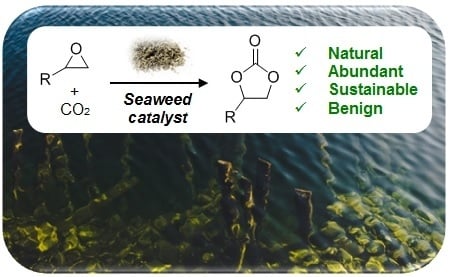

Laminaria digitata and Palmaria palmata Seaweeds as Natural Source of Catalysts for the Cycloaddition of CO2 to Epoxides

Abstract

:1. Introduction

2. Results and Discussion

2.1. Conversion to Styrene Carbonate Using Model Catalyst and Co-Catalyst

2.2. Kelp and Dulse as Catalysts

2.3. Reproducibility Using Different Kelp Seaweeds

2.3.1. Catalytic Activity

2.3.2. Metal Concentrations

2.3.3. Amino Acid Profile and Protein Content

2.4. Reuse of Kelp Seaweeds

2.5. Substrate Scope Using Kelp D as a Catalyst

3. Conclusions

4. Experimental Section

4.1. Chemicals and Equipment

4.2. Seaweed Preparation before Analysis and use as a Catalyst

4.3. Standard Synthesis of Styrene Carbonate Using Metal Halides and/or Amino Acids

4.4. Standard Synthesis of Styrene Carbonate Using Seaweeds Kelp or Dulse

4.5. Synthesis of Different Carbonates Using Kelp D

4.6. Amino Acid Profile

4.7. Reusability Study

4.8. Pressure Study

4.9. Thermal Gravimetric Infrared Spectrometry (TGIR)

4.10. ICP-MS

4.11. 1H-NMR Conversion Calculation

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Smith, M.R.; Myers, S.S. Impact of anthropogenic CO2 emissions on global human nutrition. Nat. Clim. Chang. 2018, 8, 834. [Google Scholar] [CrossRef]

- Dong, K.; Jiang, H.; Sun, R.; Dong, X. Driving forces and mitigation potential of global CO2 emissions from 1980 through 2030: Evidence from countries with different income levels. Sci. Total Environ. 2019, 649, 335–343. [Google Scholar] [CrossRef] [PubMed]

- Foster, G.L.; Rohling, E.J. Relationship between sea level and climate forcing by CO2 on geological timescales. Proc. Natl. Acad. Sci. USA 2013, 110, 1209–1214. [Google Scholar] [CrossRef] [PubMed]

- Munday, P.L.; McCormick, M.I.; Nilsson, G.E. Impact of global warming and rising CO2 levels on coral reef fishes: What hope for the future? J. Exp. Biol. 2012, 215, 3865–3873. [Google Scholar] [CrossRef] [PubMed]

- Cherchi, A.; Masina, S.; Navarra, A. Impact of extreme CO2 levels on tropical climate: A CGCM study. Clim. Dyn. 2008, 31, 743–758. [Google Scholar] [CrossRef]

- Le Quéré, C.; Andres, R.J.; Boden, T.; Conway, T.; Houghton, R.A.; House, J.I.; Marland, G.; Peters, G.P.; van der Werf, G.; Ahlström, A.; et al. The global carbon budget 1959–2011. Earth Syst. Sci. Data 2013, 5, 165–185. [Google Scholar] [CrossRef] [Green Version]

- Harwatt, H.; Sabat, J.; Eshel, G.; Soret, S.; Ripple, W. Substituting beans for beef as a contribution toward US climate change targets. Clim. Chang. 2017, 143, 261–270. [Google Scholar] [CrossRef]

- Lerner, H.; Algers, B.; Gunnarsson, S.; Nordgren, A. Stakeholders on Meat Production, Meat Consumption and Mitigation of Climate Change: Sweden as a Case. J. Agric. Environ. Ethics 2013, 26, 663–678. [Google Scholar] [CrossRef]

- Nordgren, A. Ethical Issues in Mitigation of Climate Change: The Option of Reduced Meat Production and Consumption. J. Agric. Environ. Ethics 2012, 25, 563–584. [Google Scholar] [CrossRef]

- Iwasa, S.; Nishi, T.; Nakamura, S. Enhancement of rapid charging capability of organic radical battery using ethylene carbonate-based electrolyte containing LiFSI. J. Power Sources 2018, 402, 157–162. [Google Scholar] [CrossRef]

