Hydrogel Heart Model with Temperature Memory Properties for Surgical Simulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Hydrogel Heart Model with Temperature Memory Properties

- Reproduction of the Young’s modulus of the human heart;

- Reproduction of the electrical resistivity of the human heart;

- Reproduction of the thermal conductivity and specific heat capacity of the human heart;

- Detection of the areas at which the temperature exceeds 55 °C.

2.2. Materials for Hydrogel Heart Model Preparation

3. Evaluation of Hydrogel Material

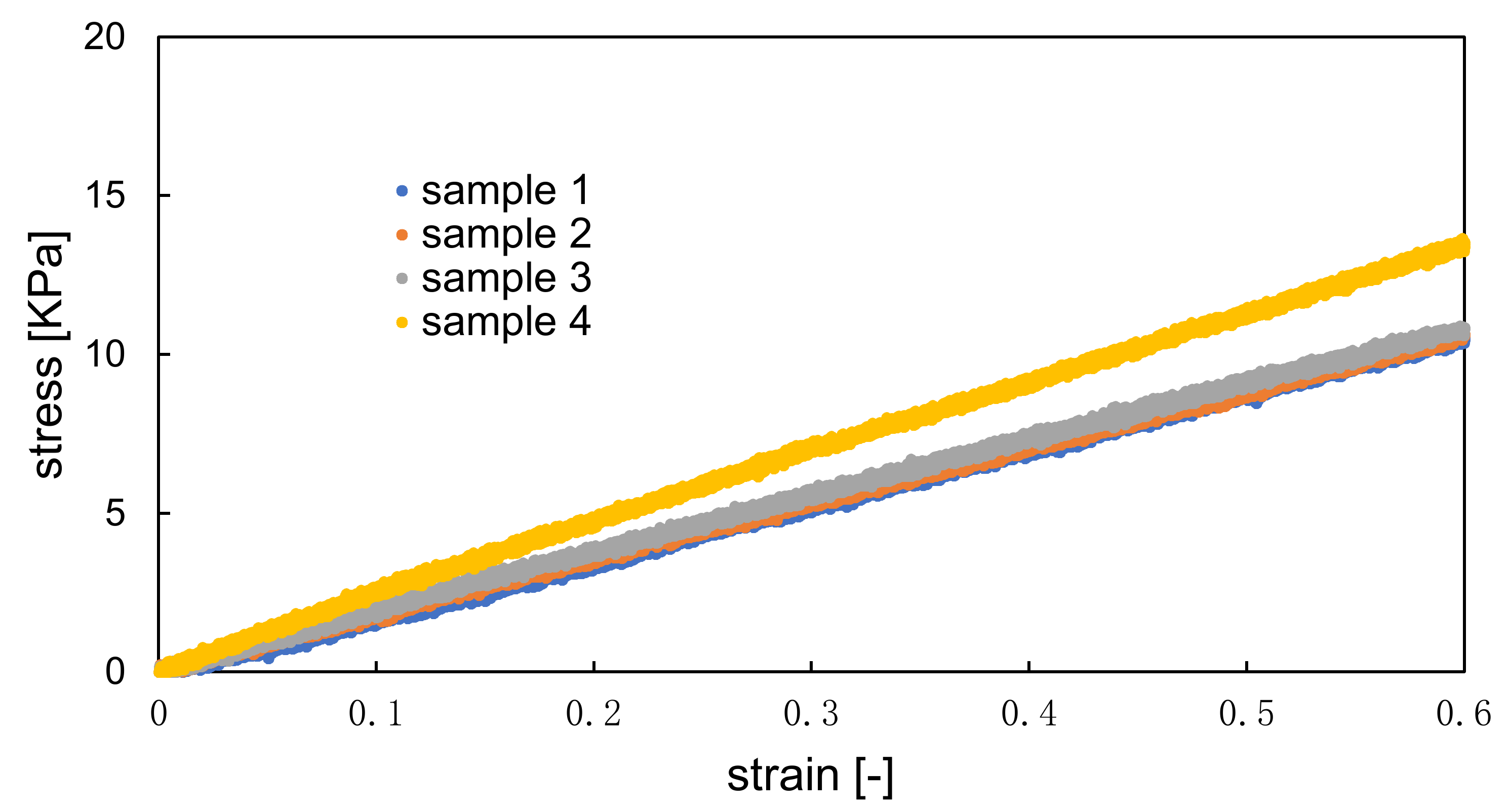

3.1. Young’s Modulus of the Hydrogel Material

