1. Introduction

Polymers are widely used in various industrial fields due to their merits, such as light weight, resistance to chemicals, resistance to the environment, easy processing, etc. It is difficult for polymers to be treated after use due to their resistance to the environment. When polymers are disposed of in a natural environment, they remain for a long time without degradation. One of the solutions to this problem of polymers after use is the development of biodegradable polymers. Biodegradable polymers can be biodegraded eventually by microorganisms in the natural environment into carbon dioxide (CO2) and water (H2O). Various types of biodegradable plastics have been developed. Among these biodegradable plastics, polycaprolactone (PCL) was developed as a biodegradable plastic of the aliphatic polyester type derived from the chemical synthesis of crude petroleum. PCL has good water, oil and chlorine resistance. It has a low melting point (ca. 60 °C), low melt viscosity and it is easy to process. The low melting-point of PCL is expected to be suitable for composting as a means of disposal, since the temperature obtained during composting routinely exceeds 60 °C. PCL is mainly used in thermoplastic polyurethanes, resins for surface coatings, adhesives and synthetic leather and fabrics. It also serves to make stiffeners for shoes and orthopedic splints, and fully biodegradable compostable bags, sutures, and fibers. PCL is often mixed with starch to obtain a good biodegradable material in order to reduce its price. Poly(lactic acid) (PLA) products have become widely used because of their biodegradability, hydrodegradability and the biorenewable profile with its source as vegetables such as corn. This allows both the prevention of environmental pollution and the use of renewable resources for a sustainable society. Biorenewable materials are materials made from biomass with absorbed carbon dioxide from the global atmosphere in modern times. The use of biorenewable materials causes a decrease in oil consumption, and the production of the CO2 in the atmosphere from the incineration of such wastes is the same as the CO2 fixed during photosynthesis by plants from the atmosphere nowadays. This concept is called “zero-emission”. In this way, global warming will be reduced. Considering these points, the use of biodegradable and biorenewable materials is expected to be promoted. For increased use of these materials in actual commercial markets, international standards for the evaluation of their biodegradability are very important. Consumers require that products made of biodegradable plastics should display their biodegradability according to international standards.

The Japan Bioplastics Association (JBPA) is a organization voluntarily founded by the major Japanese plastics producing companies and others focused on plastics, which was established with the aim of promoting the popularization of biodegradable plastics and biomass-based plastics, which play an important role in solving the recycling-technical problems [

1]. JBPA has established two identification systems related to biodegradable plastics products and biomass-based plastics products. That is, the GreenPla Identification System and the BiomassPla Identification System. There are logo marks for these systems as shown in

Figures 1 and

2.

The International Organization for Standardization (ISO) is a worldwide federation of national standard bodies (ISO member bodies) [

2,

3]. The work preparing International Standards is normally carried out through the ISO Technical Committee (TC). Each TC has subcommittees (SC) for related topics and the SC has several working groups (WG). TC61 is a TC concerning “Plastics”. WG22 was created as a new WG for “Biodegradability” under SC5 on “Physical chemical properties” by TC61 in 1993. A convener of WG22 was Dr. Sawada with the support by JBPA, since Japan insisted that it was necessary for a new working group on “biodegradability” to be established in TC61. Standards for the biodegradability of plastics in the ISO are discussed under TC61/SC5/WG22. Recently, a discussion about the concept of the bio-based content of plastics has been proposed. The ISO standards list about the biodegradation of plastics discussed under TC61/SC5/WG22 is shown as

Table 1. Eleven ISO standards, including one standard under discussion are maintained under TC61/SC5/WG22. There are nine standards for the biodegradation testing of plastics. One standard for the specification and one standard for sample preparation for the biodegradation tests exist. Nine standards for the biodegradation test can be classified by the test environment such as an aqueous solution, a compost, and soil, as shown in

Table 1. ISO 14855-1 and ISO 14855-2 are biodegradation tests in a compost, ISO 14855-1 is a pilot-scale test and ISO 14855-2 is a laboratory-scale test. According to ISO 14855-1, 50 g of a sample is required for one measurement and three test samples are required for the one measurement. Therefore, at least 150 g of a sample is required for one measurement by ISO 14855-1. On the other hand, 10 g of a sample is required according to ISO 14855-2. The Biodegradable Plastics Society (BPS), which was the former JBPA society, planned a round-robin test of biodegradation test based on ISO 14855-2 before being established as an ISO standard. After the round-robin test in Japan for four years, Dr. Uematsu with support by BPS (JBPA) proposed ISO 14855-2 as a new biodegradation evaluation method in a laboratory scale on TC61/SC5/WG22 in 2003. An international round-robin test was proposed in order to confirm this method and then seven countries (Sweden, Italy, Belgium, China, India, USA and Japan) have researched the ultimate aerobic biodegradability of plastic materials under the same conditions using the Microbial Oxidative Degradation Analyzer (MODA) apparatus based on the round-robin test (2004–2006) [

