Spent Grain from Malt Whisky: Assessment of the Phenolic Compounds

Abstract

:1. Introduction

2. Results

2.1. Characterization of Spent Grain

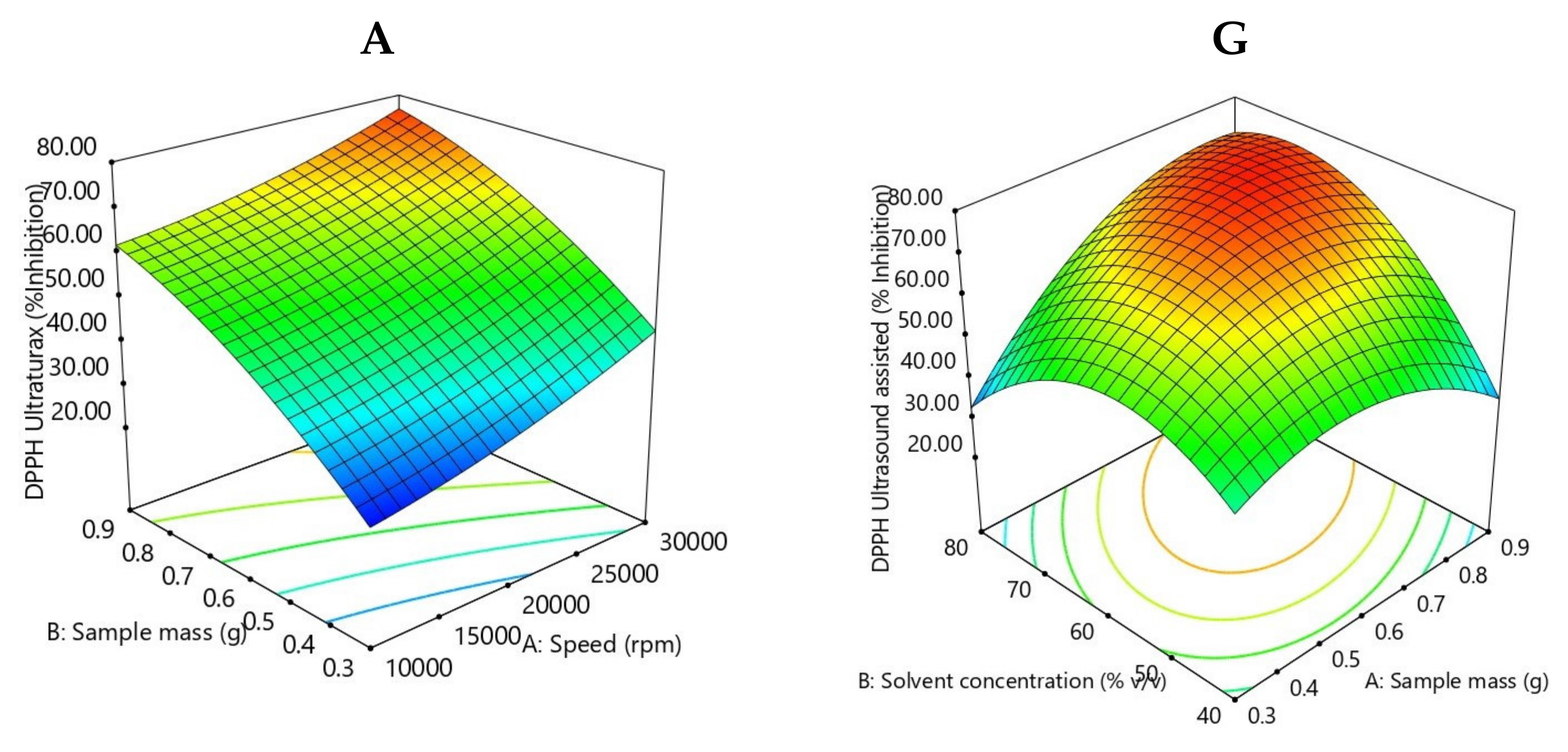

2.2. Model Fitting and Statistical Analysis

2.2.1. Optimization of Extraction Parameters and Validation of the Models

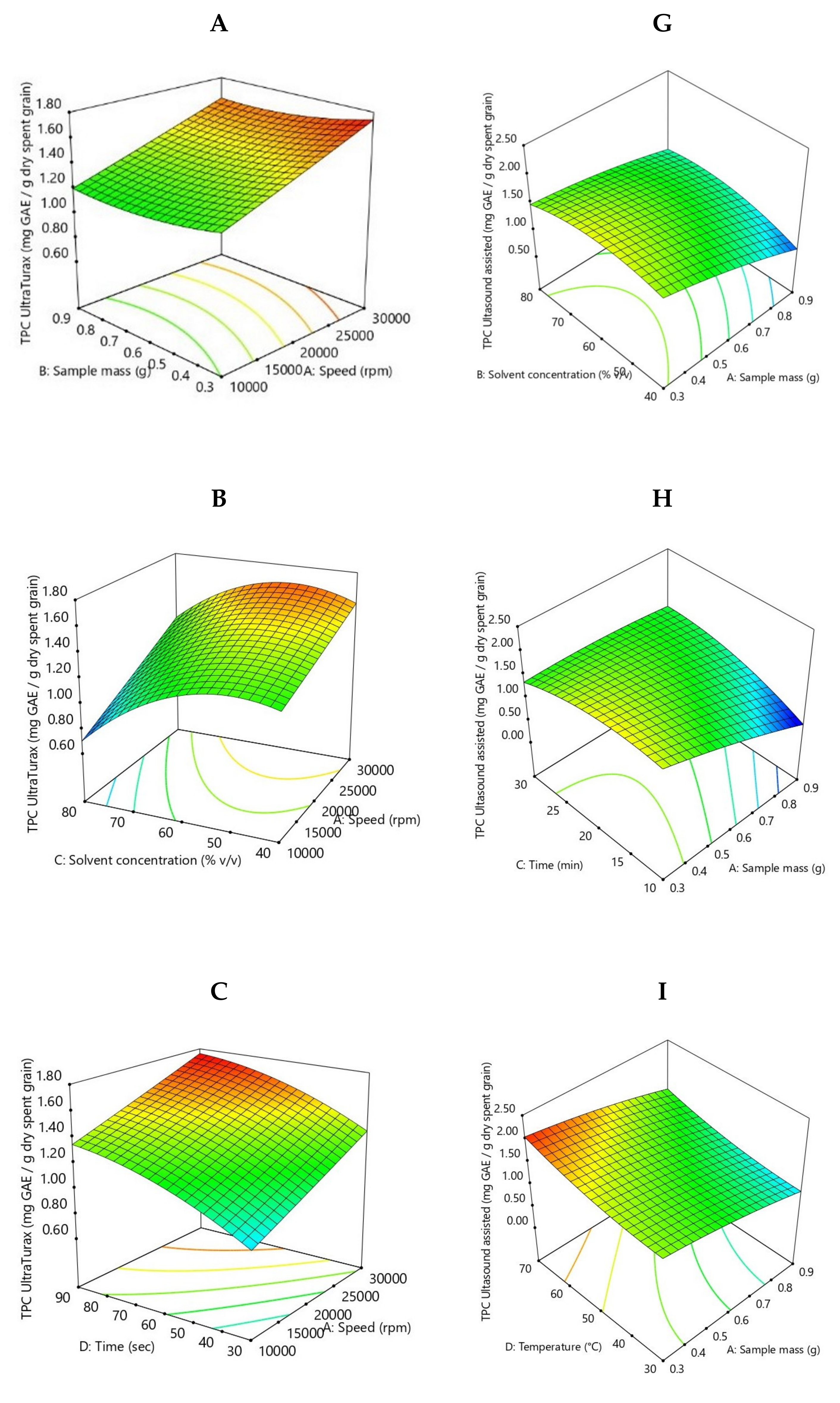

2.2.2. Total Phenolic Compounds

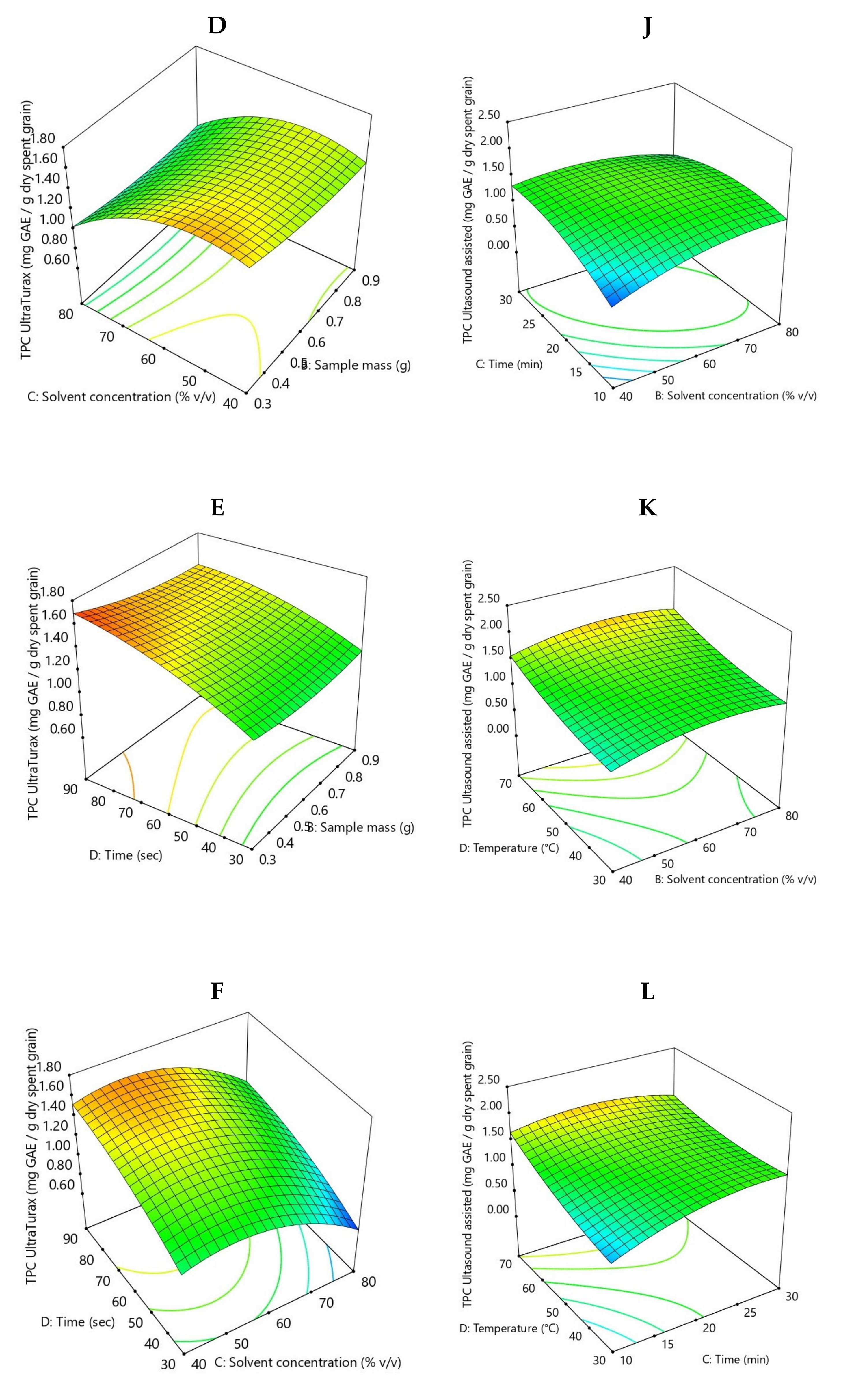

2.2.3. Total Flavonoid Content

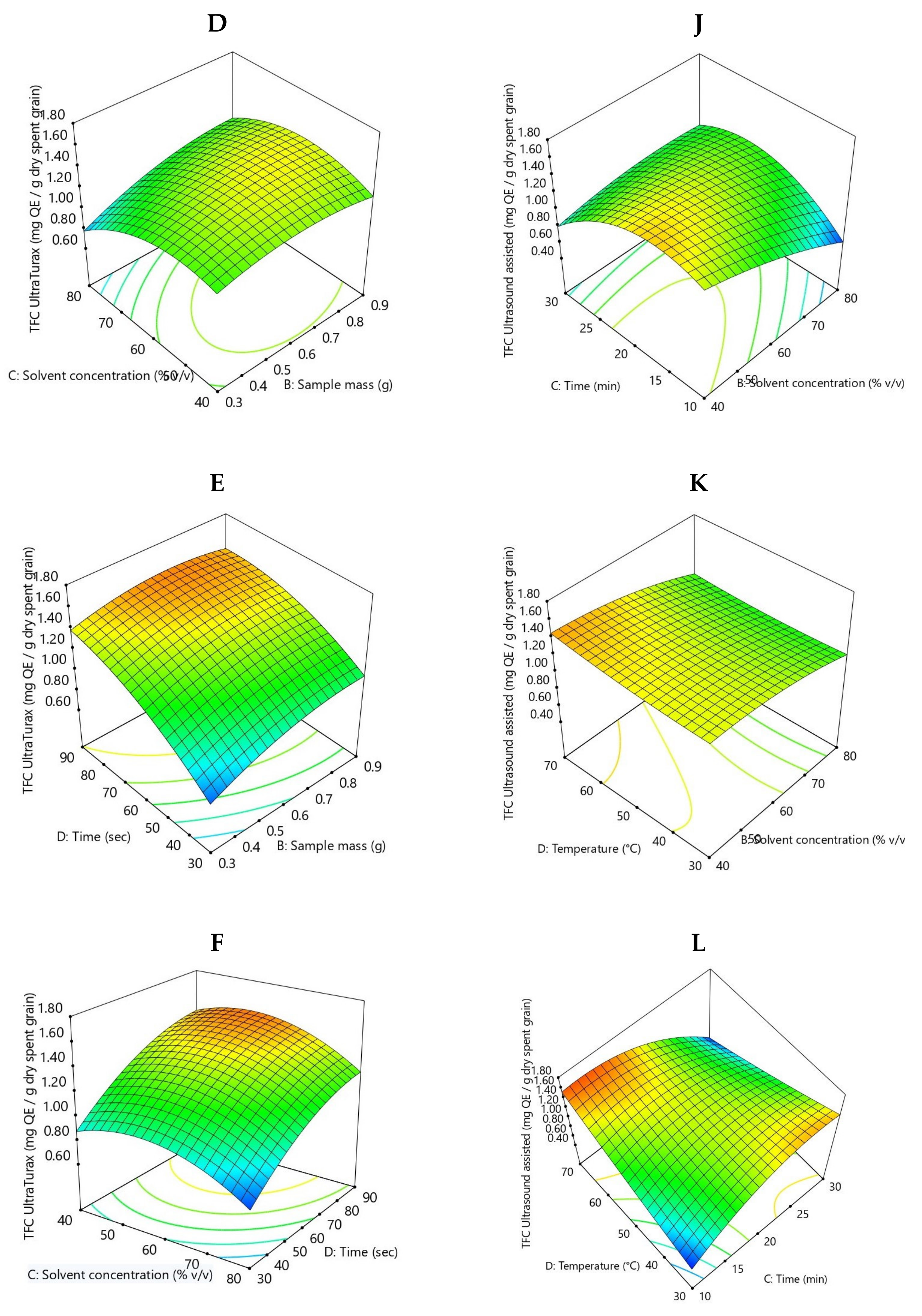

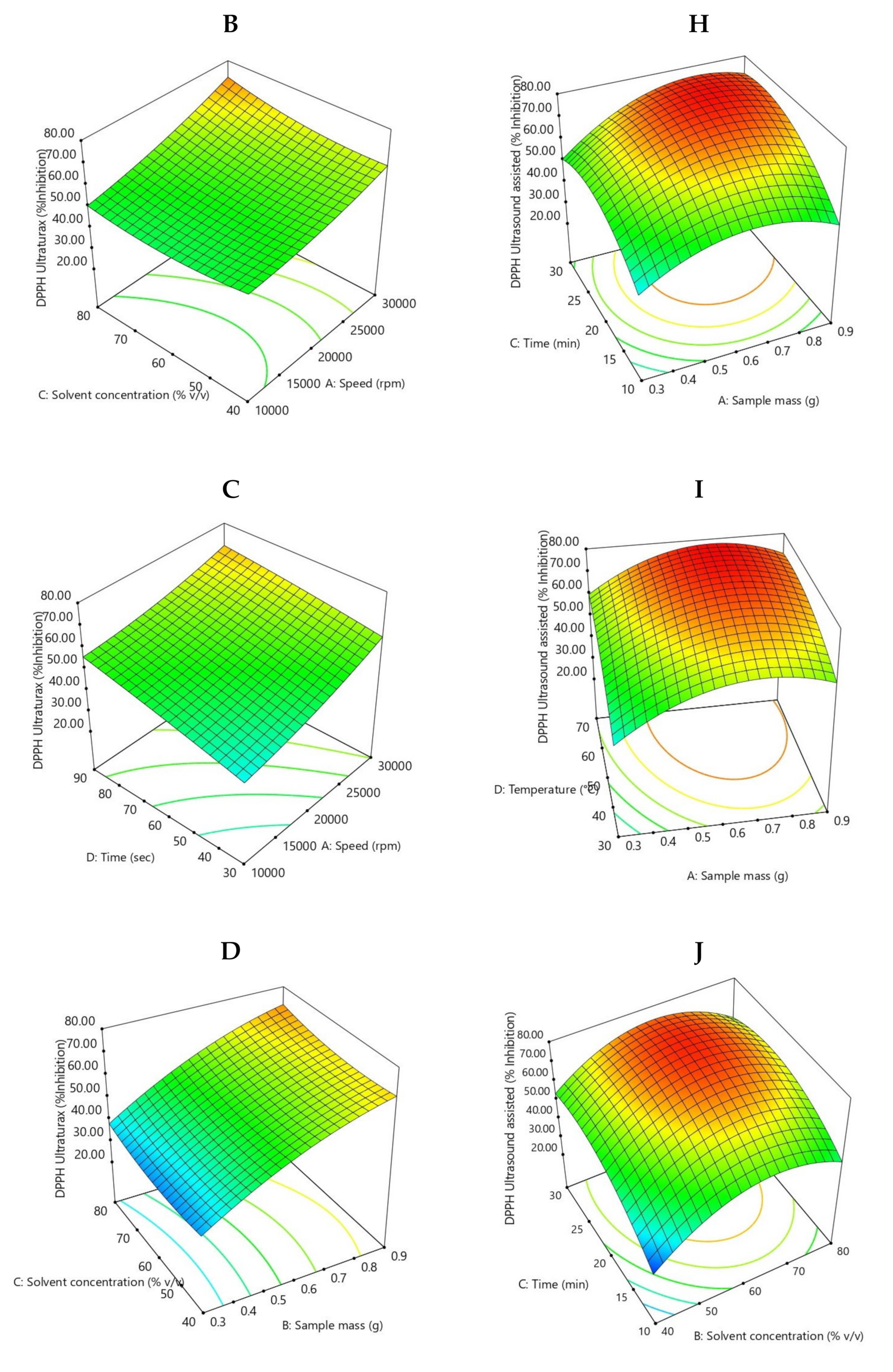

2.2.4. DPPH Assay of Scavenging Activity

2.3. HPLC Analysis of Phenolic Compounds

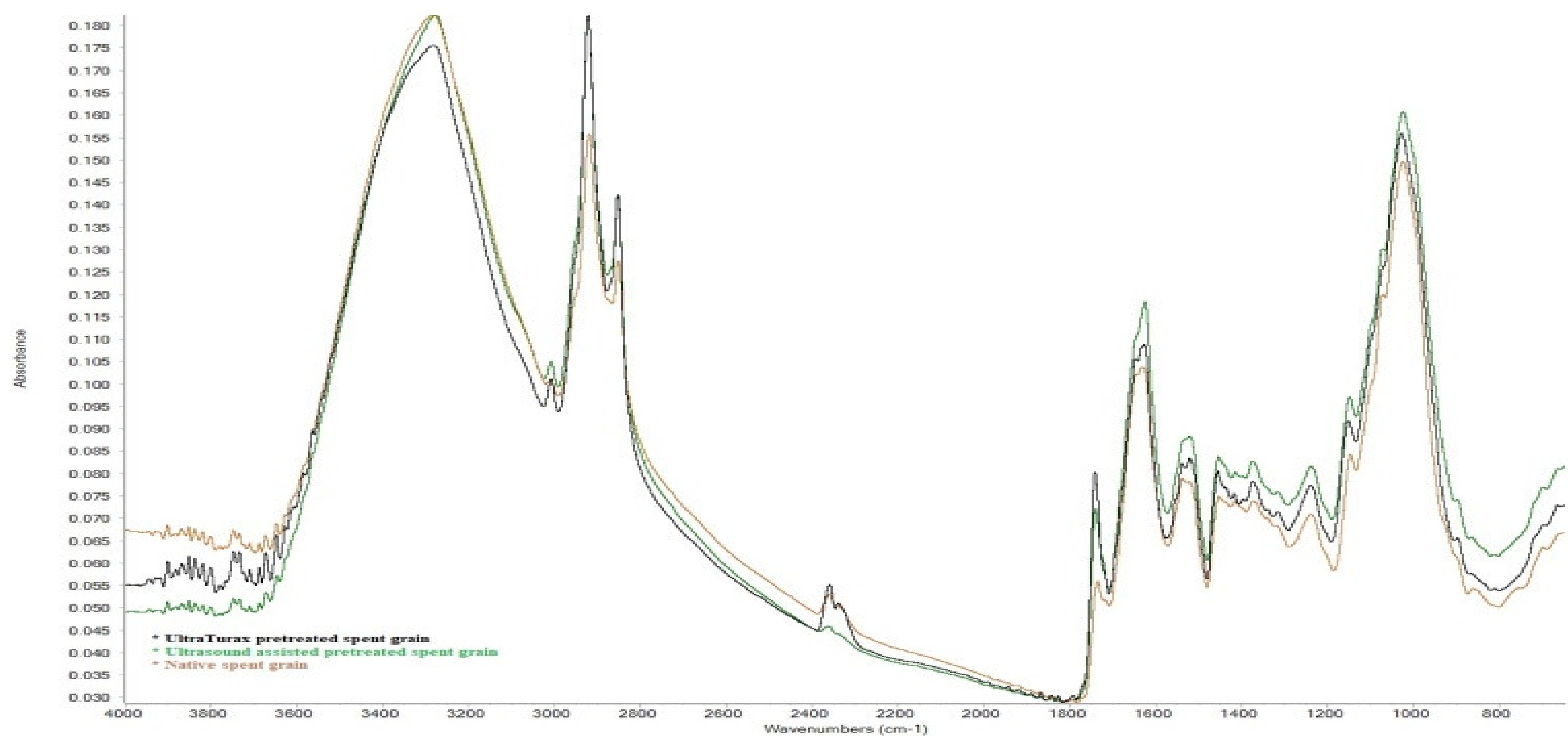

2.4. FTIR Analysis

3. Materials and Methods

3.1. Materials

3.2. Proximate Composition

3.3. FT-IR Analysis

3.4. Extract Preparation

3.4.1. Ultra-Turrax Extraction

3.4.2. Ultrasound-Assisted Extraction

3.5. Total Phenolic Content (TPC)

3.6. Flavonoid’s Content (TFC)

3.7. DPPH Assay Scavenging Activity

