Analysis of Single-Step Pretreatments for Lignocellulosic Platform Isolation as the Basis of Biorefinery Design

Abstract

:1. Introduction

2. Results and Discussion

2.1. Pretreatment Screening

| Pretreatment | Raw Material | Operating Conditions | (%) | (%) *** | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | Pressure (bar) | Log (R0) | Cellulose | Hemicellulose | Lignin | ||||

| Kraft | Eucalyptus globulus | 155 | - | 3.09 | 10.0 | 39.4 | 84.6 | 62.0 | [40] |

| Organosolv | Wheat straw | 160 | - | 3.37 | 19.6 | 93.4 | 62.5 | 77.9 | [41] |

| Ionic liquids | Corn stover | 160 | - | 4.02 | 15.5 | 81.5 | 69.2 | 75.4 | [42] |

| Diluted acid | Bamboo green | 180 | - | 3.83 | 9.9 | 98.8 | 16.6 | 57.7 | [43] |

| RAAE * | Corn stalks | 85 | 20.4 | 0.67 | 10.3 | 14.1 | 71.4 | 42.8 | [32] |

| Wet air oxidation | Rice husk | 195 | 5.0 | 3.79 | 7.1 | 75.5 | 97.3 | 86.4 | [44] |

| AFEX ** | Corn stover | 130 | 44.8 | 2.06 | 27.8 | 34.6 | 23.5 | 29.1 | [45] |

| Biological | Corn stalks | 28 | - | 2.66 | 57.0 | 41.0 | 11.0 | 14.1 | [46] |

| Biological | Switchgrass | 28 | - | 2.29 | 22.0 | 14 | 24 | 81 | [47] |

| Pretreatment | Raw Material | Operating Conditions | (%) | (%) *** | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | Pressure (bar) | Log (R0) | Cellulose | Hemicellulose | Lignin | ||||

| Steam explosion | Sugarcane bagasse | 195 | - | 3.67 | 2.3 | 81.7 | 12.1 | 92.8 | [37] |

| LHW * | Bermuda grass | 170 | - | 3.84 | 29.8 | 88.8 | 33.8 | 68.2 | [48] |

| Organosolv | Wheat straw | 160 | - | 3.34 | 19.6 | 93.4 | 62.5 | 58.9 | [41] |

| Ionic liquids | Switchgrass | 160 | - | 4.02 | 15.5 | 81.5 | 69.2 | 57.6 | [42] |

| Diluted acid | Bamboo green | 180 | - | 3.83 | 9.9 | 98.8 | 16.6 | 86.8 | [43] |

| ARP ** | Corn stover | 170 | 23.0 | 3.06 | 39.8 | 63.3 | 80.4 | 39.9 | [49] |

| Biological | Hardwood | 28 | - | 2.28 | 15.8 | 17.9 | 3.0 | 93.6 | [47] |

| Biological | Wheat straw | 28 | - | 2.48 | 16 | 94 | 49 | 67.5 | [50] |

| Pretreatment | Raw Material | Operating Conditions | (%) | (%) **** | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | Pressure (bar) | Log (R0) | Cellulose | Hemicellulose | Lignin | ||||

| Alkali | Eucalyptus camaldulensis | 150 | - | 3.25 | 6.7 | 33.3 | 63.6 | 79.9 | [51] |

| Kraft | Eucalyptus globulus | 165 | - | 3.69 | 17.2 | 51.0 | 97.4 | 65.9 | [40] |

| LHW * | Wheat straw | 190 | - | 3.95 | 41.8 | 92.3 | 64.9 | 32.9 | [52] |

| Ionic liquids | Corn stover | 140 | - | 3.43 | 49.4 | 56.9 | 94.4 | 46.8 | [53] |

