A Dual-Padded, Protrusion-Incorporated, Ring-Type Sensor for the Measurement of Food Mass and Intake

Abstract

:1. Introduction

2. Materials and Methods

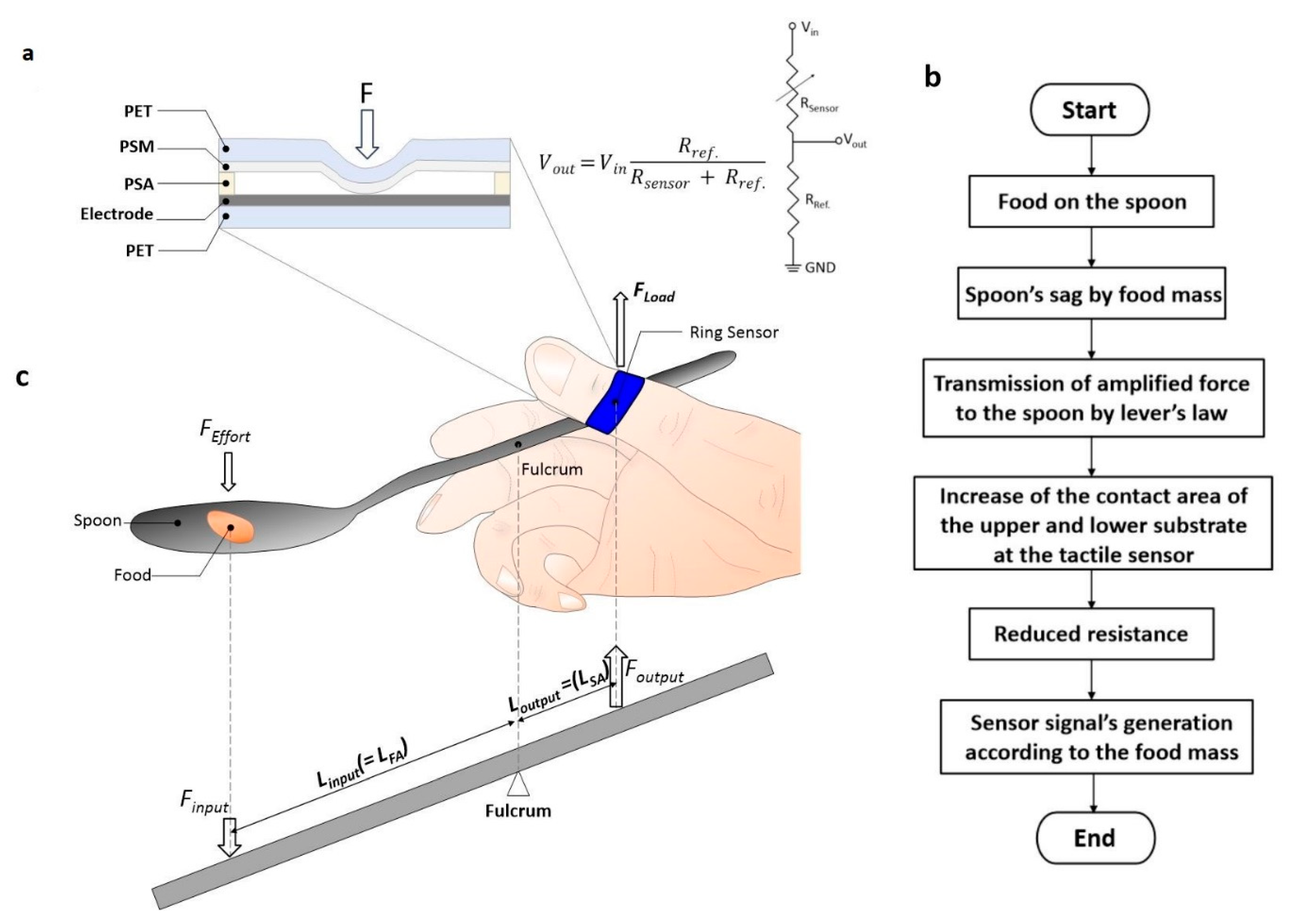

2.1. Design and Fabrication of the Ring Sensing System

2.2. Principle and Theory

3. Results

3.1. Characteristic Analysis of Sensor Signals to Spoon Arm Ratios for Different Sensor Grip Positions

3.2. Effect of the Number of Ring Sensor Pads on Ring Sensor Signals: Single Versus Dual

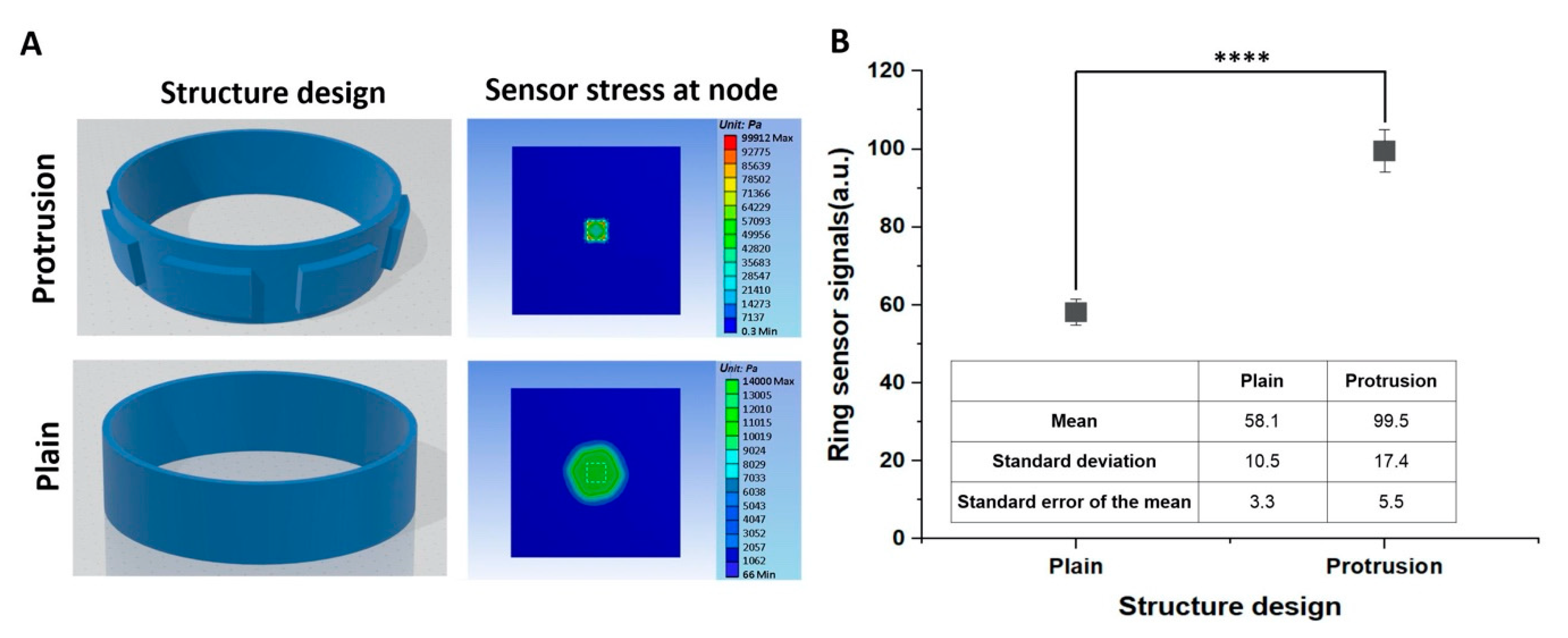

3.3. Effect of the Ring Surface Structure on Ring Sensor Signals: Plain Versus Protrusions

3.4. Ring Sensor’s Performance Analysis for Food Detection Using the F1 Score

3.5. Correlation Analysis between Food Mass and Signal of the Ring Sensor

4. Discussion

4.1. Supplementary Needs of the Ring Sensor System as a Food Mass and Intake Detector

4.2. Synergy Effect of Combining the Ring Sensor with Different Fields

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| FMI | Food mass and intake |

| EGG | Electroglottography |

| PET | Polyethylene terephthalate |

| PC | Polycarbonate |

| PMMA | Poly(methyl methacrylate) |

| PSA | Pressure-sensitive adhesive |

| FPGA | Field-programmable gate array |

| LFA | Length of the food arm |

| LSA | Length of the sensor arm |

| TP | True positive |

| FN | False negatives |

| FP | False positive |

| TN | True negative |

References

- Flegal, K.M.; Carroll, M.D.; Kit, B.K.; Ogden, C.L. Prevalence of obesity and trends in the distribution of Body Mass Index among US adults, 1999–2010. JAMA 2012, 307, 491–497. [Google Scholar] [CrossRef] [Green Version]

