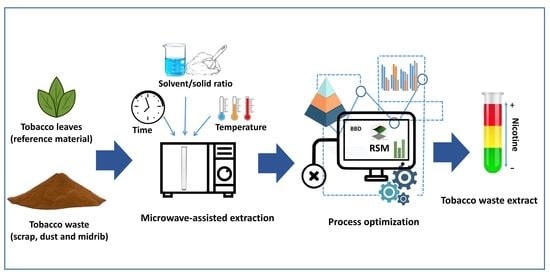

Optimization of MAE for the Separation of Nicotine and Phenolics from Tobacco Waste by Using the Response Surface Methodology Approach

Abstract

:1. Introduction

2. Results and Discussion

2.1. Bioactive Compounds Composition of Tobacco Leaves and Waste Extracts Obtained with MAE

2.2. Analysis of Response Surface Plots

2.3. Statistical Analysis

2.4. Predictive Modeling and Optimization of MAE of Bioactive Compounds from Tobacco Waste

3. Materials and Methods

3.1. Plant Material

3.2. Chemicals and Standards

3.3. Experimental Design, Process Range Conditions and Solvent Choice

3.4. Procedure for Microwave-Assisted Extraction (MAE)

3.5. High Performance Liquid Chromatography (HPLC) Analysis

3.6. Spectrophotometric Assays

3.7. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Banožić, M.; Babić, J.; Jokić, S. Recent advances in extraction of bioactive compounds from tobacco industrial waste-a review. Ind. Crop. Prod. 2020, 144, 112009. [Google Scholar] [CrossRef]

- Wang, J.; Lu, D.; Zhao, H.; Jiang, B.; Wang, J.; Ling, X.; Chai, H.; Ouyang, P. Discrimination and classification of tobacco wastes by identification and quantification of polyphenols with LC–MS/MS. J. Serb. Chem. Soc. 2010, 75, 875–891. [Google Scholar] [CrossRef]

- Rincón, J.; De Lucas, A.; García, M.A. Preliminary study on the supercritical carbon dioxide extraction of nicotine from tobacco wastes. Sep. Sci. Technol. 1998, 33, 411–423. [Google Scholar] [CrossRef]

- Hu, R.S.; Wang, J.; Li, H.; Ni, H.; Chen, Y.-F.; Zhang, Y.W.; Xiang, S.-P.; Li, H.H. Simultaneous extraction of nicotine and solanesol from waste tobacco materials by the column chromatographic extraction method and their separation and purification. Sep. Purif. Technol. 2015, 146, 1–7. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Yang, L.; Liu, B.; Lan, M.; Sun, W. Studies on thermal behavior of reconstituted tobacco sheet. Thermochim. Acta 2005, 437, 7–11. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, W. Study on supercritical fluid extraction of solanesol from industrial tobacco waste. J. Supercrit. Fluid. 2018, 138, 228–237. [Google Scholar] [CrossRef]

- Jokić, S.; Gagić, T.; Knez, Ž.; Banožić, M.; Škerget, M. Separation of active compounds from tobacco waste using subcritical water extraction. J. Supercrit. Fluid. 2019, 153, 104593. [Google Scholar] [CrossRef]

- Banožić, M.; Jozinović, A.; Grgić, J.; Miličević, B.; Jokić, S. High voltage electric discharge for recovery of chlorogenic acid from tobacco waste. Sustainability 2021, 13, 4481. [Google Scholar] [CrossRef]

- Civilini, M.; Domenis, C.; Sebastianutto, N.; Bertoldi, M. Nicotine decontamination of tobacco agro-industrial waste and its degradation by microorganisms. Waste Manag. Res. 1997, 15, 349–358. [Google Scholar] [CrossRef]

- Briški, F.; Horgas, N.; Vuković, M.; Gomzi, Z. Aerobic composting of tobacco industry solid waste—simulation of the process. Clean Technol. Environ. Policy 2003, 5, 295–301. [Google Scholar] [CrossRef]