| RAAE ** | Corn stalks | 85 | 20.4 | 0.67 | 10.3 | 14.2 | 71.4 | 87.7 | [32] |

| Organosolv | Wheat straw | 160 | - | 3.37 | 19.6 | 93.4 | 62.5 | 43.5 | [41] |

| ARP *** | Corn stover | 170 | 23.0 | 3.06 | 39.8 | 63.3 | 80.4 | 79.9 | [49] |

| Biological | Bamboo culms | 60 | - | 2.28 | 8.8 | 53.3 | 95.6 | [54] | |

| Biological | Corn stover | 28 | - | 2.66 | 58 | 51 | 64 | 45.5 | [55] |

2.2. By-Product and Inhibitors Formation

2.3. Techno-Economic Analysis

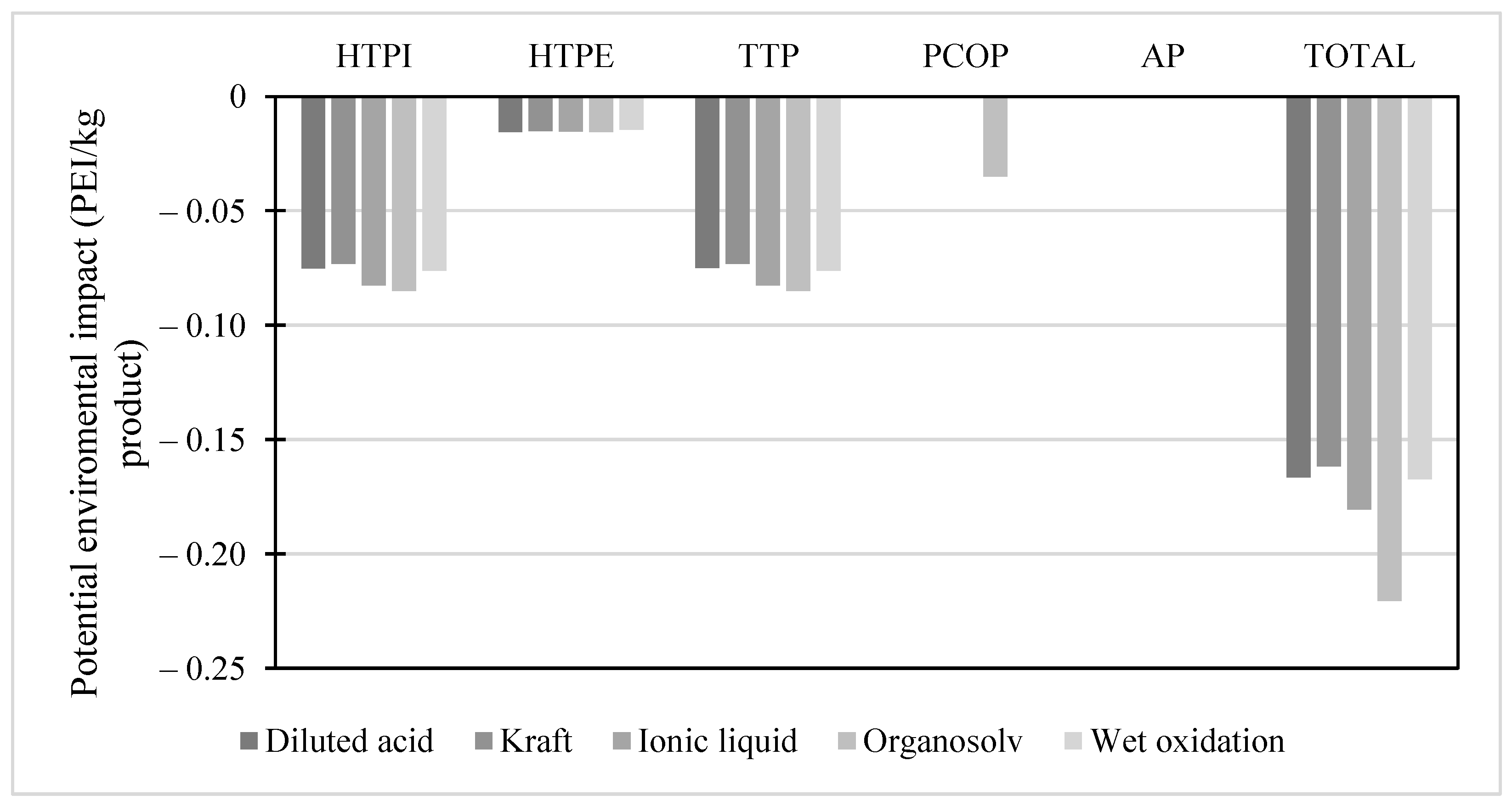

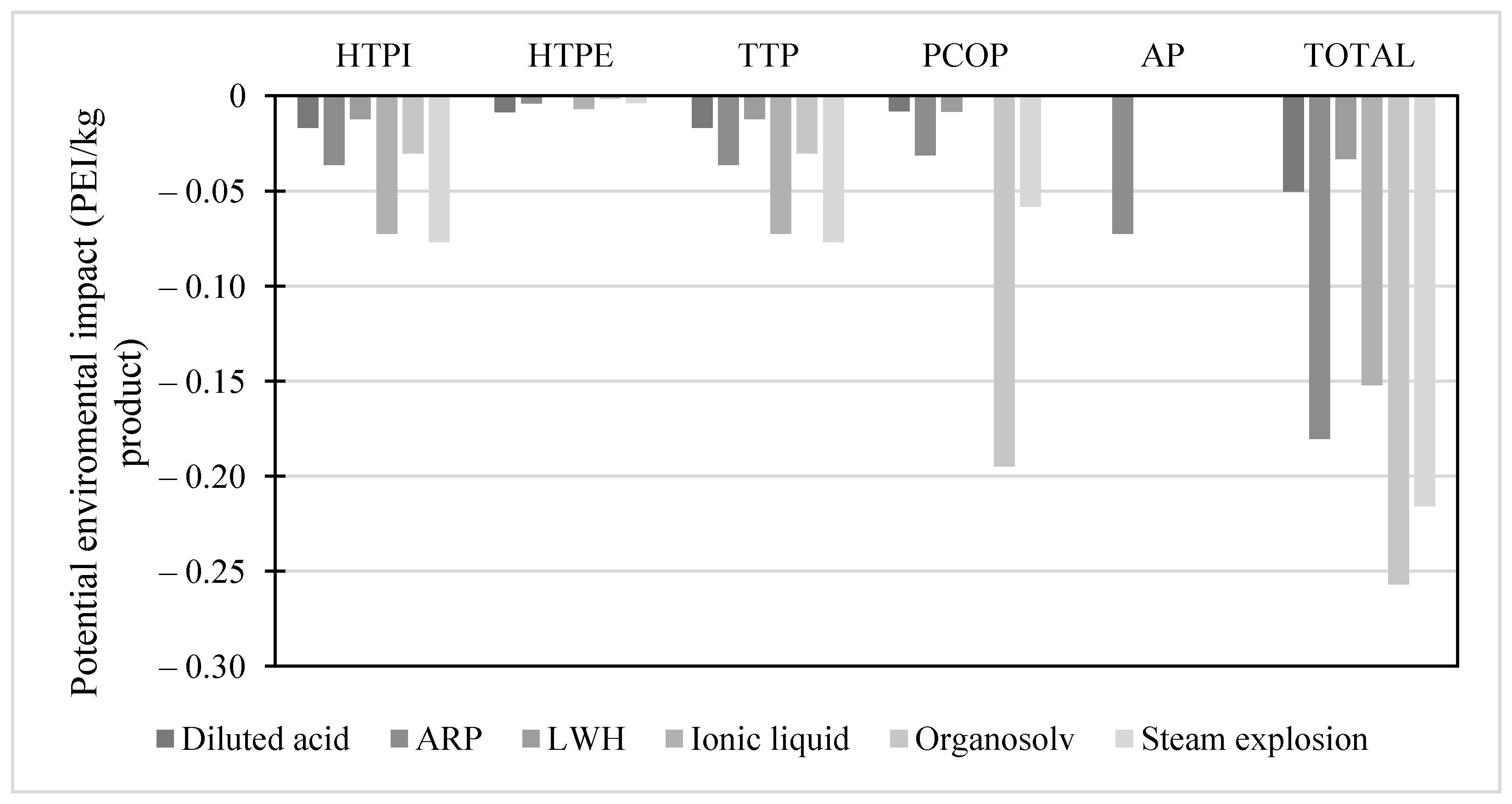

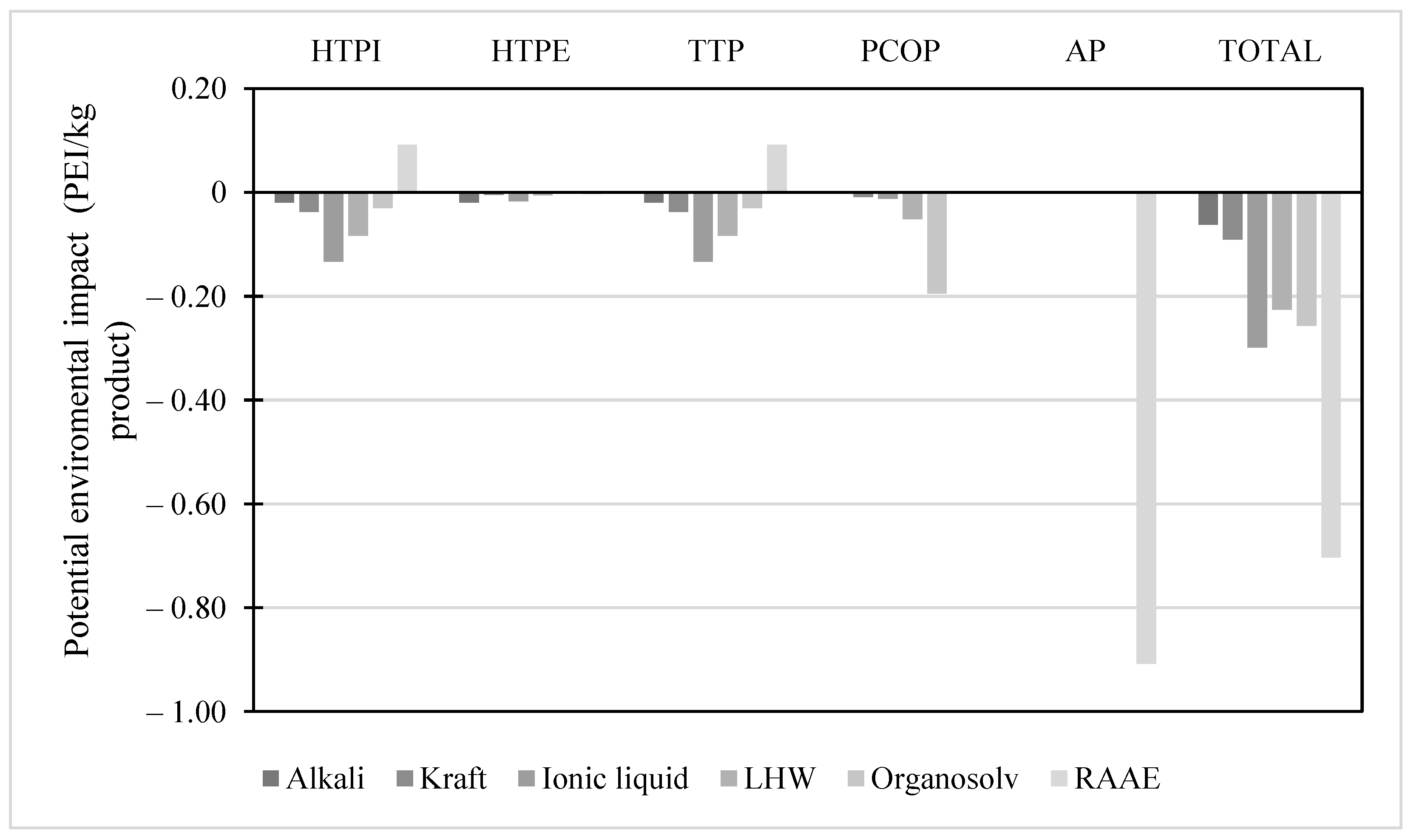

2.4. Environmental Analysis

2.5. Social Analysis

2.6. Pretreatment Efficacy

3. Methodology

3.1. Pretreatment Screening

3.2. Efficacy Assessment

3.3. Simulation Procedure

3.3.1. Techno-Economic Assessment

3.3.2. Environmental Assessment

3.3.3. Social Assessment

Stakeholder: Local Community

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moncada, B.J.; Aristizábal, M.V.; Cardona, A.C.A. Design strategies for sustainable biorefineries. Biochem. Eng. J. 2016, 116, 122–134. [Google Scholar] [CrossRef]

- Smith, R. Chemical Process: Design and Integration, 1st ed.; McGraw-Hill: Manchester, UK, 2005. [Google Scholar] [CrossRef] [Green Version]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Aristizábal, M.V.; Gómez, P.Á.; Cardona, A.C.A. Biorefineries based on coffee cut-stems and sugarcane bagasse: Furan-based compounds and alkanes as interesting products. Bioresour. Technol. 2015, 196, 480–489. [Google Scholar] [CrossRef] [PubMed]

- JSolarte-Toro, C.; Alzate, C.A.C. Biorefineries as the base for accomplishing the sustainable development goals (SDGs) and the transition to bioeconomy: Technical aspects, challenges and perspectives. Bioresour. Technol. 2021, 340, 125626. [Google Scholar] [CrossRef]