- Clark, J.H.; Farmer, T.J.; Ingram, I.D.V.; Lie, Y.; North, M. Renewable Self-Blowing Non-Isocyanate Polyurethane Foams from Lysine and Sorbitol. Eur. J. Org. Chem. 2018, 31, 4265–4271. [Google Scholar] [CrossRef]

- Tominaga, Y. Ion-conductive polymer electrolytes based on poly(ethylene carbonate) and its derivatives. Polym. J. 2017, 49, 291–299. [Google Scholar] [CrossRef]

- Guerin, W.; Diallo, A.K.; Kirilov, E.; Helou, M.; Slawinski, M.; Brusson, J.M.; Carpentier, J.F.; Guillaume, S.M. Enantiopure Isotactic PCHC Synthesized by Ring-Opening Polymerization of Cyclohexene Carbonate. Macromolecules 2014, 47, 4230–4235. [Google Scholar] [CrossRef]

- Jun, J.O.; Lee, J.; Kang, K.H.; Song, I.K. Synthesis of Dimethyl Carbonate from Ethylene Carbonate and Methanol Over Nano-Catalysts Supported on CeO2-MgO. J. Nanosci. Nanotechnol. 2015, 15, 8330–8335. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Liu, S.; Zhoua, F.; Yanga, B.; Alshammari, A.S.; Lu, L.; Deng, Y. Two-step synthesis of dimethyl carbonate from urea, ethylene glycol and methanol using acid–base bifunctional zinc-yttrium oxides. Fuel Process. Technol. 2014, 126, 359–365. [Google Scholar] [CrossRef]

- Parker, H.L.; Sherwood, J.; Hunt, A.J.; Clark, J.H. Cyclic Carbonates as Green Alternative Solvents for the Heck Reaction. ACS Sustain. Chem. Eng. 2014, 2, 1739–1742. [Google Scholar] [CrossRef]

- Castro-Osma, J.A.; Comerford, J.W.; Heath, S.; Jones, O.; Morcillo, M.; North, M. Quinine catalysed asymmetric Michael additions in a sustainable solvent. RSC Adv. 2015, 5, 3678–3685. [Google Scholar] [CrossRef]

- Wu, X.; North, M. A Bimetallic Aluminium(Salphen) Complex for the Synthesis of Cyclic Carbonates from Epoxides and Carbon Dioxide. ChemSusChem 2017, 10, 74–78. [Google Scholar] [CrossRef]

- Whiteoak, C.J.; Kielland, N.; Laserna, V.; Escudero-Adan, E.C.; Martin, E.; Kleij, A.W. A Powerful Aluminum Catalyst for the Synthesis of Highly Functional Organic Carbonates. JACS 2013, 135, 1228–1231. [Google Scholar] [CrossRef]

- Liang, S.; Liu, H.; Jiang, T.; Song, J.; Yang, G.; Han, B. Highly efficient synthesis of cyclic carbonates from CO2 and epoxides over cellulose/KI. Chem. Commun. 2011, 47, 2131–2133. [Google Scholar] [CrossRef]

- Song, J.; Zhang, Z.; Han, B.; Hu, S.; Li, W.; Xie, Y. Synthesis of cyclic carbonates from epoxides and CO2 catalyzed by potassium halide in the presence of β-cyclodextrin. Green Chem. 2008, 10, 1337. [Google Scholar] [CrossRef]

- Song, J.; Zhang, B.; Zhang, P.; Ma, J.; Liu, J.; Fan, H.; Jiang, T.; Han, B. Highly efficient synthesis of cyclic carbonates from CO2 and epoxides catalyzed by KI/lecithin. Catal. Today 2012, 183, 130–135. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, S.; Ma, X.; Liang, S.; Jiang, T.; Han, B. Synthesis of cyclic carbonates from carbon dioxide and epoxides over betaine-based catalysts. J. Mol. Catal. Chem. 2008, 284, 52–57. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, H. Histidine-catalyzed synthesis of cyclic carbonates in supercritical carbon dioxide. Sci. China Chem. 2010, 53, 1566–1570. [Google Scholar] [CrossRef]

- Fraas, F.; Partridge, E.P. Potash from Polyhalite by Reduction Process Extraction of Potassium and the Production of Potassium Carbonate. Ind. Eng. Chem. 1936, 28, 956–962. [Google Scholar] [CrossRef]

