Crack Propagation Calculations for Optical Fibers under Static Bending and Tensile Loads Using Continuum Damage Mechanics

Abstract

:1. Introduction

- Statistical method based on the failure data.

- Mechanical method based on the crack growth model.

2. Mathematical Modeling

2.1. Static Fatigue Damage Model

- The material and damage variables are isotropic.

- is equal to 0, after which dissipation with damage occurs.

- The initial state is 0.

2.2. Finite Element Modelling

2.2.1. Description of the Finite Element Model

2.2.2. Calculation of the External Loads

2.2.3. Calculation of Crack Propagation Time

3. Simulation Results and Discussion

3.1. Results at Different Bending Radii

3.2. Results at Different Tensile Forces

3.3. Results at Different Optical Fiber Diameters

4. Experimental Verification

4.1. Experimental Procedure

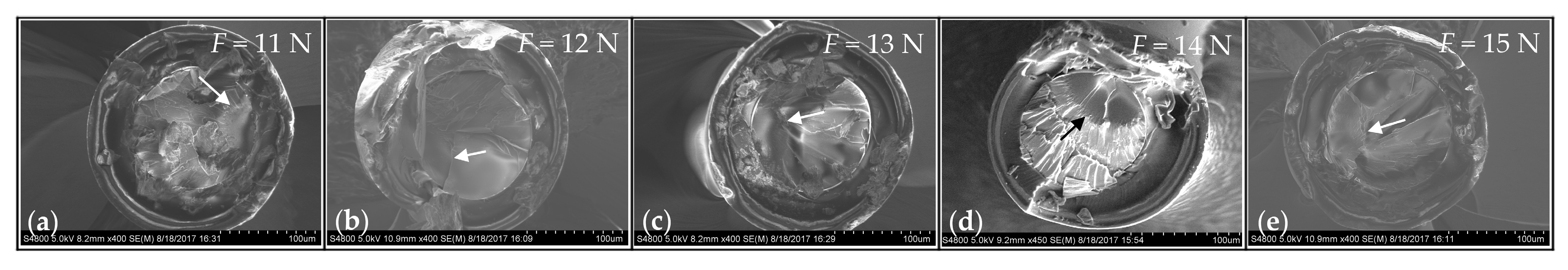

4.2. Results and Discussion

5. Conclusions

- (1)

- From the simulation results, the change of the crack-front shape in the propagation process is consistent with the observed image in the actual test, which indicates that the traces of the crack fronts present a fan-like pattern path.

- (2)

- The crack propagation process can be divided into two stages. Firstly, the crack-initiation stage lasts from the starting point to the moment that nearly 30 elements are killed, and the crack growth rates are relatively low, since a long time is taken for the material to be damaged in the first place. Then, once entering the early crack-extension stage, the crack growth rates increase rapidly as elements are killed faster until the failure criteria are met.

- (3)

- Under different bending radii, the simulated crack propagation time values show that there is an obvious inversely proportional relationship between the crack propagation time and bending radius. The reason is that a smaller bending radius causes a higher bending load on the optical fiber, and it increases the damage-accumulating speed. Additionally, compared with the test data, the simulation results have the same variation tendency and similar magnitude changes in the range of acceptable errors.

- (4)

- Based on the simulation results, greater tensile forces can easily cause elements on the crack flank to take on higher damage values and be killed, leading to the appearance of wider cracks. The phenomenon basically conforms to the test results. In addition, the simulated crack propagation times are close to the extrapolated values from fitting the curve of the experimental results.

- (5)

- The geometry size of optical fibers manufactured can seriously affect the optical fibers’ crack propagation times through the finite element analysis. Through deeply investigating simulation results, the maximum stress on the glass core decreases first and then increases along with the diameter of the glass core, which can explain the non-linear relationship between the crack propagation time and glass core diameter. Thus, there is an optimum diameter for the glass core that takes on the lowest stress, which could give an optimization policy in the size design of optical fibers to improve their usage time under static loads.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Glass, A.M.; DiGiovanni, D.J.; Strasser, T.A.; Stentz, A.J.; Slusher, R.E.; White, A.E.; Kortan, A.R.; Eggleton, B.J. Advances in fiber optics. Bell Labs Tech. J. 2000, 5, 168–187. [Google Scholar] [CrossRef]

- He, J.J.; Yang, J.S.; Wang, Y.X.; Waisman, H.; Zhang, W.F. Probabilistic Model Updating for Sizing of Hole-Edge Crack Using Fiber Bragg Grating Sensors and the High-Order Extended Finite Element Method. Sensors 2016, 16, 1956. [Google Scholar] [CrossRef] [PubMed]

