Color Regeneration from Reflective Color Sensor Using an Artificial Intelligent Technique

Abstract

:1. Introduction

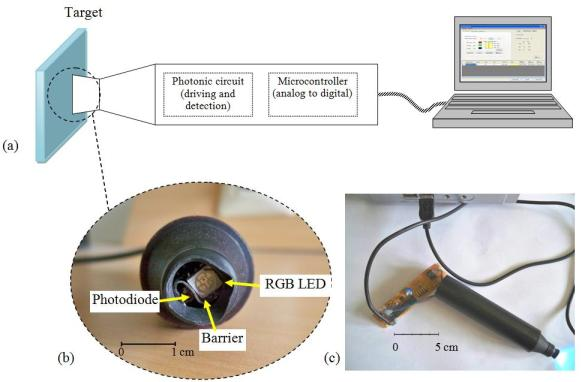

2. Brief Description of the Neural Networks

3. Reflective Color Sensing

4. Results and Discussion

5. Conclusions

Acknowledgments

References

- Endo, T; Yanagida, Y; Hatsuzawa, T. Colorimetric detection of volatile organic compounds using a colloidal crystal-based chemical sensor for environmental applications. Sens. Actuat. B 2007, 125, 589–595. [Google Scholar]

- Naydenova, I; Jallapuram, R; Toal, V; Martin, S. A visual indication of environmental humidity using a colour changing hologram recorded in a self developing photopolymer. Appl. Phys. Lett 2008, 92, 031109. [Google Scholar]

- Wang, XD; Chen, HX; Zhou, TY; Lin, ZJ; Zeng, JB; Xie, ZX; Xi, C; Wong, KY; Chen, GN; Wang, XR. Optical colorimetric sensor strip for direct readout glucose measurement. Biosens. Bioelectron 2009, 24, 3702–3705. [Google Scholar]

- Ricketts, SR; Douglas, P. A simple colorimetric luminescent oxygen sensor using a green LED with Ptoctaethylporphyrin in ethyl cellulose as the oxygen-responsive element. Sens. Actuat. B 2008, 135, 46–51. [Google Scholar]

- Ercag, E; Üzer, A; Apak, A. Selective spectrophotometric determination of TNT using a dicyclohexylamine-based colorimetric sensor. Talanta 2009, 78, 772–780. [Google Scholar]

- O’ Toole, M; Shepherd, R; Wallace, GG; Diamond, D. Inkjet printed LED based pH chemical sensor for gas sensing. Anal. Chim. Acta 2009, 652, 308–314. [Google Scholar]

- Rastegarzadeh, R; Pourreza, N; Saeedi, I. An optical redox chemical sensor for determination of iodide. Talanta 2008, 77, 1032–1036. [Google Scholar]

- Sen, A; Albarella, JD; Carey, JR; Kim, P; McNamara, WB, III. Low-cost colorimetric sensor for the quantitative detection of gaseous hydrogen sulfide. Sens. Actuat. B 2008, 134, 234–237. [Google Scholar]

- Courbat, J; Briand, D; Wöllenstein, J; De Rooij, NF. Colorimetric gas sensors based on optical waveguides made on plastic foil. Procedia Chem 2009, 1, 576–579. [Google Scholar]

- Borecki, M. Intelligent fiber optic sensor for estimating the concentration of a mixture-design and working principle. Sensors 2007, 7, 384–399. [Google Scholar]

- Saracoglu, ÖG. An artificial neural network approach for the prediction of absorption measurements of an evanescent field fiber sensor. Sensors 2008, 8, 1585–1594. [Google Scholar]

- Efendioglu, HS; Yildirim, T; Fidanboylu, K. Prediction of force measurements of a microbend sensor based on an artificial neural network. Sensors 2009, 9, 7167–7176. [Google Scholar]

- Haykin, S. Neural Networks: A Comprehensive Foundation, 2nd ed; Prentice-Hall: Englewood Cliffs, NJ, USA, 1999. [Google Scholar]

- O’ Farrell, M; Lewis, E; Flanagan, C; Lyons, WB; Jackman, N. Design of a system that uses optical-fiber sensors and neural networks to control a large-scale industrial oven by monitoring the food quality online. IEEE Sensor J 2005, 5, 1407–1420. [Google Scholar]

- O’ Farrell, M; Lewis, E; Flanagan, C; Lyons, W; Jackman, N. Comparison of k-NN and neural network methods in the classification of spectral data from an optical fibre-based sensor system used for quality control in the food industry. Sens Actuat B 2005, 111–112, 354–362. [Google Scholar]

- Afromowitz, MA; Van Liew, GS; Heimbach, DM. Clinical evaluation of burn injuries using an optical reflectance technique. IEEE Trans Biomed Eng 1987, BME-34. 114–127. [Google Scholar]

- Laming, JE; Martino, A. PC color recognition using led and software techniques. IEEE Photonic. Technol. Lett 1993, 5, 583–586. [Google Scholar]

- Yang, PK; Chen, JC; Chuang, YH. Improvement on reflective color measurement using a tri-color LED by multi-point calibration. Opt. Commun 2007, 272, 320–324. [Google Scholar]

