Measuring Reference-Free Total Displacements of Piles and Columns Using Low-Cost, Battery-Powered, Efficient Wireless Intelligent Sensors (LEWIS2)

Abstract

:1. Introduction

2. Low-Cost, Battery-Powered, Efficient Wireless Intelligent Sensor (LEWIS2)

2.1. Wireless Sensor Node Elements

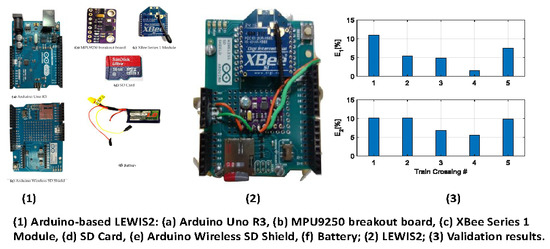

2.2. Elements of the Proposed LEWIS2

2.3. Microcontroller

2.4. Sensor

2.5. Transceiver

2.5.1. Arduino Wireless SD Shield

2.5.2. XBee Series 1 Module

2.5.3. XBee Explorer

2.6. Power Source

2.7. External Memory

3. Reference-Free Total Displacements

3.1. Principles of Total Displacement Estimation

3.2. Dynamic Displacement Estimation

3.3. Principles of Inclination Sensing and Pseudo-Static Displacement Extraction

3.4. Pseudo-Static Displacement Estimation from Rotation Data

4. Experimental Validation

4.1. Experiment

4.2. Instrumentation

5. Results and Evaluation

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Frangopol, D. Life-Cycle performance, management, and optimisation of structural systems under uncertainty: Accomplishments and challenges. Struct. Infrastruct. Eng. 2011, 7, 389–413. [Google Scholar] [CrossRef]

- Peter, C.C.; Alison, F.; Liu, S.C. Review Paper: Health Monitoring of Civil Infrastructure. Struct. Health Monit. 2003, 2, 257–267. [Google Scholar] [CrossRef] [Green Version]

- Cross, E.J.; Worden, K.; Farrar, C.R. Structural Health Monitoring for Civil Infrastructure; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 1–31. [Google Scholar]

- Chen, H.-P.; Ni, Y.-Q. Structural Health Monitoring of Large Civil Engineering Structures; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Federal Railroad Administration (FRA). Freight Rail Today; FRA: Washington, DC, USA, 2016.

- Cambridge Systematics Inc. National Rail Freight Infrastructure Capacity and Investment Study; Cambridge Systematics Inc.: Medford, MA, USA, 2007; p. 78. [Google Scholar]

- Moreu, F.; LaFave, J.M. Current Research Topics: Railroad Bridges and Structural Engineering; Newmark Structural Engineering Laboratory, University of Illinois at Urbana-Champaign: Champaign, IL, USA, 2012. [Google Scholar]

- Moreu, F.; Spencer, B.F., Jr.; Foutch, D.A.; Scola, S. Consequence-based management of railroad bridge networks. Struct. Infrastruct. Eng. 2017, 13, 273–286. [Google Scholar] [CrossRef]

- American Railway Engineering Association. Practical Guide to Railway Engineering; AREMA: Lanham, MD, USA, 2003.

- Federal Railroad Administration (FRA). Railroad Bridge Working Group Report to the Railroad Safety Advisory Committee; FRA: Washington, DC, USA, 2008.

- Wipf, T.; Ritter, M.; Wood, D. Evaluation and Field Load Testing of Timber Railroad Bridge. Transp. Res. Rec. 2000, 1696, 323–333. [Google Scholar] [CrossRef]

- Lai, Y.-C. Increasing Railway Efficiency and Capacity through Improved Operations, Control and Planning; University of Illinois at Urbana-Champaign: Champaign, IL, USA, 2008. [Google Scholar]

- Chen, W.-F.; Duan, L. Bridge Engineering Handbook: Fundamentals; CRC Press: Boca Raton, FL, USA, 2014; p. 574. [Google Scholar]

- Association of American Railroads (AAR). AAR 2013 Total Annual Spending Data; Association of American Railroads: Washington, DC, USA, 2013. [Google Scholar]

- Transportation Research Board. Maintenance and Operations of Transportation Facilities: 2005 Strategic Vision; Transportation Research Board: Washington, DC, USA, 2006. [Google Scholar]

- Moreu, F.; Li, J.; Jo, H.; Kim, R.E.; Scola, S.; Spencer, B.F.; LaFave, J.M. Reference-Free Displacements for Condition Assessment of Timber Railroad Bridges. J. Bridge Eng. 2016, 21, 04015052. [Google Scholar] [CrossRef]

- AREMA. Manual for Railway Engineering; AREMA: Lanham, MD, USA, 2010; Volume 2. [Google Scholar]

- Gavin, H.P.; Morales, R.; Reilly, K. Drift-free integrators. Rev. Sci. Instrum. 1998, 69, 2171–2175. [Google Scholar] [CrossRef]

