A Virtual Combustion Sensor Based on Ion Current for Lean-Burn Natural Gas Engine

Abstract

:1. Introduction

2. Experimental Setup

3. Results

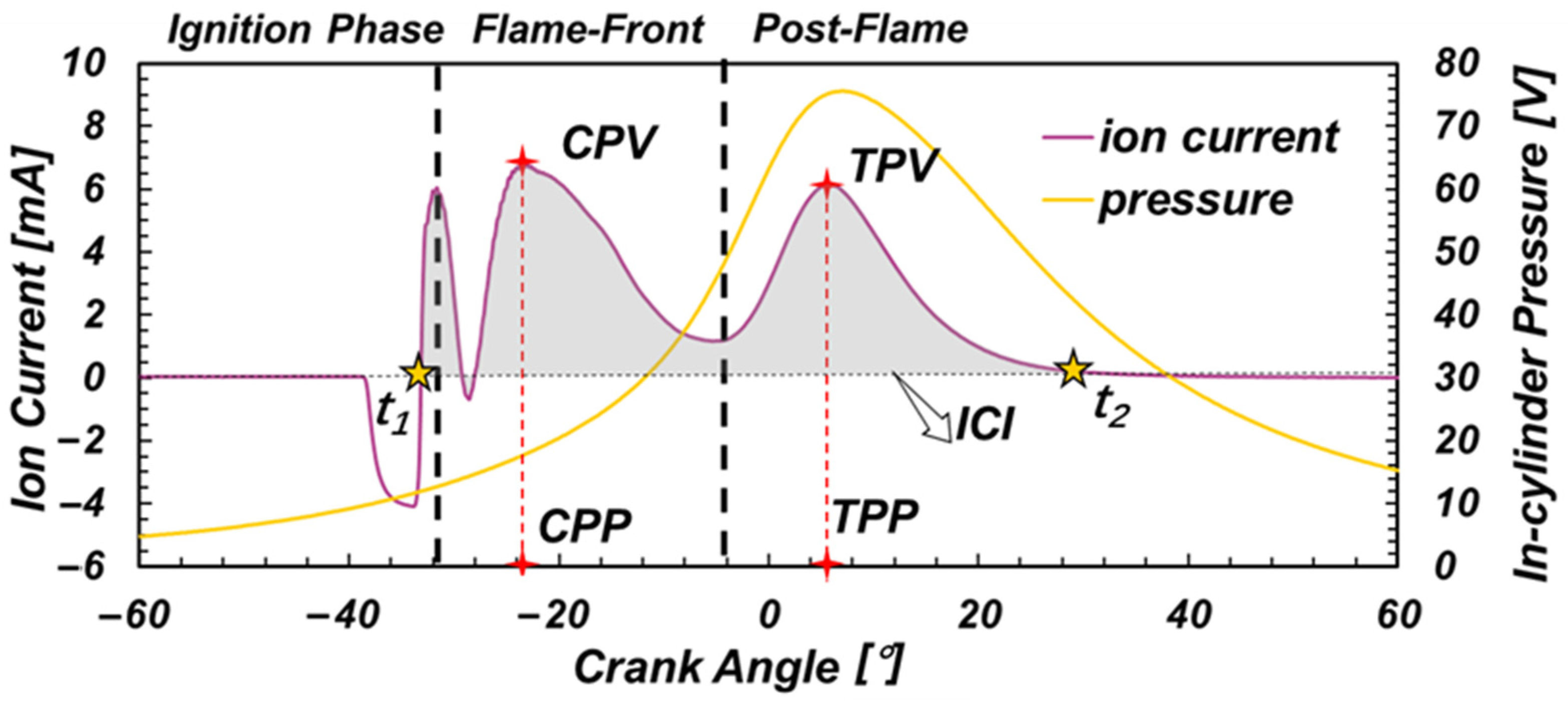

3.1. Ion Current Signals under Different Operating Conditions

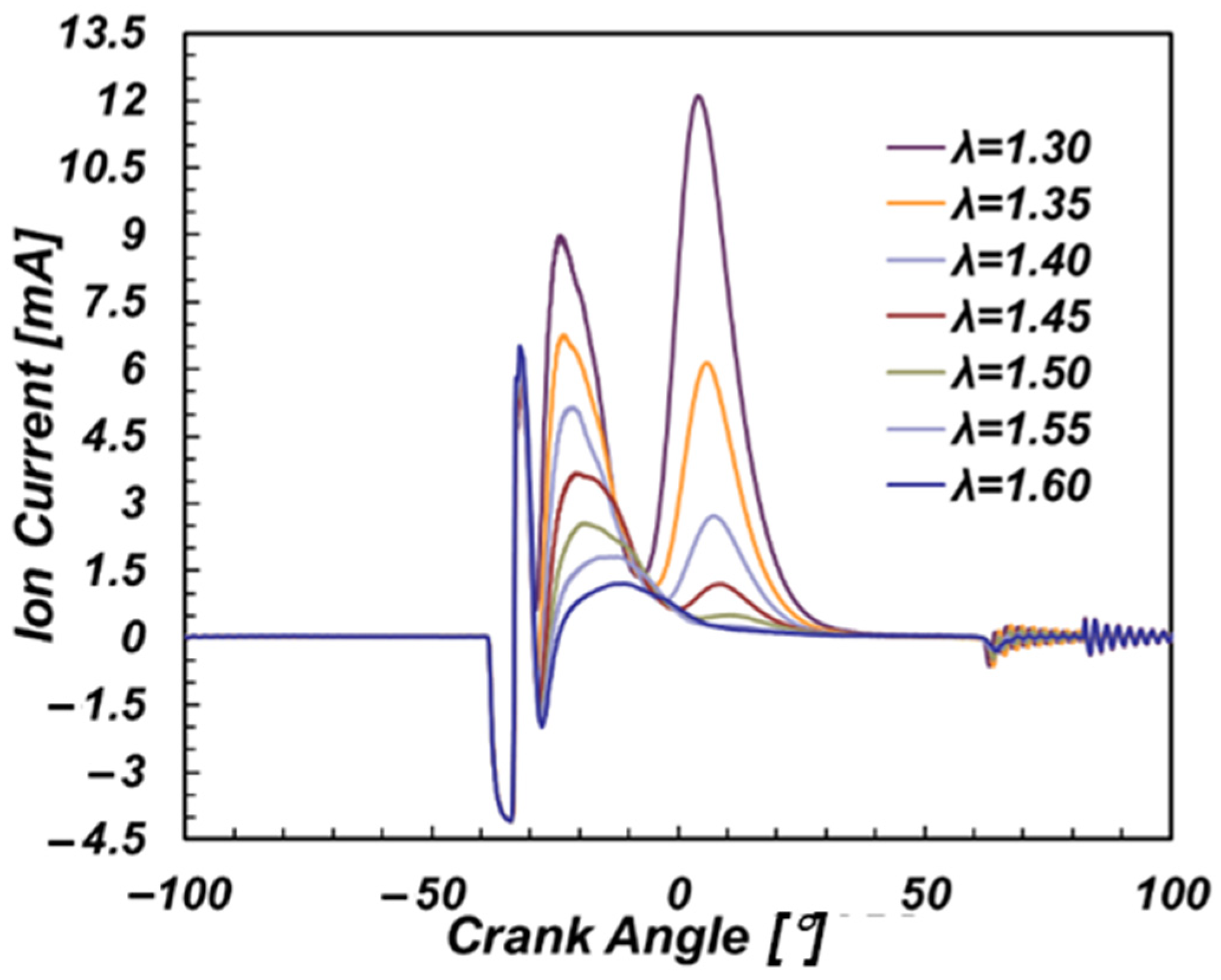

3.1.1. Excess Air Coefficient Effects on Ion Current Signals

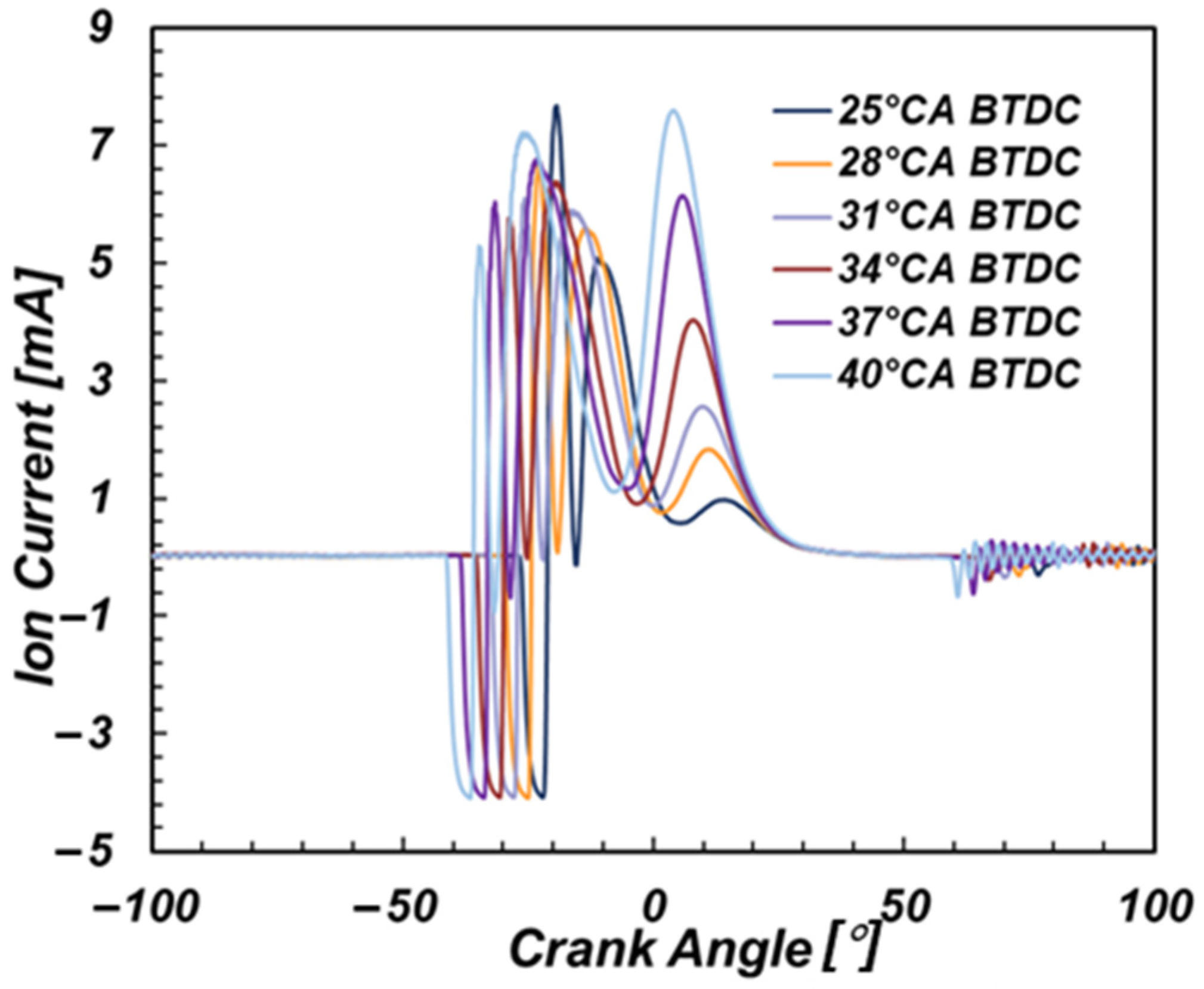

3.1.2. Ignition Timing Effects on Ion Current Signals

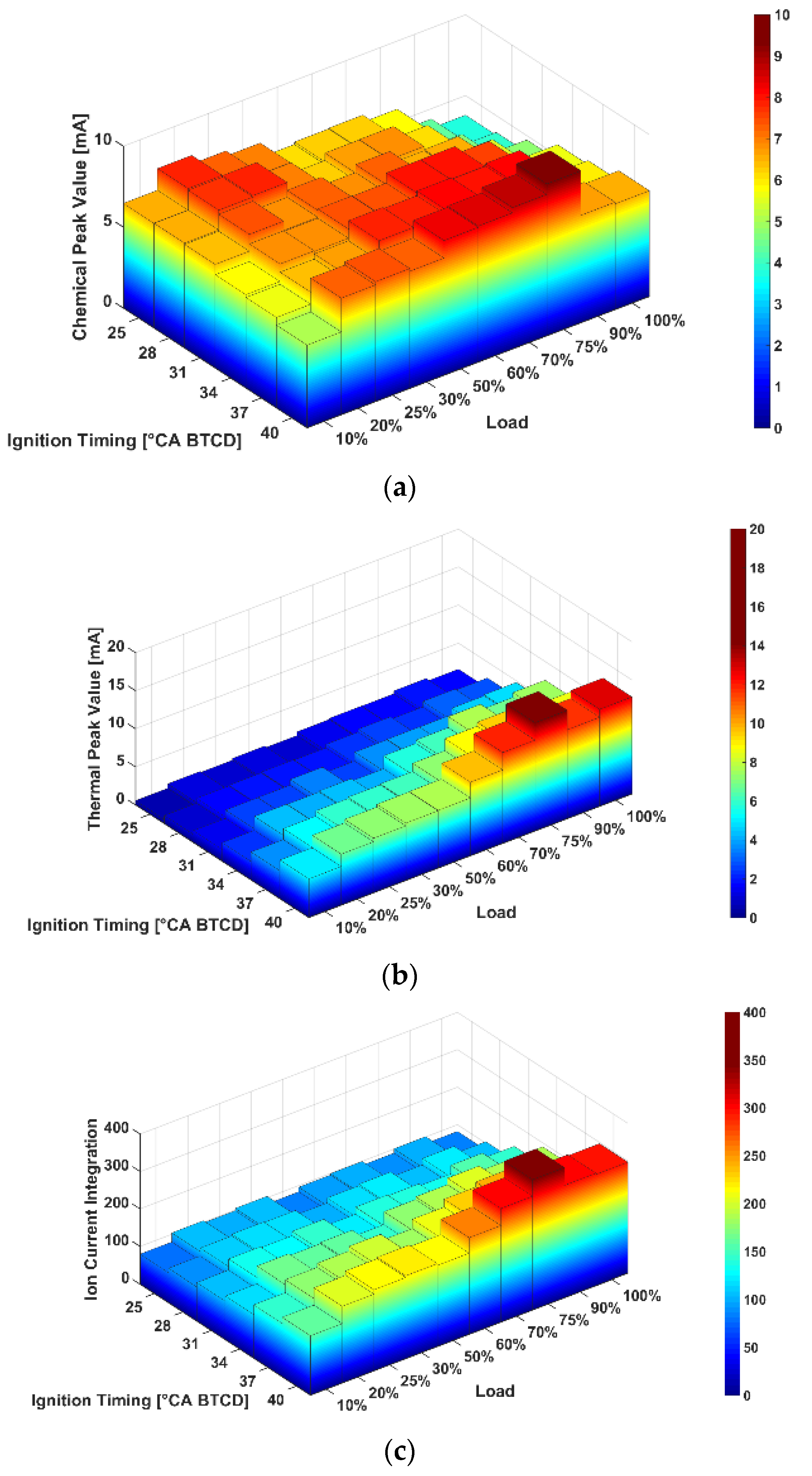

3.1.3. Engine Load Effects on Ion Current Signals

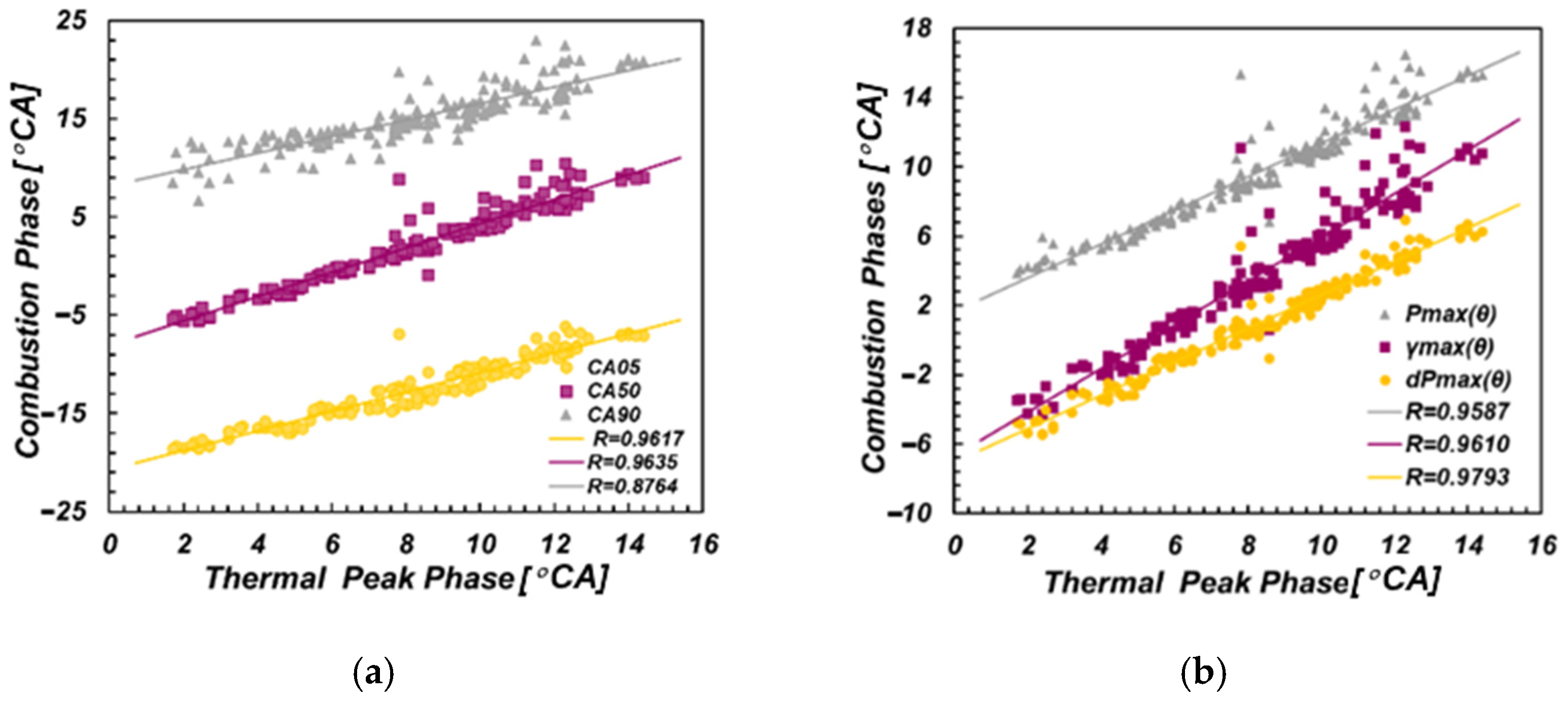

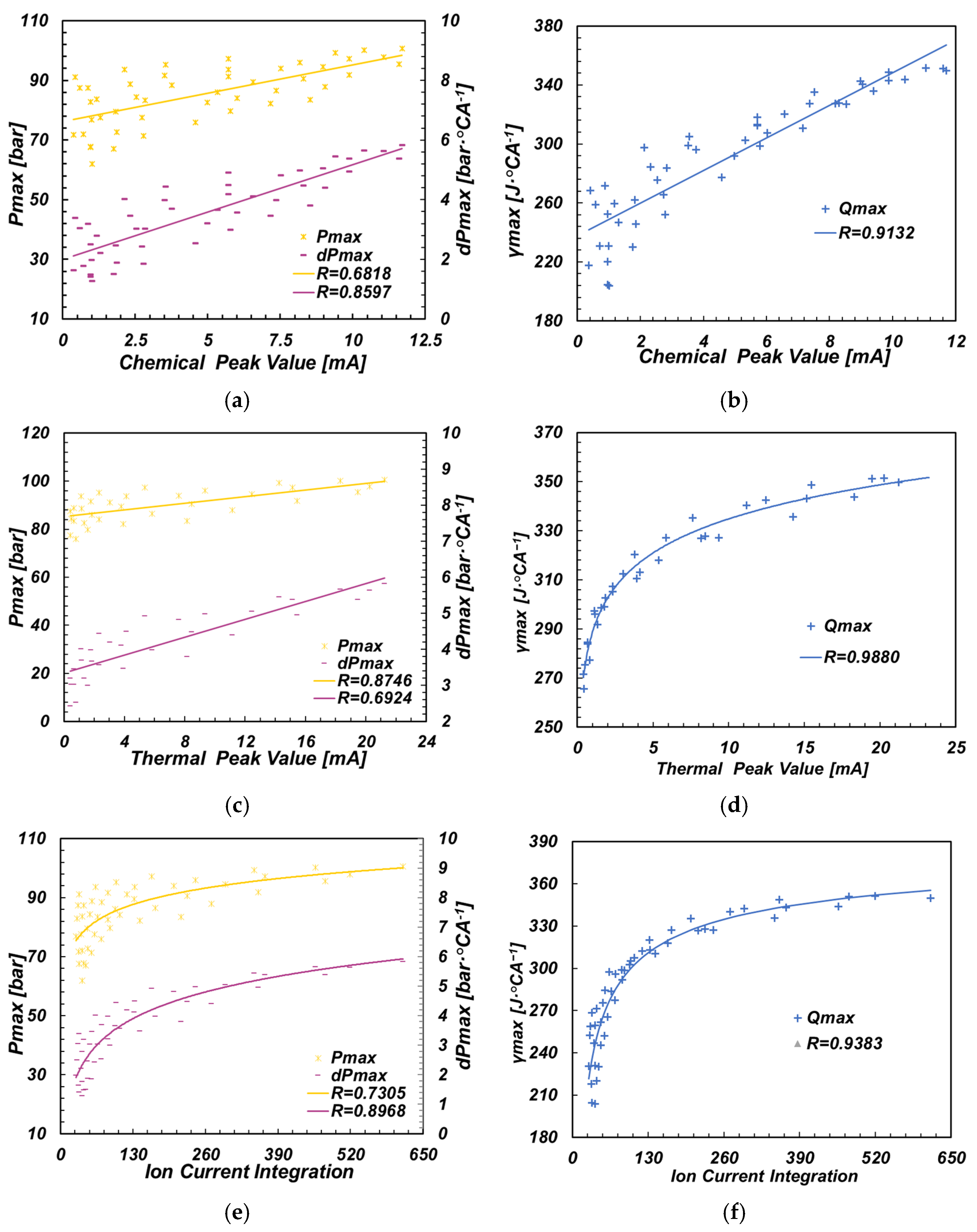

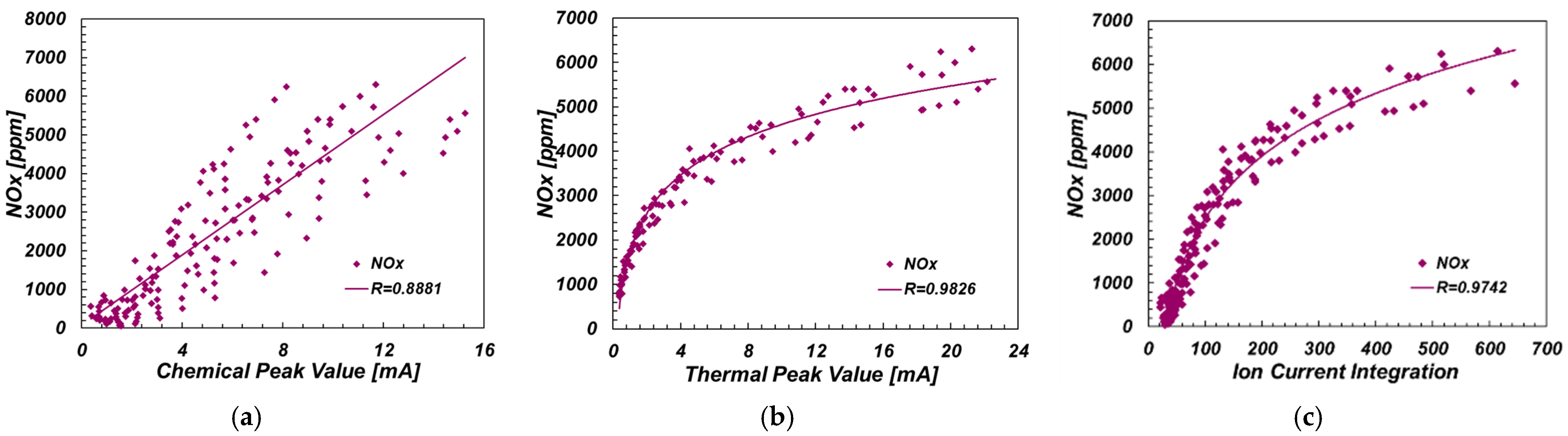

3.2. Correlation of Ion Current with Combustion and Emission Parameters

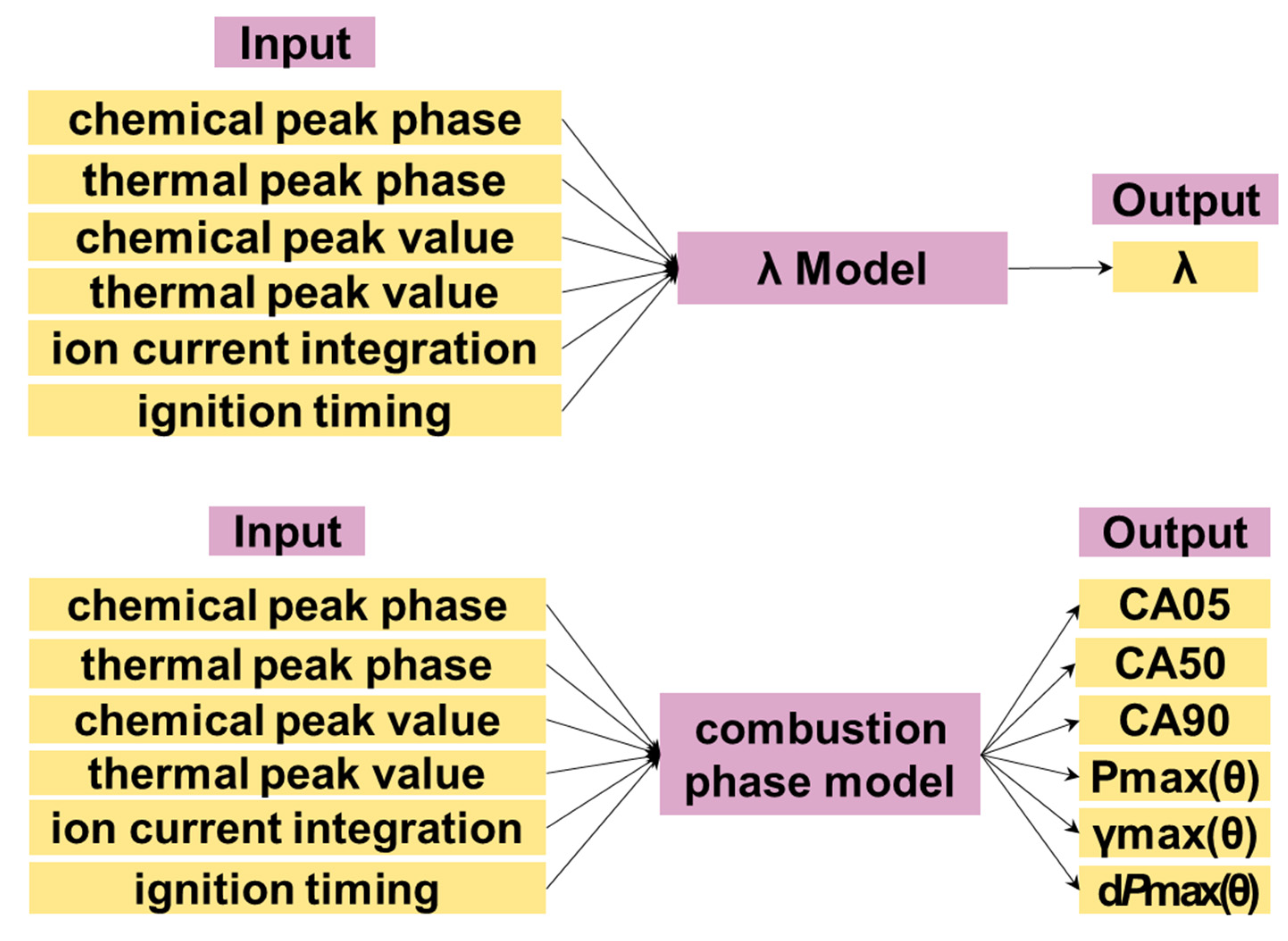

4. Virtual Combustion Sensor Based on Ion Current

4.1. ANN Neural Network Models