- Linderman, G.C.; Lu, J.; Lu, Y.; Sun, X.; Xu, W.; Nasir, K.; Schulz, W.; Jiang, L.; Krumholz, H.M. Association of Body Mass Index with blood pressure among 1.7 million Chinese adults. JAMA Netw. Open 2018, 1, e181271. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lloyd, L.J.; Langley-Evans, S.C.; McMullen, S.; Langley-Evans, S.C. Childhood obesity and adult cardiovascular disease risk: A systematic review. Int. J. Obes. 2009, 34, 18–28. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- World Health Organization. Noncommunicable Diseases Progress Monitor. 2020. Available online: https://www.who.int/publications/i/item/ncd-progress-monitor-2020 (accessed on 1 October 2020).

- Weihrauch-Blüher, S.; Schwarz, P.; Klusmann, J.-H. Childhood obesity: Increased risk for cardiometabolic disease and cancer in adulthood. Metabolism 2019, 92, 147–152. [Google Scholar] [CrossRef] [PubMed]

- Li, C.-Y.; Chen, Y.-C.; Chen, W.-J.; Huang, P.; Chu, H.-H. Proceedings of the 2013 International Symposium on Wearable Computers, ISWC ’13, Zurich, Switzerland, 9–12 September 2013; pp. 41–44.

- Roh, E.; Hwang, B.-U.; Kim, D.; Kim, B.-Y.; Lee, N.-E. Stretchable, transparent, ultrasensitive, and patchable strain sensor for human–machine interfaces comprising a nanohybrid of carbon nanotubes and conductive elastomers. ACS Nano 2015, 9, 6252–6261. [Google Scholar] [CrossRef] [PubMed]

- Tseng, P.; Napier, B.; Garbarini, L.; Kaplan, D.L.; Omenetto, F.G. Functional, RF-trilayer sensors for tooth-mounted, wireless monitoring of the oral cavity and food consumption. Adv. Mater. 2018, 30, 1703257. [Google Scholar] [CrossRef] [PubMed]

- Parate, K.; Pola, C.C.; Rangnekar, S.V.; Mendivelso-Perez, D.L.; Smith, E.A.; Hersam, M.C.; Gomes, C.L.; Claussen, J.C. Aerosol-jet-printed graphene electrochemical histamine sensors for food safety monitoring. 2D Mater. 2020, 7, 034002. [Google Scholar] [CrossRef]

- Passler, S.; Fischer, W.-J. Food intake monitoring: Automated chew event detection in chewing sounds. IEEE J. Biomed. Heal. Inform. 2014, 18, 278–289. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Zhang, N.; Wang, H.; Ding, X.; Ye, X.; Chen, G.; Cao, Y. iHear food: Eating detection using commodity bluetooth headsets. In Proceedings of the 2016 IEEE First International Conference on Connected Health: Applications, Systems and Engineering Technologies (CHASE), Washington, DC, USA, 27–29 June 2016; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2016; pp. 163–172. [Google Scholar]

- Kalantarian, H.; Alshurafa, N.; Sarrafzadeh, M. A wearable nutrition monitoring system. In Proceedings of the 2014 11th International Conference on Wearable and Implantable Body Sensor Networks, Zurich, Switzerland, 16–19 June 2014; pp. 75–80. [Google Scholar]

- Farooq, M.; Fontana, J.M.; Sazonov, E. A novel approach for food intake detection using electroglottography. Physiol. Meas. 2014, 35, 739–751. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choe, E.K.; Abdullah, S.; Rabbi, M.; Thomaz, E.; Epstein, D.A.; Cordeiro, F.; Kay, M.; Abowd, G.D.; Choudhury, T.; Fogarty, J.; et al. Semi-automated tracking: A balanced approach for self-monitoring applications. IEEE Pervasive Comput. 2017, 16, 74–84. [Google Scholar] [CrossRef] [Green Version]

- Kawano, Y.; Yanai, K. FoodCam: A real-time food recognition system on a smartphone. Multimed. Tools Appl. 2014, 74, 5263–5287. [Google Scholar] [CrossRef]

- Bettadapura, V.; Thomaz, E.; Parnami, A.; Abowd, G.D.; Essa, I. Leveraging context to support automated food recognition in restaurants. In Proceedings of the 2015 IEEE Winter Conference on Applications of Computer Vision, Waikoala, HI, USA, 5–9 January 2015; pp. 580–587. [Google Scholar]

