Biodegradable Polymers and Polymer Composites with Antibacterial Properties

Abstract

:1. Introduction

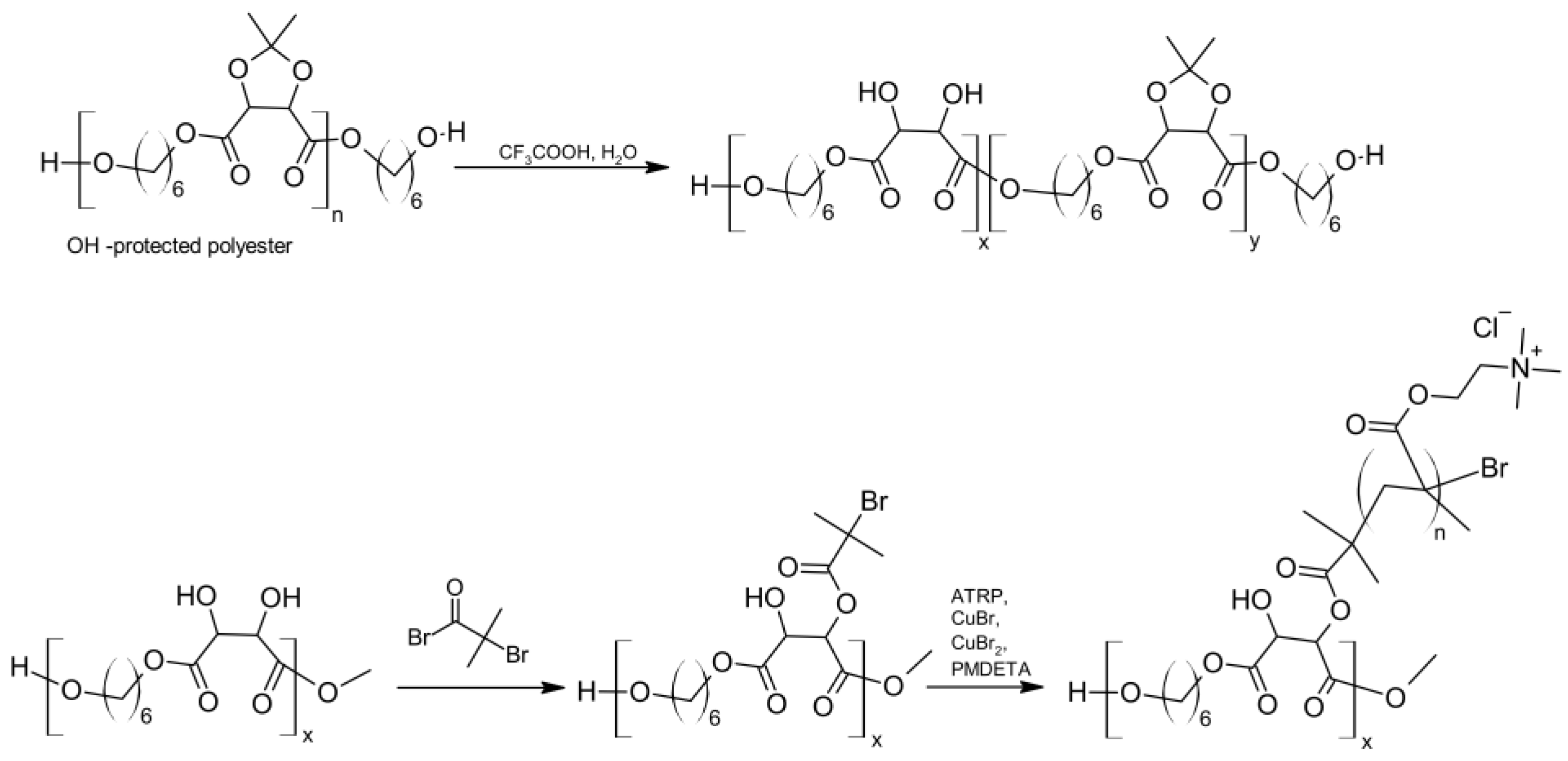

2. Mechanisms of Antibacterial Action Used in the Development of Polymers and Polymer Composites with Antibacterial Properties

3. Natural Polymers with Antibacterial and Bacteriostatic Properties

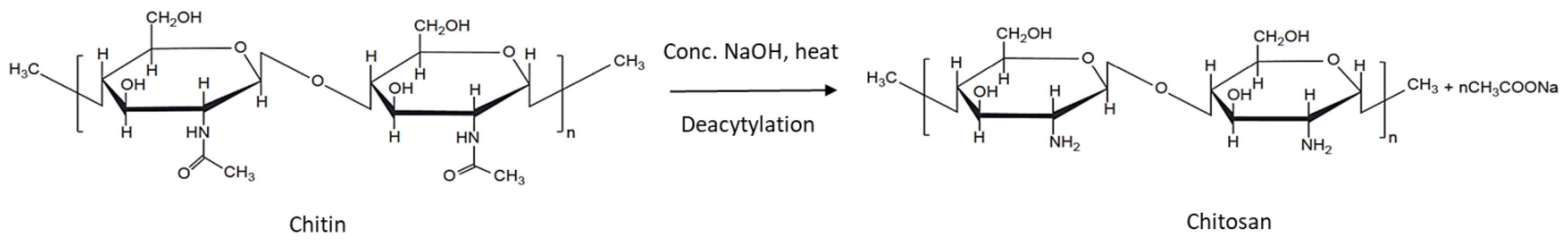

3.1. Chitosan

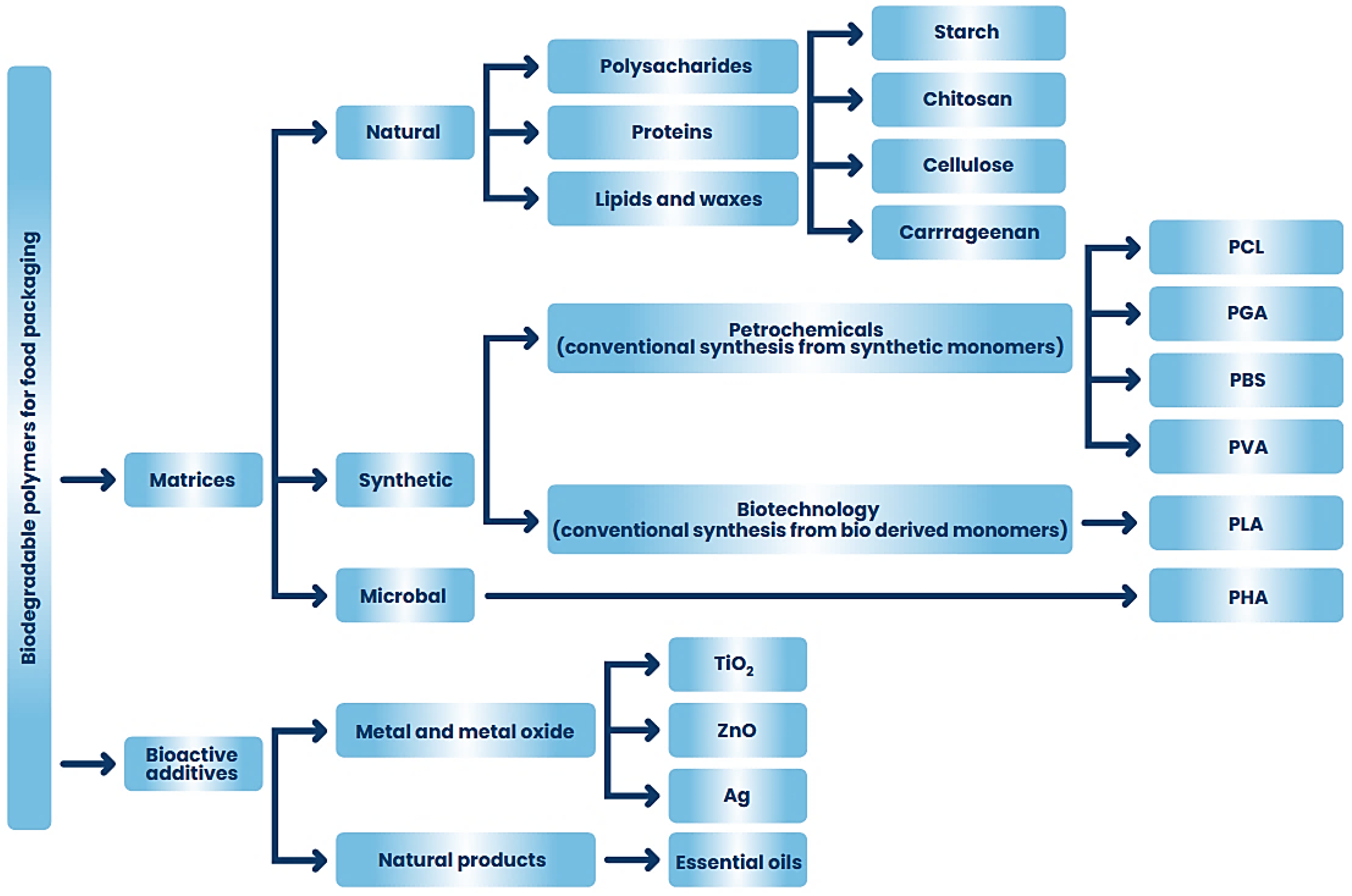

3.1.1. Factors Influencing the Antimicrobial Activity of Chitosan

3.1.2. Sources and Concentration of Chitosan

3.1.3. Structural Properties—Molecular Weight and Degree of Deacetylation

3.1.4. Effect of pH

3.1.5. Antibacterial Activity of Chitosan and Its Derivatives

- (a)

- HMw chitosan forms a dense polymeric membrane on the surface of the cell, which blocks the exchange of nutrients, leading to metabolic disorders and, consequently, to the death of microbial cells. The deposition of chitosan on the cell surface can be confirmed by SEM observation. This study was conducted by Helander et al. (2001), who observed a thicker appearance of the cell walls of chitosan-treated E. coli and Salmonella typhimurium.

- (b)

- The presence of cationic charges in chitosan is a key requirement for displaying antimicrobial activity. The cationic groups in chitosan are attracted by electrostatic interactions with negatively charged components present on the surface of the bacteria. Quaternary ammonium groups (R-NH3+) in an acidic environment (pH < 6) compete with divalent metal ions such as Ca2+ and Mg2+ present in the bacterial cell wall for bonding to polyanions, leading to an imbalance of surface potential and mutual repulsion of negatively charged particles, and finally rupture of the cell membrane.

- (c)

- As a result of electrostatic interactions between chitosan and the anionic surface of Gram-positive and Gram-negative bacteria, the cell membrane is disrupted. In Gram-positive bacteria, positively charged chitosan can electrostatically interact with negatively charged teichoic acid in peptidoglycan, destroying the cell membrane and resulting in leakage of intracellular components and simultaneous entry of chitosan into the microbial cells. In Gram-negative bacteria, the high negative charge from LPS can be neutralized by the positive charges from chitosan. As a result of this phenomenon, the OM is torn apart, and the chitosan is absorbed into the cell, resulting in the death of the bacterial cell. Several studies have indicated that chitosan can also bind to the phosphorylated mannosyl side in fungi, leading to disruption of the plasma membrane and leakage of intracellular materials.

- (d)

- LMw chitosan and its hydrolysis products can perforate the microbial cell and interact with DNA. By binding to DNA, chitosan prevents DNA transcription and interrupts the synthesis of proteins and mRNA. Studies by Fei Liu et al. (2001) used a confocal laser scanning microscope to determine the antibacterial activity of chitosan oligomers in E. coli cells. Studies have shown the presence of chitosan oligomers within microbial cells, confirming that the likely cause of the antibacterial effect was the prevention of DNA transcription. Xing et al. (2009) analyzed the effect of the concentration of oleyl chitosan (a derivative of the fatty acid chitosan) nanoparticles (OCNP) on changes in the bacterial genome. Studies have shown that negatively charged phosphate groups in DNA/RNA can react with positively charged amino groups in OCNP, thus inhibiting the activity of microorganisms. In their research, Márquez et al. (2013) analyzed the chemical-genetic interactions of low-molecular-weight chitosan with genes from S. cerevisiae. The disruption of protein synthesis by chitosan was supported by an in vivo β-galactosidase expression assay of -galactosidase, suggesting that this is a primary mode of antifungal action. Furthermore, indicated that chitosan has a minor membrane disruption effect [17,18,94,95,97,98,99].