4]. Our laboratory joined this round-robin test as the representative of Japan. Samples for the round-robin test were prepared in our laboratory. It is known that the biodegradabilities of sample depend on the sample’s size and shape. The biodegradation of various samples based on ISO 14855-2 have been studied using the international round-robin test up to now [

4–

10]. From these results, a sample preparation method has also been investigated [

6–

8]. This sample preparation method was arranged for all the biodegradation tests in the ISO standard and was proposed as a new ISO standard for TC61/SC5/WG22 by Dr. Kunioka. This standard is ISO/DIS 10210, now under discussion as shown in

Table 1. There are few articles concerning the biodegradability of polymers in a controlled compost. Especially, the studies of the biodegradability of polymers measured by ISO 14855-2 are very rare. The biodegradation of polymer composites consisting of PLA and cotton fibers has been studied [

5]. The biodegradation of poly(butylene succinate) (PBS) has been reported [

10].

In this review, the biodegradation of various types and shapes of biodegradable polymers and their products were investigated in order to confirm ISO 14855-2 and ISO/DIS 10210. The biodegradabilities of PCL and PLA in controlled compost, measured on the basis of ISO 14855-2 by MODA, are described. The sample preparation method for this measurement according to ISO/DIS 10210 was also described. The biodegradabilities of various types of samples, such as powders, plates, and films, were measured by MODA. Additionally, the biodegradation of PLA composites with cotton fibers in a controlled compost was investigated.

2. Experimental Section

2.1. Materials

Polycaprolactone (PCL) and poly(lactic acid) (PLA) were used as biodegradable plastics for the biodegradation tests. The commercial PCL pellets were kindly supplied by Daicel Chemical Industries, Ltd., Japan. The commercial PLA pellets were kindly supplied by Mitsui Chemicals, Japan. The commercial PLA film with a 25 μm thickness was kindly supplied by Unitika, Ltd., Japan. Returnable cups made of PLA which were actually used at the Aichi EXPO 2005 in Japan were used as an example of products made of biodegradable plastics. PLA and PLA composites were prepared in our laboratory by the polymerization of

l-Lactide (LA, (3

S, 6

S)-

cis-3,6-dimethyl-1,4-dioxane-2,5-dione, Tokyo Kasei, Japan) and aluminum triflate (trifluoromethanesulfonate, Al(OTf)

3; Aldrich) with and without absorbent cotton (Iwatsuki Co., Japan) [

5].

The cellulose powder of thin-layer chromatography grade with a particle size of less than 20 μm (cellulose microcrystalline; Merck, Germany), soda talc (sodium hydroxide on support, granulated about 1.6–3 mm; Merck, Germany), soda lime (sodium hydroxide on support, small granules about 1.5–3 mm; Kanto Chemical, Japan) and sea sand (sand washed, 425–850 μm; Wako Pure Chemical, Japan) were used for the biodegradation test by the Microbial Oxidative Degradation Analyzer (MODA) (Hissan Trade Co., Ltd., Japan) as received.

2.2. Preparation of Samples for Biodegradation Test

For the biodegradation test in the compost by MODA, samples were made based on their shapes such as powders and plates. The powder type samples were prepared by mechanical crushing. The polymer pellets, returnable cup, and films were crushed into powders. Samples with dry ice were mechanically crushed by a rotating mixer with titanium blades. The crushing was carried out 15 times for 3 min each at 5 min intervals to prevent overheating of the motor in the mixer. After drying under reduced pressure at room temperature, the sample powder was separated using sieves of 30 mesh (500 μm), 60 mesh (250 μm), and 125 mesh (125 μm). Standard sieves with a guarantee were used. The powders were separated by size. That is, 0–125 μm, 125–250 μm, 250–500 μm, etc. The 125–250 μm powders are recommended for the biodegradation test of the ISO standards in ISO/DIS 10210. The sieves with crude polymer powders were placed on a sieve vibrator and vibrated for 15 min.

The actual product samples were cut into plates for the biodegradation tests by MODA. The PLA returnable cup was cut into 1 cm square plates using the nippers. The PLA powders from cups were obtained from PLA plates by a rotating mechanical mixer. The PLA films were cut into 1 cm and 5 cm squares. Crushed PLA films were prepared by a mechanical mixer. The composite samples were cut into blocks for the biodegradation tests by MODA. The maximum length of each block was less than 5 mm.

