Selective and Efficient Synthesis of Pine Sterol Esters Catalyzed by Deep Eutectic Solvent

Abstract

:1. Introduction

2. Results and Discussion

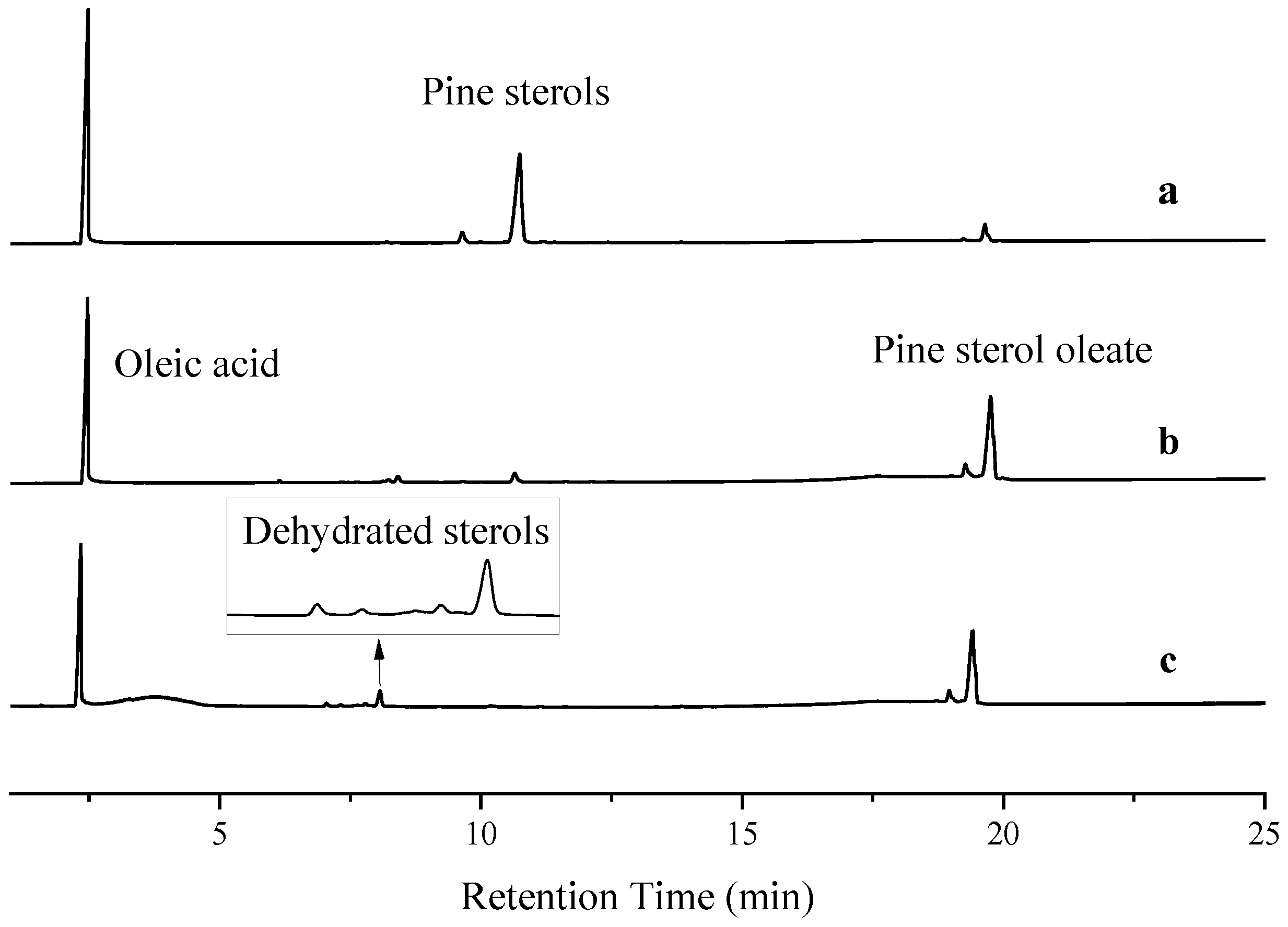

2.1. Characterization of Products

2.2. Screening of DES Catalysts

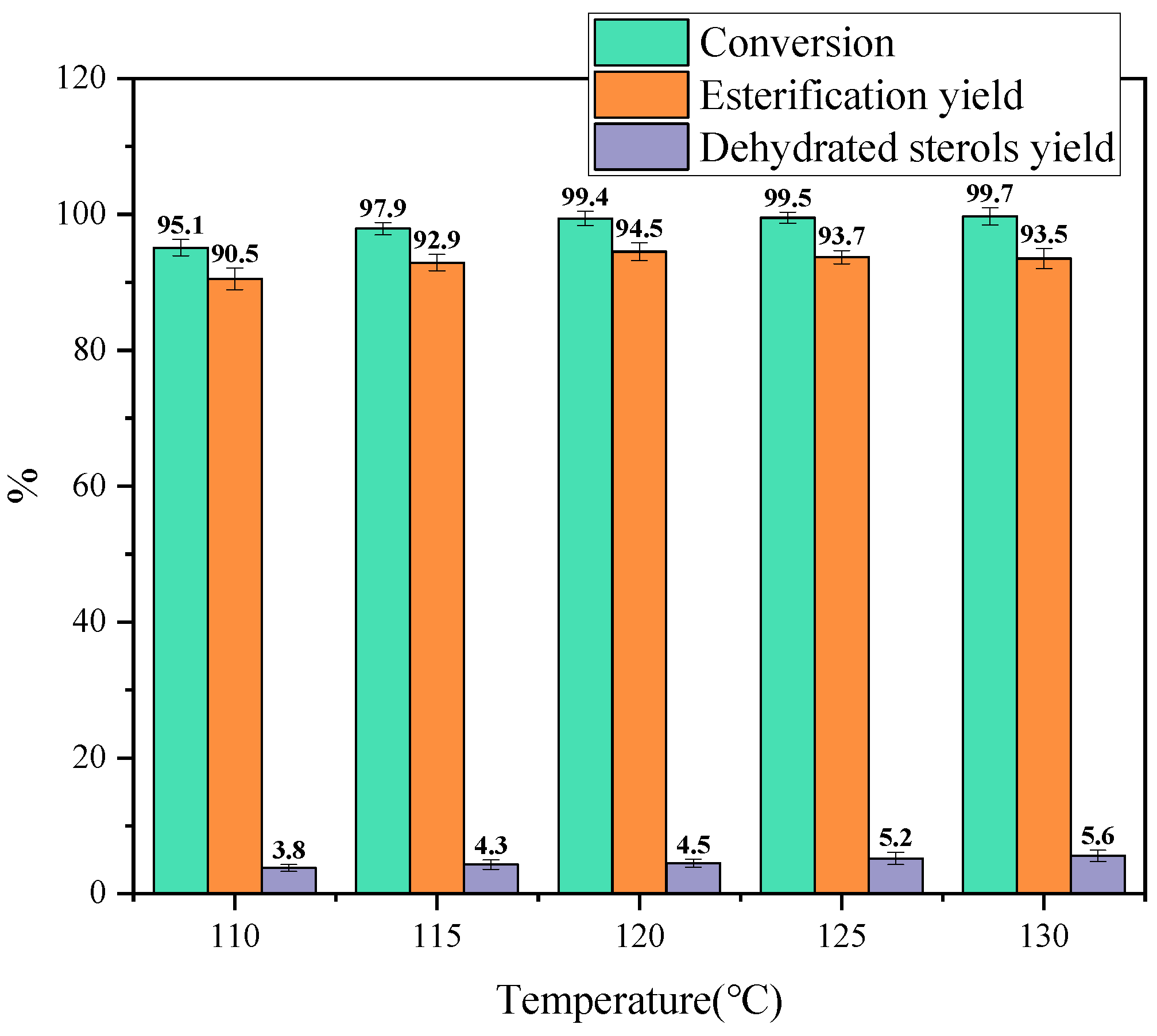

2.3. Optimization of Reaction Conditions

2.4. Esterification of Pine Sterols with Other Fatty Acids

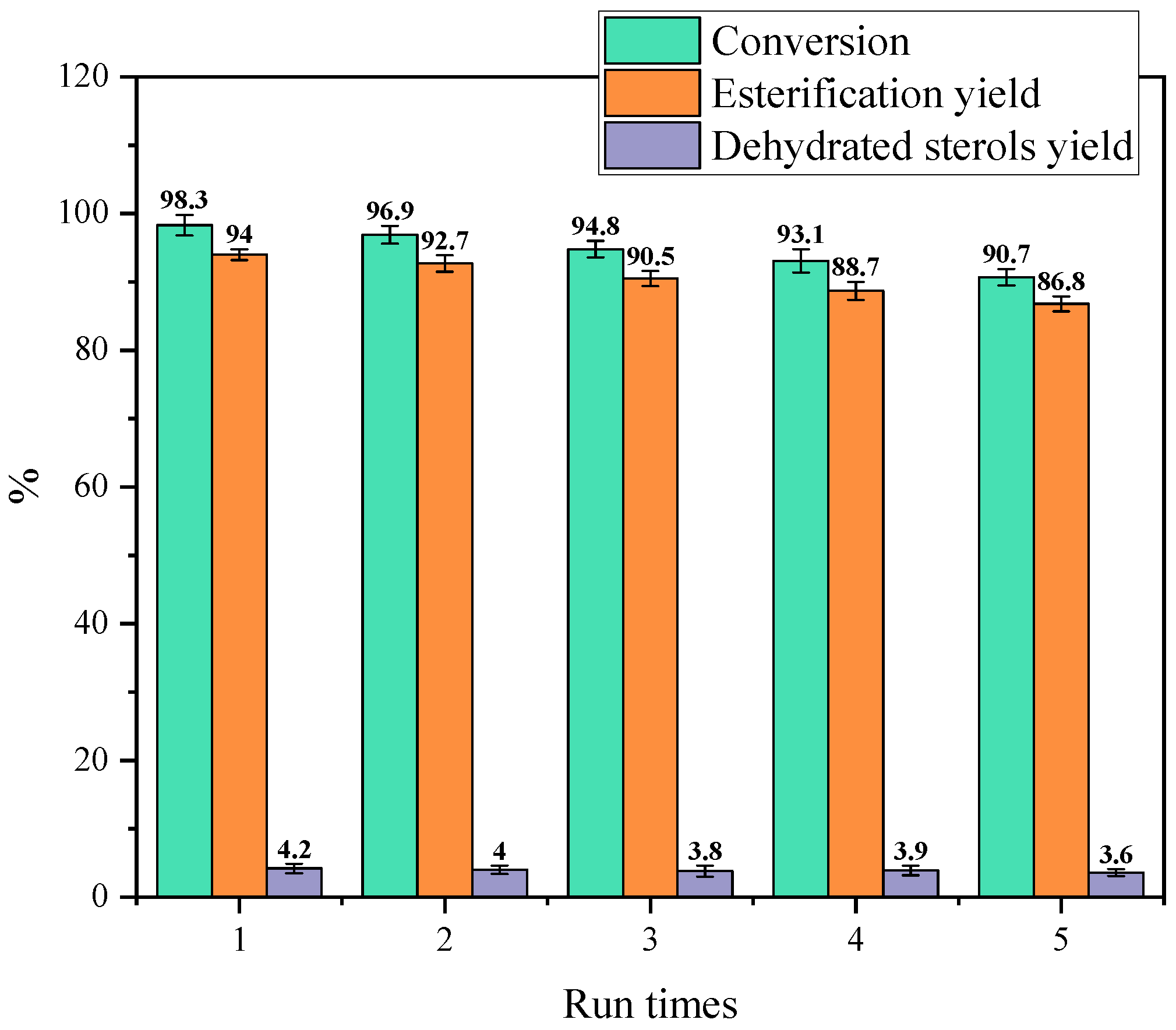

2.5. Scale-up Validation of Reactions and Reusability of Catalysts

2.6. Comparison with Other Chemical Methods for The Synthesis of Phytosterol Esters

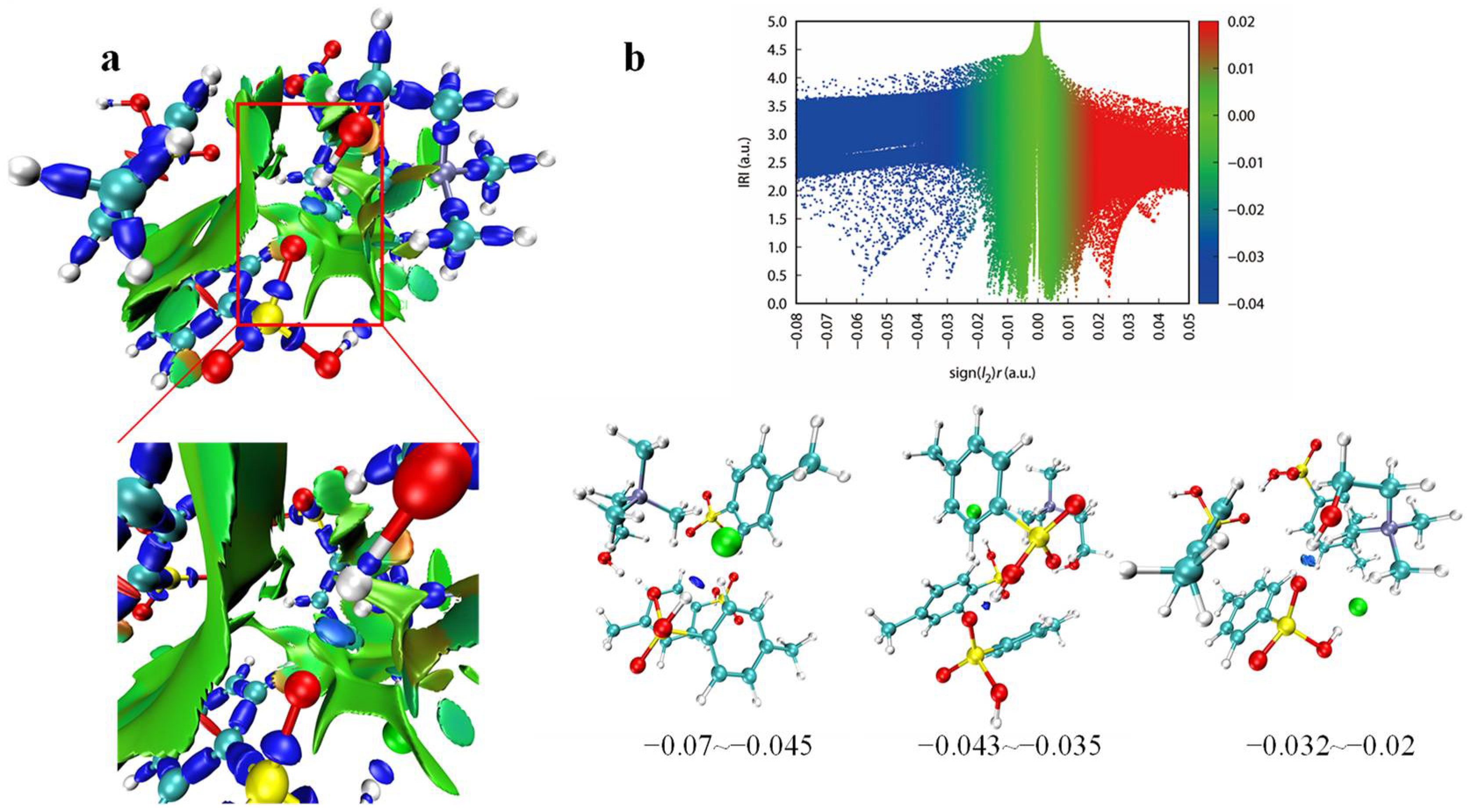

2.7. Reaction Mechanism of Sterols Dehydration

3. Materials and Methods

3.1. Materials

3.2. Preparation of DESs

3.3. Synthesis of Pine Sterol Esters

3.4. Analysis of Products

3.5. Quantum Chemical Calculations