3.2. Chitosan Derivatives

3.2.1. Chitosan Containing Quaternary Ammonium Groups

3.2.2. Carboxymethyl Chitosan

3.2.3. Sulfonated Chitosan

3.2.4. Phosphorylated Chitosan

3.2.5. Chitosan Containing Alkyl and Aromatic Groups

3.2.6. Chitosan Hydrogels

3.2.7. Chitosan-Metal Composites

3.2.8. Chitosan-Metal Oxide Composites

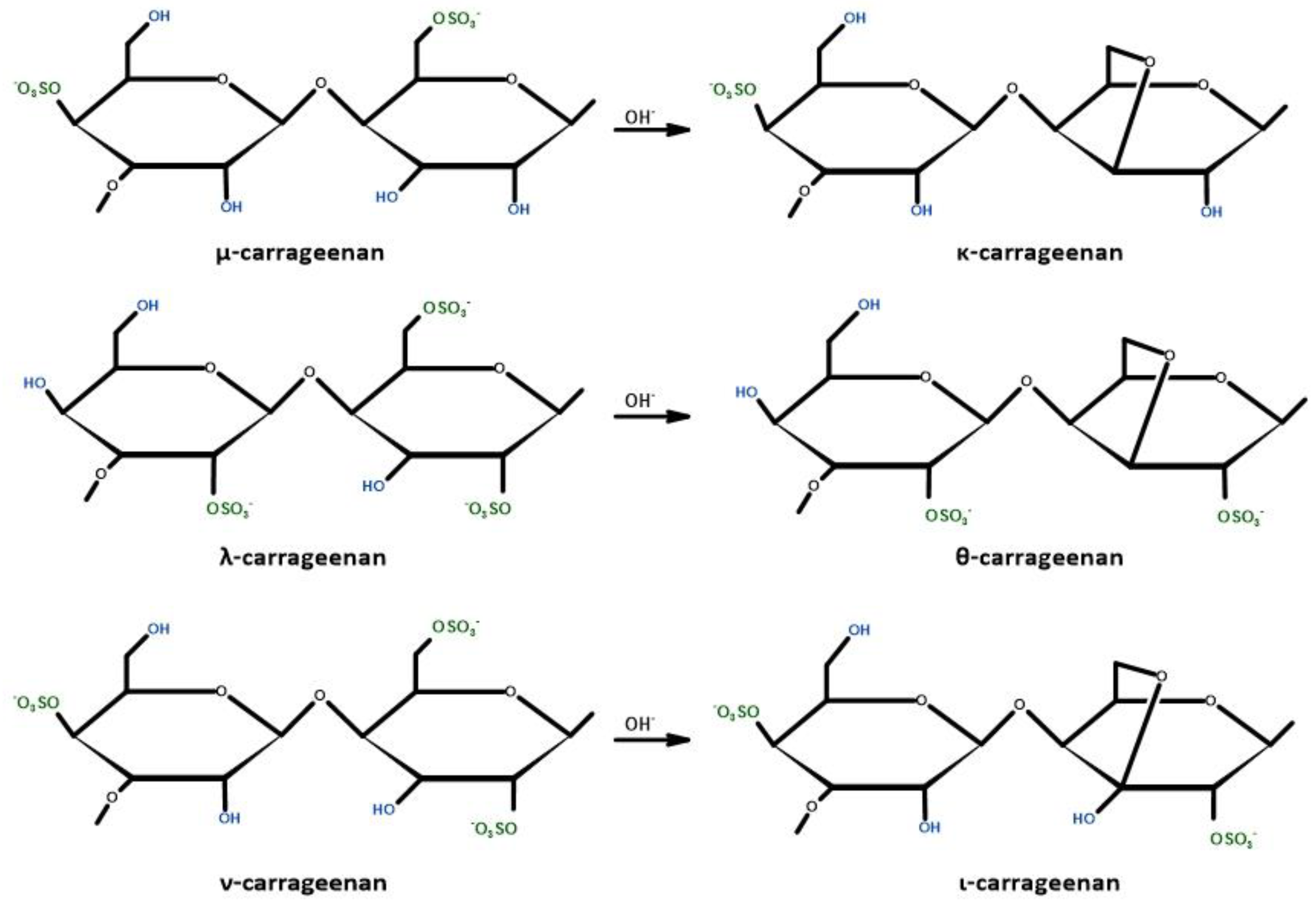

3.3. Carrageenan

3.3.1. Carrageenan Nanocomposites

3.3.2. Carrageenan Hydrogels

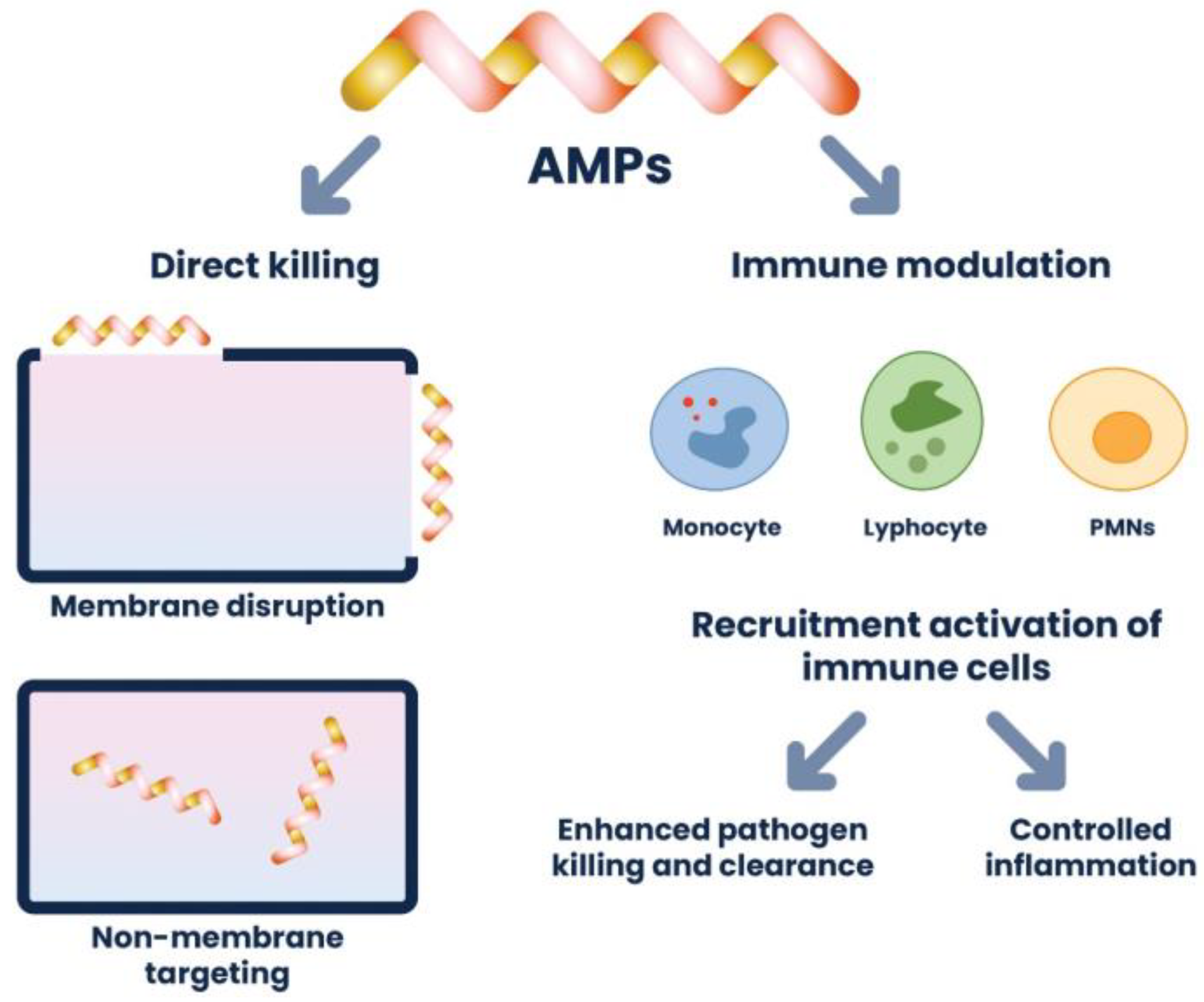

3.4. Antimicrobial Peptides (AMPs)

3.4.1. α-Helical AMPs

3.4.2. Cysteine-Rich AMPs

3.4.3. β-Sheet AMPs

3.4.4. AMPs Rich in Regular Amino Acids

3.4.5. AMPs with Rare Modified Amino Acids

3.4.6. Mechanism of Antimicrobial Peptide Action

| Peptide | Source | Active Agent | Mode of Action | References |

|---|---|---|---|---|

| α-Helical AMPs | ||||

| Cecropins | insects (e.g., Hyalophora cecropia, Musca domestica, bacteria (Helicobacter pylori), tunicates, ascarid nematodes, mammals (Ascaris suum) | strong antimicrobial activity against G+ and G− bacteria | Membrane permeabilization; Carpet model | [233,234,235] |

| Magainins | Xenopus laevis | active against G+ and G− bacteria, MIC for E. coli, S. aureus, C. albicans, P. aeruginosa and Trichomonas vaginalis is in the range of 200–300 μg/106 cfu/mL, strong activity against drug-resistant A. baumannii | Membrane permeabilization; Toroidal pore model | [185,191,236,237] |

| Dermaseptins | skin secretions of frogs (Phyllomedusa sauvagii, Phyllomedusa oreades, Phyllomedusa hypochondrialis) | active against G+ and G− bacteria, inhibition of C. albicans biofilm formation at 50 μg mL−1, MIC against E. coli 16 μM, P. aeruginosa 64 μM, S. aureus 32 μM | Membrane permeabilization; Carpet model | [238,239,240] |

| Bombinins | skin secretion of frogs (e.g., Bombina variegata, Bombina orientalis, Bombina maxima) | active against G+ (Bacillus megaterium, S. aureus) and G− (E. coli, Yersinia pseudotuberculosis, Pseudomonas aeruginosa), against Candida albicans; no appreciable hemolytic capacity | Formation of ion channels or pores | [241,242,243,244] |

| Aurein | granular dorsal glands of the Australian frog (Litoria aurea, L. raniformis) | more activity against G+ than G−, MIC for S. aureus for aurein 1.2 = 25 μg/mL, for aurein M.3 = 3.12 μg/mL, MIC for E. coli for aurein 1.2 = 200 μg/mL, for aurein M.3 = 6.25 μg/mL | Membrane permeabilization; aurein 2.2 barrel-stave model, aurein 1.2 carpet model | [186,196,245,246] |

| LL-37 | variety of cells (neutrophils, leukocytes and epithelial cells, Myelocytes, metamyelocytes), tissues, body fluids, and professional phagocytes | strong active against G+ and G− bacteria e.g., against L. monocytogenes MIC = 1.5 μgmL−1, S. aureus MIC = 3.6 μgmL−1, Bacillus subtilis MIC = 2.7 μgmL−1, E. coli MIC = 0.1 μgmL−1, Salmonella typhimurium MIC = 0.4 μgmL−1 | Membrane permeabilization; barrel-stave model and carpet model; Immune modulation | [188,200,247,248,249] |

| Cysteine rich AMPs | ||||

| α-defensins (HNP1—HNP4) | neutrophils, late promyelocytes, bone marrow, some surface epithelial cells, intestinal epithelial cells, female reproductive tract | active against G+ and G− bacteria, e.g., against L. monocytogenes MIC = 39.7 μgmL−1, S. aureus MIC = 2.2 μgmL−1, Bacillus subtilis MIC = 6.4 μgmL−1, E. coli MIC = 1.8 μgmL−1, Salmonella typhimurium MIC = 0.4 μgmL−1 | Mainly membrane permeabilization and disrupt bacterial membranes | [188,200,250] |

| β-defensins (HβD-1—HβD-4) | human (skin, respiratory tract, gastrointestinal tracts, human genomic sequences) | HβD-1—HβD-3 showed antibacterial activities against E. coli and S. aureus in a dose-dependent manner, HβD-3 showed a broad spectrum of antimicrobial activities against S. aureus, E. faecium, P. aeruginosa, K. pneumonia, S. pneumoniae, B. cepacia. HβD-4 showed antibacterial activity against on F.nucleatum, P. gingivalis, P. aeruginosa, E. faecalis | Immune modulation | [247,251,252,253,254] |

| θ-defensins | neutrophils and monocytes of the rhesus monkey | antimicrobial activities against Staphylococcus aureus, Candida albicans, Cryptococcus neoformans, E. coli | Membrane permeabilization | [203,204,255] |

| Gomesin | hemocytes of the spider Acanthoscurria gomesiana | antimicrobial activities against E. coli, P. aeruginosa, S. aureus, K. pneumoniae, B. megaterium | Membrane permeabilization; carpet/detergent mechanisms | [205,256,257] |

| Peneidines | shrimp (Penaeus vannamei, Litopenaeus vannamei) | better antimicrobial activity against G− than G+ bacteria | Binding to superficial membrane and DNA, thereby destroying the bacterial structure and/or interfering with the bacterial proliferation | [258,259] |

| Lysozyme | Insects, plants, chicken egg white, body fluids, and tissues in living organisms | most effective against G+ bacteria | Hydrolysis in microbial cell walls, which results in the rupture of the β(1,4) linkages in their peptidoglycan | [260,261,262] |

| β-sheet AMPs | ||||

| Tachyplesins | hemocytes of horseshoe crabs (Tachypleus tridentatus) | antimicrobial activity against G+ bacteria (MIC = 0.2–0.9 μM) G− bacteria (MIC = 0.3–1 μM) | Membrane permeabilization | [208,263,264] |

| Polyphemusin | hemocyte debris of horseshoe crabs (Limulus polyphemus) | antimicrobial activity against G+ bacteria: S. aureus MIC = 2 μg/mL, S. epidermidis MIC = 1 μg/mL, E. faecalis MIC = 1 μg/mL G-bacteria: E. coli MIC = 0.125–1 μg/mL, S. typhimurium MIC = 0.25–1 μg/mL, P. aeruginosa MIC = 0.25–1 μg/mL | Translocates into cells | [265,266] |

| Thanatin | insect (Podisus maculiventris) | activity against G− bacteria: MIC < 1.2 μM for E. coli, S. typhimurium, K. pneumoniae, E. cloacae; against G+ bacteria: MIC < 5 μM for A. viridans, M. luteus, B. megaterium, B. megate; No activity against S. aureus | Membrane permeabilization | [209,267] |

| Lactoferricin B | bovine, human | antimicrobial activity against G+ bacteria (S. mutans, S. epidermidis) and G− bacteria (E. coli, S. typhimurium, P. aeruginosa, B. cepacia, B. cenocepacia) | Prevents biofilm formation | [268,269] |

| AMPs rich in regular amino acids | ||||

| Histatins | salivary glands | Histatin 5: S. aureus MIC 12.5 μgmL−1, P. aeruginosa MIC 3.1 μgmL−1; MIC > 100 μgmL−1 for B. cepacia, A. xylosoxidans, S. maltophilia | Disruption of the plasma membrane | [188,200] |

| Indolicidin | cytoplasmic granules of bovine neutrophils | S. aureus MIC 2–30 μg/mL, S. hemolyticus MIC 2 μg/mL, S. epidermidis MIC 4–20 μg/mL, B. cereus MIC 12.5 μg/mL L. monocytogenes MIC 3–60 μg/mL, E. coli MIC 5–30 μg/mL, S. enterica MIC 100 μg/mL, P. aeruginosa MIC 100 μg/mL, | Membrane permeabilization; carpet model | [215,217,270,271] |

| Tritrpticin | Human, porcine | MIC 20–30 μg/mL for E. coli MIC 32 μg/mL for S. typhimurim and P. aeruginosa; MIC 8 μg/mL for B. subtilis and S. epidermidis, MIC 10–20 μg/mL for S. aureus | Inhibition of intracellular synthesis of protein, DNA, or RNA | [217,272] |

| Crotalicidin | pit viper | antibacterial activity particularly against G−; P. aeruginosa MIC 0.24–3.8 μM, K. pneumoniae MIC 1.9 μM, E. coli MIC 0.06–3.8 μM, A. baumannii MIC 3.8 μM | Membrane permeabilization | [218,273] |

| Bactenecins (Bac-5, Bac-7) | bovine neutrophils | Bac-5 is active against G− bacteria; Bac-7 has antibacterial activity against E. coli MIC 1–2 μM, S. enterica MIC 1 μM, S. marcescens MIC 1 μM, S. aureus MIC > 128 μM | Older research suggests a permeabilizing mode of action; a recent study showed no strong effect on bacterial membrane integrity | [220,221,274,275] |

| PR-39 | porcine neutrophils | E. coli MIC 1–4 μg/mL, P. aeruginosa MIC > 32 μg/mL, S. typhimurium MIC 4 μg/mL, S. enterica MIC 0.5 μM, A. pleuropneumoniae MIC 4–8 μM, S. aureus MIC > 32 μg/mL, B. cereus MIC > 32 μg/mL | Immune modulation; translocation across the membrane | [276,277,278,279] |

| AMPs with rare modified amino acids | ||||

| Nisin | Lactococcus lactis | highly active against G+ bacteria: L. monocytogenes, S. aureus, B. cereus, L. plantarum, M. luteus, and M. flavus | Membrane permeabilization | [222,280,281,282] |

| Leucocin A | Leuconostoc pseudomesenteroides | active against G+ bacteria, L. monocytogenes MIC 11.7–62.5 μM | Pore formation and ion disruption of the target cell | [283,284] |

| Protein (polypeptide) | ||||

| Sericin | wild silkworms (Antheraea pernyi, Samia cynthia ricini), domestic silkworms (Bombyx mori) | antimicrobial activity against G+ and G- bacteria, ZOI for E. coli and S. aureus 22.6 mm 22.16 mm, highly active against G+ bacteria: B. subtilis, S. aureus, S. epidermidis | no clarity as to the mode of action | [227,228] |

| Fibroin | domestic silkworms (Bombyx mori) | antibacterial effect of silk fibroin-based biomaterials | the mechanism has not yet been fully elucidated | [232] |