- Wefky, AM; Espinosa, F; Jiménez, JA; Santiso, E; Rodríguez, JM; Fernández, AJ. Alternative sensor system and MLP neural network for vehicle pedal activity estimation. Sensors 2010, 10, 3798–3814. [Google Scholar]

- Foody, GM; Cutler, ME; McMorrow, J; Pelz, D; Tangki, H; Boyd, DS; Douglas, I. Mapping the biomass of bornean tropical rain forest from remotely sensed data. Global Ecol. Biogeogr 2001, 10, 379–387. [Google Scholar]

- Kiyan, T; Yildirim, T. Breast cancer diagnosis using statistical neural networks. Istanbul Univ.–J. Elect. Elect. Eng 2004, 4, 1149–1153. [Google Scholar]

- Neural Network Toolbox. Available online at http://www.mathworks.com/access/helpdesk/help/toolbox/nnet/ (accessed on June 25, 2010).

| Photodetector readouts (volts) | RGB contents | |||||

|---|---|---|---|---|---|---|

| Surface Color | VR, R-LED | VG, G-LED | VB, B-LED | R | G | B |

| Black | 0.159 | 0.253 | 0.163 | 0 | 0 | 0 |

| (Any) | 0.800 | 1.25 | 1.77 | 135 | 90 | 225 |

| White | 3.67 | 3.66 | 3.66 | 255 | 255 | 255 |

| Training algorithm | Network type (neuron numbers in the layers) | |||

|---|---|---|---|---|

| Input | 1st hidden | 2nd hidden | Output | |

| Gradient descent with momentum and adaptive learning rate backpropagation (GDX) | 3 | 8 | 9 | 3 |

| Bayesian regularization backpropagation (BR) | 3 | 10 | 5 | 3 |

| Levenberg-Marquardt backpropagation (LM) | 3 | 5 | 9 | 3 |

| Resilient backpropagation (RP) | 3 | 5 | 9 | 3 |

| Broyden Fletcher Goldfarb Shanno quasi-Newton backpropagation (BFG) | 3 | 12 | 9 | 3 |

| Algorithm | Maximum absolute error | Un-normalized MSE | Epoch number | Time consumption (s) |

|---|---|---|---|---|

| GDX | 38 | 268 | 75,000 | 416 |

| BR | 30 | 259 | 410 | 13 |

| LM | 33 | 270 | 2,200 | 62 |

| RP | 32 | 232 | 4,000 | 22 |

| BFG | 34 | 265 | 2,200 | 110 |

| No | Inputs (analog voltages) | Outputs (RGB contents) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Real values | BR results | RP results | GDX results | ||||||||||||

| VR | VG | VB | R | G | B | R | G | B | R | G | B | R | G | B | |

| 1 | 0.88 | 1.59 | 0.48 | 90 | 135 | 45 | 91 | 146 | 33 | 102 | 142 | 19 | 98 | 150 | 30 |

| 2 | 2.14 | 1.62 | 0.46 | 180 | 135 | 45 | 190 | 145 | 24 | 182 | 143 | 13 | 184 | 151 | 21 |

| 3 | 0.35 | 0.73 | 0.91 | 45 | 45 | 135 | 42 | 39 | 165 | 48 | 33 | 164 | 40 | 37 | 172 |

| 4 | 1.00 | 0.57 | 0.69 | 135 | 45 | 135 | 144 | 37 | 130 | 144 | 16 | 143 | 138 | 13 | 153 |

| 5 | 3.55 | 0.71 | 0.87 | 225 | 45 | 135 | 248 | 17 | 157 | 240 | 16 | 145 | 243 | 15 | 165 |

| 6 | 1.30 | 0.93 | 0.38 | 135 | 90 | 45 | 147 | 97 | 20 | 135 | 103 | 18 | 131 | 95 | 19 |

| 7 | 1.91 | 3.64 | 0.73 | 135 | 225 | 45 | 110 | 244 | 15 | 104 | 244 | 20 | 97 | 249 | 11 |

| 8 | 0.54 | 1.83 | 1.46 | 45 | 135 | 135 | 18 | 143 | 137 | 22 | 144 | 134 | 33 | 140 | 132 |

| 9 | 0.94 | 3.25 | 1.27 | 45 | 225 | 135 | 54 | 225 | 152 | 30 | 226 | 137 | 66 | 222 | 145 |

| 10 | 0.58 | 0.64 | 0.93 | 135 | 45 | 180 | 126 | 25 | 200 | 133 | 17 | 200 | 123 | 18 | 205 |

| 11 | 0.60 | 1.77 | 0.82 | 45 | 135 | 90 | 29 | 142 | 78 | 31 | 147 | 81 | 46 | 140 | 87 |

| 12 | 0.48 | 1.96 | 2.58 | 45 | 135 | 225 | 20 | 146 | 251 | 29 | 135 | 240 | 21 | 143 | 233 |

| 13 | 1.36 | 1.93 | 0.90 | 135 | 135 | 90 | 123 | 136 | 95 | 137 | 150 | 75 | 130 | 145 | 93 |

