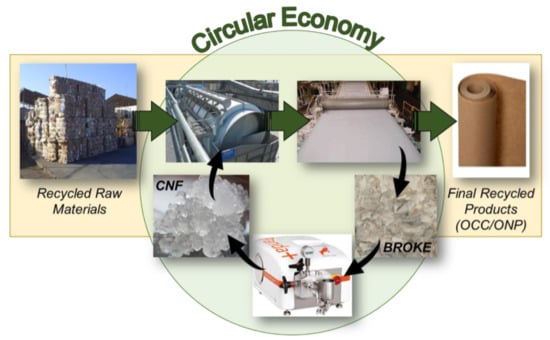

In Situ Production and Application of Cellulose Nanofibers to Improve Recycled Paper Production

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization of CNF from Recycled ONP and Recycled OCC Pulps

2.2. Effect of CNF Content on Recycled Paper and Cartonboard Properties

2.3. Effect of CNF on Retention and Drainage Process

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. CNF Production and Characterization

3.2.2. Handsheet Preparation and Characterization

3.2.3. Retention and Drainage Measurements

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Miranda, R.; Bobu, E.; Grossmann, H.; Stawicki, B.; Blanco, A. Factors influencing a higher use of recovered paper in the european paper industry. Cellul. Chem. Technol. 2010, 44, 419–430. [Google Scholar]

- Blanco, A.; Miranda, R.; Monte, M.C. Extending the limits of paper recycling: Improvements along the paper value chain. For. Syst. 2013, 22, 471–483. [Google Scholar] [CrossRef]

- CEPI. Key Statistics 2017. European Pulp and Paper Industry; CEPI: Brussels, Belgium, 2017; Available online: http://www.cepi.org/system/files/public/documents/publications/statistics/2018/210X140_CEPI_Brochure_KeyStatistics2017_WEB.pdf (accessed on 3 April 2019).

- Blanco, A.; Monte, M.C.; Campano, C.; Balea, A.; Merayo, N.; Negro, C. Nanocellulose for Industrial Use: Cellulose Nanofibers (CNF), Cellulose Nanocrystals (CNC), and Bacterial Cellulose (BC). In Handbook of Nanomaterials for Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 74–126. [Google Scholar]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindstrom, T.; Nietzsche, S.; et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef]

- Osong, S.H.; Norgren, S.; Engstrand, P. Processing of wood-based microfibrillated cellulose and nanofibrillated cellulose, and applications relating to papermaking: A review. Cellulose 2016, 23, 93–123. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Mariano, M.; Huang, J.; Lin, N.; Ahmad, I.; Dufresne, A.; Thomas, S. Recent developments on nanocellulose reinforced polymer nanocomposites: A review. Polymer 2017, 132, 368–393. [Google Scholar] [CrossRef]

- Dufresne, A. Cellulose nanomaterials as green nanoreinforcements for polymer nanocomposites. Philos. Trans. R. Soc. A 2018, 376, 2112. [Google Scholar] [CrossRef]

- Balea, A.; Blanco, A.; Negro, C. Nanocelluloses: Natural-Based Materials for Fiber-Reinforced Cement Composites. A Critical Review. Polymers 2019, 11, 518. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Mascheroni, E.; Piergiovanni, L. The potential of nanocellulose in the packaging field: A review. Packag. Technol. Sci. 2015, 28, 475–508. [Google Scholar] [CrossRef]

- Hoeng, F.; Denneulin, A.; Bras, J. Use of nanocellulose in printed electronics: A review. Nanoscale 2016, 8, 13131–13154. [Google Scholar] [CrossRef] [PubMed]

- Jorfi, M.; Foster, E.J. Recent advances in nanocellulose for biomedical applications. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X.H. Review of the applications of biocomposites in the automotive industry. Polym. Compos. 2017, 38, 2553–2569. [Google Scholar] [CrossRef]

- Balea, A.; Blanco, A.; Monte, M.C.; Merayo, N.; Negro, C. Effect of Bleached Eucalyptus and Pine Cellulose Nanofibers on the Physico-Mechanical Properties of Cartonboard. Bioresources 2016, 11, 8123–8138. [Google Scholar] [CrossRef]

