Comparison of Three Prototypes of PPG Sensors for Continual Real-Time Measurement in Weak Magnetic Field †

Abstract

:1. Introduction

2. Methods

2.1. Photoplethysmography—Types, Basic Properties, and Principles of Sensing

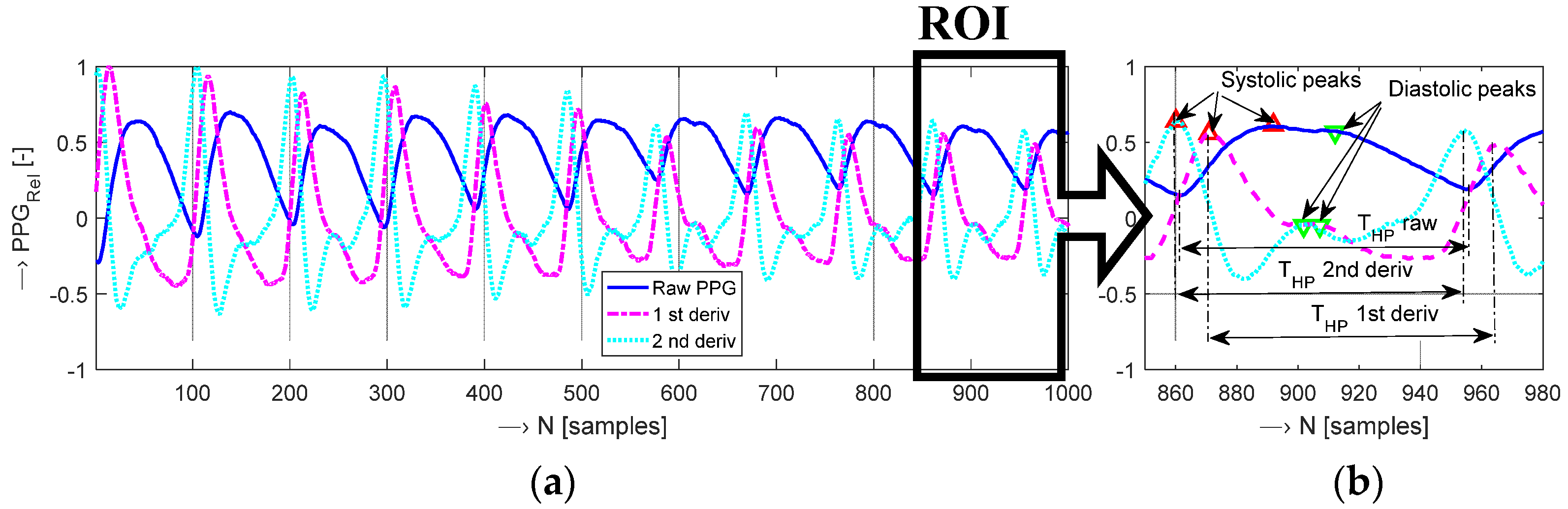

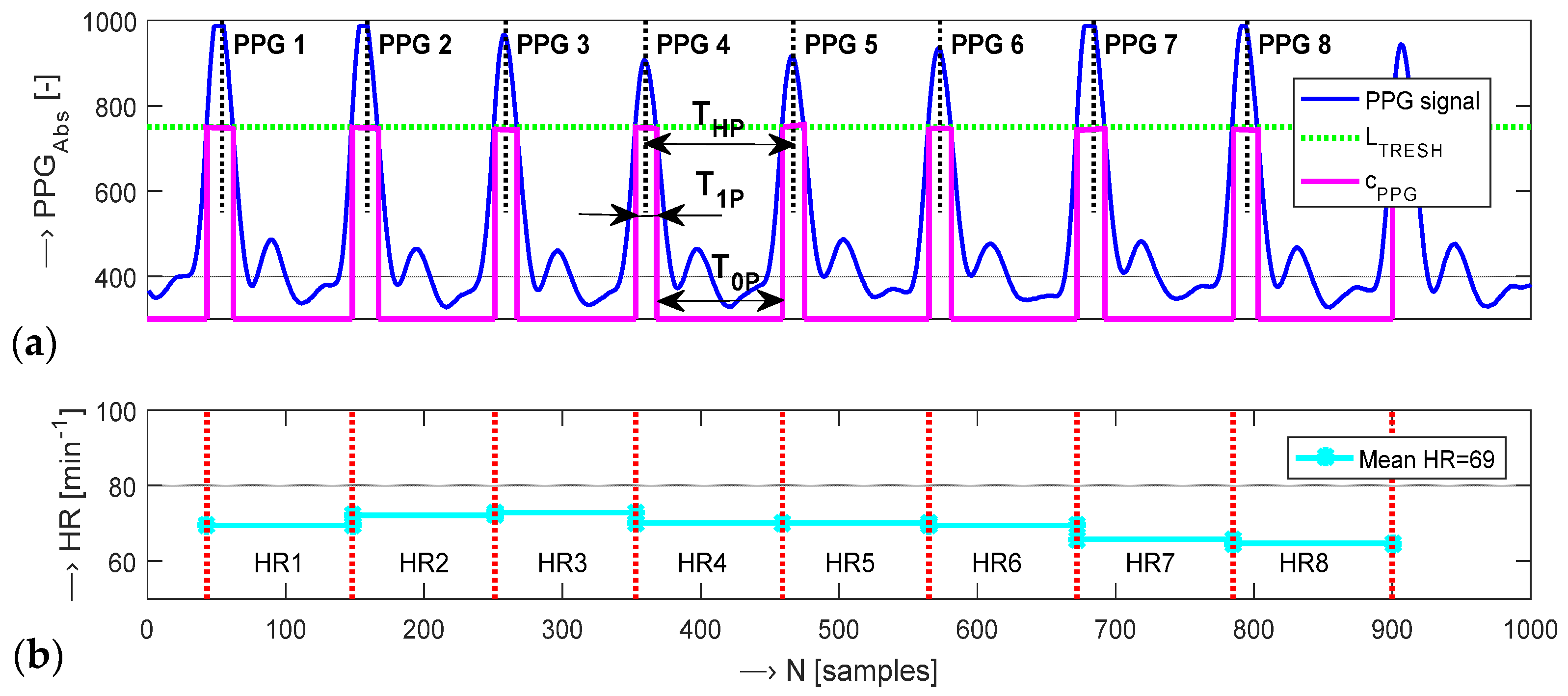

2.2. Determination of PPG Signal Properties and Heart Rate Calculation

3. Objects, Experiments, and Results

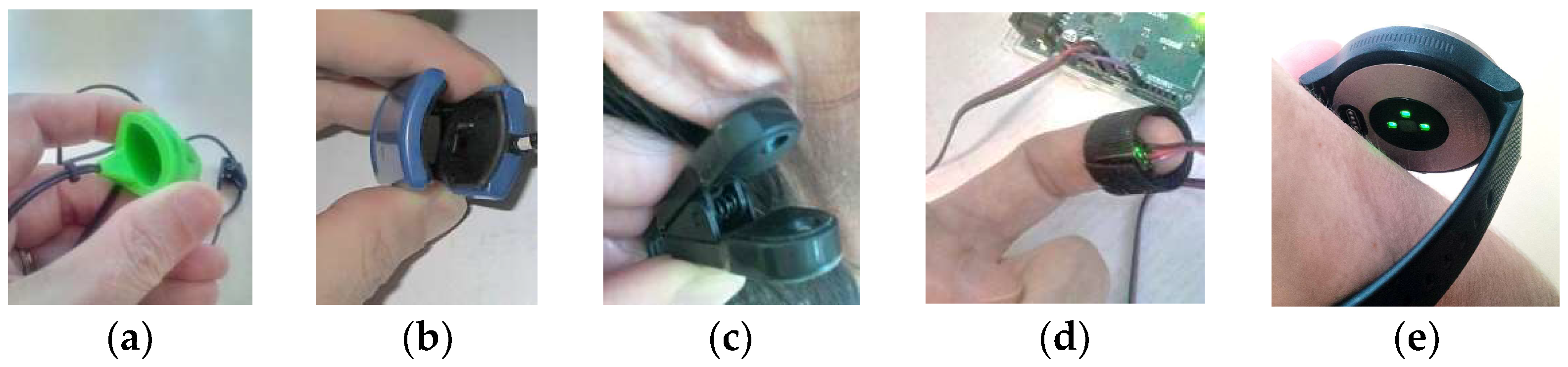

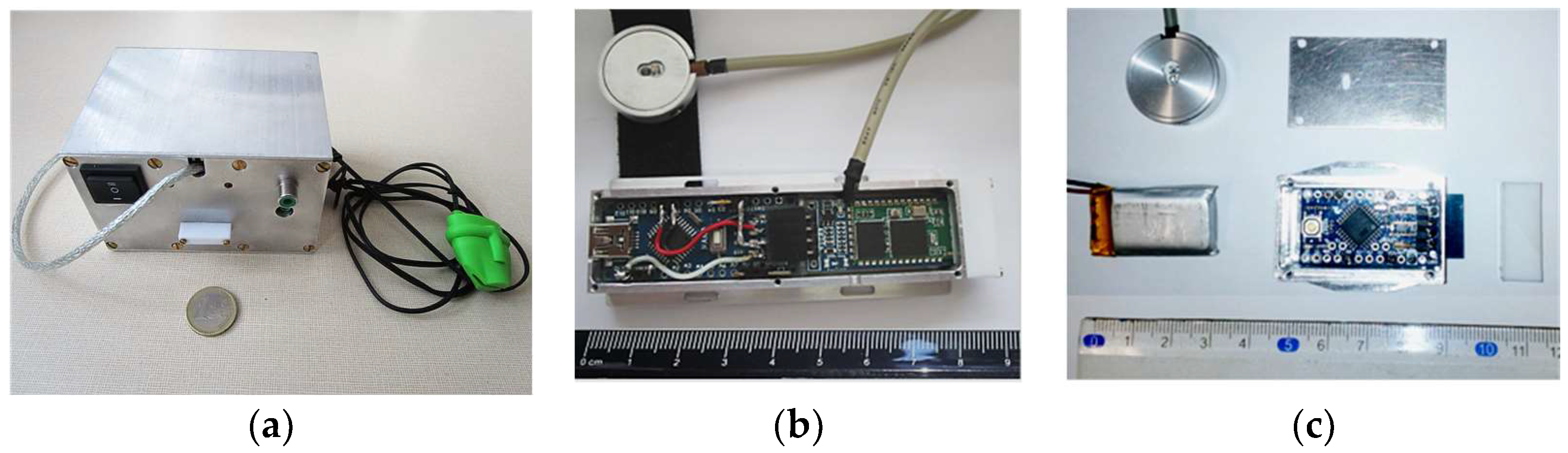

3.1. Principal Description of Developed Prototypes of PPG Sensors

- have a common basic structure consisting of four functional blocks;

- use Arduino boards based on the processor ATmega328P with integrated 10-bit A/D converters, so the theoretical maximum ADRES value is 210 = 1024;

- enable real-time PPG signal sensing in the low magnetic field with RF disturbance environment;

- the sensor’s body and optical part are covered by aluminum boxes;

- work in the slave mode: after initialization they wait for commands from the master device via the BT connection;

- PPG signal sensing in 2 operating modes: (1) PPG wave pick up in data blocks with the length of NMEAS = {1k, 4k, 10k, and 25k} using 16-bit binary data samples; (2) continual PPG signal measurement that begins and ends by <Start> and <Stop> commands;