- Cvjetko Bubalo, M.; Vidović, S.; Radojčić Redovniković, I.; Jokić, S. Green solvents for green technologies. J. Chem. Technol. Biotechnol. 2015, 90, 1631–1639. [Google Scholar] [CrossRef]

- González, A.M.; Barnes, R.M. Comparison of microwave-assisted extraction and waste extraction test (WET) preparation for inductively coupled plasma spectroscopic analyses of waste samples. Anal. Bioanal. Chem. 2002, 374, 255–261. [Google Scholar] [CrossRef]

- Belwal, T.; Chemat, F.; Venskutonis, P.R.; Cravotto, G.; Jaiswal, D.K.; Bhatt, I.D.; Devkota, H.P.; Luo, Z. Recent advances in scaling-up of non-conventional extraction techniques: Learning from successes and failures. TrAC 2020, 127, 115895. [Google Scholar] [CrossRef]

- Eskilsson, C.S.; Björklund, E. Analytical-scale microwave-assisted extraction. J. Chromatogr. A 2000, 902, 227–250. [Google Scholar] [CrossRef]

- Jassie, L.; Revesz, R.; Kierstead, T.; Hasty, E.; Metz, S. Microwave-assisted extraction of polysaccharides. In Microwave-Enhanced Chemistry; Kingston, H.M., Haswell, S.J., Eds.; American Chemical Society: Washington, DC, USA, 1997; p. 569. [Google Scholar]

- Chaturvedi, A.K. Extraction of neutraceuticals from plants by microwave assisted extraction. Sys. Rev. Pharm. 2018, 9, 31–35. [Google Scholar] [CrossRef]

- Garcia-Vaquero, M.; Ummat, V.; Tiwari, B.; Rajauria, G. Exploring ultrasound, microwave and ultrasound–microwave assisted extraction technologies to increase the extraction of bioactive compounds and antioxidants from brown macroalgae. Mar. Drugs 2020, 18, 172. [Google Scholar] [CrossRef] [Green Version]

- Bagade, S.B.; Patil, M. Recent advances in microwave assisted extraction of bioactive compounds from complex herbal samples: A review. Crit. Rev. Anal. Chem. 2019, 15, 1–12. [Google Scholar] [CrossRef]

- Zhu, X.; Su, Q.; Cai, J.; Yang, J. Optimization of microwave-assisted solvent extraction for volatile organic acids in tobacco and its comparison with conventional extraction methods. Anal. Chim. Acta 2006, 579, 88–94. [Google Scholar] [CrossRef]

- Joners, N.M.; Bernardo-Gil, M.G.; Lourenço, M.G. Comparison of methods for extraction of tobacco alkaloids. J. AOAC Int. 2001, 84, 309–316. [Google Scholar] [CrossRef] [Green Version]

- Nie, J.; Yu, G.; Song, Z.; Wang, X.; Li, Z.; She, Y.; Lee, M. Microwave-assisted deep eutectic solvent extraction coupled with headspace solid-phase microextraction followed by GC-MS for the analysis of volatile compounds from tobacco. Analytical Methods 2017, 9, 856–863. [Google Scholar] [CrossRef]

- Zhou, H.Y.; Liu, C.Z. Microwave-assisted extraction of solanesol from tobacco leaves. J. Chromatogr. A 2006, 1129, 135–139. [Google Scholar] [CrossRef]

- Machado, P.A.; Fu, H.; Kratochvil, R.J.; Yuan, Y.; Hahm, T.S.; Sabliov, C.M.; Wei, C.; Lo, Y.M. Recovery of solanesol from tobacco as a value-added byproduct for alternative applications. Bioresour. Technol. 2010, 101, 1091–1096. [Google Scholar] [CrossRef]

- Li, Z.; Huang, D.; Tang, Z.; Deng, C.; Zhang, X. Fast determination of chlorogenic acid in tobacco residues using microwave-assisted extraction and capillary zone electrophoresis technique. Talanta 2010, 82, 1181–1185. [Google Scholar] [CrossRef]