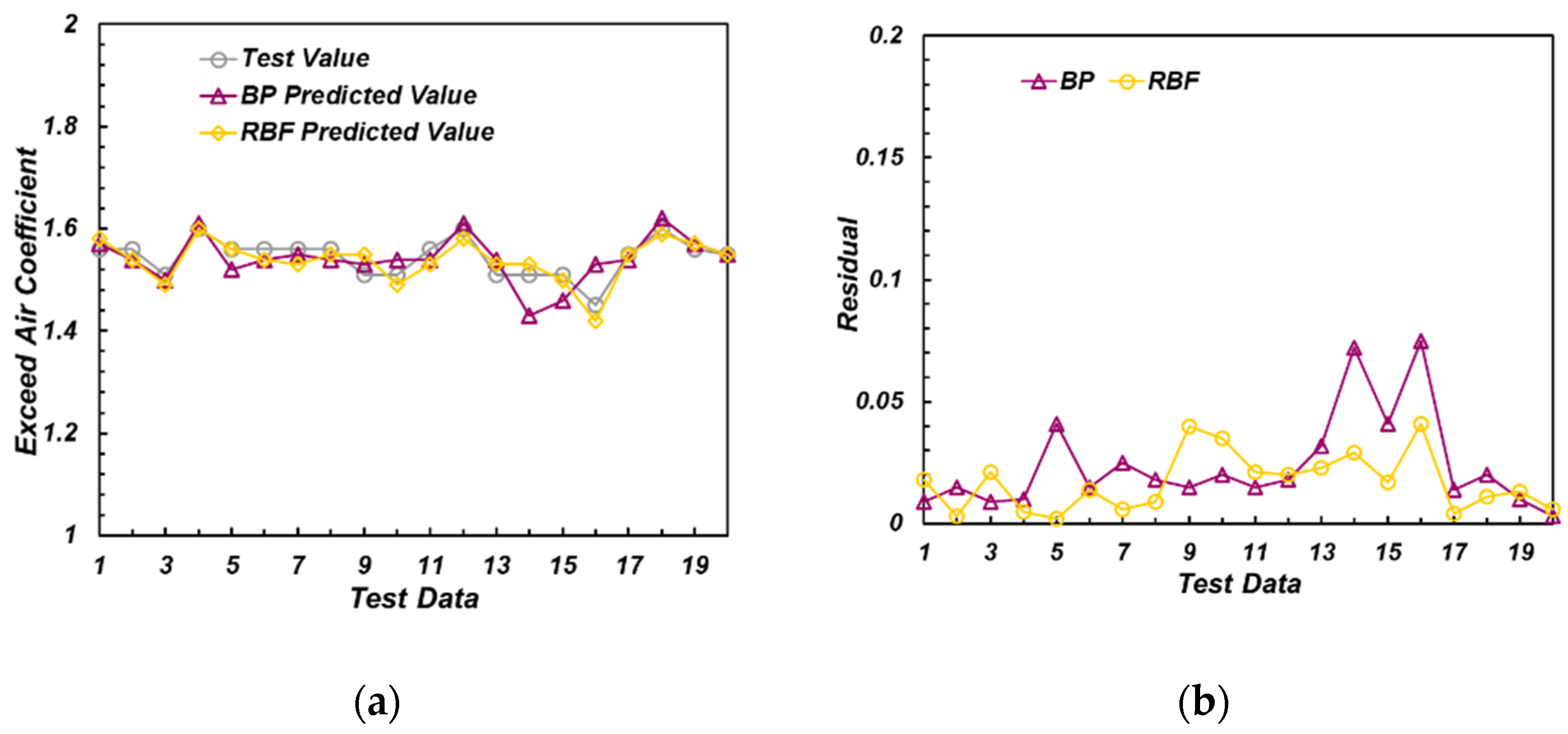

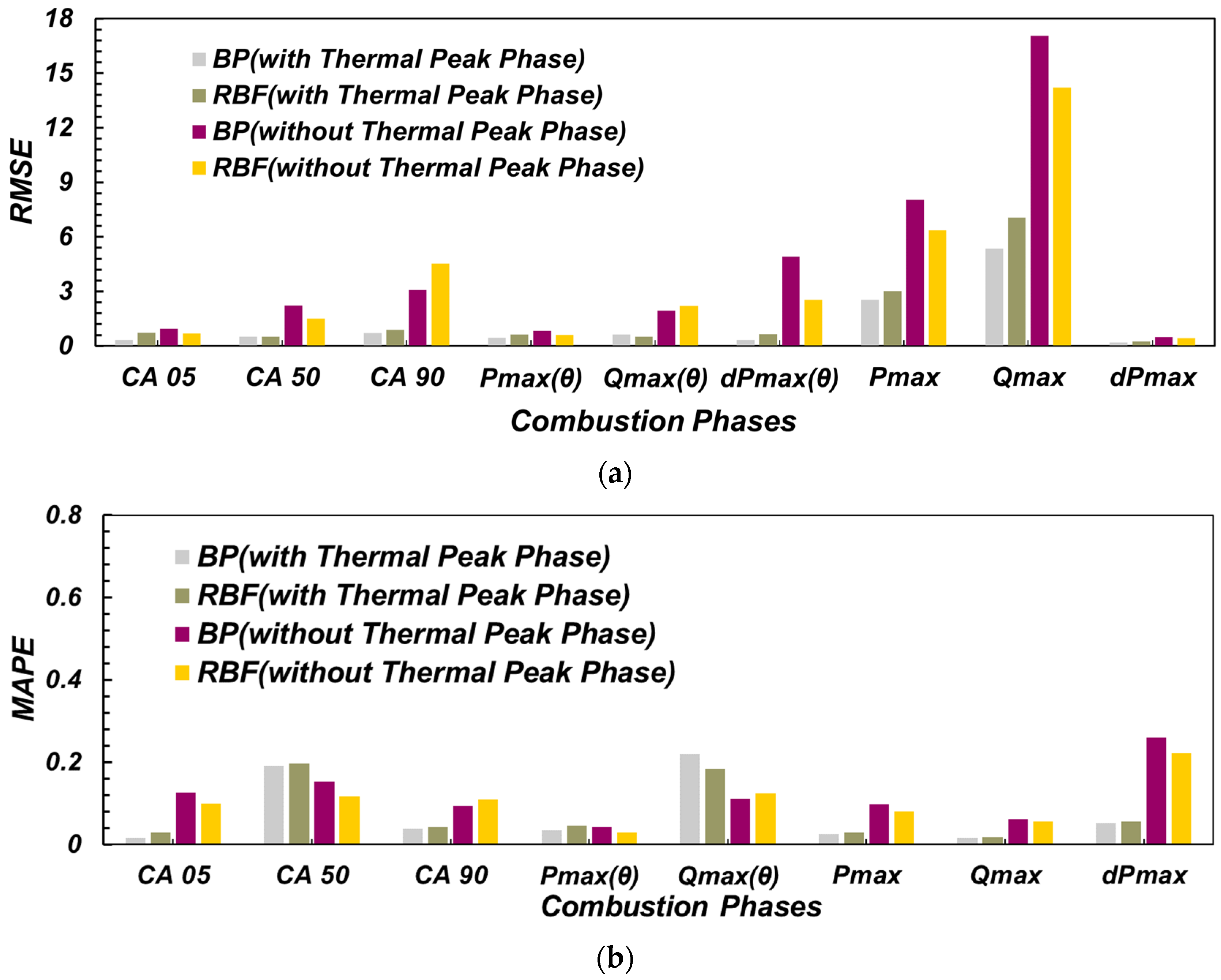

4.2. Evaluation of the Prediction Performance

5. Conclusions

- The characteristic parameters of the ion current are related to the natural gas engine operating conditions. The excess air coefficient affects the amplitude of the ion current during the whole stage, especially the thermal phase stage. When λ varies from 1.3 to 1.6, the TPV varies from 0 to 15 mA. The ignition timing affects both the amplitude and the phase of the ion current. Furthermore, CPV, TPV, ICI are sensitive to the change of engine load.

- The correlation between the ion current characteristics and the combustion characteristics are relatively high. The correlation coefficients are mostly higher than 0.85.

