Biosynthesis of α-Glucosidase Inhibitors by a Newly Isolated Bacterium, Paenibacillus sp. TKU042 and Its Effect on Reducing Plasma Glucose in a Mouse Model

Abstract

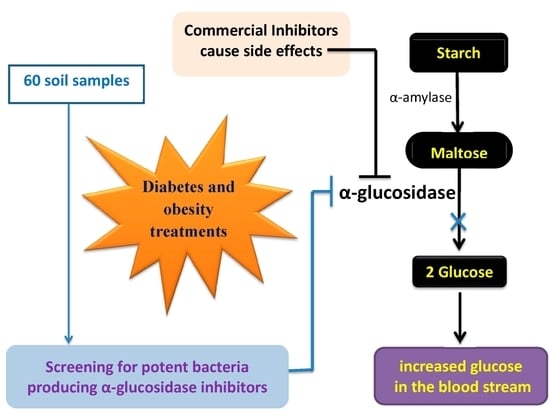

:1. Introduction

2. Results and Discussion

2.1. Isolation, Screening, and Identification of Strain TKU042

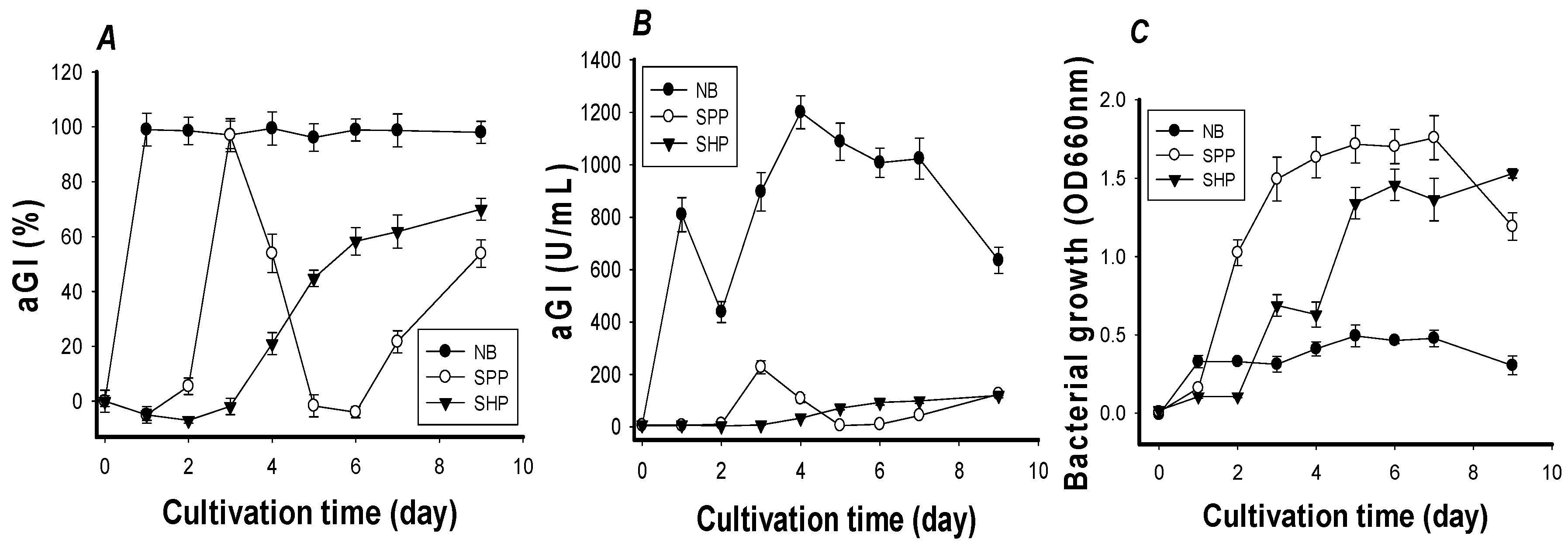

