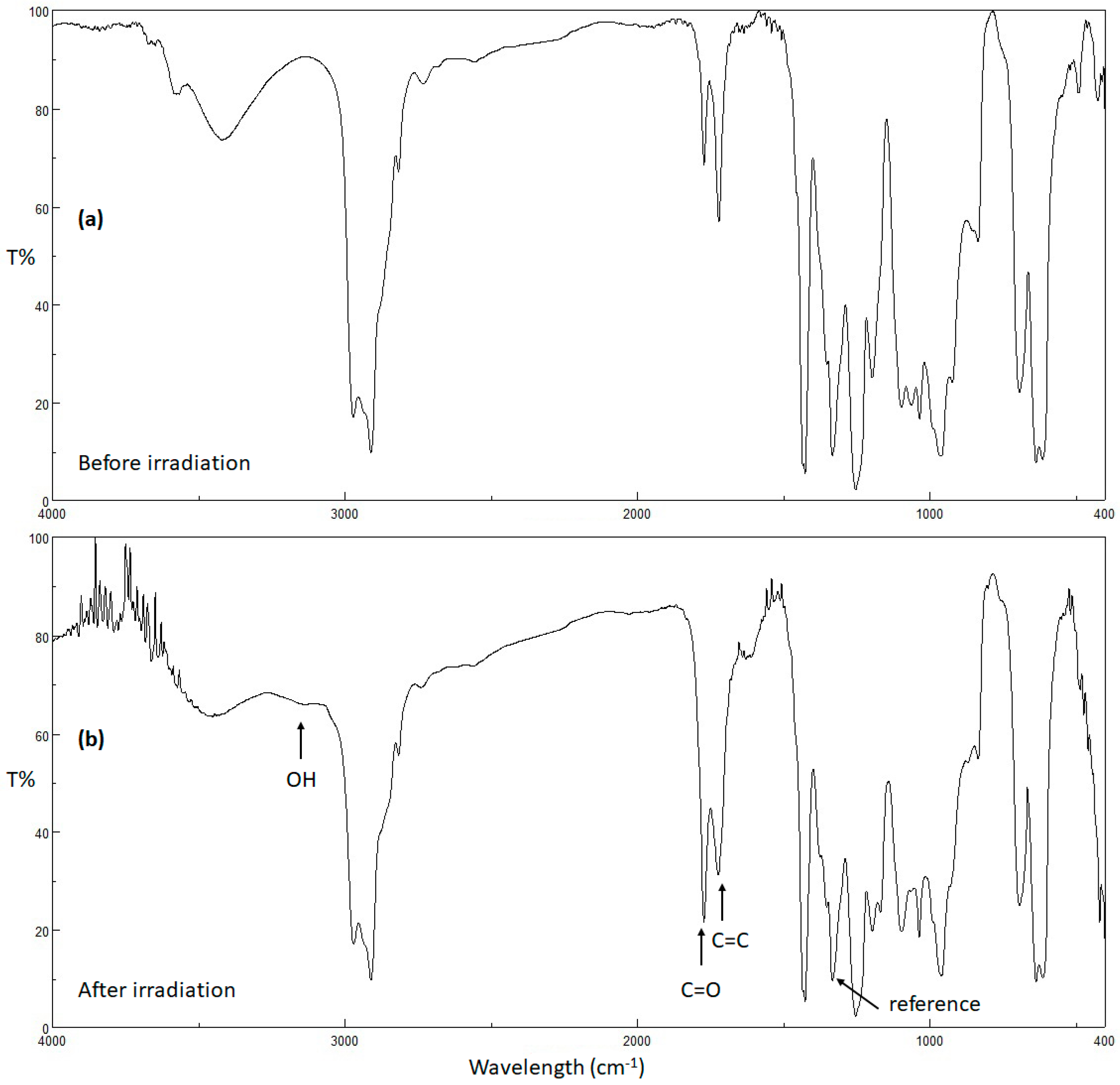

2.3. FT-IR Spectroscopy of PVC Films

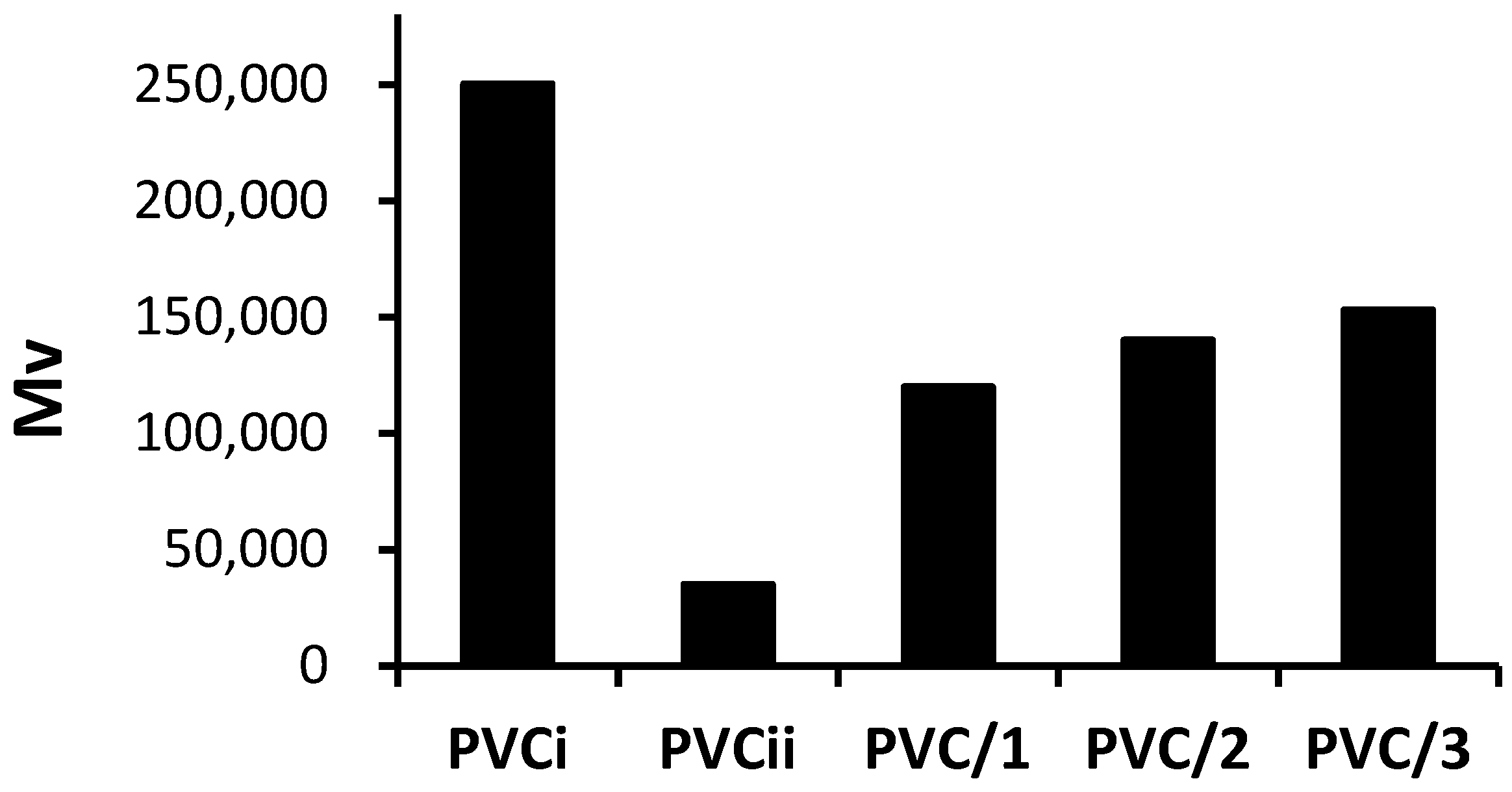

2.4. Molecular Weight of PVC Films

2.5. Surface Morphology of PVC Films

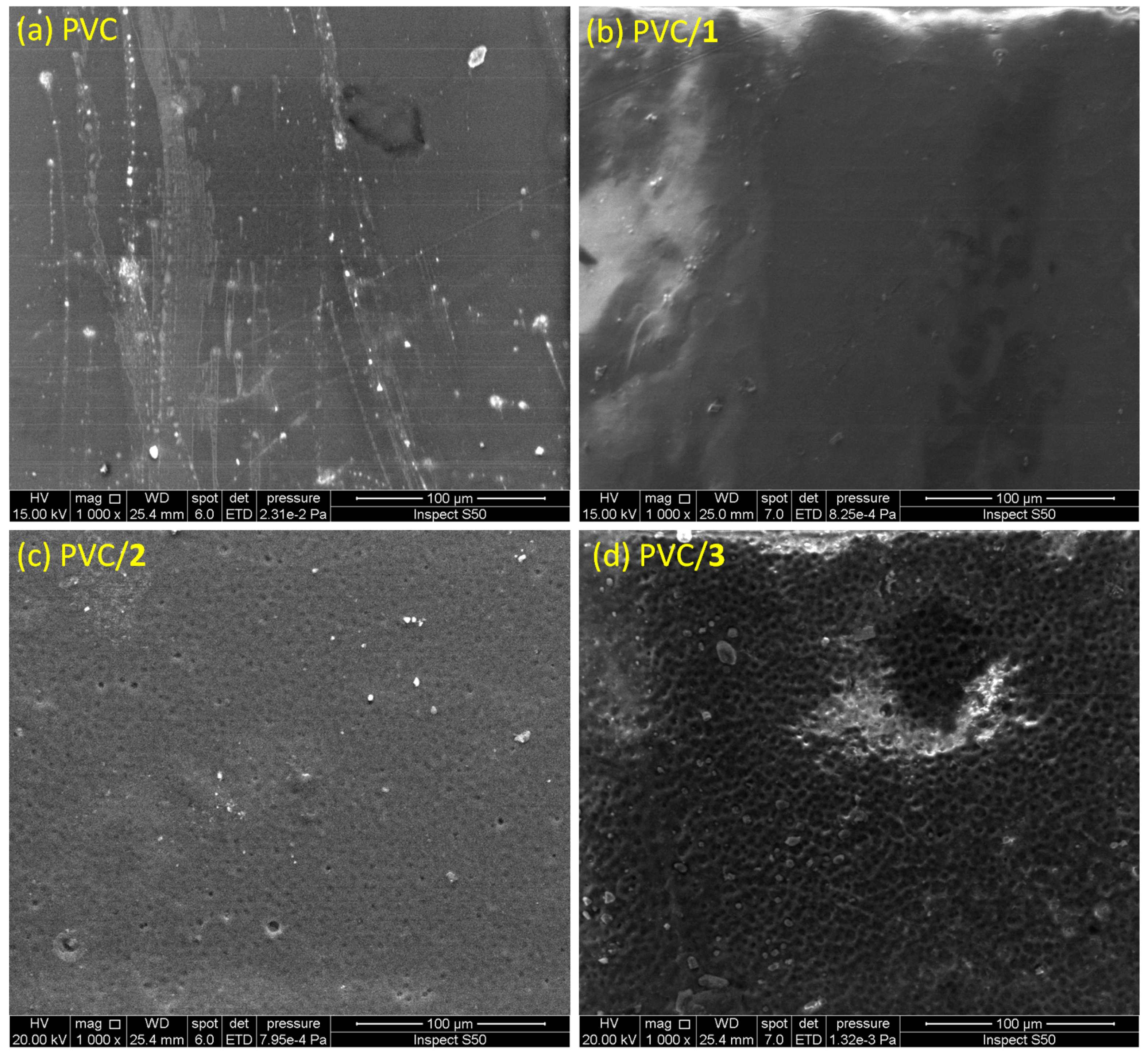

2.6. Scanning Electron Microscopy (SEM) of PVC Films

2.7. Atomic Force Microscopy (AFM) of PVC Films

2.8. Photostabilization Mechanism

3. Materials and Methods

3.1. General

3.2. Synthesis of Sn(IV) Complexes 1–3

3.3. Preparation of PVC Films

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Keneghan, B.; Egan, L. Plastics: Looking at the Future and Learning from the Past; Archetype Publications Ltd.: London, UK, 2008. [Google Scholar]

- Patrick, S.G. Practical Guide to Polyvinyl Chloride; Rapra Technology Limited: Shrewsbury, UK, 2005. [Google Scholar]

- Cadogan, D.F.; Howick, C.J. Plasticizers. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2000. [Google Scholar]

- Burgess, R.H. Manufacture and Processing of PVC; Applied Science Publishers: London, UK, 1982. [Google Scholar]

- Wickson, E.J. Handbook of Polyvinyl Chloride Formulating; John Wiley and Sons: New York, NY, USA, 1993. [Google Scholar]

