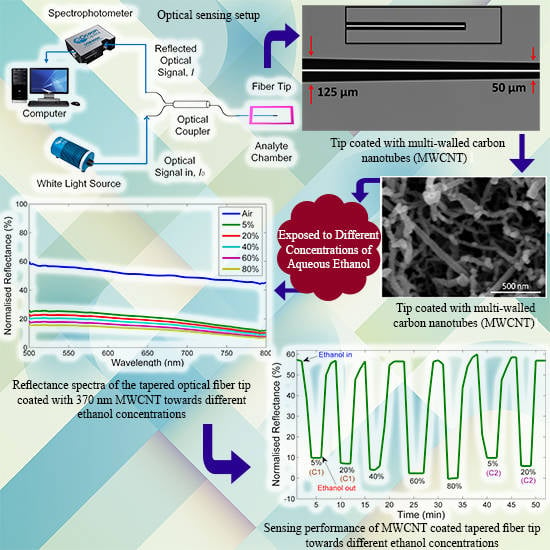

Dynamic Response of Tapered Optical Multimode Fiber Coated with Carbon Nanotubes for Ethanol Sensing Application

Abstract

:1. Introduction

2. Experimental Details

2.1. Tapered Optical Fiber

2.2. Deposition of CNT Nanostructured Thin Films

2.3. Experimental Setup

3. Results and Discussion

3.1. Tapered Optical Fiber Properties

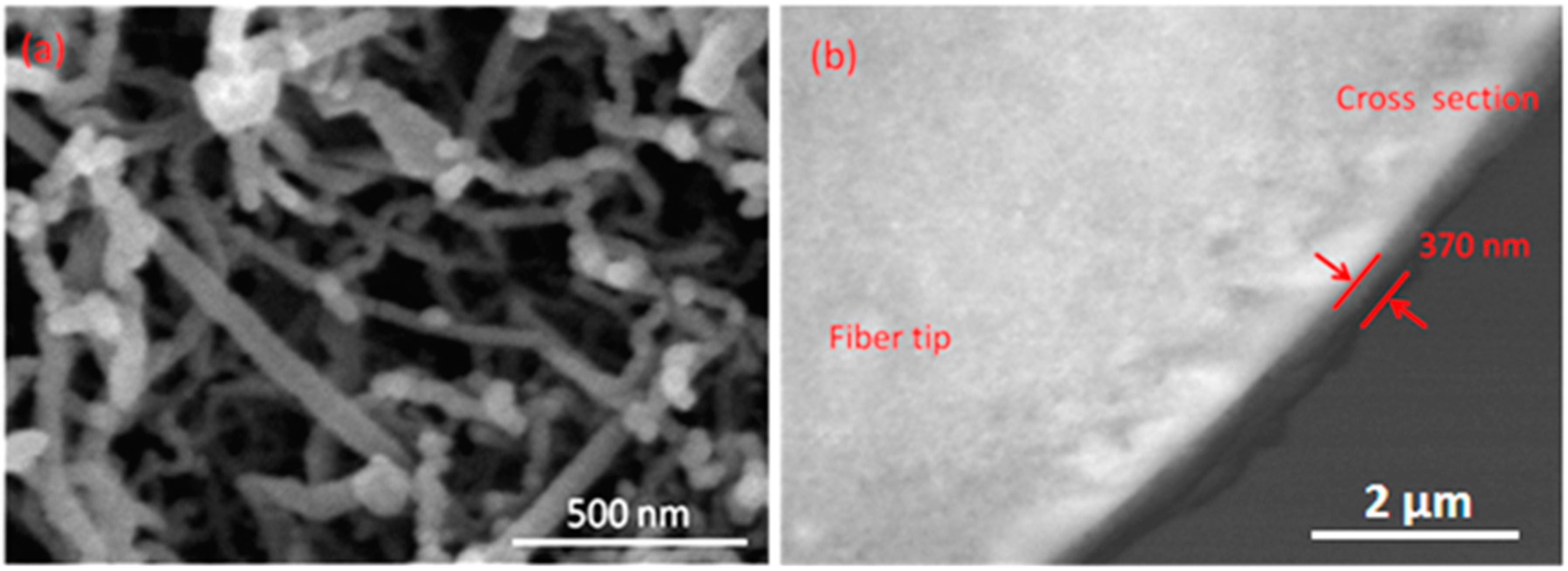

3.2. CNT Film Characterizations

3.3. Optical Reflectance Spectra Performance

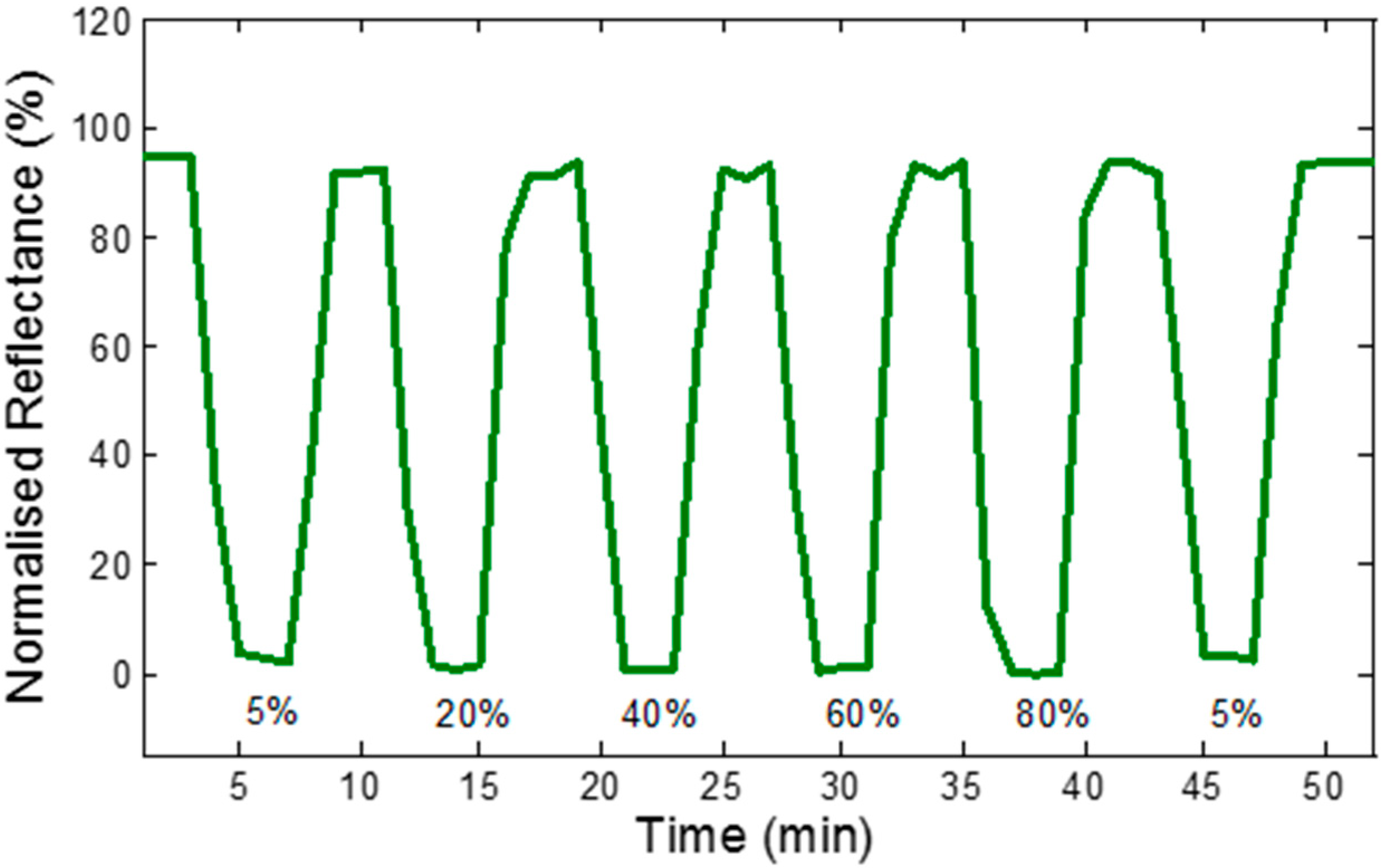

3.4. Ethanol Sensing Response

3.5. Sensitivity and Linearity of the Ethanol Fiber Sensors

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Brahim, S.; Colbern, S.; Gump, R.; Moser, A.; Grigorian, L. Carbon nanotube-based ethanol sensors. Nanotechnology 2009, 20, 1–7. [Google Scholar] [CrossRef]

- Consales, M.; Crescitelli, A.; Penza, M.; Aversa, P.; Veneri, P.D.; Giordano, M.; Cusano, A. SWCNT nano-composite optical sensors for VOC and gas trace detection. Sens. Actuators B Chem. 2009, 138, 351–361. [Google Scholar] [CrossRef]

