Enzymatic Hydrolysis Optimization of Yak Whey Protein Concentrates and Bioactivity Evaluation of the Ultrafiltered Peptide Fractions

Abstract

:1. Introduction

2. Results

2.1. The Effects of Different Enzymes on the Degree of Hydrolysis (DH) and Peptide Concentration of YWPCs

2.2. Single-Factor Experimental Results and Analysis

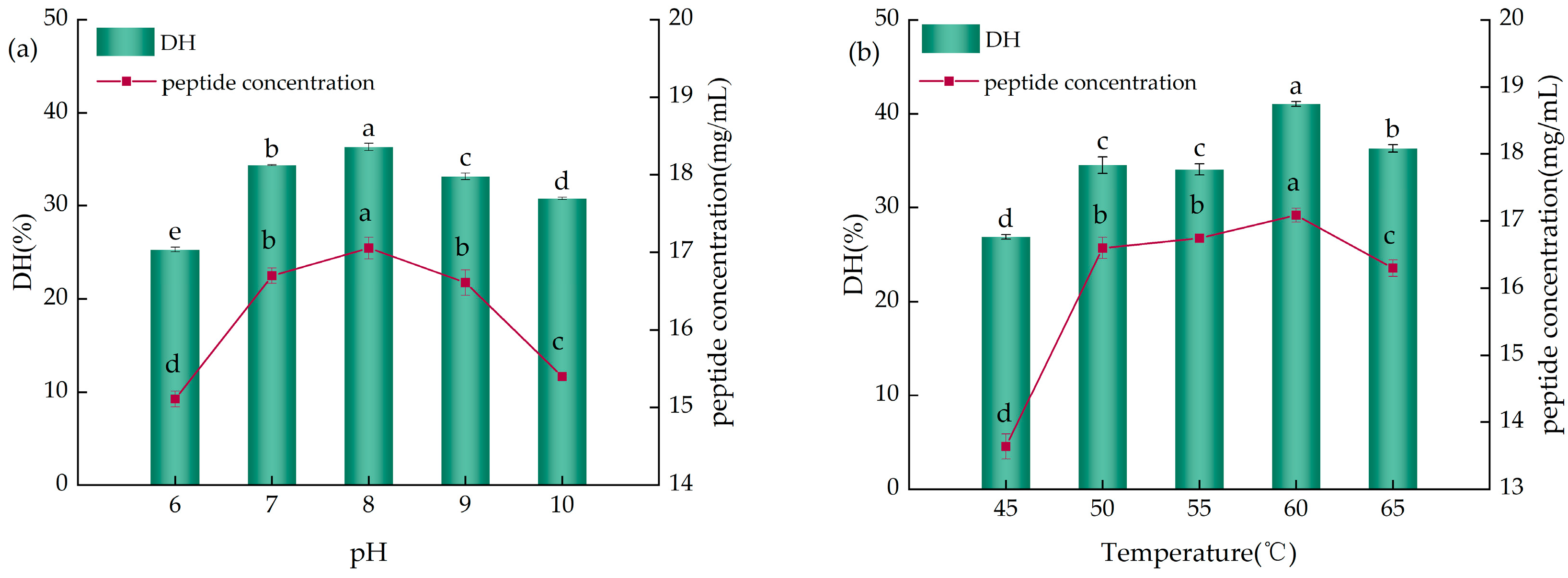

2.2.1. The Influence of pH and Temperature on the Enzymatic Hydrolysis of YWPCs

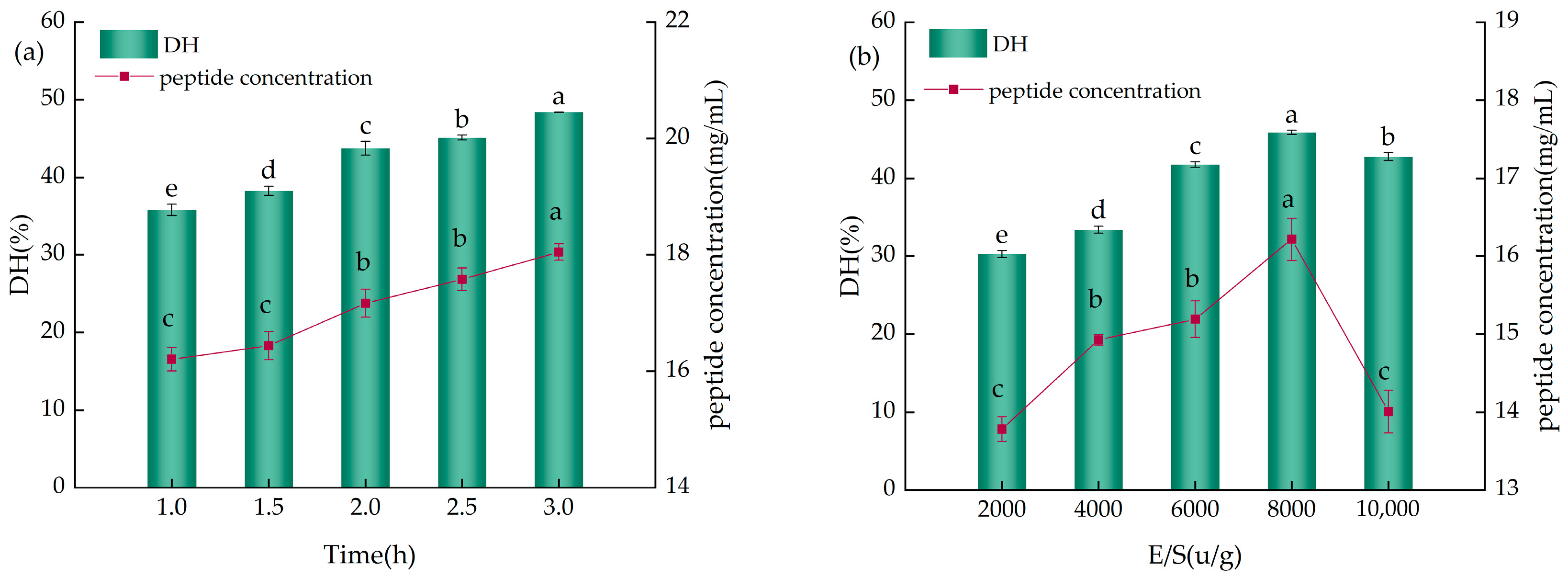