- Banožić, M.; Gagić, T.; Čolnik, M.; Knez, Ž.; Škerget, M.; Jerković, I.; Jokić, S. Sequence of supercritical CO2 extraction and subcritical H2O extraction for the separation of tobacco waste into lipophilic and hydrophilic fractions. Chem. Eng. Res. Des. 2021, 169, 103–115. [Google Scholar] [CrossRef]

- Banožić, M.; Banjari, I.; Jakovljević, M.; Šubarić, D.; Tomas, S.; Babić, J.; Jokić, S. Optimization of ultrasound-assisted extraction of some bioactive compounds from tobacco waste. Molecules 2019, 24, 1611. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Docheva, M.H.; Kochev, Y.G.; Kirkova, D.M.; Stoilova, A.B. Antioxidant activity and chemical composition of crude extracts from different tobaccos and tobacco blends. Bulg. Chem. Commun. 2020, 52, 149–154. [Google Scholar]

- Tayoub, G.; Sulaiman, H.; Alorfi, M. Determination of nicotine levels in the leaves of some Nicotiana tabacum varieties cultivated in Syria. Herba Pol. 2015, 61, 23–30. [Google Scholar] [CrossRef] [Green Version]

- Popova, V.; Ivanova, T.; Stoyanova, A.; Georgiev, V.; Hristeva, T.; Nikolova, V.; Docheva, M.; Nikolov, N.; Damianova, S. Phytochemicals in leaves and extracts of the variety “Plovdiv 7” of Bulgarian oriental tobacco (Nicotiana tabacum L.). Trends Phytochem. Res. 2018, 2, 27–36. [Google Scholar]

- Popova, V.T.; Ivanova, T.A.; Stoyanova, A.S.; Nikolova, V.V.; Docheva, M.H.; Hristeva, T.H.; Nikolov, N.P. Chemical constituents in leaves and aroma products of Nicotiana rustica L. tobacco. Int. J. Food Stud. 2020, 9, 146–159. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Jimmy, Y.Q.; Li, X.; Luo, Y.; Liu, H. Extraction and HPLC characterization of chlorogenic acid from tobacco residuals. Sep. Sci. Technol. 2007, 42, 3481–3492. [Google Scholar] [CrossRef] [Green Version]

- Kamaruddin, M.J.; Hamid, S.R.A.; Othman, S.I.A.; Alam, M.N.H.Z.; Zaini, M.A.A.; Zakaria, Z.Y. The effects of conventional and microwave heating techniques on extraction yield of Orthosiphon stamineus leaves. Chem. Eng. Trans. 2018, 63, 601–606. [Google Scholar]

- Hu, F.; Deng, C.; Liu, Y.; Zhang, X. Quantitative determination of chlorogenic acid in Honeysuckle using microwave-assisted extraction followed by nano-LC-ESI mass spectrometry. Talanta 2009, 77, 1299–1303. [Google Scholar] [CrossRef]

- Alara, O.R.; Abdurahman, N.H.; Olalere, O.A. Optimization of microwave-assisted extraction of flavonoids and antioxidants from Vernonia amygdalina leaf using response surface methodology. Food Bioprod. Process. 2018, 107, 36–48. [Google Scholar] [CrossRef] [Green Version]

- Butorac, J. Duhan; KUGLER d.o.o.: Zagreb, Croatia, 2009; pp. 106–116. [Google Scholar]

- Solarte, D.A.; Ruiz-Matute, A.I.; Chito-Trujillo, D.M.; Rada-Mendoza, M.; Sanz, M.L. Microwave assisted extraction of bioactive carbohydrates from different morphological parts of alfalfa (Medicago sativa L.). Foods 2021, 10, 346. [Google Scholar] [CrossRef]