- Mahdavian, L.; Monajjemi, M.; Mangkorntong, N. Sensor response to alcohol and chemical mechanism of carbon nanotube gas sensors. Fuller. Nanotub. Carbon Nanostruct. 2009, 17, 484–495. [Google Scholar] [CrossRef]

- Moshkalyov, S.; Moreau, A.; Guttiérrez, H.; Cotta, M.; Swart, J. Carbon nanotubes growth by chemical vapor deposition using thin film nickel catalyst. Mater. Sci. Eng. B 2004, 112, 147–153. [Google Scholar] [CrossRef]

- Penza, M.; Cassano, G.; Aversa, P.; Antolini, F.; Cusano, A.; Cutolo, A.; Giordano, M.; Nicolais, L. Alcohol detection using carbon nanotubes acoustic and optical sensors. Appl. Phys. Lett. 2004, 85, 2379–2381. [Google Scholar] [CrossRef]

- Girei, S.; Shabaneh, A.; Arasu, P.; Painam, S.; Yaacob, M. Tapered multimode fiber sensor for ethanol sensing application. In Proceedings of the 2013 IEEE 4th International Conference Photonics (ICP), Malacca, Malaysia, 28–30 October 2013; pp. 275–277.

- Jang, J.; Bae, J. Carbon nanofiber/polypyrrole nanocable as toxic gas sensor. Sens. Actuators B Chem. 2007, 122, 7–13. [Google Scholar] [CrossRef]

- Lin, Y.; Yantasee, W.; Wang, J. Carbon nanotubes (CNTs) for the development of electrochemical biosensors. Front. Biosci. 2005, 10, 582. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Cai, C. Immobilization and characterization of alcohol dehydrogenase on single-walled carbon nanotubes and its application in sensing ethanol. J. Electroanal. Chem. 2007, 602, 103–114. [Google Scholar] [CrossRef]

- Nguyen, L.Q.; Phan, P.Q.; Duong, H.N.; Nguyen, C.D.; Nguyen, L.H. Enhancement of NH3 gas sensitivity at room temperature by carbon nanotube-based sensor coated with Co nanoparticles. Sensors 2013, 13, 1754–1762. [Google Scholar] [CrossRef] [PubMed]

- Slepyan, G.Y.; Shuba, M.; Maksimenko, S.; Lakhtakia, A. Theory of optical scattering by achiral carbon nanotubes and their potential as optical nanoantennas. Phys. Rev. B 2006, 73, 1–11. [Google Scholar] [CrossRef]