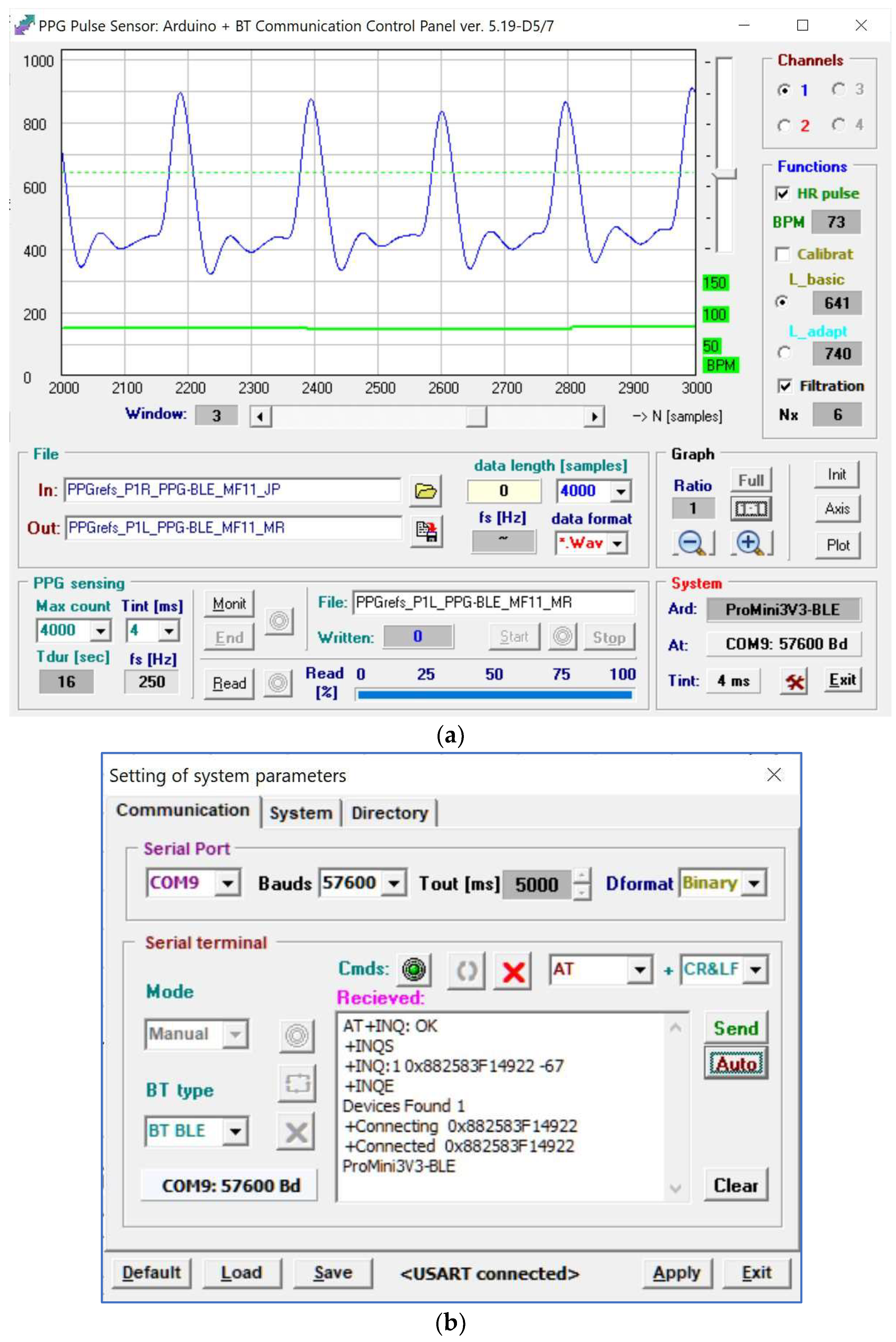

- work with the control application “PPGsens7BT.exe” developed for Windows platform (successfully tested under XP, 7, and 10 versions) created for the master device to control the PPG sensor;

- a service program implemented in the microcontroller board supports measurement and data transmission;

- adjustable time delay to read the analog signal from the optical sensor, to perform 10-bit A/D conversion and data transmission to the control device;

- transmission of data blocks with the length of NMEAS = 1k-samples are used for monitoring and display of the currently sensed PPG signal. For practical PPG signal measurement, the setting of NMEAS = 10k or 24k-samples is usually applied enabling a 1-shot storage of the PPG wave with duration of 80 or 240 s (using fS = 125 Hz). If longer time durations of sensed PPG signals are required, the signal data can be stored directly to an output wave file. Other requested time durations of sensed PPG signals can be solved using the direct storage to an output wave file.

3.2. Description of the Control Application Based on Windows Platform

3.3. Performed Measurements and Analyses

- Preliminary testing and verification of the functionality of the PPG sensors in cooperation with the control application for three operation modes: (1) without BT connection (NC), (2) after established connection to the control device (CE), (3) during real-time transmission of PPG signal samples to the control master device (MC). This phase was accompanied by a measurement of the sensor’s mean DC using a different power supply of 5/3.7 V in the 3 mentioned operation modes;

