An Eddy Current Testing Platform System for Pipe Defect Inspection Based on an Optimized Eddy Current Technique Probe Design

Abstract

:1. Introduction

2. Architecture of the Distributed System for Eddy Current Testing (DSECT) Inspection

2.1. Data Acquisition System

2.2. Pneumatic Pusher System

2.3. Response Surface Methodology (RSM)

3. Design and Operational Principles of the DSECT Probe

3.1. Rotating Magnetic Field

3.2. GMR Array Sensor

4. Optimization of DSCET Probe

5. Results

5.1. Analysis of Response Surface Methodology Models

5.1.1. Axial Defect

5.1.2. Circumference Defects

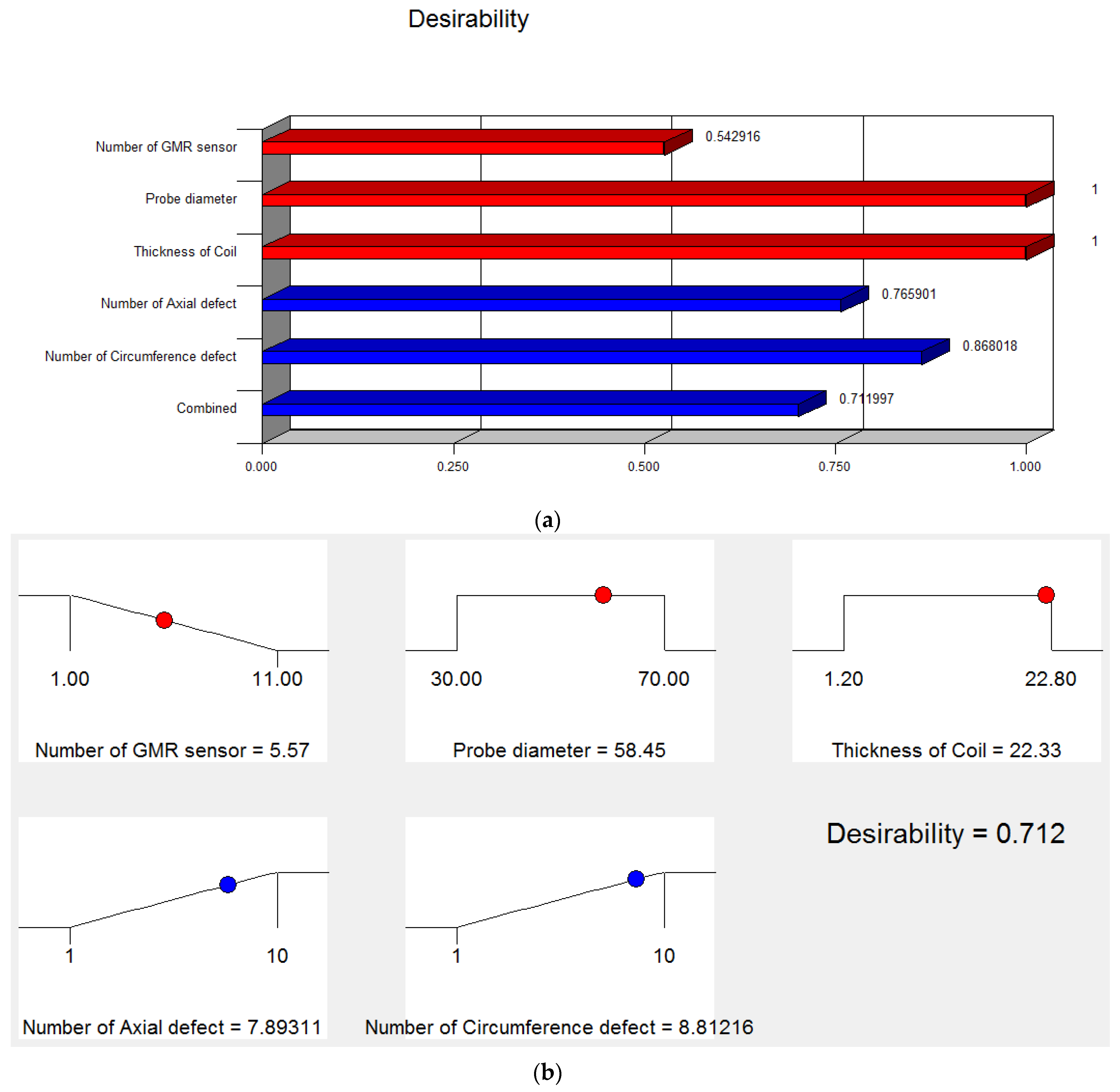

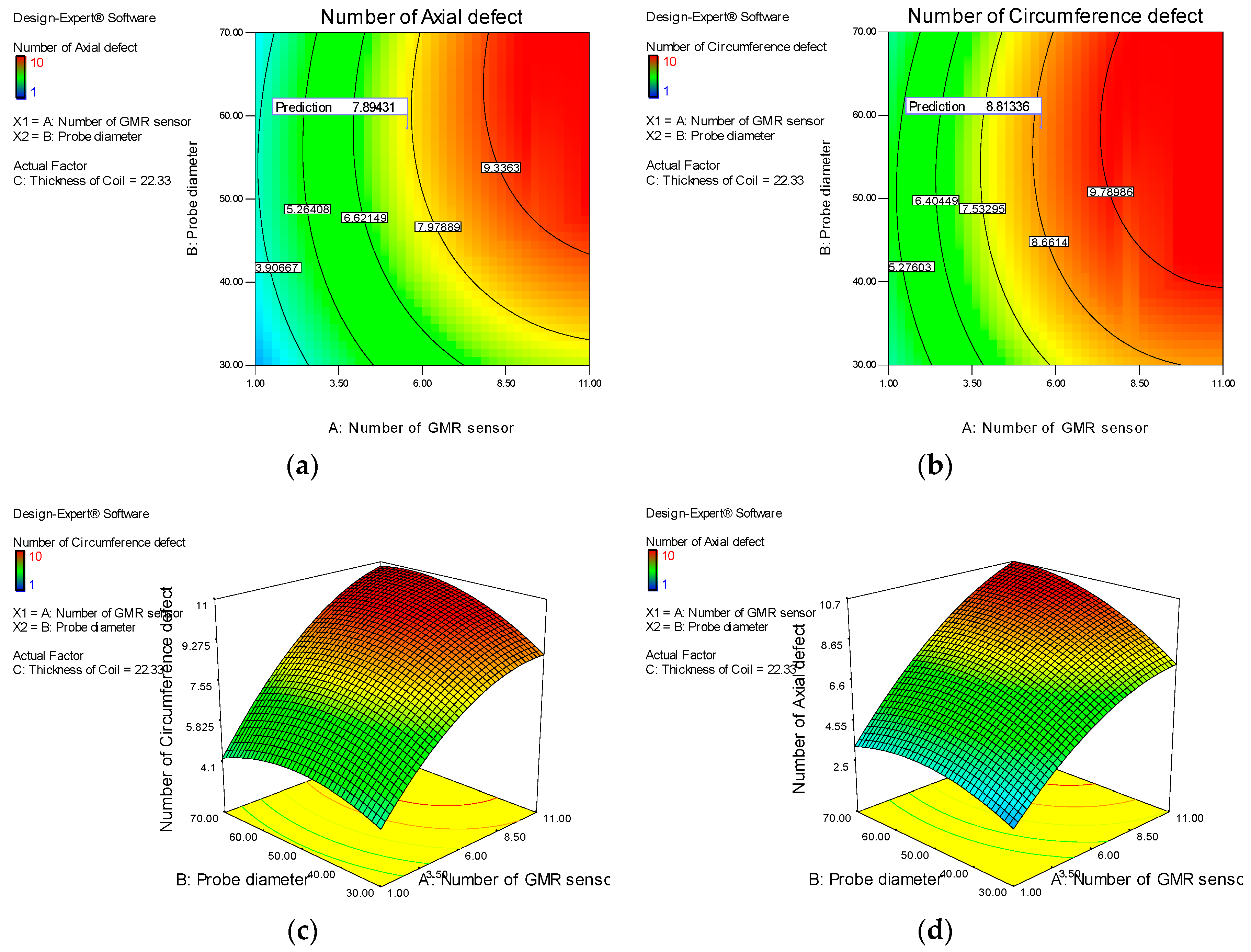

5.2. Optimized Probe Design

5.3. Simulation of the Axial and Circumference Defect for Carbon Steel Pipe

5.4. Experimental Results for Axial and Circumference Defects

5.5. Comparison Accuracy of the Probe Design