- Bansal, M.; Sharma, M.; Bullen, C.; Svirskis, D. A stability indicating HPLC method to determine actual content and stability of nicotine within electronic cigarette liquids. Int. J. Environ. Res. Public Health 2018, 13, 1737. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Šafranko, S.; Ćorković, I.; Jerković, I.; Jakovljević, M.; Aladić, K.; Šubarić, D.; Jokić, S. Green extraction techniques for obtaining bioactive compounds from mandarin peel (Citrus unshiu var. Kuno): Phytochemical analysis and process optimization. Foods 2021, 10, 1043. [Google Scholar] [CrossRef] [PubMed]

- Molnar, M.; Jerković, I.; Suknović, D.; Bilić Rajs, B.; Aladić, K.; Šubarić, D.; Jokić, S. screening of six medicinal plant extracts obtained by two conventional methods and supercritical CO2 extraction targeted on coumarin content, 2,2-Diphenyl-1-picrylhydrazyl radical scavenging capacity and total phenols content. Molecules 2017, 22, 348. [Google Scholar] [CrossRef] [Green Version]

- Jakobek, L.; Šeruga, M.; Novak, I.; Medvidović-Kosanović, M. Flavonols, phenolic acids and antioxidant activity of some red fruits. Dtsch. Lebens. Rundsch. 2007, 103, 369–378. [Google Scholar]

| Run | Yield (%) | Nicotine (%) | DPPH (%) | TPC (%) | Individual Phenolic Compounds Concentration | ||||

|---|---|---|---|---|---|---|---|---|---|

| CA (%) | Rutin (%) | NCA (%) | CCA (%) | Nicotiflorin (%) | |||||

| 1 | 57.700 | 2.442 | 72.611 | 4.144 | 0.966 | 0.327 | 0.409 | 0.432 | 0.067 |

| 2 | 52.320 | 4.781 | 75.168 | 3.933 | 0.939 | 0.256 | 0.279 | 0.168 | 0.063 |

| 3 | 44.080 | 5.095 | 69.128 | 3.733 | 1.423 | 0.161 | 0.291 | 0.399 | nd |

| 4 | 46.340 | 1.512 | 38.156 | 1.933 | 0.145 | 0.111 | 0.054 | 0.017 | nd |

| 5 | 60.780 | 3.565 | 76.350 | 4.000 | 1.143 | 0.399 | 0.344 | 0.401 | 0.072 |

| 6 | 49.860 | 4.799 | 80.761 | 4.078 | 1.501 | 0.492 | 0.323 | 0.413 | 0.072 |

| 7 | 48.120 | 5.106 | 75.328 | 3.800 | 0.979 | 0.250 | 0.244 | 0.229 | 0.044 |

| 8 | 46.001 | 5.480 | 76.926 | 4.000 | 0.864 | 0.371 | 0.226 | 0.161 | nd |

| 9 | 42.640 | 5.022 | 80.153 | 3.400 | 0.867 | 0.396 | 0.193 | 0.152 | nd |

| 10 | 55.680 | 3.066 | 53.404 | 3.000 | 0.321 | 0.314 | 0.105 | 0.095 | nd |

| 11 | 69.780 | 5.286 | 84.660 | 4.511 | 0.822 | 0.635 | 0.180 | 0.225 | 0.089 |

| 12 | 56.520 | 4.248 | 71.492 | 4.444 | 0.479 | 0.341 | 0.218 | 0.210 | 0.071 |

| 13 | 39.960 | 4.335 | 73.282 | 3.600 | 0.979 | 0.266 | 0.119 | 0.108 | 0.041 |

| 14 | 53.040 | 4.335 | 81.400 | 3.800 | 0.653 | 0.504 | 0.166 | 0.162 | 0.071 |

| 15 | 49.080 | 5.126 | 88.910 | 4.367 | 0.894 | 0.367 | 0.174 | 0.185 | 0.087 |

| 16 | 19.402 | 4.733 | 83.190 | 3.644 | 0.839 | 0.534 | 0.206 | 0.187 | 0.076 |

| 17 | 47.080 | 5.392 | 79.134 | 4.289 | 0.903 | 0.296 | 0.168 | 0.166 | 0.043 |

| Run | Yield (%) | Nicotine (%) | DPPH (%) | TPC (%) | Individual Phenolic Compounds Concentration | ||||