- Aronov, A.G.; Mukhamediyev, S.A.; Aronova, T.I. Stress state of the earth’s crust and seismicity in a potassium salt mining region of Belarus. Acta Geod. Geophys. 2014, 49, 125–134. [Google Scholar] [CrossRef]

- Ladrera, R.; Canedo-Arguelles, M.; Prat, N. Impact of potash mining in streams: The Llobregat basin (northeast Spain) as a case study. J. Limnol. 2017, 76, 343–354. [Google Scholar] [CrossRef]

- Jeswiet, J.; Archibald, J.; Thorley, U.; De Souza, E. Energy Use in Premanufacture (Mining). Procedia CIRP 2015, 29, 816–821. [Google Scholar] [CrossRef]

- Key, T.J.A.; Thorogood, M.; Keenan, J.; Long, A. Raised thyroid stimulating hormone associated with kelp intake in British vegan men. J. Hum. Nutr. Diet. 1992, 5, 323–326. [Google Scholar] [CrossRef]

- Mussig, K.; Thamer, C.; Bares, R.; Lipp, H.P.; Haring, H.U.; Gallwitz, B. Iodine-Induced Thyrotoxicosis After Ingestion of Kelp-Containing Tea. J. Gen. Intern. Med. 2006, 21, C11–C14. [Google Scholar] [CrossRef] [Green Version]

- Rosen, J.E.; Gardiner, P.; Saper, R.B.; Pearce, E.N.; Hammer, K.; Gupta-Lawrence, R.L.; Lee, S.L. Kelp use in patients with thyroid cancer. Endocrine 2014, 46, 123–130. [Google Scholar] [CrossRef]

- Peng, Y.; Hu, J.; Yang, B.; Lin, X.P.; Zhou, X.F.; Yang, X.W.; Liu, Y. Chapter 5—Chemical composition of seaweeds, Chapter 6—Seaweed proteins, peptides, and amino acids and Chapter 7—Seaweed Carbohydrates. In Seaweed Sustainability—Food and Non-Food Applications, 1st ed.; Tiwari, B.K., Troy, D.J., Eds.; Academic Press Elsevier: London, UK, 2015. [Google Scholar]

- Blunden, G.; Challen, S.B.; Woods, D.L. Seaweed extracts as fertilisers. J. Sci. Food Agric. 1968, 19, 289–292. [Google Scholar] [CrossRef] [PubMed]

- Bixler, H.J.; Porse, H. A decade of change in the seaweed hydrocolloids industry. J. Appl. Phycol. 2011, 23, 321–335. [Google Scholar] [CrossRef]

- Makkar, H.P.S.; Tran, G.; Heuzé, V.; Giger-Reverdin, S.; Lessire, M.; Lebas, F.; Ankers, P. Seaweeds for livestock diets: A review. Anim. Feed Sci. Technol. 2016, 212, 1–17. [Google Scholar] [CrossRef]

- Roshan, K.R.; Kathalikkattil, A.C.; Tharun, J.; Kim, D.W.; Won, Y.S.; Park, D.W. Amino acid/KI as multi-functional synergistic catalysts for cyclic carbonate synthesis from CO2 under mild reaction conditions: A DFT corroborated study. Dalton Trans. 2014, 43, 2023–2031. [Google Scholar] [CrossRef] [PubMed]

- Roshan, K.; Kathalikkattil, A.; Tharun, J.; Kim, D.; Won, Y.; Qi, Y.; Cheng, W.; Xu, F.; Chen, S.; Zhang, S. Amino acids/superbases as eco-friendly catalyst system for the synthesis of cyclic carbonates under metal-free and halide-free conditions. Synth. Commun. 2018, 48, 876–886. [Google Scholar] [CrossRef]

- Home—Irish Seaweeds. Available online: www.Irishseaweeds.com (accessed on 14 April 2016).