- Rabek, J.F. Oxidative Degradation of Polymers. In Degradation of Polymers. Comprehensive Chemical Kinetics; Bamford, C.H., Tipper, C.H.F., Eds.; Elsevier: Amsterdam, The Netherlands, 1975; Volume 14, pp. 425–538. [Google Scholar]

- Grassie, N.; Scott, G. Polymer Degradation and Stabilisation; Cambridge University Press: Cambridge, UK, 1988. [Google Scholar]

- Benaniba, M.T.; Belhaneche-Bensemra, N.; Gelbard, G. Stabilizing effect of epoxidized sunflower oil on the thermal degradation of poly(vinyl chloride). Polym. Degrad. Stab. 2001, 74, 501–505. [Google Scholar] [CrossRef]

- González-Ortiz, L.J.; Arellano, M.; Jasso, C.F.; Mendizábal, E.; Sánchez-Peña, M.J. Thermal stability of plasticized poly(vinyl chloride) compounds stabilized with pre-heated mixtures of calcium and/or zinc stearates. Polym. Degrad. Stab. 2005, 90, 154–161. [Google Scholar] [CrossRef]

- Starnes, W.H., Jr. Structural and mechanistic aspects of the thermal degradation of poly(vinyl chloride). Prog. Polym. Sci. 2002, 27, 2133–2170. [Google Scholar] [CrossRef]

- Braun, D. Recycling of PVC. Prog. Polym. Sci. 2002, 27, 2171–2195. [Google Scholar] [CrossRef]

- Troitskii, B.B.; Troitskaya, L.S. Degenerated branching of chain in poly(vinyl chloride) thermal degradation. Eur. Polym. J. 1999, 35, 2215–2224. [Google Scholar] [CrossRef]

- Starnes, W.H.; Ge, X. Mechanism of autocatalysis in the thermal dehydrochlorination of poly(vinyl chloride). Macromolecules 2004, 37, 352–359. [Google Scholar] [CrossRef]

- Fisch, M.H.; Bacaloglu, R. Mechanism of poly(vinyl chloride) stabilisation. Plast. Rubber Compos. 1999, 28, 119–124. [Google Scholar] [CrossRef]

- Sánchez-Jiménez, P.E.; Perejón, A.; Criado, J.M.; Diánez, M.J.; Pérez-Maqueda, L.A. Kinetic model for thermal dehydrochlorination of poly(vinyl chloride). Polymer 2010, 51, 3998–4007. [Google Scholar] [CrossRef]

- Okieimen, F.E.; Sogbaike, C.E. Thermal dehydrochlorination of poly(vinyl chloride) in the presence of Jatropha seed oil. J. Appl. Polym. Sci. 1995, 57, 513–518. [Google Scholar] [CrossRef]

- Mallakpour, S.; Sadeghzadeh, R. A benign and simple strategy for surface modification of Al2O3 nanoparticles with citric acid and L(+)-ascorbic acid and its application for the preparation of novel poly(vinyl chloride) nanocomposite films. Adv. Polym. Technol. 2017, 36, 409–417. [Google Scholar] [CrossRef]

- Sterzyński, T.; Tomaszewska, J.; Piszczek, K.; Skórczewska, K. The influence of carbon nanotubes on the PVC glass transition temperature. Compos. Sci. Technol. 2010, 70, 966–969. [Google Scholar] [CrossRef]

- Sabaa, M.W.; Oraby, E.H.; Abdel Naby, A.S.; Mohamed, R.R. Anthraquinone derivatives as organic stabilizers for rigid poly(vinyl chloride) against photo-degradation. Eur. Polym. J. 2005, 41, 2530–2543. [Google Scholar] [CrossRef]

- El-Hiti, G.A.; Alotaibi, M.H.; Ahmed, A.A.; Hamad, B.A.; Ahmed, D.S.; Ahmed, A.; Hashim, H.; Yousif, E. The morphology and performance of poly(vinyl chloride) containing melamine Schiff bases against ultraviolet light. Molecules 2019, 24, 803. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, D.S.; El-Hiti, G.A.; Hameed, A.S.; Yousif, E.; Ahmed, A. New tetra-Schiff bases as efficient photostabilizers for poly(vinyl chloride). Molecules 2017, 22, 1506. [Google Scholar] [CrossRef] [PubMed]