2.2.2. The Impact of Time and The Enzyme-to-Substrate Ratio (E/S) on the Enzymatic Hydrolysis of YWPCs

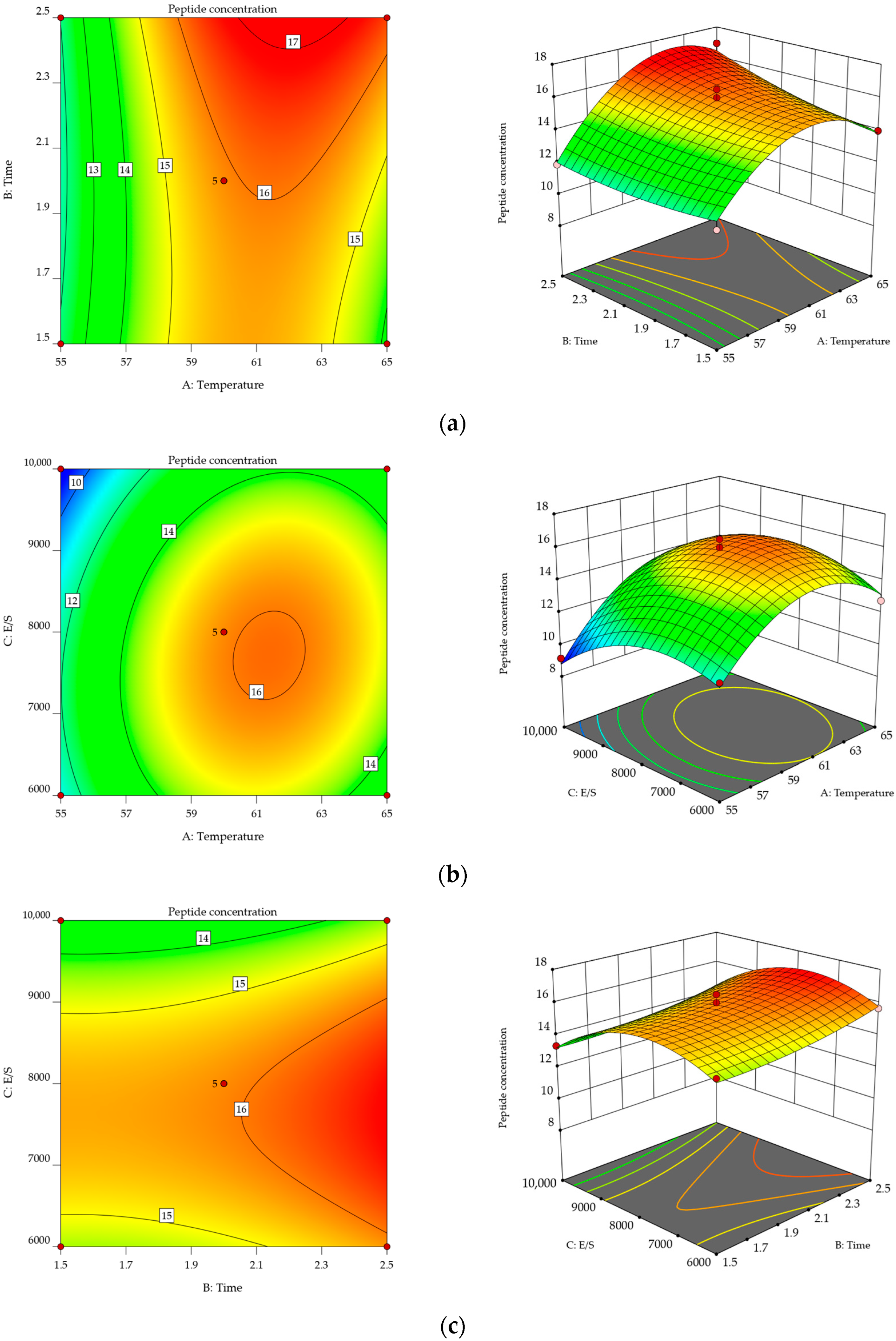

2.3. Analysis of the Results from the Response Surface Optimization Experiment

2.3.1. Results of the Response Surface Optimization Experiment and Analysis of Variance for the Regression Equation

2.3.2. Response Surface Analysis

2.4. α-Amylase-Inhibitory Activity of the Ultrafiltration Fractions of YWPC Enzymatic Hydrolysate