- Bautista, S.; Enjolras, M.; Narvaez, P.; Camargo, M.; Morel, L. Biodiesel-triple bottom line (TBL): A new hierarchical sustainability assessment framework of principles criteria & indicators (PC&I) for biodiesel production. Part II-validation. Ecol. Indic. 2016, 69, 803–817. [Google Scholar] [CrossRef]

- Alzate, C.A.C.; Aristiza, V.; Botero, J.M. Biorefineries: Design and Analysis; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2019. [Google Scholar] [CrossRef]

- Gutiérrez, C.D.B.; Serna, D.L.R.; Alzate, C.A.C. A comprehensive review on the implementation of the biorefinery concept in biodiesel production plants. Biofuel Res. J. 2017, 4, 691–703. [Google Scholar] [CrossRef]

- Aristizábal-Marulanda, V.; Alzate, C.A.C. Methods for designing and assessing biorefineries: Review. Biofuels Bioprod. Biorefining 2019, 13, 789–8082019. [Google Scholar] [CrossRef]

- Berndes, G.; Hoogwijk, M.; van den Broek, R. The contribution of biomass in the future global energy supply: A review of 17 studies. Biomass Bioenergy 2003, 25, 1–28. [Google Scholar] [CrossRef]

- Galbe, M.; Wallberg, O. Pretreatment for biorefineries: A review of common methods for efficient utilisation of lignocellulosic materials. Biotechnol. Biofuels 2019, 12, 294. [Google Scholar] [CrossRef] [Green Version]

- Chandel, A.K.; Garlapati, V.K.; Singh, A.K.; Antunes, F.A.F.; da Silva, S.S. The path forward for lignocellulose biorefineries: Bottlenecks, solutions, and perspective on commercialization. Bioresour. Technol. 2018, 264, 370–381. [Google Scholar] [CrossRef]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef] [PubMed]

- Easson, M.W.; Condon, B.; Dien, B.S.; Iten, L.; Slopek, R.; Yoshioka-Tarver, M.; Lambert, A.; Smith, J. The application of ultrasound in the enzymatic hydrolysis of switchgrass. Appl. Biochem. Biotechnol. 2011, 165, 1322–1331. [Google Scholar] [CrossRef] [PubMed]

- Gupta, R.; Khasa, Y.P.; Kuhad, R.C. Evaluation of pretreatment methods in improving the enzymatic saccharification of cellulosic materials. Carbohydr. Polym. 2011, 84, 1103–1109. [Google Scholar] [CrossRef]