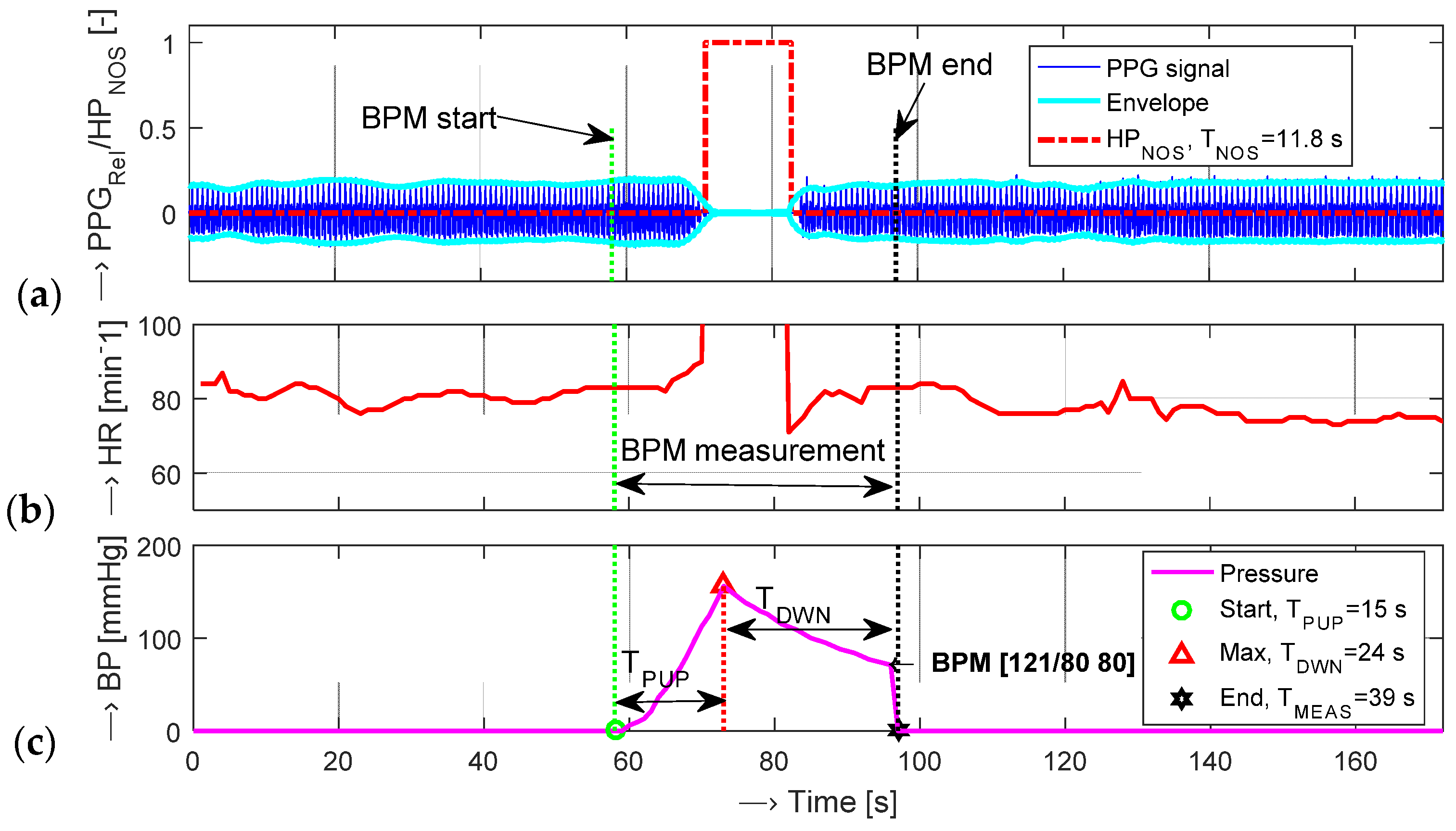

- Testing of the precision and stability of the HR values determined from the PPG signal by comparative measurement with another commercial HR measurement device (portable BPM) and by a POXI device, all in the normal laboratory conditions. In addition, a supplementary analysis of the influence of the BP/HR parallel measurement by a BPM device on the same hand as the PPG signal recording was performed;