|---|---|---|---|---|---|---|---|---|---|

| CA (%) | Rutin (%) | NCA (%) | CCA (%) | Nicotiflorin (%) | |||||

| 1 | 54.720 | 2.053 | 67.018 | 4.633 | 0.229 | 0.222 | 0.151 | 0.058 | 0.064 |

| 2 | 52.960 | 2.976 | 43.635 | 3.622 | 0.329 | 0.256 | 0.197 | 0.050 | 0.042 |

| 3 | 41.480 | 3.427 | 55.378 | 3.933 | 0.401 | 0.253 | 0.048 | 0.041 | 0.042 |

| 4 | 35.980 | 2.843 | 54.084 | 4.133 | 0.468 | 0.464 | 0.081 | 0.068 | 0.082 |

| 5 | 58.530 | 2.078 | 63.751 | 4.300 | 0.289 | 0.175 | 0.074 | 0.045 | 0.075 |

| 6 | 47.200 | 2.758 | 62.730 | 4.567 | 0.430 | 0.326 | 0.075 | 0.050 | 0.053 |

| 7 | 47.080 | 3.196 | 56.603 | 3.889 | 0.332 | 0.288 | 0.179 | 0.043 | 0.046 |

| 8 | 50.120 | 3.327 | 55.514 | 3.633 | 0.367 | 0.265 | 0.154 | 0.030 | 0.043 |

| 9 | 48.180 | 3.547 | 47.107 | 3.611 | 0.394 | 0.251 | 0.156 | 0.064 | 0.040 |

| 10 | 42.240 | 3.117 | 42.478 | 4.011 | 0.312 | 0.307 | 0.138 | 0.056 | 0.052 |

| 11 | 47.120 | 3.709 | 50.294 | 3.889 | 0.495 | 0.631 | 0.191 | 0.092 | 0.057 |

| 12 | 69.081 | 1.886 | 47.759 | 4.244 | 0.180 | 0.130 | 0.169 | 0.057 | 0.057 |

| 13 | 43.202 | 2.975 | 24.174 | 2.811 | 0.334 | 0.222 | 0.162 | 0.031 | 0.044 |

| 14 | 43.960 | 3.115 | 66.351 | 4.711 | 0.525 | 0.469 | 0.256 | 0.136 | 0.083 |

| 15 | 42.740 | 3.450 | 57.849 | 4.578 | 0.257 | 0.353 | 0.183 | 0.039 | 0.056 |

| 16 | 46.380 | 3.330 | 50.038 | 3.611 | 0.449 | 0.312 | 0.188 | 0.082 | 0.050 |

| 17 | 45.000 | 2.870 | 43.380 | 2.756 | 0.417 | 0.256 | 0.188 | 0.041 | 0.043 |

| Run | Yield (%) | Nicotine (%) | DPPH (%) | TPC (%) | Individual Phenolic Compounds Concentration | ||||