2.2. Effects of the C/N (Carbon/Nitrogen) Source on aGIs Production

2.3. Optimization of Culture Conditions

2.4. Specific aGI Activity and Antioxidant Activity of FNB

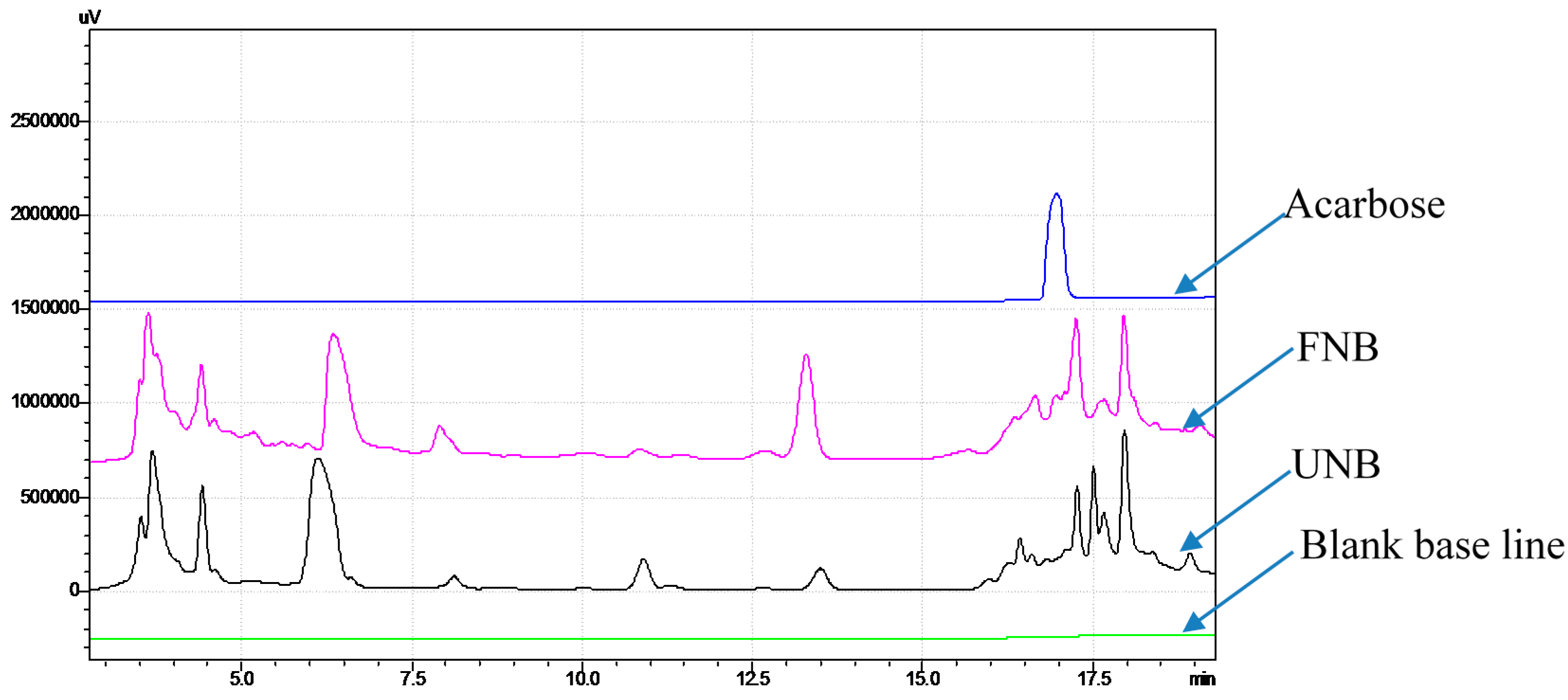

2.5. Confirmation that aGIs Contained in FNB Were Produced during NB Fermentation

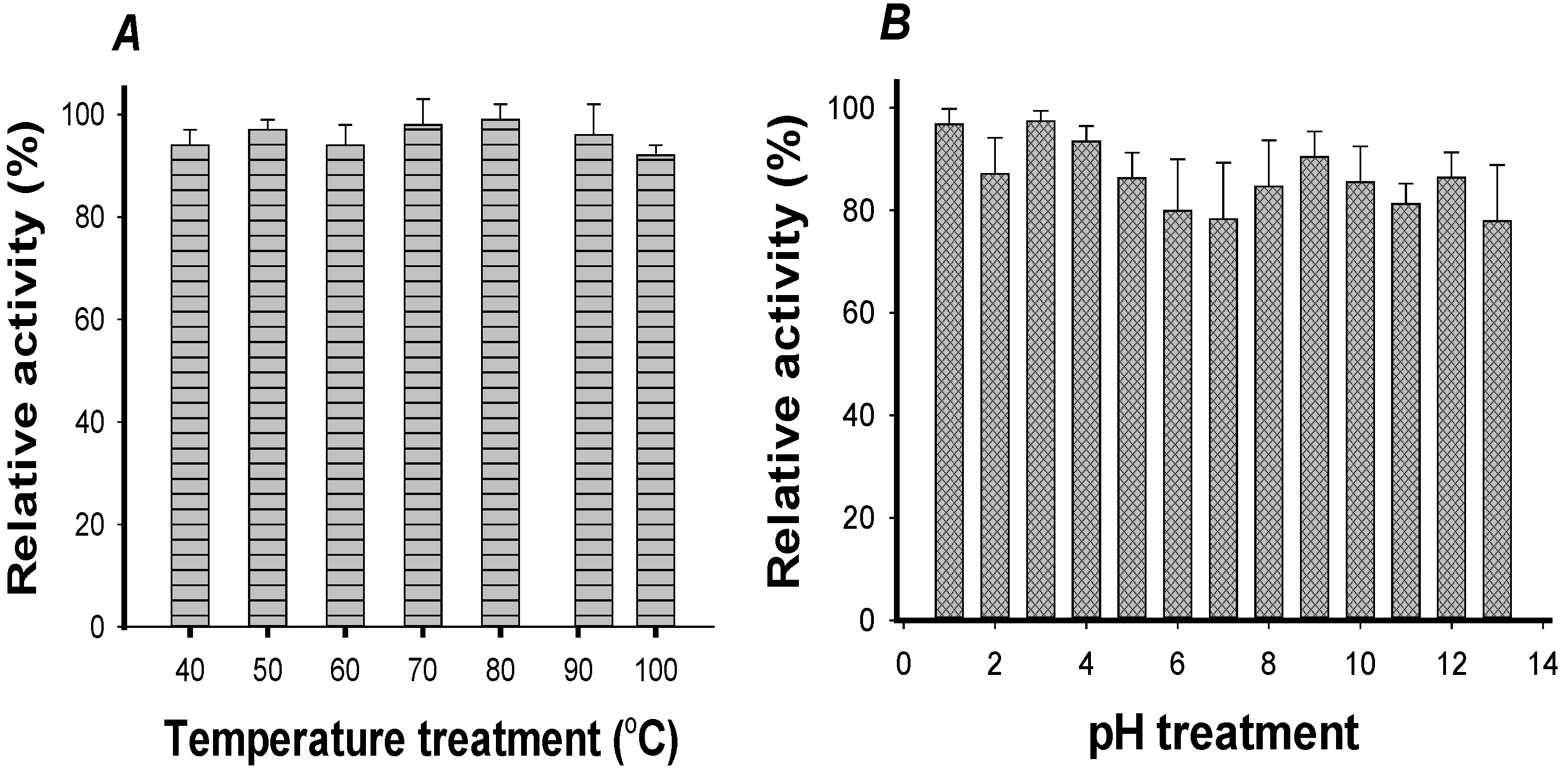

