Reactive & Efficient: Organic Azides as Cross-Linkers in Material Sciences

Abstract

:1. Introduction

1.1. General Comments for Azides

1.2. Synthesis of Azides, General Considerations

- Alkyl azides (e.g., 1,6-diazidohexane, see below):

- ◦

- Nucleophilic substitution reactions

- ◦

- Addition of hydrazoic acid to double bonds

- Aryl azides:

- ◦

- Reaction of diazonium salts with azide ions

- Sulfonyl azides (e.g., 4,4-oxydibenzenesulphonylazide (SDO)):

- ◦

- Reaction of sulfonyl halides with inorganic azides

- ◦

- Reaction of sulfonyl hydrazides with nitric acid

- Carbonyl azides:

- ◦

- Reaction of reactive carbonyl compounds with azides

1.3. Reaction of Azides—General Considerations

- Thermal or photolytic generation and further reaction of nitrenes

- Cycloadditions

- Reaction with nucleophiles

- ◦

- Staudinger reaction

- Rearrangements

2. Azido-Based High Energy Materials

2.1. Azido Binders

2.2. Azido Plasticizers

3. Cross-Linking with Organic Azides (Part I): Organic Semiconductor Devices

3.1. Bisazides: The Forefathers of Photosensitizers in Lithography

3.2. Photovoltaics—Higher Performance with Locked Morphology

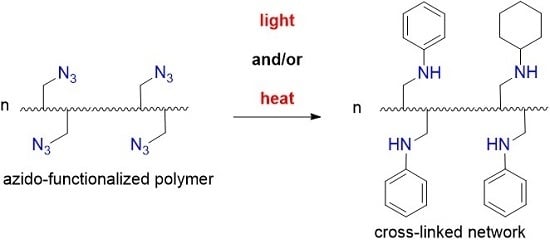

3.2.1. Azido Polymers

3.2.2. Small Molecule Azide Crosslinkers

3.3. Multilayered and Photopatternable OFETs and Organic Light-Emitting Diode (OLEDs)

3.4. Stretchable Polymer Semiconductors

4. Cross-Linking with Organic Azides (Part II): Exchange Membranes

4.1. Azides in Proton Exchange Membranes

4.2. Anion Exchange Membranes

5. Cross-Linking with Organic Azides (Part III): More Applications

5.1. Long-Chain Branching in Polyolefins

5.2. Dynamic Vulcanization

5.3. Nanoparticles

5.4. Hydrogels

5.5. Porous and Gel-Like Materials with Azides

6. Polymerization Reactions with Azides

6.1. The aza-Wittig Polymerization towards Poly(azomethine)s

6.2. The Staudinger Reaction towards Polyphosphazenes

6.3. Multicomponent Reactions with Azides

7. Summary

List of Abbreviations

| (HxN3)2-SiPc | bis(6-azidohexanoate)silicon phthalocyanine |

| 1,3-BDSA | 1,3-benzenedisulfonyl azide |

| AAPMA | 4-(acyl azido) phenylmethacrylate |

| ABAMPA | azido ester 3-azido-2,2-bis(azidomethyl)propyl 2-azidoacetate |

| BABAMP | 1,3-bis (azido acetoxy)-2,2-bis(azidomethyl) propane |

| BABP | 4,4′-bis(azidomethyl)-1,1′-biphenyl |

| BCB | benzocyclobutene |

| BDAP | bis(2,3-diazidopropylene glycol) |

| BHJ | bulk heterojunction |

| bu-NENA | butyl nitrato ethyl nitramine |

| ButBAMP | 2,2-bis(azidomethyl)propane-1,3-diyl dibutyrate |

| CA | 1,3-dipolar cycloaddition |

| CuI | copper(I) iodide |

| DADFH | 1,7-diazido-N,N,N′,N′-tetrafluoro-4,4-heptanediamine |

| DAZH | 1,6-diazidohexane |

| DEGBAA | diethylene glycol bis(azidoacetate) |

| DFT | density functional theory |

| DIANP | 1,5-diazido-3-nitrazapentane |

| DPP-10C5DE | diketopyrrolopyrrole with diethylpentanediyl linker |

| DPPTPTA | 3,6-bis(5-(4,4″-bis(3-azidopropyl)-(1,1′:3′,1″-terphenyl)-5′-yl)thiophen-2-yl)-2,5-bis(2-ethylhexyl)-2,5-dihydropyrrolo(3,4-c)pyrrole-1,4-dione |

| DUV | deep UV |

| EGBAA | ethylene glycol bis(azidoacetate) |

| ETPE | energetic thermoplastic elastomers |

| F8BT | poly(9,9-dioctylfluorene-alt-benzothiadiazole) |

| FPA | bis(4-azido-2,3,5,6-tetrafluoro-benzoate) |

| GAP | glycidyl azide polymer |

| iPP | isotactic polypropylene |

| LED | light-emitting diode |

| N3-(CPDT(FBTTh2)2) | 4-4′-bis(1-azido)undecane)dicyclopenta-(2,1-b:3,4-b′)dithio-phene-bis(5-fluoro-7-(5′-hexyl-(2,2′-bithiophene)-5-yl)benzo-(c)(1,2,5)thiadiazole) |