- Lopez-Hidalgo, A.M.; Magaña, G.; Rodriguez, F.; de Leon-Rodriguez, A.; Sanchez, A. Co-production of ethanol-hydrogen by genetically engineered Escherichia coli in sustainable biorefineries for lignocellulosic ethanol production. Chem. Eng. J. 2021, 406, 126829. [Google Scholar] [CrossRef]

- Wang, W.; Ling, H.; Zhao, H. Steam explosion pretreatment of corn straw on xylose recovery and xylitol production using hydrolysate without detoxification. Process Biochem. 2015, 50, 1623–1628. [Google Scholar] [CrossRef]

- Silveira, M.H.; Morais, A.R.; da Costa Lopes, A.M.; Olekszyszen, D.N.; Bogel-Łukasik, R.; Andreaus, J.; Pereira Ramos, L. Current Pretreatment Technologies for the Development of Cellulosic Ethanol and Biorefineries. ChemSusChem 2015, 8, 3366–3390. [Google Scholar] [CrossRef] [Green Version]

- Aden, A.; Ruth, M.; Ibsen, K.; Jechura, J.; Neeves, K.; Sheehan, J.; Wallace, B.; Montague, L.; Slayton, A.; Lukas, J. Lignocellulosic Biomass to Ethanol Process Design and Economics Utilizing Co-Current Dilute Acid Prehydrolysis and Enzymatic Hydrolysis for Corn Stover. National Renewable Energy Laboratory. 2002. Available online: http://www.osti.gov/bridge (accessed on 21 October 2022).

- Brunner, G. Processing of Biomass with Hydrothermal and Supercritical Water. In Supercritical Fluid Science and Technology; Elsevier: Amsterdam, The Netherlands, 2014; Volume 5, pp. 395–509. [Google Scholar] [CrossRef]

- Li, L.; Rowbotham, J.S.; Greenwell, H.C.; Dyer, P.W. An Introduction to Pyrolysis and Catalytic Pyrolysis: Versatile Techniques for Biomass Conversion. In New and Future Developments in Catalysis: Catalytic Biomass Conversion; Elsevier B.V.: Oxford, UK, 2013; pp. 173–208. [Google Scholar] [CrossRef]

- Ribca, I.; Jawerth, M.E.; Brett, C.J.; Lawoko, M.; Schwartzkopf, M.; Chumakov, A.; Roth, S.V.; Johansson, M. Exploring the Effects of Different Cross-Linkers on Lignin-Based Thermoset Properties and Morphologies. ACS Sustain. Chem. Eng. 2021, 9, 1692–1702. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Solarte-Toro, J.C.; Alzate, C.A.C. The potential use of lignin as a platform product in biorefineries: A review. Renew. Sustain. Energy Rev. 2021, 138, 110688. [Google Scholar] [CrossRef]

- Demirbas, M.F. Biorefineries for biofuel upgrading: A critical review. Appl. Energy 2009, 86 (Suppl. S1), S151–S161. [Google Scholar] [CrossRef]

- Karimi, K.; Taherzadeh, M.J. A critical review on analysis in pretreatment of lignocelluloses: Degree of polymerization, adsorption/desorption, and accessibility. Bioresour. Technol. 2016, 203, 348–356. [Google Scholar] [CrossRef] [Green Version]

- Nishiyama, Y. Structure and properties of the cellulose microfibril. J. Wood Sci. 2009, 55, 241–249. [Google Scholar] [CrossRef]

- Kumar, P.; Barrett, D.M.; Delwiche, M.J.; Stroeve, P. Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind. Eng. Chem. Res. 2009, 48, 3713–3729. [Google Scholar] [CrossRef]

- Zhang, Y.H.P.; Lynd, L.R. Toward an aggregated understanding of enzymatic hydrolysis of cellulose: Noncomplexed cellulase systems. Biotechnol. Bioeng. 2004, 88, 797–824. [Google Scholar] [CrossRef] [PubMed]

- Santos, E.O.; Silva, A.M.S.; Fragoso, W.D.; Pasquini, C.; Pimentel, M.F. Determination of degree of polymerization of insulating paper using near infrared spectroscopy and multivariate calibration. Vib. Spectrosc. 2010, 52, 154–157. [Google Scholar] [CrossRef]

- Harris, D.; DeBolt, S. Relative crystallinity of plant biomass: Studies on assembly, adaptation and acclimation. PLoS ONE 2008, 3, e2897. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Montipó, S.; Roslander, C.; Camassola, M.; Galbe, M.; Wallberg, O. Steam Pretreatment of Rice Hulls to Release Fermentable Saccharides: An Approach to Improve Recovery of (Hemi)Cellulosic Sugars Through Multivariate Design. Rice Sci. 2021, 28, 501–510. [Google Scholar] [CrossRef]

- Zhang, C.; Pang, F.; Li, B.; Xue, S.; Kang, Y. Recycled aqueous ammonia expansion (RAAE) pretreatment to improve enzymatic digestibility of corn stalks. Bioresour. Technol. 2013, 138, 314–320. [Google Scholar] [CrossRef]

- Bals, B.; Rogers, C.; Jin, M.; Balan, V.; Dale, B. Evaluation of Ammonia Fibre Expansion (AFEX) Pretreatment for Enzymatic Hydrolysis of Switchgrass Harvested in Different Seasons and Locations. Biotechnol. Biofuels 2010, 3, 1. [Google Scholar] [CrossRef] [Green Version]

- Jönsson, L.J.; Alriksson, B.; Nilvebrant, N.O. Bioconversion of lignocellulose: Inhibitors and detoxification. Biotechnol. Biofuels 2013, 6, 16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mishra, A.; Ghosh, S. Saccharification of kans grass biomass by a novel fractional hydrolysis method followed by co-culture fermentation for bioethanol production. Renew. Energy 2020, 146, 750–759. [Google Scholar] [CrossRef]

- Kumar, R.; Mago, G.; Balan, V.; Wyman, C.E. Physical and chemical characterizations of corn stover and poplar solids resulting from leading pretreatment technologies. Bioresour. Technol. 2009, 100, 3948–3962. [Google Scholar] [CrossRef] [PubMed]

- Fockink, D.H.; Sánchez, J.H.; Ramos, L.P. Comprehensive analysis of sugarcane bagasse steam explosion using autocatalysis and dilute acid hydrolysis (H3PO4 and H2SO4) at equivalent combined severity factors. Ind. Crops Prod. 2018, 123, 563–572. [Google Scholar] [CrossRef]