2.6. The Thermal and pH Stabilities of FNB aGIs

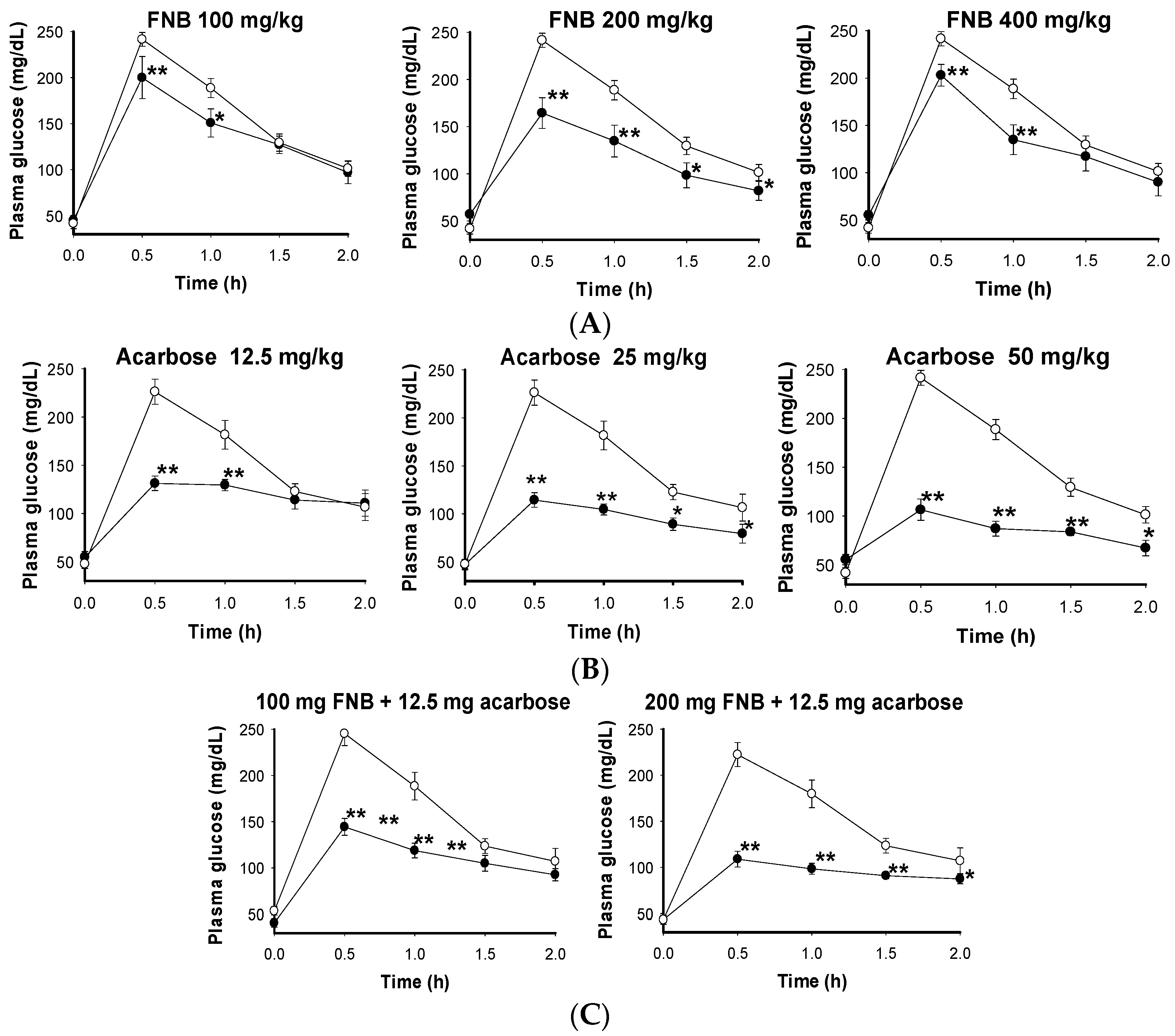

2.7. The Effects of FNB on Reducing Plasma Glucose in the Mouse Model

3. Materials and Methods

3.1. Materials

3.2. Measurement of Rat α-Glucosidase Inhibition

3.3. DPPH Radical Scavenging Activity Assay

3.4. Isolation and Screening of aGI-Producing Strains

3.5. Optimization of Culture Conditions for Synthesis of aGIs

3.6. Measurement of Inhibitor Stability

3.7. Experimental Animal Protocol

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cambell, R.K. Clarifying the role of incretin-based therapies in the treatment of type 2 diabetes mellitus. Clin. Ther. 2011, 33, 511–527. [Google Scholar] [CrossRef] [PubMed]