3.6. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gallezot, P. Conversion of biomass to selected chemical products. Chem. Soc. Rev. 2012, 41, 1538–1558. [Google Scholar] [CrossRef] [PubMed]

- Nian, B.; Cao, C.; Liu, Y. Lipase and metal chloride hydrate-natural deep eutectic solvents synergistically catalyze amidation reaction via multiple noncovalent bond interactions. ACS Sustain. Chem. Eng. 2019, 7, 18174–18184. [Google Scholar] [CrossRef]

- Nian, B.; Li, X. Can deep eutectic solvents be the best alternatives to ionic liquids and organic solvents: A perspective in enzyme catalytic reactions. Int. J. Biol. Macromol. 2022, 217, 255–269. [Google Scholar] [CrossRef] [PubMed]

- Hansen, B.B.; Spittle, S.; Chen, B.; Poe, D.; Zhang, Y.; Klein, J.M.; Horton, A.; Adhikari, L.; Zelovich, T.; Doherty, B.W.; et al. Deep eutectic solvents: A review of fundamentals and applications. Chem. Rev. 2021, 121, 1232–1285. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Wang, L.; Shao, P.; Sun, P.; Yang, C.S. A review on chemical and physical modifications of phytosterols and their influence on bioavailability and safety. Crit. Rev. Food Sci. Nutr. 2022, 62, 5638–5657. [Google Scholar] [CrossRef]

- Salehi, B.; Quispe, C.; Sharifi-Rad, J.; Cruz-Martins, N.; Nigam, M.; Mishra, A.P.; Konovalov, D.A.; Orobinskaya, V.; Abu-Reidah, I.M.; Zam, W.; et al. Phytosterols: From preclinical evidence to potential clinical applications. Front. Pharmacol. 2021, 11, 1819. [Google Scholar] [CrossRef]

- Moreau, R.A.; Nystrom, L.; Whitaker, B.D.; Winkler-Moser, J.K.; Baer, D.J.; Gebauer, S.K.; Hicks, K.B. Phytosterols and their derivatives: Structural diversity, distribution, metabolism, analysis, and health-promoting uses. Prog. Lipid Res. 2018, 70, 35–61. [Google Scholar] [CrossRef]

- Feng, S.; Belwal, T.; Li, L.; Limwachiranon, J.; Liu, X.; Luo, Z. Phytosterols and their derivatives: Potential health-promoting uses against lipid metabolism and associated diseases, mechanism, and safety issues. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1243–1267. [Google Scholar] [CrossRef]

- Katan, M.B.; Grundy, S.M.; Jones, P.; Law, M.; Miettinen, T.; Paoletti, R.; Stresa Workshop, P. Efficacy and safety of plant stanols and sterols in the management of blood cholesterol levels. Mayo Clin. Proc. 2003, 78, 965–978. [Google Scholar] [CrossRef] [Green Version]

- He, W.S.; Zhu, H.; Chen, Z.Y. Plant sterols: Chemical and enzymatic structural modifications and effects on their cholesterol-lowering activity. J. Agric. Food. Chem. 2018, 66, 3047–3062. [Google Scholar] [CrossRef]

- Nguyen, H.C.; Huang, K.-C.; Su, C.-H. Green process for the preparation of phytosterol esters: Microwave-mediated noncatalytic synthesis. Chem. Eng. J. 2020, 382, 122796. [Google Scholar] [CrossRef]