- Ibrahim, M.N.M.; Chuah, S.B.; Rosli, W.D.W. Characterization of lignin precipitated from the soda black liquor of oil pal empty fruit bunch fibers by various mineral acids. ASEAN J. Sci. Technol. Dev. 2004, 21, 57–67. [Google Scholar] [CrossRef]

- Santos, P.S.B.; Erdocia, X.; Gatto, D.A.; Labidi, J. Characterisation of Kraft lignin separated by gradient acid precipitation. Ind. Crops Prod. 2014, 55, 149–154. [Google Scholar] [CrossRef]

- Monrroy, M.; García, J.R.; Mendonça, R.T.; Baeza, J.; Freer, J. Kraft pulping of eucalyptus globulus as a pretreatment for bioethanol production by simultaneous saccharification and fermentation. J. Chil. Chem. Soc. 2012, 57, 1113–1117. [Google Scholar] [CrossRef] [Green Version]

- ISalapa; Katsimpouras, C.; Topakas, E.; Sidiras, D. Organosolv pretreatment of wheat straw for efficient ethanol production using various solvents. Biomass Bioenergy 2017, 100, 10–16. [Google Scholar] [CrossRef]

- Li, C.; Knierim, B.; Manisseri, C.; Arora, R.; Scheller, H.V.; Auer, M.; Vogel, K.P.; Simmons, B.A.; Singh, S. Comparison of dilute acid and ionic liquid pretreatment of switchgrass: Biomass recalcitrance, delignification and enzymatic saccharification. Bioresour. Technol. 2010, 101, 4900–4906. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Jiang, Z.; Fei, B.; Cai, Z.; Pan, X. Comparison of bamboo green, timber and yellow in sulfite, sulfuric acid and sodium hydroxide pretreatments for enzymatic saccharification. Bioresour. Technol. 2014, 151, 91–99. [Google Scholar] [CrossRef]

- Banerjee, S.; Sen, R.; Pandey, R.A.; Chakrabarti, T.; Satpute, D.; Giri, B.S.; Mudliar, S. Evaluation of wet air oxidation as a pretreatment strategy for bioethanol production from rice husk and process optimization. Biomass Bioenergy 2009, 33, 1680–1686. [Google Scholar] [CrossRef]

- Lau, M.W.; Gunawan, C.; Dale, B.E. The impacts of pretreatment on the fermentability of pretreated lignocellulosic biomass: A comparative evaluation between ammonia fiber expansion and dilute acid pretreatment. Biotechnol. Biofuels 2009, 2, 30. [Google Scholar] [CrossRef] [Green Version]

- Du, W.; Yu, H.; Song, L.; Zhang, J.; Weng, C.; Ma, F.; Zhang, X. The promoting effect of byproducts from Irpex lacteus on subsequent enzymatic hydrolysis of bio-pretreated cornstalks. Biotechnol. Biofuels 2011, 4, 37. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wan, C.; Li, Y. Effectiveness of microbial pretreatment by Ceriporiopsis subvermispora on different biomass feedstocks. Bioresour. Technol. 2011, 102, 7507–7512. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.M.; Jameel, H.; Venditti, R.A. A comparison of the autohydrolysis and ammonia fiber explosion (AFEX) pretreatments on the subsequent enzymatic hydrolysis of coastal Bermuda grass. Bioresour. Technol. 2010, 101, 5449–5458. [Google Scholar] [CrossRef] [PubMed]

- Tae, H.K.; Lee, Y.Y. Pretreatment and fractionation of corn stover by ammonia recycle percolation process. Bioresour. Technol. 2005, 96, 2007–2013. [Google Scholar] [CrossRef]

- Cianchetta, S.; di Maggio, B.; Burzi, P.L.; Galletti, S. Evaluation of selected white-rot fungal isolates for improving the sugar yield from wheat straw. Appl. Biochem. Biotechnol. 2014, 173, 609–623. [Google Scholar] [CrossRef]

- Oka, D.; Kobayashi, K.; Isobe, N.; Ogawa, Y.; Yokoyama, T.; Kimura, S.; Kim, U.J.; Tokuyasu, K.; Wada, M. Enzymatic hydrolysis of wood with alkaline treatment. J. Wood Sci. 2013, 59, 484–488. [Google Scholar] [CrossRef]

- Ertas, M.; Han, Q.; Jameel, H.; Chang, H. Enzymatic hydrolysis of autohydrolyzed wheat straw followed by refining to produce fermentable sugars. Bioresour. Technol. 2014, 152, 259–266. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Kumar, R.; Singh, S.; Simmons, B.A.; Balan, V.; Dale, B.E.; Wyman, C.E. Comparison of enzymatic reactivity of corn stover solids prepared by dilute acid, AFEXTM, and ionic liquid pretreatments. Biotechnol. Biofuels 2014, 7, 71. [Google Scholar] [CrossRef] [Green Version]

- Suhara, H.; Kodama, S.; Kamei, I.; Maekawa, N.; Meguro, S. Screening of selective lignin-degrading basidiomycetes and biological pretreatment for enzymatic hydrolysis of bamboo culms. Int. Biodeterior. Biodegradation 2012, 75, 176–180. [Google Scholar] [CrossRef]

- Song, L.; Yu, H.; Ma, F.; Zhang, X. Biological Pretreatment under Non-sterile Conditions for Enzymatic Hydrolysis of Corn Stover. BioResources 2013, 8, 3802–3816. [Google Scholar] [CrossRef]

- de Freitas, C.; Carmona, E.; Brienzo, M. Xylooligosaccharides production process from lignocellulosic biomass and bioactive effects. Bioact. Carbohydr. Diet. Fibre 2019, 18, 100184. [Google Scholar] [CrossRef]

- Samanta, A.K.; Jayapal, N.; Jayaram, C.; Roy, S.; Kolte, A.P.; Senani, S.; Sridhar, M. Xylooligosaccharides as prebiotics from agricultural by-products: Production and applications. Bioact. Carbohydr. Diet. Fibre 2015, 5, 62–71. [Google Scholar] [CrossRef]

- Otieno, D.O.; Ahring, B.K. The potential for oligosaccharide production from the hemicellulose fraction of biomasses through pretreatment processes: Xylooligosaccharides (XOS), arabinooligosaccharides (AOS), and mannooligosaccharides (MOS). Carbohydr. Res. 2012, 360, 84–92. [Google Scholar] [CrossRef] [PubMed]

- Panjiar, N.; Mattam, A.J.; Jose, S.; Gandham, S.; Velankar, H.R. Valorization of xylose-rich hydrolysate from rice straw, an agroresidue, through biosurfactant production by the soil bacterium Serratia nematodiphila. Sci. Total Environ. 2020, 729, 138933. [Google Scholar] [CrossRef] [PubMed]