- Kashiwagi, K.; Yamashita, S.; Set, S.Y. In-situ monitoring of optical deposition of carbon nanotubes onto fiber end. Opt. Express 2009, 17, 5711–5715. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Hu, S. Carbon nanotube-based electrochemical sensors: Principles and applications in biomedical systems. J. Sens. 2009, 2009, 1–40. [Google Scholar] [CrossRef]

- Zheng, S.; Zhu, Y.; Krishnaswamy, S. Fiber humidity sensors with high sensitivity and selectivity based on interior nanofilm-coated photonic crystal fiber long-period gratings. Sens. Actuators B Chem. 2013, 176, 264–274. [Google Scholar] [CrossRef]

- Ritchie, R.J. Consistent sets of spectrophotometric chlorophyll equations for acetone, methanol and ethanol solvents. Photosynth. Res. 2006, 89, 27–41. [Google Scholar] [CrossRef] [PubMed]

- Sekimoto, S.; Nakagawa, H.; Okazaki, S.; Fukuda, K.; Asakura, S.; Shigemori, T.; Takahashi, S. A fiber-optic evanescent-wave hydrogen gas sensor using palladium-supported tungsten oxide. Sens. Actuators B Chem. 2000, 66, 142–145. [Google Scholar] [CrossRef]

- Guo, S.; Albin, S. Transmission property and evanescent wave absorption of cladded multimode fiber tapers. Opt. Express 2003, 11, 215–223. [Google Scholar] [CrossRef] [PubMed]

- Kieu, K.Q.; Mansuripur, M. Biconical fiber taper sensors. IEEE Photon. Technol. Lett. 2006, 18, 2239–2241. [Google Scholar] [CrossRef]

- Shabaneh, A.; Girei, S.; Arasu, P.; Rahman, W.; Bakar, A.; Sadek, A.; Lim, H.N.; Huang, N.M.; Yaacob, M.H. Reflectance response of tapered optical fiber coated with graphene oxide nanostructured thin film for aqueous ethanol sensing. Opt. Commun. 2014, 331, 320–324. [Google Scholar] [CrossRef]

- Shabaneh, A.; Girei, S.; Arasu, P.; Rashid, S.; Yunusa, Z.; Mahdi, M.; Paiman, S.; Ahmad, M.Z.; Yaacob, M.H. Reflectance Response of Optical Fiber Coated with Carbon Nanotubes for Aqueous Ethanol Sensing. IEEE Photon. J. 2014, 6. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, X.; Na, N.; Liu, Z.; Han, B.; An, G. Synthesis of ZrO2-carbon nanotube composites and their application as chemiluminescent sensor material for ethanol. J. Phys. Chem. B 2006, 110, 13410–13414. [Google Scholar] [CrossRef] [PubMed]

- Valentini, L.; Cantalini, C.; Armentano, I.; Kenny, J.; Lozzi, L.; Santucci, S. Highly sensitive and selective sensors based on carbon nanotubes thin films for molecular detection. Diam. Relat. Mater. 2004, 13, 1301–1305. [Google Scholar] [CrossRef]

- Wei, B.Y.; Hsu, M.C.; Su, P.G.; Lin, H.M.; Wu, R.J.; Lai, H.J. A novel SnO2 gas sensor doped with carbon nanotubes operating at room temperature. Sens. Actuators B Chem. 2004, 101, 81–89. [Google Scholar] [CrossRef]

- Leung, A.; Shankar, P.M.; Mutharasan, R. A review of fiber-optic biosensors. Sens. Actuators B Chem. 2007, 125, 688–703. [Google Scholar] [CrossRef]

- Wu, R.J.; Huang, Y.C.; Yu, M.R.; Lin, T.H.; Hung, S.L. Application of m-CNTs/NaClO4/Ppy to a fast response, room working temperature ethanol sensor. Sens. Actuators B Chem. 2008, 134, 213–218. [Google Scholar] [CrossRef]