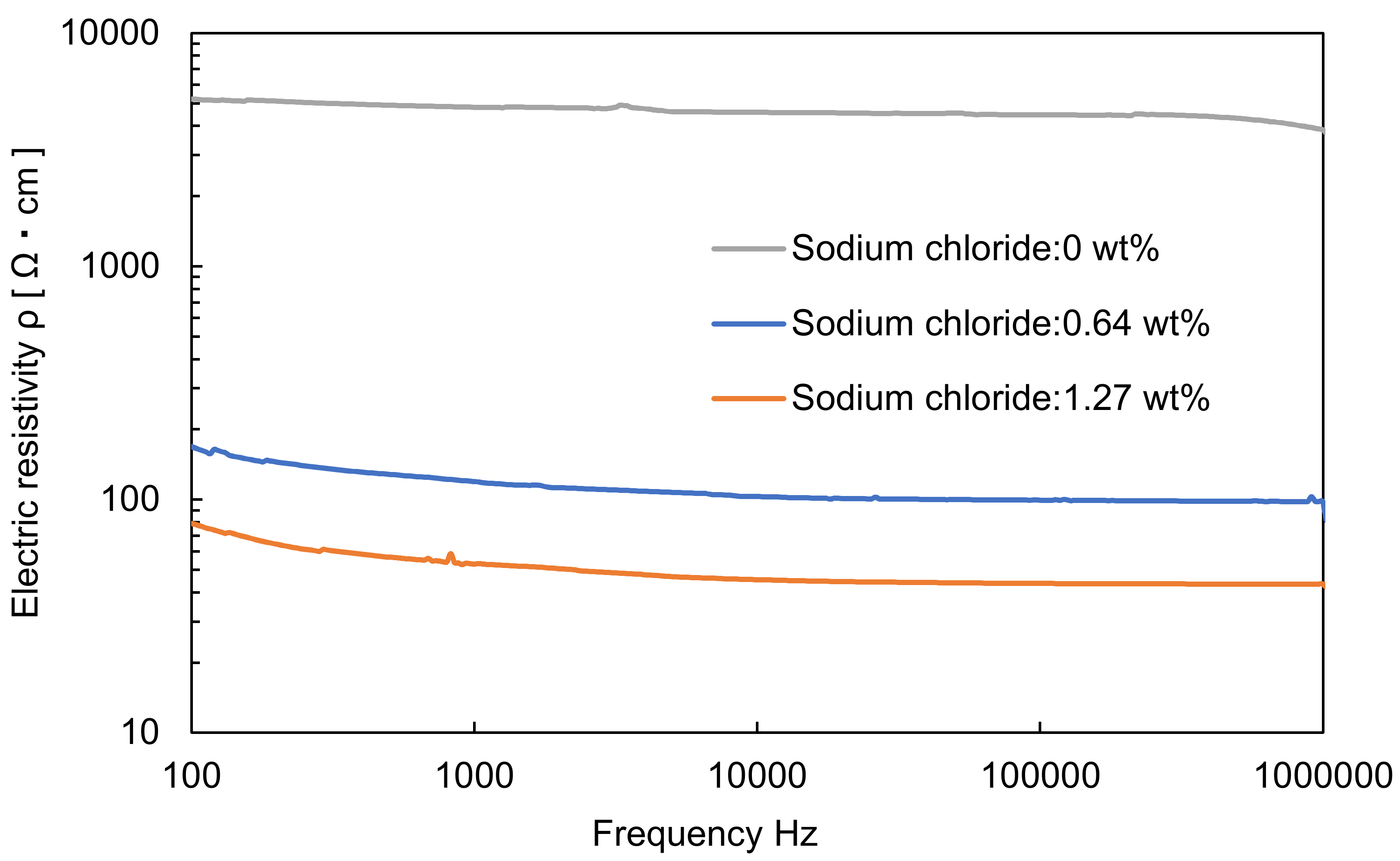

3.2. Electrical Resistivity of the Hydrogel Material

3.3. Thermal Properties of the Hydrogel Material

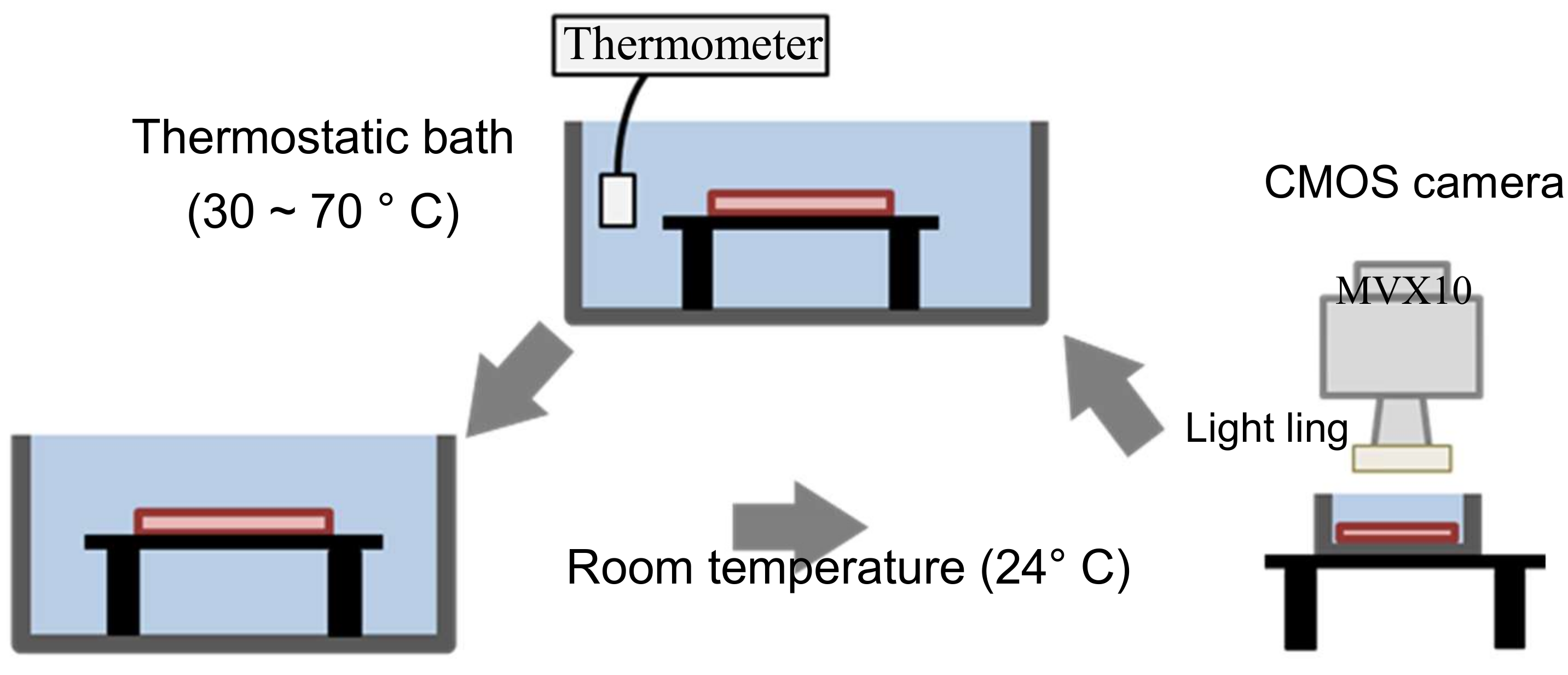

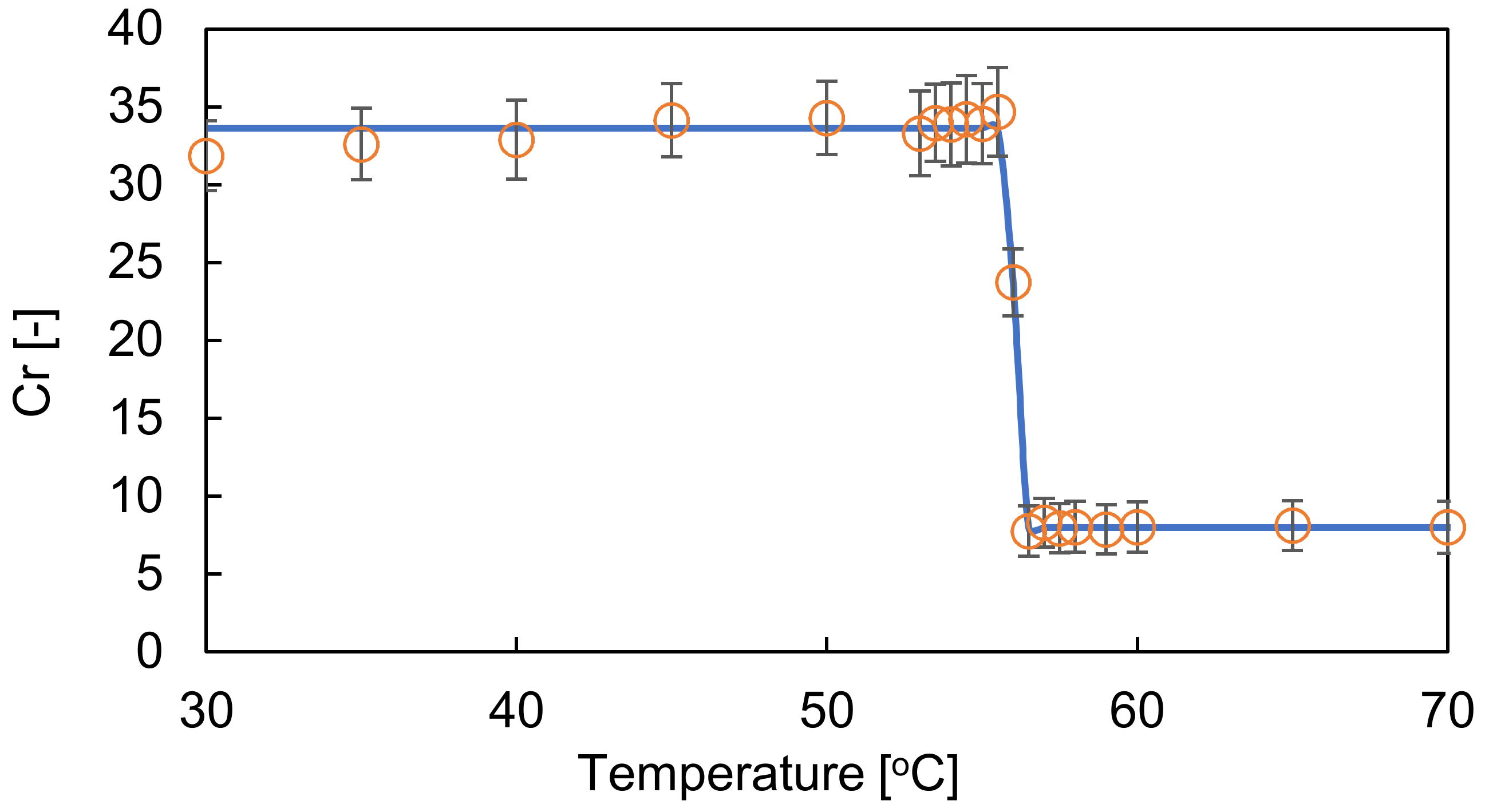

3.4. Calibration of Hydrogel Material Color with Temperature

- The hydrogel material was immersed in the thermostatic chamber at 30 °C for 5 min;

- The hydrogel material was removed from the chamber and put in water at 24 °C for 5 min;

- The hydrogel material was moved from the water to the microscope and the image was acquired;

- The above process was repeated from 30–70 °C. In the range 55–60 °C, temperature was changed in 0.5 °C intervals.

