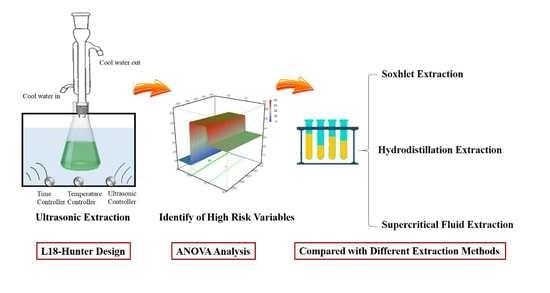

Quickly Identifying High-Risk Variables of Ultrasonic Extraction Oil from Multi-Dimensional Risk Variable Patterns and a Comparative Evaluation of Different Extraction Methods on the Quality of Forsythia suspensa Seed Oil

Abstract

:1. Introduction

2. Results and Discussion

2.1. Model Fitting of UE

2.1.1. Analysis of the Model

2.1.2. Model Fitting of Extraction Yield

2.1.3. Model Fitting of DPPH Scavenging Activity

2.1.4. Validation the Model

2.2. Compared with Different Extraction Methods

2.2.1. FT-IR Spectroscopy Analysis

2.2.2. Composition of Oil Obtained by Different Methods

2.2.3. Antioxidant Activity of Oil Obtained by Different Methods

3. Materials and Methods

3.1. Samples and Reagents

3.2. Extraction of Oil

3.2.1. L18 Hunter Design-Assisted UE

3.2.2. Soxhlet Extraction (SE)

3.2.3. Hydrodistillation Extraction (HD)

3.2.4. Supercritical Fluid Extraction (SFE)

3.3. Determination of Extraction Yield (Yield %)

3.4. Characterization of Oil by GC-MS

3.5. Determination of Antioxidant Activity: DPPH Assay (DPPH %)

3.6. FT-IR Spectroscopy

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xia, E.; Ai, X.; Zang, Y.; Guan, T.; Xu, R.; Li, B. Ultrasound-assisted extraction of phillyrin from Forsythia suspensa. Ultrason. Sonochem. 2011, 18, 549–552. [Google Scholar] [CrossRef]

- Wang, Z.; Xia, Q.; Liu, X.; Liu, W.; Huang, W.; Mei, X.; Luo, J.; Shan, M.; Lin, R.; Zou, D.; et al. Phytochemistry, pharmacology, quality control and future research of Forsythia suspensa (Thunb.) Vahl: A review. J. Ethnopharmacol. 2018, 210, 318–339. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.; Lu, X.; Tong, X.; Dong, Y.; Tang, L.; Liu, M. Forsythiae Fructus: A review on its phytochemistry, quality control, pharmacology and pharmacokinetics. Molecules 2017, 22, 1466. [Google Scholar] [CrossRef]

- Safaryan, M.J.; Ganjloo, A.; Bimakr, M.; Zarringhalami, S. Optimization of ultrasound-assisted extraction, preliminary characterization and in vitro antioxidant activity of polysaccharides from green pea pods. Foods 2016, 5, 78. [Google Scholar] [CrossRef] [PubMed]

- Vuong, Q.V.; Nguyen, V.T.; Thanh, D.T.; Bhuyan, D.J.; Goldsmith, C.D.; Sadeqzadeh, E.; Scarlett, C.J.; Bowyer, M.C. Optimization of ultrasound-assisted extraction conditions for euphol from the medicinal plant, Euphorbia tirucalli, using response surface methodology. Ind. Crop. Prod. 2015, 63, 197–202. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.G.; Meullemiestre, A.; Fabiano-Tixier, A.S.; Abert-Vian, M. Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhou, C.; Wang, B.; Yagoub, A.E.A.; Ma, H.; Zhang, X.; Wu, M. Study of ultrasonic cavitation during extraction of the peanut oil at varying frequencies. Ultrason Sonochem. 2017, 37, 106–113. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, J.; Zhang, H.; Dzah, C.S.; Zandile, M.; Duan, Y.; Ma, H.; Luo, X. Advances in ultrasound assisted extraction of bioactive compounds from cash crops—A review. Ultrason Sonochem. 2018, 48, 538–549. [Google Scholar] [CrossRef]