- Zibaii, M.; Latifi, H.; Karami, M.; Gholami, M.; Hosseini, S.; Ghezelayagh, M. Non-adiabatic tapered optical fiber sensor for measuring the interaction between α-amino acids in aqueous carbohydrate solution. Meas. Sci. Technol. 2010, 21, 1–12. [Google Scholar] [CrossRef]

- DiLeo, R.A.; Landi, B.J.; Raffaelle, R.P. Purity assessment of multiwalled carbon nanotubes by Raman spectroscopy. J. Appl. Phys. 2007, 101, 064307:1–064307:5. [Google Scholar] [CrossRef]

- Bokobza, L.; Zhang, J. Raman spectroscopic characterization of multiwall carbon nanotubes and of composites. Express Polym. Lett. 2012, 6, 601–608. [Google Scholar] [CrossRef]

- Xiong, F.; Zhu, W.; Lin, H.; Meng, X. Fiber-optic sensor based on evanescent wave absorbance around 2.7 μm for determining water content in polar organic solvents. Appl. Phys. B 2014, 115, 129–135. [Google Scholar] [CrossRef]

- Arasu, P.; Noor, A.; Shabaneh, A.; Girei, S.; Mahdi, M.; Lim, H.; Rashid, H.A.; Yaacob, M.H. Absorbance properties of gold coated fiber Bragg grating sensor for aqueous ethanol. J. Eur. Opt. Soc-Rapid 2014, 9. [Google Scholar] [CrossRef]

- Shabaneh, A.; Arasu, P.; Girei, S.; Paiman, S.; Mahdi, M.; Huang, N.M.; Yaacob, M. Reflectance response of optical fiber sensor coated with graphene oxide towards ethanol. In Proceedings of the 2013 IEEE 4th International Conference on Photonics (ICP), Malacca, Malaysia, 28–30 October 2013; pp. 272–274.

- Cao, W.; Duan, Y. Optical fiber-based evanescent ammonia sensor. Sens. Actuators B Chem. 2005, 110, 252–259. [Google Scholar] [CrossRef]

- Someya, T.; Small, J.; Kim, P.; Nuckolls, C.; Yardley, J.T. Alcohol vapor sensors based on single-walled carbon nanotube field effect transistors. Nano Lett. 2003, 3, 877–881. [Google Scholar] [CrossRef]

- Ou, J.; Yaacob, M.; Campbell, J.; Kalantar-Zadeh, K.; Wlodarski, W. H2 sensing performance of optical fiber coated with nano-platelet WO3 film. Sens. Actuators B Chem. 2012, 5, 1204–1207. [Google Scholar]

- Ouyang, M.; Li, W.J. Reusable CNTs-based chemical sensors. In Proceedings of the 2009 IEEE International Conference on Nano/Molecular Medicine and Engineering (NANOMED), Tainan, Taiwan, 18–21 October 2009; pp. 188–192.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shabaneh, A.; Girei, S.; Arasu, P.; Mahdi, M.; Rashid, S.; Paiman, S.; Yaacob, M. Dynamic Response of Tapered Optical Multimode Fiber Coated with Carbon Nanotubes for Ethanol Sensing Application. Sensors 2015, 15, 10452-10464. https://doi.org/10.3390/s150510452

Shabaneh A, Girei S, Arasu P, Mahdi M, Rashid S, Paiman S, Yaacob M. Dynamic Response of Tapered Optical Multimode Fiber Coated with Carbon Nanotubes for Ethanol Sensing Application. Sensors. 2015; 15(5):10452-10464. https://doi.org/10.3390/s150510452

Chicago/Turabian StyleShabaneh, Arafat, Saad Girei, Punitha Arasu, Mohd Mahdi, Suraya Rashid, Suriati Paiman, and Mohd Yaacob. 2015. "Dynamic Response of Tapered Optical Multimode Fiber Coated with Carbon Nanotubes for Ethanol Sensing Application" Sensors 15, no. 5: 10452-10464. https://doi.org/10.3390/s150510452