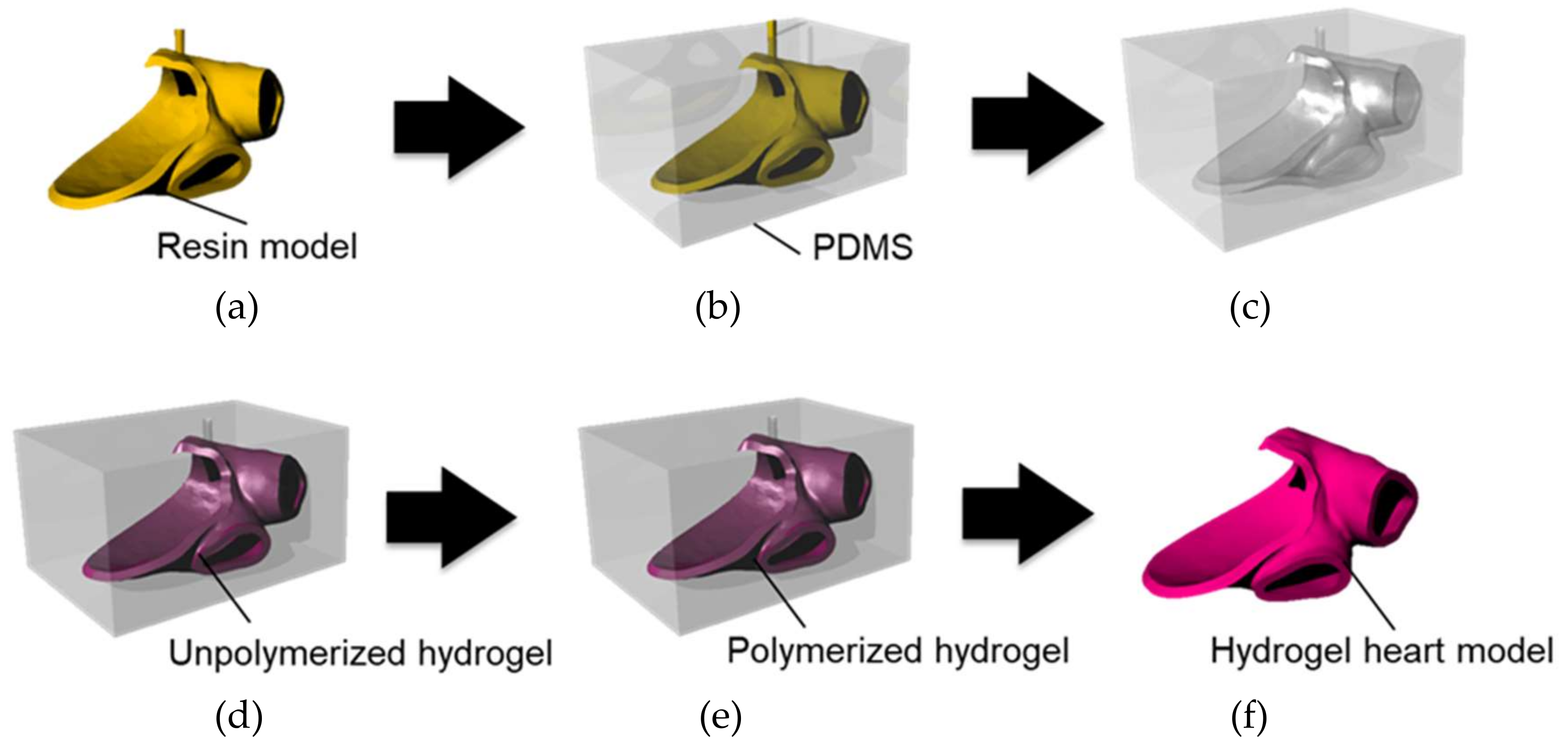

4. Fabrication of Hydrogel Heart Model with Temperature Memory Functionality

- A resin model of a heart model was fabricated from 3D data using a commercial 3D printer.

- The resin model was introduced into uncured PDMS.

- After curing the PDMS, the resin model was removed to make a hollow PDMS mold.

- Unpolymerized hydrogel material was introduced into the PDMS mold.

- The hydrogel material is irradiated with UV (375–405 nm) light from the periphery of the PDMS mold for photo-polymerization of the hydrogel.

- The polymerized hydrogel heart model was removed from the PDMS mold.