- Lakshmanasenthil, S.; Vinothkumar, T.; Geetharamani, D.; Marudhupandi, T.; Suja, G.; Sindhu, N.S. Fucoidan—A novel α-amylase inhibitor from Turbinaria ornata with relevance to NIDDM therapy. Biocatal. Agric. Biotechnol. 2014, 3, 66–70. [Google Scholar] [CrossRef]

- DeMelo, E.B.; Gomes, A.; Carvalha, I. α- and β-Glucosidase inhibitors: Chemical structure and biological activity. J. Tetrahedron 2006, 62, 10277–10302. [Google Scholar]

- Yin, Z.; Zhang, W.; Feng, F.; Zhang, Y.; Kang, W. α-Glucosidase inhibitors isolated from medicinal plants. Food Sci. Hum. Wellness 2014, 3, 136–174. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, Y.Q.; Yamaki, K.; Li, L.T. Anti-α-glucosidase activity of Chinese traditionally fermented soybean (douchi). Food Chem. 2007, 103, 1091–1096. [Google Scholar] [CrossRef]

- Fujita, H.; Yamagami, T.; Ohshima, K. Long-term ingestion of touchi-extract, a α-glucosidase inhibitor, by borderline and mild type-2 diabetic subjects is safe and significantly reduces blood glucose levels. Nutr. Res. 2003, 23, 713–722. [Google Scholar] [CrossRef]

- Wang, G.; Peng, Z.; Wang, J.; Li, X.; Li, J. Synthesis, in vitro evaluation and molecular docking studies of novel triazine-triazole derivatives as potential α-glucosidase inhibitors. Eur. J. Med. Chem. 2017, 125, 423–429. [Google Scholar] [CrossRef] [PubMed]

- Ezure, Y.; Maruo, S.; Miyazaki, K.; Kawamata, M. Moranoline (1-deoxynojirimycin) fermentation and its improvement. Agric. Biol. Chem. Tokyo 1985, 49, 1119–1125. [Google Scholar]

- Kameda, Y.; Asano, N.; Yoshikawa, M.; Takeuchi, M.; Yamaguchi, T.; Matsui, K.; Horii, S.; Fukase, H. Valiolamine, a new α-glucosidase inhibiting amino-cyclitol produced by Streptomyces hygroscopicus. J. Antibiot. 1984, 37, 1301–1307. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Lee, J.Y.; Hwang, K.Y.; Cho, Y.S.; Park, Y.S.; Kang, K.D.; Seong, S.I. Isolation and identification of a Bacillus sp. producing α-glucosidase inhibitor 1-deoxynojirimycin. Korean J. Microbiol. Biotechnol. 2011, 39, 49–55. [Google Scholar]

- Onose, S.; Ikeda, R.; Nakagawa, K.; Kimura, T.; Yamagishi, K.; Higuchi, O.; Miyazawa, T. Production of the α-glycosidase inhibitor 1-deoxynojirimycin from Bacillus species. Food Chem. 2013, 138, 516–523. [Google Scholar] [CrossRef] [PubMed]

- Nam, H.; Jung, H.; Karuppasamy, S.; Park, Y.S.; Cho, Y.S.; Lee, J.Y.; Seong, S.; Suh, J.G. Anti-diabetic effect of the soybean extract fermented by Bacillus subtilis MORI in db/db mice. Food Sci. Biotechnol. 2012, 21, 1669–1676. [Google Scholar] [CrossRef]