- Nosrati-Ghods, N.; Harrison, S.T.L.; Isafiade, A.J.; Tai, S.L. Analysis of ethanol production from xylose using Pichia stipitis in microaerobic conditions through experimental observations and kinetic modelling. Biochem. Eng. J. 2020, 164, 107754. [Google Scholar] [CrossRef]

- Bondar, M.; da Fonseca, M.M.R.; Cesário, M.T. Xylonic acid production from xylose by Paraburkholderia sacchari. Biochem. Eng. J. 2021, 170, 107982. [Google Scholar] [CrossRef]

- Poveda-Giraldo, J.A.; Cardona, C.A. Biorefinery potential of Eucalyptus grandis to produce phenolic compounds and biogas. Can. J. For. Res. 2020, 51, 89–100. [Google Scholar] [CrossRef]

- Cazacu, G.; Pascu, M.C.; Profire, L.; Kowarski, A.I.; Mihaes, M.; Vasile, C. Lignin role in a complex polyolefin blend. Ind. Crops Prod. 2004, 20, 261–273. [Google Scholar] [CrossRef]

- Tejado, A.; Peña, C.; Labidi, J.; Echeverria, J.M.; Mondragon, I. Physico-chemical characterization of lignins from different sources for use in phenol-formaldehyde resin synthesis. Bioresour. Technol. 2007, 98, 1655–1663. [Google Scholar] [CrossRef]

- Wahlbom, C.F.; Hahn-Hägerdal, B. Furfural, 5-hydroxymethyl furfural, and acetoin act as external electron acceptors during anaerobic fermentation of xylose in recombinant Saccharomyces cerevisiae. Biotechnol. Bioeng. 2002, 78, 172–178. [Google Scholar] [CrossRef]

- Mathew, A.K.; Abraham, A.; Mallapureddy, K.K.; Sukumaran, R.K. Lignocellulosic Biorefinery Wastes, or Resources? In Waste Biorefinery: Potential and Perspectives; Elsevier: Oxford, UK, 2018; pp. 267–297. [Google Scholar] [CrossRef]

- Pampulha, M.E.; Loureiro-Dias, M.C. Combined effect of acetic acid, pH and ethanol on intracellular pH of fermenting yeast. Appl. Microbiol. Biotechnol. 1989, 31, 547–550. [Google Scholar] [CrossRef]

- Chuetor, S.; Panakkal, E.J.; Ruensodsai, T.; Cheenkachorn, K.; Kirdponpattara, S.; Cheng, Y.S.; Sriariyanun, M. Improvement of enzymatic saccharification and ethanol production from rice straw using recycled ionic liquid: The effect of anti-solvent mixture. Bioengineering 2022, 9, 115. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Seabright, K.; Bajaj, I.; Keffer, D.J.; Alonso, D.M.; Hsieh, C.T.; Li, M.; Chen, H.; Gandomi, Y.A.; Maravelias, C.T.; et al. Performance and Economic Analysis of Organosolv Softwood and Herbaceous Lignins to Activated Carbons as Electrode Materials in Supercapacitors. Front. Energy Res. 2022, 10, 849949. [Google Scholar] [CrossRef]

- Li, Y.; Pan, L.; Zeng, X.; Zhang, R.; Li, X.; Li, J.; Xing, H.; Bao, J. Ammonia exposure causes the imbalance of the gut-brain axis by altering gene networks associated with oxidative metabolism, inflammation and apoptosis. Ecotoxicol. Environ. Saf. 2021, 224, 112668. [Google Scholar] [CrossRef] [PubMed]

- Arias, W.A.A.; Pineda, J.C.; Toro, O.J.S.; Alzate, C.A.C. Comparative analysis of different amylaceous raw materials for obtaining fuel alcohol. In Proceedings of the XXIV Congreso Colombiano de Ingeniería Química, Cali, Colombia, 24–26 September 2007. [Google Scholar]

- Alzate, C.C.; Rodríguez, M.M.; Suárez, J.Q. Selection of appropriate technologies for fuel ethanol production. Ing. De Recur. Nat. Ambiente 2004, 2, 48–55. [Google Scholar]

- Serna-loaiza, S.; Carmona-garcia, E.; Cardona, C.A. Potential raw materials for biorefineries to ensure food security: The Cocoyam case. Ind. Crops Prod. 2018, 126, 92–102. [Google Scholar] [CrossRef]

- Win, N.N.; Weinwurm, F.; Friedl, A. Investigation of organosolv and hot-compressed water pretreatments of rice straw. Biomass Convers. Biorefin. 2016, 6, 355–364. [Google Scholar] [CrossRef]

- Hoşgün, E.Z.; Ay, S.B.; Bozan, B. Effect of sequential pretreatment combinations on the composition and enzymatic hydrolysis of hazelnut shells. Prep. Biochem. Biotechnol. 2020, 51, 570–579. [Google Scholar] [CrossRef]

- Tang, W.; Wu, X.; Huang, C.; Huang, C.; Lai, C.; Yong, Q. Enhancing enzymatic digestibility of waste wheat straw by presoaking to reduce the ash-influencing effect on autohydrolysis. Biotechnol. Biofuels 2019, 12, 222. [Google Scholar] [CrossRef] [Green Version]

- Mood, S.H.; Golfeshan, A.H.; Tabatabaei, M.; Jouzani, G.S.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Shrotri, A.; Kobayashi, H.; Fukuoka, A. Catalytic Conversion of Structural Carbohydrates and Lignin to Chemicals. Adv. Catal. 2017, 60, 59–123. [Google Scholar] [CrossRef]

- Deshavath, N.N.; Dasu, V.V.; Goud, V.; Rao, P.S. Development of dilute sulfuric acid pretreatment method for the enhancement of xylose fermentability. Biocatal. Agric. Biotechnol. 2017, 11, 224–230. [Google Scholar] [CrossRef]

- Martinkus, N.; Latta, G.; Rijkhoff, S.A.; Mueller, D.; Hoard, S.; Sasatani, D.; Pierobon, F.; Wolcott, M. A multi-criteria decision support tool for biorefinery siting: Using economic, environmental, and social metrics for a refined siting analysis. Biomass Bioenergy 2019, 128, 105330. [Google Scholar] [CrossRef]

- Wooley, R.J.; Putsche, V. Development of an ASPEN PLUS Physical Property Database for Biofuels Components; NREL/MP-425-20685; National Renewable Energy Lab: Golden, CO, USA, 1996. [Google Scholar]

- Peters, M.; Timmerhaus, K.; West, R. Plant Design and Economics for Chemical Engineers, 5th ed.; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Maister, K.; di Noi, C.; Ciroth, A.; Srocka, M. PSILCA Database v.3 Documentation; PSILCA: Berlin, Germany, 2020. [Google Scholar]

- Food and Agriculture Organization of the United Nations. AQUASTAT. FAO. 2021. Available online: https://tableau.apps.fao.org/views/ReviewDashboard-v1/country_dashboard?%3Aembed=y&%3AisGuestRedirectFromVizportal=y (accessed on 16 November 2022).