3.4.7. Antimicrobial Peptides in Clinical Trials

4. Synthetic Biodegradable Polymers with Antibacterial Properties

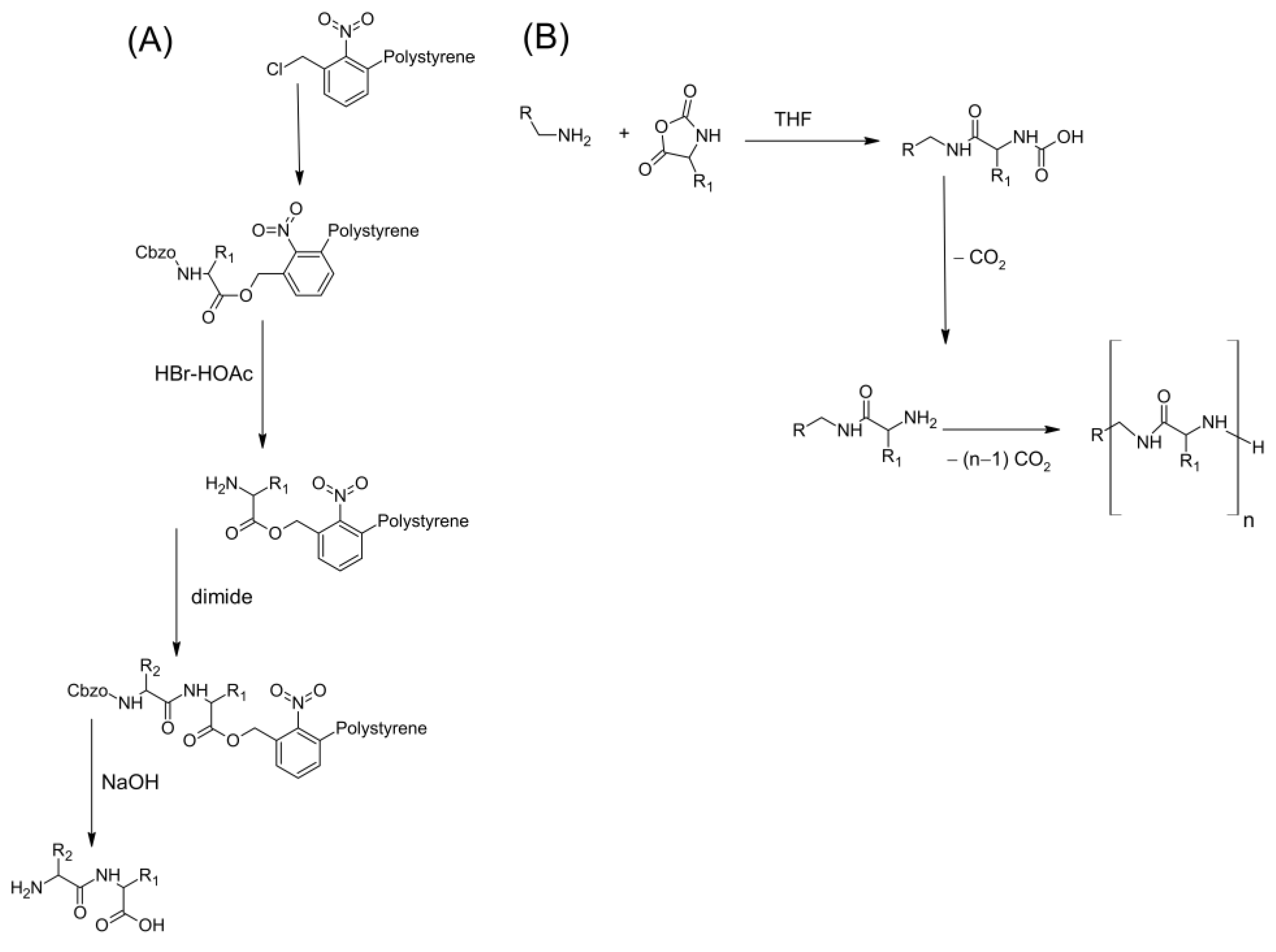

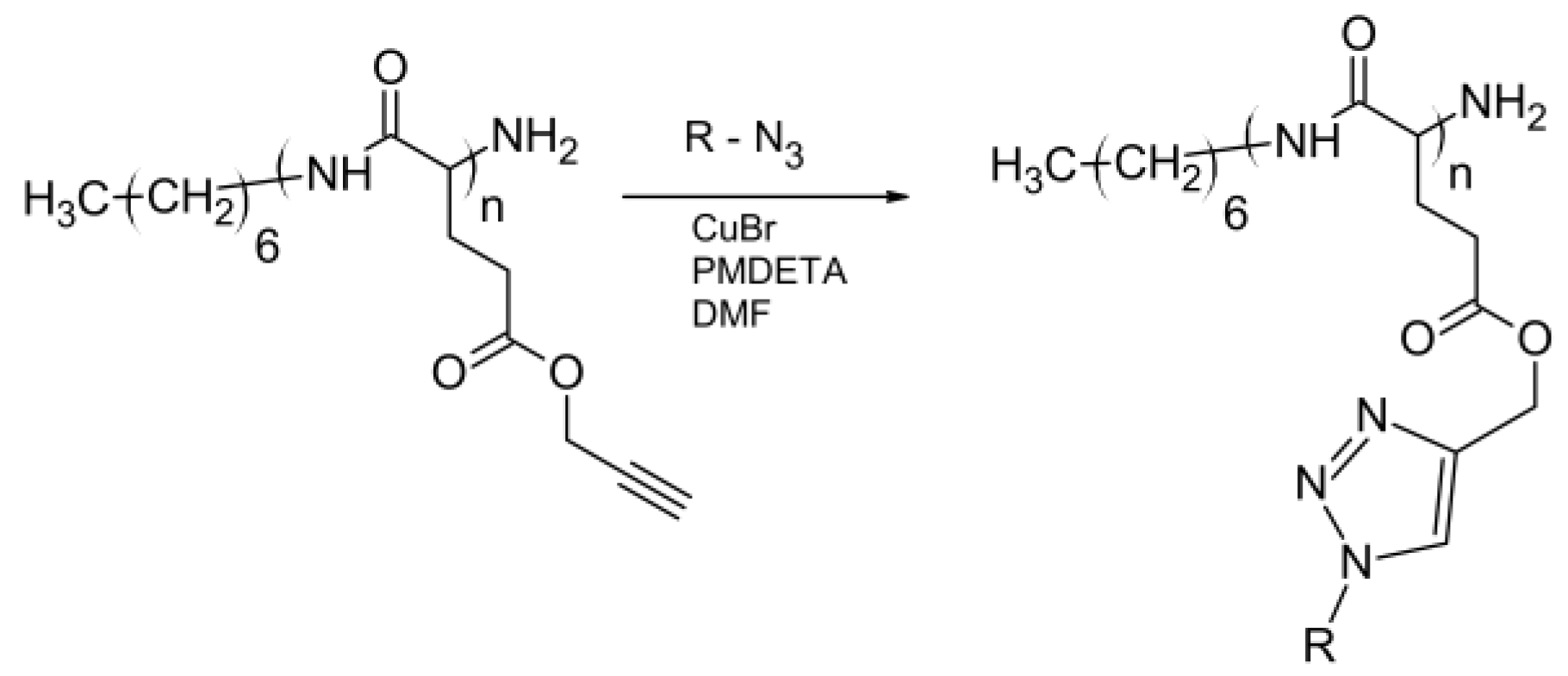

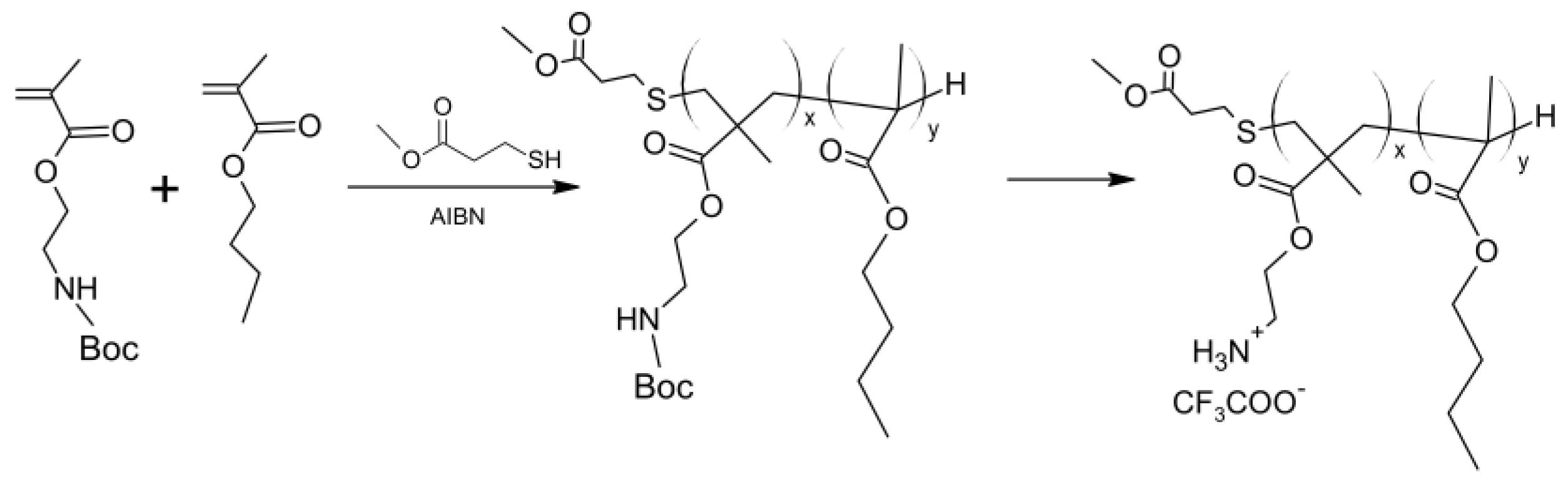

4.1. Biomimetic Polymers

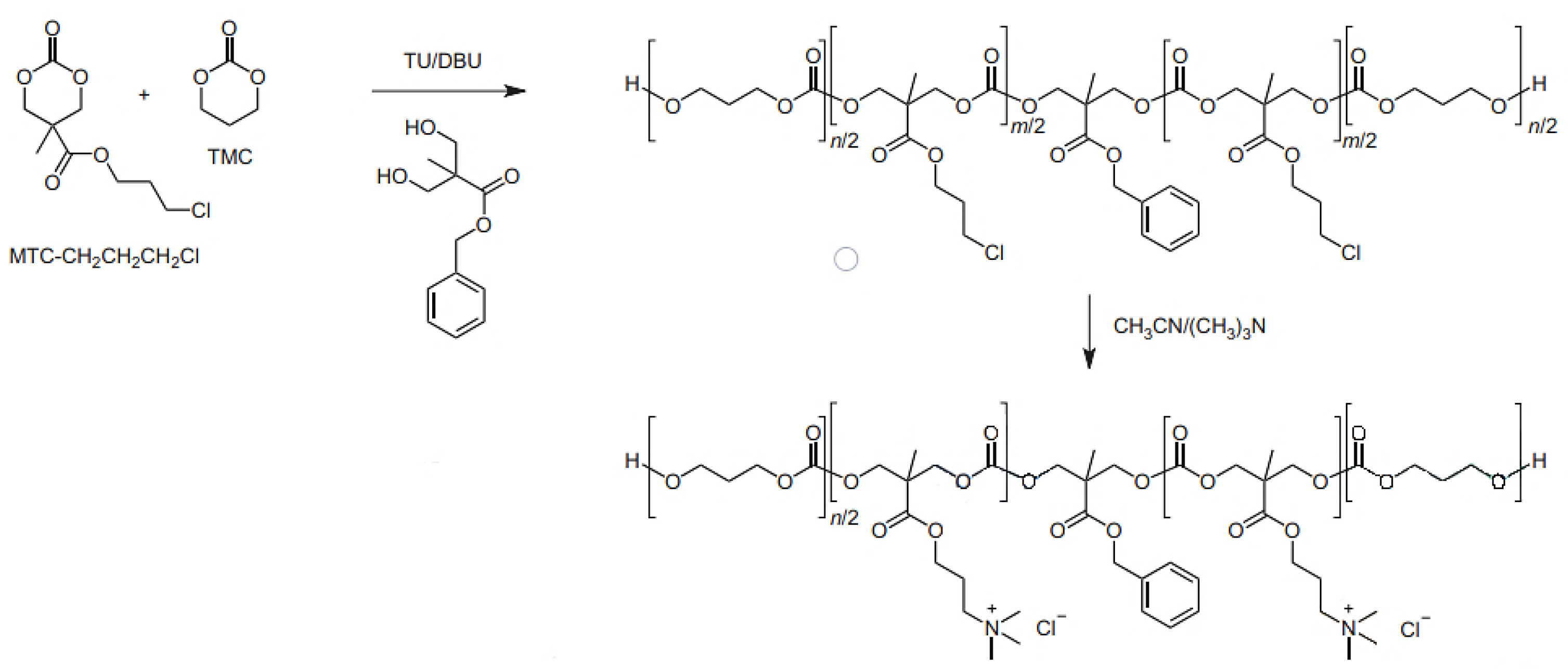

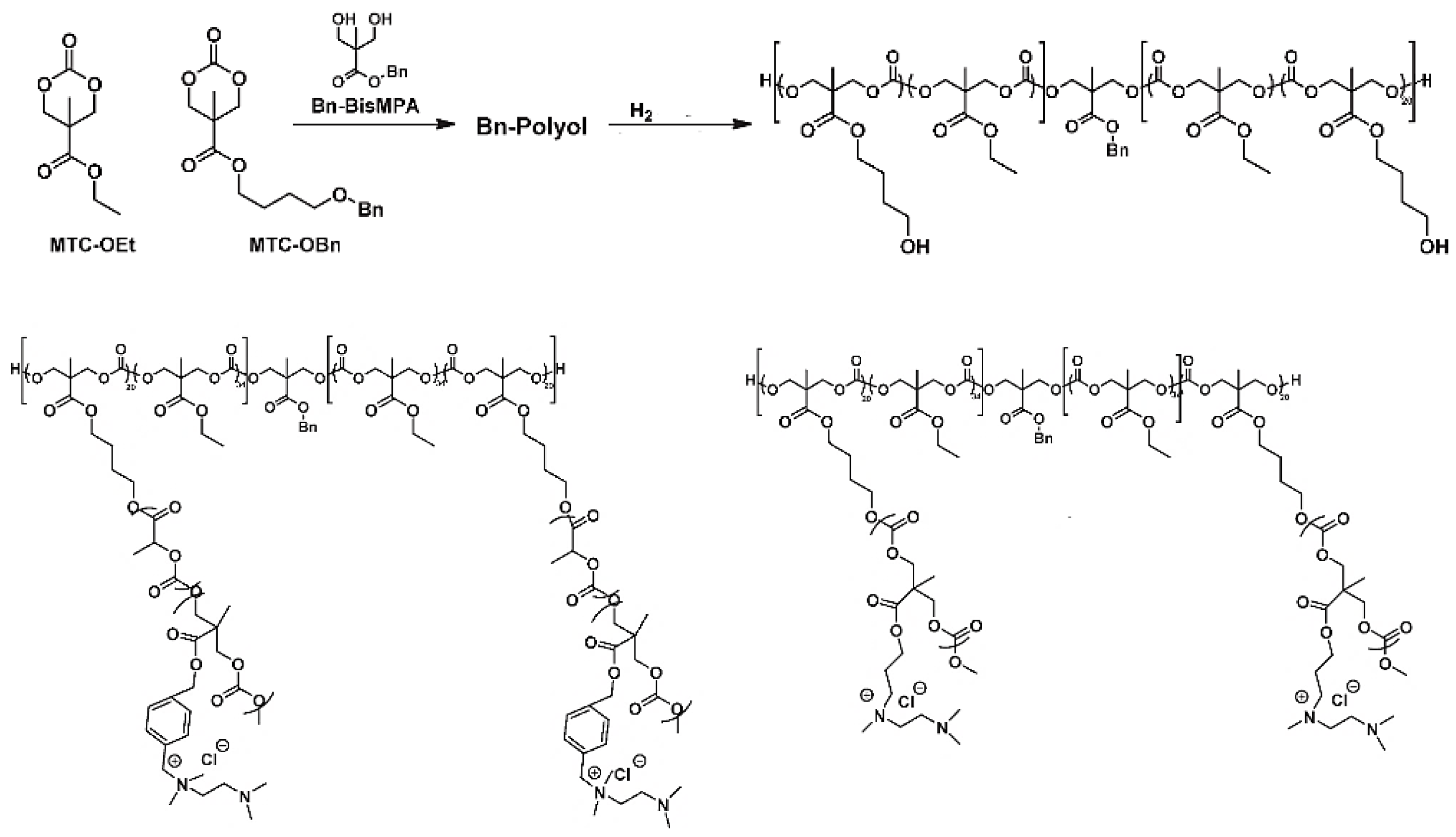

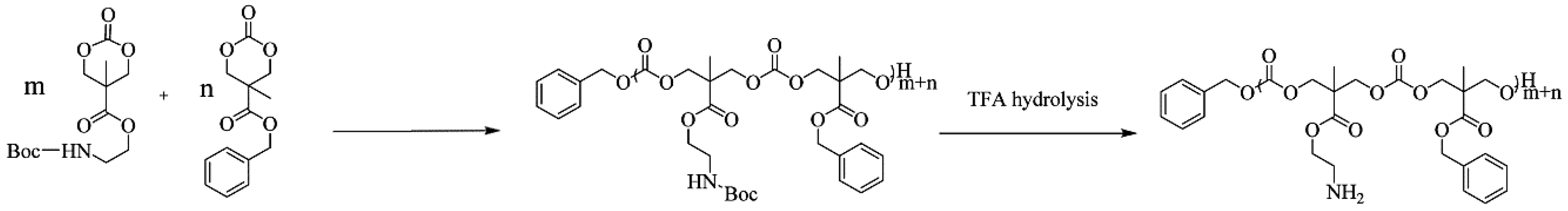

4.2. Polycarbonates and Carbonates Copolymers

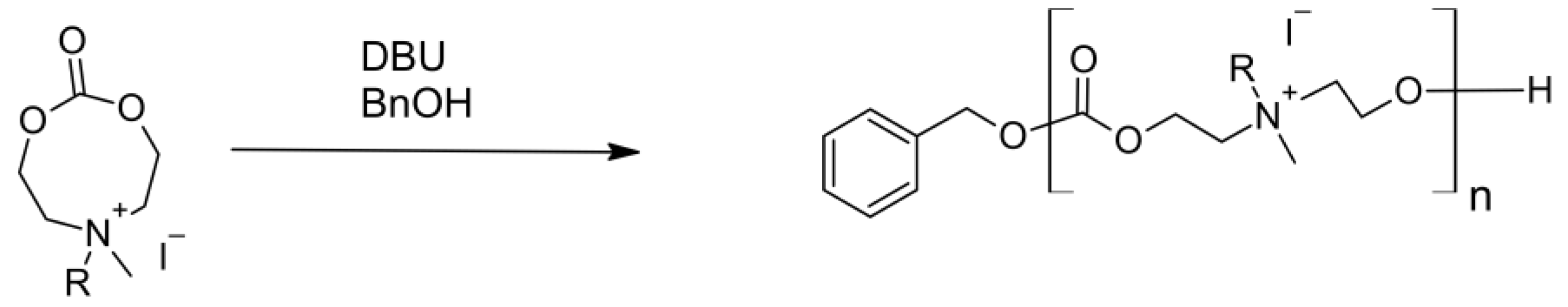

4.3. Antibacterial Biodegradable Polyesters

4.4. Polyamines and Polyesteramines

5. Biodegradable Polymer Composites with Antibacterial Properties

6. Application of Biodegradable Polymers and Antibacterial Polymer Composites in the Food Industry and Agricultural Technology

