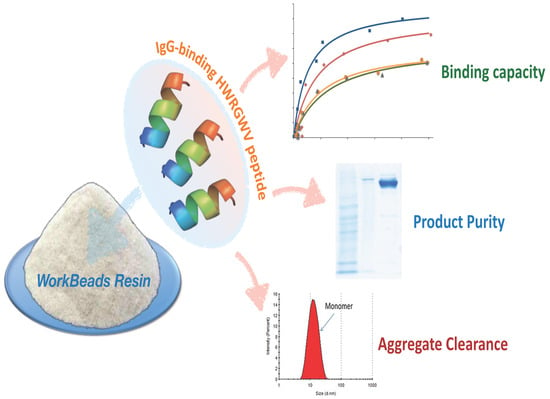

Optimization of Sequence, Display, and Mode of Operation of IgG-Binding Peptide Ligands to Develop Robust, High-Capacity Affinity Adsorbents That Afford High IgG Product Quality

Abstract

:1. Introduction

2. Results and Discussion

2.1. Resin Fabrication

2.2. Effect of Spacer Arms

2.2.1. Effect of Spacer Arm and Ligand Density on Dynamic Binding Capacity (DBC)

2.2.2. Effect of Spacer Arm on the Purity of Eluted IgG

2.3. Optimization of Process Conditions

2.4. Studies on Ligand Variants

2.4.1. Adsorption Isotherm

2.4.2. Purification of Mab Using Ligand Variants Constructed with Non-Natural Amino Acids

2.5. Removal of Aggregates

3. Materials and Methods

3.1. Materials

3.2. Peptide Coupling onto the WorkBeads 40 ACT Resins

3.3. Adsorption Isotherm Measurements

3.4. Determination of Dynamic Binding Capacity

3.5. Purification of IgG1 from CHO Cell Culture Supernatants

3.6. Determination of DNA Content

3.7. Determination of Host Cell Protein (HCP) Content

3.8. Aggregate Removal

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CHO | Chinese hamster ovary |

| DADPA | diaminodipropyl amine |

| DCM | dichloromethane |

| DIPEA | diisopropylethylamine |

| DMF | N,N-dimethylformamide |

| EDA | ethylene diamine |

| EDC | 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide |

| EDT | ethandithiol |

| Fmoc | fluorenylmethyloxycarbonyl |

| HMDA | hexamethylene diamine |

| IAA | iodoacetic acid |

| IgG | Immunoglobulin G |

| PBS | phosphate buffer saline |

| SDS-PAGE | sodium dodecyl sulfate polyacrylamide gel electrophoresis |

| TEA | triethylamine |

| TREN | tris(2-aminoethyl)amine |

| WB | WorkBeads 40 ACT resin |

References

- Grilo, A.L.; Mantalaris, A. The increasingly human and profitable monoclonal antibody market. Trends Biotechnol. 2019, 37, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Guan, D.; Chen, Z. Challenges and recent advances in affinity purification of tag-free proteins. Biotechnol. Lett. 2014, 36, 1391–1406. [Google Scholar] [CrossRef] [PubMed]

- Harrison, R.G.; Todd, P.W.; Rudge, S.R.; Petrides, D.P. Bioseparations Science and Engineering; Oxford University Press: Oxford, UK, 2015. [Google Scholar]

- Gagnon, P. Technology trends in antibody purification. J. Chromatogr. A 2012, 1221, 57–70. [Google Scholar] [CrossRef] [PubMed]

- Islam, T.; Aguilar-Yañez, J.M.; Simental-Martínez, J.; Ortiz-Alcaraz, C.I.; Rito-Palomares, M.; Fernandez-Lahore, M. A novel strategy for the purification of a recombinant protein using ceramic fluorapatite-binding peptides as affinity tags. J. Chromatogr. A 2014, 1339, 26–33. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rosa, P.A.; Azevedo, A.M.; Sommerfeld, S.; Mutter, M.; Bäcker, W.; Aires-Barros, M.R. Continuous purification of antibodies from cell culture supernatant with aqueous two-phase systems: From concept to process. Biotechnol. J. 2013, 8, 352–362. [Google Scholar] [CrossRef] [Green Version]

- Jungbauer, A.; Hahn, R. Ion-exchange chromatography. Methods Enzymol. 2009, 463, 349–371. [Google Scholar] [PubMed]