2.3. Preparation of Controlled Compost

The controlled compost (YK-5, Hissan Trading Co., Ltd., Japan) for MODA based on ISO 14855-2 was prepared as follows. The waste material of used wood blocks for growing mushrooms and also chicken droppings were composted for 7 months. During this period, mature compost was prepared. After preparation, this obtained compost was sieved using a 4.7 mesh (4 mm) sieve, kept at room temperature and prevented from drying. The properties of this compost are shown in

Table 2. This compost can be kept at room temperature for a long time, at least five years. Before using this compost (YK-5), an activation step (preincubation) was required to recover the biological activities for the respiration and biodegradation by microorganisms.

The compost (ca. 80 g) was mixed sea sand (425–850 μm, ca. 320 g). The controlled compost was prepared by adding adequate water to this mixture in order to control water content of the original compost over 80%, where the water content is determined as a weight ratio of total water (adding water and water included the compost) to volatile solids of the original compost. The weight indicated in parenthesis is that for one reaction vessel. Preincubation was performed once for the total amount of blanks and samples using a big container (5 L). Sea sand was added to make good homogeneous conditions and a better aerobic environment inside the compost. This compost for the activation step was mixed once a day and the water content of 65 wt% for 7 days at 58 °C was controlled.

2.4. Biodegradation Measurement Based on ISO 14855-2

A biodegradation test was performed using the MODA apparatus in controlled compost at 58 °C as shown in

Figure 3. The scheme is shown in

Figure 4. A 10 g sample was well mixed in the activated compost with sea sand (ca. 400 g) and transferred to a reaction vessel. Compost with no sample was used as the blank to determine the respiration activity of this compost. The biodegradation tests were performed at 58 °C at a 10 mL/min air (CO

2-free) flow rate for 30–130 days. The activated compost used in this study produced 50 mg CO

2 per gram of volatile solids of this compost over the first 10 days. In almost all cases, the number of experimental replicates of the blank or sample was two (duplicate). The produced CO

2 amounts were measured once a day by measuring the weights of an absorption column for carbon dioxide and an absorption column for water. The degree of biodegradation percentage was calculated from the produced CO

2 amount from which was subtracted the respiration CO

2 amount determined from a blank, and the theoretically produced CO

2 amount of the added sample. For example, 10 g of PLA could be changed with 18.3 g of CO

2 which was the theoretical amount for the 100% biodegradation. Once a week, the sample and compost were well mixed and the water content was controlled. The absorbed CO

2 amounts for the absorption columns reached 40% of the theoretical absorption capacity, and the chemicals (soda lime and soda talc) inside the columns were changed. This test method is based on ISO 14855-2.

2.5. Particle Size Measurement of Powder Samples

The particle sizes of the powder samples were measured by optical microscopy using a digital camera. The diameter lengths of at least 100 particles were measured from optical microscopy photographs for one fractionated polymer powder. The maximum length of each particle was measured as the diameter of each particle. The average diameter of the polymer powders was determined to be the number average of these diameters in the photographs.

4. Conclusions

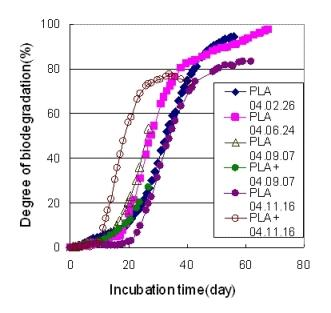

The biodegradabilities of polycaprolactone (PCL) samples and poly(lactic acid) PLA samples in a controlled compost at 58 °C were investigated according to ISO 14855-2. Sample preparation of the polymer pellets, polymer films, polymer products, and polymer composites regulated by ISO/DIS 10210 were investigated for ISO 14855-2. Polymer powder samples were obtained from PCL pellets and PLA pellets by mechanically crushing and sieving. Cut and crushed film samples were obtained from the PLA films. Plate samples and powder samples were obtained from the PLA returnable cups. Block samples were obtained from the PLA composites with cotton fibers.

The biodegradations of the above samples were measured by the Microbial Oxidative Degradation Analyzer (MODA). The reproducibility and repeatability of the biodegradation tests using MODA were confirmed for cellulose powders as the reference material, PCL powders and PLA powders. Results of the biodegradation tests for the PLA films, PLA cup and PLA composites are shown.

It was found that biodegradabilities of polymer pellets, polymer films, polymer products and polymer composites in a controlled compost can be evaluated according to ISO 14855-2 and ISO/DIS 10210 using the MODA apparatus. Final degrees of biodegradation and biodegradation curves by biodegradation tests based on ISO 14855-2 for samples prepared from biodegradable polymers with various shapes based on ISO/DIS 10210 in this review show almost the same tendency. This fact indicates that samples derived from the polymers and their products based on ISO/DIS 10210 can be evaluated based on ISO 14855-2.