- Mouahid, A.; Dufour, C.; Badens, E. Supercritical CO2 extraction from endemic Corsican plants; comparison of oil composition and extraction yield with hydrodistillation method. J. CO2 Util. 2017, 20, 263–273. [Google Scholar] [CrossRef]

- Bayrak, S.; Sökmen, M.; Aytac, E.; Sökmen, A. Conventional and supercritical fluid extraction (SFE) of colchicine from Colchicum speciosum. Ind. Crop. Prod. 2019, 128, 80–84. [Google Scholar] [CrossRef]

- Ferreira, S.L.C.; Silva, J.M.M.; Felix, C.S.A.; da Silva, D.L.F.; Santos, A.S.; Santos, N.J.H.; de Souza, C.T.; Cruz, J.R.A.; Sounza, A.S. Multivariate optimization techniques in food analysis–A review. Food Chem. 2019, 273, 3–8. [Google Scholar] [CrossRef] [PubMed]

- Amiri, S.; Shakeri, A.; Sohrabi, M.R.; Khalajzadeh, S.; Ghasemi, E. Optimization of ultrasonic assisted extraction of fatty acids from Aesculus hippocastanum fruit by response surface methodology. Food Chem. 2019, 271, 762–766. [Google Scholar] [CrossRef] [PubMed]

- Mohammadpour, H.; Sadrameli, S.M.; Eslami, F.; Asoodeh, A. Optimization of ultrasound-assisted extraction of Moringa peregrina oil with response surface methodology and comparison with Soxhlet method. Ind. Crop. Prod. 2019, 131, 106–116. [Google Scholar] [CrossRef]

- Hu, J.; Jia, X.; Fang, X.; Li, P.; He, C.; Chen, M. Ultrasonic extraction, antioxidant and anticancer activities of novel polysaccharides from Chuanxiong rhizome. Int. J. Biol. Macromol. 2016, 85, 277–284. [Google Scholar] [CrossRef] [PubMed]

- Sicaire, A.G.; Vian, M.A.; Fine, F.; Carré, P.; Tostain, S.; Chemat, F. Ultrasound induced green solvent extraction of oil from oleaginous seeds. Ultrason Sonochem. 2016, 31, 319–329. [Google Scholar] [CrossRef] [PubMed]

- Zidan, A.S.; Ebeed, M.; Elghamry, H.; Badawy, A. Nicotinamide pelletization by fluidized hot melt granulation: L18 Hunter design to screen high risk variables. Int. J. Pharm. 2014, 466, 83–95. [Google Scholar] [CrossRef] [PubMed]

- Rogowska, M.; Lenart, M.; Srečec, S.; Ziaja, M.; Parzonko, A.; Bazylko, A. Chemical composition, antioxidative and enzyme inhibition activities of chickweed herb (Stelaria media L.; Vill.) ethanolic and aqueous extracts. Ind. Crop. Prod. 2017, 97, 448–454. [Google Scholar] [CrossRef]

- Utama-Ang, N.; Phawatwiangnak, K.; Naruenaartwongsakul, S.; Samakradhamrongthai, R. Antioxidative effect of Assam Tea (Camellia sinesis Var. Assamica) extract on rice bran oil and its application in breakfast cereal. Food Chem. 2017, 221, 1733–1740. [Google Scholar] [CrossRef] [PubMed]

- Vijayanand, P.; Jyothi, V.; Aditya, N.; Mounika, A. Development and characterization of solid lipid nanoparticles containing herbal extract: in vivo antidepressant activity. J. Drug Deliv. 2018, 2018, 2908626. [Google Scholar] [CrossRef]

- Afshari, K.; Samavati, V.; Shahidi, S.A. Ultrasonic-assisted extraction and in-vitro antioxidant activity of polysaccharide from Hibiscus leaf. Int. J. Biol. Macromol. 2015, 74, 558–567. [Google Scholar] [CrossRef]

- Huang, S.M.; Kuo, C.H.; Chen, C.A.; Liu, Y.C.; Shieh, C.J. RSM and ANN modeling-based optimization approach for the development of ultrasound-assisted liposome encapsulation of piceid. Ultrason Sonochem. 2017, 36, 112–122. [Google Scholar] [CrossRef] [PubMed]