- Martínez, W.A.; Rojas, M.P.; García, J.S.; Martínez, J.F.; Rodríguez, R.A. Proyección Demanda Energía Eléctrica Gas Natural y Combustibles Líquidos 2022–2036; UPME: Bogotá, Colombia, 2021. [Google Scholar]

| Lignocellulosic Fraction | Pretreatment | Yield (kg 100 kg−1) **** | Utilities | ||

|---|---|---|---|---|---|

| Cooling Water (ton h−1) | Steam (ton h−1) | Electricity (kW) | |||

| Cellulose | Wet oxidation | 20.9 | 4220 | 59.6 *** | 147.6 |

| RAAE | 20.2 | 5260 | 547.7 * | 8589.0 | |

| Organosolv | 18.1 | 22,200 | 190.4 * 25.8 ** | 226.3 | |

| Diluted acid | 20.3 | 1580 | 21.2 *** | 9.4 | |

| Kraft | 20.2 | 1580 | 33.3 ** | 151.8 | |

| Ionic liquid | 18.9 | 3720 | 247.3 * 7.8 ** | 361.9 | |

| Hemicellulose | Steam explosion | 9.9 | 1.1 *** | 61.20 | |

| LHW | 11.5 | 1500 | 18.4 ** | 111.8 | |

| Ionic liquid | 0.7 | 327 | 247.3 ** 7.8 ** | 361.9 | |

| Organosolv | 12.2 | 22,100 | 25.4 ** | 308.9 | |

| Diluted acid | 12.8 | 1540 | 21.2 *** | 109.3 | |

| ARP | 8.1 | - | 4.1 ** | 105.1 | |

| Lignin | Alkali | 14.2 | 5860 | 69.4 ** | 236.8 |

| Kraft | 21.6 | 1220 | 16.9 ** | 122.8 | |

| Ionic liquid | 3.4 | 244 | 1.3 * 7.4 *** | 264.3 | |

| LHW | 13.9 | 136 | 4.1 *** | 64.3 | |

| Organosolv | 13.9 | 22,100 | 190.2 * 25.4 ** | 308.9 | |

| RAAE | 15.9 | 5260 | 547.7 * | 8589.0 | |

| Lignocellulosic Fraction | Pretreatment | CapEx (M-USD) | OpEx (M-USD Year−1) | ||||

|---|---|---|---|---|---|---|---|

| Raw Materials | Utilities | Depreciation | Others * | Total | |||

| Cellulose | Wet oxidation | 2.46 | 0.63 | 6.76 | 0.58 | 0.16 | 8.13 |

| RAAE | 6.65 | 1296.46 | 48.23 | 1.57 | 0.41 | 1346.67 | |

| Organosolv | 3.73 | 40.54 | 25.28 | 0.88 | 0.24 | 66.93 | |

| Diluted acid | 0.81 | 0.79 | 2.83 | 0.19 | 0.06 | 3.88 | |

| Kraft | 2.25 | 764.03 | 3.73 | 0.53 | 0.15 | 768.44 | |

| Ionic liquid | 1.96 | 6603.88 | 18.67 | 0.46 | 0.13 | 6623.14 | |

| Hemicellulose | Steam explosion | 0.63 | 0.44 | 0.75 | 0.15 | 0.05 | 1.39 |

| LHW | 0.88 | 0.41 | 2.60 | 0.21 | 0.06 | 3.28 | |

| Ionic liquid | 2.45 | 6603.88 | 18.66 | 0.58 | 0.16 | 6623.27 | |

| Organosolv | 4.09 | 40.76 | 15.80 | 0.97 | 0.26 | 67.30 | |

| Diluted acid | 0.96 | 0.79 | 2.83 | 0.23 | 0.07 | 3.92 | |

| ARP | 1.12 | 0.89 | 0.38 | 0.26 | 0.08 | 1.61 | |

| Lignin | Alkali | 1.62 | 41.60 | 8.19 | 0.38 | 0.11 | 50.28 |

| Kraft | 0.99 | 1.20 | 2.38 | 0.23 | 0.07 | 3.89 | |

| Ionic liquid | 2.15 | 197.47 | 1.51 | 0.51 | 0.14 | 199.63 | |

| LHW | 0.60 | 0.37 | 0.96 | 0.14 | 0.05 | 1.52 | |

| Organosolv | 4.09 | 40.54 | 25.29 | 0.97 | 0.26 | 67.05 | |

| RAAE | 6.45 | 1181.08 | 48.23 | 1.52 | 0.40 | 1231.23 | |

| Lignocellulosic Fraction | Pretreatment | (%) | (%) | (%) | (%) |

|---|---|---|---|---|---|

| Cellulose | Wet oxidation | 1.00 | 1.74 × 10−3 | 2.03 × 10−4 | 1.71 × 10−5 |

| RAAE | 3.27 | 0.32 × 10−3 | 0.01 | 1.53 × 10−4 | |

| Organosolv | 5.20 | 9.05 × 10−3 | 3.11 × 10−4 | 6.06 × 10−5 | |

| Diluted acid | 0.37 | 6.51 × 10−4 | 1.29 × 10−4 | 6.09 × 10−6 | |

| Kraft | 5.62 | 0.10 × 10−3 | 2.08 × 10−4 | 9.56 × 10−6 | |

| Ionic liquid | 0.13 | 2.21 × 10−4 | 4.97 × 10−4 | 7.14 × 10−5 | |

| Hemicellulose | Steam explosion | 0.04 | 6.63 × 10−5 | 2.03 × 10−4 | 3.07 × 10−7 |