- Plat, J.; Van Onselen, E.N.M.; Van Heugten, M.M.A.; Mensink, R.P. Effects on serum lipids, lipoproteins and fat soluble antioxidant concentrations of consumption frequency of margarines and shortenings enriched with plant stanol esters. Eur. J. Clin. Nutr. 2000, 54, 671–677. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, H.; Li, S.; Liu, J.; Wang, S.; Xu, H.; Hu, Y. Green and efficient synthesis of pine sterol oleate catalyzed by SO3H-functionalized ionic liquid. J. Chem. Technol. Biotechnol. 2022, 97, 3083–3090. [Google Scholar] [CrossRef]

- Chang, M.; Zhang, T.; Feng, W.; Wang, T.; Liu, R.; Jin, Q.; Wang, X. Preparation of highly pure stigmasteryl oleate by enzymatic esterification of stigmasterol enriched from soybean phytosterols. LWT-Food Sci. Technol. 2020, 128, 109464. [Google Scholar] [CrossRef]

- He, W.S.; Hu, D.; Wang, Y.; Chen, X.Y.; Jia, C.S.; Ma, H.L.; Feng, B. A novel chemo-enzymatic synthesis of hydrophilic phytosterol derivatives. Food Chem. 2016, 192, 557–565. [Google Scholar] [CrossRef]

- Wang, S.; Li, S.; Liu, R.; Zhang, W.; Xu, H.; Hu, Y. Immobilization of Interfacial Activated Candida rugosa Lipase Onto Magnetic Chitosan Using Dialdehyde Cellulose as Cross-Linking Agent. Front. Bioeng. Biotechnol. 2022, 10, 946117. [Google Scholar] [CrossRef]

- Zheng, M.M.; Lu, Y.; Huang, F.H.; Wang, L.; Guo, P.M.; Feng, Y.Q.; Deng, Q.C. Lipase immobilization on hyper-cross-linked polymer-coated silica for biocatalytic synthesis of phytosterol esters with controllable fatty acid composition. J. Agric. Food. Chem. 2013, 61, 231–237. [Google Scholar] [CrossRef]

- Qianchun, D.; Pin, Z.; Qingde, H.; Fenghong, H.; Fang, W.; Mingming, Z.; Xiao, Y.; Qi, Z.; Chang, Z. Chemical synthesis of phytosterol esters of polyunsaturated fatty acids with ideal oxidative stability. Eur. J. Lipid Sci. Technol. 2011, 113, 441–449. [Google Scholar] [CrossRef]

- Meng, X.; Pan, Q.; Yang, T. Synthesis of phytosteryl esters by using alumina-supported zinc oxide (ZnO/Al2O3) from esterification production of phytosterol with fatty acid. J. Am. Oil Chem. Soc. 2010, 88, 143–149. [Google Scholar] [CrossRef]

- Robles-Manuel, S.; Barrault, J.; Valange, S. Selective synthesis of phytosterol esters from natural sterols and fatty methyl esters over Mg-containing solid catalysts. Comptes Rendus Chim. 2011, 14, 656–662. [Google Scholar] [CrossRef]

- He, W.S.; Li, L.L.; Huang, Q.J.; Yin, J.; Cao, X.C. Highly efficient synthesis of phytosterol linolenate in the presence of Bronsted acidic ionic liquid. Food Chem. 2018, 263, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; He, W.; Jia, C.; Ma, Y.; Zhang, X.; Feng, B. Efficient synthesis of phytosteryl esters using the Lewis acidic ionic liquid. J. Mol. Catal. A Chem. 2012, 357, 39–43. [Google Scholar] [CrossRef]

- Savinova, T.S.; Dovbnya, D.V.; Khomutov, S.M.; Kazantsev, A.V.; Huy, L.D.; Lukashev, N.V.; Donova, M.V. Conversion of Soybean Phytosterol into Androsta-4, 9 (11)-diene-3, 17-dione. Appl. Biochem. Microbiol. 2020, 56, 459–466. [Google Scholar] [CrossRef]

- Morais, R.M.S.C.; Morais, A.M.M.B.; Dammak, I.; Bonilla, J.; Sobral, P.J.A.; Laguerre, J.C.; Afonso, M.J.; Ramalhosa, E.C.D. Functional dehydrated foods for health preservation. J. Food Qual. 2018, 2018, 1739636. [Google Scholar] [CrossRef] [Green Version]

- Smith, E.L.; Abbott, A.P.; Ryder, K.S. Deep eutectic solvents (DESs) and their applications. Chem. Rev. 2014, 114, 11060–11082. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Häkkinen, R.; Abbott, A.P. Deep eutectic solvents—Teaching nature lessons that it knew already. In Eutectic Solvents and Stress in Plants; Academic Press: Cambridge, MA, USA, 2021; Volume 97, pp. 1–16. [Google Scholar]

- Hayyan, A.; Ali Hashim, M.; Mjalli, F.S.; Hayyan, M.; AlNashef, I.M. A novel phosphonium-based deep eutectic catalyst for biodiesel production from industrial low grade crude palm oil. Chem. Eng. Sci. 2013, 92, 81–88. [Google Scholar] [CrossRef]