- Marasini, N.; Tran, T.H.; Poundel, B.K.; Choi, H.G.; Yong, C.S.; Kim, J.O. Statistical modeling, optimization and characterization of spray-dried solid self-microemulsifying drug delivery system using design of experiments. Chem. Pharm. Bull. 2013, 16, 184–193. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, Y.; Wei, S.; Yan, Z. Application of response surface methodology to optimise supercritical carbon dioxide extraction of essential oil from Cyperus rotundus Linn. Food Chem. 2012, 132, 582–587. [Google Scholar] [CrossRef] [PubMed]

- Raza, A.; Li, F.; Xu, X.; Tang, J. Optimization of ultrasonic-assisted extraction of antioxidant polysaccharides from the stem of Trapa quadrispinosa using response surface methodology. Int. J. Biol. Macromol. 2017, 94, 335–344. [Google Scholar] [CrossRef] [PubMed]

- Juhaimi, F.A.L.; Özcan, M.M.; Ghafoor, K.; Babiker, E.E. The effect of microwave roasting on bioactive compounds, antioxidant activity and fatty acid composition of apricot kernel and oils. Food Chem. 2018, 243, 414–419. [Google Scholar] [CrossRef] [PubMed]

- Zeng, W.C.; He, Q.; Sun, Q.; Zhong, K.; Gao, H. Antibacterial activity of water-soluble extract from pine needles of Cedrus deodara. Int. J. Food Microbiol. 2012, 153, 78–84. [Google Scholar] [CrossRef] [PubMed]

- Ming, L.; Li, Z.; Wu, F.; Du, F.; Feng, Y. A two-step approach for fluidized bed granulation in pharmaceutical processing: Assessing different models for design and control. PLoS ONE 2017, 12, e0180209. [Google Scholar] [CrossRef]

- Li, Z.; Xian, J.; Wu, F.; Lin, X.; Shen, L.; Feng, Y. Development of TCM-based composite particles for direct compaction by particle design. Powder Technol. 2018, 338, 481–492. [Google Scholar] [CrossRef]

- Rahman, Z.; Khan, M.A. Hunter screening design to understand the product variability of solid dispersion formulation of a peptide antibiotic. Int. J. Pharm. 2013, 456, 572–582. [Google Scholar] [CrossRef]

- Dai, Q.; Yang, Y.; Chen, K.; Cheng, Z.; Ni, Y.; Li, J. Optimization of supercritical CO2 operative parameters to simultaneously increase the extraction yield of oil and pentacyclic triterpenes from artichoke leaves and stalks by response surface methodology and ridge analysis. Eur. J. Lipid Sci. Tech. 2019, 121, 1800120. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, Y.; Liang, H.; Chen, Q.; Zhao, P.; Tao, J. Identification of Portulaca oleracea L. from different sources using GC–MS and FT-IR spectroscopy. Talanta 2010, 81, 129–135. [Google Scholar] [CrossRef] [PubMed]

- Rakmai, J.; Cheirsilp, B.; Mejuto, J.C.; Simal-Gándara, J.; Torrado-Agrasar, A. Antioxidant and antimicrobial properties of encapsulated guava leaf oil in hydroxypropyl-beta-cyclodextrin. Ind. Crop. Prod. 2018, 111, 219–225. [Google Scholar] [CrossRef]

- Jiao, J.; Fu, Y.; Zu, Y.; Luo, M.; Wang, W.; Zhang, L.; Li, J. Enzyme-assisted microwave hydro-distillation essential oil from Fructus forsythia, chemical constituents, and its antimicrobial and antioxidant activities. Food Chem. 2012, 134, 235–243. [Google Scholar] [CrossRef]

- Xu, Y.Q.; Ji, W.B.; Yu, P.; Chen, J.X.; Wang, F.; Yin, J.F. Effect of extraction methods on the chemical components and taste quality of green tea extract. Food Chem. 2018, 248, 146–154. [Google Scholar] [CrossRef] [PubMed]

