Liquid Crystals in Tribology

Abstract

:1. Introduction

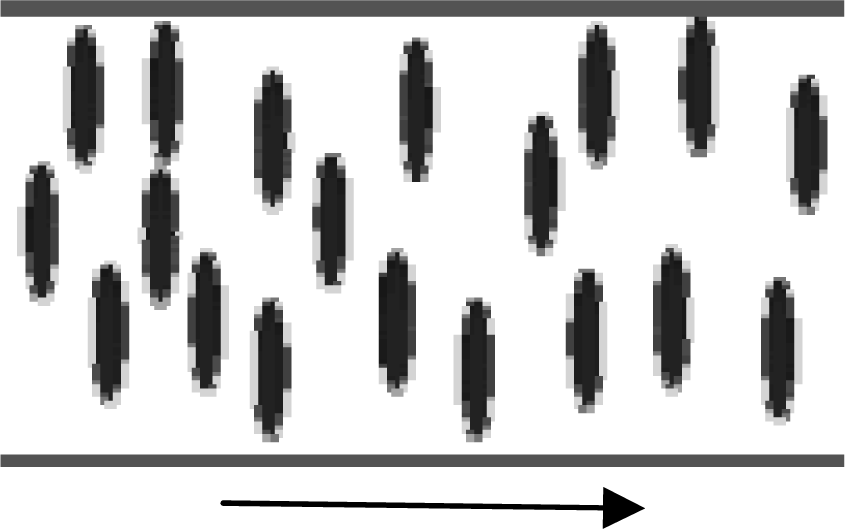

1.1. Liquid Crystals

1.2. Tribology

2. Liquid Crystals in Tribology

2.1. Thermotropic MLCs

2.2. Lyotropic Liquid Crystals

2.3. MLCs as Lubricants of Polymers. Polymer Dispersed MLCs (PDMLCs)

3. Recent Developments and Conclusion

Acknowledgments

References

- Baron, M. Definition of basic terms relating to low molar mass and polymer liquid crystals. Pure Appl. Chem 2001, 73, 845–895. [Google Scholar]

- Hutchings, IM. Tribology Friction and Wear of Engineering Materials; Edward Arnold: London, UK, 1992. [Google Scholar]

- Gellman, AJ; Ko, JS. The current status of tribological surface science. Tribol. Lett 2001, 10, 39–44. [Google Scholar]

- McFadden, C; Soto, C; Spencer, ND. Adsorption and surface chemistry in tribology. Tribol. Int 1997, 30, 881–888. [Google Scholar]

- Somorjai, GA. Progress in our understanding of structure bonding and reactivity of metal surfaces and adsorbed monolayers at the molecular level: A 25 year perspective. Progr. Surf. Sci 1995, 50, 3–29. [Google Scholar]

- Cho, YK; Cai, L; Granick, S. Molecular tribology of lubricants and additives. Tribol. Int 1997, 30, 889–894. [Google Scholar]

- Davidson, JE; Hinchley, SL; Harris, SG; Parkin, A; Parsons, S; Tasker, PA. Molecular dynamics simulations to aid the rational design of organic friction modifiers. J. Mol. Graphs. Modell 2006, 25, 495–506. [Google Scholar]

- Gribailo, AP; Kupreev, MP; Zamyatnin, VO. Effect of liquid-crystals on lubricating properties of mineral-oils. Chem. Technol. Fuels Oils 1983, 19, 342–345. [Google Scholar]

- Fischer, TE; Bhattacharya, S; Salher, R; Lauer, JL; Ahn, YJ. Lubrication by a smectic liquid-crystal. Tribol. Trans 1988, 31, 442–448. [Google Scholar]

- Eidenschink, R. Liquid-crystals in variable friction devices. Angew. Chem. Int. Ed 1988, 27, 1579–1580. [Google Scholar]