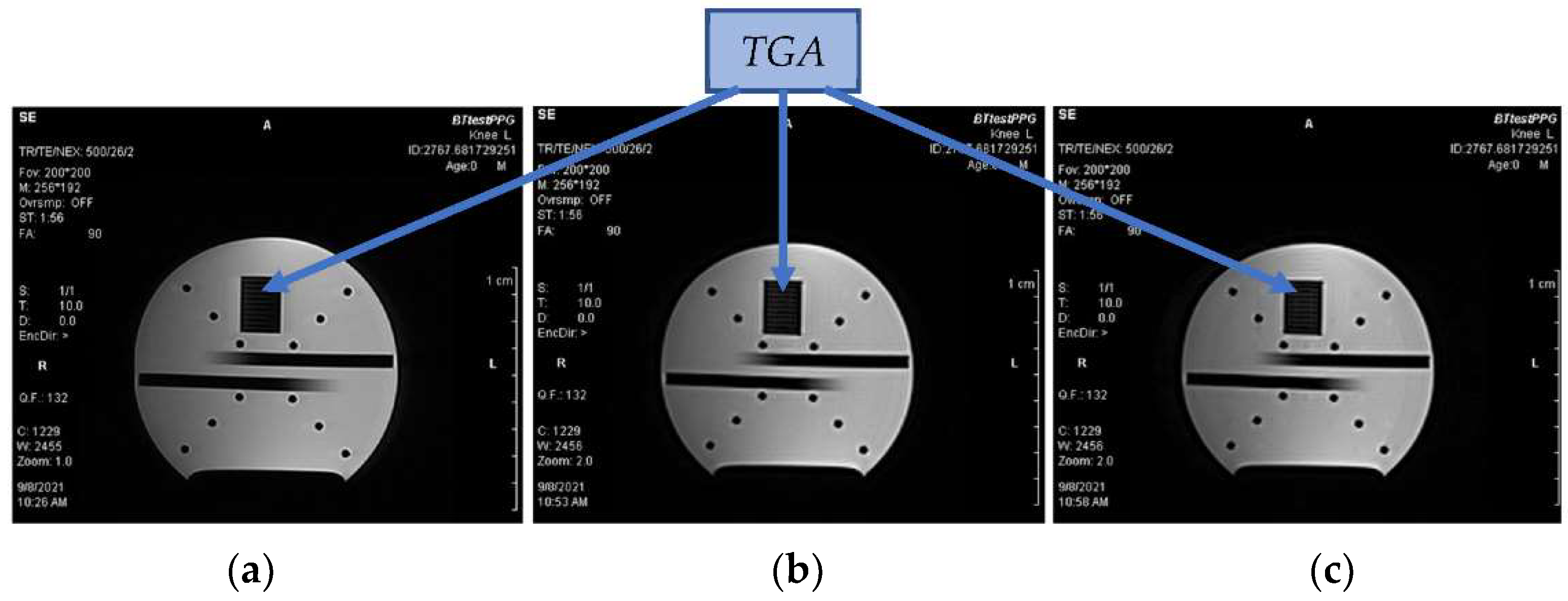

- Analyzing the functionality, quality, and stability of the BT connection between the tested PPG sensor located inside the scanning area of the MRI device and the control device located outside the shielding cage. Additional testing of the influence of the BT transmission in the scanning area on the quality of the finally obtained MR images;

- First-step measurement of the PPG signals in a low magnetic field environment of the MRI device, analysis of the PPG signal properties.

3.4. Experimental Conditions

4. Discussion of Obtained Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Steckner, M.C. A review of MRI acoustic noise and its potential impact on patient and worker health. eMagRes 2020, 9, 21–38. [Google Scholar] [CrossRef]

- Celka, P.; Charlton, P.H.; Farukh, B.; Chowienczyk, P.; Alastruey, J. Influence of mental stress on the pulse wave features of photoplethysmograms. Healthc. Technol. Lett. 2020, 7, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Charlton, P.H.; Marozas, V. Wearable photoplethysmography devices. In Photoplethysmography: Technology, Signal Analysis, and Applications; Kyriacou, P.A., Allen, J., Eds.; Elsevier: London, UK, 2022; pp. 401–438. [Google Scholar] [CrossRef]

- Jarchi, D.; Salvi, D.; Tarassenko, L.; Clifton, D.A. Validation of instantaneous respiratory rate using reflectance PPG from different body positions. Sensors 2018, 18, 3705. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rundo, F.; Conoci, S.; Ortis, A.; Battiato, S. An advanced bio-inspired photoplethysmography (PPG) and ECG pattern recognition system for medical assessment. Sensors 2018, 18, 405. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Allen, J. Photoplethysmography and its application in clinical physiological measurement. Physiol. Meas. 2007, 28, R1–R39. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mainka, A.; Platzek, I.; Mattheus, W.; Fleischer, M.; Müller, A.S. Three-dimensional vocal tract morphology based on multiple magnetic resonance images is highly reproducible during sustained phonation. J. Voice 2017, 31, e11–e504. [Google Scholar] [CrossRef] [PubMed]