- Sodeifian, G.; Sajadian, S.A.; Ardestani, N.S. Supercritical fluid extraction of omega-3 from dracocephalum kotschyi seed oil: process optimization and oil properties. J. Supercrit. Fluid. 2017, 119, 139–149. [Google Scholar] [CrossRef]

- Goyeneche, R.; Fanovich, A.; Rodrigues, C.R.; Nicolao, M.C.; Scala, K.D. Supercritical CO2 extraction of bioactive compounds from radish leaves: Yield, antioxidant capacity and cytotoxicity. J. Supercrit. Fluid. 2018, 135, 78–83. [Google Scholar] [CrossRef]

- Thoo, Y.Y.; Ho, S.K.; Liang, J.Y.; Ho, C.W.; Tan, C.P. Effects of binary solvent extraction system, extraction time and extraction temperature on phenolic antioxidants and antioxidant capacity from mengkudu (Morinda citrifolia). Food Chem. 2010, 120, 290–295. [Google Scholar] [CrossRef]

- Rai, A.; Mohanty, B.; Bhargava, R. Modeling and response surface analysis of supercritical extraction of watermelon seed oil using carbon dioxide. Sep. Purif. Technol. 2015, 141, 354–365. [Google Scholar] [CrossRef]

- Da Silva, D.T.; Herrera, R.; Heinzmann, B.M.; Calvo, J.; Labidi, J. Nectandra grandiflora by-products obtained by alternative extraction methods as a source of phytochemicals with antioxidant and antifungal properties. Molecules 2018, 23, 372. [Google Scholar] [CrossRef]

- Chenni, M.; El Abed, D.; Rakotomanomana, N.; Fernandez, X.; Chemat, F. Comparative study of essential oils extracted from egyptian basil leaves (ocimum basilicum l.) using hydro-distillation and solvent-free microwave extraction. Molecules 2016, 21, 113. [Google Scholar] [CrossRef]

- Rovetto, L.J.; Aieta, N.V. Supercritical carbon dioxide extraction of cannabinoids from Cannabis sativa L. J. Supercrit Fluid. 2017, 129, 16–27. [Google Scholar] [CrossRef]

- Kueh, B.W.B.; Yusup, S.; Osman, N. Supercritical carbon dioxide extraction of Melaleuca cajuputi leaves for herbicides allelopathy: Optimization and kinetics modelling. J. CO2 Util. 2018, 24, 220–227. [Google Scholar] [CrossRef]

- Deng, J.; Xu, Z.; Xiang, C.; Liu, J.; Zhou, L.; Li, T.; Yang, Z.; Ding, C. Comparative evaluation of maceration and ultrasonic-assisted extraction of phenolic compounds from fresh olives. Ultrason Sonochem. 2017, 37, 328–334. [Google Scholar] [CrossRef] [PubMed]

- Benito-Román, O.; Rodríguez-Perrino, M.; Sanz, M.T.; Melgosa, R.; Beltrán, S. Supercritical carbon dioxide extraction of quinoa oil: Study of the influence of process parameters on the extraction yield and oil quality. J. Supercrit. Fluid. 2018, 139, 62–71. [Google Scholar] [CrossRef] [Green Version]

- Materazzi, S.; Gregori, A.; Ripani, L.; Apriceno, A.; Risoluti, R. Cocaine profiling: Implementation of a predictive model by ATR-FTIR coupled with chemometrics in forensic chemistry. Talanta 2017, 166, 328–335. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the compounds are not available from the authors. |

| Run | Pattern | X1 | X2 | X3 | X4 | X5 | X6 | Yield (%) | DPPH (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 000001 | 40 | 45 | 9 | 3 | 400 | ET | 14.9 | 54.9 |