3.8. Analysis of Phenolic Compound by HPLC-DAD

3.9. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Wiśniewska, P.; Boqué, R.; Borràs, E.; Busto, O.; Wardencki, W.; Namieśnik, J.; Dymerski, T. Authentication of whisky due to its botanical origin and way of production by instrumental analysis and multivariate classification methods. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2017, 173, 849–853. [Google Scholar] [CrossRef] [PubMed]

- Joshi, I.; Truong, V.K.; Elbourne, A.; Chapman, J.; Cozzolino, D. Influence of the scanning temperature on the classification of whisky samples analysed by UV-VIS spectroscopy. Appl. Sci. 2019, 9, 3254. [Google Scholar] [CrossRef] [Green Version]

- Pawlaczyk, A.; Gajek, M.; Jozwik, K.; Szynkowska, M.I. Multielemental analysis of various kinds of whisky. Molecules 2019, 24, 1193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gunes, B.; Stokes, J.; Davis, P.; Connolly, C.; Lawler, J. Optimisation of anaerobic digestion of pot ale after thermochemical pre-treatment through Response Surface Methodology. Biomass Bioenergy 2021, 144, 105902. [Google Scholar] [CrossRef]

- Eriksson, O.; Jonsson, D.; Hillman, K. Life cycle assessment of Swedish single malt whisky. J. Clean. Prod. 2016, 112, 229–237. [Google Scholar] [CrossRef]

- Wanikawa, A. Flavors in Malt Whisky: A Review. J. Am. Soc. Brew. Chem. 2020, 78, 260–278. [Google Scholar] [CrossRef]

- Jeleń, H.H.; Majcher, M.; Szwengiel, A. Key odorants in peated malt whisky and its differentiation from other whisky types using profiling of flavor and volatile compounds. LWT 2019, 107, 56–63. [Google Scholar] [CrossRef]

- Pandey, A.; Du, G.; Sanromán, M.Á.; Soccol, C.R.; Dussap, C.G. (Eds.) Current Developments in Biotechnology and Bioengineering: Food and Beverages Industry; Elsevier: Amsterdam, The Netherlands, 2016; pp. 154–196. [Google Scholar]