6.1. Polysaccharides Composites

6.1.1. Starch

6.1.2. Chitosan

6.1.3. Cellulose

6.1.4. Alginates and Carrageenans

6.2. PLA, PGA, PCL, PBS Composites

6.3. PHA Composites

6.4. PVA Composites

6.5. Proteins

6.6. Lipids and Waxes

7. The Use of Biodegradable Antibacterial Polymers in Biomedical Applications

7.1. Biodegradable and Antibacterial Wound-Dressings

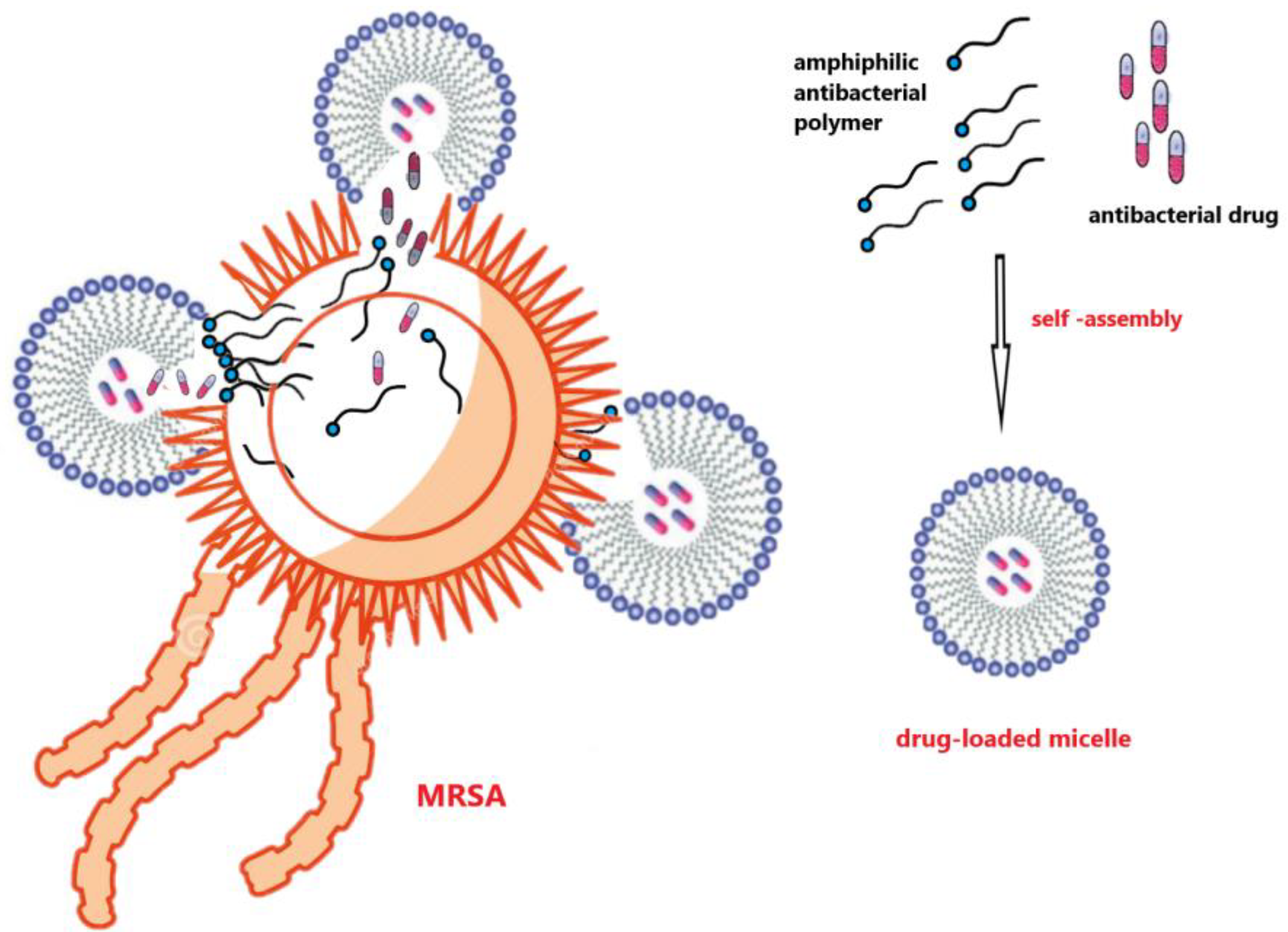

7.2. Biodegradable Drug Release Systems with Antibacterial Properties

8. Conclusions and Perspectives

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, M.; Ge, L.; Lyu, Y.; Zi, Y.; Li, X.; Li, D.; Mu, C. Preparation, Characterization and Antibacterial Activity of Oxidized κ-Carrageenan. Carbohydr. Polym. 2017, 174, 1051–1058. [Google Scholar] [CrossRef] [PubMed]

- Lai, E.P.C.; Iqbal, Z.; Avis, T.J. Combating Antimicrobial Resistance in Foodborne Microorganisms. J. Food Prot. 2016, 79, 321–336. [Google Scholar] [CrossRef] [PubMed]

- Antimicrobial Resistance. Available online: https://www.who.int/news-room/fact-sheets/detail/antimicrobial-resistance (accessed on 18 February 2023).

- Silhavy, T.J.; Kahne, D.; Walker, S. The Bacterial Cell Envelope. Cold Spring Harb. Perspect. Biol. 2010, 2, a000414. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Li, X.; Saravanan, R.; Li, C.M.; Leong, S.S.J. Antimicrobial Macromolecules: Synthesis Methods and Future Applications. RSC Adv. 2012, 2, 4031–4044. [Google Scholar] [CrossRef]

- Hoque, J.; Akkapeddi, P.; Yadav, V.; Manjunath, G.B.; Uppu, D.S.S.M.; Konai, M.M.; Yarlagadda, V.; Sanyal, K.; Haldar, J. Broad Spectrum Antibacterial and Antifungal Polymeric Paint Materials: Synthesis, Structure–Activity Relationship, and Membrane-Active Mode of Action. ACS Appl. Mater. Interfaces 2015, 7, 1804–1815. [Google Scholar] [CrossRef] [PubMed]

- Wimley, W.C. Describing the Mechanism of Antimicrobial Peptide Action with the Interfacial Activity Model. ACS Chem. Biol. 2010, 5, 905–917. [Google Scholar] [CrossRef]

- Cox, G.; Wright, G.D. Intrinsic Antibiotic Resistance: Mechanisms, Origins, Challenges and Solutions. Int. J. Med. Microbiol. 2013, 303, 287–292. [Google Scholar] [CrossRef]

- A Review of Antimicrobial Peptides and Their Therapeutic Potential as Anti-Infective Drugs: Current Eye Research: Vol 30, No 7. Available online: https://www.tandfonline.com/doi/full/10.1080/02713680590968637 (accessed on 12 February 2023).

- Yang, Y.; Cai, Z.; Huang, Z.; Tang, X.; Zhang, X. Antimicrobial Cationic Polymers: From Structural Design to Functional Control. Polym. J. 2018, 50, 33–44. [Google Scholar] [CrossRef]

- Zhang, L.; Peng, X.-M.; Damu, G.L.V.; Geng, R.-X.; Zhou, C.-H. Comprehensive Review in Current Developments of Imidazole-Based Medicinal Chemistry. Med. Res. Rev. 2014, 34, 340–437. [Google Scholar] [CrossRef]

- Rychter, P.; Rogacz, D.; Lewicka, K.; Lacik, I. Poly(Methylene-Co-Cyanoguanidine) as an Eco-Friendly Nitrogen Fertilizer with Prolonged Activity. J. Polym. Environ. 2019, 27, 1317–1332. [Google Scholar] [CrossRef]

- Palermo, E.F.; Kuroda, K. Chemical Structure of Cationic Groups in Amphiphilic Polymethacrylates Modulates the Antimicrobial and Hemolytic Activities. Biomacromolecules 2009, 10, 1416–1428. [Google Scholar] [CrossRef] [PubMed]

- Ng, V.W.L.; Tan, J.P.K.; Leong, J.; Voo, Z.X.; Hedrick, J.L.; Yang, Y.Y. Antimicrobial Polycarbonates: Investigating the Impact of Nitrogen-Containing Heterocycles as Quaternizing Agents. Macromolecules 2014, 47, 1285–1291. [Google Scholar] [CrossRef]

- No, H.K.; Park, N.Y.; Lee, S.H.; Meyers, S.P. Antibacterial Activity of Chitosans and Chitosan Oligomers with Different Molecular Weights. Int. J. Food Microbiol. 2002, 74, 65–72. [Google Scholar] [CrossRef] [PubMed]

- Chung, Y.; Su, Y.; Chen, C.; Jia, G.; Wang, H.; Wu, J.C.G.; Lin, J. Relationship between Antibacterial Activity of Chitosan and Surface Characteristics of Cell Wall. Acta Pharmacol. Sin. 2004, 25, 932–936. [Google Scholar] [PubMed]

- Sahariah, P.; Másson, M. Antimicrobial Chitosan and Chitosan Derivatives: A Review of the Structure–Activity Relationship. Biomacromolecules 2017, 18, 3846–3868. [Google Scholar] [CrossRef]

- Yan, D.; Li, Y.; Liu, Y.; Li, N.; Zhang, X.; Yan, C. Antimicrobial Properties of Chitosan and Chitosan Derivatives in the Treatment of Enteric Infections. Molecules 2021, 26, 7136. [Google Scholar] [CrossRef]

- Zhong, Y.; Godwin, P.; Jin, Y.; Xiao, H. Biodegradable Polymers and Green-Based Antimicrobial Packaging Materials: A Mini-Review. Adv. Ind. Eng. Polym. Res. 2020, 3, 27–35. [Google Scholar] [CrossRef]

- Li, Z.; Yang, F.; Yang, R. Synthesis and Characterization of Chitosan Derivatives with Dual-Antibacterial Functional Groups. Int. J. Biol. Macromol. 2015, 75, 378–387. [Google Scholar] [CrossRef]

- Fernandez-Saiz, P.; Lagaron, J.M.; Ocio, M.J. Optimization of the Biocide Properties of Chitosan for Its Application in the Design of Active Films of Interest in the Food Area. Food Hydrocoll. 2009, 23, 913–921. [Google Scholar] [CrossRef]

- Engler, A.C.; Tan, J.P.K.; Ong, Z.Y.; Coady, D.J.; Ng, V.W.L.; Yang, Y.Y.; Hedrick, J.L. Antimicrobial Polycarbonates: Investigating the Impact of Balancing Charge and Hydrophobicity Using a Same-Centered Polymer Approach. Biomacromolecules 2013, 14, 4331–4339. [Google Scholar] [CrossRef]

- Carmona-Ribeiro, A.M.; De Melo Carrasco, L.D. Cationic Antimicrobial Polymers and Their Assemblies. Int. J. Mol. Sci. 2013, 14, 9906–9946. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, S.; Liu, R.; Lemke, J.J.; Hayouka, Z.; Welch, R.A.; Weisblum, B.; Masters, K.S.; Gellman, S.H. Effects of Cyclic vs. Acyclic Hydrophobic Subunits on the Chemical Structure and Biological Properties of Nylon-3 Copolymers. ACS Macro Lett. 2013, 2, 753–756. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Chen, Y.P.; Yao, K.; Wilbon, P.A.; Zhang, W.; Ren, L.; Zhou, J.; Nagarkatti, M.; Wang, C.; Chu, F.; et al. Robust Antimicrobial Compounds and Polymers Derived from Natural Resin Acids. Chem. Commun. 2011, 48, 916–918. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Huang, Y.; Riduan, S.N.; Gao, S.; Yang, Y.; Fan, W.; Zhang, Y. Main-Chain Imidazolium Oligomer Material as a Selective Biomimetic Antimicrobial Agent. Biomaterials 2012, 33, 8625–8631. [Google Scholar] [CrossRef]

- Pascual, A.; Tan, J.P.K.; Yuen, A.; Chan, J.M.W.; Coady, D.J.; Mecerreyes, D.; Hedrick, J.L.; Yang, Y.Y.; Sardon, H. Broad-Spectrum Antimicrobial Polycarbonate Hydrogels with Fast Degradability. Biomacromolecules 2015, 16, 1169–1178. [Google Scholar] [CrossRef]

- Guo, J.; Qin, J.; Ren, Y.; Wang, B.; Cui, H.; Ding, Y.; Mao, H.; Yan, F. Antibacterial Activity of Cationic Polymers: Side-Chain or Main-Chain Type? Polym. Chem. 2018, 9, 4611–4616. [Google Scholar] [CrossRef]

- Pham, P.; Oliver, S.; Boyer, C. Design of Antimicrobial Polymers. Macromol. Chem. Phys. 2022, 224, 2200226. [Google Scholar] [CrossRef]

- Irzhak, V.I. A Structural Characteristic of Hyperbranched Polymers. Polym. Sci. Ser. B 2009, 51, 143–148. [Google Scholar] [CrossRef]

- Wei, T.; Zhan, W.; Cao, L.; Hu, C.; Qu, Y.; Yu, Q.; Chen, H. Multifunctional and Regenerable Antibacterial Surfaces Fabricated by a Universal Strategy. ACS Appl. Mater. Interfaces 2016, 8, 30048–30057. [Google Scholar] [CrossRef]

- Li, P.; Poon, Y.F.; Li, W.; Zhu, H.-Y.; Yeap, S.H.; Cao, Y.; Qi, X.; Zhou, C.; Lamrani, M.; Beuerman, R.W.; et al. A Polycationic Antimicrobial and Biocompatible Hydrogel with Microbe Membrane Suctioning Ability. Nat. Mater. 2011, 10, 149–156. [Google Scholar] [CrossRef]

- Malin, J.J.; de Leeuw, E. Therapeutic Compounds Targeting Lipid II for Antibacterial Purposes. Infect. Drug Resist. 2019, 12, 2613–2625. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ding, S.; Shen, J.; Zhu, K. Nonribosomal Antibacterial Peptides That Target Multidrug-Resistant Bacteria. Nat. Prod. Rep. 2019, 36, 573–592. [Google Scholar] [CrossRef] [PubMed]

- Ling, L.L.; Schneider, T.; Peoples, A.J.; Spoering, A.L.; Engels, I.; Conlon, B.P.; Mueller, A.; Schäberle, T.F.; Hughes, D.E.; Epstein, S.; et al. A New Antibiotic Kills Pathogens without Detectable Resistance. Nature 2015, 517, 455–459. [Google Scholar] [CrossRef] [PubMed]

- Plectasin, a Fungal Defensin, Targets the Bacterial Cell Wall Precursor Lipid II|Science. Available online: https://www.science.org/doi/10.1126/science.1185723 (accessed on 12 February 2023).

- Scherer, K.M.; Spille, J.-H.; Sahl, H.-G.; Grein, F.; Kubitscheck, U. The Lantibiotic Nisin Induces Lipid II Aggregation, Causing Membrane Instability and Vesicle Budding. Biophys. J. 2015, 108, 1114–1124. [Google Scholar] [CrossRef] [PubMed]

- Chindera, K.; Mahato, M.; Kumar Sharma, A.; Horsley, H.; Kloc-Muniak, K.; Kamaruzzaman, N.F.; Kumar, S.; McFarlane, A.; Stach, J.; Bentin, T.; et al. The Antimicrobial Polymer PHMB Enters Cells and Selectively Condenses Bacterial Chromosomes. Sci. Rep. 2016, 6, 23121. [Google Scholar] [CrossRef]

- Chin, W.; Zhong, G.; Pu, Q.; Yang, C.; Lou, W.; De Sessions, P.F.; Periaswamy, B.; Lee, A.; Liang, Z.C.; Ding, X.; et al. A Macromolecular Approach to Eradicate Multidrug Resistant Bacterial Infections While Mitigating Drug Resistance Onset. Nat. Commun. 2018, 9, 917. [Google Scholar] [CrossRef]

- Zhou, M.; Qian, Y.; Xie, J.; Zhang, W.; Jiang, W.; Xiao, X.; Chen, S.; Dai, C.; Cong, Z.; Ji, Z.; et al. Poly(2-Oxazoline)-Based Functional Peptide Mimics: Eradicating MRSA Infections and Persisters While Alleviating Antimicrobial Resistance. Angew. Chem. Int. Ed. 2020, 59, 6412–6419. [Google Scholar] [CrossRef]

- Structures of Proline-Rich Peptides Bound to the Ribosome Reveal a Common Mechanism of Protein Synthesis Inhibition|Nucleic Acids Research|Oxford Academic. Available online: https://academic.oup.com/nar/article/44/5/2439/2465042 (accessed on 12 February 2023).

- Fernandes, M.M.; Carvalho, E.O.; Lanceros-Mendez, S. Electroactive Smart Materials: Novel Tools for Tailoring Bacteria Behavior and Fight Antimicrobial Resistance. Front. Bioeng. Biotechnol. 2019, 7, 277. [Google Scholar] [CrossRef]

- Ando, M.; Tamakura, D.; Inoue, T.; Takumi, K.; Yamanaga, T.; Todo, R.; Hosoya, K.; Onishi, O. Electric Antibacterial Effect of Piezoelectric Poly(Lactic Acid) Fabric. Jpn. J. Appl. Phys. 2019, 58, SLLD09. [Google Scholar] [CrossRef]

- Carvalho, E.O.; Fernandes, M.M.; Padrao, J.; Nicolau, A.; Marqués-Marchán, J.; Asenjo, A.; Gama, F.M.; Ribeiro, C.; Lanceros-Mendez, S. Tailoring Bacteria Response by Piezoelectric Stimulation. ACS Appl. Mater. Interfaces 2019, 11, 27297–27305. [Google Scholar] [CrossRef]

- Tan, G.; Wang, S.; Zhu, Y.; Zhou, L.; Yu, P.; Wang, X.; He, T.; Chen, J.; Mao, C.; Ning, C. Surface-Selective Preferential Production of Reactive Oxygen Species on Piezoelectric Ceramics for Bacterial Killing. ACS Appl. Mater. Interfaces 2016, 8, 24306–24309. [Google Scholar] [CrossRef] [PubMed]

- Gorodzha, S.N.; Muslimov, A.R.; Syromotina, D.S.; Timin, A.S.; Tcvetkov, N.Y.; Lepik, K.V.; Petrova, A.V.; Surmeneva, M.A.; Gorin, D.A.; Sukhorukov, G.B.; et al. A Comparison Study between Electrospun Polycaprolactone and Piezoelectric Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Scaffolds for Bone Tissue Engineering. Colloids Surf. B Biointerfaces 2017, 160, 48–59. [Google Scholar] [CrossRef] [PubMed]

- Guerin, S.; Tofail, S.A.M.; Thompson, D. Organic Piezoelectric Materials: Milestones and Potential. NPG Asia Mater. 2019, 11, 10. [Google Scholar] [CrossRef]

- Ando, M.; Takeshima, S.; Ishiura, Y.; Ando, K.; Onishi, O. Piezoelectric Antibacterial Fabric Comprised of Poly(l-Lactic Acid) Yarn. Jpn. J. Appl. Phys. 2017, 56, 10PG01. [Google Scholar] [CrossRef]

- Gazvoda, L.; Nanut, M.P.; Spreitzer, M.; Vukomanović, M. Antimicrobial Activity of Piezoelectric Polymer: Piezoelectricity as the Reason for Damaging Bacterial Membrane. Biomater. Sci. 2022, 10, 4933–4948. [Google Scholar] [CrossRef] [PubMed]

- Timofeeva, L.; Kleshcheva, N. Antimicrobial Polymers: Mechanism of Action, Factors of Activity, and Applications. Appl. Microbiol. Biotechnol. 2011, 89, 475–492. [Google Scholar] [CrossRef]