- The virtual sensor based on the ion current has good prediction results for excess air coefficient, combustion phase parameters, combustion amplitude parameters and NOx emission. For the prediction of excess air coefficient, combustion phase parameters and combustion peak, the accuracy of the BP neural network is higher than that of RBF when there is a thermal phase in an ion current signal. When the thermal phase of the ion current disappears, RBF shows a higher prediction accuracy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ajay, S.V.; Sandeep, C.; Ashish, K.; Anurag, G.; Ranjeet, K. A review on performance, combustion and emissions utilizing alternative fuels. Mater. Today Proc. 2022. [Google Scholar] [CrossRef]

- Carrie, H.; Mateos, K. Advances in combustion control for natural gas–diesel dual fuel compression ignition engines in automotive applications: A review. Renew. Sustain. Energy Rev. 2021, 148, 111291. [Google Scholar] [CrossRef]

- Liu, J.; Guo, Q.; Guo, J.; Wang, F. Optimization of a diesel/natural gas dual fuel engine under different diesel substitution ratios. Fuel 2021, 305, 121522. [Google Scholar] [CrossRef]

- Zhu, J.; Shan, C.; Nishida, K.; Long, W.; Dong, D. Simultaneous PIV/LIF-PIV measurements and numerical simulation of liquid flow and ambient gas flow for transient diesel spray. Fuel 2022, 309, 122211. [Google Scholar] [CrossRef]

- Xu, S.; Huang, S.; Huang, R.; Wei, W.; Cheng, X.; Ma, Y.; Zhang, Y. Estimation of turbulence characteristics from PIV in a high-pressure fan-stirred constant volume combustion chamber. Appl. Therm. Eng. 2017, 110, 346–355. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, W.; Wang, D.; Tan, M.; Liu, Z.; Dou, H. A novel combustion evaluation method based on in-cylinder pressure traces for diesel/natural gas dual fuel engines. Energy 2016, 115, 1130–1137. [Google Scholar] [CrossRef]