- Ali, G.Q.; El-Hiti, G.A.; Tomi, I.H.R.; Haddad, R.; Al-Qaisi, A.J.; Yousif, E. Photostability and performance of polystyrene films containing 1,2,4-triazole-3-thiol ring system Schiff bases. Molecules 2016, 21, 1699. [Google Scholar] [CrossRef]

- Yousif, E.; El-Hiti, G.A.; Hussain, Z.; Altaie, A. Viscoelastic, spectroscopic and microscopic study of the photo irradiation effect on the stability of PVC in the presence of sulfamethoxazole Schiff’s bases. Polymers 2015, 7, 2190–2204. [Google Scholar] [CrossRef]

- Deanin, R.D.; Reynolds, H.H.; Ozcayir, Y. Thermal stabilization of polyvinyl chloride by group II metal laurates. J. Appl. Polym. Sci. 1969, 13, 1247–1252. [Google Scholar] [CrossRef]

- Birmingham, J.N. The effect of surface oxidation and titanium dioxide on exterior PVC color retention. J. Vinyl Addit. Technol. 1995, 1, 84–87. [Google Scholar] [CrossRef]

- Cheng, Q.; Li, C.; Pavlinek, V.; Saha, P.; Wang, H. Surface-modified antibacterial TiO2/Ag+ nanoparticles: Preparation and properties. Appl. Surf. Sci. 2006, 252, 4154–4160. [Google Scholar] [CrossRef]

- Folarin, O.M.; Sadiku, E.R. Thermal stabilizers for poly(vinyl chloride): A review. Int. J. Phys. Sci. 2011, 6, 4323–4330. [Google Scholar] [CrossRef]

- Balakit, A.A.; Ahmed, A.; El-Hiti, G.A.; Smith, K.; Yousif, E. Synthesis of new thiophene derivatives and their use as photostabilizers for rigid poly(vinyl chloride). Int. J. Polym. Sci. 2015, 2015, 510390. [Google Scholar] [CrossRef]

- Sabaa, M.W.; Mikhael, M.G.; Mohamed, N.A.; Yassin, A.A. N-Substituted maleimides as thermal stabilizers for rigid polyvinylchloride. Angew. Makromol. Chem. 1989, 168, 23–25. [Google Scholar] [CrossRef]

- Schiller, M. PVC Additives: Performance, Chemistry, Developments, and Sustainability; Carl Hanser Verlag: Munich, Germany, 2015. [Google Scholar]

- Yousif, E.; Hasan, A.; El-Hiti, G.A. Spectroscopic, physical and topography of photochemical process of PVC films in the presence of Schiff base metal complexes. Polymers 2016, 8, 204. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.M.; El-Hiti, G.A.; Yousif, E. Photostabilizing efficiency of poly(vinyl chloride) in the presence of organotin(IV) complexes as photostabilizers. Molecules 2016, 21, 1151. [Google Scholar] [CrossRef] [PubMed]

- Ghazi, D.; El-Hiti, G.A.; Yousif, E.; Ahmed, D.S.; Alotaibi, M.H. The effect of ultraviolet irradiation on the physicochemical properties of poly(vinyl chloride) films containing organotin(IV) complexes as photostabilizers. Molecules 2018, 23, 254. [Google Scholar] [CrossRef] [PubMed]

- Hadi, A.G.; Jawad, K.; Yousif, E.; El-Hiti, G.A.; Alotaibi, M.H.; Ahmed, D.S. Synthesis of telmisartan organotin(IV) complexes and their use as carbon dioxide capture media. Molecules 2019, 24, 1631. [Google Scholar] [CrossRef] [PubMed]

- Alotaibi, M.H.; El-Hiti, G.A.; Hashim, H.; Hameed, A.S.; Ahmed, D.S.; Yousif, E. SEM analysis of the tunable honeycomb structure of irradiated poly(vinyl chloride) films doped with polyphosphate. Heliyon 2018, 4, e01013. [Google Scholar] [CrossRef] [PubMed]

- Hashim, H.; El-Hiti, G.A.; Alotaibi, M.H.; Ahmed, D.S.; Yousif, E. Fabrication of ordered honeycomb porous poly(vinyl chloride) thin film doped with a Schiff base and nickel(II) chloride. Heliyon 2018, 4, e00743. [Google Scholar] [CrossRef] [PubMed]

- Yousif, E.; Ahmed, D.S.; El-Hiti, G.A.; Alotaibi, M.H.; Hashim, H.; Hameed, A.S.; Ahmed, A. Fabrication of novel ball-like polystyrene films containing Schiff base microspheres as photostabilizers. Polymers 2018, 10, 1185. [Google Scholar] [CrossRef]