- Daute, M.; Jack, F.; Baxter, I.; Harrison, B.; Grigor, J.; Walker, G. Comparison of Three Approaches to Assess the Flavour Characteristics of Scotch Whisky Spirit. Appl. Sci. 2021, 11, 1410. [Google Scholar] [CrossRef]

- Gunes, B.; Stokes, J.; Davis, P.; Connolly, C.; Lawler, J. Pre-treatments to enhance biogas yield and quality from anaerobic digestion of whiskey distillery and brewery wastes: A review. Renew. Sustain. Energy Rev. 2019, 113, 109281. [Google Scholar] [CrossRef]

- Jackson, S.A.; Kang, X.; O’Shea, R.; O’Leary, N.; Murphy, J.D.; Dobson, A.D. Anaerobic digestion performance and microbial community structures in biogas production from whiskey distillers organic by-products. Bioresour. Technol. Rep. 2020, 12, 100565. [Google Scholar] [CrossRef]

- Duguid, L.; Strachan, P. Sustainable Energy Using Anaerobic Digestion of By-Products: Islay Whisky Industry Case Study; University of Strathclyde: Glasgow, Scotland, 2016. [Google Scholar]

- Akunna, J.C.; Walker, G.M. Co-products from malt whisky production and their utilisation. In The Alcohol Textbook; Ethanol Technology Institute: Duluth, GA, USA, 2017; pp. 529–537. [Google Scholar]

- White, J.S.; Traub, J.E.; Maskell, D.L.; Hughes, P.S.; Harper, A.J.; Willoughby, N.A. Recovery and applications of proteins from distillery by-products. Protein Byprod. 2016, 235–253. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Pre-treatments used for the recovery of brewer’s spent grain—A minireview. J. Agroaliment. Process. Technol. 2020, 26, 304–312. [Google Scholar]

- White, J.S.; Stewart, K.L.; Maskell, D.L.; Diallo, A.; Traub-Modinger, J.E.; Willoughby, N.A. Characterization of Pot Ale from a Scottish Malt Whisky Distillery and Potential Applications. ACS Omega 2020, 5, 6429–6440. [Google Scholar] [CrossRef] [PubMed]

- Chetrariu, A.; Dabija, A. Brewer’s spent grains: Possibilities of valorization, a review. Appl. Sci. 2020, 10, 5619. [Google Scholar] [CrossRef]