| NIPAM | N-isopropylacrylamide |

| NP | nanoparticle |

| OFET | organic field-effect transistor |

| OLED | organic light-emitting diode |

| OPV | organic photovoltaics |

| OSC | organic solar cell |

| P3HT | poly(3-hexylthio-phene-2,5-diyl) |

| PA | phosphoric acid |

| PC61BM | phenyl-C61-butyric acid methyl ester |

| PC71BM | (6,6)-phenyl-C71-butyric acid methyl ester |

| PCBM | phenyl-Cn-butyric acid methyl ester (in general C61) |

| PCE | power conversion efficiency |

| PDMS | poly(dimethylsiloxane) |

| PEDT | poly(3,4-ethylenedioxythiophene) |

| PEMFCs | proton exchange membrane fuel cells |

| DMFCs | direct methanol fuel cells |

| PETKAA | pentaerythritol tetrakis(azidoacetate) |

| PFBA | propane-1,3-diyl bis(4-azido-2,3,5,6-tetrafluorobenzoate) |

| PMIPK | poly(methyl isopropenyl ketone |

| PMMA | poly(methyl methacrylate |

| poly-AMMO | poly(3-azidomethyl-3-methyloxetane) |

| poly-BAMO | poly(3,3–bis(azidomethyl)oxetane) |

| POSS | polyhedral oligomeric silsesquioxanes |

| pp | polypropylene |

| PSSH | poly(styrenesulfonic acid) |

| PTAA | poly(triaryl amine) |

| PTPA | poly(triphenylamine) |

| PVK:PBD | poly(vinylcarbazole)-2-tert-butylphenyl-5-biphenyl-1,3,4-oxadiazol |

| rGO | reduced graphene |

| SDO | 4,4′-oxybis-benzenesulfonyl azide |

| sFPA | sterically hindered bis(fluorophenyl azides) |

| SiIDT-BT/PC71BM | silaindacenodithiophene-benzotriazole |

| SPES | poly(ether sulfone) |

| TAP-Ac | triazido pentaerythrite acetate |

| TBA-X | 1,2-bis((4-(azidomethyl)phenethyl)thio)ethane |

| TFB | poly(9,9 di-n-octylfluorene-alt-(1,4-phenylene-((4-sec-butylphenyl)imino)-1,4-phenylene) |

| THF | tetrahydrofuran |

| TMETA | 1,1,1-tris(azidomethyl)ethane |

| TMNTAA | trimethylol nitromethane tris(azidoacetate) |

| TPBA | 1,3,5,7-tetrakis-(p-azidobenzyl)-adamantane |

| TPE | tetraphenylethene |

| TPT-N3 | tris(4-(5′-(3-azidopropyl)-2,2′-bithiophen5-yl)phenyl)amine |

| PBI | polybenzimidazole |

| X-PTCAzide | crosslinked poly triarylamine-carbazoyl azide (poly 4-(9-(6-azidohexyl)-9H-carbazol-3-yl)-N-(4-butylphenyl)-N-phenylaniline) |

Funding

Acknowledgments

Conflicts of Interest

References

- Griess, P. On a new series of bodies in which nitrogen is substituted for hydrogen. Philos. Trans. R. Soc. Lond. 1864, 154, 667–731. [Google Scholar] [CrossRef] [Green Version]

- Hepher, M.; Wagner, H.M. Azide Resin Photolithographic Composition. US Patent No. US2852379A, 16 September 1958. [Google Scholar]

- Manchado, M.A.L.; Kenny, J.M. Use of benzene-1,3-bis(sulfonyl)azide as crosslinking agent of TPVS based on EPDM rubber-polyolefin blends. Rubber Chem. Technol. 2001, 74, 198–210. [Google Scholar] [CrossRef]

- Baker, D.A.; East, G.C.; Mukhopadhyay, S.K. Mechanical and thermal properties of acrylic fibers crosslinked with disulfonyl azides. J. Appl. Polym. Sci. 2002, 84, 1309–1319. [Google Scholar] [CrossRef]

- Avadanei, M.; Grigoriu, G.E.; Barboiu, V. Photocrosslinking of poly-1,2-butadiene in the presence of benzophenone and aromatic diazide. Rev. Roum. De Chim. 2003, 48, 813–819. [Google Scholar]

- Jørgensen, J.K.; Stori, A.; Redford, K.; Ommundsen, E. Introduction of long-chain branches in linear polyethylene by light cross-linking with 1,3-benzenedisulfonyl azide. Polymer 2005, 46, 12256–12266. [Google Scholar] [CrossRef]

- Zielińska, A.J.; Noordermeer, J.W.M.; Talma, A.G.; van Duin, M. Di-azides cross-linked, iPP/EPDM-based thermoplastic vulcanizates. Eur. Polym. J. 2011, 47, 2311–2320. [Google Scholar] [CrossRef]

- Liu, B.; Png, R.-Q.; Zhao, L.-H.; Chua, L.-L.; Friend, R.H.; Ho, P.K.H. High internal quantum efficiency in fullerene solar cells based on crosslinked polymer donor networks. Nat. Commun. 2012, 3, 1321. [Google Scholar] [CrossRef]

- Chiang, M.; Wheeler, R. H—N3 and CH3—N3 bond dissociation energies. Can. J. Chem. 1968, 46, 3785–3788. [Google Scholar] [CrossRef]