- Hansen, H.L.; Patil, S. Speech under stress: Analysis, modeling and recognition. In Speaker Classification I; Muller, C., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; Volume LNAI 4343, pp. 108–137. [Google Scholar] [CrossRef]

- Schickhofer, L.; Malinen, J.; Mihaescu, M. Compressible flow simulations of voiced speech using rigid vocal tract geometries acquired by MRI. J. Acoust. Soc. Am. 2019, 145, 2049–2061. [Google Scholar] [CrossRef] [PubMed]

- Přibil, J.; Přibilová, A.; Frollo, I. Physiological impact of vibration and noise in an open-air magnetic resonance imager: Analysis of a PPG signal of an examined person. Proceedings 2020, 42, 14. [Google Scholar] [CrossRef] [Green Version]

- Přibil, J.; Přibilová, A.; Frollo, I. Comparative measurement of the PPG signal on different human body positions by sensors working in reflection and transmission modes. Eng. Proc. 2020, 2, 69. [Google Scholar] [CrossRef]

- Přibil, J.; Přibilová, A.; Frollo, I. Two realizations of the wearable PPG sensor working in reflectance mode for measurement in weak magnetic field. Eng. Proc. 2021, 10, 55. [Google Scholar] [CrossRef]

- E-Scan Opera. Image Quality and Sequences Manual; Revision 830023522; Esaote S.p.A.: Genoa, Italy, 2008. [Google Scholar]

- Smith, A.G. Introduction to Arduino: A Piece of Cake; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2011; 170p. [Google Scholar]

- Elgendi, M. PPG Signal Analysis: An Introduction Using MATLAB, 1st ed.; CRC Press: Abingdon, OX, USA, 2021; pp. 27–36. [Google Scholar]

- Caesarendra, W.; Hishamuddin, T.A.; Lai, D.T.C.; Husaini, A.; Nurhasanah, L.; Glowacz, A.; Alfarisy, G.A.F. An embedded system using convolutional neural network model for online and real-time ECG signal classification and prediction. Diagnostics 2022, 12, 795. [Google Scholar] [CrossRef] [PubMed]

