Electrophoretic Separation on an Origami Paper-Based Analytical Device Using a Portable Power Bank

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

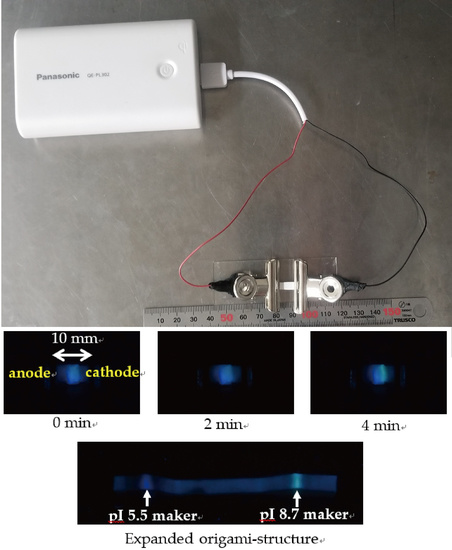

3.1. pH Distribution

3.2. pI Marker Separation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Martinez, A.W.; Phillips, S.T.; Butte, M.J.; Whitesides, G.M. Patterned paper as a platform for inexpensive, low-volume, portable bioassays. Angew. Chem. Int. Ed. 2007, 46, 1318–1320. [Google Scholar]

- Yetisen, A.K.; Akram, M.S.; Lowe, C.R. Paper-based microfluidic point-of-care diagnostic devices. Lab Chip 2013, 13, 2210–2251. [Google Scholar] [PubMed]

- Adkins, J.; Boehle, K.; Henry, C. Electrochemical paper-based microfluidic devices. Electrophoresis 2015, 36, 1811–1824. [Google Scholar] [PubMed]

- Cate, D.M.; Adkins, J.A.; Mettakoonpitak, J.; Henry, C.S. Recent Developments in Paper-Based Microfluidic Devices. Anal. Chem. 2015, 87, 19–41. [Google Scholar] [CrossRef]

- Yamada, K.; Henares, T.G.; Suzuki, K.; Citterio, D. Paper-based inkjet-printed microfluidic analytical devices. Angew. Chem. Int. Ed. 2015, 54, 5294–5310. [Google Scholar] [CrossRef]

- Yang, Y.; Noviana, E.; Nguyen, M.P.; Geiss, B.J.; Dandy, D.S.; Henry, C.S. Paper-Based Microfluidic Devices: Emerging Themes and Applications. Anal. Chem. 2016, 89, 71–91. [Google Scholar]

- Sher, M.; Zhuang, R.; Demirci, U.; Asghar, W. Paper-based analytical devices for clinical diagnosis: Recent advances in the fabrication techniques and sensing mechanisms. Expert Rev. Mol. Diagn. 2017, 17, 351–366. [Google Scholar] [PubMed]

- Smith, S.; Korvink, J.G.; Mager, D.; Land, K. The potential of paper-based diagnostics to meet the ASSURED criteria. RSC Adv. 2018, 8, 34012–34034. [Google Scholar]

- Salentijn, G.I.; Grajewski, M.; Verpoorte, E. Reinventing (Bio)chemical Analysis with Paper. Anal. Chem. 2018, 10, 2659–2665. [Google Scholar]

- Carrell, C.; Kava, A.; Nguyen, M.; Menger, R.; Munshi, Z.; Call, Z.; Nussbaum, M.; Henry, C. Beyond the lateral flow assay: A review of paper-based microfluidics. Microelectron. Eng. 2019, 206, 45–54. [Google Scholar] [CrossRef]

- Ma, J.; Yan, S.; Miao, C.; Li, L.; Shi, W.; Liu, X.; Luo, Y.; Liu, T.; Lin, B.; Wu, W.; et al. Paper Microfluidics for Cell Analysis. Adv. Healthc. Mater. 2019, 8, e1801084. [Google Scholar] [PubMed]

- Dungchai, W.; Chailapakul, O.; Henry, C.S. Electrochemical Detection for Paper-Based Microfluidics. Anal. Chem. 2009, 81, 5821–5826. [Google Scholar] [PubMed]