| LHW | 0.36 | 6.19 × 10−4 | 0.01 | 5.27 × 10−6 | |

| Ionic liquids | 0.13 | 2.18 × 10−4 | 3.11 × 10−4 | 7.14 × 10−5 | |

| Organosolv | 5.20 | 9.04 × 10−3 | 1.29 × 10−4 | 6.05 × 10−5 | |

| Diluted acid | 0.36 | 6.33 × 10−4 | 2.08 × 10−4 | 6.09 × 10−6 | |

| ARP | 0.21 | 9.47 × 10−7 | 4.97 × 10−4 | 1.17 × 10−6 | |

| Lignin | Alkali | 1.39 | 2.42 × 10−3 | 2.03 × 10−4 | 1.99 × 10−5 |

| Kraft | 0.29 | 5.00 × 10−4 | 0.01 | 4.85 × 10−6 | |

| Ionic liquid | 0.06 | 9.98 × 10−5 | 3.11 × 10−4 | 2.48 × 10−6 | |

| LHW | 0.03 | 5.60 × 10−5 | 1.29 × 10−4 | 1.18 × 10−6 | |

| Organosolv | 5.19 | 9.03 × 10−3 | 2.08 × 10−4 | 6.05 × 10−5 | |

| RAAE | 1.46 | 2.55 × 10−3 | 4.97 × 10−4 | 1.53 × 10−4 |

| Lignocellulosic Fraction | Pretreatment | Evaluative Indicator | |||||||||||

| By-Products | Inhibitors | CapEx | OpEx | Total Using | Total Using | ||||||||

| Weight Factor (%) * | |||||||||||||

| 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 100 | - | ||

| Weight Factor (%) ** | |||||||||||||

| 8 | 10 | 8 | 10 | 12 | 11 | 12 | 12 | 15 | 3 | - | 100 | ||

| Cellulose | Wet oxidation | 9 | 6 | 5 | 8 | 10 | 5 | 4 | 7 | 6 | 8 | 6.8 | 6.7 |

| RAAE | 8 | 8 | 6 | 7 | 8 | 1 | 3 | 2 | 0 | 8 | 5.1 | 4.5 | |

| Organosolv | 9 | 8 | 8 | 6 | 4 | 3 | 5 | 6 | 9 | 6 | 6.3 | 6.3 | |

| Diluted acid | 9 | 6 | 7 | 4 | 9 | 7 | 8 | 8 | 6 | 8 | 7.2 | 7.1 | |

| Kraft | 9 | 4 | 7 | 7 | 4 | 6 | 5 | 3 | 6 | 6 | 5.8 | 5.6 | |

| Ionic liquid | 9 | 9 | 4 | 7 | 8 | 2 | 4 | 1 | 7 | 8 | 5.9 | 5.6 | |

| Hemicellulose | LHW | 7 | 8 | 8 | 5 | 8 | 8 | 7 | 8 | 8 | 7 | 7.7 | 7.6 |

| Organosolv | 6 | 7 | 7 | 5 | 3 | 3 | 9 | 8 | 6 | 6 | 6.4 | 6.2 | |

| Ionic liquids | 8 | 6 | 7 | 3 | 5 | 1 | 7 | 6 | 6 | 8 | 5.7 | 5.5 | |

| Dilute acid | 7 | 4 | 8 | 5 | 8 | 9 | 7 | 8 | 7 | 7 | 7.1 | 7.1 | |

| ARP | 7 | 7 | 4 | 6 | 8 | 8 | 7 | 6 | 7 | 7 | 6.8 | 6.9 | |

| Steam explosion | 7 | 7 | 9 | 8 | 8 | 8 | 8 | 8 | 8 | 7 | 7.5 | 7.5 | |

| Lignin | Alkali | 6 | 8 | 7 | 9 | 10 | 5 | 8 | 6 | 7 | 8 | 7.4 | 7.4 |

| Organosolv | 6 | 4 | 6 | 6 | 8 | 2 | 4 | 5 | 8 | 8 | 5.7 | 5.6 | |

| Kraft | 10 | 7 | 7 | 9 | 10 | 6 | 8 | 8 | 7 | 6 | 7.7 | 7.8 | |

| LHW | 7 | 3 | 7 | 7 | 8 | 8 | 8 | 8 | 8 | 8 | 7.2 | 7.2 | |

| Ionic liquid | 9 | 5 | 7 | 8 | 4 | 8 | 5 | 3 | 8 | 6 | 6.4 | 6.3 | |

| RAAE | 9 | 9 | 6 | 8 | 4 | 1 | 2 | 1 | 7 | 8 | 5.6 | 5.2 | |

| Scale | Description | Group |

|---|---|---|

| 1 | Fundamental research | Research |

| 2 | Technology formulation | |

| 3 | Applied research (proof of concept) | |

| 4 | Small-scale development (laboratory scale) | Development |

| 5 | Scale-up development (pilot scale) | |

| 6 | Full-scale development | |

| 7 | System validated in simulation | Innovation |

| 8 | System validated in real life | |

| 9 | Commercial application |

| Parameter | Mass Composition (g 100 g−1) on a Dry Basis |

|---|---|

| Initial moisture | 12.01 |

| Cellulose | 29.34 |

| Hemicellulose | 15.02 |

| Lignin | 29.14 |

| Total extract | 7.86 |

| Fats | 3.80 |

| Protein | 1.29 |

| Pectin | 13.55 |

| Ash | 18.52 |

| Input | Cost (USD ton−1) | Reference |

|---|---|---|

| Rice husk | 20 | Colombian regional market |

| Sodium carbonate | 234 | Means of Alibaba * |

| Ammonia | 450 | |

| Ethanol | 863 | Colombian regional market |

| Sulfuric acid | 94 | Means of Alibaba * |

| Sodium hydroxide | 450 | |

| Sodium sulfide | 350 | |

| Ionic liquid | 13,500 |

| Stakeholder | Subcategory | Indicator | Unit |

|---|---|---|---|

| Local community | Access to material resources | Level of industrial water use (withdrawal) Level of industrial water use (renewable) Energy demand Extraction of fossil fuels | % % % % |

| Indicator | Equation |

|---|---|

| Level of industrial water use (withdrawal) | |

| Level of industrial water use (renewable) | |

| Energy demand | |

| Extraction of fossil fuels |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poveda-Giraldo, J.A.; Garcia-Vallejo, M.C.; Cardona Alzate, C.A. Analysis of Single-Step Pretreatments for Lignocellulosic Platform Isolation as the Basis of Biorefinery Design. Molecules 2023, 28, 1278. https://doi.org/10.3390/molecules28031278

Poveda-Giraldo JA, Garcia-Vallejo MC, Cardona Alzate CA. Analysis of Single-Step Pretreatments for Lignocellulosic Platform Isolation as the Basis of Biorefinery Design. Molecules. 2023; 28(3):1278. https://doi.org/10.3390/molecules28031278

Chicago/Turabian StylePoveda-Giraldo, Jhonny Alejandro, Maria Camila Garcia-Vallejo, and Carlos Ariel Cardona Alzate. 2023. "Analysis of Single-Step Pretreatments for Lignocellulosic Platform Isolation as the Basis of Biorefinery Design" Molecules 28, no. 3: 1278. https://doi.org/10.3390/molecules28031278