- Hayyan, A.; Hashim, M.A.; Hayyan, M.; Mjalli, F.S.; AlNashef, I.M. A new processing route for cleaner production of biodiesel fuel using a choline chloride based deep eutectic solvent. J. Clean. Prod. 2014, 65, 246–251. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, H.; Liu, J.; Dong, W.; Cao, Z.; Hu, X.; Zhou, Z. Acidic deep eutectic solvents with long carbon chains as catalysts and reaction media for biodiesel production. Renew. Energy 2020, 162, 1842–1853. [Google Scholar] [CrossRef]

- Shen, Z.; Chen, L.; Cheng, H.; Qi, Z. Selective synthesis of glyceryl monolaurate intensified by boric acid based deep eutectic solvent. Catal. Today 2021, 407, 291–300. [Google Scholar] [CrossRef]

- Chen, B.; Peng, Z.; Li, C.; Feng, Y.; Sun, Y.; Tang, X.; Zeng, X.; Lin, L. Catalytic conversion of biomass to furanic derivatives with deep eutectic solvents. ChemSusChem 2021, 14, 1496–1506. [Google Scholar] [CrossRef]

- Qin, H.; Hu, X.; Wang, J.; Cheng, H.; Chen, L.; Qi, Z. Overview of acidic deep eutectic solvents on synthesis, properties and applications. Green Energy Environ. 2020, 5, 8–21. [Google Scholar] [CrossRef]

- Clydesdale, F.M. Color Perception and Food Quality. J. Food Qual. 1991, 14, 61–74. [Google Scholar] [CrossRef]

- He, B.; Deng, T.; Li, J.; Yan, F.; Wang, H.; Huang, Y.; Peng, C. An innovative auto-catalytic esterification for the production of phytosterol esters: Experiment and kinetics. RSC Adv. 2014, 4, 64319–64327. [Google Scholar] [CrossRef]

- He, W.S.; Ma, Y.; Pan, X.X.; Li, J.J.; Wang, M.G.; Yang, Y.B.; Jia, C.S.; Zhang, X.M.; Feng, B. Efficient solvent-free synthesis of phytostanyl esters in the presence of acid-surfactant-combined catalyst. J. Agric. Food. Chem. 2012, 60, 9763–9769. [Google Scholar] [CrossRef]

- Liu, W.; Xiao, B.; Wang, X.; Chen, J.; Yang, G. Solvent-free synthesis of phytosterol linoleic acid esters at low temperature. RSC Adv. 2021, 11, 10738–10746. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, T.; Zhang, Y.; Wu, Z.; Zhang, P.; Liu, R.; Chang, M.; Wang, X. Microwave-assisted catalytic synthesis of phytosterol esters. Int. J. Food Sci. Technol. 2022, 57, 3162–3170. [Google Scholar] [CrossRef]

- Kostestkyy, P.; Maheswari, J.P.; Mpourmpakis, G. Understanding the Importance of Carbenium Ions in the Conversion of Biomass-Derived Alcohols with First-Principles Calculations. J. Phys. Chem. C 2015, 119, 16139–16147. [Google Scholar] [CrossRef]

- Kostetskyy, P.; Zervoudis, N.A.; Mpourmpakis, G. Carboranes: The strongest Brønsted acids in alcohol dehydration. Catal. Sci. Technol. 2017, 7, 2001–2011. [Google Scholar] [CrossRef]

- Lu, T.; Chen, Q. Independent gradient model based on Hirshfeld partition: A new method for visual study of interactions in chemical systems. J. Comput. Chem. 2022, 43, 539–555. [Google Scholar] [CrossRef]

- Abbott, A.P.; Boothby, D.; Capper, G.; Davies, D.L.; Rasheed, R.K. Deep eutectic solvents formed between choline chloride and carboxylic acids: Versatile alternatives to ionic liquids. J. Am. Chem. Soc. 2004, 126, 9142–9147. [Google Scholar] [CrossRef]

- Dai, Y.; van Spronsen, J.; Witkamp, G.J.; Verpoorte, R.; Choi, Y.H. Natural deep eutectic solvents as new potential media for green technology. Anal. Chim. Acta 2013, 766, 61–68. [Google Scholar] [CrossRef] [PubMed]

- Guajardo, N.; Müller, C.R.; Schrebler, R.; Carlesi, C.; Domínguez de María, P. Deep eutectic solvents for organocatalysis, biotransformations, and multistep organocatalyst/enzyme combinations. ChemCatChem 2016, 8, 1020–1027. [Google Scholar] [CrossRef]

- Yin, J.; Wang, J.; Li, Z.; Li, D.; Yang, G.; Cui, Y.; Wang, A.; Li, C. Deep desulfurization of fuels based on an oxidation/extraction process with acidic deep eutectic solvents. Green Chem. 2015, 17, 4552–4559. [Google Scholar] [CrossRef]

- Alhassan, Y.; Kumar, N.; Bugaje, I.M. Catalytic upgrading of waste tire pyrolysis oil via supercritical esterification with deep eutectic solvents (green solvents and catalysts). J. Energy Inst. 2016, 89, 683–693. [Google Scholar] [CrossRef]

- Lu, T. Molclus Program. Available online: http://www.keinsci.com/research/molclus.html (accessed on 9 May 2022).