- Cummins, P.M.; O’Connor, B.F. Hydrophobic interaction chromatography. Protein Chromatogr. Methods Protoc. 2011, 87, 431–437. [Google Scholar]

- Hagel, L.; Haneskog, L. Size-Exclusion Chromatography; eLS: Princeton, NJ, USA, 2010. [Google Scholar]

- Coelho, L.C.; Santos, A.F.; Napoleão, T.H.; Correia, M.T.; Paiva, P.M. Protein Purification by Affinity Chromatography; Intech Open: London, UK, 2012. [Google Scholar]

- Arora, S.; Ayyar, B.V.; O’Kennedy, R. Affinity Chromatography for Antibody Purification. In Protein Downstream Processing; Labrou, N.E., Ed.; Humana Press: New York, NY, USA, 2014; pp. 497–516. [Google Scholar]

- Carter-Franklin, J.N.; Victa, C.; McDonald, P.; Fahrner, R. Fragments of protein A eluted during protein A affinity chromatography. J. Chromatogr. A 2007, 1163, 105–111. [Google Scholar] [CrossRef]

- Sadavarte, R.; Spearman, M.; Okun, N.; Butler, M.; Ghosh, R. Purification of chimeric heavy chain monoclonal antibody EG2-hFc using hydrophobic interaction membrane chromatography: An alternative to protein-A affinity chromatography. Biotechnol. Bioeng. 2014, 111, 1139–1149. [Google Scholar] [CrossRef]

- Naik, A.D.; Raina, M.; Lali, A.M. AbSep—An amino acid based pseudobioaffinity adsorbent for the purification of immunoglobulin G. J. Chromatogr. A 2011, 1218, 1756–1766. [Google Scholar] [CrossRef]

- Islam, T.; Fernández-Lahore, M. A modular approach to multifunctional polypeptide/ceramic fluorapatite-based self-assembled system in affinity chromatography for the purification of human Immunoglobulin G. J. Mol. Recognit. 2015. [Google Scholar] [CrossRef]

- Roque, A.C.A.; Lowe, C.R.; Taipa, M.Â. Antibodies and genetically engineered related molecules: Production and purification. Biotechnol. Prog. 2004, 20, 639–654. [Google Scholar] [CrossRef] [PubMed]

- Menegatti, S.; Naik, A.D.; Gurgel, P.V.; Carbonell, R.G. Purification of polyclonal antibodies from Cohn fraction II + III, skim milk, and whey by affinity chromatography using a hexamer peptide ligand. J. Sep. Sci. 2012, 35, 3139–3148. [Google Scholar] [CrossRef]

- Islam, T.; Bibi, N.S.; Vennapusa, R.R.; Fernandez-Lahore, M. Selection of ceramic fluorapatite-binding peptides from phage display combinatorial peptide library: Optimum affinity tags for fluorapatite chromatography. J. Mol. Recognit. 2013. [Google Scholar] [CrossRef] [PubMed]

- Camperi, S.A.; Martínez-Ceron, M.C.; Giudicessi, S.L.; Marani, M.M.; Albericio, F.; Cascone, O. Peptide affinity chromatography based on combinatorial strategies for protein purification. In Protein Downstream Processing; Springer: Berlin, Germany, 2014; pp. 277–302. [Google Scholar]

- Liu, Z.; Gurgel, P.V.; Carbonell, R.G. Purification of human immunoglobulins A, G and M from Cohn fraction II/III by small peptide affinity chromatography. J. Chromatogr. A 2012, 1262, 169–179. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Gurgel, P.V.; Williams, D.K.; Bobay, B.G.; Cavanagh, J.; Muddiman, D.C.; Carbonell, R.G. Binding site on human immunoglobulin G for the affinity ligand HWRGWV. J. Mol. Recognit. 2010, 23, 271–282. [Google Scholar] [CrossRef] [PubMed]

- Menegatti, S.; Hussain, M.; Naik, A.D.; Carbonell, R.G.; Rao, B.M. mRNA display selection and solid-phase synthesis of Fc-binding cyclic peptide affinity ligands. Biotechnol. Bioeng. 2013, 110, 857–870. [Google Scholar] [CrossRef] [PubMed]