- Bräse, S.; Banert, K. (Eds.) Organic Azides Syntheses and Applications; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2010; p. 507. [Google Scholar]

- Bräse, S.; Gil, C.; Knepper, K.; Zimmermann, V. Organic azides. An exploding diversity of a unique class of compounds. Angew. Chem. Int. Ed. 2005, 44, 5188–5240. [Google Scholar] [CrossRef]

- Jung, N.; Bräse, S. Vinyl and Alkynyl Azides: Well-known intermediates in the focus of modern synthetic methods. Angew. Chem. Int. Ed. 2012, 51, 12169–12171. [Google Scholar] [CrossRef]

- Gritsan, N.; Platz, M. Photochemistry of azides: The azide/nitrene interface. In Organic Azides; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2010; pp. 311–372. [Google Scholar]

- Borden, W.T.; Gritsan, N.P.; Hadad, C.M.; Karney, W.L.; Kemnitz, C.R.; Platz, M.S. The interplay of theory and experiment in the study of phenylnitrene. Acc. Chem. Res. 2000, 33, 765–771. [Google Scholar] [CrossRef] [PubMed]

- Leyva, E.; Platz, M.S.; Persy, G.; Wirz, J. Photochemistry of phenyl azide: The role of singlet and triplet phenylnitrene as transient intermediates. J. Am. Chem. Soc. 1986, 108, 3783–3790. [Google Scholar] [CrossRef]

- Platz, M.S. Comparison of phenylcarbene and phenylnitrene. Acc. Chem. Res. 1995, 28, 487–492. [Google Scholar] [CrossRef]

- Poe, R.; Schnapp, K.; Young, M.J.T.; Grayzar, J.; Platz, M.S. Chemistry and kinetics of singlet pentafluorophenylnitrene. J. Am. Chem. Soc. 1992, 114, 5054–5067. [Google Scholar] [CrossRef]

- Schuster, G.B.; Platz, M.S. Photochemistry of phenyl azide. Adv. Photochem. 1992, 17, 69–143. [Google Scholar]

- Gritsan, N.P.; Gudmundsdottir, A.D.; Tigelaar, D.; Zhu, Z.; Karney, W.L.; Hadad, C.M.; Platz, M.S. A Laser flash photolysis and quantum chemical study of the fluorinated derivatives of singlet phenylnitrene. J. Am. Chem. Soc. 2001, 123, 1951–1962. [Google Scholar] [CrossRef]

- Gritsan, N.P.; Yuzawa, T.; Platz, M.S. Direct observation of singlet phenyl nitrene and measurement of its rate of rearrangement. J. Am. Chem. Soc. 1997, 119, 5059–5060. [Google Scholar] [CrossRef]

- Gritsan, N.P.; Zhai, H.B.; Yuzawa, T.; Karweik, D.; Brooke, J.; Platz, M.S. Spectroscopy and kinetics of singlet perfluoro-4-biphenylnitrene and singlet perfluorophenylnitrene. J. Phys. Chem. A 1997, 101, 2833–2840. [Google Scholar] [CrossRef]

- Gritsan, N.P.; Zhu, Z.; Hadad, C.M.; Platz, M.S. Laser flash photolysis and computational study of singlet phenylnitrene. J. Am. Chem. Soc. 1999, 121, 1202–1207. [Google Scholar] [CrossRef]

- Pritchina, E.A.; Gritsan, N.P.; Maltsev, A.; Bally, T.; Autrey, T.; Liu, Y.; Wang, Y.; Toscano, J.P. Matrix isolation, time-resolved IR, and computational study of the photochemistry of benzoyl azide. Phys. Chem. Chem. Phys. 2003, 5, 1010–1018. [Google Scholar] [CrossRef]

- Tsao, M.-L.; Gritsan, N.; James, T.R.; Platz, M.S.; Hrovat, D.A.; Borden, W.T. Study of the chemistry of ortho- and para-biphenylnitrenes by laser flash photolysis and time-resolved IR experiments and by B3LYP and CASPT2 calculations. J. Am. Chem. Soc. 2003, 125, 9343–9358. [Google Scholar] [CrossRef] [PubMed]

- Teipel, U. Production of particles of explosives. Propellants Explos. Pyrotech. 1999, 24, 134–139. [Google Scholar] [CrossRef]

- Gaur, B.; Lochab, B.; Choudhary, V.; Varma, I.K. Azido polymers—Energetic binders for solid rocket propellants. J. Macromol. Sci. Part C 2003, 43, 505–545. [Google Scholar] [CrossRef]

- Wang, G.; Luo, Y. Characterization of P(BAMO/AMMO) ETPE prepared using different diisocyanates. Propellants Explos. Pyrotech. 2016, 41, 850–854. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, G.; Li, J.; Sun, S.; Luo, Y.; Li, X. High azide content hyperbranched star copolymer as energetic materials. Ind. Eng. Chem. Res. 2018, 57, 13962–13972. [Google Scholar] [CrossRef]

- Keicher, T.; Kuglstatter, W.; Eisele, S.; Wetzel, T.; Krause, H. Isocyanate-free curing of glycidyl azide polymer (GAP) with bis-propargyl-succinate (II). Propellants Explos. Pyrotech. 2009, 34, 210–217. [Google Scholar] [CrossRef]