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aggarwal, R.; Darzi, A. Surgical Research Review From scalpel to simulator: A surgical journey. Surgery 2008, 145, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Scott, D.J.; Dunnington, G.L. The New ACS/APDS Skills Curriculum: Moving the Learning Curve Out of the Operating Room. J. Gastrointest. Surg. 2008, 12, 213–221. [Google Scholar] [CrossRef] [PubMed]

- Wignall, G.R.; Denstedt, J.D.; Preminger, G.M.; Cadeddu, J.A.; Pearle, M.S.; Sweet, R.M.; McDougall, E.M. Surgical Simulation: A Urological Perspective. J. Urol. 2008, 179, 1690–1699. [Google Scholar] [CrossRef] [PubMed]

- Saifi, J.; Chang, B.B.; Paty, P.S.K.; Kaufrnan, J.; Leather, R.P.; Shah, D.M. An animal model for instructing and the study of in situ arterial bypass. J. Vasc. Surg. 1990, 12, 4–6. [Google Scholar] [CrossRef]

- Shinbane, J.S.; Wood, M.A.; Jensen, D.N.; Ellenbogen, K.A.; Fitzpatrick, A.P.; Scheinman, M.M. Tachycardia-Induced Cardiomyopathy: A Review of Animal Models and Clinical Studies. J. Am. Coll. Cardiol. 1997, 29, 709–715. [Google Scholar] [CrossRef]

- Patterson, E.J.; Scudamore, C.H.; Owen, D.A.; Nagy, A.G.; Buczkowski, A.K. Radiofrequency Ablation of Porcine Liver In Vivo Effects of Blood Flow and Treatment Time on Lesion Size. Ann. Surg. 1998, 227, 559–565. [Google Scholar] [CrossRef] [PubMed]

- Dorrance, H.R.; Oien, K.; Dwyer, P.J.O. Effects of laparoscopy on intraperitoneal tumor growth and distant metastases in an animal model. Surgery 1999, 126, 35–40. [Google Scholar] [CrossRef] [PubMed]

- Satava, R.M. Virtual reality surgical simulator. Surg. Endosc. 1993, 7, 203–205. [Google Scholar] [CrossRef] [PubMed]

- Scheinman, M.M.; Morady, F.; Hess, D.S.; Gonzalez, R. Catheter-induced ablation of the atrioventricular junction to control refractory supraventricular arrhythmias. JAMA 1982, 248, 851–855. [Google Scholar] [CrossRef] [PubMed]

- Gallagher, J.J.; Svenson, R.H.; Kasell, J.H.; German, L.D.; Bardy, G.H.; Broughton, A.; Critelli, G. Catheter technique for closed-chest ablation of the atrioventricular conduction system. N. Engl. J. Med. 1982, 306, 194–200. [Google Scholar] [CrossRef] [PubMed]

- Ben-Haim, S.A.; Osadchy, D.; Scnuster, I.; Gepstein, L.; Hayam, G.; Josephson, M.E. Nonfluoroscopic, in vivo navigation and mapping technology. Nat. Med. 1996, 2, 1393–1395. [Google Scholar] [CrossRef] [PubMed]

- Gepstein, L.; Hayam, G.; Ben-Haim, S.A. A novel method for nonfluoroscopic catheter-based electroanatomical mapping of the heart: In vitro and in vivo accuracy results. Circulation 1997, 95, 1611–1622. [Google Scholar] [CrossRef] [PubMed]

- Ikeda, S.; Arai, F.; Fukuda, T.; Negoro, M.; Irie, K. An In Vitro Patient-Specific Biological Model of the Cerebral Artery Reproduced with a Membranous Configuration for Simulating Endovascular Intervention. J. Robot. Mechatron. 2005, 17, 327–334. [Google Scholar] [CrossRef]

- Lavergne, T.H.; Guize, L.; Le Heuzey, J.Y.; Carcone, P.; Geslin, J.; Cousin, M.T. Closed-chest atrioventricular junction ablation by high-frequency energy transcatheter desiccation. Lancet 1986, 2, 858–859. [Google Scholar] [CrossRef]

- Davis, M.J.; Murdock, C. Radiofrequency catheter ablation of refractory ventricular tachycardia. Pacing Clin. Electrophysiol. 1988, 11, 725–729. [Google Scholar] [CrossRef] [PubMed]