- Zhu, Y.P.; Yamaki, K.; Yoshihashi, T.; Ohnishi, K.M.; Li, X.T.; Cheng, Y.Q.; Mori, Y.; Li, L.T. Purification and identification of 1-deoxynojirimycin (DNJ) in okara fermented by Bacillus subtilis B2 from Chinese traditional food (meitaoza). J. Agric. Food Chem. 2010, 58, 4097–4103. [Google Scholar] [CrossRef] [PubMed]

- Cho, Y.S.; Park, Y.S.; Lee, J.Y.; Kang, K.D.; Hwang, K.Y.; Seong, S.I. Hypoglycemic effect of culture broth of Bacillus subtilis S10 producing 1-deoxynojirimycin. J. Korean Soc. Food Sci. Nutr. 2008, 37, 1401–1407. [Google Scholar] [CrossRef]

- Zheng, Y.G.; Xue, Y.P.; Shen, Y.C. Production of valienamine by a newly isolated strain: Stenotrophomonas maltrophilia. Enzym. Microb. Technol. 2006, 39, 1060–1065. [Google Scholar] [CrossRef]

- Schmidt, D.D.; Frommer, W.; Junge, B.; Müller, L.; Wingender, W.; Truscheit, E.; Schäfer, D. α-Glucosidase inhibitors, new complex oligosaccharides of microbial origin. Naturwissenschaften 1977, 64, 535–536. [Google Scholar] [CrossRef] [PubMed]

- Fujita, H.; Yamagami, T.; Ohshima, K. Efficacy and safety of Touchi extract, an a-glucosidase inhibitor derived from fermented soybeans, in non-insulin-dependent diabetic mellitus. J. Nutr. Biochem. 2001, 12, 351–356. [Google Scholar]

- McCue, P.; Kwon, Y.I.; Shetty, K. Anti-diabetic and antihypertensive potential of sprouted and solid-state bioprocessed soybean. Asian Pac. J. Clin. Nutr. 2005, 14, 145–152. [Google Scholar]

- Jing, L.; Zong, S.; Li, J.; Surhio, M.M.; Ye, M. Purification, structural features and inhibition activity on α-glucosidase of a novel polysaccharide from Lachnum YM406. Process Biochem. 2016, 51, 1706–1713. [Google Scholar] [CrossRef]

- Wang, S.L.; Li, H.T.; Zhang, L.J.; Lin, Z.H.; Kuo, Y.H. Conversion of squid pen to homogentisic acid via Paenibacillus sp. TKU036 and the antioxidant and anti-inflammatory activities of homogentisic acid. Mar. Drugs 2016, 14, 183. [Google Scholar] [CrossRef] [PubMed]

- Liang, T.W.; Wang, S.L. Recent advances in exopolysaccharides from Paenibacillus spp.: Production, isolation, structure, and bioactivities. Mar. Drugs 2015, 13, 1847–1863. [Google Scholar] [CrossRef] [PubMed]

- Liang, T.W.; Tseng, S.C.; Wang, S.L. Production and characterization of antioxidant properties of exopolysaccharides from Paenibacillus mucilaginosus TKU032. Mar. Drugs 2016, 14, 40. [Google Scholar] [CrossRef] [PubMed]

- Liang, T.W.; Wu, C.C.; Cheng, W.T.; Chen, Y.C.; Wang, C.L.; Wang, I.L.; Wang, S.L. Exopolysaccharides and antimicrobial biosurfactants produced by Paenibacillus macerans TKU029. Appl. Biochem. Biotechnol. 2014, 172, 933–950. [Google Scholar] [CrossRef] [PubMed]

- Sermsathanaswadi, J.; Baramee, S.; Tachaapaikoon, C.; Pason, P.; Ratanakhanokchai, K.; Kosugi, A. The family 22 carbohydrate-binding module of bifunctional xylanase/β-glucanase Xyn10E from Paenibacillus curdlanolyticus B-6 has an important role in lignocellulose degradation. Enzym. Microb. Technol. 2017, 96, 75–84. [Google Scholar] [CrossRef] [PubMed]