- Beebe, T.R.; Hii, P.; Reinking, P. Oxidative cleavage of 1,2-diols with N-iodosuccinimide. J. Org. Chem. 1981, 46, 1927–1929. [Google Scholar] [CrossRef]

- Mojtahedi, M.M.; Saidi, M.R.; Bolourtchian, M.; Shirzi, J.S. Microwave assisted selective oxidation of benzylic alcohols with calcium hypochlorite under solvent-free conditions. Monatsh. Chem. 2001, 132, 655–658. [Google Scholar] [CrossRef]

- Ren, Q.G.; Chen, S.Y.; Zhou, X.T.; Ji, H.B. Highly efficient controllable oxidation of alcohols to aldehydes and acids with sodium periodate catalyzed by water-soluble metalloporphyrins as biomimetic catalyst. Bioorg. Med. Chem. 2010, 18, 8144–8149. [Google Scholar] [CrossRef]

- Spaha, I.F.; Edsall, J.T. Amino Acid Composition of Human and Bovine Serum Mercaptalbumins. J. Biol. Chem. 1964, 239, 850–854. [Google Scholar]

- Meussen, B.J.; van Zeeland, A.N.T.; Bruins, M.E.; Sanders, J.P.M. A Fast and Accurate UPLC Method for Analysis of Proteinogenic Amino Acids. Food Anal. Methods 2014, 7, 1047–1055. [Google Scholar] [CrossRef]

Sample Availability: Not available. |

| Amino Acid Co-catalyst | Conversion to 2a Using Metal Halide Catalyst 1 | Basic Sites 2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| KI | KBr | KCl | NaI | NaBr | NaCl | CaCl2 | None | ||

| Histidine | 75.2 | 76.3 | 61.7 | 49.8 | 67.2 | 77.5 | 80.0 | 39.1 | 1 (2°) |

| Lysine | 63.9 | 44.1 | 8.0 | 56.2 | 58.8 | 12.1 | 18.7 | 9.7 | 1 (1°) |

| Glycine | 79.5 | 10.2 | 0.8 | 97.1 | 41.2 | 0.0 | 11.8 | 0.0 | 0 |

| None | 100.0 | 0.9 | 1.0 | 23.1 | 2.8 | 1.0 | 0.0 | 0.0 | 0 |

| Seaweed | Particle Size (µm) | Carbonate 2a (%) | Diol 3a (%) | BA 1 4a (%) | CPE 2 5a (%) | PAA 3 6a (%) | Total Conversion from 1a (%) | Selectivity (%) |

|---|---|---|---|---|---|---|---|---|

| Kelp | <125 | 29.9 | 47.9 | 0.6 | 10.5 | 1.8 | 90.1 | 33.2 |

| 125–300 | 2.9 | 59.0 | 0.3 | 12.9 | 0.8 | 75.6 | 3.8 | |

| 300–500 | 33.2 | 23.9 | 0.7 | 9.0 | 1.7 | 67.8 | 49.0 | |

| Dulse | <125 | 19.4 | 26.4 | 0.4 | 5.2 | 0.8 | 52.2 | 37.2 |

| 125–300 | 4.3 | 25.1 | 0.4 | 4.9 | 0.6 | 34.8 | 12.3 | |

| 300–500 | 16.2 | 14.0 | 0.5 | 4.4 | 1.0 | 35.5 | 45.7 |

| Kelp | Particle Size/µm | Carbonate 2a (%) | Diol 3a (%) | BA 4a (%) | CPE 5a (%) | PAA 6a (%) | Total Conversion from 1a (%) | Selectivity (%) 3 |

|---|---|---|---|---|---|---|---|---|

| Kelp B (18/09/17) 1 | <125 | 27.6 | 26.2 | 0.5 | 12.3 | 2.0 | 68.1 | 40.5 |

| 125–300 | 8.4 | 24.0 | 0.5 | 11.3 | 1.7 | 45.4 | 18.5 | |

| 300–500 | 19.9 | 22.2 | 0.5 | 9.8 | 2.1 | 53.6 | 35.3 | |

| >500 | 6.9 | 38.0 | 0.6 | 15.6 | 1.9 | 62.4 | 11.1 | |

| Kelp C (15/11/17) 1 | <125 | 26.4 | 27.4 | 0.5 | 12.2 | 1.7 | 67.6 | 39.0 |

| 125–300 | 5.9 | 30.5 | 0.5 | 13.0 | 1.5 | 50.9 | 11.6 | |

| 300–500 | 21.7 | 23.8 | 0.5 | 10.9 | 1.8 | 58.2 | 37.2 | |

| >500 | 25.6 | 32.7 | 0.4 | 13.2 | 3.1 | 74.7 | 34.4 | |

| Kelp D (20/11/17) 1 | <125 | 38.8 (63.7) 2 | 35.2 (28.2) | 0.6 (0.1) | 11.3 (8.1) | 1.6 (0.07) | 86.9 (100) | 44.6 (63.7) |