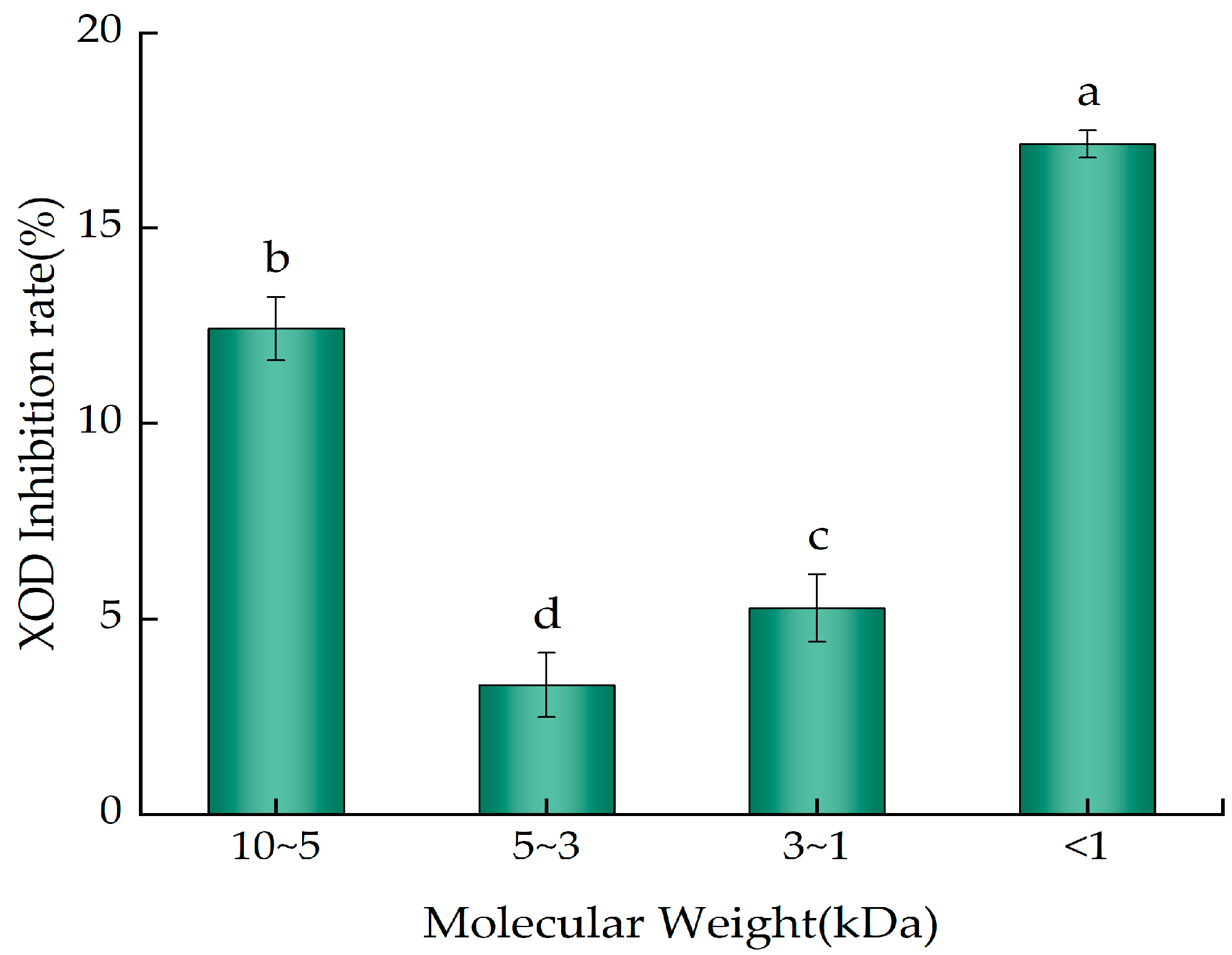

2.5. XOD-Inhibitory Activity of the Ultrafiltration Fractions of YWPC Enzymatic Hydrolysate

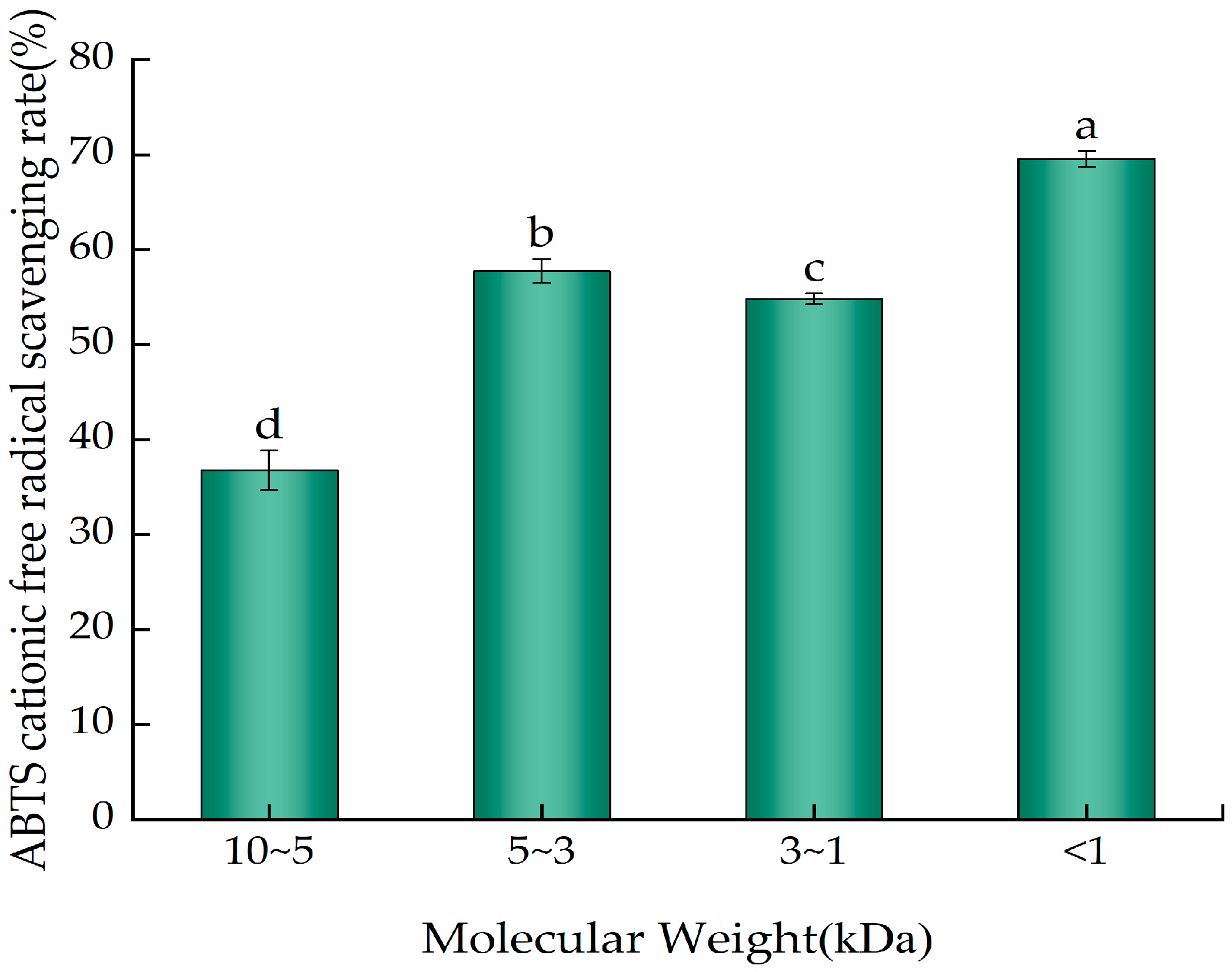

2.6. ABTS Cation Radical Scavenging Ability of the Ultrafiltration Fractions of YWPC Enzymatic Hydrolysate

3. Discussion

4. Materials and Methods

4.1. Materials and Reagents

4.2. Preparation of YWPCs

4.3. Preparation of YWPC Hydrolysate

4.4. Optimization of YWPC Hydrolysis Process

4.4.1. Selection of Proteases

4.4.2. Single-Factor Experimental Design

4.4.3. Response Surface Optimization

4.5. Measurement of DH

4.6. Peptide Concentration Determination

4.7. Ultrafiltration Purification of YWPCs’ Enzymatic Products

4.8. Determination of α-Amylase-Inhibitory Activity

4.9. Determination of XOD-Inhibitory Activity

4.10. ABTS Cation Radical Scavenging Ability Determination

4.11. Data Processing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baldasso, C.; Barros, T.C.; Tessaro, I.C. Concentration and purification of whey proteins by ultrafiltration. Desalination 2011, 278, 381–386. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, Y.; Zheng, X.; Guo, J.; Duan, H.; Zhou, S.; Yan, W. Yak Milk: Nutritional Value, Functional Activity, and Current Applications. Foods 2023, 12, 2090. [Google Scholar] [CrossRef]

