Effects of Operating Temperature on Droplet Casting of Flexible Polymer/Multi-Walled Carbon Nanotube Composite Gas Sensors

Abstract

:1. Introduction

2. Materials

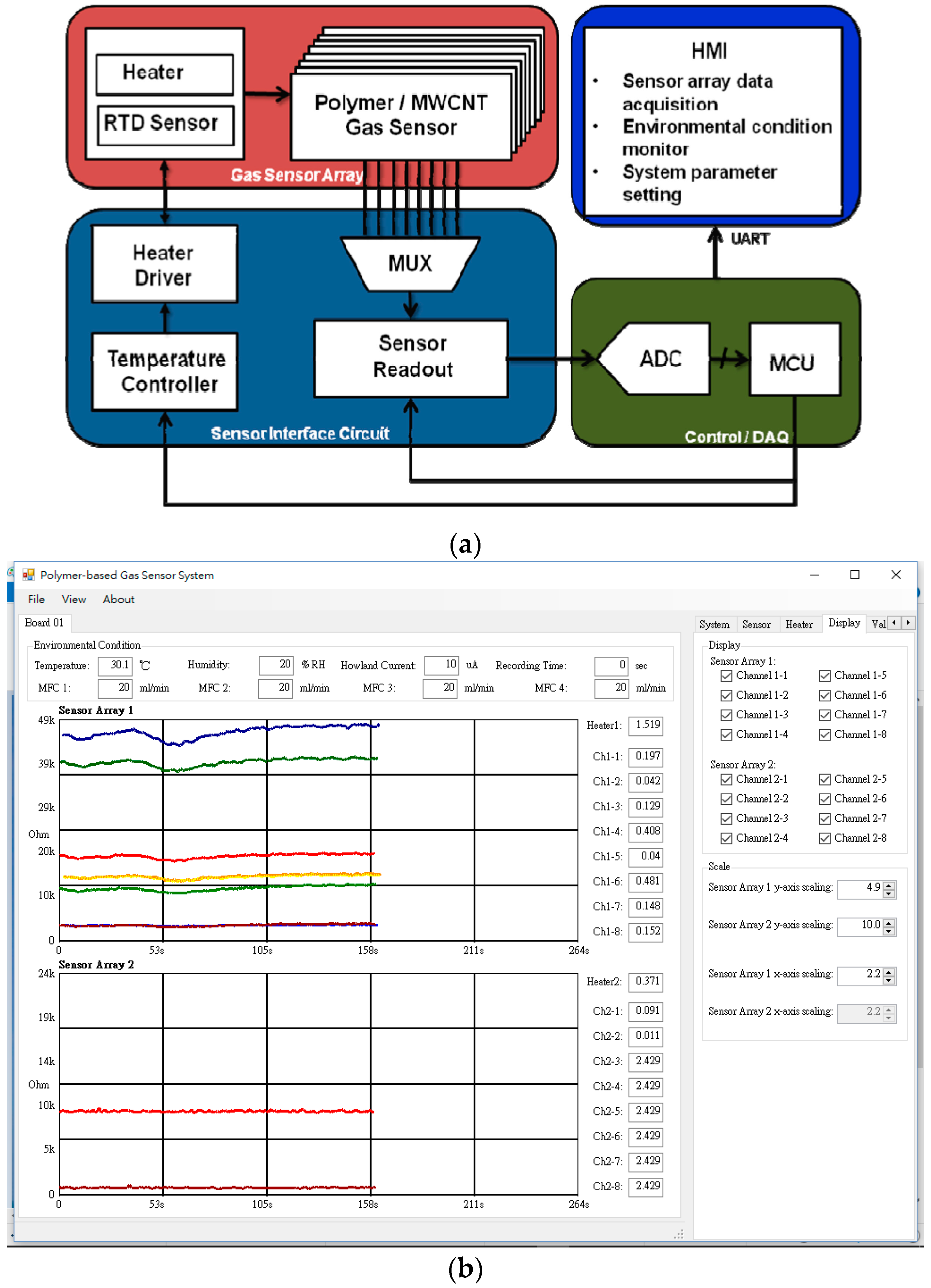

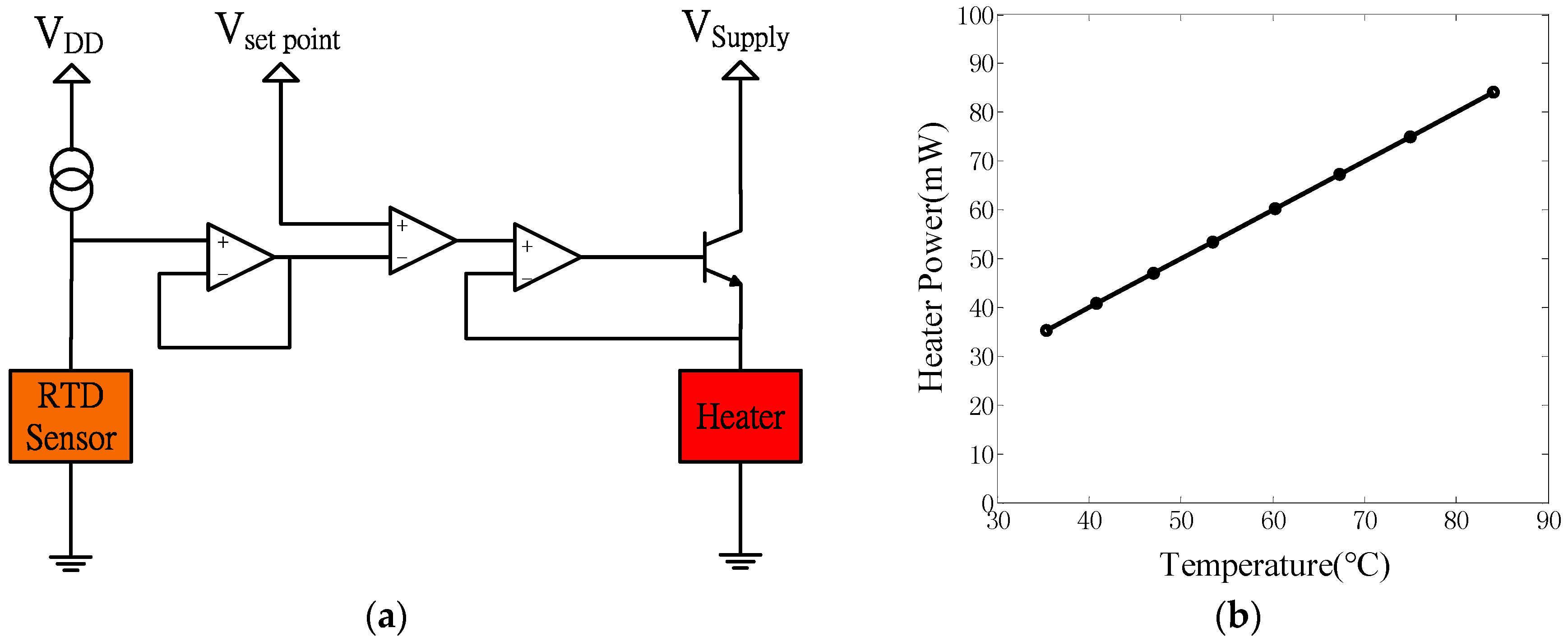

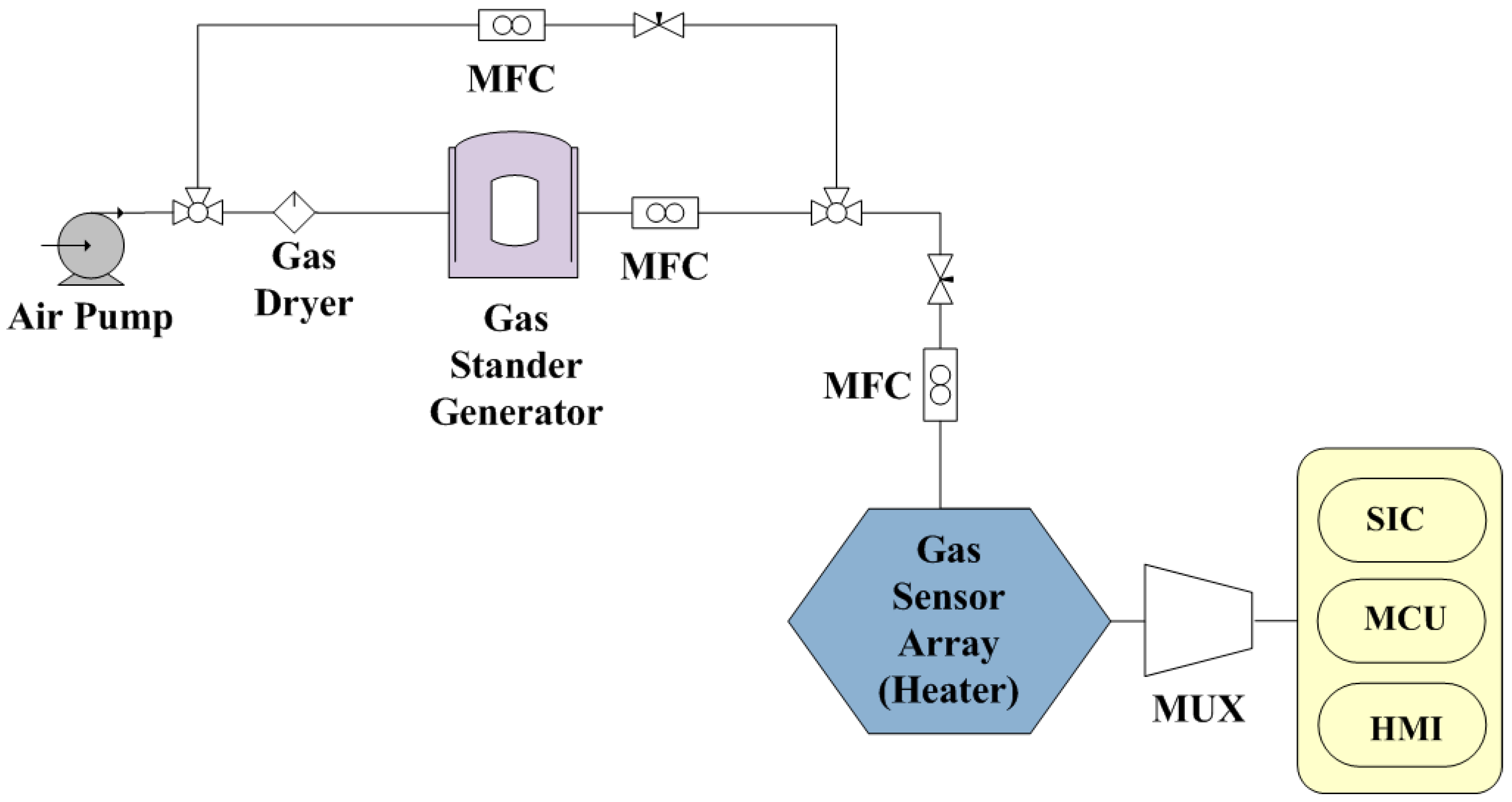

3. Design and Fabrication