- Foltanyi, F.; Hawkins, J.E.; Panovic, I.; Bird, E.J.; Gloster, T.M.; Lancefield, C.S.; Westwood, N.J. Analysis of the product streams obtained on butanosolv pretreatment of draff. Biomass Bioenergy 2020, 141, 105680. [Google Scholar] [CrossRef]

- Martín-García, B.; Tylewicz, U.; Verardo, V.; Pasini, F.; Gómez-Caravaca, A.M.; Caboni, M.F.; Dalla Rosa, M. Pulsed electric field (PEF) as pre-treatment to improve the phenolic compounds recovery from brewers’ spent grains. Innov. Food Sci. Emerg. Technol. 2020, 64, 102402. [Google Scholar] [CrossRef]

- Alonso-Riaño, P.; Sanz, M.T.; Benito-Román, O.; Beltrán, S.; Trigueros, E. Subcritical water as hydrolytic medium to recover and fractionate the protein fraction and phenolic compounds from craft brewer’s spent grain. Food Chem. 2021, 351, 129264. [Google Scholar] [CrossRef] [PubMed]

- McCarthy, A.L.; O’Callaghan, Y.C.; Piggott, C.O.; FitzGerald, R.J.; O’Brien, N.M. Brewers’ spent grain; bioactivity of phenolic component, its role in animal nutrition and potential for incorporation in functional foods: A review. Proc. Nutr. Soc. 2013, 72, 117–125. [Google Scholar] [CrossRef] [Green Version]

- Moreira, M.M.; Morais, S.; Carvalho, D.O.; Barros, A.A.; Delerue-Matos, C.; Guido, L.F. Brewer’s spent grain from different types of malt: Evaluation of the antioxidant activity and identification of the major phenolic compounds. Food Res. Int. 2013, 54, 382–388. [Google Scholar] [CrossRef] [Green Version]

- Da Costa Maia, I.; dos Santos D’Almeida, C.T.; Freire, D.M.G.; Cavalcanti, E.D.A.C.; Cameron, L.C.; Dias, J.F.; Ferreira, M.S.L. Effect of solid-state fermentation over the release of phenolic compounds from brewer’s spent grain revealed by UPLC-MSE. LWT 2020, 133, 110136. [Google Scholar] [CrossRef]

- Patrignani, M.; Brantsen, J.F.; Awika, J.M.; Conforti, P.A. Application of a novel microwave energy treatment on brewers’ spent grain (BSG): Effect on its functionality and chemical characteristics. Food Chem. 2021, 346, 128935. [Google Scholar] [CrossRef] [PubMed]

- Mussatto, S.I.; Ballesteros, L.F.; Martins, S.; Teixeira, J.A. Extraction of antioxidant phenolic compounds from spent coffee grounds. Sep. Purif. Technol. 2011, 83, 173–179. [Google Scholar] [CrossRef] [Green Version]

- Kumari, B.; Tiwari, B.K.; Walsh, D.; Griffin, T.P.; Islam, N.; Lyng, J.G.; Rai, D.K. Impact of pulsed electric field pre-treatment on nutritional and polyphenolic contents and bioactivities of light and dark brewer’s spent grains. Innov. Food Sci. Emerg. Technol. 2019, 54, 200–210. [Google Scholar] [CrossRef]

- Stefanello, F.S.; Dos Santos, C.O.; Bochi, V.C.; Fruet, A.P.B.; Soquetta, M.B.; Dörr, A.C.; Nörnberg, J.L. Analysis of polyphenols in brewer’s spent grain and its comparison with corn silage and cereal brans commonly used for animal nutrition. Food Chem. 2018, 239, 385–401. [Google Scholar] [CrossRef]

- Petrón, M.J.; Andrés, A.I.; Esteban, G.; Timón, M.L. Study of antioxidant activity and phenolic compounds of extracts obtained from different craft beer by-products. J. Cereal Sci. 2021, 98, 103162. [Google Scholar] [CrossRef]

- Meneses, N.G.; Martins, S.; Teixeira, J.A.; Mussatto, S.I. Influence of extraction solvents on the recovery of antioxidant phenolic compounds from brewer’s spent grains. Sep. Purif. Technol. 2013, 108, 152–158. [Google Scholar] [CrossRef] [Green Version]

- Carciochi, R.A.; Sologubik, C.A.; Fernández, M.B.; Manrique, G.D.; D’Alessandro, L.G. Extraction of antioxidant phenolic compounds from brewer’s spent grain: Optimization and kinetics modeling. Antioxidants 2018, 7, 45. [Google Scholar] [CrossRef] [Green Version]

- Bower, J. Scotch Whisky: History, Heritage and the Stock Cycle. Beverages 2016, 2, 11. [Google Scholar] [CrossRef]

- Barker, J.E. Calcium Hydroxide Treatment of Spent Grains from the Scotch Whisky Industry. Ph.D. Thesis, University of Glasgow, Scottish Agricultural College, Nutrition and Microbiology Department, Auchincruive, UK, 1991. [Google Scholar]

- Del Río, J.C.; Prinsen, P.; Gutiérrez, A. Chemical composition of lipids in brewer’s spent grain: A promising source of valuable phytochemicals. J. Cereal Sci. 2013, 58, 248–254. [Google Scholar] [CrossRef] [Green Version]

- Andres, A.I.; Petron, M.J.; Lopez, A.M.; Timon, M.L. Optimization of extraction conditions to improve phenolic content and in vitro antioxidant activity in craft brewers’ spent grain using response surface methodology (RSM). Foods 2020, 9, 1398. [Google Scholar] [CrossRef]