- Balakit, A.A.; Smith, K.; El-Hiti, G.A. Synthesis and characterization of a new photochromic alkylene sulfide derivative. J. Sulfur Chem. 2018, 39, 182–192. [Google Scholar] [CrossRef]

- Altaee, N.; El-Hiti, G.A.; Fahdil, A.; Sudesh, K.; Yousif, E. Screening and evaluation of poly(3-hydroxybutyrate) with Rhodococcus equi using different carbon sources. Arab. J. Sci. Eng. 2017, 42, 2371–2379. [Google Scholar] [CrossRef]

- Altaee, N.; El-Hiti, G.A.; Fahdil, A.; Sudesh, K.; Yousif, E. Biodegradation of different formulations of polyhydroxybutyrate films in soil. SpringerPlus 2016, 5, 762. [Google Scholar] [CrossRef] [PubMed]

- Yousif, E.; El-Hiti, G.A.; Haddad, R.; Balakit, A.A. Photochemical stability and photostabilizing efficiency of poly(methyl methacrylate) based on 2-(6-methoxynaphthalen-2-yl)propanoate metal ion complexes. Polymers 2015, 7, 1005–1019. [Google Scholar] [CrossRef]

- Choong, C.-S.; Win, Y.-F.; Ha, S.-T.; Yousif, E. Synthesis, characterization and antibacterial activity of organotin(IV) complexes derivatives of 2-chloro-4-nitrobenzoic acid. Asian J. Chem. 2004, 26, 2949–2953. [Google Scholar] [CrossRef]

- Berger, J. Monitoring Dissolution of Nonsteroidal Anti-Inflammatory Drugs Using Infrared Spectroscopy. Master’s Thesis, Seton Hall University, South Orange, NJ, USA, 2015. [Google Scholar]

- Singh, H.L.; Singh, J. Synthesis, spectroscopic, molecular structure, and antibacterial studies of dibutyltin(IV) Schiff base complexes derived from phenylalanine, isoleucine, and glycine. Bioinorg. Chem. Appl. 2014, 2014, 716578. [Google Scholar] [CrossRef] [PubMed]

- Adeyemi, J.O.; Onwudiwe, D.C.; Hosten, E.C. Organotin(IV) complexes derived from N-ethyl-N-phenyldithiocarbamate: Synthesis, characterization and thermal studies. J. Saudi Chem. Soc. 2018, 22, 427–438. [Google Scholar] [CrossRef]

- Nath, M.; Singh, H.; Kumar, P.; Song, X.; Eng, G. Organotin(IV) tryptophanylglycinates: Potential non-steroidal antiinflammatory agents; crystal structure of dibutyltin(IV) tryptophanylglycinate. Appl. Organomet. Chem. 2009, 23, 347–358. [Google Scholar] [CrossRef]

- Masood, H.; Ali, S.; Mazhar, M.; Shahzadi, S.; Shahid, K. 1H, 13C, 119Sn NMR, mass, Mössbauer and biological studies of tri-, di- and chlorodiorganotin(IV) carboxylates. Turk. J. Chem. 2004, 28, 75–85. [Google Scholar]

- Pejchal, V.; Holeček, J.; Nádvorník, M.; Lyčka, A. 13C and 119Sn NMR spectra of some mono-n-butyltin(IV) compounds. Collect. Czech. Chem. Commun. 1995, 60, 1492–1501. [Google Scholar] [CrossRef]

- Shahid, K.; Ali, S.; Shahzadi, S.; Badshah, A.; Khan, K.M.; Maharvi, G.M. Organotin(IV) complexes of aniline derivatives. I. Synthesis, spectral and antibacterial studies of di- and triorganotin(IV) derivatives of 4-bromomaleanilic acid. Synth. React. Inorg. Met. Org. Chem. 2003, 33, 1221–1235. [Google Scholar] [CrossRef]

- Rehman, W.; Baloch, M.K.; Badshah, A.; Ali, S. Synthesis and characterization of biologically potent di-organotin(IV) complexes of mono-methyl glutarate. J. Chin. Chem. Soc. 2005, 52, 231–236. [Google Scholar] [CrossRef]