| 125–300 | 9.4 | 37.5 | 0.6 | 15.4 | 1.5 | 63.7 | 14.7 | |

| 300–500 | 30.2 | 27.7 | 0.6 | 11.4 | 1.5 | 70.8 | 42.6 | |

| >500 | 37.3 | 36.2 | 0.3 | 12.6 | 2.5 | 88.6 | 42.1 |

| Kelp | Harvest Date | Metal Concentrations (mg g−1) | <125 µm Conversion to 2a (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Li | Na | Mg | Al | K | Ca | Fe | Cu | Zn | Sr | Ba | |||

| B | 18/09/17 | 0.02 | 41.3 | 8.5 | 0.22 | 15.4 | 17.2 | 0.11 | 0.13 | 0.67 | 1.36 | 0.06 | 27.6 |

| C | 15/11/17 | 0.02 | 43.9 | 10.4 | 0.27 | 14.5 | 14.5 | 0.10 | 0.09 | 0.33 | 1.17 | 0.09 | 26.4 |

| D | 20/11/17 | 0.02 | 48.6 | 10.3 | 0.36 | 25.4 | 13.3 | 0.21 | 0.12 | 0.26 | 1.13 | 0.07 | 38.8 |

| Kelp | Use | Carbonate 2a (%) | Reduction in Activity (%) 1 | Diol 3a (%) | Ratio 2a:3a | BA 4a (%) | CPE 5a (%) | PAA 6a (%) | Selectivity (%) |

|---|---|---|---|---|---|---|---|---|---|

| B | 1st | 27.6 | - | 26.2 | 1:0.95 | 0.5 | 12.3 | 2.0 | 40.5 |

| 2nd | 6.4 | 76.8 | 21.9 | 1:3.47 | 0.4 | 5.5 | 0.9 | 18.4 | |

| C | 1st | 26.4 | - | 27.4 | 1:1.04 | 0.5 | 12.2 | 1.7 | 39.0 |

| 2nd | 7.5 | 71.6 | 23.7 | 1:3.15 | 0.4 | 6.6 | 1.0 | 19.4 | |

| D | 1st | 38.8 | - | 35.2 | 1:0.91 | 0.6 | 11.3 | 1.6 | 44.6 |

| 2nd | 16.3 | 58.0 | 20.3 | 1:1.25 | 0.8 | 6.5 | 1.2 | 44.2 |

| Epoxide | 2a–g (%) | 3a–g (%) | Ratio 2a–g:3a–g | 4a–g (%) | 5a–g (%) | 6a–g (%) | Total Conversion from 1a (%) | Selectivity (%) |

|---|---|---|---|---|---|---|---|---|

| 1a | 38.8 | 35.2 | 1:0.91 | 0.6 | 11.3 | 1.6 | 86.9 | 44.6 |

| 1b | 43.8 | 28.7 | 1:0.66 | 0.03 | 27.4 | 0 | 100 | 43.8 |

| 1c | 42.2 | 44.7 | 1:1.06 | 0.0 | 13.0 | 0 | 100 | 42.2 |

| 1d 1 | 20.6 | 20.8 | 1:1.01 | 0.4 | 0.6 | 0.4 | 54.6 | 37.7 |

| 1e | 0.5 | 8.6 | 1:18.5 | 0.0 | 0.0 | 0.1 | 9.1 | 5.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Comerford, J.W.; Gray, T.; Lie, Y.; Macquarrie, D.J.; North, M.; Pellis, A. Laminaria digitata and Palmaria palmata Seaweeds as Natural Source of Catalysts for the Cycloaddition of CO2 to Epoxides. Molecules 2019, 24, 269. https://doi.org/10.3390/molecules24020269

Comerford JW, Gray T, Lie Y, Macquarrie DJ, North M, Pellis A. Laminaria digitata and Palmaria palmata Seaweeds as Natural Source of Catalysts for the Cycloaddition of CO2 to Epoxides. Molecules. 2019; 24(2):269. https://doi.org/10.3390/molecules24020269

Chicago/Turabian StyleComerford, James W., Thomas Gray, Yann Lie, Duncan J. Macquarrie, Michael North, and Alessandro Pellis. 2019. "Laminaria digitata and Palmaria palmata Seaweeds as Natural Source of Catalysts for the Cycloaddition of CO2 to Epoxides" Molecules 24, no. 2: 269. https://doi.org/10.3390/molecules24020269