- Kocaman, E.S.; Akay, E.; Yilmaz, C.; Turkmen, H.S.; Misirlioglu, I.B.; Suleman, A.; Yildiz, M. Monitoring the damage state of fiber reinforced composites using an FBG network for failure prediction. Materials 2017, 10, 32. [Google Scholar] [CrossRef] [PubMed]

- Risch, B.G.; Fox, S.; Delden, R.A.V.; Comteq, D.; Ijzerweg, T.B.V. Lifetime prediction of fiber optic cable materials for nuclear power applications: Evaluation of failure mechanism, end of life criteria, and test methodology. In Proceedings of the 59th International Wire and Cable Symposium, Providence, RI, USA, 7–10 November 2010; pp. 183–191. [Google Scholar]

- Xia, D.Z.; Yu, C.; Kong, L. The development of micromachined gyroscope structure and circuitry technology. Sensors 2014, 14, 1394–1473. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.Z.; Jin, L.; Liang, Y.Z.; Ma, J.; Guan, B.O. Corrugated-diaphragm based fiber laser hydrophone with Sub-100 μPa/Hz1/2 resolution. Sensors 2017, 17, 1219. [Google Scholar] [CrossRef]

- Annovazzi-Ledi, V.; Donati, S.; Merlo, S.; Zapelloni, G. Statistical analysis of fiber failures under bending-stress fatigue. J. Lightwave Technol. 1997, 15, 288–293. [Google Scholar] [CrossRef]

- Yang, Y. Reliability assessment of optical fibers under tension and bending loads. Appl. Surf. Sci. 2003, 250, 104–108. [Google Scholar]

- Matthewson, M.; Kurkjian, C.R. Environmental effects on the static fatigue of silica optical fiber. J. Am. Ceram. Soc. 1988, 71, 177–183. [Google Scholar] [CrossRef]

- Wang, T.; Vazirani, H.; Schonhorn, H.; Zupko, H. Effects of water and moisture on strengths of optical glass (silica) fibers coated with a UV-cured epoxy acrylate. J. Appl. Polym. Sci. 1979, 23, 887–892. [Google Scholar] [CrossRef]

- Hasløv, P.; Jensen, K.B.; Skovgaard, N.H. Degradation of stressed optical fibers in water: New worst-case lifetime estimation model. J. Am. Ceram. Soc. 1994, 77, 1531–1536. [Google Scholar] [CrossRef]

- Armstrong, J.L.; Matthewson, M.J.; Kurkjian, C.R. Humidity dependence of the fatigue of high-strength fused silica optical fibers. J. Am. Ceram. Soc. 2000, 83, 3100–3109. [Google Scholar] [CrossRef]

- El Abdi, R.; Rujinski, A.; Poulain, M.; Severin, I. Damage of optical fibers under wet environments. Exp. Mech. 2010, 50, 1225–1234. [Google Scholar] [CrossRef]

- Wysokiński, K.; Stańczyk, T.; Gibała, K.; Tenderenda, T.; Ziołowicz, A.; Słowikowski, M.; Broczkowska, M.; Nasiłowski, T. New methods of enhancing the thermal durability of silica optical fibers. Materials 2014, 7, 6947–6964. [Google Scholar] [CrossRef] [PubMed]

- Griffioen, W.W. Evaluation of optical fiber lifetime models based on the power law. Opt. Eng. 1994, 33, 488–497. [Google Scholar] [CrossRef]

- Matthewson, M.J. Optical fiber reliability models. SPIE Crit. Rev. Opt. Sci. Technol. 1993, 50, 3–31. [Google Scholar]

- Lawn, B. An atomistic model of kinetic crack growth in brittle solids. J. Mater. Sci. 1975, 10, 469–480. [Google Scholar] [CrossRef]

- Matthewson, M. Optical fiber reliability implications of uncertainty in the fatigue crack growth model. Opt. Eng. 1991, 30, 737–745. [Google Scholar]

- Evans, A. Slow crack growth in brittle materials under dynamic loading conditions. Int. J. Fract. 1974, 10, 251–259. [Google Scholar] [CrossRef]

- Lenoe, E.M.; Neal, D.M. Assessment of strength-probability-time relationships in ceramics. In Cracks and Fracture; ASTM International: West Conshohocken, PA, USA, 1976. [Google Scholar]

- Hillig, W.; Charles, R. Surfaces, stress-dependent surface reactions, and strength. High Strength Mater. 1965, 1965, 682–705. [Google Scholar]