| 14 | 3.66 | 1.89 | 0.97 | 225 | 135 | 90 | 251 | 134 | 84 | 242 | 141 | 96 | 255 | 130 | 92 |

| 15 | 1.28 | 1.06 | 1.11 | 135 | 90 | 135 | 145 | 93 | 149 | 147 | 93 | 157 | 137 | 87 | 139 |

| 16 | 3.66 | 1.00 | 1.01 | 225 | 90 | 135 | 253 | 67 | 139 | 252 | 68 | 148 | 253 | 60 | 133 |

| 17 | 1.80 | 3.00 | 1.01 | 135 | 180 | 90 | 154 | 170 | 115 | 149 | 205 | 104 | 135 | 196 | 95 |

| 18 | 0.88 | 2.03 | 1.60 | 90 | 135 | 135 | 88 | 147 | 147 | 100 | 149 | 129 | 107 | 148 | 144 |

| 19 | 1.23 | 3.64 | 1.48 | 90 | 225 | 135 | 76 | 253 | 153 | 92 | 249 | 154 | 91 | 253 | 151 |

| 20 | 0.80 | 1.25 | 1.77 | 135 | 90 | 225 | 134 | 97 | 227 | 139 | 90 | 239 | 147 | 89 | 238 |

| 21 | 0.63 | 1.97 | 2.59 | 90 | 135 | 225 | 98 | 142 | 251 | 89 | 137 | 242 | 93 | 141 | 252 |

| 22 | 2.36 | 1.73 | 1.19 | 180 | 135 | 135 | 182 | 125 | 131 | 196 | 140 | 121 | 177 | 141 | 127 |

| 23 | 1.61 | 2.96 | 1.55 | 135 | 180 | 135 | 141 | 169 | 164 | 137 | 198 | 139 | 131 | 187 | 150 |

| 24 | 1.17 | 1.98 | 2.07 | 135 | 135 | 180 | 137 | 134 | 186 | 133 | 143 | 181 | 146 | 152 | 174 |

| 25 | 1.94 | 1.62 | 1.64 | 180 | 135 | 180 | 179 | 120 | 180 | 182 | 131 | 179 | 167 | 138 | 162 |

| 26 | 3.65 | 1.88 | 1.85 | 225 | 135 | 180 | 251 | 128 | 178 | 254 | 132 | 188 | 254 | 139 | 190 |

| 27 | 2.16 | 2.93 | 1.40 | 180 | 180 | 135 | 170 | 157 | 154 | 174 | 197 | 127 | 150 | 184 | 139 |

| 28 | 1.45 | 3.01 | 2.36 | 135 | 180 | 180 | 143 | 183 | 204 | 133 | 200 | 182 | 140 | 193 | 200 |

| 29 | 1.53 | 3.65 | 2.17 | 135 | 225 | 180 | 123 | 254 | 197 | 123 | 249 | 186 | 118 | 249 | 184 |

| 30 | 3.09 | 3.66 | 2.06 | 180 | 225 | 135 | 199 | 250 | 152 | 205 | 241 | 144 | 200 | 251 | 145 |

| 31 | 1.65 | 1.75 | 2.16 | 180 | 135 | 225 | 183 | 123 | 227 | 175 | 132 | 227 | 180 | 140 | 213 |

| 32 | 2.95 | 1.74 | 2.11 | 225 | 135 | 225 | 226 | 123 | 242 | 243 | 129 | 225 | 232 | 139 | 229 |

| 33 | 1.67 | 3.65 | 3.56 | 135 | 225 | 225 | 162 | 238 | 254 | 143 | 247 | 255 | 154 | 236 | 253 |

| No | Real | BR | RP | LM | BFG | GDX |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | ||||||

| 3 | ||||||

| 4 | ||||||

| 5 | ||||||

| 6 | ||||||

| 7 | ||||||

| 8 | ||||||

| 9 | ||||||

| 10 | ||||||

| 11 | ||||||

| 12 | ||||||

| 13 | ||||||

| 14 | ||||||

| 15 | ||||||

| 16 | ||||||

| 17 | ||||||

| 18 | ||||||

| 19 | ||||||

| 20 | ||||||

| 21 | ||||||

| 22 | ||||||

| 23 | ||||||

| 24 | ||||||

| 25 | ||||||

| 26 | ||||||

| 27 | ||||||

| 28 | ||||||

| 29 | ||||||

| 30 | ||||||

| 31 | ||||||

| 32 | ||||||

| 33 | ||||||

© 2010 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Saracoglu, Ö.G.; Altural, H. Color Regeneration from Reflective Color Sensor Using an Artificial Intelligent Technique. Sensors 2010, 10, 8363-8374. https://doi.org/10.3390/s100908363

Saracoglu ÖG, Altural H. Color Regeneration from Reflective Color Sensor Using an Artificial Intelligent Technique. Sensors. 2010; 10(9):8363-8374. https://doi.org/10.3390/s100908363

Chicago/Turabian StyleSaracoglu, Ömer Galip, and Hayriye Altural. 2010. "Color Regeneration from Reflective Color Sensor Using an Artificial Intelligent Technique" Sensors 10, no. 9: 8363-8374. https://doi.org/10.3390/s100908363