- Yi, T.-H.; Li, H.-N.; Gu, M. Experimental assessment of high-rate GPS receivers for deformation monitoring of bridge. Measurement 2013, 46, 420–432. [Google Scholar] [CrossRef]

- Kaloop, M.R.; Li, H. Multi input–single output models identification of tower bridge movements using GPS monitoring system. Measurement 2014, 47, 531–539. [Google Scholar] [CrossRef]

- Staszewski, W.; Jenal, R.; Klepka, A.; Szwedo, M.; Uhl, T. A Review of Laser Doppler Vibrometry for Structural Health Monitoring Applications. Key Eng. Mater. 2012, 518, 1–15. [Google Scholar] [CrossRef]

- Metni, N.; Hamel, T. A UAV for bridge inspection: Visual servoing control law with orientation limits. Autom. Constr. 2007, 17, 3–10. [Google Scholar] [CrossRef]

- Liu, P.; Chen, A.; Huang, Y.-N.; Han, J.-Y.; Lai, J.-S.; Kang, S.-C.; Wu, T.-H.R.; Wen, M.-C.; Tsai, M.-H. A review of rotorcraft Unmanned Aerial Vehicle (UAV) developments and applications in civil engineering. Smart Struct. Syst. 2014, 13, 1065–1094. [Google Scholar] [CrossRef]

- Zhang, C.; Elaksher, A. An Unmanned Aerial Vehicle-Based Imaging System for 3D Measurement of Unpaved Road Surface Distresses1. Comput.-Aided Civ. Infrastruct. Eng. 2012, 27, 118–129. [Google Scholar] [CrossRef]

- Reagan, D.; Sabato, A.; Niezrecki, C. Unmanned aerial vehicle acquisition of three-dimensional digital image correlation measurements for structural health monitoring of bridges. In Proceedings of the Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure 2017, Portland, OR, USA, 26–29 March 2017; p. 1016909. [Google Scholar]

- Yoon, H.; Hoskere, V.; Park, J.-W.; Spencer, B.F. Cross-Correlation-Based Structural System Identification Using Unmanned Aerial Vehicles. Sensors 2017, 17, 2075. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Sim, S.; Jung, H. Displacement Estimation Using Multimetric Data Fusion. IEEE/ASME Trans. Mechatron. 2013, 18, 1675–1682. [Google Scholar] [CrossRef]

- Ozdagli, A.I.; Liu, B.; Moreu, F. Low-cost, efficient wireless intelligent sensors (LEWIS) measuring real-time reference-free dynamic displacements. Mech. Syst. Signal Process. 2018, 107, 343–356. [Google Scholar] [CrossRef]

- Chintalapudi, K.; Fu, T.; Paek, J.; Kothari, N.; Rangwala, S.; Caffrey, J.; Govindan, R.; Johnson, E.; Masri, S. Monitoring civil structures with a wireless sensor network. IEEE Internet Comput. 2006, 10, 26–34. [Google Scholar] [CrossRef]

- Frangopol, D.M.; Messervey, T.B. Maintenance Principles for Civil Structures. In Encyclopedia of Structural Health Monitoring; American Cancer Society: Atlanta, GA, USA, 2009. [Google Scholar]

- Ko, J.M.; Ni, Y.Q. Technology development in structural health monitoring of large-scale bridge. Eng. Struct. 2005, 27, 1715–1725. [Google Scholar] [CrossRef]

- Doebling, S.W.; Farrar, C.R.; Prime, M.B.; Shevitz, D.W. Damage Identification and Health Monitoring of Structural and Mechanical Systems from Changes in Their Vibration Characteristics: A Literature Review; LA-13070-MS; Los Alamos National Lab: Los Alamos, NM, USA, 1996.

- Sohn, H. A Review of Structural Health Monitoring Literature: 1996–2001; Los Alamos National Lab: Los Alamos, NM, USA, 2004. [Google Scholar]

- Akyildiz, I.F.; Su, W.; Sankarasubramaniam, Y.; Cayirci, E. Wireless sensor networks: A survey. Comput. Netw. 2002, 38, 393–422. [Google Scholar] [CrossRef]

- Arduino. Arduino Uno Rev3. Available online: https://store.arduino.cc/usa/arduino-uno-rev3 (accessed on 21 December 2018).

- Banzi, M. Getting Started with Arduino; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2011; p. 131. [Google Scholar]

- Invensense. MPU-9250 Product Specification Document Number: PS-MPU-9250A-01 Revision: 1.1; Invensense: San José, CA, USA, 2018. [Google Scholar]

- Adafruit Industries. Adafruit MMA8451 Accelerometer Breakout; Adafruit Industries: New York, NY, USA, 2017. [Google Scholar]

- XBee Explorer. SparkFun XBee Explorer USB-WRL-11812-SparkFun Electronics. Available online: https://www.sparkfun.com/products/11812 (accessed on 21 December 2018).