4. Experiments and Discussion

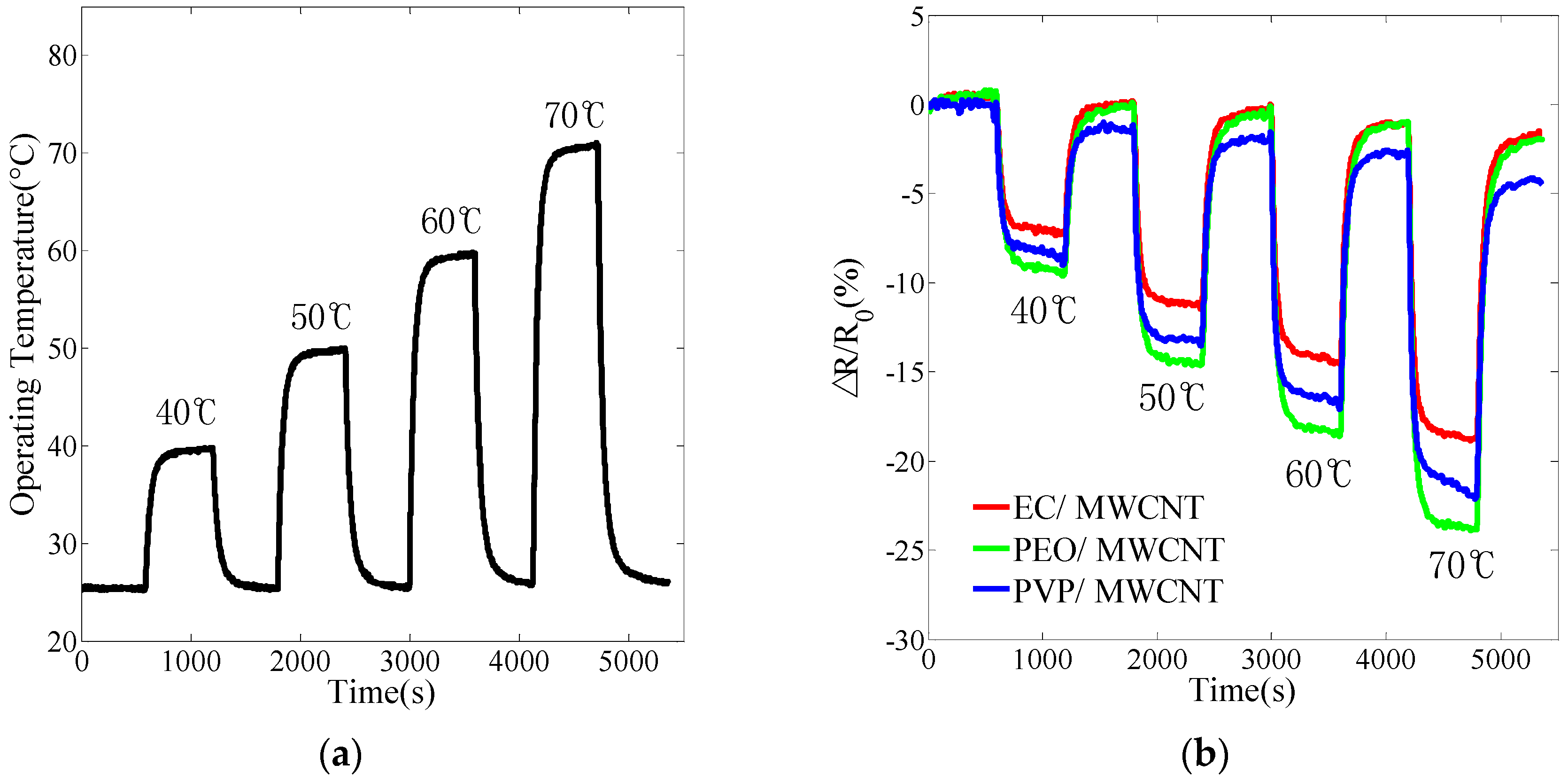

4.1. Transient Response of the Polymer/MWCNT Composite Film

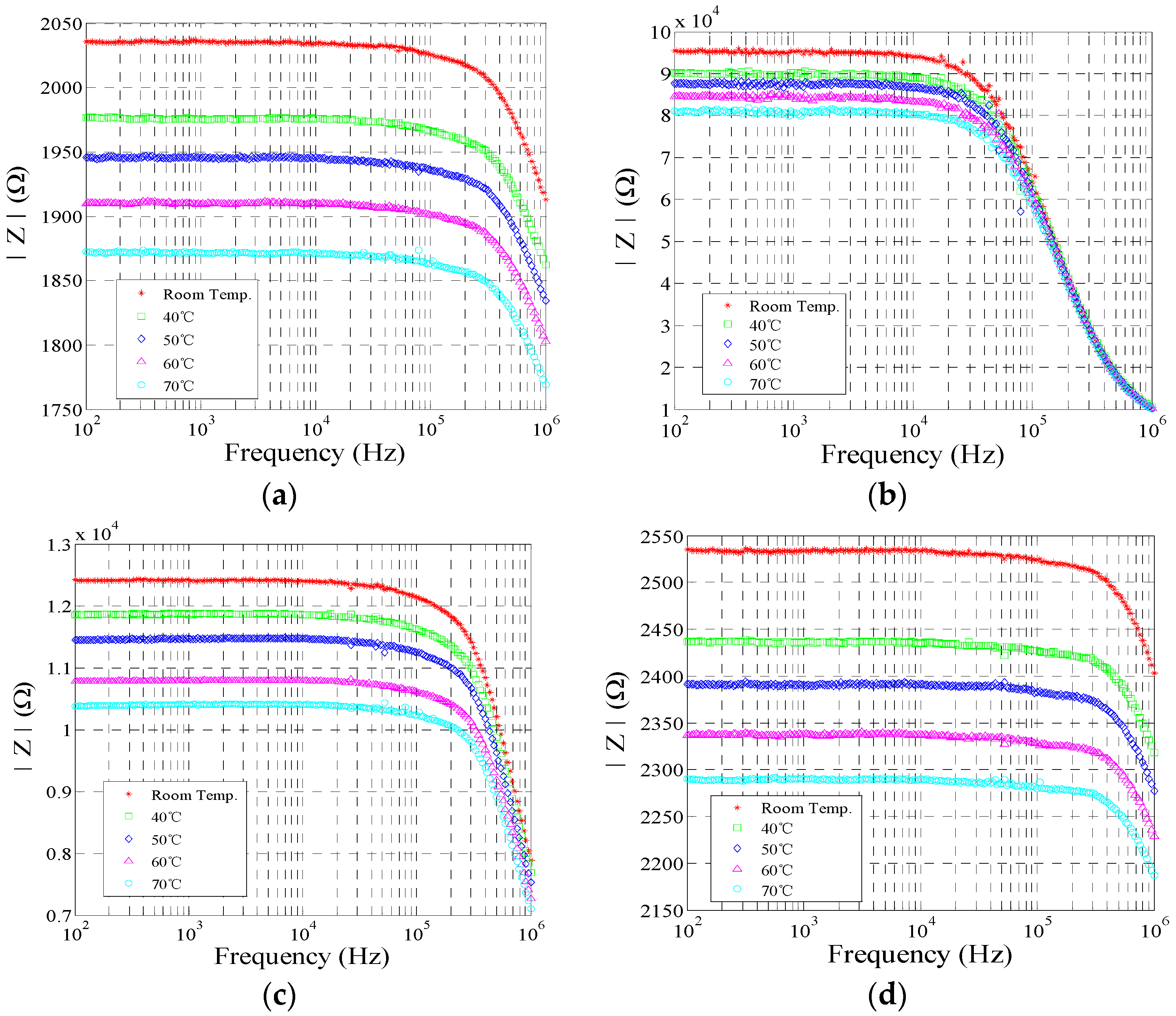

4.2. Impedance Spectrum Property

4.3. The Response of the Sensor Array

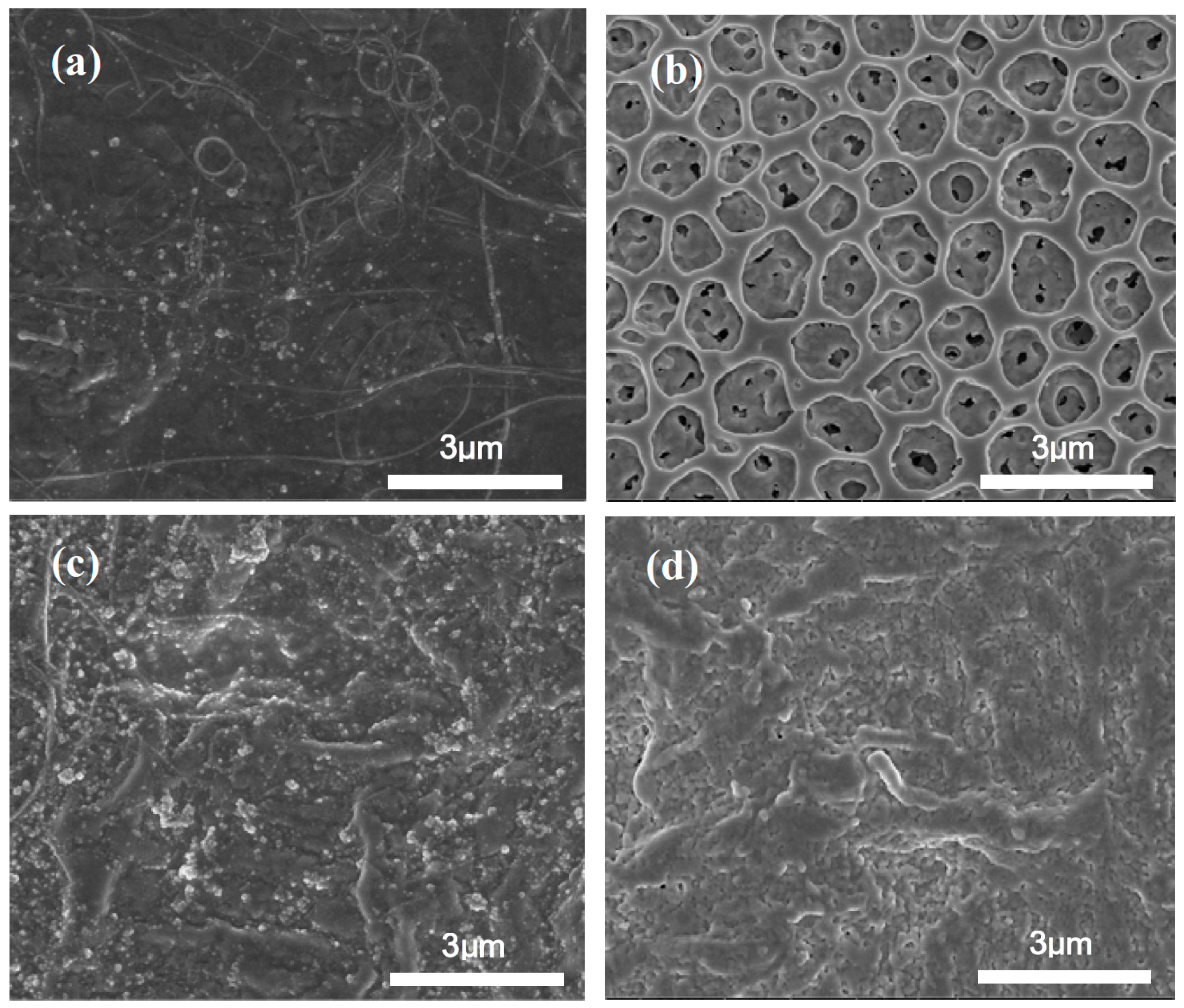