- Mozammil Hasnain, S.M.; Hasnain, M.S.; Nayak, A.K. Natural Polysaccharides. In Natural Polysaccharides in Drug Delivery and Biomedical Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–14. ISBN 978-0-12-817055-7. [Google Scholar]

- Thakur, V.K.; Thakur, M.K. (Eds.) Handbook of Polymers for Pharmaceutical Technologies; John Wiley & Sons: Hoboken, NJ, USA; Scrivener Publishing LLC: Hoboken, NJ, USA; Salem, MA, USA, 2015; ISBN 978-1-119-04135-1. [Google Scholar]

- Muñoz-Bonilla, A.; Echeverria, C.; Sonseca, Á.; Arrieta, M.P.; Fernández-García, M. Bio-Based Polymers with Antimicrobial Properties towards Sustainable Development. Materials 2019, 12, 641. [Google Scholar] [CrossRef]

- Xie, J.-H.; Jin, M.-L.; Morris, G.A.; Zha, X.-Q.; Chen, H.-Q.; Yi, Y.; Li, J.-E.; Wang, Z.-J.; Gao, J.; Nie, S.-P.; et al. Advances on Bioactive Polysaccharides from Medicinal Plants. Crit. Rev. Food Sci. Nutr. 2016, 56, S60–S84. [Google Scholar] [CrossRef]

- Yu, Y.; Shen, M.; Song, Q.; Xie, J. Biological Activities and Pharmaceutical Applications of Polysaccharide from Natural Resources: A Review. Carbohydr. Polym. 2018, 183, 91–101. [Google Scholar] [CrossRef]

- Zhong, K.; Wang, Q. Optimization of Ultrasonic Extraction of Polysaccharides from Dried Longan Pulp Using Response Surface Methodology. Carbohydr. Polym. 2010, 80, 19–25. [Google Scholar] [CrossRef]

- Kozarski, M.; Klaus, A.; Niksic, M.; Van Griensven, L.J.L.D.; Vrvic, M.; Jakovljevic, D. Polysaccharides of Higher Fungi: Biological Role, Structure, and Antioxidative Activity. Hem. Ind. 2014, 68, 305–320. [Google Scholar] [CrossRef]

- Pushpamalar, J.; Veeramachineni, A.K.; Owh, C.; Loh, X.J. Biodegradable Polysaccharides for Controlled Drug Delivery. ChemPlusChem 2016, 81, 504–514. [Google Scholar] [CrossRef] [PubMed]

- Qiu, A.; Wang, Y.; Zhang, G.; Wang, H. Natural Polysaccharide-Based Nanodrug Delivery Systems for Treatment of Diabetes. Polymers 2022, 14, 3217. [Google Scholar] [CrossRef] [PubMed]

- Younes, I.; Rinaudo, M. Chitin and Chitosan Preparation from Marine Sources. Structure, Properties and Applications. Mar. Drugs 2015, 13, 1133–1174. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Zhang, C.; Cao, X.; Feng, B.; Li, X. Intestinal Population in Host with Metabolic Syndrome during Administration of Chitosan and Its Derivatives. Molecules 2020, 25, 5857. [Google Scholar] [CrossRef]

- de Queiroz Antonino, R.S.C.M.; Lia Fook, B.R.P.; de Oliveira Lima, V.A.; de Farias Rached, R.Í.; Lima, E.P.N.; da Silva Lima, R.J.; Peniche Covas, C.A.; Lia Fook, M.V. Preparation and Characterization of Chitosan Obtained from Shells of Shrimp (Litopenaeus vannamei Boone). Mar. Drugs 2017, 15, 141. [Google Scholar] [CrossRef]

- Hajji, S.; Younes, I.; Ghorbel-Bellaaj, O.; Hajji, R.; Rinaudo, M.; Nasri, M.; Jellouli, K. Structural Differences between Chitin and Chitosan Extracted from Three Different Marine Sources. Int. J. Biol. Macromol. 2014, 65, 298–306. [Google Scholar] [CrossRef]

- Aranaz, I.; Alcántara, A.R.; Civera, M.C.; Arias, C.; Elorza, B.; Heras Caballero, A.; Acosta, N. Chitosan: An Overview of Its Properties and Applications. Polymers 2021, 13, 3256. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, M.; Li, P.; Wang, K.; Fang, L.; Ren, F.; Lu, G.; Lu, X. The Interaction of Chitosan and BMP-2 Tuned by Deacetylation Degree and PH Value. J. Biomed. Mater. Res. A 2019, 107, 769–779. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Yu, H.; Abdin, Z.u.; Chen, Y.; Chen, Q.; Zhou, W.; Zhang, H.; Chen, X. Recent Progress on Synthesis, Property and Application of Modified Chitosan: An Overview. Int. J. Biol. Macromol. 2016, 88, 333–344. [Google Scholar] [CrossRef]

- Kim, S. Competitive Biological Activities of Chitosan and Its Derivatives: Antimicrobial, Antioxidant, Anticancer, and Anti-Inflammatory Activities. Int. J. Polym. Sci. 2018, 2018, e1708172. [Google Scholar] [CrossRef]

- Li, J.; Zhuang, S. Antibacterial Activity of Chitosan and Its Derivatives and Their Interaction Mechanism with Bacteria: Current State and Perspectives. Eur. Polym. J. 2020, 138, 109984. [Google Scholar] [CrossRef]

- Hosseinnejad, M.; Jafari, S.M. Evaluation of Different Factors Affecting Antimicrobial Properties of Chitosan. Int. J. Biol. Macromol. 2016, 85, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Ardean, C.; Davidescu, C.M.; Nemeş, N.S.; Negrea, A.; Ciopec, M.; Duteanu, N.; Negrea, P.; Duda-Seiman, D.; Musta, V. Factors Influencing the Antibacterial Activity of Chitosan and Chitosan Modified by Functionalization. Int. J. Mol. Sci. 2021, 22, 7449. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Xing, R.; Liu, S.; Yu, H.; Li, K.; Qin, Y.; Li, P. Molecular Weight and PH Effects of Aminoethyl Modified Chitosan on Antibacterial Activity in Vitro. Int. J. Biol. Macromol. 2012, 50, 918–924. [Google Scholar] [CrossRef] [PubMed]

- Kong, M.; Chen, X.G.; Xing, K.; Park, H.J. Antimicrobial Properties of Chitosan and Mode of Action: A State of the Art Review. Int. J. Food Microbiol. 2010, 144, 51–63. [Google Scholar] [CrossRef]

- Verlee, A.; Mincke, S.; Stevens, C.V. Recent Developments in Antibacterial and Antifungal Chitosan and Its Derivatives. Carbohydr. Polym. 2017, 164, 268–283. [Google Scholar] [CrossRef]

- Younes, I.; Sellimi, S.; Rinaudo, M.; Jellouli, K.; Nasri, M. Influence of Acetylation Degree and Molecular Weight of Homogeneous Chitosans on Antibacterial and Antifungal Activities. Int. J. Food Microbiol. 2014, 185, 57–63. [Google Scholar] [CrossRef]

- Takahashi, T.; Imai, M.; Suzuki, I.; Sawai, J. Growth Inhibitory Effect on Bacteria of Chitosan Membranes Regulated with Deacetylation Degree. Biochem. Eng. J. 2008, 40, 485–491. [Google Scholar] [CrossRef]

- Qin, C.; Li, H.; Xiao, Q.; Liu, Y.; Zhu, J.; Du, Y. Water-Solubility of Chitosan and Its Antimicrobial Activity. Carbohydr. Polym. 2006, 63, 367–374. [Google Scholar] [CrossRef]

- Ezati, P.; Rhim, J.W. PH-Responsive Chitosan-Based Film Incorporated with Alizarin for Intelligent Packaging Applications. Food Hydrocoll. 2020, 102, 105629. [Google Scholar] [CrossRef]

- Kulikov, S.N.; Tikhonov, V.E.; Bezrodnykh, E.A.; Lopatin, S.A.; Varlamov, V.P. Comparative Evaluation of Antimicrobial Activity of Oligochitosans against Klebsiella Pneumoniae. Russ. J. Bioorganic Chem. 2015, 41, 57–62. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, H.F.G.; Attjioui, M.; Leitão, A.; Moerschbacher, B.M.; Cavalheiro, É.T.G. Characterization, Solubility and Biological Activity of Amphihilic Biopolymeric Schiff Bases Synthesized Using Chitosans. Carbohydr. Polym. 2019, 220, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Kaplan, S.; Aslan, S.; Ulusoy, S.; Oral, A. Natural-Based Polymers for Antibacterial Treatment of Absorbent Materials. J. Appl. Polym. Sci. 2020, 137, 48302. [Google Scholar] [CrossRef]

- Ashry, N.M.; El Bahgy, H.E.K.; Mohamed, A.; Alsubhi, N.H.; Alrefaei, G.I.; Binothman, N.; Alharbi, M.; Selim, S.; Almuhayawi, M.S.; Alharbi, M.T.; et al. Evaluation of Graphene Oxide, Chitosan and Their Complex as Antibacterial Agents and Anticancer Apoptotic Effect on HeLa Cell Line. Front. Microbiol. 2022, 13, 922324. [Google Scholar] [CrossRef] [PubMed]

- Laokuldilok, T.; Potivas, T.; Kanha, N.; Surawang, S.; Seesuriyachan, P.; Wangtueai, S.; Phimolsiripol, Y.; Regenstein, J.M. Physicochemical, Antioxidant, and Antimicrobial Properties of Chitooligosaccharides Produced Using Three Different Enzyme Treatments. Food Biosci. 2017, 18, 28–33. [Google Scholar] [CrossRef]

- Hmed, A.A.; Sofy, A.R.; Sharaf, A.E.-M.M.A.; El-Dougdoug, K.A. Effectiveness of Chitosan as Naturally-Derived Antimicrobial to Fulfill the Needs of Today’s Consumers Looking for Food without Hazards of Chemical Preservatives. J. Microbiol. Res. 2017, 7, 55–67. [Google Scholar]

- Abdeltwab, W.; Fathy, Y.; Azab, W.; Eldeghedy, M.; Ebid, W. Antimicrobial Effect of Chitosan and Nano-Chitosan against Some Pathogens and Spoilage Microorganisms. J. Adv. Lab. Res. Biol. 2019, 10, 8–15. [Google Scholar]

- Rahimi, M.; Ahmadi, R.; Samadi Kafil, H.; Shafiei-Irannejad, V. A Novel Bioactive Quaternized Chitosan and Its Silver-Containing Nanocomposites as a Potent Antimicrobial Wound Dressing: Structural and Biological Properties. Mater. Sci. Eng. C 2019, 101, 360–369. [Google Scholar] [CrossRef]

- Si, Z.; Hou, Z.; Vikhe, Y.S.; Thappeta, K.R.V.; Marimuthu, K.; De, P.P.; Ng, O.T.; Li, P.; Zhu, Y.; Pethe, K.; et al. Antimicrobial Effect of a Novel Chitosan Derivative and Its Synergistic Effect with Antibiotics. ACS Appl. Mater. Interfaces 2021, 13, 3237–3245. [Google Scholar] [CrossRef]

- Abdel-Monem, R.A.; Khalil, A.M.; Darwesh, O.M.; Hashim, A.I.; Rabie, S.T. Antibacterial Properties of Carboxymethyl Chitosan Schiff-Base Nanocomposites Loaded with Silver Nanoparticles. J. Macromol. Sci. Part A 2020, 57, 145–155. [Google Scholar] [CrossRef]

- de Britto, D.; Celi Goy, R.; Campana Filho, S.P.; Assis, O.B.G. Quaternary Salts of Chitosan: History, Antimicrobial Features, and Prospects. Int. J. Carbohydr. Chem. 2011, 2011, e312539. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, C.; Wang, X.; Fang, Q.; Huang, J. Synthesis, Characterization, and Antimicrobial Activities of Sulfonated Chitosan. Carbohydr. Polym. 2017, 155, 321–328. [Google Scholar] [CrossRef] [PubMed]

- Shanmugam, A.; Kathiresan, K.; Nayak, L. Preparation, Characterization and Antibacterial Activity of Chitosan and Phosphorylated Chitosan from Cuttlebone of Sepia Kobiensis (Hoyle, 1885). Biotechnol. Rep. 2015, 9, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Haj, N.Q.; Mohammed, M.O.; Mohammood, L.E. Synthesis and Biological Evaluation of Three New Chitosan Schiff Base Derivatives. ACS Omega 2020, 5, 13948–13954. [Google Scholar] [CrossRef] [PubMed]

- Du, W.-L.; Niu, S.-S.; Xu, Y.-L.; Xu, Z.-R.; Fan, C.-L. Antibacterial Activity of Chitosan Tripolyphosphate Nanoparticles Loaded with Various Metal Ions. Carbohydr. Polym. 2009, 75, 385–389. [Google Scholar] [CrossRef]

- Brown, S.; Santa Maria, J.P.; Walker, S. Wall Teichoic Acids of Gram-Positive Bacteria. Annu. Rev. Microbiol. 2013, 67, 313–336. [Google Scholar] [CrossRef]

- Khalid, S.; Piggot, T.J.; Samsudin, F. Atomistic and Coarse Grain Simulations of the Cell Envelope of Gram-Negative Bacteria: What Have We Learned? Acc. Chem. Res. 2019, 52, 180–188. [Google Scholar] [CrossRef]

- Feng, P.; Luo, Y.; Ke, C.; Qiu, H.; Wang, W.; Zhu, Y.; Hou, R.; Xu, L.; Wu, S. Chitosan-Based Functional Materials for Skin Wound Repair: Mechanisms and Applications. Front. Bioeng. Biotechnol. 2021, 9, 650598. [Google Scholar] [CrossRef]

- Helander, I.M.; Nurmiaho-Lassila, E.L.; Ahvenainen, R.; Rhoades, J.; Roller, S. Chitosan Disrupts the Barrier Properties of the Outer Membrane of Gram-Negative Bacteria. Int. J. Food Microbiol. 2001, 71, 235–244. [Google Scholar] [CrossRef]

- Xing, K.; Chen, X.G.; Liu, C.S.; Cha, D.S.; Park, H.J. Oleoyl-Chitosan Nanoparticles Inhibits Escherichia Coli and Staphylococcus aureus by Damaging the Cell Membrane and Putative Binding to Extracellular or Intracellular Targets. Int. J. Food Microbiol. 2009, 132, 127–133. [Google Scholar] [CrossRef] [PubMed]

- Galván Márquez, I.; Akuaku, J.; Cruz, I.; Cheetham, J.; Golshani, A.; Smith, M.L. Disruption of Protein Synthesis as Antifungal Mode of Action by Chitosan. Int. J. Food Microbiol. 2013, 164, 108–112. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Feng, X.; Yang, S.; Fu, G.; Wang, T.; Su, Z. Chitosan Kills Escherichia Coli through Damage to Be of Cell Membrane Mechanism. Carbohydr. Polym. 2010, 3, 493–499. [Google Scholar] [CrossRef]

- Jiménez-Gómez, C.P.; Cecilia, J.A. Chitosan: A Natural Biopolymer with a Wide and Varied Range of Applications. Molecules 2020, 25, 3981. [Google Scholar] [CrossRef]

- Zhou, Z.; Yan, D.; Cheng, X.; Kong, M.; Liu, Y.; Feng, C.; Chen, X. Biomaterials Based on N,N,N-Trimethyl Chitosan Fibers in Wound Dressing Applications. Int. J. Biol. Macromol. 2016, 89, 471–476. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, R.R.; Elella, M.H.A.; Sabaa, M.W. Synthesis, Characterization and Applications of N-Quaternized Chitosan/Poly(Vinyl Alcohol) Hydrogels. Int. J. Biol. Macromol. 2015, 80, 149–161. [Google Scholar] [CrossRef] [PubMed]

- El-Shafei, A.M.; Fouda, M.M.G.; Knittel, D.; Schollmeyer, E. Antibacterial Activity of Cationically Modified Cotton Fabric with Carboxymethyl Chitosan. J. Appl. Polym. Sci. 2008, 110, 1289–1296. [Google Scholar] [CrossRef]

- Yin, M.; Lin, X.; Ren, T.; Li, Z.; Ren, X.; Huang, T.-S. Cytocompatible Quaternized Carboxymethyl Chitosan/Poly(Vinyl Alcohol) Blend Film Loaded Copper for Antibacterial Application. Int. J. Biol. Macromol. 2018, 120, 992–998. [Google Scholar] [CrossRef]

- Huang, S.; Wang, J.; Zhang, Y.; Yu, Z.; Qi, C. Quaternized Carboxymethyl Chitosan-Based Silver Nanoparticles Hybrid: Microwave-Assisted Synthesis, Characterization and Antibacterial Activity. Nanomaterials 2016, 6, 118. [Google Scholar] [CrossRef]

- Yang, J.; Xie, Q.; Zhu, J.; Zou, C.; Chen, L.; Du, Y.; Li, D. Preparation and in Vitro Antioxidant Activities of 6-Amino-6-Deoxychitosan and Its Sulfonated Derivatives. Biopolymers 2015, 103, 539–549. [Google Scholar] [CrossRef]

- Ouerghemmi, S.; Dimassi, S.; Tabary, N.; Leclercq, L.; Degoutin, S.; Chai, F.; Pierlot, C.; Cazaux, F.; Ung, A.; Staelens, J.-N.; et al. Synthesis and Characterization of Polyampholytic Aryl-Sulfonated Chitosans and Their in Vitro Anticoagulant Activity. Carbohydr. Polym. 2018, 196, 8–17. [Google Scholar] [CrossRef] [PubMed]