- Blanco Jerez, L.M.; Rangel Oyervides, L.D.; Gómez, A.; Jiménez-Pérez, V.M.; Muñoz-Flores, B.M. Electrochemical metallization with Sn of (E)-4-((4-nitrobenzylidene)amino)phenol in non-aqueous media: Characterization and biological activity of the organotin compound. Int. J. Electrochem. Sci. 2016, 11, 45–53. [Google Scholar]

- Pospíšil, J.; Nešpurek, S. Photostabilization of coatings. Mechanisms and performance. Prog. Polym. Sci. 2000, 25, 1261–1335. [Google Scholar] [CrossRef]

- Gardette, J.-L.; Gaumet, S.; Lemaire, J. Photooxidation of poly(vinyl chloride). 1. A reexamination of the mechanism. Macromolecules 1989, 22, 2576–2581. [Google Scholar] [CrossRef]

- Gaumet, S.; Gardette, J.-L. Photo-oxidation of poly(vinyl chloride): Part 2—A comparative study of the carbonylated products in photo-chemical and thermal oxidations. Polym. Degrad. Stab. 1991, 33, 17–34. [Google Scholar] [CrossRef]

- Mark, J.E. Physical Properties of Polymers Handbook; Springer: New York, NY, USA, 2007. [Google Scholar]

- Pepperl, G. Molecular weight distribution of commercial PVC. J. Vinyl Addit. Technol. 2000, 6, 88–92. [Google Scholar] [CrossRef]

- Shaalan, N.; Laftah, N.; El-Hiti, G.A.; Alotaibi, M.H.; Muslih, R.; Ahmed, D.S.; Yousif, E. Poly(vinyl chloride) photostabilization in the presence of Schiff bases containing a thiadiazole moiety. Molecules 2018, 23, 913. [Google Scholar] [CrossRef] [PubMed]

- Kayyarapu, B.; Kumar, M.Y.; Mohommad, H.B.; Neeruganti, G.O.; Chekuri, R. Structural, thermal and optical properties of pure and Mn2+ doped poly(vinyl chloride) films. Mater. Res. 2016, 19, 1167–1175. [Google Scholar] [CrossRef]

- See, C.H.; O’Haver, J. Atomic force microscopy characterization of ultrathin polystyrene films formed by admicellar polymerization on silica disks. J. Appl. Polym. Sci. 2003, 89, 36–46. [Google Scholar] [CrossRef]

- Pospíšil, J.; Klemchuk, P.P. Oxidation Inhibition in Organic Materials; CRC Press: Boca Raton, FL, USA, 1989; pp. 48–49. [Google Scholar]

- Sabaa, M.W.; Oraby, E.H.; Abdul Naby, A.S.; Mohamed, R.R. N-Phenyl-3-substituted-5-pyrazolone derivatives as organic stabilizers for rigid poly(vinyl chloride) against photodegradation. J. Appl. Polym. Sci. 2006, 101, 1543–1555. [Google Scholar] [CrossRef]

- Li, D.; Zhou, M.; Xie, L.; Yu, X.; Yu, Y.; Ai, H.; Tang, S. Synergism of pentaerythritol-zinc with β-diketone and calcium stearate in poly(vinyl chloride) thermal stability. Polym. J. 2013, 45, 775–782. [Google Scholar] [CrossRef]

Sample Availability: Samples of the naproxen diorganotin(IV) complexes are available from the authors. |

| Sn(IV) Complex | R | Color | Yield (%) | Melting Point (°C) | Calcd. (Found) (%) | |

|---|---|---|---|---|---|---|

| C | H | |||||

| 1 | Bu | white | 79 | 106–108 | 62.53 (62.58) | 6.41 (6.57) |

| 2 | Ph | brown | 85 | 82–84 | 65.68 (65.42) | 4.96 (5.12) |

| 3 | Me | pale orange | 86 | 129–131 | 59.33 (59.57) | 5.31 (5.49) |

| Sn(IV) Complex | FT-IR (ν, cm−1) | ||||

|---|---|---|---|---|---|

| C=O (as) | C=O (s) | C=C | Sn–C | Sn–O | |

| 1 | 1643 | 1541 | 1458 | 526 | 445 |

| 2 | 1643 | 1541 | 1456 | 524 | 449 |

| 3 | 1651 | 1548 | 1454 | 524 | 447 |

| Sn(IV) Complex | 1H-NMR (300 MHz; DMSO-d6, ppm) |

|---|---|

| 1 | 7.78–7.71 (m, 6H, Ar), 7.35 (d, J = 7.8 Hz, 2H, Ar), 7.27 (s, 2H, Ar), 7.13 (d, J = 7.8 Hz, 2H, Ar), 3.93 (s, 6H, 2OMe), 3.77 (q, J = 7.1 Hz, 2H, 2CH), 1.42 (d, J = 7.1 Hz, 6H, 2Me), 1.22–1.19 (m, 8H, 4CH2), 1.00 (m, 4H, 2CH2), 0.57 (t, J = 7.4 Hz, 6H, 2Me) |