- Shi, R.; Liu, Y.; Mu, Q.; Jiang, Z.; Yang, S. Biochemical characterization of a novel l-asparaginase from Paenibacillus barengoltzii being suitable for acrylamide reduction in potato chips and mooncakes. Int. J. Biol. Macromol. 2017, 96, 93–99. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Fu, X.; Yan, Q.; Guo, Y.; Liu, Z.; Jiang, Z. Cloning, expression, purification and application of a novel chitinase from a thermophilic marine bacterium Paenibacillus barengoltzii. Food Chem. 2016, 192, 1041–1048. [Google Scholar] [CrossRef] [PubMed]

- Seo, D.J.; Lee, Y.S.; Kim, K.Y.; Jung, W.J. Antifungal activity of chitinase obtained from Paenibacillus ehimensis MA2012 against conidial of Collectotrichum gloeosporioides in vitro. Microb. Pathogenes. 2016, 96, 10–14. [Google Scholar] [CrossRef] [PubMed]

- Hong, C.E.; Kwon, S.Y.; Park, J.M. Biocontrol activity of Paenibacillus polymyxa AC-1 against Pseudomonas syringae and its interaction with Arabidopsis thaliana. Microbiol. Res. 2016, 185, 13–21. [Google Scholar] [CrossRef] [PubMed]

- Lal, S.; Tabacchioni, S. Ecology and biotechnological potential of Paenibacillus polymyxa: A minirevie. Indian J. Microbiol. 2009, 49, 2–10. [Google Scholar] [CrossRef] [PubMed]

- Puri, A.; Padda, K.P.; Chanway, C.P. Evidence of nitrogen fixation and growth promotion in canola (Brassica napus L.) by an endophytic diazotroph Paenibacillus polymyxa P2b-2R. Biol. Fertil. Soils 2016, 52, 119–125. [Google Scholar] [CrossRef]

- Zhu, Y.P.; Yin, L.J.; Cheng, Y.Q.; Yamaki, K.; Mori, Y.; Su, Y.C.; Li, L.T. Effects of sources of carbon and nitrogen on production of α-glucosidase inhibitor by a newly isolated strain of Bacillus subtilis B2. Food Chem. 2008, 109, 737–742. [Google Scholar] [CrossRef]

- Nguyen, V.B.; Nguyen, Q.V.; Nguyen, A.D.; Wang, S.L. Screening and evaluation of α-glucosidase inhibitors from indigenous medicinal plants in Dak Lak Province, Vietnam. Res. Chem. Intermed. 2015. [Google Scholar] [CrossRef]

- Zhang, L.; Hogan, S.; Li, J.; Sun, S.; Canning, C.; Zheng, S.J.; Zhou, K. Grape skin extract inhibits mammalian intestinal α-glucosidase activity and suppresses postprandial glycemic response in streptozocin-treated mice. Food Chem. 2011, 126, 466–471. [Google Scholar] [CrossRef]

- Trinh, B.T.D.; Staerk, D.; Jäger, A.K. Screening for potential α-glucosidase and α-amylase inhibitory constituents from selected Vietnamese plants used to treat type 2 diabetes. J. Ethnopharmacol. 2016, 186, 189–195. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.B.; Nguyen, Q.V.; Nguyen, A.D.; Wang, S.L. Porcine pancreatic α-amylase inhibitors from Euonymus laxiflorus Champ. Res. Chem. Intermed. 2017, 43, 259–269. [Google Scholar] [CrossRef]

- Kwon, Y.I.; Jang, H.D.; Shetty, K. Evaluation of Rhodiola crenulata and Rhodiola rosea for management of type II diabetes and hypertension. Asia Pac. J. Clin. Nutr. 2006, 15, 425–432. [Google Scholar] [PubMed]

- Kim, Y.; Wang, M.; Rhee, H. A novel α-glucosidase inhibitor from pine bark. J. Carbohydr. Res. 2004, 339, 715–717. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Yin, Y.; Zhao, W.; Yu, Y.; Liu, B.; Liu, J.; Chen, F. Novel peptides derived from egg white protein inhibiting α-glucosidase. Food Chem. 2011, 129, 1376–1382. [Google Scholar] [CrossRef]