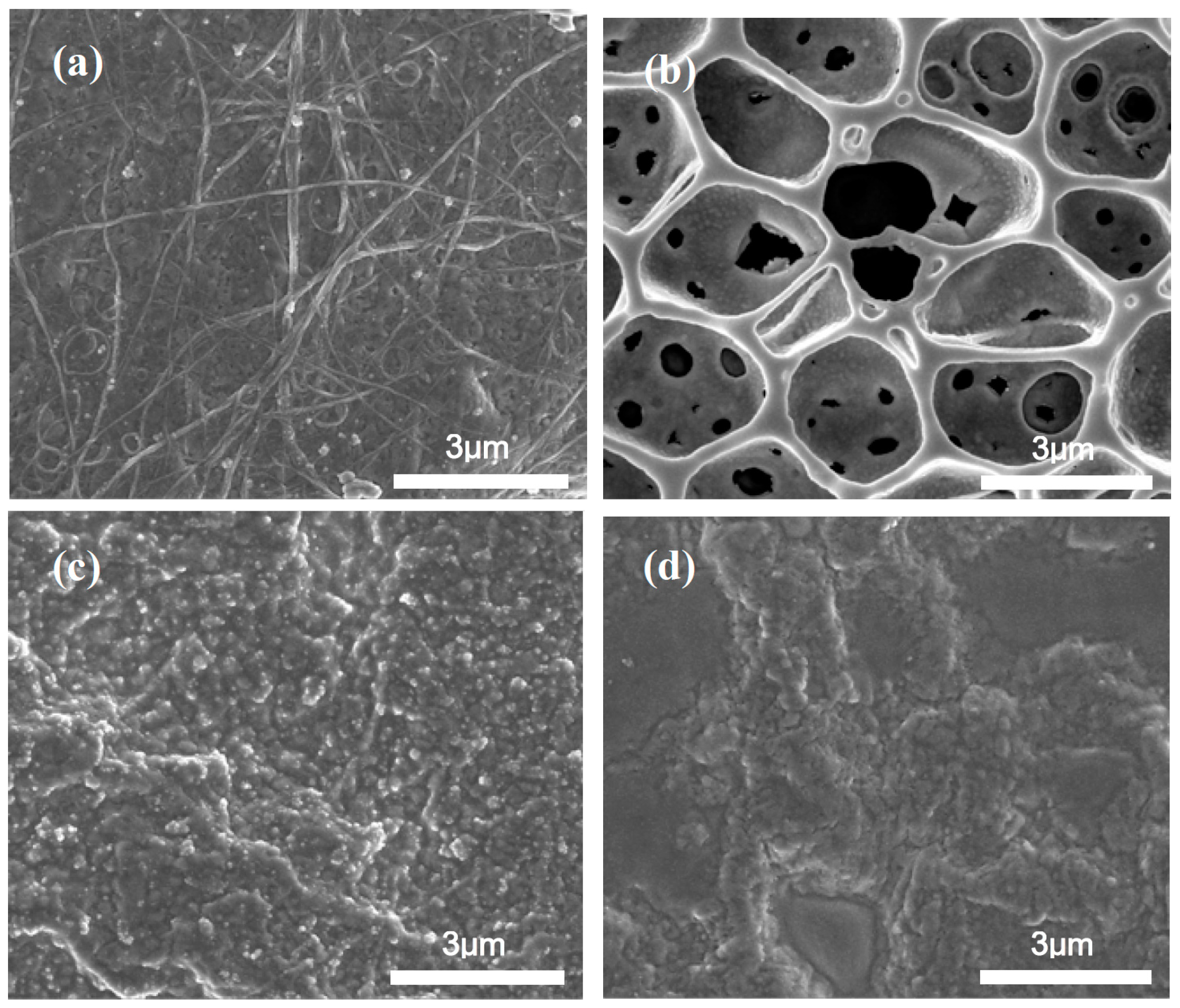

4.4. SEM Morphology of Polymer/MWCNT Composite Films

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ryan, M.A.; Shevade, A.V.; Zhou, H.; Homer, M.L. Polymer-carbon black composite sensors in an electronic nose for air-quality monitoring. MRS Bull. 2004, 29, 714–719. [Google Scholar] [CrossRef] [PubMed]

- Lonergan, M.C.; Severin, E.J.; Doleman, B.J.; Beaber, S.A.; Grubbs, R.H.; Lewis, N.S. Array-based vapor sensing using chemically sensitive, carbon black-polymer resistors. Chem. Mater. 1996, 8, 2298–2312. [Google Scholar] [CrossRef]

- Ryan, M.A.; Lewis, N.S. Low power, lightweight vapor sensing using arrays of conducting polymer composite chemically-sensitive resistors. Enantiomer 2000, 6, 159–170. [Google Scholar]

- Hafaiedh, I.; Elleuch, W.; Clément, P.; Llobet, E.; Abdelghani, A. Multi-walled carbon nanotubes for volatile organic compound detection. Sens. Actuators B Chem. 2013, 182, 344–350. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Z.; Hou, Z.; Xu, D.; Wei, L.; Kong, E.S.W.; Zhang, Y. Flexible gas sensors with assembled carbon nanotube thin films for DMMP vapor detection. Sens. Actuators B Chem. 2010, 150, 708–714. [Google Scholar] [CrossRef]