- Barchan, GP; Milaev, AG; Gumenchuk, IG. Effect of the mesomorphic state-isotropic liquid-phase transition on lubricating properties of liquid-crystalline mixtures. Chem. Technol. Fuels Oils 1988, 24, 550–551. [Google Scholar]

- Eidenschink, R. A novel application of liquid-crystals in tribology. Liq. Cryst 1989, 5, 1517–1521. [Google Scholar]

- Tichi, JA; Rhim, Y. A theory for the lubrication of layered liquid-crystals. J. Tribol. Trans. ASME 1989, 111, 169–174. [Google Scholar]

- Tichi, JA. Lubrication theory for nematic liquid-crystals. Tribol. Trans 1990, 33, 363–370. [Google Scholar]

- Biresaw, G (Ed.) Tribology and the Liquid-Crystalline State ACS Symposium Series, 441; American Chemical Society: Washington DC, USA, 1990.

- Cognard, J. Lubrication with liquid-crystals. In Tribology and the Liquid-Crystalline State ACS Symposium Series, 441; Biresaw, G, Ed.; American Chemical Society: Washington DC, USA, 1990; pp. 1–47. [Google Scholar]

- Biresaw, G; Zadnik, DA. Temperature effects on the tribological properties of thermotropic liquid-crystals. In Tribology and the Liquid-Crystalline State ACS Symposium Series, 441; Biresaw, G, Ed.; American Chemical Society: Washington DC, USA, 1990; pp. 83–90. [Google Scholar]

- Kumar, K; Shah, DO. Effects of liquid-crystalline structures on lubrication of aluminium surfaces. In Tribology and the Liquid-Crystalline State ACS Symposium Series, 441; Biresaw, G, Ed.; American Chemical Society: Washington DC, USA, 1990; pp. 91–100. [Google Scholar]

- Friberg, SE; Ward, AJ; Gunsel, S; Lockwood, FE. Lyotropic liquid-crystals in lubrication. In Tribology and the Liquid-Crystalline State ACS Symposium Series, 441; Biresaw, G, Ed.; American Chemical Society: Washington DC, USA, 1990; pp. 101–111. [Google Scholar]

- Lee, HS; Winoto, SH; Winer, WO; Chiu, M; Friberg, SE. Film thickness and frictional behaviour of some liquid-crystals in concentrated point contacts. In Tribology and the Liquid-Crystalline State ACS Symposium Series, 441; Biresaw, G, Ed.; American Chemical Society: Washington DC, USA, 1990; pp. 113–125. [Google Scholar]

- Lockwood, FE; Friberg, S. Tribological properties of liquid-crystals. Abstr. Pap. Am. Chem. Soc 1989, 198, 145. [Google Scholar]

- Nakano, K. Scaling law on molecular orientation and effective viscosity of liquid-crystalline boundary films. Tribol. Lett 2003, 14, 17–24. [Google Scholar]

- Kupchinov, BI; Ermakov, SF; Rodnenkov, VG; Bobrysheva, SN; Beloenko, ED. The effect of liquid crystals on joint lubrication. Wear 1994, 171, 7–12. [Google Scholar]

- Waters, EPJ; Spedding, PL; Dohert, AP; Spedding, RL. Wear of the artificial hip joint material under lubrication. Asia-Paific J. Chem. Eng 2009, 4, 80–89. [Google Scholar]

- Kimura, Y; Nakano, K; Kato, T; Morishita, S. Control of friction coefficient by applying electric-fields across liquid-crystal boundary films. Wear 1994, 175, 143–149. [Google Scholar]

- Ruths, M; Steinberg, S; Israelachvili, JN. Effects of confinement and shear on the properties of thin films of thermotropic liquid crystal. Langmuir 1996, 12, 6637–6650. [Google Scholar]

- Artsyukhovich, A; Broekman, LD; Salmeron, M. Friction of the liquid crystal 8CB as probed by the surface forces apparatus. Langmuir 1999, 15, 2217–2223. [Google Scholar]