- Khattak, S.; Wahid, F.; Liu, L.-P.; Jia, S.-R.; Chu, L.-Q.; Xie, Y.-Y.; Li, Z.-X.; Zhong, C. Applications of Cellulose and Chitin/Chitosan Derivatives and Composites as Antibacterial Materials: Current State and Perspectives. Appl. Microbiol. Biotechnol. 2019, 103, 1989–2006. [Google Scholar] [CrossRef] [PubMed]

- Tan, M.; Wang, H.; Wang, Y.; Chen, G.; Yuan, L.; Chen, H. Recyclable Antibacterial Material: Silicon Grafted with 3,6-O-Sulfated Chitosan and Specifically Bound by Lysozyme. J. Mater. Chem. B 2014, 2, 569–576. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Liu, Y.; Yang, L.; Zhou, F. Synthesis of Sulfonated Chitosan and Its Antibiofilm Formation Activity against E. coli and S. aureus. Int. J. Biol. Macromol. 2019, 129, 980–988. [Google Scholar] [CrossRef] [PubMed]

- Pestov, A.; Bratskaya, S. Chitosan and Its Derivatives as Highly Efficient Polymer Ligands. Molecules 2016, 21, 330. [Google Scholar] [CrossRef] [PubMed]

- Suchyta, D.J.; Soto, R.J.; Schoenfisch, M.H. Selective Monophosphorylation of Chitosan via Phosphorus Oxychloride. Polym. Chem. 2017, 8, 2552–2558. [Google Scholar] [CrossRef] [PubMed]

- Imran, M.; Sajwan, M.; Alsuwayt, B.; Asif, M. Synthesis, Characterization and Anticoagulant Activity of Chitosan Derivatives. Saudi Pharm. J. 2020, 28, 25–32. [Google Scholar] [CrossRef]

- Soliman, E.A.; El-Kousy, S.M.; Abd-Elbary, H.M.; Abou-zeid, A.R. Low Molecular Weight Chitosan-Based Schiff Bases: Synthesis, Characterization and Antibacterial Activity. Am. J. Food Technol. 2012, 8, 17–30. [Google Scholar] [CrossRef]

- Hassan, M.A.; Omer, A.M.; Abbas, E.; Baset, W.M.A.; Tamer, T.M. Preparation, Physicochemical Characterization and Antimicrobial Activities of Novel Two Phenolic Chitosan Schiff Base Derivatives. Sci. Rep. 2018, 8, 11416. [Google Scholar] [CrossRef]

- Tamer, T.M.; Hassan, M.A.; Omer, A.M.; Baset, W.M.A.; Hassan, M.E.; El-Shafeey, M.E.A.; Eldin, M.S.M. Synthesis, Characterization and Antimicrobial Evaluation of Two Aromatic Chitosan Schiff Base Derivatives. Process Biochem. 2016, 51, 1721–1730. [Google Scholar] [CrossRef]

- Hassan, M.A.; Tamer, T.M.; Omer, A.M.; Baset, W.M.A.; Abbas, E.; Mohy-Eldin, M.S. Therapeutic Potential of Two Formulated Novel Chitosan Derivatives with Prominent Antimicrobial Activities against Virulent Microorganisms and Safe Profiles toward Fibroblast Cells. Int. J. Pharm. 2023, 634, 122649. [Google Scholar] [CrossRef] [PubMed]

- Tamer, T.M.; ElTantawy, M.M.; Brussevich, A.; Nebalueva, A.; Novikov, A.; Moskalenko, I.V.; Abu-Serie, M.M.; Hassan, M.A.; Ulasevich, S.; Skorb, E.V. Functionalization of Chitosan with Poly Aromatic Hydroxyl Molecules for Improving Its Antibacterial and Antioxidant Properties: Practical and Theoretical Studies. Int. J. Biol. Macromol. 2023, 234, 123687. [Google Scholar] [CrossRef] [PubMed]

- Dashtimoghadam, E.; Hasani-Sadrabadi, M.M.; Moaddel, H. Structural Modification of Chitosan Biopolymer as a Novel Polyelectrolyte Membrane for Green Power Generation. Polym. Adv. Technol. 2010, 21, 726–734. [Google Scholar] [CrossRef]

- Islam, S.; Bhuiyan, M.A.R.; Islam, M.N. Chitin and Chitosan: Structure, Properties and Applications in Biomedical Engineering. J. Polym. Environ. 2017, 25, 854–866. [Google Scholar] [CrossRef]

- Wu, T.; Huang, J.; Jiang, Y.; Hu, Y.; Ye, X.; Liu, D.; Chen, J. Formation of Hydrogels Based on Chitosan/Alginate for the Delivery of Lysozyme and Their Antibacterial Activity. Food Chem. 2018, 240, 361–369. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Zhu, Z.; Wu, D.; Gan, W.; Zhu, S.; Li, W.; Tian, J.; Li, L.; Zhou, C.; Lu, L. Antibacterial Poly (Ethylene Glycol) Diacrylate/Chitosan Hydrogels Enhance Mechanical Adhesiveness and Promote Skin Regeneration. Carbohydr. Polym. 2019, 225, 115110. [Google Scholar] [CrossRef]

- Hu, H.; Ye, B.; Lv, Y.; Zhang, Q. Preparing Antibacterial and In-Situ Formable Double Crosslinking Chitosan/Hyaluronan Composite Hydrogels. Mater. Lett. 2019, 254, 17–20. [Google Scholar] [CrossRef]

- Nešović, K.; Janković, A.; Radetić, T.; Vukašinović-Sekulić, M.; Kojić, V.; Živković, L.; Perić-Grujić, A.; Rhee, K.Y.; Mišković-Stanković, V. Chitosan-Based Hydrogel Wound Dressings with Electrochemically Incorporated Silver Nanoparticles—In Vitro Study. Eur. Polym. J. 2019, 121, 109257. [Google Scholar] [CrossRef]

- Jiang, M.; Li, S.; Ming, P.; Guo, Y.; Yuan, L.; Jiang, X.; Liu, Y.; Chen, J.; Xia, D.; He, Y.; et al. Rational Design of Porous Structure-Based Sodium Alginate/Chitosan Sponges Loaded with Green Synthesized Hybrid Antibacterial Agents for Infected Wound Healing. Int. J. Biol. Macromol. 2023, 237, 123944. [Google Scholar] [CrossRef]

- Raghavendra, G.M.; Jung, J.; Kim, D.; Seo, J. Microwave Assisted Antibacterial Chitosan-Silver Nanocomposite Films. Int. J. Biol. Macromol. 2016, 84, 281–288. [Google Scholar] [CrossRef]

- An, J.; Ji, Z.; Wang, D.; Luo, Q.; Li, X. Preparation and Characterization of Uniform-Sized Chitosan/Silver Microspheres with Antibacterial Activities. Mater. Sci. Eng. C 2014, 36, 33–41. [Google Scholar] [CrossRef] [PubMed]

- Lu, B.; Lu, F.; Ran, L.; Yu, K.; Xiao, Y.; Li, Z.; Dai, F.; Wu, D.; Lan, G. Imidazole-Molecule-Capped Chitosan–Gold Nanocomposites with Enhanced Antimicrobial Activity for Treating Biofilm-Related Infections. J. Colloid Interface Sci. 2018, 531, 269–281. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Mehmood, S.; Shafiq, M.; Yasin, T.; Akhter, Z.; Ahmad, S. Structural and Antimicrobial Properties of Irradiated Chitosan and Its Complexes with Zinc. Radiat. Phys. Chem. 2013, 91, 138–142. [Google Scholar] [CrossRef]

- Mallick, S.; Sharma, S.; Banerjee, M.; Ghosh, S.S.; Chattopadhyay, A.; Paul, A. Iodine-Stabilized Cu Nanoparticle Chitosan Composite for Antibacterial Applications. ACS Appl. Mater. Interfaces 2012, 4, 1313–1323. [Google Scholar] [CrossRef] [PubMed]

- Mallick, S.; Sanpui, P.; Ghosh, S.S.; Chattopadhyay, A.; Paul, A. Synthesis, Characterization and Enhanced Bactericidal Action of a Chitosan Supported Core–Shell Copper–Silver Nanoparticle Composite. RSC Adv. 2015, 5, 12268–12276. [Google Scholar] [CrossRef]

- Li, Q.; Lu, F.; Zhou, G.; Yu, K.; Lu, B.; Xiao, Y.; Dai, F.; Wu, D.; Lan, G. Silver Inlaid with Gold Nanoparticle/Chitosan Wound Dressing Enhances Antibacterial Activity and Porosity, and Promotes Wound Healing. Biomacromolecules 2017, 18, 3766–3775. [Google Scholar] [CrossRef]

- Khan, S.B.; Ali, F.; Kamal, T.; Anwar, Y.; Asiri, A.M.; Seo, J. CuO Embedded Chitosan Spheres as Antibacterial Adsorbent for Dyes. Int. J. Biol. Macromol. 2016, 88, 113–119. [Google Scholar] [CrossRef]

- Yusof, N.A.A.; Zain, N.M.; Pauzi, N. Synthesis of ZnO Nanoparticles with Chitosan as Stabilizing Agent and Their Antibacterial Properties against Gram-Positive and Gram-Negative Bacteria. Int. J. Biol. Macromol. 2019, 124, 1132–1136. [Google Scholar] [CrossRef]

- Perelshtein, I.; Ruderman, E.; Perkas, N.; Tzanov, T.; Beddow, J.; Joyce, E.; Mason, T.J.; Blanes, M.; Mollá, K.; Patlolla, A.; et al. Chitosan and Chitosan–ZnO-Based Complex Nanoparticles: Formation, Characterization, and Antibacterial Activity. J. Mater. Chem. B 2013, 1, 1968–1976. [Google Scholar] [CrossRef]

- Tran, C.D.; Makuvaza, J.; Munson, E.; Bennett, B. Biocompatible Copper Oxide Nanoparticle Composites from Cellulose and Chitosan: Facile Synthesis, Unique Structure, and Antimicrobial Activity. ACS Appl. Mater. Interfaces 2017, 9, 42503–42515. [Google Scholar] [CrossRef]

- Zhang, L.; Ding, Y.; Povey, M.; York, D. ZnO Nanofluids—A Potential Antibacterial Agent. Prog. Nat. Sci. 2008, 18, 939–944. [Google Scholar] [CrossRef]

- Espitia, P.J.P.; de Fátima Ferreira Soares, N.; dos Reis Coimbra, J.S.; de Andrade, N.J.; Souza Cruz, R.; Alves Medeiros, E.A. Zinc Oxide Nanoparticles: Synthesis, Antimicrobial Activity and Food Packaging Applications. Food Bioprocess Technol. 2012, 5, 1447–1464. [Google Scholar] [CrossRef]

- Wrońska, N.; Katir, N.; Miłowska, K.; Hammi, N.; Nowak, M.; Kędzierska, M.; Anouar, A.; Zawadzka, K.; Bryszewska, M.; El Kadib, A.; et al. Antimicrobial Effect of Chitosan Films on Food Spoilage Bacteria. Int. J. Mol. Sci. 2021, 22, 5839. [Google Scholar] [CrossRef] [PubMed]

- Mujeeb Rahman, P.; Abdul Mujeeb, V.M.; Muraleedharan, K.; Thomas, S.K. Chitosan/Nano ZnO Composite Films: Enhanced Mechanical, Antimicrobial and Dielectric Properties. Arab. J. Chem. 2018, 11, 120–127. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Kaewklin, P. Fabrication and Characterization of Chitosan-Titanium Dioxide Nanocomposite Film as Ethylene Scavenging and Antimicrobial Active Food Packaging. Food Hydrocoll. 2018, 84, 125–134. [Google Scholar] [CrossRef]

- Xing, Y.; Li, X.; Guo, X.; Li, W.; Chen, J.; Liu, Q.; Xu, Q.; Wang, Q.; Yang, H.; Shui, Y.; et al. Effects of Different TiO2 Nanoparticles Concentrations on the Physical and Antibacterial Activities of Chitosan-Based Coating Film. Nanomaterials 2020, 10, 1365. [Google Scholar] [CrossRef]

- Noreen, A.; Zia, K.M.; Zuber, M.; Ali, M.; Mujahid, M. A Critical Review of Algal Biomass: A Versatile Platform of Bio-Based Polyesters from Renewable Resources. Int. J. Biol. Macromol. 2016, 86, 937–949. [Google Scholar] [CrossRef]

- Necas, J.; Bartosikova, L. Carrageenan: A Review. Vet. Med. 2013, 58, 187–205. [Google Scholar] [CrossRef]

- Zia, K.M.; Tabasum, S.; Nasif, M.; Sultan, N.; Aslam, N.; Noreen, A.; Zuber, M. A Review on Synthesis, Properties and Applications of Natural Polymer Based Carrageenan Blends and Composites. Int. J. Biol. Macromol. 2017, 96, 282–301. [Google Scholar] [CrossRef]

- Campo, V.L.; Kawano, D.F.; da Silva, D.B.; Carvalho, I. Carrageenans: Biological Properties, Chemical Modifications and Structural Analysis—A Review. Carbohydr. Polym. 2009, 77, 167–180. [Google Scholar] [CrossRef]

- Varela, P.; Fiszman, S.M. Hydrocolloids in Fried Foods. A Review. Food Hydrocoll. 2011, 25, 1801–1812. [Google Scholar] [CrossRef]

- Cheng, C.; Chen, S.; Su, J.; Zhu, M.; Zhou, M.; Chen, T.; Han, Y. Recent Advances in Carrageenan-Based Films for Food Packaging Applications. Front. Nutr. 2022, 9, 1004588. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Jiang, X.; Aubree, E.; Boulenguer, P.; Critchley, A.T. Preparation and In Vivo. Antitumor Activity of κ-Carrageenan Oligosaccharides. Pharm. Biol. 2006, 44, 646–650. [Google Scholar] [CrossRef]

- Yuan, H.; Song, J.; Li, X.; Li, N.; Dai, J. Immunomodulation and Antitumor Activity of κ-Carrageenan Oligosaccharides. Cancer Lett. 2006, 243, 228–234. [Google Scholar] [CrossRef]

- Yuan, H.; Song, J.; Li, X.; Li, N.; Liu, S. Enhanced Immunostimulatory and Antitumor Activity of Different Derivatives of κ-Carrageenan Oligosaccharides from Kappaphycus Striatum. J. Appl. Phycol. 2011, 23, 59–65. [Google Scholar] [CrossRef]

- Amin, M.L.; Mawad, D.; Dokos, S.; Koshy, P.; Martens, P.J.; Sorrell, C.C. Immunomodulatory Properties of Photopolymerizable Fucoidan and Carrageenans. Carbohydr. Polym. 2020, 230, 115691. [Google Scholar] [CrossRef]

- Liang, W.; Mao, X.; Peng, X.; Tang, S. Effects of Sulfate Group in Red Seaweed Polysaccharides on Anticoagulant Activity and Cytotoxicity. Carbohydr. Polym. 2014, 101, 776–785. [Google Scholar] [CrossRef]

- Liu, J.; Dong, Y.; Ma, Z.; Rao, Z.; Zheng, X.; Tang, K. Soluble Soybean Polysaccharide/Carrageenan Antibacterial Nanocomposite Films Containing Green Synthesized Silver Nanoparticles. ACS Appl. Polym. Mater. 2022, 4, 5608–5618. [Google Scholar] [CrossRef]

- Tang, S.; Zheng, J. Antibacterial Activity of Silver Nanoparticles: Structural Effects. Adv. Healthc. Mater. 2018, 7, 1701503. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Wang, L.-F. Preparation and Characterization of Carrageenan-Based Nanocomposite Films Reinforced with Clay Mineral and Silver Nanoparticles. Appl. Clay Sci. 2014, 97–98, 174–181. [Google Scholar] [CrossRef]

- Roy, S.; Shankar, S.; Rhim, J.-W. Melanin-Mediated Synthesis of Silver Nanoparticle and Its Use for the Preparation of Carrageenan-Based Antibacterial Films. Food Hydrocoll. 2019, 88, 237–246. [Google Scholar] [CrossRef]

- Saedi, S.; Shokri, M.; Rhim, J.-W. Preparation of Carrageenan-Based Nanocomposite Films Incorporated with Functionalized Halloysite Using AgNP and Sodium Dodecyl Sulfate. Food Hydrocoll. 2020, 106, 105934. [Google Scholar] [CrossRef]

- Kim, Y.H.; Bang, Y.-J.; Yoon, K.S.; Priyadarshi, R.; Rhim, J.-W. Pine Needle (Pinus densiflora) Extract-Mediated Synthesis of Silver Nanoparticles and the Preparation of Carrageenan-Based Antimicrobial Packaging Films. J. Nanomater. 2022, 2022, 1–15. [Google Scholar] [CrossRef]

- Gün Gök, Z.; Karayel, M.; Yiğitoğlu, M. Synthesis of Carrageenan Coated Silver Nanoparticles by an Easy Green Method and Their Characterization and Antimicrobial Activities. Res. Chem. Intermed. 2021, 47, 1843–1864. [Google Scholar] [CrossRef]

- Pramesti, E.S.; Febriani, N.A.; ‘Aisy, R.N.; Salsabila, S.; Rachmawati, V.P.N.; Susilowati, E. Synthesis of Silver/K-Caragenan Nanocomposites Assisted with Microwave Iradiation as a Potential Antibacterial Material. J. Phys. Conf. Ser. 2022, 2190, 012004. [Google Scholar] [CrossRef]