- Fărcaş, A.C.; Socaci, S.A.; Dulf, F.V.; Tofană, M.; Mudura, E.; Diaconeasa, Z. Volatile profile, fatty acids composition and total phenolics content of brewers’ spent grain by-product with potential use in the development of new functional foods. J. Cereal Sci. 2015, 64, 34–42. [Google Scholar] [CrossRef]

- Guido, L.F.; Moreira, M.M. Techniques for Extraction of Brewer’s Spent Grain Polyphenols:a Review. Food Bioprocess Technol. 2017, 10, 1192–1209. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Poojary, M.M.; Choudhary, A.; Rai, D.K.; Lund, M.N.; Tiwari, B.K. Ultrasound processing of coffee silver skin, brewer’s spent grain and potato peel wastes for phenolic compounds and amino acids: A comparative study. J. Food Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Stefanello, F.S.; Fruet AP, B.; Trombetta, F.; da Fonseca PA, F.; da Silva MD, S.; Stefanello, S.; Nörnberg, J.L. Stability of vacuum-packed meat from finishing steers fed different inclusion levels of brewer’s spent grain. Meat Sci. 2019, 147, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Jaiswal, A.K.; Abu-Ghannam, N. Optimization of fermentation conditions for the utilization of brewing waste to develop a nutraceutical rich liquid product. Ind. Crops Prod. 2013, 44, 272–282. [Google Scholar] [CrossRef] [Green Version]

- Pedro, A.C.; Granato, D.; Rosso, N.B. Extraction of anthocyanins and polyphenols from black rice Oryza sativa L. by modeling and assessing their reversibility and stability. Food Chem. 2016, 191, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Shih, Y.T.; Wang, W.; Hasenbeck, A.; Stone, D.; Zhao, Y. Investigation of physicochemical, nutritional, and sensory qualities of muffins incorporated with dried brewer’s spent grain flours as a source of dietary fiber and protein. J. Food Sci. 2020, 85, 3943–3953. [Google Scholar] [CrossRef] [PubMed]

- Socaci, S.; Fărcaş, A.C.; Cristian, D.; Rusu, B.; Tofan, M. Influence of the extraction solvent on phenolic content, antioxidant, antimicrobial and antimutagenic activities of brewers’ spent grain. J. Cereal Sci. 2018. [Google Scholar] [CrossRef]

- Skendi, A.; Harasym, J.; Galanakis, C.M. Recovery of high added-value compounds from brewing and distillate processing by-products. In Sustainable Recovery and Reutilization of Cereal Processing by-Products; Elsevier, Woodhead Publishing: Sawston, Cambridge, UK, 2018; pp. 189–225. [Google Scholar]

- Arnao, M.B. Some methodological problems in the determination of antioxidant activity using chromogen radicals: A practical case. Trends Food Sci. Technol. 2000, 11, 419–421. [Google Scholar] [CrossRef]

- Hassan, S.S.; Tiwari, B.K.; Williams, G.A.; Jaiswal, A.K. Bioresource Technology Reports Bioprocessing of brewers’ spent grain for production of xylanopectinolytic enzymes by Mucor sp. Bioresour. Technol. Rep. 2020, 9, 100371. [Google Scholar] [CrossRef]

- Bayu, A.; Nandiyanto, D.; Oktiani, R.; Ragadhita, R. How to Read and Interpret FTIR Spectroscope of Organic Material. Indones. J. Sci. Technol. 2019, 1, 97–118. [Google Scholar] [CrossRef]

- Lee, S.C.; Prosky, L.; DeVries, J.W. Determination of total, soluble, and insoluble, dietary fibre in foods-enzymatic-gravimetric method, MES-TRIS buffer: Collaborative study. J. Assoc. 1992, 75, 395–416. [Google Scholar]

- Leite, P.; Silva, C.; Salgado, J.M.; Belo, I. Simultaneous production of lignocellulolytic enzymes and extraction of antioxidant compounds by solid-state fermentation of agro-industrial wastes. Ind. Crops Prod. 2019, 137, 315–322. [Google Scholar] [CrossRef] [Green Version]

- Singleton, V.L.; Orthofer, R.M.; Ramuela-Raventos, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin- Ciocalteau reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar]

- Spinelli, S.; Conte, A.; Del Nobile, M.A. Microencapsulation of extracted bioactive compounds from brewer’s spent grain to enrich fish-burgers. Food Bioprod. Process 2016, 100, 450–456. [Google Scholar] [CrossRef]

- Ikram, S.; Zhang, H.; Ahmed, M.S.; Wang, J. Ultrasonic pretreatment improved the antioxidant potential of enzymatic protein hydrolysates from highland barley brewer’s spent grain (BSG). J. Food Sci. 2020, 85, 1045–1059. [Google Scholar] [CrossRef]

- Alonso-riaño, P.; Diez, S.; Blanco, B.; Beltr, S. Water Ultrasound-Assisted Extraction of Polyphenol Compounds from Brewer’s Spent Grain: Kinetic Study, Extract Characterization, and Concentration. Antioxidants 2020, 9, 265. [Google Scholar] [CrossRef] [Green Version]