- Zhu, F.; Bosch, M.; Woo, I.; Kim, S.; Boushey, C.J.; Ebert, D.S.; Delp, E.J. The use of mobile devices in aiding dietary assessment and evaluation. IEEE J. Sel. Top. Signal. Process. 2010, 4, 756–766. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liang, Y.; Li, J. Computer vision-based food calorie estimation: Dataset, method, and experiment. arXiv 2017, arXiv:1705.07632. [Google Scholar]

- Gao, J.; Tan, W.; Ma, L.; Wang, Y.; Tang, W. MUSEFood: Multi-Sensor-based food volume estimation on smartphones. In Proceedings of the 2019 IEEE SmartWorld, Ubiquitous Intelligence & Computing, Advanced & Trusted Computing, Scalable Computing & Communications, Cloud & Big Data Computing, Internet of People and Smart City Innovation (SmartWorld/SCALCOM/UIC/ATC/CBDCom/IOP/SCI), Leicester, UK, 19–23 August 2019; pp. 899–906. [Google Scholar]

- Yang, X.; Doulah, A.; Farooq, M.; Parton, J.; McCrory, M.A.; Higgins, J.A.; Sazonov, E. Statistical models for meal-level estimation of mass and energy intake using features derived from video observation and a chewing sensor. Sci. Rep. 2019, 9, 45. [Google Scholar] [CrossRef] [PubMed]

- Thomaz, E.; Essa, I.; Abowd, G.D. A practical approach for recognizing eating moments with wrist-mounted inertial sensing. In Proceedings of the 2015 ACM International Joint Conference on Pervasive and Ubiquitous Computing, Osaka, Japan, 7–11 September 2015; pp. 1029–1040. [Google Scholar]

- Farooq, M.; Sazonov, E. A novel wearable device for food intake and physical activity recognition. Sensors 2016, 16, 1067. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farooq, M.; Sazonov, E. Accelerometer-based detection of food intake in free-living individuals. IEEE Sens. J. 2018, 18, 3752–3758. [Google Scholar] [CrossRef] [PubMed]

- Chung, J.; Oh, W.; Baek, D.; Ryu, S.; Lee, W.G.; Bang, H. Design and evaluation of smart glasses for food intake and physical activity classification. J. Vis. Exp. 2018, e56633. [Google Scholar] [CrossRef] [PubMed]

- Chung, J.; Chung, J.; Oh, W.; Yoo, Y.; Lee, W.G.; Bang, H. A glasses-type wearable device for monitoring the patterns of food intake and facial activity. Sci. Rep. 2017, 7, 41690. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Han, D.Y.; Park, B.O.; Kim, J.W.; Lee, J.H.; Lee, W.G. Non-verbal communication and touchless activation of a radio-controlled car via facial activity recognition. Int. J. Precis. Eng. Manuf. 2020, 21, 1035–1046. [Google Scholar] [CrossRef]

| Movement Categories | Actual Activities | ||

|---|---|---|---|

| Food on Spoon | No Food on Spoon | ||

| Category I (Vertical movement) | Food on spoon | 141 | 2 |

| No food on spoon | 9 | 148 | |

| Accuracy | 0.963 | ||

| F1 score | 0.962 | ||

| Category II (Circular movement on the plane) | Food on spoon | 148 | 3 |

| No food on spoon | 2 | 147 | |

| Accuracy | 0.983 | ||

| F1 score | 0.983 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, W.; Lee, J.; Lee, W.G. A Dual-Padded, Protrusion-Incorporated, Ring-Type Sensor for the Measurement of Food Mass and Intake. Sensors 2020, 20, 5623. https://doi.org/10.3390/s20195623

Hong W, Lee J, Lee WG. A Dual-Padded, Protrusion-Incorporated, Ring-Type Sensor for the Measurement of Food Mass and Intake. Sensors. 2020; 20(19):5623. https://doi.org/10.3390/s20195623

Chicago/Turabian StyleHong, Wonki, Jungmin Lee, and Won Gu Lee. 2020. "A Dual-Padded, Protrusion-Incorporated, Ring-Type Sensor for the Measurement of Food Mass and Intake" Sensors 20, no. 19: 5623. https://doi.org/10.3390/s20195623