- Balea, A.; Merayo, N.; Fuente, E.; Delgado-Aguilar, M.; Mutje, P.; Blanco, A.; Negro, C. Valorization of Corn Stalk by the Production of Cellulose Nanofibers to Improve Recycled Paper Properties. Bioresources 2016, 11, 3416–3431. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Gonzalez, I.; Pelach, M.A.; De La Fuente, E.; Negro, C.; Mutje, P. Improvement of deinked old newspaper/old magazine pulp suspensions by means of nanofibrillated cellulose addition. Cellulose 2015, 22, 789–802. [Google Scholar] [CrossRef]

- Eriksen, O.; Syverud, K.; Gregersen, O. The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nord. Pulp. Pap. Res. J. 2008, 23, 299–304. [Google Scholar] [CrossRef]

- Gonzalez, I.; Boufi, S.; Pelach, M.A.; Alcala, M.; Vilaseca, F.; Mutje, P. Nanofibrillated Cellulose as Paper Additive in Eucalyptus Pulps. Bioresources 2012, 7, 5167–5180. [Google Scholar] [CrossRef]

- Taipale, T.; Osterberg, M.; Nykanen, A.; Ruokolainen, J.; Laine, J. Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 2010, 17, 1005–1020. [Google Scholar] [CrossRef]

- Petroudy, S.R.D.; Syverud, K.; Chinga-Carrasco, G.; Ghasemain, A.; Resalati, H. Effects of bagasse microfibrillated cellulose and cationic polyacrylamide on key properties of bagasse paper. Carbohydr. Polym. 2014, 99, 311–318. [Google Scholar] [CrossRef]

- Balea, A.; Merayo, N.; De La Fuente, E.; Negro, C.; Blanco, A. Assessing the influence of refining, bleaching and TEMPO-mediated oxidation on the production of more sustainable cellulose nanofibers and their application as paper additives. Ind. Crop Prod. 2017, 97, 374–387. [Google Scholar] [CrossRef]

- Jonoobi, M.; Mathew, A.P.; Oksman, K. Producing low-cost cellulose nanofiber from sludge as new source of raw materials. Ind. Crop Prod. 2012, 40, 232–238. [Google Scholar] [CrossRef]

- Campano, C.; Miranda, R.; Merayo, N.; Negro, C.; Blanco, A. Direct production of cellulose nanocrystals from old newspapers and recycled newsprint. Carbohydr. Polym. 2017, 173, 489–496. [Google Scholar] [CrossRef] [PubMed]

- Campano, C.; Merayo, N.; Balea, A.; Tarres, Q.; Delgado-Aguilar, M.; Mutje, P.; Negro, C.; Blanco, A. Mechanical and chemical dispersion of nanocelluloses to improve their reinforcing effect on recycled paper. Cellulose 2018, 25, 269–280. [Google Scholar] [CrossRef]

- Campano, C.; Merayo, N.; Negro, C.; Blanco, A. In situ production of bacterial cellulose to economically improve recycled paper properties. Int. J. Biol. Macromol. 2018, 118, 1532–1541. [Google Scholar] [CrossRef] [PubMed]

- Chirayil, C.J.; Mathew, L.; Thomas, S. Review of recent research in nano cellulose preparation from different lignocellulosic fibers. Rev. Adv. Mater. Sci. 2014, 37, 20–28. [Google Scholar]

- Mishra, R.K.; Sabu, A.; Tiwari, S.K. Materials chemistry and the futurist eco-friendly applications of nanocellulose: Status and prospect. J. Saudi Chem. Soc. 2018, 22, 949–978. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Gonzalez, I.; Tarres, Q.; Pelach, M.A.; Alcala, M.; Mutje, P. The key role of lignin in the production of low-cost lignocellulosic nanofibres for papermaking applications. Ind. Crop Prod. 2016, 86, 295–300. [Google Scholar] [CrossRef]

- Ferrer, A.; Quintana, E.; Filpponen, I.; Solala, I.; Vidal, T.; Rodriguez, A.; Laine, J.; Rojas, O.J. Effect of residual lignin and heteropolysaccharides in nanofibrillar cellulose and nanopaper from wood fibers. Cellulose 2012, 19, 2179–2193. [Google Scholar] [CrossRef]