- Reyes, M.; Melgar, A.; Pérez, A.; Giménez, B. Study of the cycle-to-cycle variations of an internal combustion engine fueled with natural gas/hydrogen blends from the diagnosis of combustion pressure. Int. J. Hydrogen Energy 2013, 38, 15477–15487. [Google Scholar] [CrossRef] [Green Version]

- Gao, Z.; Deng, Y.; Wen, Y.; Lu, J.; Du, Z.; Tang, C.; Tomita, E.; Tan, Y. Deep-learning based in-cylinder pressure modeling and resolution of ion current signals. Fuel 2020, 282, 118722. [Google Scholar] [CrossRef]

- Zhu, D.; Deng, J.; Wang, S.; Zhang, H.; Wu, Z.; Andert, J.; Li, L. Cycle resolved control for HCCI engine load range expansion by combining ion current and pressure sensor. Proc. Combust. Inst. 2021, 38, 5685–5694. [Google Scholar] [CrossRef]

- Gao, Z.; Li, B.; Li, C.; Liu, B.; Liu, S.; Wu, X.; Huang, Z. Investigation on characteristics of ion current in a methanol direct-injection spark-ignition engine. Fuel 2015, 141, 185–191. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, X.; Hou, X.; Hu, S. Relationship of the combustion characteristics of natural gas-hydrogen/carbon dioxide mixtures with the ion current and pressure parameters. J. Energy Inst. 2019, 92, 1014–1022. [Google Scholar] [CrossRef]

- Wang, J.; Hu, Z.; Zhu, D.; Ding, W.; Li, L.; Yan, W.; Jian, T.; Chen, L. In Cycle Pre-Ignition Diagnosis and Super-Knock Suppression by Employing Ion Current in a GDI Boosted Engine; Technical Paper No. 2020-01-1148; SAE: Warrendale, PA, USA, 2020; p. 1e1148. [Google Scholar]

- Song, Z.; Zhang, X.; Wang, Y.; Hu, Z. Evaluation mass fraction burned obtained from the ion current signal fueled with hydrogen/carbon dioxide and natural gas. Int. J. Hydrogen Energy 2019, 44, 25257–25264. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, X.; Zhang, J.; Cao, J. Predicting the heat release rate of ion current combustion process fueled with hydrogen/carbon dioxide and natural gas. J. Energy Eng. 2019, 145, 4018068. [Google Scholar] [CrossRef]

- Andersson, I.; Eriksson, L. A Parametric Model for Ionization Current in a Four Stroke SI Engine. J. Dyn. Syst. Meas. Control 2009, 131, 211–216. [Google Scholar] [CrossRef]

- Malaczynski, G.; Roth, G.; Johnson, D. Ion-Sense-Based Real-Time Combustion Sensing for Closed Loop Engine Control. SAE Int. J. Engines 2013, 6, 267–277. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Ye, J.; Deng, J.; Wu, Z. Ion current signal and characteristics of ethanol/gasoline dual fuel HCC combustionI. Fuel 2016, 166, 42–50. [Google Scholar] [CrossRef]