- Min, B.S.; Park, Y.C.; Yoo, J.C. A study on the triazole crosslinked polymeric binder based on glycidyl azide polymer and dipolarophile curing agents. Propellants Explos. Pyrotech. 2012, 37, 59–68. [Google Scholar] [CrossRef]

- Cheng, T. Review of novel energetic polymers and binders—High energy propellant ingredients for the new space race. Des. Monomers Polym. 2019, 22, 54–65. [Google Scholar] [CrossRef] [Green Version]

- Mohan, Y.M.; Mani, Y.; Raju, K.M. Synthesis of azido polymers as potential energetic propellant binders. Des. Monomers Polym. 2006, 9, 201–236. [Google Scholar] [CrossRef]

- Kumari, D.; Yamajala, K.D.B.; Singh, H.; Sanghavi, R.R.; Asthana, S.N.; Raju, K.; Banerjee, S. Application of azido esters as energetic plasticizers for LOVA propellant formulations. Propellants Explos. Pyrotech. 2013, 38, 805–809. [Google Scholar] [CrossRef]

- Ghosh, K.; Pant, C.S.; Sanghavi, R.; Adhav, S.; Singh, A. Studies on triple base gun propellant based on two energetic azido esters. J. Energ. Mater. 2008, 27, 40–50. [Google Scholar] [CrossRef]

- Drees, D.; Löffel, D.; Messmer, A.; Schmid, K. Synthesis and characterization of azido plasticizer. Propellants Explos. Pyrotech. 1999, 24, 159–162. [Google Scholar] [CrossRef]

- Wang, Y.L.; Liu, Y.J.; Lu, T.T.; Gao, F.L.; Zhao, B.D. Synthesis and properties of 3-azido-2,2-bis(azidomethyl)propyl 2-azidoacetate: A potential azido ester plasticizer. Chempluschem 2019, 84, 107–111. [Google Scholar] [PubMed]

- Zhao, B.D.; Gao, F.L.; Wang, Y.L.; Liu, Y.J.; Chen, B.; Pan, Y.F. Azido energetic plasticizers for gun and rocket propellants. Prog. Chem. 2019, 31, 475–490. [Google Scholar]

- Zohari, N.; Abrishami, F.; Sheibani, N. A novel simple correlation for predicting glass transition temperature of energetic azido-ester plasticizers through molecular structures. J. Therm. Anal. Calorim. 2017, 127, 2243–2251. [Google Scholar] [CrossRef]

- Zhang, G.; Li, J.; Sun, S.; Luo, Y. Azido-terminated hyperbranched multi-arm copolymer as energetic macromolecular plasticizer. Propellants Explos. Pyrotech. 2019, 44, 345–354. [Google Scholar] [CrossRef]

- Roy, D.; Basu, P.K.; Raghunathan, P.; Eswaran, S.V. Photo-induced crosslinking mechanism in azide-novolac negative photoresists: Molecular level investigation using NMR spectroscopy. Magn. Reson. Chem. 2003, 41, 671–678. [Google Scholar] [CrossRef]

- Nonogaki, S. Recent resist developments in Japan—A review. Polym. Eng. Sci. 1983, 23, 985–989. [Google Scholar] [CrossRef]

- Han, C.C.; Corelli, J.C. Wet and dry developable photosensitive deep UV resist. Microelectron. Eng. 1987, 6, 413–419. [Google Scholar] [CrossRef]

- Han, C.C.; Corelli, J.C.; McDonald, J.F. Photosensitive UV resist of poly(methyl methacrylate) containing a bisazide compound. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1988, 32, 422–426. [Google Scholar] [CrossRef]

- Iwayanagi, T.; Kohashi, T.; Nonogaki, S. Azide photoresists for deep U.V. lithography. J. Electrochem. Soc. 1980, 127, 2759–2760. [Google Scholar] [CrossRef]

- Airinei, A.; Rusu, E.; Barboiu, V.; Timpu, D. Spectroscopic investigation of some aromatic azides. J. Optoelectron. Adv. Mat. 2007, 9, 1029–1032. [Google Scholar]

- Cai, S.X.; Nabity, J.C.; Wybourne, M.N.; Keana, J.F.W. Bis(perfluorophenyl)azides: Efficient crosslinking agents for deep-UV and electron beam lithography. Chem. Mater. 1990, 2, 631–633. [Google Scholar] [CrossRef]

- Cai, S.; Keana, J.; Nabity, J.C.; Wybourne, M.N. Conducting polymers as deep-UV and electron beam resists: Direct production of micrometer scale conducting structures from poly(3-octylthiophene). J. Mol. Electron. 1991, 7, 63–68. [Google Scholar]

- Yan, M.; Cai, S.X.; Wybourne, M.N.; Keana, J.F.W. Evaluation of bis(perfluorophenyl azide)s as cross-linkers for a soluble polyimide. J. Mater. Chem. 1996, 6, 1249–1252. [Google Scholar] [CrossRef]

- Yan, M.D.; Wybourne, M.N.; Keana, J.F.W. Bis(perfluorophenyl azides) as highly efficient crosslinking agents for poly(vinyl phenol). React. Funct. Polym. 2000, 43, 221–225. [Google Scholar] [CrossRef]