- Fassina, G.; Ruvo, M.; Palombo, G.; Verdoliva, A.; Marino, M. Novel ligands for the affinity-chromatographic purification of antibodies. J. Biochem. Biophys. Methods 2001, 49, 481–490. [Google Scholar] [CrossRef]

- Lund, L.N.; Gustavsson, P.-E.; Michael, R.; Lindgren, J.; Nørskov-Lauritsen, L.; Lund, M.; Houen, G.; Staby, A.; Hilaire, P.M.S. Novel peptide ligand with high binding capacity for antibody purification. J. Chromatogr. A 2012, 1225, 158–167. [Google Scholar] [CrossRef]

- Carbonell, R.; Yang, H.; Wang, G.; Gurgel, P. Purification of Immunoglobulins Using Affinity Chromatography and Peptide Ligands. U.S. Patent 7,408,03, 5 August 2008. [Google Scholar]

- Choe, W.; Durgannavar, T.A.; Chung, S.J. Fc-Binding Ligands of Immunoglobulin G: An Overview of High Affinity Proteins and Peptides. Materials 2016, 9, 994. [Google Scholar] [CrossRef]

- Yang, H.; Gurgel, P.V.; Carbonell, R.G. Hexamer peptide affinity resins that bind the Fc region of human immunoglobulin G. J. Peptide Res. 2005, 66, 120–137. [Google Scholar] [CrossRef]

- Islam, N.; Shen, F.; Gurgel, P.V.; Rojas, O.J.; Carbonell, R.G. Dynamic and equilibrium performance of sensors based on short peptide ligands for affinity adsorption of human IgG using surface plasmon resonance. Biosens. Bioelectron. 2014, 58, 380–387. [Google Scholar] [CrossRef] [PubMed]

- Naik, A.D.; Menegatti, S.; Reese, H.R.; Gurgel, P.V.; Carbonell, R.G. Process for Purification of Monoclonal Antibody Expressed in Transgenic Lemna Plant Extract Using Dextran-Coated Charcoal and Hexamer Peptide Affinity Resin. J. Chromatogr. A 2012, 1260, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Gurgel, P.V.; Carbonell, R.G. Purification of human immunoglobulin G via Fc-specific small peptide ligand affinity chromatography. J. Chromatogr. A 2009, 1216, 910–918. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.; Thamamongood, T.; Sakamoto, S.; Handa, H.; Yamaguchi, Y. Affinity Chromatographic Materials. Encycl. Polym. Nanomater. 2015, 1–7. [Google Scholar] [CrossRef]

- Kish, W.S.; Naik, A.D.; Menegatti, S.; Carbonell, R.G. Peptide-based affinity adsorbents with high binding capacity for the purification of monoclonal antibodies. Ind. Eng. Chem. Res. 2012, 52, 8800–8811. [Google Scholar] [CrossRef]

- Busini, V.; Moiani, D.; Moscatelli, D.; Zamolo, L.; Cavallotti, C. Investigation of the influence of spacer arm on the structural evolution of affinity ligands supported on agarose. J. Phys. Chem. B 2006, 110, 23564–23577. [Google Scholar] [CrossRef] [PubMed]

- Lalli, E.; Sarti, G.C.; Boi, C. Effect of the spacer arm on non-specific binding in membrane affinity chromatography. MRS Commun. 2018, 8, 65–70. [Google Scholar] [CrossRef]

- Bai, J.S.; Bai, S.; Shi, Q.H.; Sun, Y. Purification of supercoiled plasmid DNA from clarified bacterial lysate by arginine-affinity chromatography: Effects of spacer arms and ligand density. J. Sep. Sci. 2014, 37, 1386–1395. [Google Scholar] [CrossRef]

- Heldt, C.L.; Gurgel, P.V.; Jaykus, L.A.; Carbonell, R.G. Influence of peptide ligand surface density and ethylene oxide spacer arm on the capture of porcine parvovirus. Biotechnol. Prog. 2009, 25, 1411–1418. [Google Scholar] [CrossRef] [Green Version]

- Iacob, R.E.; Bou-Assaf, G.M.; Makowski, L.; Engen, J.R.; Berkowitz, S.A.; Houde, D. Investigating monoclonal antibody aggregation using a combination of H/DX-MS and other biophysical measurements. J. Pharm. Sci. 2013, 102, 4315–4329. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Jiménez, J.; Salmerón-García, A.; Cabeza, J.; Vélez, C.; Capitán-Vallvey, L.F.; Navas, N. The Effects of Light-Accelerated Degradation on the Aggregation of Marketed Therapeutic Monoclonal Antibodies Evaluated by Size-Exclusion Chromatography with Diode Array Detection. J. Pharm. Sci. 2016, 105, 1405–1418. [Google Scholar] [CrossRef]