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zou, L.; Ferrier, G.A.; Afshar, S.; Yu, Q.; Chen, L.; Bao, X. Distributed brillouin scattering sensor for discrimination of wall-thinning defects in steel pipe under internal pressure. Appl. Opt. 2004, 43, 1583–1588. [Google Scholar] [CrossRef] [PubMed]

- Rifai, D.; Abdalla, A.N. Defect Signal Analysis for Nondestructive Testing. ARPN J. Eng. Appl. Sci. 2015, 11, 1–14. [Google Scholar]

- Rifai, D.; Abdalla, A.N.; Khamsah, N.; Aizat, M. Subsurface Defects Evaluation using Eddy Current Testing. Indian J. Sci. Technol. 2016, 9. [Google Scholar] [CrossRef]

- Rifai, D.; Abdalla, A.; Ali, K.; Razali, R. Giant Magnetoresistance Sensors: A Review on Structures and Non-Destructive Eddy Current Testing Applications. Sensors 2016, 16, 298. [Google Scholar] [CrossRef] [PubMed]

- Du, W.; Dutt, A.; Scallion, K. Design of a GMR Sensor Array System for Robotic Pipe Inspection. In Proceedings of the 2010 IEEE SENSORS, Waikoloa, HI, USA, 1–4 November 2010; pp. 2551–2554.