- Bahadoran, A.; Najafizadeh, M.; Liu, Q.; De Lile, J.R.; Zhang, D.; Masudy-Panah, S.; Ramakrishna, S.; Fakhri, A.; Gupta, V.K. Co-Doping Silver and Iron on Graphitic Carbon Nitride-Carrageenan Nanocomposite for the Photocatalytic Process, Rapidly Colorimetric Detection and Antibacterial Properties. Surf. Interfaces 2021, 26, 101279. [Google Scholar] [CrossRef]

- Saedi, S.; Shokri, M.; Priyadarshi, R.; Rhim, J.-W. Silver Ion Loaded 3-Aminopropyl Trimethoxysilane-Modified Fe3O4 Nanoparticles for the Fabrication of Carrageenan-Based Active Packaging Films. Colloids Surf. B Biointerfaces 2021, 208, 112085. [Google Scholar] [CrossRef] [PubMed]

- Saedi, S.; Shokri, M.; Priyadarshi, R.; Rhim, J.-W. Carrageenan-Based Antimicrobial Films Integrated with Sulfur-Coated Iron Oxide Nanoparticles (Fe3O4 @SNP). ACS Appl. Polym. Mater. 2021, 3, 4913–4923. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Fabrication of Copper Sulfide Nanoparticles and Limonene Incorporated Pullulan/Carrageenan-Based Film with Improved Mechanical and Antibacterial Properties. Polymers 2020, 12, 2665. [Google Scholar] [CrossRef]

- Li, F.; Liu, Y.; Cao, Y.; Zhang, Y.; Zhe, T.; Guo, Z.; Sun, X.; Wang, Q.; Wang, L. Copper Sulfide Nanoparticle-Carrageenan Films for Packaging Application. Food Hydrocoll. 2020, 109, 106094. [Google Scholar] [CrossRef]

- Ezati, P.; Riahi, Z.; Rhim, J.-W. Carrageenan-Based Functional Films Integrated with CuO-Doped Titanium Nanotubes for Active Food-Packaging Applications. ACS Sustain. Chem. Eng. 2021, 9, 9300–9307. [Google Scholar] [CrossRef]

- Sudhakar, M.P.; Venkatnarayanan, S.; Dharani, G. Fabrication and Characterization of Bio-Nanocomposite Films Using κ-Carrageenan and Kappaphycus Alvarezii Seaweed for Multiple Industrial Applications. Int. J. Biol. Macromol. 2022, 219, 138–149. [Google Scholar] [CrossRef] [PubMed]

- Mirzaei, A.; Esmkhani, M.; Zallaghi, M.; Nezafat, Z.; Javanshir, S. Biomedical and Environmental Applications of Carrageenan-Based Hydrogels: A Review. J. Polym. Environ. 2023, 31, 1679–1705. [Google Scholar] [CrossRef]

- Jaiswal, L.; Shankar, S.; Rhim, J.-W.; Hahm, D.-H. Lignin-Mediated Green Synthesis of AgNPs in Carrageenan Matrix for Wound Dressing Applications. Int. J. Biol. Macromol. 2020, 159, 859–869. [Google Scholar] [CrossRef] [PubMed]

- Abdelgawad, A.M.; El-Naggar, M.E.; Elsherbiny, D.A.; Ali, S.; Abdel-Aziz, M.S.; Abdel-Monem, Y.K. Antibacterial Carrageenan/Cellulose Nanocrystal System Loaded with Silver Nanoparticles, Prepared via Solid-State Technique. J. Environ. Chem. Eng. 2020, 8, 104276. [Google Scholar] [CrossRef]

- Muthulakshmi, L.; Pavithra, U.; Sivaranjani, V.; Balasubramanian, N.; Sakthivel, K.M.; Pruncu, C.I. A Novel Ag/Carrageenan–Gelatin Hybrid Hydrogel Nanocomposite and Its Biological Applications: Preparation and Characterization. J. Mech. Behav. Biomed. Mater. 2021, 115, 104257. [Google Scholar] [CrossRef]

- Oun, A.A.; Rhim, J.-W. Carrageenan-Based Hydrogels and Films: Effect of ZnO and CuO Nanoparticles on the Physical, Mechanical, and Antimicrobial Properties. Food Hydrocoll. 2017, 67, 45–53. [Google Scholar] [CrossRef]

- Ngwabebhoh, F.A.; Patwa, R.; Zandraa, O.; Saha, N.; Saha, P. Preparation and Characterization of Injectable Self-Antibacterial Gelatin/Carrageenan/Bacterial Cellulose Hydrogel Scaffolds for Wound Healing Application. J. Drug Deliv. Sci. Technol. 2021, 63, 102415. [Google Scholar] [CrossRef]

- Tavakoli, S.; Mokhtari, H.; Kharaziha, M.; Kermanpur, A.; Talebi, A.; Moshtaghian, J. A Multifunctional Nanocomposite Spray Dressing of Kappa-Carrageenan-Polydopamine Modified ZnO/L-Glutamic Acid for Diabetic Wounds. Mater. Sci. Eng. C 2020, 111, 110837. [Google Scholar] [CrossRef]

- Khodaei, T.; Nourmohammadi, J.; Ghaee, A.; Khodaii, Z. An Antibacterial and Self-Healing Hydrogel from Aldehyde-Carrageenan for Wound Healing Applications. Carbohydr. Polym. 2023, 302, 120371. [Google Scholar] [CrossRef]

- Johnson, A.; Kong, F.; Miao, S.; Lin, H.-T.V.; Thomas, S.; Huang, Y.-C.; Kong, Z.-L. Therapeutic Effects of Antibiotics Loaded Cellulose Nanofiber and κ-Carrageenan Oligosaccharide Composite Hydrogels for Periodontitis Treatment. Sci. Rep. 2020, 10, 18037. [Google Scholar] [CrossRef] [PubMed]

- Özbaş, Z.; Özkahraman, B.; Bayrak, G.; Kılıç Süloğlu, A.; Perçin, I.; Boran, F.; Tamahkar, E. Poly(Vinyl Alcohol)/(Hyaluronic Acid-g-Kappa-Carrageenan) Hydrogel as Antibiotic-Releasing Wound Dressing. Chem. Pap. 2021, 75, 6591–6600. [Google Scholar] [CrossRef]

- Alinavaz, S.; Mahdavinia, G.R.; Jafari, H.; Hazrati, M.; Akbari, A. Hydroxyapatite (HA)-Based Hybrid Bionanocomposite Hydrogels: Ciprofloxacin Delivery, Release Kinetics and Antibacterial Activity. J. Mol. Struct. 2021, 1225, 129095. [Google Scholar] [CrossRef]

- Jiang, L.; Chen, Q.; Liu, J.; Zhu, Z.; Shao, W. Antibacterial Performance of Berberine Loaded Carrageenan/Konjac Glucomannan Hydrogels. Mater. Express 2021, 11, 1516–1522. [Google Scholar] [CrossRef]

- Jaiswal, L.; Shankar, S.; Rhim, J.-W. Carrageenan-Based Functional Hydrogel Film Reinforced with Sulfur Nanoparticles and Grapefruit Seed Extract for Wound Healing Application. Carbohydr. Polym. 2019, 224, 115191. [Google Scholar] [CrossRef]

- Khan, M.U.A.; Razaq, S.I.A.; Mehboob, H.; Rehman, S.; Al-Arjan, W.S.; Amin, R. Antibacterial and Hemocompatible PH-Responsive Hydrogel for Skin Wound Healing Application: In Vitro Drug Release. Polymers 2021, 13, 3703. [Google Scholar] [CrossRef]

- Polat, T.G.; Duman, O.; Tunç, S. Agar/κ-Carrageenan/Montmorillonite Nanocomposite Hydrogels for Wound Dressing Applications. Int. J. Biol. Macromol. 2020, 164, 4591–4602. [Google Scholar] [CrossRef]

- Bahar, A.; Ren, D. Antimicrobial Peptides. Pharmaceuticals 2013, 6, 1543–1575. [Google Scholar] [CrossRef]

- Reddy, K.V.R.; Yedery, R.D.; Aranha, C. Antimicrobial Peptides: Premises and Promises. Int. J. Antimicrob. Agents 2004, 24, 536–547. [Google Scholar] [CrossRef]

- Kumar, P.; Kizhakkedathu, J.; Straus, S. Antimicrobial Peptides: Diversity, Mechanism of Action and Strategies to Improve the Activity and Biocompatibility In Vivo. Biomolecules 2018, 8, 4. [Google Scholar] [CrossRef]

- Jenssen, H.; Hamill, P.; Hancock, R.E.W. Peptide Antimicrobial Agents. Clin. Microbiol. Rev. 2006, 19, 491–511. [Google Scholar] [CrossRef] [PubMed]

- Fazly Bazzaz, B.S.; Seyedi, S.; Hoseini Goki, N.; Khameneh, B. Human Antimicrobial Peptides: Spectrum, Mode of Action and Resistance Mechanisms. Int. J. Pept. Res. Ther. 2021, 27, 801–816. [Google Scholar] [CrossRef]

- Hancock, R.E.W.; Lehrer, R. Cationic Peptides: A New Source of Antibiotics. Trends Biotechnol. 1998, 16, 82–88. [Google Scholar] [CrossRef] [PubMed]

- Cociancich, S.; Bulet, P.; Hetru, C.; Hoffmann, J.A. The Inducible Antibacterial Peptides of Insects. Parasitol. Today 1994, 10, 132–139. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Lee, D.G. Antimicrobial Peptides (AMPs) with Dual Mechanisms: Membrane Disruption and Apoptosis. J. Microbiol. Biotechnol. 2015, 25, 759–764. [Google Scholar] [CrossRef]

- Lehmann, J.; Retz, M.; Sidhu, S.S.; Suttmann, H.; Sell, M.; Paulsen, F.; Harder, J.; Unteregger, G.; Stöckle, M. Antitumor Activity of the Antimicrobial Peptide Magainin II against Bladder Cancer Cell Lines. Eur. Urol. 2006, 50, 141–147. [Google Scholar] [CrossRef]

- Lorin, C.; Saidi, H.; Belaid, A.; Zairi, A.; Baleux, F.; Hocini, H.; Bélec, L.; Hani, K.; Tangy, F. The Antimicrobial Peptide Dermaseptin S4 Inhibits HIV-1 Infectivity in Vitro. Virology 2005, 334, 264–275. [Google Scholar] [CrossRef]

- Conlon, J.M.; Kolodziejek, J.; Nowotny, N. Antimicrobial Peptides from Ranid Frogs: Taxonomic and Phylogenetic Markers and a Potential Source of New Therapeutic Agents. Biochim. Biophys. Acta (BBA)-Proteins Proteom. 2004, 1696, 1–14. [Google Scholar] [CrossRef]

- Lai, R.; Liu, H.; Lee, W.H.; Zhang, Y. An Anionic Antimicrobial Peptide from Toad Bombina Maxima. Biochem. Biophys. Res. Commun. 2002, 295, 796–799. [Google Scholar] [CrossRef]

- Rozek, T.; Wegener, K.L.; Bowie, J.H.; Olver, I.N.; Carver, J.A.; Wallace, J.C.; Tyler, M.J. The Antibiotic and Anticancer Active Aurein Peptides from the Australian Bell Frogs Litoria Aurea and Litoria Raniformis: The Solution Structure of Aurein 1.2. Eur. J. Biochem. 2000, 267, 5330–5341. [Google Scholar] [CrossRef]

- Ogan, A.; Yüce-Dursun, B.; Abdullah, D.; Beyler-Çiğil, A.; Kahraman, M.V.; Çağlayan, P.; Birbir, M.; Mutlu, Ö.; Gülsoy, N. Preparation and Antimicrobial Properties of LL-37 Peptide Immobilized Lignin/Caprolactone Polymer Film. Polym. Adv. Technol. 2020, 31, 2222–2228. [Google Scholar] [CrossRef]

- Ganz, T. Defensins: Antimicrobial Peptides of Innate Immunity. Nat. Rev. Immunol. 2003, 3, 710–720. [Google Scholar] [CrossRef] [PubMed]

- Boman, H.G. Peptide Antibiotics and Their Role in Innate Immunity. Annu. Rev. Immunol. 1995, 13, 61–92. [Google Scholar] [CrossRef] [PubMed]

- De Smet, K.; Contreras, R. Human Antimicrobial Peptides: Defensins, Cathelicidins and Histatins. Biotechnol. Lett. 2005, 27, 1337–1347. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Niyonsaba, F.; Ushio, H.; Hara, M.; Yokoi, H.; Matsumoto, K.; Saito, H.; Nagaoka, I.; Ikeda, S.; Okumura, K.; et al. Antimicrobial Peptides Human β-Defensin (HBD)-3 and HBD-4 Activate Mast Cells and Increase Skin Vascular Permeability. Eur. J. Immunol. 2007, 37, 434–444. [Google Scholar] [CrossRef]

- Skeate, J.G.; Segerink, W.H.; Garcia, M.D.; Fernandez, D.J.; Prins, R.; Lühen, K.P.; Voss, F.O.; Da Silva, D.M.; Kast, W.M. Theta-Defensins Inhibit High-Risk Human Papillomavirus Infection Through Charge-Driven Capsid Clustering. Front. Immunol. 2020, 11, 561843. [Google Scholar] [CrossRef]

- Selsted, M.E. θ-Defensins: Cyclic Antimicrobial Peptides Produced by Binary Ligation of Truncated α-Defensins. Curr. Protein Pept. Sci. 2004, 5, 365–371. [Google Scholar] [CrossRef]

- Garcia, A.E.; Ösapay, G.; Tran, P.A.; Yuan, J.; Selsted, M.E. Isolation, Synthesis, and Antimicrobial Activities of Naturally Occurring θ-Defensin Isoforms from Baboon Leukocytes. Infect. Immun. 2008, 76, 5883–5891. [Google Scholar] [CrossRef]

- Tanner, J.; Deplazes, E.; Mancera, R. The Biological and Biophysical Properties of the Spider Peptide Gomesin. Molecules 2018, 23, 1733. [Google Scholar] [CrossRef]

- Dimarcq, J.; Bulet, P.; Hetru, C.; Hoffmann, J. Cysteine-rich Antimicrobial Peptides in Invertebrates. Pept. Sci. 1998, 47, 465–477. [Google Scholar] [CrossRef]

- Khorshidian, N.; Khanniri, E.; Koushki, M.R.; Sohrabvandi, S.; Yousefi, M. An Overview of Antimicrobial Activity of Lysozyme and Its Functionality in Cheese. Front. Nutr. 2022, 9, 833618. [Google Scholar] [CrossRef] [PubMed]

- Edwards, I.A.; Elliott, A.G.; Kavanagh, A.M.; Blaskovich, M.A.T.; Cooper, M.A. Structure-Activity and-Toxicity Relationships of the Antimicrobial Peptide Tachyplesin-1. ACS Infect. Dis. 2017, 3, 917–926. [Google Scholar] [CrossRef] [PubMed]

- Dash, R.; Bhattacharjya, S. Thanatin: An Emerging Host Defense Antimicrobial Peptide with Multiple Modes of Action. Int. J. Mol. Sci. 2021, 22, 1522. [Google Scholar] [CrossRef] [PubMed]

- Otvos, L. Antibacterial Peptides and Proteins with Multiple Cellular Targets. J. Pept. Sci. 2005, 11, 697–706. [Google Scholar] [CrossRef] [PubMed]

- Yamauchi, K.; Wakabayashi, H.; Shin, K.; Takase, M. Bovine Lactoferrin: Benefits and Mechanism of Action against Infections. Biochem. Cell Biol. 2006, 84, 291–296. [Google Scholar] [CrossRef] [PubMed]

- Boman, H.G. Antibacterial Peptides: Basic Facts and Emerging Concepts. J. Intern. Med. 2003, 254, 197–215. [Google Scholar] [CrossRef]

- Kościuczuk, E.M.; Lisowski, P.; Jarczak, J.; Strzałkowska, N.; Jóźwik, A.; Horbańczuk, J.; Krzyżewski, J.; Zwierzchowski, L.; Bagnicka, E. Cathelicidins: Family of Antimicrobial Peptides. A Review. Mol. Biol. Rep. 2012, 39, 10957–10970. [Google Scholar] [CrossRef]

- Infante, V.V.; Miranda-Olvera, A.D.; De Leon-Rodriguez, L.M.; Anaya-Velazquez, F.; Rodriguez, M.C.; Avila, E.E. Effect of the Antimicrobial Peptide Tritrpticin on the In Vitro Viability and Growth of Trichomonas Vaginalis. Curr. Microbiol. 2011, 62, 301–306. [Google Scholar] [CrossRef]

- Batista Araujo, J.; Sastre de Souza, G.; Lorenzon, E.N. Indolicidin Revisited: Biological Activity, Potential Applications and Perspectives of an Antimicrobial Peptide Not yet Fully Explored. World J. Microbiol. Biotechnol. 2022, 38, 39. [Google Scholar] [CrossRef]

- Wang, G. (Ed.) Antimicrobial Peptides: Discovery, Design and Novel Therapeutic Strategies; Advances in molecular and cellular microbiology; CABI: Wallingford, UK; Cambridge, MA, USA, 2010; ISBN 978-1-84593-657-0. [Google Scholar]

- Yang, S.-T.; Yub Shin, S.; Kim, Y.-C.; Kim, Y.; Hahm, K.-S.; Kim, J.I. Conformation-Dependent Antibiotic Activity of Tritrpticin, a Cathelicidin-Derived Antimicrobial Peptide. Biochem. Biophys. Res. Commun. 2002, 296, 1044–1050. [Google Scholar] [CrossRef]