- Wright, B.J.; Zevchak, S.E.; Wright, J.M.; Drake, M.A. The impact of agglomeration and storage on flavor and flavor stability of whey protein concentrate 80% and whey protein isolate. J. Food Sci. 2009, 74, S17–S29. [Google Scholar] [CrossRef]

- Fan, Q.; Wanapat, M.; Yan, T.; Hou, F. Altitude influences microbial diversity and herbage fermentation in the rumen of yaks. BMC Microbiol. 2020, 20, 370. [Google Scholar] [CrossRef] [PubMed]

- Gao, R.P.; Liang, Q.; Bai, L.L. Effect of protein content on the functional properties of yak whey protein concentrates. Food Sci. 2021, 42, 1–7. [Google Scholar] [CrossRef]

- Olvera-Rosales, L.B.; Cruz-Guerrero, A.E.; García-Garibay, J.M.; Gómez-Ruíz, L.C.; Contreras-López, E.; Guzmán-Rodríguez, F.; González-Olivares, L.G. Bioactive peptides of whey: Obtaining, activity, mechanism of action, and further applications. Crit. Rev. Food Sci. Nutr. 2023, 63, 10351–10381. [Google Scholar] [CrossRef]

- Jia, C.L.; Hussain, N.; Joy Ujiroghene, O.; Pang, X.Y.; Zhang, S.W.; Lu, J.; Liu, L.; Lv, J.P. Generation and characterization of dipeptidyl peptidase-IV inhibitory peptides from trypsin-hydrolyzed α-lactalbumin-rich whey proteins. Food Chem. 2020, 318, 126333. [Google Scholar] [CrossRef] [PubMed]