- Idziak, SHJ; Koltover, I; Davidson, P; Ruths, M; Li, YL; Israelachvili, JN; Safinya, CR. Structure under confinement in a smectic–A and lyotropic surfactant hexagonal phase. Phys. B 1996, 221, 289–295. [Google Scholar]

- Dushkin, CD; Kurihara, K. Nanotribology of thin liquid-crystal films studied by the shear force resonance method. Coll. Surf. A-Physicochem. Eng. Aspects 1997, 130, 131–139. [Google Scholar]

- Janik, J; Tadmor, R; Klein, J. Shear of molecularly confined liquid crystals. 1. Orientation and transitions under confinement. Langmuir 1997, 13, 4466–4473. [Google Scholar]

- Li, JW; Wang, C; Shang, GY; Xu, QM; Lin, Z; Guan, JJ; Bai, CL. Friction coefficients derived from apparent height variations in contact mode atomic force microscopy images. Langmuir 1999, 15, 7662–7669. [Google Scholar]

- Kupchinov, BI; Rodnenkov, VG; Ermakov, SF; Parkalov, VP. A study of lubrication by liquid crystals. Tribol. Int 1991, 24, 25–28. [Google Scholar]

- Vekteris, V; Murachver, A. Effectiveness of liquid-crystal admixtures in the lubricating oil for a multi-operational machine. Lubr. Eng 1995, 51, 851–853. [Google Scholar]

- Eidenschink, R; Hager, AM. Reduction of friction through presmectic lubricants. Mol. Cryst. Liq. Cryst. Sci. Technol. Sect. A. Mol. Cryst. Liq. Cryst 1997, 304, 513–517. [Google Scholar]

- Mori, S; Iwata, H. Relationship between tribological performance of liquid crystals and their molecular structure. Tribol. Int 1996, 29, 35–39. [Google Scholar]

- Janik, J; Tadmor, R; Klein, J. Shear of molecularly confined liquid crystals. 2. Stress anisotropy across a model nematogen compressed between sliding solid surfaces. Langmuir 2001, 17, 5476–5485. [Google Scholar]

- Bermúdez, MD; Martínez-Nicolás, G; Carrión-Vilches, FJ. Tribological properties of liquid crystals as lubricant additives. Wear 1997, 212, 188–194. [Google Scholar]

- Yao, JB; Wang, GL; Xu, Z; Yin, JX; Wen, SZ. The tribological performance of nematic liquid crystal 4-n-pentyl-4′-cyanobiphenyl (5CB) as a lubricant additive. Lubr. Eng 2000, 56, 21–25. [Google Scholar]

- Shen, MW; Luo, JB; Wen, SZ; Yao, JB. Investigation of the liquid crystal additive influence on film formation in nano scale. Lubr. Eng 2002, 58, 18–23. [Google Scholar]

- Shen, MW; Luo, JB; Wen, SZ; Yao, JB. Nano-tribological properties and mechanisms of the liquid crystal as an additive. Chin. Sci. Bull 2001, 46, 1227–1232. [Google Scholar]

- Molenda, J; Makowska, M. Tribochemical behaviour of the selected mesogenic additive in n-hexadecane. Tribol. Lett 2006, 21, 39–45. [Google Scholar]

- Wazynska, B; Okowiak, JA. Tribological properties of nematic and smectic liquid crystalline mixtures used as lubricants. Tribol. Lett 2006, 24, 1–5. [Google Scholar]

- Wazynska, B; Okowiak, JA; Kolacz, S; Malysa, A. Tribological properties of parffin oil doped with liquid crystalline mezogenes. Opto-Electronics Rev 2008, 16, 267–270. [Google Scholar]

- Iglesias, P; Bermúdez, MD; Carrión, FJ; Martínez-Nicolás, G. Friction and wear of aluminium-steel contacts lubricated with ordered fluids-neutral and ionic liquid crystals as oil additives. Wear 2004, 256, 386–392. [Google Scholar]