- Wang, F.; Gu, H.W.; Swager, T.M. Carbon nanotube/polythiophene chemiresistive sensors for chemical warfare agents. J. Am. Chem. Soc. 2008, 130, 5392–5393. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.P.; Yuan, C.L. The fabrication of a MWNTs–polymer composite chemoresistive sensor array to discriminate between chemical toxic agents. J. Mater. Sci. 2009, 44, 5485–5493. [Google Scholar] [CrossRef]

- Philip, B.; Abraham, J.K.; Chandrasekhar, A. Carbon nanotube/PMMA composite thin films for gas-sensing applications. Smart Mater. Struct. 2003, 12, 935–939. [Google Scholar] [CrossRef]

- Li, J.; Lu, Y.; Ye, Q.; Cinke, M.; Han, J.; Meyyappan, M. Carbon nanotube sensors for gas and organic vapor detection. Nano Lett. 2003, 3, 929–933. [Google Scholar] [CrossRef]

- Abraham, J.K.; Philip, B.; Witchurch, A.; Varadan, V.K.; Reddy, C.C. A compact wireless gas sensor using a carbon nanotube/PMMA thin film chemiresistor. Smart Mater. Struct. 2004, 13, 1045–1049. [Google Scholar] [CrossRef]

- Zhang, B.; Fu, R.W.; Zhang, M.Q.; Dong, X.M.; Lan, P.L.; Qiu, J.S. Preparation and characterization of gas-sensitive composites from multi-walled carbon nanotubes/ polystyrene. Sens. Actuators B Chem. 2005, 109, 323–328. [Google Scholar] [CrossRef]

- Niu, L.; Luo, Y.; Li, Z. A highly selective chemical gas sensor based on functionalization of multi-walled carbon nanotubes with poly(ethylene glycol). Sens. Actuators B Chem. 2007, 126, 361–367. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube–polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Llobet, E. Gas sensors using carbon nanomaterials: A review. Sens. Actuators B Chem. 2013, 179, 32–45. [Google Scholar] [CrossRef]

- Barsan, N.; Weimar, U. Understanding the fundamental principles of metal oxide based gas sensors; the example of CO sensing with SnO2 sensors in the presence of humidity. J. Phys. Condends. Matter 2003, 15, R813. [Google Scholar] [CrossRef]

- Chiou, J.C.; Tsai, S.W.; Lin, C.Y. Liquid Phase Deposition Based SnO2 Gas Sensor Integrated with TaN Heater on a Micro-hotplate. IEEE Sens. J. 2013, 13, 2466–2473. [Google Scholar] [CrossRef]

- Berger, F.; Sanchez, J.; Heintz, O. Detection of hydrogen fluoride using SnO2-based gas sensors: Understanding of the reactional mechanism. Sens. Actuators B Chem. 2009, 143, 152–157. [Google Scholar] [CrossRef]

- Bai, H.; Shi, G. Gas sensors based on conducting polymers. Sens. J. 2007, 7, 267–307. [Google Scholar] [CrossRef]

- Ryan, M.A.; Homer, M.L.; Buehler, M.G.; Manatt, K.S.; Zee, F.; Graf, J. Monitoring the Air Quality in a Closed Chamber Using an Electronic Nose. In Proceedings of the 27th International Conference on Environmental Systems, Lake Tahoe, NV, USA, 14–17 July 1997.

- Kim, Y.S.; Ha, S.C.; Yang, Y.; Kim, Y.J.; Cho, S.M.; Yang, H.; Kim, Y.T. Portable Electronic Nose System Based on the Carbon Black-Polymer Composite Sensor Array. Sens. Actuators B Chem. 2005, 108, 285–291. [Google Scholar] [CrossRef]

- Xie, H.F.; Yang, Q.D.; Sun, X.X.; Yang, J.J.; Huang, Y.P. Gas sensor arrays based on polymer-carbon black to detect organic vapors at low concentration. Sens. Actuators B Chem. 2006, 113, 887–891. [Google Scholar] [CrossRef]

- Buehler, M.G.; Ryan, M.A. Temperature and humidity dependence of a polymer-based gas sensor. Proc. SPIE 1997, 3082, 40–48. [Google Scholar]

- Homer, M.L.; Lim, J.R.; Manatt, K.; Kisor, A.; Manfreda, A.M.; Lara, L.; Jewell, A.D.; Yen, S.P.S.; Zhou, H.; Shevade, A.V.; et al. Temperature effects on polymer-carbon composite sensors: Evaluating the role of polymer molecular weight and carbon loading. Proc. IEEE Sens. 2003, 2, 877–881. [Google Scholar]

- Ha, S.C.; Yang, Y.S.; Kim, Y.S.; Kim, S.H.; Kim, Y.J.; Cho, S.M. Environmental temperature-independent gas sensor array based on polymer composite. Sens. Actuators B Chem. 2005, 108, 258–264. [Google Scholar] [CrossRef]