- Schnapp, K.A.; Poe, R.; Leyva, E.; Soundararajan, N.; Platz, M.S. Exploratory photochemistry of fluorinated aryl azides. Implications for the design of photoaffinity labeling reagents. Bioconjug. Chem. 1993, 4, 172–177. [Google Scholar] [CrossRef]

- Voigt, A. Zur Chemie Photolytisch Generierter Arylnitrenein Polymermatrizen. Ph.D. Thesis, Humboldt University of Berlin, Berlin, Germany, 1998. [Google Scholar]

- Touwslager, F.J.; Willard, N.P.; de Leeuw, D.M. I-Line lithography of poly-(3,4-ethylenedioxythiophene) electrodes and application in all-polymer integrated circuits. Appl. Phys. Lett. 2002, 81, 4556–4558. [Google Scholar] [CrossRef]

- Cheng, P.; Zhan, X. Stability of organic solar cells: Challenges and strategies. Chem. Soc. Rev. 2016, 45, 2544–2582. [Google Scholar] [CrossRef]

- Dang, M.T.; Hirsch, L.; Wantz, G.; Wuest, J.D. Controlling the morphology and performance of bulk heterojunctions in solar cells. Lessons learned from the benchmark poly(3-hexylthiophene):[6,6]-phenyl-C61-butyric acid methyl ester system. Chem. Rev. 2013, 113, 3734–3765. [Google Scholar] [CrossRef]

- Lu, L.; Yu, L. Understanding low bandgap polymer PTB7 and optimizing polymer solar cells based on it. Adv. Mater. 2014, 26, 4413–4430. [Google Scholar] [CrossRef] [PubMed]

- Nam, C.-Y.; Qin, Y.; Park, Y.S.; Hlaing, H.; Lu, X.; Ocko, B.M.; Black, C.T.; Grubbs, R.B. Photo-cross-linkable azide-functionalized polythiophene for thermally stable bulk heterojunction solar cells. Macromolecules 2012, 45, 2338–2347. [Google Scholar] [CrossRef]

- Chen, X.; Chen, L.; Chen, Y. The effect of photocrosslinkable groups on thermal stability of bulk heterojunction solar cells based on donor–acceptor-conjugated polymers. J. Polym. Sci. Part A Polym. Chem. 2013, 51, 4156–4166. [Google Scholar] [CrossRef]

- Png, R.-Q.; Chia, P.-J.; Tang, J.-C.; Liu, B.; Sivaramakrishnan, S.; Zhou, M.; Khong, S.-H.; Chan, H.S.O.; Burroughes, J.H.; Chua, L.-L.; et al. High-performance polymer semiconducting heterostructure devices by nitrene-mediated photocrosslinking of alkyl side chains. Nat. Mater. 2009, 9, 152. [Google Scholar] [CrossRef] [PubMed]

- Tao, C.; Aljada, M.; Shaw, P.E.; Lee, K.H.; Cavaye, H.; Balfour, M.N.; Borthwick, R.J.; James, M.; Burn, P.L.; Gentle, I.R.; et al. Controlling hierarchy in solution-processed polymer solar cells based on crosslinked P3HT. Adv. Energy Mater. 2013, 3, 105–112. [Google Scholar] [CrossRef]

- Rumer, J.W.; Ashraf, R.S.; Eisenmenger, N.D.; Huang, Z.; Meager, I.; Nielsen, C.B.; Schroeder, B.C.; Chabinyc, M.L.; McCulloch, I. Dual function additives: A small molecule crosslinker for enhanced efficiency and stability in organic solar cells. Adv. Energy Mater. 2015, 5, 1401426. [Google Scholar] [CrossRef] [Green Version]

- Chao, Y.-C.; Chuang, C.-H.; Hsu, H.-L.; Wang, H.-J.; Hsu, Y.-C.; Chen, C.-P.; Jeng, R.-J. Enhanced thermal stability of organic photovoltaics via incorporating triphenylamine derivatives as additives. Sol. Energy Mater. Sol. Cells 2016, 157, 666–675. [Google Scholar] [CrossRef]

- Awada, H.; Gorisse, T.; Peresutti, R.; Tjoutis, T.; Moreau, J.J.E.; Wantz, G.; Dautel, O.J. Bis-azide low-band gap cross-linkable molecule N3-[CPDT(FBTTh2)2] to fully thermally stabilize organic solar cells based on P3HT:PC61BM. ACS Omega 2017, 2, 1340–1349. [Google Scholar] [CrossRef]

- Chao, Y.-C.; Liao, Y.-H.; Hsu, H.-L.; Jiang, B.-H.; Kao, J.-C.; Lai, T.-H.; Chen, C.-P.; Jeng, R.-J. Enhanced device performance and stability of organic photovoltaics incorporating a star-shaped multifunctional additive. ACS Appl. Energy Mater. 2019, 2, 833–843. [Google Scholar] [CrossRef]

- Landerer, D.; Sprau, C.; Baumann, D.; Pingel, P.; Leonhard, T.; Zimmermann, D.; Chochos, C.L.; Krüger, H.; Janietz, S.; Colsmann, A. Thermal stabilization of the bulk-heterojunction morphology in polymer:Fullerene solar cells using a bisazide cross-linker. Sol. RRL 2019, 3, 1800266. [Google Scholar] [CrossRef]