- Liang, T.W.; Chen, W.T.; Lin, Z.H.; Kuo, Y.H.; Nguyen, A.D.; Pan, P.S.; Wang, S.L. An amphiprotic novel chitosanase from Bacillus mycoides and its application in the production of chitooligomers with their antioxidant and anti-inflammatory evaluation. Int. J. Mol. Sci. 2016, 17, 1302. [Google Scholar] [CrossRef] [PubMed]

- Arai, I.; Amagaya, S.; Komatsu, Y.; Okada, M.; Hayashi, T.; Kasai, M.; Arisawa, M.; Momose, Y. Improving effects of the extracts from Eugenia uniflora on hyperglycemia and hypertriglyceridemia in mice. J. Ethnopharmacol. 1999, 68, 307–314. [Google Scholar] [CrossRef]

| Compared Factors | Before Optimization | After Optimization |

|---|---|---|

| C/N source | SPP | NB |

| Cultivation temperature (°C) | 37 | 30 |

| C/N Concentration (%) | 1 | 0.8–1.2 |

| Medium/flask volume ratio | 2/5 | 2/5 |

| Seed culture (%) | 1 | 1 |

| Inhibition (IC50 μg/mL) | 3900 ± 120 | 81 ± 4.3 |

| aGIs Productivity (U/mL) | 220 | 5000 |

| Enzyme | n | Inhibition of FNB | Inhibition of Acarbose | ||

|---|---|---|---|---|---|

| IC50 (µg/mL) | Maximum Inhibitory Activity (%) | IC50 (µg/mL) | Maximum Inhibitory Activity (%) | ||

| S. cerevisiae α-glucosidase | 3 | 81 ± 4.3 c,d | 92 ± 3.2 | 1395 ± 5 a | 63 ± 2.5 |

| Rat α-glucosidase | 3 | 101 ± 5.1 c | 95 ± 2.1 | 107 ± 2.5 c | 89 ± 2.4 |

| B. stearothermophilus α-glucosidase | 3 | 36.7 ± 1.7 c,d | 98.2 ± 1.3 | 0.012 ± 0.001 d | 100 ± 1.2 |

| Rice α-glucosidase | 3 | 508 ± 17 b | 94 ± 2.3 | 2.92 ± 0.67 d | 100 ± 1.4 |

| Porcine pancreatic α-amylase | 3 | - | - | ND | ND |

| B. subtilis α-amylase | 3 | - | - | ND | ND |

| Papain protease | 3 | - | - | ND | ND |

| Bromelain protease | 3 | - | - | ND | ND |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, V.B.; Nguyen, A.D.; Kuo, Y.-H.; Wang, S.-L. Biosynthesis of α-Glucosidase Inhibitors by a Newly Isolated Bacterium, Paenibacillus sp. TKU042 and Its Effect on Reducing Plasma Glucose in a Mouse Model. Int. J. Mol. Sci. 2017, 18, 700. https://doi.org/10.3390/ijms18040700

Nguyen VB, Nguyen AD, Kuo Y-H, Wang S-L. Biosynthesis of α-Glucosidase Inhibitors by a Newly Isolated Bacterium, Paenibacillus sp. TKU042 and Its Effect on Reducing Plasma Glucose in a Mouse Model. International Journal of Molecular Sciences. 2017; 18(4):700. https://doi.org/10.3390/ijms18040700

Chicago/Turabian StyleNguyen, Van Bon, Anh Dzung Nguyen, Yao-Haur Kuo, and San-Lang Wang. 2017. "Biosynthesis of α-Glucosidase Inhibitors by a Newly Isolated Bacterium, Paenibacillus sp. TKU042 and Its Effect on Reducing Plasma Glucose in a Mouse Model" International Journal of Molecular Sciences 18, no. 4: 700. https://doi.org/10.3390/ijms18040700