- Athira, S.; Mann, B.; Saini, P.; Sharma, R.; Kumar, R.; Singh, A.K. Production and characterisation of whey protein hydrolysate having antioxidant activity from cheese whey. J. Sci. Food Agric. 2015, 95, 2908–2915. [Google Scholar] [CrossRef] [PubMed]

- Ooi, E.M.; Adams, L.A.; Zhu, K.; Lewis, J.R.; Kerr, D.A.; Meng, X.; Solah, V.; Devine, A.; Binns, C.W.; Prince, R.L. Consumption of a whey protein-enriched diet may prevent hepatic steatosis associated with weight gain in elderly women. Nutr. Metab. Cardiovasc. Dis. 2015, 25, 388–395. [Google Scholar] [CrossRef]

- Ozorio, L.; Matsubara, N.K.; da Silva-Santos, J.E.; Henry, G.; Le Gouar, Y.; Jardin, J.; Mellinger-Silva, C.; Cabral, L.M.C.; Dupont, D. Gastrointestinal digestion enhances the endothelium-dependent vasodilation of a whey hydrolysate in rat aortic rings. Food Res. Int. 2020, 133, 109188. [Google Scholar] [CrossRef]

- Sah, B.N.P.; Vasiljevic, T.; McKechnie, S.; Donkor, O.N. Antioxidative and antibacterial peptides derived from bovine milk proteins. Crit. Rev. Food Sci. Nutr. 2018, 58, 726–740. [Google Scholar] [CrossRef] [PubMed]