- Kalonia, C.; Toprani, V.; Toth, R.T.; Wahome, N.; Gabel, I.; Middaugh, C.R.; Volkin, D.B. Effects of Protein Conformation, Apparent Solubility, and Protein-Protein Interactions on the Rates and Mechanisms of Aggregation for an IgG1 Monoclonal Antibody. J. Phys. Chem. B 2016, 120, 7062–7075. [Google Scholar] [CrossRef] [PubMed]

- Ratanji, K.D.; Derrick, J.P.; Dearman, R.J.; Kimber, I. Immunogenicity of therapeutic proteins: Influence of aggregation. J. Immunotoxicol. 2014, 11, 99–109. [Google Scholar] [CrossRef] [PubMed]

- Bessa, J.; Boeckle, S.; Beck, H.; Buckel, T.; Schlicht, S.; Ebeling, M.; Kiialainen, A.; Koulov, A.; Boll, B.; Weiser, T. The immunogenicity of antibody aggregates in a novel transgenic mouse model. Pharm. Res. 2015, 32, 2344–2359. [Google Scholar] [CrossRef] [PubMed]

- Kuriakose, A.; Chirmule, N.; Nair, P. Immunogenicity of Biotherapeutics: Causes and Association with Posttranslational Modifications. J. Immunol. Res. 2016, 2016. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, M.; Bryson, C.J.; Cloake, E.A.; Welch, K.; Filipe, V.; Romeijn, S.; Hawe, A.; Jiskoot, W.; Baker, M.P.; Fogg, M.H. Small amounts of sub-visible aggregates enhance the immunogenic potential of monoclonal antibody therapeutics. Pharm. Res. 2015, 32, 1383–1394. [Google Scholar] [CrossRef]

- Freitag, A.J.; Shomali, M.; Michalakis, S.; Biel, M.; Siedler, M.; Kaymakcalan, Z.; Carpenter, J.F.; Randolph, T.W.; Winter, G.; Engert, J. Investigation of the immunogenicity of different types of aggregates of a murine monoclonal antibody in mice. Pharm. Res. 2015, 32, 430–444. [Google Scholar] [CrossRef]

- Mazzer, A.R.; Perraud, X.; Halley, J.; O’Hara, J.; Bracewell, D.G. Protein A chromatography increases monoclonal antibody aggregation rate during subsequent low pH virus inactivation hold. J. Chromatogr. A 2015, 1415, 83–90. [Google Scholar] [CrossRef] [Green Version]

- Menegatti, S.; Bobay, B.G.; Ward, K.L.; Islam, T.; Kish, W.S.; Naik, A.D.; Carbonell, R.G. Design of protease-resistant peptide ligands for the purification of antibodies from human plasma. J. Chromatogr. A 2016, 1445, 93–104. [Google Scholar] [CrossRef]

- Lefkowitz, R.B.; Marciniak, J.Y.; Hu, C.M.; Schmid-Schönbein, G.W.; Heller, M.J. An electrophoretic method for the detection of chymotrypsin and trypsin activity directly in whole blood. Electrophoresis 2010, 31, 403–410. [Google Scholar] [CrossRef] [PubMed]

- Naik, A.D.; Menegatti, S.; Gurgel, P.V.; Carbonell, R.G. Performance of hexamer peptide ligands for affinity purification of immunoglobulin G from commercial cell culture media. J. Chromatogr. A 2011, 1218, 1691–1700. [Google Scholar] [CrossRef] [PubMed]

- Levy, N.E.; Valente, K.N.; Lee, K.H.; Lenhoff, A.M. Host cell protein impurities in chromatographic polishing steps for monoclonal antibody purification. Biotechnol. Bioeng. 2016, 113, 1260–1272. [Google Scholar] [CrossRef]

- Boas, U.; Mirsharghi, S. Color test for selective detection of secondary amines on resin and in solution. Org. Lett. 2014, 16, 5918–5921. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, C.R.; Tamashiro, W.M.S.C.; Bueno, S.M.A. Evaluation of OPS-agarose pseudo-affinity adsorption IgG 2a mouse monoclonal antibody. Process Biochem. 2015, 50, 2267–2274. [Google Scholar] [CrossRef] [Green Version]