- Lan, W.J.; Maxwell, E.J.; Parolo, C.; Bwambok, D.K.; Subramaniam, A.B.; Whitesides, G.M. Paper-based electroanalytical devices with an integrated, stable reference electrode. Lab Chip 2013, 13, 4103–4108. [Google Scholar] [CrossRef]

- Matsuda, Y.; Shibayama, S.; Uete, K.; Yamaguchi, H.; Niimi, T. Electric conductive pattern element fabricated using commercial inkjet printer for paper-based analytical devices. Anal. Chem. 2015, 87, 5762–5765. [Google Scholar] [PubMed]

- Carvalhal, R.F.; Simão Kfouri, M.; de Oliveira Piazetta, M.H.; Gobbi, A.L.; Kubota, L.T. Electrochemical Detection in a Paper-Based Separation Device. Anal. Chem. 2010, 82, 1162–1165. [Google Scholar]

- Shiroma, L.Y.; Santhiago, M.; Gobbi, A.L.; Kubota, L.T. Separation and electrochemical detection of paracetamol and 4-aminophenol in a paper-based microfluidic device. Anal. Chim. Acta 2012, 725, 44–50. [Google Scholar]

- Tao, Z.; Sato, M.; Wu, K.; Kiyota, H.; Yamaguchi, T.; Nakano, T. A simple, rapid method for gizzerosine analysis in fish meal by paper electrophoresis. Fish. Sci. 2012, 78, 923–926. [Google Scholar]

- OuYang, L.; Wang, C.; Du, F.; Zheng, T.; Liang, H. Electrochromatographic separations of multi-component metal complexes on a microfluidic paper-based device with a simplified photolithography. RSC Adv. 2014, 4, 1093–1101. [Google Scholar] [CrossRef]

- Ge, L.; Wang, S.; Ge, S.; Yu, J.; Yan, M.; Li, N.; Huang, J. Electrophoretic separation in a microfluidic paper-based analytical device with an on-column wireless electrogenerated chemiluminescence detector. Chem. Commun. 2014, 50, 5699–5702. [Google Scholar]

- Xu, C.; Zhong, M.; Cai, L.; Zheng, Q.; Zhang, X. Sample injection and electrophoretic separation on a simple laminated paper based analytical device. Electrophoresis 2016, 37, 476–481. [Google Scholar]

- Luo, L.; Li, X.; Crooks, R.M. Low-Voltage Origami-Paper-Based Electrophoretic Device for Rapid Protein Separation. Anal. Chem. 2014, 86, 12390–12397. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Ma, B.; Xie, S.F.; Liu, K.; Fang, F. Simultaneous electrokinetic concentration and separation of proteins on a paper-based analytical device. RSC Adv. 2017, 7, 4011–4016. [Google Scholar]

- Zhan, W.; Alvarez, J.; Crooks, R.M. Electrochemical Sensing in Microfluidic Systems Using Electrogenerated Chemiluminescence as a Photonic Reporter of Redox Reactions. J. Am. Chem. Soc. 2002, 124, 13265–13270. [Google Scholar] [CrossRef]

- Li, X.; Luo, L.; Crooks, R.M. Low-voltage paper isotachophoresis device for DNA focusing. Lab Chip 2015, 15, 4090–4098. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matsuda, Y.; Sakai, K.; Yamaguchi, H.; Niimi, T. Electrophoretic Separation on an Origami Paper-Based Analytical Device Using a Portable Power Bank. Sensors 2019, 19, 1724. https://doi.org/10.3390/s19071724

Matsuda Y, Sakai K, Yamaguchi H, Niimi T. Electrophoretic Separation on an Origami Paper-Based Analytical Device Using a Portable Power Bank. Sensors. 2019; 19(7):1724. https://doi.org/10.3390/s19071724

Chicago/Turabian StyleMatsuda, Yu, Katsunori Sakai, Hiroki Yamaguchi, and Tomohide Niimi. 2019. "Electrophoretic Separation on an Origami Paper-Based Analytical Device Using a Portable Power Bank" Sensors 19, no. 7: 1724. https://doi.org/10.3390/s19071724