- Derue, L.; Dautel, O.; Tournebize, A.; Drees, M.; Pan, H.; Berthumeyrie, S.; Pavageau, B.; Cloutet, E.; Chambon, S.; Hirsch, L.; et al. Thermal stabilisation of polymer–fullerene bulk heterojunction morphology for efficient photovoltaic solar cells. Adv. Mater. 2014, 26, 5831–5838. [Google Scholar] [CrossRef] [PubMed]

- Cho, N.; Yip, H.-L.; Davies, J.A.; Kazarinoff, P.D.; Zeigler, D.F.; Durban, M.M.; Segawa, Y.; O’Malley, K.M.; Luscombe, C.K.; Jen, A.K.-Y. In-situ crosslinking and n-doping of semiconducting polymers and their application as efficient electron-transporting materials in inverted polymer solar cells. Adv. Energy Mater. 2011, 1, 1148–1153. [Google Scholar] [CrossRef]

- Grant, T.M.; Gorisse, T.; Dautel, O.; Wantz, G.; Lessard, B.H. Multifunctional ternary additive in bulk heterojunction OPV: Increased device performance and stability. J. Mater. Chem. A 2017, 5, 1581–1587. [Google Scholar] [CrossRef]

- Watson, B.L.; Rolston, N.; Bush, K.A.; Taleghani, L.; Dauskardt, R.H. Synthesis and use of a hyper-connecting cross-linking agent in the hole-transporting layer of perovskite solar cells. J. Mater. Chem. A 2017, 5, 19267–19279. [Google Scholar] [CrossRef]

- Watson, B.L.; Rolston, N.; Printz, A.D.; Dauskardt, R.H. Scaffold-reinforced perovskite compound solar cells. Energy Environ. Sci. 2017, 10, 2500–2508. [Google Scholar] [CrossRef]

- Park, J.; Lee, C.; Jung, J.; Kang, H.; Kim, K.H.; Ma, B.W.; Kim, B.J. Facile photo-crosslinking of azide-containing hole-transporting polymers for highly efficient, solution-processed, multilayer organic light emitting devices. Adv. Funct. Mater. 2014, 24, 7588–7596. [Google Scholar] [CrossRef]

- Huang, C.-W.; Chang, F.-C.; Chu, Y.-L.; Lai, C.-C.; Lin, T.-E.; Zhu, C.-Y.; Kuo, S.-W. A solvent-resistant azide-based hole injection/transporting conjugated polymer for fluorescent and phosphorescent light-emitting diodes. J. Mater. Chem. C 2015, 3, 8142–8151. [Google Scholar] [CrossRef]

- Kim, K.; Shin, S.; Kim, S.H.; Lee, J.; An, T.K. High-efficiency nitrene-based crosslinking agent for robust dielectric layers and high-performance solution-processed organic field-effect transistors. Appl. Surf. Sci. 2019, 479, 280–286. [Google Scholar] [CrossRef]

- Png, R.-Q.; Chia, P.-J.; Sivaramakrishnan, S.; Wong, L.-Y.; Zhou, M.; Chua, L.-L.; Ho, P.K.-H. Electromigration of the conducting polymer in organic semiconductor devices and its stabilization by cross-linking. Appl. Phys. Lett. 2007, 91, 013511. [Google Scholar] [CrossRef]

- Wang, G.-J.N.; Zheng, Y.; Zhang, S.; Kang, J.; Wu, H.-C.; Gasperini, A.; Zhang, H.; Gu, X.; Bao, Z. Tuning the cross-linker crystallinity of a stretchable polymer semiconductor. Chem. Mater. 2018, 31, 6465–6475. [Google Scholar] [CrossRef]

- Oh, Y.S.; Lee, H.J.; Yoo, M.; Kim, H.J.; Han, J.; Kim, T.H. Synthesis of novel crosslinked sulfonatod poly(ether sulfone)s using bisazide and their properties for fuel cell application. J. Membr. Sci. 2008, 323, 309–315. [Google Scholar] [CrossRef]

- Oh, Y.-S.; Lee, H.-J.; Yoo, M.; Kim, H.-J.; Han, J.; Kim, K.; Hong, J.-D.; Kim, T.-H. Azide-assisted cross-linked sulfonated poly(ether sulfone)s as stable and highly conductive membranes with low methanol diffusion coefficients. Chem. Commun. 2008, 17, 2028–2030. [Google Scholar] [CrossRef] [PubMed]

- Thankamony, R.L.; Hwang, J.M.; Kim, T.H. Azide-assisted terminal crosslinking of ionomeric blocks: Effects on morphology and proton conductivity. J. Membr. Sci. 2012, 392, 58–65. [Google Scholar] [CrossRef]

- Thankamony, R.L.; Lee, M.G.; Kim, K.; Hong, J.D.; Kim, T.H.; Lee, H.J.; Kim, H.J.; Nam, S.; Lim, Y.B. Terminally-crosslinked sulfonated poly(fluorenyl ether sulfone) as a highly conductive and stable proton exchange membrane. Macromol. Res. 2010, 18, 992–1000. [Google Scholar] [CrossRef]