- Le, M.; Kim, J.; Do, H.S.; Lee, J. 2-D Vector Field Visualization of Corrosion in a Small-Bore Piping System Using Bobbin-Type Integrated Hall and GMR Sensors Arrays. In Proceedings of the 2014 IEEE Sensors Application Symposium, Queenstown, New Zealand, 18–20 February 2014; pp. 38–41.

- SThrough, P.W.; Cheng, W. Pulsed Eddy Current Testing of Carbon Steel Pipes’ Wall-thinning through Insulation and Cladding. J. Nondestruct. Eval. 2012, 31, 215–224. [Google Scholar]

- Vacher, F.; Decitre, J.M.; Fermon, C.; Pannetier, M. Non Destructive Testing with GMR Magnetic Sensor Arrays. In Proceedings of the 9th ECNDT, Berlin, Fermany, 15 September 2006; pp. 1–8.

- Rocha, T.J.; Ramos, H.G.; Ribeiro, A.L.; Pasadas, D.J.; Angani, C.S. Studies to optimize the probe response for velocity induced eddy current testing in aluminium. Measurement 2015, 67, 108–115. [Google Scholar] [CrossRef]

- Zhou, H.T.; Hou, K.; Pan, H.L.; Chen, J.J.; Wang, Q.M. Study on the Optimization of Eddy Current Testing Coil and the Defect Detection Sensitivity. Procedia Eng. 2015, 130, 1649–1657. [Google Scholar] [CrossRef]

- Cardoso, F.A.; Rosado, L.; Ferreira, R.; Paz, E.; Cardoso, S.; Ramos, P.M.; Piedade, M.; Freitas, P.P. Improved magnetic tunnel junctions design for the detection of superficial defects by eddy currents testing. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Rosado, L.S.; Gonzalez, J.C.; Santos, T.G.; Ramos, P.M.; Piedade, M. Geometric optimization of a differential planar eddy currents probe for non-destructive testing. Sens. Actuators A Phys. 2013, 197, 96–105. [Google Scholar] [CrossRef]

- Li, M.; Lowther, D. NDT sensor design optimization for accurate crack reconstruction. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2012, 31, 792–802. [Google Scholar] [CrossRef]

- Ali, K.; Abdalla, A.N.A.; Rifai, D.; Faraj, M. A Review On System Development in Eddy Current Testing and Technique for Defect Classification and Characterization; The Institution of Engineering and Technology: Derby, UK, 2017. [Google Scholar]

- Khuri, A.I.; Mukhopadhyay, S. Response surface methodology. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 128–149. [Google Scholar] [CrossRef]

| Probe Design Parameter and Respond | Target | Lower Limit | Upper Limit |

|---|---|---|---|

| Number of GMR sensor | Minimize | 1 | 11 |

| Probe diameter (mm) | Minimize | 30 | 70 |

| Coil thickness (mm) | Minimize | 1.2 | 22.8 |

| Axial defect | Maximize | 1 | 10 |

| Circumference defect | Maximize | 1 | 10 |

| Run | Factor 1 A: Number GMR Sensor | Factor 2 B: Probe Diameter (mm) | Factor 3 C: Thickness of Coil (mm) | Response 1 Axial Defect Detect | Response 2 Circumference Defect Detect |