- Fuller, S; Li, Y; Tiddy, GJT; Wynjones, E; Arnell, RD. Formulation of lyotropic lamellar phases of surfactants as novel lubricants. Langmuir 1995, 11, 1980–1983. [Google Scholar]

- Ma, CS; Li, GZ; Shen, QA. Study of lyotropic liquid crystal in lubrication on aluminum alloy surfaces. J. Dispersion Sci. Technol 1999, 20, 1025–1030. [Google Scholar]

- Boschkova, K; Elvesjo, J; Kronberg, B. Frictional properties of lyotropic liquid crystalline mesophases at surfaces. Colloid Surf. A-Physicochem. Eng. Asp 2000, 166, 67–77. [Google Scholar]

- Ouchi, Y; Mori, I; Sei, M; Ito, E; Araki, T; Ishii, H; Seki, K; Kondo, K. Polarized XANES studies on the rubbed polyimide for liquid crystal alignment. New applicability to the tribology of the polymer systems. Physica B 1995, 208, 209, 407–408. [Google Scholar]

- Sulek, MW; Bocho-Janiszewska, A. The effect of ethoxylated esters on the lubricating properties of their aqueous solutions. Tribol. Lett 2006, 24, 187–194. [Google Scholar]

- Sulek, MW; Wasilewski, T. Tribological properties of aqueous solutions of alkyl polyglucosides. Wear 2006, 260, 193–204. [Google Scholar]

- Sulek, MW; Wasilewski, T. Antiseizure properties of aqueous solutions of compounds forming liquid crystalline structures. Tribol. Lett 2005, 18, 197–205. [Google Scholar]

- Ma, KF; Somashekhar, BS; Gowda, GAN; Khetrapal, CL; Weiss, RG. Induced amphotropic and thermotropic ionic liquid crystallinity in phosphonium halides. “Lubrication” by hydroxyl groups. Langmuir 2008, 24, 2746–2758. [Google Scholar]

- Kikuchi, H; Logan, JA; Yoon, DY. Study of local stress, morphology and liquid-crystal alignment on buffed polyimide surfaces. J. Appl. Phys 1996, 79, 6811–6817. [Google Scholar]

- Abe, S; Kijima, M; Shirawata, H. Friction-induced uniaxial orientation of a liquid crystalline N-substituted polypyrrole. J. Mater. Chem 2000, 10, 1509–1510. [Google Scholar]

- Wacharawichanant, S; Thongyai, S; Tanodekaew, S; Higgins, JS; Clarke, N. Spinodal decomposition as a probe to measure the effects on molecular motion in poly(styrene-cp-acrylonitrile) and poly(methylmethacrylate) blends after mixing with a low molar mass liquid crystal or commercial lubricant. Polymer 2006, 45, 2201–2209. [Google Scholar]

- Takada, S; Yamamoto, T. Tribological characteristics of liquid crystal/polymer blended film (part 1)—Preparation of blended film and frictional characteristics. J. Jpn. Soc. Tribol 2001, 46, 805–813. [Google Scholar]

- Bermúdez, MD; Carrión-Vilches, FJ; Martínez-Nicolás, G. Wear of liquid crystal-additivated polymers against steel. J. Appl. Polym. Sci 1999, 74, 831–837. [Google Scholar]

- Bermúdez, MD; Carrión-Vilches, FJ; Martínez-Mateo, I; Martínez-Nicolás, G. Comparative study of the tribological properties of polyamide 6 filled with molybdenum disulfide and liquid-crystalline additives. J. Appl. Polym. Sci 2001, 81, 2426–2432. [Google Scholar]

- Bermúdez, MD; Brostow, W; Carrión-Vilches, FJ; Cervantes, JJ; Pietkiewicz, D. Friction and multiple scratch behavior of polymer plus monomer liquid crystal systems. Polymer 2005, 46, 347–362. [Google Scholar]