| 2 | −−−−−1 | 20 | 30 | 6 | 2 | 300 | PE | 0.5 | 6.0 |

| 3 | −.0−−1 | 20 | 60 | 6 | 2 | 500 | ET | 8.6 | 54.6 |

| 4 | −−.6−1 | 20 | 30 | 12 | 4 | 300 | EA | 9.5 | 33.8 |

| 5 | −7.6−1 | 20 | 60 | 6 | 4 | 300 | PE | 3.6 | 13.0 |

| 6 | −−−−−1 | 20 | 30 | 6 | 2 | 300 | PE | 0.4 | 6.2 |

| 7 | ++−+−0 | 60 | 60 | 6 | 4 | 300 | PE | 11.9 | 22.9 |

| 8 | ++++++ | 60 | 60 | 12 | 4 | 500 | PE | 15.8 | 1.8 |

| 9 | 000003 | 40 | 45 | 9 | 3 | 400 | PE | 10.3 | 5.2 |

| 10 | +−−++− | 60 | 30 | 6 | 4 | 500 | ET | 15.4 | 48.7 |

| 11 | −1.4+− | 20 | 60 | 12 | 2 | 300 | ET | 10.5 | 45.7 |

| 12 | +−−−−+ | 60 | 30 | 6 | 2 | 300 | PE | 9.0 | 1.3 |

| 13 | +++−−− | 60 | 60 | 12 | 2 | 300 | ET | 12.5 | 55.3 |

| 14 | −−.3−− | 20 | 30 | 12 | 2 | 500 | PE | 12.8 | 9.3 |

| 15 | −5.8−− | 20 | 60 | 12 | 4 | 500 | PE | 3.5 | 3.1 |

| 16 | +−+−+0 | 60 | 30 | 12 | 2 | 500 | PE | 13.4 | 10.5 |

| 17 | +−++−− | 60 | 30 | 12 | 4 | 300 | ET | 15.2 | 64.5 |

| 18 | −−−+−− | 20 | 30 | 6 | 4 | 500 | ET | 9.2 | 43.7 |

| 19 | 000002 | 40 | 45 | 9 | 3 | 400 | EA | 9.0 | 12.2 |

| 20 | ++−−+0 | 60 | 60 | 6 | 2 | 500 | PE | 13.3 | 14.6 |

| 21 | ++++++ | 60 | 60 | 12 | 4 | 500 | PE | 15.1 | 1.3 |

| Term | Yield (%) | DPPH (%) | ||

|---|---|---|---|---|

| Estimate | p-Value | Estimate | p-Value | |

| Intercept | 10.64 | <0.0001 | 27.43 | <0.0001 * |

| X1 | 3.26 | 0.0003 * | 1.23 | 0.5380 |

| X2 | −0.07 | 0.9119 | 0.17 | 0.9299 |

| X3 | 1.37 | 0.0592 * | 0.10 | 0.9597 |

| X4 | 0.24 | 0.7271 | 1.04 | 0.6051 |

| X5 | 1.46 | 0.0439 * | −2.94 | 0.1557 |

| X6 [EA] | 0.09 | 0.9498 | −5.79 | 0.2041 |

| X6 [ET] | 1.68 | 0.1114 | 25.06 | <0.0001 * |

| X6 [PE] | −1.77 | 0.0853 * | −19.28 | <0.0001 * |

| ANOVA | 0.0013 * | <0.0001 * | ||

| R2 | 0.7925 | 0.9160 | ||

| RMSE | 2.6787 | 7.9503 | ||

| Yield (%) | DPPH (%) | ||

|---|---|---|---|

| T–1 | PV | 17.1 | 50.8 |

| EV | 17.0 | 49.4 | |

| PE | −0.2 | −2.8 | |

| T–2 | PV | 15.5 | 19.9 |

| EV | 14.0 | 20.6 | |

| PE | −10.1 | 3.1 | |

| T–3 | PV | 13.6 | 6.5 |

| EV | 16.2 | 4.1 | |

| PE | 16.1 | −56.2 |

| No. | Compounds | CAS | Peak Area (%) | |||||

|---|---|---|---|---|---|---|---|---|

| Ultrasonic Extraction | SFE | HD | SE | |||||

| T-1 | T-2 | T-3 | ||||||

| 1 | alpha-Pinene | 80-56-8 | 10 | 10.6 | 13.3 | 20.4 | 15.9 | |

| 2 | alpha-Thujene | 2867-5-2 | 1.2 | 1.1 | 1.1 | |||

| 3 | beta-Pinene | 127-91-3 | 20.7 | 46.0 | 46.1 | 52.4 | 46.7 | 47.2 |

| 4 | Sabinene | 3387-41-5 | 11.4 | 20.9 | 18.8 | 19.4 | 17 | 18.6 |

| 5 | Mycrene | 123-35-3 | 2.4 | 3.2 | 2.8 | 2.5 | 2.4 | 2.6 |

| 6 | alpha-Terpinene | 99-86-5 | 1.0 | 1.0 | ||||

| 7 | Limonene | 138-86-3 | 2.3 | 2.4 | 2.1 | 2.1 | 1.8 | 2.1 |