- Nanotech. Turnigy Nano-Tech 1000mah 2S 25~50C Lipo Pack. Available online: https://hobbyking.com/en_us/turnigy-nano-tech-1000mah-2s-25-50c-lipo-pack.html?___store=en_us (accessed on 21 December 2018).

- Ozdagli, A.I.; Gomez, J.A.; Moreu, F. Real-Time Reference-Free Displacement of Railroad Bridges during Train-Crossing Events. J. Bridge Eng. 2017, 22, 04017073. [Google Scholar] [CrossRef]

- Lee, H.S.; Hong, Y.H.; Park, H.W. Design of an FIR filter for the displacement reconstruction using measured acceleration in low-frequency dominant structures. Int. J. Numer. Methods Eng. 2010, 82, 403–434. [Google Scholar] [CrossRef]

- Park, J.-W.; Sim, S.-H.; Jung, H.-J. Wireless displacement sensing system for bridges using multi-sensor fusion. Smart Mater. Struct. 2014, 23, 045022. [Google Scholar] [CrossRef]

- Park, J.-W.; Lee, K.-C.; Sim, S.-H.; Jung, H.-J.; Spencer, B.F., Jr. Traffic Safety Evaluation for Railway Bridges Using Expanded Multisensor Data Fusion. Comput.-Aided Civ. Infrastruct. Eng. 2016, 31, 749–760. [Google Scholar] [CrossRef]

- Fisher, C.J. Using an Accelerometer for Inclination Sensing; Analog Devices: Norwood, MA, USA, 2010; p. 8. [Google Scholar]

- Davisson, M.T. Lateral load capacity of piles. In Proceedings of the 49th Annual Meeting of the Highway Research Board, Washington, DC, USA, 12–16 January 1970. [Google Scholar]

- Moreu, F.; Jo, H.; Li, J.; Kim, R.E.; Cho, S.; Kimmle, A.; Scola, S.; Le, H.; Spencer, B.F.; LaFave, J.M. Dynamic Assessment of Timber Railroad Bridges Using Displacements. J. Bridge Eng. 2015, 20, 04014114. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Capacity | 1000 mAh |

| Voltage | 2S1P/2 Cell/7.4 V |

| Weight | 60 g (including plug, wire, and case) |

| Dimensions | 71 × 35 × 12 mm |

| Element | Description | Price, $ |

|---|---|---|

| Arduino Uno R3 | Microcontroller | $4.00–25.00 |

| MPU9250 | Sensor | $9.99 |

| XBee Series 1 Module | Wireless transmission module | $25.00 |

| Arduino Wireless SD Shield | Communication XBee and Arduino Uno R3 | $15.00 |

| Battery | Nanotech LiPo 1000 mAh rechargeable battery | $6.33 |

| SD Card | SanDisk Ultra 80 MBs MicroSD Card, 16GB | $10.00 |

| Total | $70.35–91.35 |

| Train Number | Velocity km/h (mph) |

|---|---|

| 1 | 24.9 (15.5) |

| 2 | 33.9 (21.0) |

| 3 | 31.1 (19.3) |

| 4 | 41.5 (25.8) |

| 5 | 41.0 (25.5) |

| Train Number | Dynamic Displacement | Pseudo-Static Displacement | ||

|---|---|---|---|---|

| 1 | 19.61 | 19.24 | 68.70 | 24.83 |

| 2 | 28.70 | 20.70 | 50.98 | 20.86 |

| 3 | 2.83 | 13.36 | 67.23 | 19.50 |

| 4 | 27.62 | 20.93 | 57.80 | 19.48 |

| 5 | 4.77 | 12.44 | 70.26 | 21.12 |

| Train Number | ||

|---|---|---|

| 1 | 10.94 | 10.11 |

| 2 | 5.35 | 10.10 |

| 3 | 4.91 | 6.77 |

| 4 | 1.60 | 5.60 |

| 5 | 7.45 | 9.90 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguero, M.; Ozdagli, A.; Moreu, F. Measuring Reference-Free Total Displacements of Piles and Columns Using Low-Cost, Battery-Powered, Efficient Wireless Intelligent Sensors (LEWIS2). Sensors 2019, 19, 1549. https://doi.org/10.3390/s19071549

Aguero M, Ozdagli A, Moreu F. Measuring Reference-Free Total Displacements of Piles and Columns Using Low-Cost, Battery-Powered, Efficient Wireless Intelligent Sensors (LEWIS2). Sensors. 2019; 19(7):1549. https://doi.org/10.3390/s19071549

Chicago/Turabian StyleAguero, Marlon, Ali Ozdagli, and Fernando Moreu. 2019. "Measuring Reference-Free Total Displacements of Piles and Columns Using Low-Cost, Battery-Powered, Efficient Wireless Intelligent Sensors (LEWIS2)" Sensors 19, no. 7: 1549. https://doi.org/10.3390/s19071549