- Pérez-Peinado, C.; Dias, S.A.; Domingues, M.M.; Benfield, A.H.; Freire, J.M.; Rádis-Baptista, G.; Gaspar, D.; Castanho, M.A.R.B.; Craik, D.J.; Henriques, S.T.; et al. Mechanisms of Bacterial Membrane Permeabilization by Crotalicidin (Ctn) and Its Fragment Ctn(15–34), Antimicrobial Peptides from Rattlesnake Venom. J. Biol. Chem. 2018, 293, 1536–1549. [Google Scholar] [CrossRef] [PubMed]

- Bandeira, I.C.J.; Bandeira-Lima, D.; Mello, C.P.; Pereira, T.P.; De Menezes, R.R.P.P.B.; Sampaio, T.L.; Falcão, C.B.; Rádis-Baptista, G.; Martins, A.M.C. Antichagasic Effect of Crotalicidin, a Cathelicidin-like Vipericidin, Found in Crotalus durissus terrificus Rattlesnake’s Venom Gland. Parasitology 2018, 145, 1059–1064. [Google Scholar] [CrossRef] [PubMed]

- Price, R.L.; Bugeon, L.; Mostowy, S.; Makendi, C.; Wren, B.W.; Williams, H.D.; Willcocks, S.J. In Vitro and in Vivo Properties of the Bovine Antimicrobial Peptide, Bactenecin 5. PLoS ONE 2019, 14, e0210508. [Google Scholar] [CrossRef] [PubMed]

- Ho, Y.-H.; Shah, P.; Chen, Y.-W.; Chen, C.-S. Systematic Analysis of Intracellular-Targeting Antimicrobial Peptides, Bactenecin 7, Hybrid of Pleurocidin and Dermaseptin, Proline–Arginine-Rich Peptide, and Lactoferricin B, by Using Escherichia coli Proteome Microarrays. Mol. Cell. Proteom. 2016, 15, 1837–1847. [Google Scholar] [CrossRef] [PubMed]

- Tong, Z.; Ni, L.; Ling, J. Antibacterial Peptide Nisin: A Potential Role in the Inhibition of Oral Pathogenic Bacteria. Peptides 2014, 60, 32–40. [Google Scholar] [CrossRef] [PubMed]

- Talapko, J.; Meštrović, T.; Juzbašić, M.; Tomas, M.; Erić, S.; Horvat Aleksijević, L.; Bekić, S.; Schwarz, D.; Matić, S.; Neuberg, M.; et al. Antimicrobial Peptides—Mechanisms of Action, Antimicrobial Effects and Clinical Applications. Antibiotics 2022, 11, 1417. [Google Scholar] [CrossRef]

- Zhang, Q.-Y.; Yan, Z.-B.; Meng, Y.-M.; Hong, X.-Y.; Shao, G.; Ma, J.-J.; Cheng, X.-R.; Liu, J.; Kang, J.; Fu, C.-Y. Antimicrobial Peptides: Mechanism of Action, Activity and Clinical Potential. Mil. Med. Res. 2021, 8, 48. [Google Scholar] [CrossRef]

- Choi, K.-Y.; Chow, L.N.Y.; Mookherjee, N. Cationic Host Defence Peptides: Multifaceted Role in Immune Modulation and Inflammation. J. Innate Immun. 2012, 4, 361–370. [Google Scholar] [CrossRef]

- Pollini, M.; Paladini, F. Bioinspired Materials for Wound Healing Application: The Potential of Silk Fibroin. Materials 2020, 13, 3361. [Google Scholar] [CrossRef]

- Manesa, K.C.; Kebede, T.G.; Dube, S.; Nindi, M.M. Profiling of Silk Sericin from Cocoons of Three Southern African Wild Silk Moths with a Focus on Their Antimicrobial and Antioxidant Properties. Materials 2020, 13, 5706. [Google Scholar] [CrossRef]

- Ahamad, S. Extraction and Evaluation of Antimicrobial Potential of Antheraea Mylitta Silk Sericin. Int. Jouinal Recent Sci. Res. 2018, 9, 23019–23022. [Google Scholar]

- Tao, G.; Cai, R.; Wang, Y.; Zuo, H.; He, H. Fabrication of Antibacterial Sericin Based Hydrogel as an Injectable and Mouldable Wound Dressing. Mater. Sci. Eng. C 2021, 119, 111597. [Google Scholar] [CrossRef] [PubMed]

- Xue, R.; Liu, Y.; Zhang, Q.; Liang, C.; Qin, H.; Liu, P.; Wang, K.; Zhang, X.; Chen, L.; Wei, Y. Shape Changes and Interaction Mechanism of Escherichia coli Cells Treated with Sericin and Use of a Sericin-Based Hydrogel for Wound Healing. Appl. Environ. Microbiol. 2016, 82, 4663–4672. [Google Scholar] [CrossRef] [PubMed]

- Das, G.; Seo, S.; Yang, I.-J.; Nguyen, L.T.H.; Shin, H.-S.; Patra, J.K. Synthesis of Biogenic Gold Nanoparticles by Using Sericin Protein from Bombyx mori Silk Cocoon and Investigation of Its Wound Healing, Antioxidant, and Antibacterial Potentials. Int. J. Nanomed. 2023, 18, 17–34. [Google Scholar] [CrossRef] [PubMed]

- Ghalei, S.; Handa, H. A Review on Antibacterial Silk Fibroin-Based Biomaterials: Current State and Prospects. Mater. Today Chem. 2022, 23, 100673. [Google Scholar] [CrossRef]

- Peng, J.; Wu, Z.; Liu, W.; Long, H.; Zhu, G.; Guo, G.; Wu, J. Antimicrobial Functional Divergence of the Cecropin Antibacterial Peptide Gene Family in Musca Domestica. Parasit. Vectors 2019, 12, 537. [Google Scholar] [CrossRef]

- Jiang, R.; Zhang, P.; Wu, X.; Wang, Y.; Rehman, T.; Yao, X.; Luo, Y.; Yang, Z. Expression of Antimicrobial Peptide Cecropin P1 in Saccharomyces cerevisiae and Its Antibacterial and Antiviral Activity in Vitro. Electron. J. Biotechnol. 2021, 50, 16–22. [Google Scholar] [CrossRef]

- Wang, M.; Lin, J.; Sun, Q.; Zheng, K.; Ma, Y.; Wang, J. Design, Expression, and Characterization of a Novel Cecropin A-Derived Peptide with High Antibacterial Activity. Appl. Microbiol. Biotechnol. 2019, 103, 1765–1775. [Google Scholar] [CrossRef]

- Maloy, W.L.; Kari, U.P. Structure-Activity Studies on Magainins and Other Host Defense Peptides. Biopolymers 1995, 37, 105–122. [Google Scholar] [CrossRef]

- Kim, M.; Kang, N.; Ko, S.; Park, J.; Park, E.; Shin, D.; Kim, S.; Lee, S.; Lee, J.; Lee, S.; et al. Antibacterial and Antibiofilm Activity and Mode of Action of Magainin 2 against Drug-Resistant Acinetobacter Baumannii. Int. J. Mol. Sci. 2018, 19, 3041. [Google Scholar] [CrossRef]

- Belmadani, A.; Semlali, A.; Rouabhia, M. Dermaseptin-S1 Decreases Candida albicans Growth, Biofilm Formation and the Expression of Hyphal Wall Protein 1 and Aspartic Protease Genes. J. Appl. Microbiol. 2018, 125, 72–83. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Chen, D.; Wang, L.; Lin, C.; Ma, C.; Xi, X.; Chen, T.; Shaw, C.; Zhou, M. Dermaseptin-PH: A Novel Peptide with Antimicrobial and Anticancer Activities from the Skin Secretion of the South American Orange-Legged Leaf Frog, Pithecopus (Phyllomedusa) hypochondrialis. Molecules 2017, 22, 1805. [Google Scholar] [CrossRef] [PubMed]

- Bartels, E.J.H.; Dekker, D.; Amiche, M. Dermaseptins, Multifunctional Antimicrobial Peptides: A Review of Their Pharmacology, Effectivity, Mechanism of Action, and Possible Future Directions. Front. Pharmacol. 2019, 10, 1421. [Google Scholar] [CrossRef] [PubMed]

- Simmaco, M.; Kreil, G.; Barra, D. Bombinins, Antimicrobial Peptides from Bombina Species. Biochim. Biophys. Acta (BBA)-Biomembr. 2009, 1788, 1551–1555. [Google Scholar] [CrossRef]

- Coccia, C.; Rinaldi, A.C.; Luca, V.; Barra, D.; Bozzi, A.; Di Giulio, A.; Veerman, E.C.I.; Mangoni, M.L. Membrane Interaction and Antibacterial Properties of Two Mildly Cationic Peptide Diastereomers, Bombinins H2 and H4, Isolated from Bombina Skin. Eur. Biophys. J. 2011, 40, 577–588. [Google Scholar] [CrossRef]

- Mangoni, M.L.; Grovale, N.; Giorgi, A.; Mignogna, G.; Simmaco, M.; Barra, D. Structure-Function Relationships in Bombinins H, Antimicrobial Peptides from Bombina Skin Secretions☆. Peptides 2000, 21, 1673–1679. [Google Scholar] [CrossRef]

- Lipscomb, T.H.; Middleton, E.R. Towards Finding the Antimicrobial Mechanism of Action of Bombina Maxima’s Maximin 3, Using GROMACS. Ph.D. Thesis, University of New York, New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Manzo, G.; Ferguson, P.M.; Hind, C.K.; Clifford, M.; Gustilo, V.B.; Ali, H.; Bansal, S.S.; Bui, T.T.; Drake, A.F.; Atkinson, R.A.; et al. Temporin L and Aurein 2.5 Have Identical Conformations but Subtly Distinct Membrane and Antibacterial Activities. Sci. Rep. 2019, 9, 10934. [Google Scholar] [CrossRef]

- Ramezanzadeh, M.; Saeedi, N.; Mesbahfar, E.; Farrokh, P.; Salimi, F.; Rezaei, A. Design and Characterization of New Antimicrobial Peptides Derived from Aurein 1.2 with Enhanced Antibacterial Activity. Biochimie 2021, 181, 42–51. [Google Scholar] [CrossRef]

- Chen, X.; Niyonsaba, F.; Ushio, H.; Okuda, D.; Nagaoka, I.; Ikeda, S.; Okumura, K.; Ogawa, H. Synergistic Effect of Antibacterial Agents Human β-Defensins, Cathelicidin LL-37 and Lysozyme against Staphylococcus aureus and Escherichia coli. J. Dermatol. Sci. 2005, 40, 123–132. [Google Scholar] [CrossRef]

- Ridyard, K.E.; Overhage, J. The Potential of Human Peptide LL-37 as an Antimicrobial and Anti-Biofilm Agent. Antibiotics 2021, 10, 650. [Google Scholar] [CrossRef]

- Noore, J.; Noore, A.; Li, B. Cationic Antimicrobial Peptide LL-37 Is Effective against Both Extra- and Intracellular Staphylococcus aureus. Antimicrob. Agents Chemother. 2013, 57, 1283–1290. [Google Scholar] [CrossRef] [PubMed]

- Oppenheim, J.J. Roles of Antimicrobial Peptides Such as Defensins in Innate and Adaptive Immunity. Ann. Rheum. Dis. 2003, 62, ii17–ii21. [Google Scholar] [CrossRef] [PubMed]

- Dhople, V.; Krukemeyer, A.; Ramamoorthy, A. The Human Beta-Defensin-3, an Antibacterial Peptide with Multiple Biological Functions. Biochim. Biophys. Acta (BBA)-Biomembr. 2006, 1758, 1499–1512. [Google Scholar] [CrossRef] [PubMed]

- Inthanachai, T.; Thammahong, A.; Edwards, S.W.; Virakul, S.; Kiatsurayanon, C.; Chiewchengchol, D. The Inhibitory Effect of Human Beta-Defensin-3 on Candida glabrata Isolated from Patients with Candidiasis. Immunol. Investig. 2021, 50, 80–91. [Google Scholar] [CrossRef] [PubMed]

- Pazgier, M.; Hoover, D.M.; Yang, D.; Lu, W.; Lubkowski, J. Human β-Defensins. Cell. Mol. Life Sci. CMLS 2006, 63, 1294–1313. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y.; Wang, Y.; Rao, N.; Li, J.; Li, X.; Fang, T.; Zhao, Y.; Ge, L. Activation and Biological Properties of Human β Defensin 4 in Stem Cells Derived from Human Exfoliated Deciduous Teeth. Front. Physiol. 2019, 10, 1304. [Google Scholar] [CrossRef]

- Tran, D.; Tran, P.A.; Tang, Y.-Q.; Yuan, J.; Cole, T.; Selsted, M.E. Homodimeric θ-Defensins from Rhesus MacaqueLeukocytes. J. Biol. Chem. 2002, 277, 3079–3084. [Google Scholar] [CrossRef]

- Fázio, M.A.; Oliveira, V.X.; Bulet, P.; Miranda, M.T.M.; Daffre, S.; Miranda, A. Structure-Activity Relationship Studies of Gomesin: Importance of the Disulfide Bridges for Conformation, Bioactivities, and Serum Stability. Biopolymers 2006, 84, 205–218. [Google Scholar] [CrossRef]

- Moraes, L.G.M.; Fázio, M.A.; Vieira, R.F.F.; Nakaie, C.R.; Miranda, M.T.M.; Schreier, S.; Daffre, S.; Miranda, A. Conformational and Functional Studies of Gomesin Analogues by CD, EPR and Fluorescence Spectroscopies. Biochim. Biophys. Acta (BBA)-Biomembr. 2007, 1768, 52–58. [Google Scholar] [CrossRef]

- Xiao, B.; Liao, X.; Wang, H.; He, J.; Li, C. BigPEN, an Antimicrobial Peptide of Penaeidin Family from Shrimp Litopenaeus vannamei with Membrane Permeable and DNA Binding Activity. Fish Shellfish Immunol. Rep. 2021, 2, 100034. [Google Scholar] [CrossRef]

- Cuthbertson, B.J.; Deterding, L.J.; Williams, J.G.; Tomer, K.B.; Etienne, K.; Blackshear, P.J.; Büllesbach, E.E.; Gross, P.S. Diversity in Penaeidin Antimicrobial Peptide Form and Function. Dev. Comp. Immunol. 2008, 32, 167–181. [Google Scholar] [CrossRef] [PubMed]

- Leśnierowski, G.; Yang, T. Lysozyme and Its Modified Forms: A Critical Appraisal of Selected Properties and Potential. Trends Food Sci. Technol. 2021, 107, 333–342. [Google Scholar] [CrossRef]

- Branen, J.K.; Davidson, P.M. Enhancement of Nisin, Lysozyme, and Monolaurin Antimicrobial Activities by Ethylenediaminetetraacetic Acid and Lactoferrin. Int. J. Food Microbiol. 2004, 90, 63–74. [Google Scholar] [CrossRef] [PubMed]

- Masschalck, B.; Michiels, C.W. Antimicrobial Properties of Lysozyme in Relation to Foodborne Vegetative Bacteria. Crit. Rev. Microbiol. 2003, 29, 191–214. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; So, L.-Y.; Chen, F.; Liang, J.; Chow, H.-Y.; Wong, K.-Y.; Wan, S.; Jiang, T.; Yu, R. Influences of Disulfide Connectivity on Structure and Antimicrobial Activity of Tachyplesin I. J. Pept. Sci. 2018, 24, e3087. [Google Scholar] [CrossRef] [PubMed]

- Tam, J.P.; Lu, Y.-A.; Yang, J.-L. Marked Increase in Membranolytic Selectivity of Novel Cyclic Tachyplesins Constrained with an Antiparallel Two-β Strand Cystine Knot Framework. Biochem. Biophys. Res. Commun. 2000, 267, 783–790. [Google Scholar] [CrossRef] [PubMed]

- Powers, J.-P.S.; Rozek, A.; Hancock, R.E.W. Structure–Activity Relationships for the β-Hairpin Cationic Antimicrobial Peptide Polyphemusin I. Biochim. Biophys. Acta (BBA)-Proteins Proteom. 2004, 1698, 239–250. [Google Scholar] [CrossRef]

- Zhang, L.; Scott, M.G.; Yan, H.; Mayer, L.D.; Hancock, R.E.W. Interaction of Polyphemusin I and Structural Analogs with Bacterial Membranes, Lipopolysaccharide, and Lipid Monolayers. Biochemistry 2000, 39, 14504–14514. [Google Scholar] [CrossRef]

- Fehlbaum, P.; Bulet, P.; Chernysh, S.; Briand, J.P.; Roussel, J.P.; Letellier, L.; Hetru, C.; Hoffmann, J.A. Structure-Activity Analysis of Thanatin, a 21-Residue Inducible Insect Defense Peptide with Sequence Homology to Frog Skin Antimicrobial Peptides. Proc. Natl. Acad. Sci. USA 1996, 93, 1221–1225. [Google Scholar] [CrossRef]

- Jenssen, H.; Hancock, R. Antimicrobial Properties of Lactoferrin. Biochimie 2009, 91, 19–29. [Google Scholar] [CrossRef]

- Tomita, M.; Bellamy, W.; Takase, M.; Yamauchi, K.; Wakabayashi, H.; Kawase, K. Potent Antibacterial Peptides Generated by Pepsin Digestion of Bovine Lactoferrin. J. Dairy Sci. 1991, 74, 4137–4142. [Google Scholar] [CrossRef] [PubMed]

- Friedrich, C.L.; Moyles, D.; Beveridge, T.J.; Hancock, R.E.W. Antibacterial Action of Structurally Diverse Cationic Peptides on Gram-Positive Bacteria. Antimicrob. Agents Chemother. 2000, 44, 2086–2092. [Google Scholar] [CrossRef] [PubMed]