- Bamdad, F.; Bark, S.; Kwon, C.H.; Suh, J.W.; Sunwoo, H. Anti-Inflammatory and Antioxidant Properties of Peptides Released from β-Lactoglobulin by High Hydrostatic Pressure-Assisted Enzymatic Hydrolysis. Molecules 2017, 22, 949. [Google Scholar] [CrossRef]

- Fan, F.; Shi, P.; Chen, H.; Tu, M.; Wang, Z.; Lu, W.; Du, M. Identification and availability of peptides from lactoferrin in the gastrointestinal tract of mice. Food Funct. 2019, 10, 879–885. [Google Scholar] [CrossRef]

- Wu, R.; Wu, C.; Liu, D.; Yang, X.; Huang, J.; Zhang, J.; Liao, B.; He, H.; Li, H. Overview of Antioxidant Peptides Derived from Marine Resources: The Sources, Characteristic, Purification, and Evaluation Methods. Appl. Biochem. Biotechnol. 2015, 176, 1815–1833. [Google Scholar] [CrossRef]

- Saeedi, P.; Petersohn, I.; Salpea, P.; Malanda, B.; Karuranga, S.; Unwin, N.; Colagiuri, S.; Guariguata, L.; Motala, A.A.; Ogurtsova, K.; et al. Global and regional diabetes prevalence estimates for 2019 and projections for 2030 and 2045: Results from the International Diabetes Federation Diabetes Atlas, 9th edition. Diabetes Res. Clin. Pract. 2019, 157, 107843. [Google Scholar] [CrossRef]

- Kaur, N.; Kumar, V.; Nayak, S.K.; Wadhwa, P.; Kaur, P.; Sahu, S.K. Alpha-amylase as molecular target for treatment of diabetes mellitus: A comprehensive review. Chem. Biol. Drug Des. 2021, 98, 539–560. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, G.Z.; Li, X.T.; Zhao, B.D.; Zhou, S.M. Enzymatic Hydrolysis of Protein from Small Yellow Croaker (Psendosciaena polyactis) and Evaluation of Its Antioxidant Activity. J. Food Biochem. 2013, 7, 278–285. [Google Scholar] [CrossRef]

- Sun, C.; Shan, Y.; Tang, X.; Han, D.; Wu, X.; Wu, H.; Hosseininezhad, M. Effects of enzymatic hydrolysis on physicochemical property and antioxidant activity of mulberry (Morus atropurpurea Roxb.) leaf protein. Food Sci. Nutr. 2021, 9, 5379–5390. [Google Scholar] [CrossRef]

- Wang, L.; Mao, X.Y.; Cheng, X.; Xiong, X.X.; Ren, F.Z. Effect of enzyme type and hydrolysis conditions on the in vitro angiotensin I—Converting enzyme inhibitory activity and ash content of hydrolysed whey protein isolate. J. Food Biochem. 2010, 45, 807–812. [Google Scholar] [CrossRef]

- Ghosh, A.; Das, P.; Sinha, K. Modeling of biosorption of Cu(II) by alkali-modified spent tea leaves using response surface methodology (RSM) and artificial neural network (ANN). Appl. Water Sci. 2015, 5, 191–199. [Google Scholar] [CrossRef]

- Ngoh, Y.Y.; Gan, C.Y. Enzyme-assisted extraction and identification of antioxidative and α-amylase inhibitory peptides from Pinto beans (Phaseolus vulgaris cv. Pinto). Food Chem. 2016, 190, 331–337. [Google Scholar] [CrossRef]

- Li, Q.Y.; Shi, C.C.; Wang, M.; Zhou, M.; Liang, M.; Zhang, T.; Yuan, E.D.; Wang, Z.; Yao, M.J.; Ren, J.Y. Tryptophan residue enhances in vitro walnut protein-derived peptides exerting xanthine oxidase inhibition and antioxidant activities. J. Funct. Foods 2019, 53, 276–285. [Google Scholar] [CrossRef]

- Xie, J.; Du, M.; Shen, M.; Wu, T.; Lin, L. Physico-chemical properties, antioxidant activities and angiotensin-I converting enzyme inhibitory of protein hydrolysates from Mung bean (Vigna radiate). Food Chem. 2019, 270, 243–250. [Google Scholar] [CrossRef]