- Zamolo, L.; Salvalaglio, M.; Cavallotti, C.; Galarza, B.; Sadler, C.; Williams, S.; Hofer, S.; Horak, J.; Lindner, W. Experimental and theoretical investigation of effect of spacer arm and support matrix of synthetic affinity chromatographic materials for the purification of monoclonal antibodies. J. Phys. Chem. B 2010, 114, 9367–9380. [Google Scholar] [CrossRef] [PubMed]

- Acikara, Ö.B.; Ergene, B.; Çitoğlu, G.S.; Özbilgin, S. Affinity Chromatography and Importance in Drug Discovery; INTECH Open Access Publisher: London, UK, 2013. [Google Scholar]

- Boi, C.; Dimartino, S.; Hofer, S.; Horak, J.; Williams, S.; Sarti, G.C.; Lindner, W. Influence of different spacer arms on Mimetic Ligand™ A2P and B14 membranes for human IgG purification. J. Chromatogr. B 2011, 879, 1633–1640. [Google Scholar] [CrossRef] [PubMed]

- Savane, T.S.; Kumar, S.; Janakiraman, V.N.; Kamalanathan, A.S.; Vijayalakshmi, M.A. Molecular insight in the purification of immunoglobulin by pseudobiospecific ligand l-histidine and histidyl moieties in histidine ligand affinity chromatography (HLAC) by molecular docking. J. Chromatogr. B 2016, 1021, 129–136. [Google Scholar] [CrossRef]

- Dias, A.M.; dos Santos, R.; Iranzo, O.; Roque, A.C. Affinity adsorbents for proline-rich peptide sequences: A new role for WW domains. RSC Adv. 2016, 6, 68979–68988. [Google Scholar] [CrossRef]

- Liese, S.; Netz, R.R. Influence of length and flexibility of spacers on the binding affinity of divalent ligands. Beilstein J. Org. Chem. 2015, 11, 804–816. [Google Scholar] [CrossRef] [Green Version]

- Hogwood, C.E.; Bracewell, D.G.; Smales, C.M. Measurement and control of host cell proteins (HCPs) in CHO cell bioprocesses. Curr. Opin. Biotechnol. 2014, 30, 153–160. [Google Scholar] [CrossRef] [PubMed]

- Hahn, R.; Schlegel, R.; Jungbauer, A. Comparison of protein A affinity sorbents. J. Chromatogr. B 2003, 790, 35–51. [Google Scholar] [CrossRef]

- Kang, H.J.; Choe, W.; Min, J.-K.; Lee, Y.-m.; Kim, B.M.; Chung, S.J. Cyclic peptide ligand with high binding capacity for affinity purification of immunoglobulin G. J. Chromatogr. A 2016, 1466, 105–112. [Google Scholar] [CrossRef] [PubMed]

- Tong, H.F.; Lin, D.Q.; Chu, W.N.; Zhang, Q.L.; Gao, D.; Wang, R.Z.; Yao, S.J. Multimodal charge-induction chromatography for antibody purification. J. Chromatogr. A 2016, 1429, 258–264. [Google Scholar] [CrossRef] [PubMed]

- Rosenberg, A.S. Effects of protein aggregates: An immunologic perspective. AAPS J. 2006, 8, E501–E507. [Google Scholar] [CrossRef] [PubMed]

- Carpenter, J.F.; Randolph, T.W.; Jiskoot, W.; Crommelin, D.J.; Middaugh, C.R.; Winter, G.; Fan, Y.X.; Kirshner, S.; Verthelyi, D.; Kozlowski, S. Overlooking subvisible particles in therapeutic protein products: Gaps that may compromise product quality. J. Pharm. Sci. 2009, 98, 1201–1205. [Google Scholar] [CrossRef] [PubMed]

- Cromwell, M.E.; Hilario, E.; Jacobson, F. Protein aggregation and bioprocessing. AAPS J. 2006, 8, E572–E579. [Google Scholar] [CrossRef]