|---|---|---|---|---|---|

| 1 | 6.00 | 50.00 | 6.16 | 1 | 1 |

| 2 | 6.00 | 50.00 | 12.00 | 7 | 8 |

| 3 | 11.00 | 30.00 | 1.20 | 3 | 4 |

| 4 | 6.00 | 50.00 | 12.00 | 7 | 8 |

| 5 | 1.00 | 30.00 | 1.20 | 1 | 1 |

| 6 | 1.00 | 70.00 | 1.20 | 1 | 2 |

| 7 | 11.00 | 30.00 | 22.80 | 7 | 8 |

| 8 | 6.00 | 16.36 | 12.00 | 3 | 4 |

| 9 | 2.41 | 50.00 | 12.00 | 1 | 1 |

| 10 | 11.00 | 70.00 | 1.20 | 5 | 6 |

| 11 | 6.00 | 50.00 | 30.16 | 9 | 10 |

| 12 | 1.00 | 70.00 | 22.80 | 2 | 3 |

| 13 | 1.00 | 30.00 | 22.80 | 2 | 4 |

| 14 | 6.00 | 83.64 | 12.00 | 7 | 8 |

| 15 | 6.00 | 50.00 | 12.00 | 6 | 7 |

| 16 | 6.00 | 50.00 | 12.00 | 8 | 9 |

| 17 | 6.00 | 50.00 | 12.00 | 7 | 8 |

| 18 | 6.00 | 50.00 | 12.00 | 7 | 8 |

| 19 | 14.41 | 50.00 | 12.00 | 8 | 9 |

| 20 | 11.00 | 70.00 | 22.80 | 10 | 10 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob> F Prob > F | Remarks |

|---|---|---|---|---|---|---|

| Model | 164.81 | 9 | 18.31 | 20.38 | <0.0001 | significant |

| A-Nu sensor | 69.34 | 1 | 69.34 | 77.16 | <0.0001 | significant |

| B-diameter | 10.07 | 1 | 10.07 | 11.21 | 0.0074 | significant |

| C-coil thickness | 43.79 | 1 | 43.79 | 48.73 | <0.0001 | significant |

| AC | 6.13 | 1 | 6.13 | 6.82 | 0.0260 | significant |

| A2 | 16.14 | 1 | 16.14 | 17.96 | 0.0017 | significant |

| B2 | 11.20 | 1 | 11.20 | 12.46 | 0.0054 | significant |

| C2 | 11.20 | 1 | 11.20 | 12.46 | 0.0054 | significant |

| Residual | 8.99 | 10 | 0.90 | |||

| Lack of Fit | 6.99 | 5 | 1.40 | 3.49 | 0.0980 | not significant |

| Pure Error | 2.00 | 5 | 0.40 | |||

| Cor Total | 173.80 | 19 |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value Prob > F Prob > F | Remarks |

|---|---|---|---|---|---|---|

| Model | 177.10 | 9 | 19.68 | 19.97 | <0.0001 | significant |

| A-Nu sensor | 72.45 | 1 | 72.45 | 73.53 | <0.0001 | significant |

| B-diameter | 8.43 | 1 | 8.43 | 8.55 | 0.0152 | significant |

| C-coil thickness | 53.92 | 1 | 53.92 | 54.73 | <0.0001 | significant |

| A2 | 20.30 | 1 | 20.30 | 20.61 | 0.0011 | significant |

| B2 | 10.01 | 1 | 10.01 | 10.16 | 0.0097 | significant |

| C2 | 14.71 | 1 | 14.71 | 14.93 | 0.0031 | significant |

| Residual | 9.85 | 10 | 0.99 | significant | ||

| Lack of Fit | 7.85 | 5 | 1.57 | 3.93 | 0.0798 | not significant significant |

| Pure Error | 2.00 | 5 | 0.40 | |||

| Cor Total | 186.95 | 19 |

| Type of Defect | Dimension | ||

|---|---|---|---|

| Width (mm) | Length (mm) | Depth (mm) | |

| Axial | 12 | 2 | 5 |

| Circumference | 2 | 12 | 5 |

| Defect | Prediction | Experimental | Error (%) |

|---|---|---|---|

| Axial | 7.89535 | 8 | −1.32 |

| Circumference | 8.8141 | 9 | −2.11 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rifai, D.; Abdalla, A.N.; Razali, R.; Ali, K.; Faraj, M.A. An Eddy Current Testing Platform System for Pipe Defect Inspection Based on an Optimized Eddy Current Technique Probe Design. Sensors 2017, 17, 579. https://doi.org/10.3390/s17030579

Rifai D, Abdalla AN, Razali R, Ali K, Faraj MA. An Eddy Current Testing Platform System for Pipe Defect Inspection Based on an Optimized Eddy Current Technique Probe Design. Sensors. 2017; 17(3):579. https://doi.org/10.3390/s17030579

Chicago/Turabian StyleRifai, Damhuji, Ahmed N. Abdalla, Ramdan Razali, Kharudin Ali, and Moneer A. Faraj. 2017. "An Eddy Current Testing Platform System for Pipe Defect Inspection Based on an Optimized Eddy Current Technique Probe Design" Sensors 17, no. 3: 579. https://doi.org/10.3390/s17030579

APA StyleRifai, D., Abdalla, A. N., Razali, R., Ali, K., & Faraj, M. A. (2017). An Eddy Current Testing Platform System for Pipe Defect Inspection Based on an Optimized Eddy Current Technique Probe Design. Sensors, 17(3), 579. https://doi.org/10.3390/s17030579