- Shazly, A.B.; Mu, H.; Liu, Z.; El-Aziz, M.A.; Zeng, M.; Qin, F.; Zhang, S.; He, Z.; Chen, J. Release of antioxidant peptides from buffalo and bovine caseins: Influence of proteases on antioxidant capacities. Food Chem. 2019, 274, 261–267. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, J.M.; Munekata, P.E.S.; Gόmez, B.; Barba, F.J.; Mora, L.; Pérez-Santaescolástica, C.; Toldrá, F. Bioactive peptides as natural antioxidants in food products—A review. Trends Food Sci. Tech. 2018, 79, 136–147. [Google Scholar] [CrossRef]

- Du, X.; Jing, H.; Wang, L.; Huang, X.; Wang, X.; Wang, H. Characterization of structure, physicochemical properties, and hypoglycemic activity of goat milk whey protein hydrolysate processed with different proteases. LWT Food Sci. Technol. 2022, 159, 113257. [Google Scholar] [CrossRef]

- Liu, F.F.; Li, Y.Q.; Wang, C.Y.; Liang, Y.; Zhao, X.Z.; He, J.X.; Mo, H.Z. Physicochemical, functional and antioxidant properties of mung bean protein enzymatic hydrolysates. Food Chem. 2022, 393, 133397. [Google Scholar] [CrossRef]

- Wal, J.M. Structure and function of milk allergens. Allergy 2001, 56, 35–38. [Google Scholar] [CrossRef]

- Wang, X.; Yu, H.; Xing, R.; Liu, S.; Chen, X.; Li, P. Optimization of Oyster (Crassostrea talienwhanensis) Protein Hydrolysates Using Response Surface Methodology. Molecules 2020, 25, 2844. [Google Scholar] [CrossRef]

- Al-Bukhaiti, W.Q.; Al-Dalali, S.; Noman, A.; Qiu, S.; Abed, S.M.; Qiu, S.X. Response Surface Modeling and Optimization of Enzymolysis Parameters for the In Vitro Antidiabetic Activities of Peanut Protein Hydrolysates Prepared Using Two Proteases. Foods 2022, 11, 3303. [Google Scholar] [CrossRef]

- Rubén, V.; Cristina, M.V.; Blanca, H.L. Release of dipeptidyl peptidase IV, α-amylase and α-glucosidase inhibitory peptides from quinoa (Chenopodium quinoa Willd.) during in vitro simulated gastrointestinal digestion. J. Funct. Foods 2017, 35, 531–539. [Google Scholar] [CrossRef]

- Deng, F.; Liang, Y.; Lei, Y.; Xiong, S.; Rong, J.; Hu, Y. Development and Identification of Novel α-Glucosidase Inhibitory Peptides from Mulberry Leaves. Foods 2023, 12, 3917. [Google Scholar] [CrossRef]

- Li, Q.; Kang, X.; Shi, C.; Li, Y.; Majumder, K.; Ning, Z.; Ren, J. Moderation of hyperuricemia in rats via consuming walnut protein hydrolysate diet and identification of new antihyperuricemic peptides. Food Funct. 2018, 9, 107–116. [Google Scholar] [CrossRef]

- He, W.; Su, G.; Sun-Waterhouse, D.; Waterhouse, G.I.N.; Zhao, M.; Liu, Y. In vivo anti-hyperuricemic and xanthine oxidase inhibitory properties of tuna protein hydrolysates and its isolated fractions. Food Chem. 2019, 272, 453–461. [Google Scholar] [CrossRef]

- Ali, H.; Masoud, R.; Saber, K.; Ali, M.; Mehrdad, N.; Joe Mac, R. Optimization of Antioxidant Peptides Production from the Mantle of Cuttlefish (Sepia pharaonis) Using RSM and Fractionation. J. Aquat. Food Prod. Technol. 2019, 28, 392–401. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, M.; Zhao, B.; Yang, F. Isolation of antioxidant peptides from yak casein hydrolysate. RSC Adv. 2020, 10, 19844–19851. [Google Scholar] [CrossRef]

- Nielsen, P.M.; Petersen, D.; Dambmann, C. Improved Method for Determining Food Protein Degree of Hydrolysis. J. Food Sci. 2001, 66, 642–646. [Google Scholar] [CrossRef]

- Xing, Z.; Hou, X.S.; Tang, Y.X.; He, R.H.; Mintah, B.K.; Dabbour, M.; Ma, H.L. Monitoring of polypeptide content in the solid-state fermentation process of rapeseed meal using NIRS and chemometrics. J. Food Process Eng. 2018, 41, e12853. [Google Scholar] [CrossRef]