- Papadimitriou, K.D.; Paloukis, F.; Neophytides, S.G.; Kallitsis, J.K. Cross-linking of side chain unsaturated aromatic polyethers for high temperature polymer electrolyte membrane fuel cell applications. Macromolecules 2011, 44, 4942–4951. [Google Scholar] [CrossRef]

- Su, J.; Pu, H.T.; Chang, Z.H.; Wan, D.C. A facile crosslinking method of polybenzimidazole with sulfonyl azide groups for proton conducting membranes. Polymer 2012, 53, 3587–3593. [Google Scholar] [CrossRef]

- He, S.; Liu, L.; Wang, X.; Zhang, S.; Guiver, M.D.; Li, N. Azide-assisted self-crosslinking of highly ion conductive anion exchange membranes. J. Membr. Sci. 2016, 509, 48–56. [Google Scholar] [CrossRef]

- He, Y.; Tong, C.; Geng, L.; Liu, L.; Lü, C. Enhanced performance of the sulfonated polyimide proton exchange membranes by graphene oxide: Size effect of graphene oxide. J. Membr. Sci. 2014, 458, 36–46. [Google Scholar] [CrossRef]

- Andresen, A.; Cordes, H.-G.; Herwig, J.; Kaminsky, W.; Merck, A.; Mottweiler, R.; Pein, J.; Sinn, H.; Vollmer, H.-J. Halogen-free soluble Ziegler catalysts for the polymerization of ethylene. Control of molecular weight by choice of temperature. Angew. Chem. Int. Ed. Engl. 1976, 15, 630–632. [Google Scholar] [CrossRef]

- Damiron, D.; Okhay, N.; Al Akhrass, S.; Cassagnau, P.; Drockenmuller, E. Crosslinked PDMS elastomers and coatings from the thermal curing of vinyl-functionalized PDMS and a diazide aliphatic crosslinker. J. Polym. Sci. Part A Polym. Chem. 2012, 50, 98–107. [Google Scholar] [CrossRef]

- Van der Ende, A.E.; Harrell, J.; Sathiyakumar, V.; Meschievitz, M.; Katz, J.; Adcock, K.; Harth, E. “Click” reactions: Novel chemistries for forming well-defined polyester nanoparticles. Macromolecules 2010, 43, 5665–5671. [Google Scholar] [CrossRef]

- Jiang, X.Y.; Pu, H.T.; Wang, P. Polymer nanoparticles via intramolecular crosslinking of sulfonyl azide functionalized polymers. Polymer 2011, 52, 3597–3602. [Google Scholar] [CrossRef]

- Zhang, S.; Adamson, D.H.; Prud’homme, R.K.; Link, A.J. Photocrosslinking the polystyrene core of block-copolymer nanoparticles. Polym. Chem. 2011, 2, 665–671. [Google Scholar] [CrossRef]

- Curtius, T. Ueber Stickstoffwasserstoffsäure (Azoimid) N3H. Ber. Der Dtsch. Chem. Ges. 1890, 23, 3023–3033. [Google Scholar] [CrossRef] [Green Version]

- Zheng, H.T.; Ye, X.D.; Wang, H.; Yan, L.F.; Bai, R.K.; Hu, W.Q. A facile one-pot strategy for preparation of small polymer nanoparticles by self-crosslinking of amphiphilic block copolymers containing acyl azide groups in aqueous media. Soft Matter 2011, 7, 3956–3962. [Google Scholar] [CrossRef]

- Bentz, K.C.; Savin, D.A. Hollow polymer nanocapsules: Synthesis, properties, and applications. Polym. Chem. 2018, 9, 2059–2081. [Google Scholar] [CrossRef]

- Odinokov, A.V.; Dzhons, D.Y.; Budruev, A.V.; Mochalova, A.E.; Smirnova, L.A. Chitosan modified with terephthaloyl diazide as a drug delivery system. Russ. Chem. Bull. 2016, 65, 1122–1130. [Google Scholar] [CrossRef]

- Xu, Q. Nanoporous Materials: Synthesis and Applications; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Plietzsch, O.; Schilling, C.I.; Grab, T.; Grage, S.L.; Ulrich, A.S.; Comotti, A.; Sozzani, P.; Muller, T.; Bräse, S. Click chemistry produces hyper-cross-linked polymers with tetrahedral cores. New. J. Chem. 2011, 35, 1577–1581. [Google Scholar] [CrossRef]

- Inglis, A.J.; Pierrat, P.; Muller, T.; Bräse, S.; Barner-Kowollik, C. Well-defined star shaped polymer-fullerene hybrids via click chemistry. Soft Matter 2010, 6, 82–84. [Google Scholar] [CrossRef]

- Pierrat, P.; Vanderheiden, S.; Muller, T.; Bräse, S. Functionalization of hexakis methanofullerene malonate crown-ethers: Promising octahedral building blocks for molecular networks. Chem. Commun. 2009, 1748–1750. [Google Scholar] [CrossRef]

- Begum, S.; Hassan, Z.; Bräse, S.; Wöll, C.; Tsotsalas, M. Metal–organic framework-templated biomaterials: Recent progress in synthesis, functionalization, and applications. Acc. Chem. Res. 2019, 52, 1598–1610. [Google Scholar] [CrossRef] [PubMed]