- Grimme, S.; Bannwarth, C.; Shushkov, P. A robust and accurate tight-binding quantum chemical method for structures, vibrational frequencies, and noncovalent interactions of large molecular systems parametrized for all spd-block elements (Z= 1–86). J. Chem. Theory Comput. 2017, 13, 1989–2009. [Google Scholar] [CrossRef] [PubMed]

- Naseem, Z.; Shehzad, R.A.; Ihsan, A.; Iqbal, J.; Zahid, M.; Pervaiz, A.; Sarwari, G. Theoretical investigation of supramolecular hydrogen-bonded choline chloride-based deep eutectic solvents using density functional theory. Chem. Phys. Lett. 2021, 769, 138427. [Google Scholar] [CrossRef]

- Shaibuna, M.; Abbas, A.; Kariyottu Kuniyil, M.J.; Sreekumar, K. Sustainable synthesis of 1, 8-dioxooctahydroxanthenes in deep eutectic solvents (DESs). New J. Chem. 2021, 45, 8335–8344. [Google Scholar] [CrossRef]

- Marenich, A.V.; Cramer, C.J.; Truhlar, D.G. Universal solvation model based on solute electron density and on a continuum model of the solvent defined by the bulk dielectric constant and atomic surface tensions. J. Phys. Chem. B 2009, 113, 6378–6396. [Google Scholar] [CrossRef]

- Boys, S.F.; Bernardi, F. The calculation of small molecular interactions by the differences of separate total energies. Some procedures with reduced errors. Mol. Phys. 1970, 19, 553–566. [Google Scholar] [CrossRef]

- Lu, T.; Chen, F. Multiwfn: A multifunctional wavefunction analyzer. J. Comput. Chem. 2012, 33, 580–592. [Google Scholar] [CrossRef]

- William, H.; Andrew, D.; Klaus, S. VMD: Visual molecular dynamics. J. Mol. Graph. 1996, 14, 33–88. [Google Scholar] [CrossRef]

| Entries | DESs | Conversion (%) | Esterification Yield (%) | Dehydrated Sterols Yield (%) | Others (%) |

|---|---|---|---|---|---|

| 1 | ChCl/ZnCl2(1:2) | 39.5 ± 1.5 | 36.4 ± 1.9 | 2.3 ± 0.5 | 0.8 ± 0.6 |

| 2 | ChCl/SnCl2(1:2) | 55.3 ± 1.9 | 51.3 ± 2.1 | 3.4 ± 0.3 | 0.6 ± 0.5 |

| 3 | ChCl/Benzoic acid (BEN) (1:1) | 49.9 ± 0.9 | 46.7 ± 1.1 | 2.3 ± 0.6 | 0.9 ± 0.7 |

| 4 | ChCl/Oxalic acid (OA) (1:1) | 44.2 ± 2.1 | 40.5 ± 1.6 | 2.5 ± 1.1 | 1.2 ± 1.1 |

| 5 | ChCl/Citric acid (CA) (1:1) | 38.5 ± 1.7 | 35.2 ± 1.5 | 2.2 ± 0.9 | 1.1 ± 0.8 |

| 6 | ChCl/Urea (1:2) | 35.9 ± 1.3 | 33.1 ± 1.3 | 2.4 ± 0.9 | 0.4 ± 0.2 |

| 7 | ChCl/Lactic acid (HL) (1:2) | 43.8 ± 1.3 | 40.8 ± 1.5 | 2.4 ± 0.8 | 0.6 ± 0.3 |

| 8 | ChCl/Sulfosalicylic acid (SSA) (1:2) | 95.9 ± 1.8 | 89.7 ± 1.6 | 5.3 ± 1.1 | 0.9 ± 0.7 |

| 9 | ChCl/PTSA (1:2) | 99.9 ± 1.2 | 65.3 ± 0.6 | 31.1 ± 0.5 | 3.5 ± 0.5 |

| 10 | ChCl/SSA (1:2) b | 75.9 ± 1.3 | 72.0 ± 1.2 | 3.6 ± 0.6 | 0.3 ± 0.3 |

| 11 | ChCl/PTSA (1:2) b | 95.0 ± 0.8 | 90.0 ± 1.1 | 4.6 ± 0.5 | 0.4 ± 0.3 |

| 12 | TBAC/PTSA (1:2) b | 92.6 ± 1.5 | 87.5 ± 1.9 | 4.4 ± 0.8 | 0.7 ± 0.2 |

| 13 | TBAB/PTSA (1:2) b | 92.4 ± 1.3 | 86.8 ± 1.3 | 4.7 ± 0.7 | 0.9 ± 0.5 |

| 14 | ChCl/PTSA (1:3) b | 97.9 ± 1.6 | 92.9 ± 2.0 | 4.1 ± 0.5 | 0.9 ± 0.4 |

| 15 | ChCl/PTSA (1:4) b | 98.1 ± 1.5 | 92.0 ± 1.7 | 5.3 ± 0.6 | 0.8 ± 0.6 |

| 16 | PTSA b | 98.7 ± 1.3 | 88.6 ± 1.7 | 8.9 ± 0.5 | 1.2 ± 0.8 |

| 17 | PTSA c | 98.3 ± 1.7 | 88.7 ± 1.5 | 8.5 ± 0.5 | 1.1 ± 0.5 |

| Fatty Acid | Conversion (%) | Esterification Yield (%) | Dehydrated Sterols Yield (%) |