| Factor | Ultra-Turrax Pretreatment | Ultrasound-Assisted Pretreatment | ||||

|---|---|---|---|---|---|---|

| −1 | 0 | +1 | −1 | 0 | +1 | |

| Stirring rate (rpm) (X1) | 10,000 | 20,000 | 30,000 | |||

| Sample mass (g) (X2) | 0.3 | 0.6 | 0.9 | |||

| Solvent concentration (%v/v) (X3) | 40 | 60 | 80 | |||

| Time (sec) (X4) | 30 | 60 | 90 | |||

| Sample mass (g) (X1) | 0.3 | 0.6 | 0.9 | |||

| Solvent concentration (%v/v) (X2) | 40 | 60 | 80 | |||

| Time (sec) (X3) | 10 | 20 | 30 | |||

| Temperature (°C) (X4) | 30 | 50 | 70 | |||

| Ultra−Turax Extraction | Ultrasound Assisted Extraction | |||||

|---|---|---|---|---|---|---|

| TPC | TFC | DPPH | TPC | TFC | DPPH | |

| R2 | 0.9173 | 0.9031 | 0.9477 | 0.8882 | 0.8994 | 0.9483 |

| Adjusted R2 | 0.8208 | 0.7900 | 0.8868 | 0.7578 | 0.7820 | 0.8881 |

| F value | 9.51 | 7.99 | 15.54 | 6.81 | 7.66 | 15.73 |

| p value | 0.0002 | 0.0005 | <0.0001 | 0.001 | 0.0006 | <0.0001 |

| Lack of Fit | 0.0126 | 0.3498 | 0.0529 | 0.6296 | 0.1416 | 0.4432 |

| Constant | +1.40 | +1.36 | +54.75 | +1.44 | +1.28 | +74.13 |

| X1 | +0.22 *** | +0.12 ** | +8.42 *** | −0.32 *** | −0.02 | +7.03 *** |

| X2 | −0.05 | +0.10 * | +16.89 *** | +0.07 | −0.14 ** | +5.92 ** |

| X3 | −0.20 *** | −0.11 * | +1.86 | +0.12 * | −0.02 | +9.13 *** |

| X4 | +0.22 *** | +0.28 *** | +6.45 *** | +0.25 *** | +0.04 | +7.99 *** |

| X1X2 | −0.01 | +0.002 | −0.97 | +0.11 | −0.20 * | +12.19*** |

| X1X3 | +0.05 | +0.21 | +2.38 | +0.27* | +0.23 ** | +3.59 |

| X1X4 | −0.01 | −0.09** | −1.58 | −0.001 | −0.15 * | −1.38 |

| X2X3 | +0.03 | +0.08 | +0.09 | −0.19 | +0.22 * | −2.83 |

| X2X4 | −0.04 | −0.06 | −0.31 | −0.02 | −0.03 | −1.05 |

| X3X4 | −0.004 | −0.007 | +1.27 | −0.16 | −0.47 *** | −9.22 ** |

| X12 | +0.004 | +0.05 | +2.08 | −0.06 | +0.03 | −11.77 *** |

| X22 | +0.05 | −0.09 | −4.41 | −0.18 * | −0.07 | −16.27 *** |

| X32 | −0.24 ** | −0.19 ** | +2.90 | −0.19 * | −0.32 *** | −10.06 *** |

| X42 | −0.08 | −0.12 | −0.51 | +0.10 | +0.03 | −4.83 * |

| Factor | Ultra-Turrax Pretreatment | Ultrasound-Assisted Pretreatment | ||

|---|---|---|---|---|

| Predicted Value | Verified Value | Predicted Value | Verified Value | |

| X1 | 29,999.9 rpm | 30,000 rpm | 0.875 g | 0.875 g |

| X2 | 0.849 g | 0.849 g | 77.7% | 78% |

| X3 | 54.0% | 54% | 21.7 min | 22 min |

| X4 | 89.9 s | 90 s | 68.8 °C | 70 °C |

| TPC (mg GAE/g dry spent grain) | 1.40 ± 0.13 | 1.37 ± 0.11 | 1.44 ± 0.19 | 1.42 ± 0.15 |

| TFC (mg QE/g dry spent grain) | 1.36 ± 0.13 | 1.34 ± 0.15 | 1.29 ± 0.15 | 1.25 ± 0.11 |

| DPPH (%Inhibition) | 54.75 ± 4.85 | 54.77 ± 3.75 | 74.13 ± 5.03 | 74.20 ± 4.39 |

| Compound | Molecular Weight | Wavelength (nm) | Retention Time (min) | Ultra-Turrax Phenolic Content (mg/100g dw) | Ultrasound-Assisted Phenolic Content (mg/100g dw) |

|---|---|---|---|---|---|

| Protocatechuic acid | 154.12 | 280 nm | 13.756 | 0.7 ± 0.05 | N.D. |

| p-hydroxybenzoic acid | 138.12 | 280 nm | 17.876 | 1.1 ± 0.06 | N.D. |

| Vanillic acid | 168.14 | 280 nm | 22.627 | 3.1 ± 0.8 | 10.0 ± 1.03 |

| Caffeic acid | 180.159 | 320 nm | 20.557 | 0.7 ± 0.03 | N.D. |

| Chlorogenic acid | 354.31 | 320 nm | 21.971 | 5.4 ± 1.1 | N.D. |

| p-coumaric acid | 164.047 | 320 nm | 27.503 | 20.4 ± 1.72 | 14.0 ± 1.14 |

| Rosmarinic acid | 360.31 | 320 nm | 30.989 | 6.5 ± 0.96 | 4.0 ± 0.76 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chetrariu, A.; Dabija, A. Spent Grain from Malt Whisky: Assessment of the Phenolic Compounds. Molecules 2021, 26, 3236. https://doi.org/10.3390/molecules26113236

Chetrariu A, Dabija A. Spent Grain from Malt Whisky: Assessment of the Phenolic Compounds. Molecules. 2021; 26(11):3236. https://doi.org/10.3390/molecules26113236

Chicago/Turabian StyleChetrariu, Ancuța, and Adriana Dabija. 2021. "Spent Grain from Malt Whisky: Assessment of the Phenolic Compounds" Molecules 26, no. 11: 3236. https://doi.org/10.3390/molecules26113236