- Kachanov, L.M. Time of the rupture process under creep conditions, Izy Akad. Nank SSR Otd Tech Nauk 1958, 8, 26–31. [Google Scholar]

- Lemaitre, J.; Chaboche, J.L. Damage mechanics. In Mechanics of Solid Materials; Cambridge University Press: Cambridge, UK, 1994; Volume 7, pp. 346–463. ISBN 0521328535. [Google Scholar]

- Sun, X.; Khaleel, M.A. Modeling of glass fracture damage using continuum damage mechanics-static spherical indentation. Int. J. Damage Mech. 2004, 13, 263–285. [Google Scholar] [CrossRef]

- Ismail, J.; Zaïri, F.; Naït-Abdelaziz, M.; Azari, Z. Computational modelling of static indentation-induced damage in glass. Comput. Mater. Sci. 2008, 42, 407–415. [Google Scholar] [CrossRef]

- Bernard, C.; Delaizir, G.; Sangleboeuf, J.C.; Keryvin, V.; Lucas, P.; Bureau, B.; Zhang, X.H.; Rouxel, T. Room temperature viscosity and delayed elasticity in infrared glass fiber. J. Eur. Ceram. Soc. 2007, 27, 3253–3259. [Google Scholar] [CrossRef]

- Vannoni, M.; Sordini, A.; Molesini, G. Relaxation time and viscosity of fused silica glass at room temperature. Eur. Phys. J. E Soft Matter Biol. Phys. 2011, 34, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Lemaitre, J. A Course on Damage Mechanics; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Skontorp, A.; Cammas, J. Static fatigue life of silica optical fibers and the significance of fiber coating and handling. Proc. SPIE 2001, 4328, 96–105. [Google Scholar]

- Sun, X.; Wimmer, S.A.; Karrt, D.G. Shear band initiation of brittle damage materials. Int. J. Damage Mech. 1996, 5, 403–421. [Google Scholar] [CrossRef]

- Sun, X.; Khaleel, M.A.; Davies, R.W. Modeling of stone-impact resistance of monolithic glass ply using continuum damage mechanics. Int. J. Damage Mech. 2005, 14, 165–178. [Google Scholar] [CrossRef]

- Mao, J.; Zhu, J.; Bao, S.; Luo, L.; Gao, Z. Creep deformation and damage behavior of reactor pressure vessel under core meltdown scenario. Int. J. Press. Vessel. Pip. 2016, 139, 107–116. [Google Scholar] [CrossRef]

- Im, J.I.; Roh, Y.R. A finite element analysis of an interferometric optical fiber hydrophone. J. Acoust. Soc. Am. 1998, 103, 2425–2431. [Google Scholar] [CrossRef]

- Muraoka, M.; Abe, H. Subcritical crack growth in silica optical fibers in wide range of crack velocities. J. Am. Ceram. Soc. 1996, 79, 51–57. [Google Scholar] [CrossRef]

- Muraoka, M.; Abe, H. Measurement of small-crack growth in optical glass fiber and evaluation of crack growth law. Trans. Jpn. Soc. Mech. Eng. Ser. A 1991, 672–677. [Google Scholar] [CrossRef]

- Muraoka, M.; Abé, H.; Aizawa, N. The distribution of the stress intensity factor along the front of the growing crack in an optical glass fiber. J. Electron. Packag. 1992, 114, 403–406. [Google Scholar] [CrossRef]

| #1 | #2 | #3 | #4 | #5 | |

|---|---|---|---|---|---|

| Glass core diameter (μm) | 45 | 80 | 125 | 200 | 300 |

| Inner coating diameter (μm) | 77 | 120 | 187 | 230 | 330 |

| Outer coating diameter (μm) | 115 | 165 | 245 | 500 | 650 |

| Critical crack depth (μm) | 11 | 22 | 32 | 50 | 79 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Cui, Y.; Gong, W. Crack Propagation Calculations for Optical Fibers under Static Bending and Tensile Loads Using Continuum Damage Mechanics. Sensors 2017, 17, 2633. https://doi.org/10.3390/s17112633

Chen Y, Cui Y, Gong W. Crack Propagation Calculations for Optical Fibers under Static Bending and Tensile Loads Using Continuum Damage Mechanics. Sensors. 2017; 17(11):2633. https://doi.org/10.3390/s17112633

Chicago/Turabian StyleChen, Yunxia, Yuxuan Cui, and Wenjun Gong. 2017. "Crack Propagation Calculations for Optical Fibers under Static Bending and Tensile Loads Using Continuum Damage Mechanics" Sensors 17, no. 11: 2633. https://doi.org/10.3390/s17112633