|---|---|---|---|---|---|---|---|---|---|

| CA (%) | Rutin (%) | NCA (%) | CCA (%) | Nicotiflorin (%) | |||||

| 1 | 49.640 | 2.720 | 14.571 | 1.397 | 0.273 | 0.126 | 0.181 | 0.028 | 0.040 |

| 2 | 38.560 | 3.270 | 21.793 | 1.840 | 0.880 | 0.514 | 0.226 | 0.066 | 0.090 |

| 3 | 35.640 | 3.717 | 23.867 | 1.963 | 0.584 | 0.568 | 0.228 | 0.074 | 0.099 |

| 4 | 42.920 | 3.505 | 18.335 | 1.480 | 0.425 | 0.313 | 0.177 | 0.038 | 0.050 |

| 5 | 58.230 | 2.628 | 12.266 | 1.448 | 1.112 | 0.284 | 0.188 | 0.030 | 0.050 |

| 6 | 37.820 | 3.930 | 26.658 | 2.027 | 0.454 | 0.501 | 0.235 | 0.059 | 0.088 |

| 7 | 37.800 | 4.064 | 30.166 | 1.928 | 0.952 | 0.496 | 0.232 | 0.062 | 0.086 |

| 8 | 47.960 | 3.238 | 36.389 | 2.257 | 1.019 | 0.505 | 0.245 | 0.116 | 0.070 |

| 9 | 48.075 | 3.467 | 9.040 | 2.196 | 0.932 | 0.534 | 0.344 | 0.117 | 0.074 |

| 10 | 47.520 | 4.840 | 12.343 | 2.763 | 0.945 | 0.218 | 0.119 | 0.012 | 0.039 |

| 11 | 39.080 | 3.349 | 44.123 | 2.182 | 0.237 | 0.422 | 0.219 | 0.066 | 0.079 |

| 12 | 52.880 | 2.654 | 19.565 | 1.922 | 0.484 | 0.180 | 0.274 | 0.219 | 0.041 |

| 13 | 38.320 | 3.405 | 31.396 | 2.336 | 0.737 | 0.602 | 0.245 | 0.068 | 0.095 |

| 14 | 46.440 | 3.293 | 26.709 | 2.277 | 0.546 | 0.333 | 0.203 | 0.036 | 0.051 |

| 15 | 29.420 | 3.408 | 27.478 | 2.231 | 1.135 | 0.418 | 0.236 | 0.249 | 0.073 |

| 16 | 40.680 | 3.196 | 32.241 | 2.657 | 0.473 | 0.534 | 0.245 | 0.243 | 0.092 |

| 17 | 38.960 | 3.169 | 31.396 | 2.697 | 0.931 | 0.485 | 0.252 | 0.073 | 0.085 |

| Run | Yield (%) | Nicotine (%) | DPPH (%) | TPC (%) | Individual Phenolic Compounds Concentration | ||||