|---|---|---|---|

| Lauric acid (C12:0) b | 99.4 ± 1.2 | 94.9 ± 1.0 | 4.5 ± 0.8 |

| Myristic acid (C14:0) | 99.2 ± 1.6 | 94.5 ± 1.2 | 4.7 ± 0.7 |

| Palmitic acid (C16:0) | 98.7 ± 1.1 | 94.3 ± 1.3 | 4.4 ± 1.0 |

| Stearic acid (C18:0) | 97.9 ± 0.9 | 93.6 ± 1.0 | 4.3 ± 0.7 |

| Oleic acid (C18:1) | 98.5 ± 1.0 | 94.1 ± 1.1 | 4.1 ± 0.6 |

| Linoleic acid (C18:2) | 98.0 ± 1.5 | 93.6 ± 1.2 | 4.4 ± 0.5 |

| Linolenic acid (C18:3) | 97.9 ± 1.7 | 93.4 ± 1.5 | 4.5 ± 0.9 |

| Catalyst | Conditions | Result | Reference | ||||

|---|---|---|---|---|---|---|---|

| Catalyst Dose (%, Based on Mass of Phytosterols) | Molar Ratio of Fatty Acids to Phytosterols | Reaction Temperature (°C) | Reaction Time (h) | Conversion (%) | Esterification Yield (%) | ||

| H2SO4 | 1 | 1.5:1 | 170 | 2 | 98.2 | 67.3 | [19] |

| NaHSO4 | 1 | 1.5:1 | 170 | 2 | 95.4 | 75.5 | [19] |

| ZnO | 1 | 1.5:1 | 170 | 8 | 84.2 | 82.9 | [19] |

| Catalyst free | 0 | 3:1 | 220 | 4 | 99.1 | 94.9 | [34] |

| Catalyst free (microwave irradiation) | 0 | 5:1 | 180 | 0.83 | 95.4 | - | [11] |

| DBSA | 20(mol%) | 3:1 | 60 | 20 | 95.0 | - | [36] |

| DBSA (microwave irradiation) | 20(mol%) | 2.5:1 | 60 | 1 | 94.3 | - | [37] |

| [BSO3HMIm]Ts | 7 | 2:1 | 140 | 2.5 | 98.4 | 93.9 | [13] |

| ChCl/SnCl2(2:1) | 7 | 3:1 | 150 | 4 | - | 92.3 | [22] |

| ChCl/PTSA (1:3) | 1.5 | 1.5:1 | 120 | 3 | 98.5 | 94.1 | This study |

| Organic Salt | Hydrogen Bond Donor (HBD) | Salt:HBD (Molar Ratio) | Ref |

|---|---|---|---|

| ChCl | ZnCl2 | 1:2 | [22] |

| ChCl | SnCl2 | 1:2 | [22] |

| ChCl | Oxalic acid (OA) | 1:1 | [41] |

| ChCl | Benzoic acid (BEN) | 1:1 | [41] |

| ChCl | Citric acid (CA) | 1:1 | [41] |

| ChCl | Lactic acid (HL) | 1:1 | [42] |

| ChCl | Urea | 1:2 | [43] |

| ChCl | Sulfosalicylic acid (SSA) | 1:2 | [44] |

| ChCl | PTSA | 1:2 | [44] |

| TBAC | PTSA | 1:2 | [44] |

| TBAB | PTSA | 1:2 | [29] |

| ChCl | PTSA | 1:3 | [28] |

| ChCl | PTSA | 1:4 | [45] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, H.; Lu, Z.; Xu, H.; Wang, S.; Nian, B.; Hu, Y. Selective and Efficient Synthesis of Pine Sterol Esters Catalyzed by Deep Eutectic Solvent. Molecules 2023, 28, 993. https://doi.org/10.3390/molecules28030993

Shi H, Lu Z, Xu H, Wang S, Nian B, Hu Y. Selective and Efficient Synthesis of Pine Sterol Esters Catalyzed by Deep Eutectic Solvent. Molecules. 2023; 28(3):993. https://doi.org/10.3390/molecules28030993

Chicago/Turabian StyleShi, Honggang, Zeping Lu, Huajin Xu, Shushu Wang, Binbin Nian, and Yi Hu. 2023. "Selective and Efficient Synthesis of Pine Sterol Esters Catalyzed by Deep Eutectic Solvent" Molecules 28, no. 3: 993. https://doi.org/10.3390/molecules28030993