- Nitzan, M.; Ovadia-Blechman, Z. Physical and physiological interpretations of the PPG signal. In Photoplethysmography: Technology, Signal Analysis, and Applications; Kyriacou, P.A., Allen, J., Eds.; Elsevier: London, UK, 2022; pp. 319–339. [Google Scholar] [CrossRef]

- Ahmed, H.; Rony, R.J. Understanding self-reported stress among drivers and designing stress monitor using heart rate variability. Qual. User Exp. 2021, 6, 4. [Google Scholar] [CrossRef]

- Blazek, V.; Venema, B.; Leonhardt, S.; Blazek, P. Customized optoelectronic in-ear sensor approaches for unobtrusive continuous monitoring of cardiorespiratory vital signs. Int. J. Ind. Eng. Manag. 2018, 9, 197–203. [Google Scholar] [CrossRef]

- Pulse Oximeter Model 2500 A. Operator’s Manual. © 2014 Nonin Medical, Inc., USA. Available online: https://www.nonin.com/products/palmsat-2500/ (accessed on 7 June 2020).

- Easy Pulse Sensor (Version 1.1). Overview-Embedded Lab. Available online: http://embedded-lab.com/blog/easy-pulse-version-1-1-sensor-overview (accessed on 6 June 2019).

- Kettler Consul Super–Art. Nr. 07954-900. User Manual. Available online: https://www.libble.eu/kettler/c457749/ (accessed on 14 July 2020).

- Garmin Vívoactive® 3. Available online: https://www.garmin.com/en-US/p/571520#specs (accessed on 25 May 2020).

- Hui, M.L.; Nisar, H.; Ho, Y.K.; Chiong, T.P. A video based heart rate monitoring system for drivers using photoplethysmography signal. In Proceedings of the 2018 IEEE Region 10 Humanitarian Technology Conference, Colombo, Sri Lanka, 6–8 December 2018; p. 8629825. [Google Scholar] [CrossRef]

- Mejía-Mejía, E.; Allen, J.; Budidha, K.; El-Hajj, C.; Kyriacou, P.A.; Charlton, P.H. Photoplethysmography signal processing and synthesis. In Photoplethysmography: Technology, Signal Analysis, and Applications; Kyriacou, P.A., Allen, J., Eds.; Elsevier: London, UK, 2022; pp. 69–145. [Google Scholar] [CrossRef]

- Bonomi, A.G.; Schipper, F.; Eerikäinen, L.M.; Margarito, J.; Van Dinther, R.; Muesch, G.; De Morree, H.M.; Aarts, R.M.; Babaeizadeh, S.; McManus, D.D.; et al. Atrial fibrillation detection using a novel cardiac ambulatory monitor based on photo-plethysmography at the wrist. J. Am. Heart Assoc. 2018, 7, e009351. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Neshitov, A.; Tyapochkin, K.; Smorodnikova, E.; Pravdin, P. Wavelet analysis and self-similarity of photoplethysmography signals for HRV estimation and quality assessment. Sensors 2021, 21, 6798. [Google Scholar] [CrossRef] [PubMed]

- Arduino UNO R3. Available online: https://docs.arduino.cc/hardware/uno-rev3 (accessed on 20 July 2020).

- Suwarjono, S.; Wayangkau, I.H.; Istanto, T.; Rachmat, R.; Marsujitullah, M.; Hariyanto, H.; Caesarendra, W.; Legutko, S.; Glowacz, A. Design of a home fire detection system using Arduino and SMS gateway. Knowledge 2021, 1, 61–74. [Google Scholar] [CrossRef]

- Arduino and Bluetooth Module HC-06. Available online: https://www.aranacorp.com/en/arduino-and-bluetooth-module-hc-06/ (accessed on 21 October 2020).

- Pulse Sensor Amped Product (Adafruit 1093): World Famous Electronics LLC. Ecommerce Getting Starter Guide. Available online: https://pulsesensor.com/pages/code-and-guide (accessed on 16 July 2020).

- Arduino Nano Official Store. Available online: http://arduino.cc/en/Main/ArduinoBoardNano (accessed on 21 October 2020).

- Using the Arduino Pro Mini 3.3V. Available online: https://learn.sparkfun.com/tutorials/using-the-arduino-pro-mini-33v (accessed on 7 April 2021).

- MLT-BT05 4.0 Bluetooth Serial Communication Module. Available online: https://www.techonicsltd.com/product/mlt-bt05-ble4-0/ (accessed on 12 May 2021).

- Microlife BP A150 AFIB. Available online: https://www.microlife.cz/produkty/krevni-tlak/automaticke-tlakomery/bp-a150-afib (accessed on 12 May 2019).