- Staudinger, H.; Meyer, J. Über neue organische phosphorverbindungen III. Phosphinmethylenderivate und phosphinimine. Helv. Chim. Acta 1919, 2, 635–646. [Google Scholar] [CrossRef] [Green Version]

- Wittig, G.; Geissler, G. Zur reaktionsweise des pentaphenyl-phosphors und einiger derivate. Justus Liebigs Ann. Der Chem. 1953, 580, 44–57. [Google Scholar] [CrossRef]

- Miyake, J.; Chujo, Y. The aza-Wittig polymerization: An efficient method for the construction of carbon-nitrogen double bonds-containing polymers. Macromolecules 2008, 41, 5671–5673. [Google Scholar] [CrossRef]

- Miyake, J.; Chujo, Y. Aza-Wittig polymerization: A simple method for the synthesis of regioregular poly(azomethine)s. Macromolecules 2008, 41, 9677–9682. [Google Scholar] [CrossRef]

- Miyake, J.; Tsuji, Y.; Nagai, A.; Chujo, Y. Aza-Wittig polymerization: Kinetic study and efficient end functionalization of poly(azomethine)s. Macromolecules 2009, 42, 3463–3468. [Google Scholar] [CrossRef]

- Gleria, M.; De Jaeger, R. Polyphosphazenes: A review. In New Aspects in Phosphorus Chemistry V; Majoral, J.-P., Ed.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 165–251. [Google Scholar]

- Sundhoro, M.; Park, J.; Wu, B.; Yan, M. Synthesis of polyphosphazenes by a fast perfluoroaryl azide-mediated staudinger reaction. Macromolecules 2018, 51, 4532–4540. [Google Scholar] [CrossRef]

- Xu, X.; Cheng, D.; Li, J.; Guo, H.; Yan, J. Copper-catalyzed highly efficient multicomponent reactions: Synthesis of 2-(sulfonylimino)-4-(alkylimino)azetidine derivatives. Org. Lett. 2007, 9, 1585–1587. [Google Scholar] [CrossRef]

- Han, T.; Deng, H.; Qiu, Z.; Zhao, Z.; Zhang, H.; Zou, H.; Leung, N.L.C.; Shan, G.; Elsegood, M.R.J.; Lam, J.W.Y.; et al. Facile multicomponent polymerizations toward unconventional luminescent polymers with readily openable small heterocycles. J. Am. Chem. Soc. 2018, 140, 5588–5598. [Google Scholar] [CrossRef] [Green Version]

| Azide Crosslinker | Active Layer (1:x(CL):1) | Crosslinking Method | Reference PCE w/o CL | PCE (%) Post Annealing | PCE (%) Retention after Ageing (t, T) |

|---|---|---|---|---|---|

| P3HT-N5 | P3HT-N5:0:PC61BM | DUV (60 min) a | 2.2 | 1.5 | 67 (40 h, 110 °C) |

| N3-CPDT(FBTTh2)2 [62] | P3HT:0.2:PC61BM | thermally (130–150 °C) via CA | - | 3.5 | >99 (24 h, 150 °C) |

| BAPB [65] | P3HT:0.05:PC61BM | thermally (150 °C) via CA | 3.3 | 3.0 | 92 (122 h, 150 °C) 90 (120 d, 85 °C) |

| DAZH [60] | SiIDTBT:0.1:C70BM | DUV (10 min) | 6.0 | 5.7 | 82 (130 h, 85 °C, N2 atmosphere) |

| TBA-X [64] | P3HT:0.07:PC61BM | thermally (150 °C) via CA | 3.7 | 3.3 | 87 (200 h, 120 °C) |

| sFPA [59] b | P3HT:0.12:PC61BM | DUV (5 min, 90 °C) | 3.3 | 3.0 | - |

| Bis(BFPA) [66] c | P3HT:0.1:PC61BM | DUV (5 min, rt) | - | 3.4 | 88 (20 d in air, rt) |

| DPPTPTA [63] | PTB7Th:0.05:PC61BM | thermally (10 min, 150 °C) | 6.7 | 7.3 | 55 (18 h, 150 °C) |

| (HxN3)2-SiPc [67] | P3HT:0.08:PC61BM | thermally (10 min, 80 °C) | 3.4 d | 3.3 | 97 (23 h, 150 °C) |

| TBT-N3 [61] | P3HT:0.05:PC61BM | thermally (20 min, 150 °C) | 3.4 e | 3.4 | 60 (24 h, 150 °C) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schock, M.; Bräse, S. Reactive & Efficient: Organic Azides as Cross-Linkers in Material Sciences. Molecules 2020, 25, 1009. https://doi.org/10.3390/molecules25041009

Schock M, Bräse S. Reactive & Efficient: Organic Azides as Cross-Linkers in Material Sciences. Molecules. 2020; 25(4):1009. https://doi.org/10.3390/molecules25041009

Chicago/Turabian StyleSchock, Marvin, and Stefan Bräse. 2020. "Reactive & Efficient: Organic Azides as Cross-Linkers in Material Sciences" Molecules 25, no. 4: 1009. https://doi.org/10.3390/molecules25041009