|---|---|---|---|---|---|---|---|---|---|

| CA (%) | Rutin (%) | NCA (%) | CCA (%) | Nicotiflorin (%) | |||||

| 1 | 49.000 | 1.503 | 30.960 | 1.552 | 0.101 | 0.103 | 0.077 | 0.001 | 0.037 |

| 2 | 52.760 | 1.310 | 29.642 | 1.054 | 0.192 | 0.100 | 0.069 | nd | nd |

| 3 | 49.280 | 1.656 | 23.352 | 1.280 | 0.153 | 0.104 | 0.056 | nd | nd |

| 4 | 42.520 | 1.619 | 59.896 | 2.806 | 0.014 | 0.166 | 0.323 | 0.444 | 0.075 |

| 5 | 57.960 | 1.325 | 32.553 | 1.288 | 0.185 | 0.099 | 0.081 | 0.001 | nd |

| 6. | 37.840 | 1.379 | 40.716 | 1.484 | 0.250 | 0.140 | 0.090 | 0.009 | nd |

| 7 | 47.600 | 1.543 | 38.173 | 1.328 | 0.193 | 0.099 | 0.076 | 0.242 | nd |

| 8 | 51.440 | 1.322 | 45.969 | 2.637 | 0.193 | 0.106 | 0.064 | nd | 0.073 |

| 9 | 53.100 | 1.323 | 44.296 | 1.266 | 0.208 | 0.119 | 0.070 | nd | nd |

| 10 | 47.160 | 0.867 | 33.322 | 1.302 | 0.212 | 0.113 | 0.056 | nd | nd |

| 11 | 43.600 | 1.628 | 48.652 | 1.393 | 0.190 | 0.094 | 0.055 | nd | nd |

| 12 | 52.400 | 1.247 | 31.014 | 1.713 | 0.113 | 0.096 | 0.090 | nd | 0.074 |

| 13 | 49.600 | 1.403 | 45.902 | 2.294 | 0.188 | 0.095 | 0.068 | nd | nd |

| 14 | 49.160 | 1.272 | 42.623 | 2.261 | 0.202 | 0.120 | 0.088 | nd | nd |

| 15 | 41.900 | 1.783 | 36.132 | 1.479 | 0.266 | 0.141 | 0.086 | nd | nd |

| 16 | 51.720 | 1.442 | 42.489 | 1.274 | 0.228 | 0.098 | 0.076 | nd | nd |

| 17 | 50.400 | 1.431 | 43.961 | 1.238 | 0.211 | 0.115 | 0.074 | nd | nd |

| Leaves | Scrap | Dust | Midrib | |

|---|---|---|---|---|

| Criteria: Maximum extraction yield with maximum nicotine content | ||||

| Temperature (°C) | 80.0 | 80.0 | 80.31 | 80.0 |

| Time (min) | 5.0 | 5.0 | 5.0 | 25.0 |

| Solvent/solid ratio (mL/g) | 26.1 | 29.8 | 30.01 | 30.00 |

| Predicted yield value (%) | 68.624 | 49.868 | 48.888 | 53.455 |

| Predicted nicotine value (%) | 5.638 | 3.268 | 4.058 | 1.603 |

| Criteria: Maximum extraction yield with minimum nicotine content | ||||

| Temperature (°C) | 120.0 | 120.0 | 119.3 | 120.0 |

| Time (min) | 25.0 | 25.0 | 19.4 | 11.2 |

| Solvent/solid ratio (mL/g) | 10.0 | 19.1 | 30.0 | 30.0 |

| Predicted yield value (%) | 66.123 | 68.315 | 58.233 | 55.961 |

| Predicted nicotine value (%) | 2.311 | 1.870 | 2.628 | 1.045 |

| Run | Temperature (°C) | Time (min) | Solvent/Solid Ratio (mL/g) |

|---|---|---|---|

| 1 | 120 | 15 | 10 |

| 2 | 100 | 15 | 20 |

| 3 | 80 | 25 | 20 |

| 4 | 80 | 15 | 10 |

| 5 | 120 | 15 | 30 |

| 6 | 100 | 25 | 10 |

| 7 | 100 | 15 | 20 |

| 8 | 100 | 15 | 20 |

| 9 | 80 | 15 | 30 |

| 10 | 100 | 5 | 30 |

| 11 | 80 | 5 | 20 |

| 12 | 120 | 25 | 20 |

| 13 | 100 | 15 | 20 |

| 14 | 120 | 5 | 20 |

| 15 | 100 | 5 | 10 |

| 16 | 100 | 25 | 30 |

| 17 | 100 | 15 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banožić, M.; Banjari, I.; Flanjak, I.; Paštar, M.; Vladić, J.; Jokić, S. Optimization of MAE for the Separation of Nicotine and Phenolics from Tobacco Waste by Using the Response Surface Methodology Approach. Molecules 2021, 26, 4363. https://doi.org/10.3390/molecules26144363

Banožić M, Banjari I, Flanjak I, Paštar M, Vladić J, Jokić S. Optimization of MAE for the Separation of Nicotine and Phenolics from Tobacco Waste by Using the Response Surface Methodology Approach. Molecules. 2021; 26(14):4363. https://doi.org/10.3390/molecules26144363

Chicago/Turabian StyleBanožić, Marija, Ines Banjari, Ivana Flanjak, Mate Paštar, Jelena Vladić, and Stela Jokić. 2021. "Optimization of MAE for the Separation of Nicotine and Phenolics from Tobacco Waste by Using the Response Surface Methodology Approach" Molecules 26, no. 14: 4363. https://doi.org/10.3390/molecules26144363

APA StyleBanožić, M., Banjari, I., Flanjak, I., Paštar, M., Vladić, J., & Jokić, S. (2021). Optimization of MAE for the Separation of Nicotine and Phenolics from Tobacco Waste by Using the Response Surface Methodology Approach. Molecules, 26(14), 4363. https://doi.org/10.3390/molecules26144363