- China Berry Hospital Oxycare Pulse Oximeter for Kids. Available online: https://berrymedical.en.made-in-china.com/product/zsuQEvPLsqcJ/Ch (accessed on 12 May 2021).

- RSSI-Received Signal Strength Indication. Available online: https://www.rfwireless-world.com/Terminology/RSSI-Received-Signal-Strength-Indication.html (accessed on 3 February 2022).

| Sensor Prototype | Optical Sensor Part | Mounting Method | Wearable | Arduino Board (1) | BT Module/Standard | Sensor’s Body Dimensions (L × W × H) | Sensor’s Body Weight |

|---|---|---|---|---|---|---|---|

| PPG-EP | HRM-2511E | rubber ring | No | Uno v. 3.0 | HC-06/BT 2.0 | 105 × 70 × 80 mm | 445 g |

| PPG-PS1 | Adafruit 1093 | 1” aluminum target fixed by elastic ribbon | Yes | Nano v. 3.0 | HC-06/BT 2.0 | 80 × 20 × 10 mm | 38 g |

| PPG-BLE | Adafruit 1093 | Yes | Pro Mini v. 2.0 | MLT-BT05/BT4.1 BLE | 40 × 25 × 15 mm | 40 g (2) |

| Sensor Prototype | Sensor Working Mode | Processor fCLK | Max. BT Baud Rate | Supported fS for PPG Signals | Power Supply (Voltage/Capacity) |

|---|---|---|---|---|---|

| PPG-EP | transmittance | 16 MHz | 115,200 bps | {100, 125, 200, 250, 500, 1000} Hz | 5 V/22,000 mAh |

| PPG-PS1 | reflectance | 16 MHz | 115,200 bps | {100, 125, 200, 250, 500, 1000} Hz | 5 V/2200 mAh |

| PPG-BLE | reflectance | 8 MHz | 57,600 bps | {100, 125, 200, 250, 500} Hz | 3.7 V/125 mAh |

| Sensor Type | Supplying Method | Functional State | ||

|---|---|---|---|---|

| NC | CE | MC | ||

| PPG-EP | 5 V Power bank via USB | 53 mA | 60 mA | 68 mA |

| PPG-PS1 | 5 V Power bank via USB | 18 mA | 26 mA | 30 mA |

| PPG-BLE | 3.7 V Li-Po battery cell | 13.5 mA | 14 mA | 17 mA |

| Sensor (A)/Parameters | HRVAR [%] | HRDIFF [%] | ||||

|---|---|---|---|---|---|---|

| Left | Right | Both | Left | Right | Both | |

| PPG-EP | 3.16 | 2.66 | 2.91 | −1.48 | −1.24 | −1.36 |

| PPG-PS1 | 4.35 | 3.78 | 4.06 | 2.52 | 1.89 | 2.21 |

| PPG-BLE | 3.76 | 3.61 | 3.68 | −1.82 | −1.16 | −1.49 |

| BT Module (A)/Condition | OD&NS | CD&NS | CD&RS |

|---|---|---|---|

| HC-06 (5 V, BT 2.0) | −60 dBm | −90 dBm | −91 dBm |

| MLT-BT05 (3.3 V, BT 4.1) | −86 dBm | −92 dBm | −94 dBm |

| Parameter/Condition (A) | PPG-EP (CD&NS/CD&RS) | PPG-PS1 (CD&NS/CD&RS) | PPG-BLE (CD&NS/CD&RS) | |||

|---|---|---|---|---|---|---|

| Male | Female | Male | Female | Male | Female | |

| PPGRANGE [%] | 55/52 | 49/47 | 50/48 | 45/42 | 45/43 | 41/40 |

| HPRIPP [%] | 13/14 | 15/16 | 15/17 | 18/20 | 15/16 | 17/18 |

| HRVAR [%] | 1.8/1.9 | 2.4/3.2 | 2.9/4.7 | 3.4/6.2 | 2.7/3.8 | 3.1/5.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Přibil, J.; Přibilová, A.; Frollo, I. Comparison of Three Prototypes of PPG Sensors for Continual Real-Time Measurement in Weak Magnetic Field. Sensors 2022, 22, 3769. https://doi.org/10.3390/s22103769

Přibil J, Přibilová A, Frollo I. Comparison of Three Prototypes of PPG Sensors for Continual Real-Time Measurement in Weak Magnetic Field. Sensors. 2022; 22(10):3769. https://doi.org/10.3390/s22103769

Chicago/Turabian StylePřibil, Jiří, Anna Přibilová, and Ivan Frollo. 2022. "Comparison of Three Prototypes of PPG Sensors for Continual Real-Time Measurement in Weak Magnetic Field" Sensors 22, no. 10: 3769. https://doi.org/10.3390/s22103769