| 2 | 7.82–7.46 (m, 16H, Ar), 7.40 (d, J = 7.6 Hz, 2H, Ar), 7.29 (s, 2H, Ar), 7.15 (d, J = 7.6 Hz, 2H, Ar), 3.94 (s, 6H, 2OMe), 3.87 (q, J = 7.2 Hz, 2H, 2CH), 1.47 (d, J = 7.2 Hz, 6H, 2Me) |

| 3 | 7.81–7.71 (m, 6H, Ar), 7.39 (d, J = 7.6 Hz, 2H, Ar), 7.28 (s, 2H, Ar), 7.14 (d, J = 7.6 Hz, 2H, Ar), 3.93 (s, 6H, 2OMe), 3.83 (q, J = 7.2 Hz, 2H, 2CH), 1.42 (d, J = 7.2 Hz, 6H, 2Me), 0.57 (s, 6H, 2Me) |

| Sn(IV) Complex | 13C-NMR (75 MHz; DMSO-d6, ppm) |

|---|---|

| 1 | 175.9 (C=O), 157.5, 133.7, 133.1, 129.5, 129.1, 128.0, 127.5, 125.9, 119.0, 106.2, 55.6 (OMe), 43.7 (CH), 31.5 (CH2), 26.0 (CH2), 25.6 (CH2), 15.9 (Me), 15.0 (Me) |

| 2 | 175.8 (C=O), 157.7, 136.7, 136.2, 133.8, 133.6, 129.6, 129.4, 128.9, 128.7, 128.0, 127.8, 126.9, 119.1, 106.2, 55.6 (OMe), 44.7 (CH), 18.9 (Me) |

| 3 | 174.8 (C=O), 157.6, 136.8, 133.7, 129.6, 128.9, 127.5, 126.9, 126.0, 119.3, 106.2, 55.6 (OMe), 45.0 (CH), 18.9 (Me), 18.5 (Me) |

| Photoirradiated PVC Film (300 h) | Rq |

|---|---|

| PVC blank | 457.6 |

| PVC/1 | 130.3 |

| PVC/2 | 126.6 |

| PVC/3 | 87.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hadi, A.G.; Yousif, E.; El-Hiti, G.A.; Ahmed, D.S.; Jawad, K.; Alotaibi, M.H.; Hashim, H. Long-Term Effect of Ultraviolet Irradiation on Poly(vinyl chloride) Films Containing Naproxen Diorganotin(IV) Complexes. Molecules 2019, 24, 2396. https://doi.org/10.3390/molecules24132396

Hadi AG, Yousif E, El-Hiti GA, Ahmed DS, Jawad K, Alotaibi MH, Hashim H. Long-Term Effect of Ultraviolet Irradiation on Poly(vinyl chloride) Films Containing Naproxen Diorganotin(IV) Complexes. Molecules. 2019; 24(13):2396. https://doi.org/10.3390/molecules24132396

Chicago/Turabian StyleHadi, Angham G., Emad Yousif, Gamal A. El-Hiti, Dina S. Ahmed, Khudheyer Jawad, Mohammad Hayal Alotaibi, and Hassan Hashim. 2019. "Long-Term Effect of Ultraviolet Irradiation on Poly(vinyl chloride) Films Containing Naproxen Diorganotin(IV) Complexes" Molecules 24, no. 13: 2396. https://doi.org/10.3390/molecules24132396

APA StyleHadi, A. G., Yousif, E., El-Hiti, G. A., Ahmed, D. S., Jawad, K., Alotaibi, M. H., & Hashim, H. (2019). Long-Term Effect of Ultraviolet Irradiation on Poly(vinyl chloride) Films Containing Naproxen Diorganotin(IV) Complexes. Molecules, 24(13), 2396. https://doi.org/10.3390/molecules24132396