| 8 | Eucalyptol | 470-82-6 | 4.2 | |||||

| 9 | Terpinene | 99-85-4 | 3.1 | 1.3 | ||||

| 10 | gama-Terpinene | 99-85-4 | 1.0 | 1.8 | 1.1 | |||

| 11 | Cymene | 99-87-6 | 1.4 | |||||

| 12 | Pimelic ketone | 108-94-1 | 1.6 | |||||

| 13 | Menth-2-en-1-ol | 29803-82-5 | 1.3 | 1.1 | ||||

| 14 | Sabinene hydrate | 17699-16-0 | 7.3 | 1.1 | ||||

| 15 | trans-Sabinene hydrate | 176699-16-0 | 8.7 | 1.3 | ||||

| 16 | Terpinen-4-ol | 562-74-3 | 22.6 | 4.3 | 2.8 | 1.4 | 3.5 | 3.8 |

| 17 | trans-Pinocarveol | 1674-08-4 | 1.0 | |||||

| 18 | alpha-Terpineol | 98-55-5 | 2.0 | |||||

| 19 | gama-Cadinene | 39029-41-9 | 1.4 | |||||

| 20 | delta-Cadinene | 483-76-1 | 2.0 | |||||

| Independent Variables | Level in the Experiments | Test Formulation | |||||

|---|---|---|---|---|---|---|---|

| −1 | 0 | 1 | T-1 | T-2 | T-3 | ||

| Time (min) | X1 | 20 | 40 | 60 | 60 | 60 | 60 |

| Temperature (°C) | X2 | 30 | 45 | 60 | 45 | 45 | 45 |

| Solvent-to-solid ratio | X3 | 6 | 9 | 12 | 12 | 12 | 12 |

| Particle size (mm) | X4 | 2 | 3 | 4 | 3 | 3 | 3 |

| Power (W) | X5 | 300 | 400 | 500 | 500 | 500 | 500 |

| Type of solvent | X6 | ET | EA | PE | ET | PE | EA |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ming, L.; Huang, H.; Jiang, Y.; Cheng, G.; Zhang, D.; Li, Z. Quickly Identifying High-Risk Variables of Ultrasonic Extraction Oil from Multi-Dimensional Risk Variable Patterns and a Comparative Evaluation of Different Extraction Methods on the Quality of Forsythia suspensa Seed Oil. Molecules 2019, 24, 3445. https://doi.org/10.3390/molecules24193445

Ming L, Huang H, Jiang Y, Cheng G, Zhang D, Li Z. Quickly Identifying High-Risk Variables of Ultrasonic Extraction Oil from Multi-Dimensional Risk Variable Patterns and a Comparative Evaluation of Different Extraction Methods on the Quality of Forsythia suspensa Seed Oil. Molecules. 2019; 24(19):3445. https://doi.org/10.3390/molecules24193445

Chicago/Turabian StyleMing, Liangshan, Hao Huang, Yumao Jiang, Gengjinsheng Cheng, Daoying Zhang, and Zhe Li. 2019. "Quickly Identifying High-Risk Variables of Ultrasonic Extraction Oil from Multi-Dimensional Risk Variable Patterns and a Comparative Evaluation of Different Extraction Methods on the Quality of Forsythia suspensa Seed Oil" Molecules 24, no. 19: 3445. https://doi.org/10.3390/molecules24193445

APA StyleMing, L., Huang, H., Jiang, Y., Cheng, G., Zhang, D., & Li, Z. (2019). Quickly Identifying High-Risk Variables of Ultrasonic Extraction Oil from Multi-Dimensional Risk Variable Patterns and a Comparative Evaluation of Different Extraction Methods on the Quality of Forsythia suspensa Seed Oil. Molecules, 24(19), 3445. https://doi.org/10.3390/molecules24193445