- Ha, S.C.; Kim, Y.S.; Yang, Y.; Kim, Y.J.; Cho, S.M.; Yang, H.; Kim, Y.T. Integrated and microheater embedded gas sensor array based on the polymer composites dispensed in micromachined wells. Sens. Actuators B Chem. 2005, 105, 549–555. [Google Scholar] [CrossRef]

- Kim, Y.S. Microheater-integrated single gas sensor array chip fabricated on flexible polyimide substrate. Sens. Actuators B Chem. 2006, 114, 410–417. [Google Scholar] [CrossRef]

- Santucci, S.; Picozzi, S.; Gregorio, F.D.; Lozzi, L.; Cantalini, C.; Valentini, L.; Kenny, J.M.; Delley, B. NO and CO gas adsorption on carbon nanotubes: Experiment and theory. J. Chem. Phys. 2003, 119, 10904–10910. [Google Scholar] [CrossRef]

- Mangu, R.; Rajaputra, S.; Singh, V.P. MWCNT–polymer composites as highly sensitive and selective room temperature gas sensors. Nanotechnology 2011, 22, 215502. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Hussain, S.; Singh, S.; Islam, S.S. MWCNT-conducting polymer composite based ammonia gas sensors: A new approach for complete recovery process. Sens. Actuators B Chem. 2014, 194, 213–219. [Google Scholar] [CrossRef]

- Wu, C.C.; Chiou, J.C.; Wang, Y.P.; Wang, L.C. Flexible polymer/multi-walled carbon nanotube composite sensor array equipped with microheater for gas sensing. In Proceedings of the 2016 International Conference on Manipulation, Automation and Robotics at Small Scales (MARSS), Paris, France, 18–22 July 2016.

- Hierlemann, A.; Zellers, E.T. Use of linear solvation energy relationships for modeling responses from polymer-coated acoustic-wave vapor sensors. Anal. Chem. 2001, 73, 3458–3466. [Google Scholar] [CrossRef] [PubMed]

- Chuang, P.K.; Wang, L.C.; Kuo, C.T. Development of a high performance integrated sensor chip with a multi-walled carbon nanotube assisted sensing array. Thin Solid Films 2013, 529, 205–208. [Google Scholar] [CrossRef]

- Zee, F.; Judy, J.W. Micromachined polymer-based chemical gas sensor array. Sens. Actuators B Chem. 2001, 72, 120–128. [Google Scholar] [CrossRef]

- García-Guzmán, J.; Ulivieri, N.; Cole, M.; Gardner, J.W. Design and simulation of a smart ratiometric ASIC chip for VOC monitoring. Sens. Actuators B Chem. 2003, 95, 232–243. [Google Scholar] [CrossRef]

- Kim, J.C.; Chung, J.T.; Lee, D.J.; Kim, Y.K.; Kim, J.W.; Hwang, S.W.; Ju, B.K.; Yun, S.K.; Park, H.W. Development of temperature feedback control system for piezo-actuated display package. Sens. Actuators A Phys. 2009, 151, 213–219. [Google Scholar] [CrossRef]

- Amrani, M.E.H.; Persaud, K.C.; Payne, P.A. High-Frequency Measurements of Conducting Polymers—Development of a New Technique for Sensing Volatile Chemicals. Meas. Sci. Technol. 1995, 6, 1500–1507. [Google Scholar] [CrossRef]

- Li, Q.; Xue, Q.Z.; Gao, X.L.; Zheng, Q.B. Temperature dependence of the electrical properties of the carbon nanotube/polymer composites. Express Polym. Lett. 2009, 3, 769–777. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.X.; Wu, P.X.; Cheng, Z.-Y.; Ingram, J.; Jeelani, S. Improvement in electrical, thermal and mechanical properties of epoxy by filling carbon nanotube. Express Polym. Lett. 2008, 2, 40–48. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiou, J.-C.; Wu, C.-C.; Huang, Y.-C.; Chang, S.-C.; Lin, T.-M. Effects of Operating Temperature on Droplet Casting of Flexible Polymer/Multi-Walled Carbon Nanotube Composite Gas Sensors. Sensors 2017, 17, 4. https://doi.org/10.3390/s17010004

Chiou J-C, Wu C-C, Huang Y-C, Chang S-C, Lin T-M. Effects of Operating Temperature on Droplet Casting of Flexible Polymer/Multi-Walled Carbon Nanotube Composite Gas Sensors. Sensors. 2017; 17(1):4. https://doi.org/10.3390/s17010004

Chicago/Turabian StyleChiou, Jin-Chern, Chin-Cheng Wu, Yu-Chieh Huang, Shih-Cheng Chang, and Tse-Mei Lin. 2017. "Effects of Operating Temperature on Droplet Casting of Flexible Polymer/Multi-Walled Carbon Nanotube Composite Gas Sensors" Sensors 17, no. 1: 4. https://doi.org/10.3390/s17010004