- Apostolidis, E.; Li, L.; Lee, C.; Seeram, N.P. In vitro evaluation of phenolic-enriched maple syrup extracts for inhibition of carbohydrate hydrolyzing enzymes relevant to type 2 diabetes management. J. Funct. Foods 2011, 3, 100–106. [Google Scholar] [CrossRef]

- Umamaheswari, M.; AsokKumar, K.; Somasundaram, A.; Sivashanmugam, T.; Subhadradevi, V.; Ravi, T.K. Xanthine oxidase inhibitory activity of some Indian medical plants. J. Ethnopharmacol. 2007, 109, 547–551. [Google Scholar] [CrossRef] [PubMed]

| Run | A Temperature (°C) | B Time (h) | C E/S (U/g) | Polypeptide Concentration (mg/mL) |

|---|---|---|---|---|

| 1 | 60 | 2 | 8000 | 15.46 |

| 2 | 60 | 2 | 8000 | 15.68 |

| 3 | 65 | 1.5 | 8000 | 13.99 |

| 4 | 60 | 1.5 | 10,000 | 13.36 |

| 5 | 65 | 2.5 | 8000 | 16.92 |

| 6 | 55 | 2.5 | 8000 | 11.89 |

| 7 | 55 | 2 | 6000 | 11.53 |

| 8 | 60 | 2 | 8000 | 16.01 |

| 9 | 60 | 2 | 8000 | 16.50 |

| 10 | 55 | 1.5 | 8000 | 11.65 |

| 11 | 55 | 2 | 10,000 | 9.15 |

| 12 | 65 | 2 | 10,000 | 12.75 |

| 13 | 60 | 2.5 | 10,000 | 14.20 |

| 14 | 60 | 1.5 | 6000 | 14.75 |

| 15 | 65 | 2 | 6000 | 12.77 |

| 16 | 60 | 2.5 | 6000 | 15.66 |

| 17 | 60 | 2 | 8000 | 15.68 |

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 71.30 | 9 | 7.92 | 31.98 | <0.0001 | Significant |

| A-Temperature | 18.64 | 1 | 18.64 | 75.22 | <0.0001 | ** |

| B-Time | 3.03 | 1 | 3.03 | 12.21 | 0.0101 | * |

| C-E/S | 3.45 | 1 | 3.45 | 13.91 | 0.0074 | ** |

| AB | 1.81 | 1 | 1.81 | 7.30 | 0.0305 | * |

| AC | 1.39 | 1 | 1.39 | 5.62 | 0.0496 | * |

| BC | 0.0012 | 1 | 0.0012 | 0.0049 | 0.9459 | |

| A2 | 28.42 | 1 | 28.42 | 114.71 | <0.0001 | ** |

| B2 | 0.4997 | 1 | 0.4997 | 2.02 | 0.1985 | |

| C2 | 12.43 | 1 | 12.43 | 50.16 | 0.0002 | ** |

| Residual | 1.73 | 7 | 0.2477 | |||

| Lack of fit | 1.08 | 3 | 0.3592 | 2.19 | 0.2321 | no Significant |

| Pure error | 0.6567 | 4 | 0.1642 | |||

| Cor total | 73.03 | 16 | ||||

| R2 = 0.9763 | R2Adj = 0.9457 | |||||

| Proteases | Temperature (°C) | pH |

|---|---|---|

| Papain | 50 | 7 |

| Trypsin | 37 | 8 |

| Alkaline | 55 | 8 |

| Parameters | Coded Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| A Temperature (°C) | 55 | 60 | 65 |

| B Time (h) | 1.5 | 2 | 2.5 |

| C E/S (U/g) | 6000 | 8000 | 10,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, L.; Li, X.; Zhao, B.; Song, X.; Zhang, Y.; Liang, Q. Enzymatic Hydrolysis Optimization of Yak Whey Protein Concentrates and Bioactivity Evaluation of the Ultrafiltered Peptide Fractions. Molecules 2024, 29, 1403. https://doi.org/10.3390/molecules29061403

Hao L, Li X, Zhao B, Song X, Zhang Y, Liang Q. Enzymatic Hydrolysis Optimization of Yak Whey Protein Concentrates and Bioactivity Evaluation of the Ultrafiltered Peptide Fractions. Molecules. 2024; 29(6):1403. https://doi.org/10.3390/molecules29061403

Chicago/Turabian StyleHao, Lingshen, Xuefei Li, Baotang Zhao, Xuemei Song, Yan Zhang, and Qi Liang. 2024. "Enzymatic Hydrolysis Optimization of Yak Whey Protein Concentrates and Bioactivity Evaluation of the Ultrafiltered Peptide Fractions" Molecules 29, no. 6: 1403. https://doi.org/10.3390/molecules29061403