- Gupta, A. Measurement and Analysis of Ionization Current Signal in a Single Cylinder Diesel Engine; Wayne State University: Detroit, MI, USA, 2008. [Google Scholar]

- Dong, G.; Chen, Y.; Li, L.; Wu, Z.; Dibble, R. A skeletal gasoline flame ionization mechanism for combustion timing prediction on HCCI engines. Proc. Combust. Inst. 2017, 36, 3669–3676. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Shi, J.; Deng, J.; Miao, X.; Liu, Y.; Pan, S.; Li, L. Misfire and knock detection based on the ion current inside a passive pre-chamber of gasoline engine. Fuel 2022, 311, 122528. [Google Scholar] [CrossRef]

- Kang, Z.; Wu, Z.; Fu, L.; Deng, J.; Hu, Z.; Li, L. Experimental Study of Ion Current Signals and Characteristics in an Internal Combustion Rankine Cycle Engine Based on Water Injection. J. Eng. Gas Turbines Power 2018, 140, 111506. [Google Scholar] [CrossRef]

- Giglio, V.; Police, G.; Rispoli, N.; di Gaeta, A.; Cecere, M.; Della, R.L. Experimental Investigation on the Use of Ion Current on SI Engines for Knock Detection; Technical Paper No. 2009-01-2745; SAE: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Yoshimura, K.; Tokunaga, Y.; Hashimoto, D.; Sakurai, H. Knock and Misfire Detection Using ion Current Measurement for Ultra-Lean Burn Medium Speed Gas Engine; Technical Paper No. 2007-01-2078; SAE: Warrendale, PA, USA, 2007. [Google Scholar]

- Budko, A.Y.; Medvedev, M.Y.; Budko, R.Y.; Ivashin, P.V.; Tverdokhlebov, A.Y.; Gerasimov, D.N.; Rakhmanov, V.V. Analysis of ion current integral characteristics for estimation of combustion process parameters in internal combustion engines. Int. J. Mech. Eng. Robot. Res. 2017, 6, 188.e93. [Google Scholar] [CrossRef]

- Fang, C.; Ouyang, M.; Yang, F. Real-time start of combustion detection based on cylinder pressure signals for compression ignition engines. Appl. Therm. Energy 2017, 114, 264–270. [Google Scholar] [CrossRef]

- Fiedkiewicz, L.; Pielecha, I.; Wisłocki, K. Use of the gas ionization signal for combustion process diagnostics in the cylinder of a spark ignition engine. Combust Engines 2017, 171, 196–200. [Google Scholar] [CrossRef]

- Carlos, G.; Pla, B.; Bares, P. Cylinder charge composition observation based on in-cylinder pressure measurement. Measurement 2019, 131, 559–568. [Google Scholar] [CrossRef]

- Rao, R.; Honnery, D. The prediction of torque in a diesel engine using ion currents and artificial neural networks. Int. J. Eng. Res. 2014, 15, 370–380. [Google Scholar] [CrossRef]

- Rivara, N.; Dickinson, P.; Shenton, A. A neural network implementation of peak pressure position control by ionization current feedback. J. Dyn. Syst. 2009, 131, 051003. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Lu, H.; Deng, J.; Hu, Z. In-Cycle Knocking Detection and Feedback Control Based on In-Cylinder Pressure and Ion Current Signal in a GDI Engine; Technical Report No. 2016-01-0816; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

| Parameters | Value |

|---|---|

| Diameter/mm | 129 |

| Stoke/mm | 165 |

| Compression ratio | 10:1 |

| Fuel injection type | PFI (port fuel injection) |

| Engine speed/(r·min−1) | 1500 |

| Load | Ignition Timing | λ |

|---|---|---|

| 10% | 25–40 °CA BTDC | 1.2–1.6 |

| 20% | 25–40 °CA BTDC | 1.2–1.6 |

| 25% | 25–40 °CA BTDC | X-0.2–1.6 |

| 30% | 25–40 °CA BTDC | 1.2–1.6 |

| 40% | 25–40 °CA BTDC | 1.2–1.6 |

| 50% | 25–40 °CA BTDC | X-1.2–1.6 |

| 60% | 25–40 °CA BTDC | X-0.2–1.6 |

| 70% | 25–40 °CA BTDC | X-0.2–1.6 |

| 75% | 25–40 °CA BTDC | X-0.2–1.6 |

| 80% | 25–40 °CA BTDC | X-0.2–1.6 |

| 90% | 25–40 °CA BTDC | X-0.2–1.6 |

| CA05 | CA50 | CA90 | Pmax(θ) | γ(θ) | dPmax(θ) | ||

|---|---|---|---|---|---|---|---|

| CPP | λ = 1.3 | 0.9668 | 0.9658 | 0.9203 | 0.9513 | 0.9563 | 0.9624 |

| λ = 1.4 | 0.9019 | 0.9136 | 0.8986 | 0.8911 | 0.8999 | 0.9113 | |

| λ = 1.5 | 0.9059 | 0.9066 | 0.9040 | 0.9078 | 0.9008 | 0.3274 | |

| TPP | 0.9617 | 0.9635 | 0.8764 | 0.9793 | 0.9610 | 0.9793 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhou, T.; Dong, Q.; Cheng, Z.; Yang, X. A Virtual Combustion Sensor Based on Ion Current for Lean-Burn Natural Gas Engine. Sensors 2022, 22, 4660. https://doi.org/10.3390/s22134660

Wang X, Zhou T, Dong Q, Cheng Z, Yang X. A Virtual Combustion Sensor Based on Ion Current for Lean-Burn Natural Gas Engine. Sensors. 2022; 22(13):4660. https://doi.org/10.3390/s22134660

Chicago/Turabian StyleWang, Xiaoyan, Tanqing Zhou, Quan Dong, Zhaolin Cheng, and Xiyu Yang. 2022. "A Virtual Combustion Sensor Based on Ion Current for Lean-Burn Natural Gas Engine" Sensors 22, no. 13: 4660. https://doi.org/10.3390/s22134660