- Yu, D.; Song, Y.; Huang, R.Y.-C.; Swanson, R.K.; Tan, Z.; Schutsky, E.; Lewandowski, A.; Chen, G.; Li, Z.J. Molecular perspective of antibody aggregates and their adsorption on Protein A resin. J. Chromatogr. A 2016, 1457, 66–75. [Google Scholar] [CrossRef]

- Fekete, S.; Beck, A.; Veuthey, J.-L.; Guillarme, D. Theory and practice of size exclusion chromatography for the analysis of protein aggregates. J. Pharm. Biomed. Anal. 2014, 101, 161–173. [Google Scholar] [CrossRef]

- Vázquez-Rey, M.; Lang, D.A. Aggregates in monoclonal antibody manufacturing processes. Biotechnol. Bioeng. 2011, 108, 1494–1508. [Google Scholar] [CrossRef]

- Chollangi, S.; Parker, R.; Singh, N.; Li, Y.; Borys, M.; Li, Z. Development of robust antibody purification by optimizing protein-A chromatography in combination with precipitation methodologies. Biotechnol. Bioeng. 2015, 112, 2292–2304. [Google Scholar] [CrossRef] [PubMed]

| (A) | (B) | |||

|---|---|---|---|---|

| Spacer | Ligand Density (μmol/mL Adsorbent) | DBC (mg·IgG/mL Adsorbent) | Ligand Density on TREN-WB (μmol/mL Adsorbent) | DBC (mg·IgG/mL Adsorbent) |

| TREN | 72 | 65 | 22 | 61 |

| DADPA | 63 | 54 | 37 | 64 |

| mDADPA | 32 | 38 | 53 | 64 |

| HMDA | 57 | 51 | 72 | 65 |

| EDA | 70 | 42 | - | - |

| Spacer | Yield (%) | HCP LRV | DNA LRV |

|---|---|---|---|

| TREN | 97 | 1.04 | 4 |

| DADPA | 96 | 1.16 | 4 |

| HDMA | 98 | 0.97 | 4 |

| EDA | 94 | 1.12 | 4 |

| mDADPA | 93 | 1.34 | 4 |

| Ligand | Qmax (mg·IgG/mL Adsorbent) | KD (µM) |

|---|---|---|

| HWRGWV | 85 | 1.04 |

| Ac-HWRGWV | 72 | 1.16 |

| HWCitGWV | 49 | 0.97 |

| Ac-HWCitGWV | 50 | 1.12 |

| Protein A [59] (MabSelect SuRe) | 77 | - |

| Ligand | Washing Buffer | HCP LRV | DNA LRV |

|---|---|---|---|

| HWRGWV | PBS, pH 7.4 | 1.04 | ~4 |

| HWCitGWV | PBS, pH 7.4 | 1.58 | ~4 |

| Ac-HWRGWV | PBS, pH 7.4 | 1.38 | ~4 |

| Ac-HWCitGWV | PBS, pH 7.4 | 1.76 | ~4 |

| Ac-HWCitGWV | 1 M NaCl in PBS, pH 7.4 | 2.15 | ~4 |

| Ac-HWCitGWV | 0.1 M Tris HCl, pH 9 | 2.07 | ~4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Islam, T.; Naik, A.D.; Hashimoto, Y.; Menegatti, S.; Carbonell, R.G. Optimization of Sequence, Display, and Mode of Operation of IgG-Binding Peptide Ligands to Develop Robust, High-Capacity Affinity Adsorbents That Afford High IgG Product Quality. Int. J. Mol. Sci. 2019, 20, 161. https://doi.org/10.3390/ijms20010161

Islam T, Naik AD, Hashimoto Y, Menegatti S, Carbonell RG. Optimization of Sequence, Display, and Mode of Operation of IgG-Binding Peptide Ligands to Develop Robust, High-Capacity Affinity Adsorbents That Afford High IgG Product Quality. International Journal of Molecular Sciences. 2019; 20(1):161. https://doi.org/10.3390/ijms20010161

Chicago/Turabian StyleIslam, Tuhidul, Amith D. Naik, Yasuhiro Hashimoto, Stefano Menegatti, and Ruben G. Carbonell. 2019. "Optimization of Sequence, Display, and Mode of Operation of IgG-Binding Peptide Ligands to Develop Robust, High-Capacity Affinity Adsorbents That Afford High IgG Product Quality" International Journal of Molecular Sciences 20, no. 1: 161. https://doi.org/10.3390/ijms20010161