- Borggrefe, M.; Budde, T.; Podczeck, A.; Breithardt, G. High frequency alternating current ablation of an accessory pathway in humans. J. Am. Coll. Cardiol. 1987, 10, 576–582. [Google Scholar] [CrossRef]

- Cappato, R.; Calkins, H.; Chen, S.A.; Davies, W.; Iesaka, Y.; Kalman, J.; Kim, Y.H.; Klein, G.; Natale, A.; Packer, D.; et al. Prevalence and causes of fatal outcome in catheter ablation of atrial fibrillation. J. Am. Coll. Cardiol. 2009, 53, 1798–1803. [Google Scholar] [CrossRef] [PubMed]

- Martinek, M.; Bencsik, G.; Aichinger, J.; Hassanein, S.; Schoefl, R.; Kuchinka, P.; Nesser, H.J.; Purerfellner, H. Esophageal damage during radiofrequency ablation of atrial fibrillation: Impact of energy settings, lesion sets, and esophageal visualization. J. Cardiovasc. Electrophysiol. 2009, 20, 726–733. [Google Scholar] [CrossRef] [PubMed]

- Hayakwa, T.; Maruyama, H.; Watanabe, T.; Arai, F. Three-Dimensional Blood Vessel Model with Temperature-Indicating Function for Evaluation of Thermal Damage During Surgery. Sensors 2018, 18, 345. [Google Scholar] [CrossRef] [PubMed]

- Sommer, G.; Schriefl, A.J.; Andrä, M.; Sacherer, M.; Viertler, C.; Wolinski, H.; Holzapfel, G.A. Biomechanical properties and microstructure of human ventricular myocardium. Acta Biomater. 2015, 24, 172–192. [Google Scholar] [CrossRef] [PubMed]

- Geddes, L.A.; Baker, L.E. The specific resistance of biological materials–A compendium of data for the biomedical engineer and physiologist. Med. Biol. Eng. 1967, 5, 271–293. [Google Scholar] [CrossRef] [PubMed]

- Werner, J.; Buse, M. Temperature profiles with respect to inhomogeneity and geometry of the human body. J. Appl. Physiol. 1988, 65, 1110–1118. [Google Scholar] [CrossRef] [PubMed]

- Cai, D.; Song, M. Latex technology as a simple route to improve the thermal conductivity of a carbon nanotube/polymer composite. Carbon 2008, 46, 2107–2112. [Google Scholar] [CrossRef]

- Xie, X.; Li, D.; Tsai, T.-H.; Liu, J.; Braun, P.V.; Cahill, D.G. Thermal Conductivity, Heat Capacity, and Elastic Constants of Water-Soluble Polymers and Polymer Blends. Macromolecules 2016, 494, 972–978. [Google Scholar] [CrossRef]

| Thermo-Sensitive Dye | Polyurethane | 20%PVA | DI Water | NaCl | DMSO | Photo-Initiator |

|---|---|---|---|---|---|---|

| 10 g | 20 g | 20 g | 150 g | 1.35 g | 10 g | 200 mg |

| Parameter | Human Heart (Literature) | Heart Model |

|---|---|---|

| Young’s modulus [kPa] | 20.3 [20] | 20.0 |

| Electric resistivity [] | 132 [21] | 98.1 |

| Thermal conductivity [] | 0.47 [22] | 1.33 |

| Specific heat capacity [] | 3.55 [22] | 4.0 |

| 20.0 | 7.98 | 25.6 | 56.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maruyama, H.; Yokota, Y.; Hosono, K.; Arai, F. Hydrogel Heart Model with Temperature Memory Properties for Surgical Simulation. Sensors 2019, 19, 1102. https://doi.org/10.3390/s19051102

Maruyama H, Yokota Y, Hosono K, Arai F. Hydrogel Heart Model with Temperature Memory Properties for Surgical Simulation. Sensors. 2019; 19(5):1102. https://doi.org/10.3390/s19051102

Chicago/Turabian StyleMaruyama, Hisataka, Yuki Yokota, Keisuke Hosono, and Fumihito Arai. 2019. "Hydrogel Heart Model with Temperature Memory Properties for Surgical Simulation" Sensors 19, no. 5: 1102. https://doi.org/10.3390/s19051102