- Ferrer, A.; Filpponen, I.; Rodriguez, A.; Laine, J.; Rojas, O.J. Valorization of residual Empty Palm Fruit Bunch Fibers (EPFBF) by microfluidization: Production of nanofibrillated cellulose and EPFBF nanopaper. Bioresource Technol. 2012, 125, 249–255. [Google Scholar] [CrossRef]

- Merayo, N.; Balea, A.; de la Fuente, E.; Blanco, A.; Negro, C. Interactions between cellulose nanofibers and retention systems in flocculation of recycled fibers. Cellulose 2017, 24, 677–692. [Google Scholar] [CrossRef]

- Merayo, N.; Balea, A.; de la Fuente, E.; Blanco, A.; Negro, C. Synergies between cellulose nanofibers and retention additives to improve recycled paper properties and the drainage process. Cellulose 2017, 24, 2987–3000. [Google Scholar] [CrossRef]

- Balea, A.; Merayo, N.; Fuente, E.; Negro, C.; Delgado-Aguilar, M.; Mutje, P.; Blanco, A. Cellulose nanofibers from residues to improve linting and mechanical properties of recycled paper. Cellulose 2018, 25, 1339–1351. [Google Scholar] [CrossRef]

- Johnson, D.A.; Paradis, M.A.; Bilodeau, M.; Crossley, B.; Foulger, M.; Gelinas, P. Effects of cellulosic nanofibrils on papermaking properties of fine papers. Tappi. J. 2016, 15, 395–402. [Google Scholar]

- Balea, A.; Blanco, A.; Merayo, N.; Negro, C. Effect of nanofibrillated cellulose to reduce linting on high filler-loaded recycled papers. Appita J. 2016, 69, 148–156. [Google Scholar]

- Saito, T.; Kimura, S.; Nishiyama, Y.; Isogai, A. Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 2007, 8, 2485–2491. [Google Scholar] [CrossRef] [PubMed]

- Habibi, Y.; Chanzy, H.; Vignon, M.R. TEMPO-mediated surface oxidation of cellulose whiskers. Cellulose 2006, 13, 679–687. [Google Scholar] [CrossRef]

- Marx-Figini, M. Significance of the intrinsic viscosity ratio of unsubstituted and nitrated cellulose in different solvents. Die Angew. Makromol. Chem. 1978, 72, 161–171. [Google Scholar] [CrossRef]

- Henriksson, M.; Berglund, L.A.; Isaksson, P.; Lindstrom, T.; Nishino, T. Cellulose nanopaper structures of high toughness. Biomacromolecules 2008, 9, 1579–1585. [Google Scholar] [CrossRef]

Sample Availability: Not available. |

| Item | Units | Recycled ONP | Recycled OCC |

|---|---|---|---|

| Fibers | |||

| Length weighted in length | (μm) | 861 | 1054 |

| Average width | (μm) | 21.4 | 22.2 |

| Coarseness | (mg/m) | 0.141 | 0.159 |

| Microfibrils | (%) | 1.72 | 1.35 |

| Broken ends | (%) | 37.2 | 34.1 |

| Average angle | (º) | 130.3 | 133.5 |

| Kinked fibers | (%) | 13.70 | 13.54 |

| Average curl | (%) | 5.89 | 5.64 |

| Pulps | |||

| Kappa index | 40 | 72 | |

| Fibers | (number × 106/g) | 15.82 | 11.80 |

| Aggregates | (number/g) | 98,837 | 92,667 |

| Fines | (number/g) | 118,646 | 92,322 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balea, A.; Sanchez-Salvador, J.L.; Monte, M.C.; Merayo, N.; Negro, C.; Blanco, A. In Situ Production and Application of Cellulose Nanofibers to Improve Recycled Paper Production. Molecules 2019, 24, 1800. https://doi.org/10.3390/molecules24091800

Balea A, Sanchez-Salvador JL, Monte MC, Merayo N, Negro C, Blanco A. In Situ Production and Application of Cellulose Nanofibers to Improve Recycled Paper Production. Molecules. 2019; 24(9):1800. https://doi.org/10.3390/molecules24091800

Chicago/Turabian StyleBalea, Ana, Jose Luis Sanchez-Salvador, M. Concepcion Monte, Noemi Merayo, Carlos Negro, and Angeles Blanco. 2019. "In Situ Production and Application of Cellulose Nanofibers to Improve Recycled Paper Production" Molecules 24, no. 9: 1800. https://doi.org/10.3390/molecules24091800