- Brostow, W; Jaklewicz, M. Friction and scratch resistance of polymer liquid crystals: Effects of magnetic field orientation. J. Mater. Res 2004, 19, 1038–1042. [Google Scholar]

- Minami, I. Ionic liquids in tribology. Molecules 2009, 14, 2286–2305. [Google Scholar]

- Bermúdez, MD; Jiménez, AE; Sanes, J; Carrión, FJ. Ionic liquids as advanced lubricant fluids. Molecules 2009, 14, 2888–2908. [Google Scholar]

- Yang, HM; Yang, M; Zhang, Y; Chen, GX. In situ synthesis and lubrication of Pb nanoparticles in lamellar liquid crystal. Colloid J 2004, 66, 635–641. [Google Scholar]

- Yang, HM; Yang, M; Guo, R. Tribology properties of CdS nanoparticles in situ synthesized in lamellar liquid crystal system of Triton X-100/C10H21OH/H2O. J. Dispers. Sci. Technol 2005, 26, 477–482. [Google Scholar]

- Yang, HM; Guo, R; Wang, HQ. Lubrication of the mixed system of Triton X-100/n-C10H21OH/H2O lamellar liquid crystal and ZnS nanoparticles. Coll. Surf. A-Physicochem. Eng. Aspects 2001, 180, 243–251. [Google Scholar]

- Dai, T; Ge, LL; Guo, R. Microstructure of lamellar liquid crystal in Tween 85/[Bmim]PF6/H2O system and applications as Ag nanoparticle synthesis and lubrication. J. Mater. Res 2009, 4, 333–341. [Google Scholar]

- Song, G; Han, J; Bo, J; Guo, R. Synthesis of polyaniline nanostructures in different lamellar liquid crystals and application to lubrication. J. Mater. Sci 2009, 44, 715–720. [Google Scholar]

- Ding, Y; Xu, B; Guo, R; Shen, M. The preparation of silver sulphide nanoparticles in lamellar liquid crystal and application to lubrication. Mater. Res. Bull 2005, 40, 575–582. [Google Scholar]

- Jiang, WQ; Yu, B; Liu, WM; Hao, JC. Carbon nanotubes incorporated within lyotropic hexagonal liquid crystal formed in room-temperature ionic liquids. Langmuir 2007, 23, 8549–8553. [Google Scholar]

- Ge, LL; Chen, LP; Guo, R. Microstructure and lubrication properties of lamellar liquid crystal in Brij30/[Bmim]PF6/H2O system. Tribol. Lett 2007, 28, 123–130. [Google Scholar]

- Vekteris, V; Mokshin, V. Tribological research of industrial oil with liquid-crystal additives. Mater. Sci 2008, 44, 730–734. [Google Scholar]

- Whitby, RD. Developing liquid crystals as lubricants. Tribol. Lubr. Technol 2009, 65, 96. [Google Scholar]

© 2009 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Carrión, F.-J.; Martínez-Nicolás, G.; Iglesias, P.; Sanes, J.; Bermúdez, M.-D. Liquid Crystals in Tribology. Int. J. Mol. Sci. 2009, 10, 4102-4115. https://doi.org/10.3390/ijms10094102

Carrión F-J, Martínez-Nicolás G, Iglesias P, Sanes J, Bermúdez M-D. Liquid Crystals in Tribology. International Journal of Molecular Sciences. 2009; 10(9):4102-4115. https://doi.org/10.3390/ijms10094102

Chicago/Turabian StyleCarrión, Francisco-José, Ginés Martínez-Nicolás, Patricia Iglesias, José Sanes, and María-Dolores Bermúdez. 2009. "Liquid Crystals in Tribology" International Journal of Molecular Sciences 10, no. 9: 4102-4115. https://doi.org/10.3390/ijms10094102