Three-Degree-of-Freedom Voice Coil Actuator Driven by a Four-Phase Current

Abstract

:1. Introduction

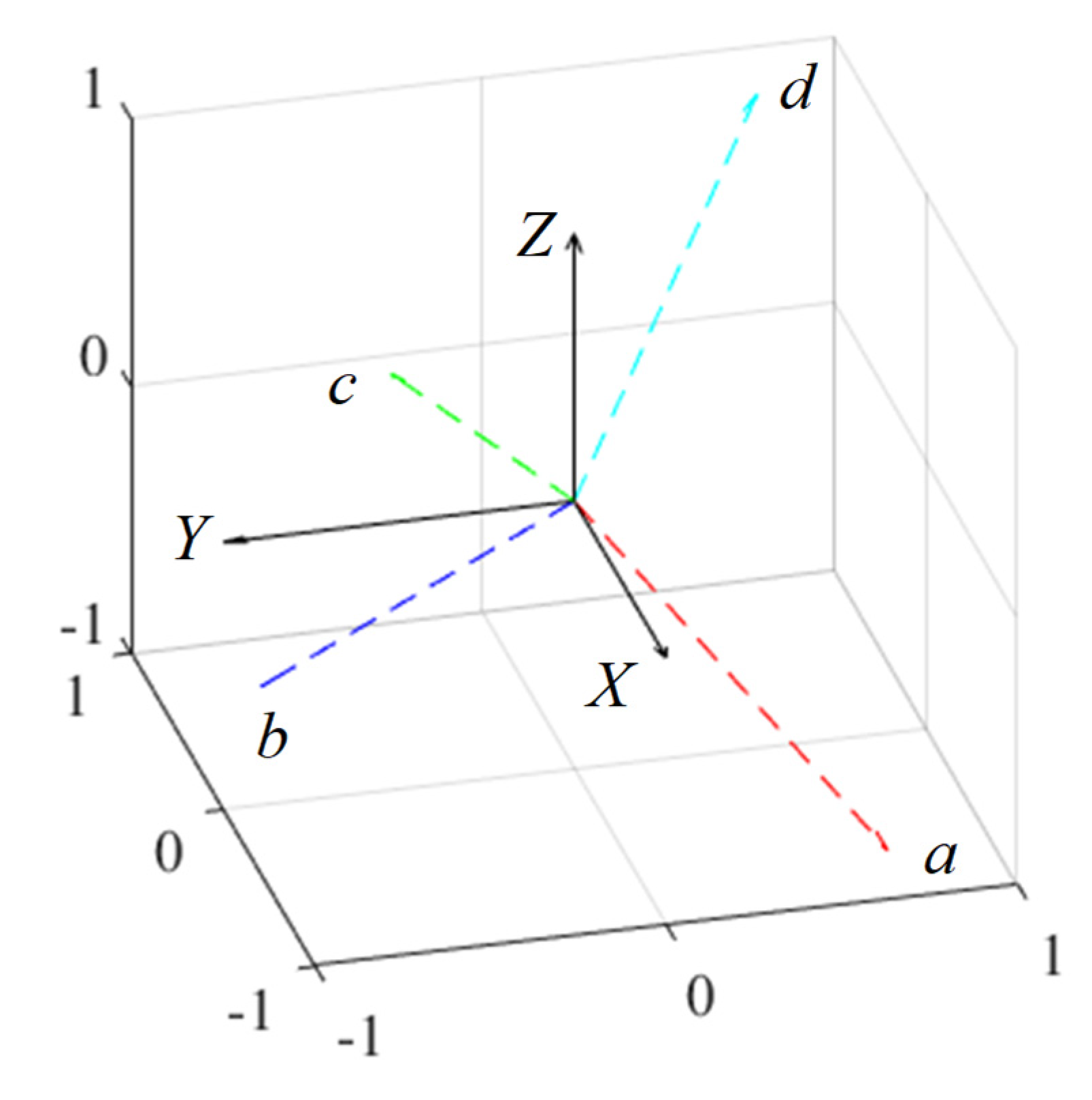

2. Three-Degree-of-Freedom Voice Coil Actuator

2.1. Basic Structure

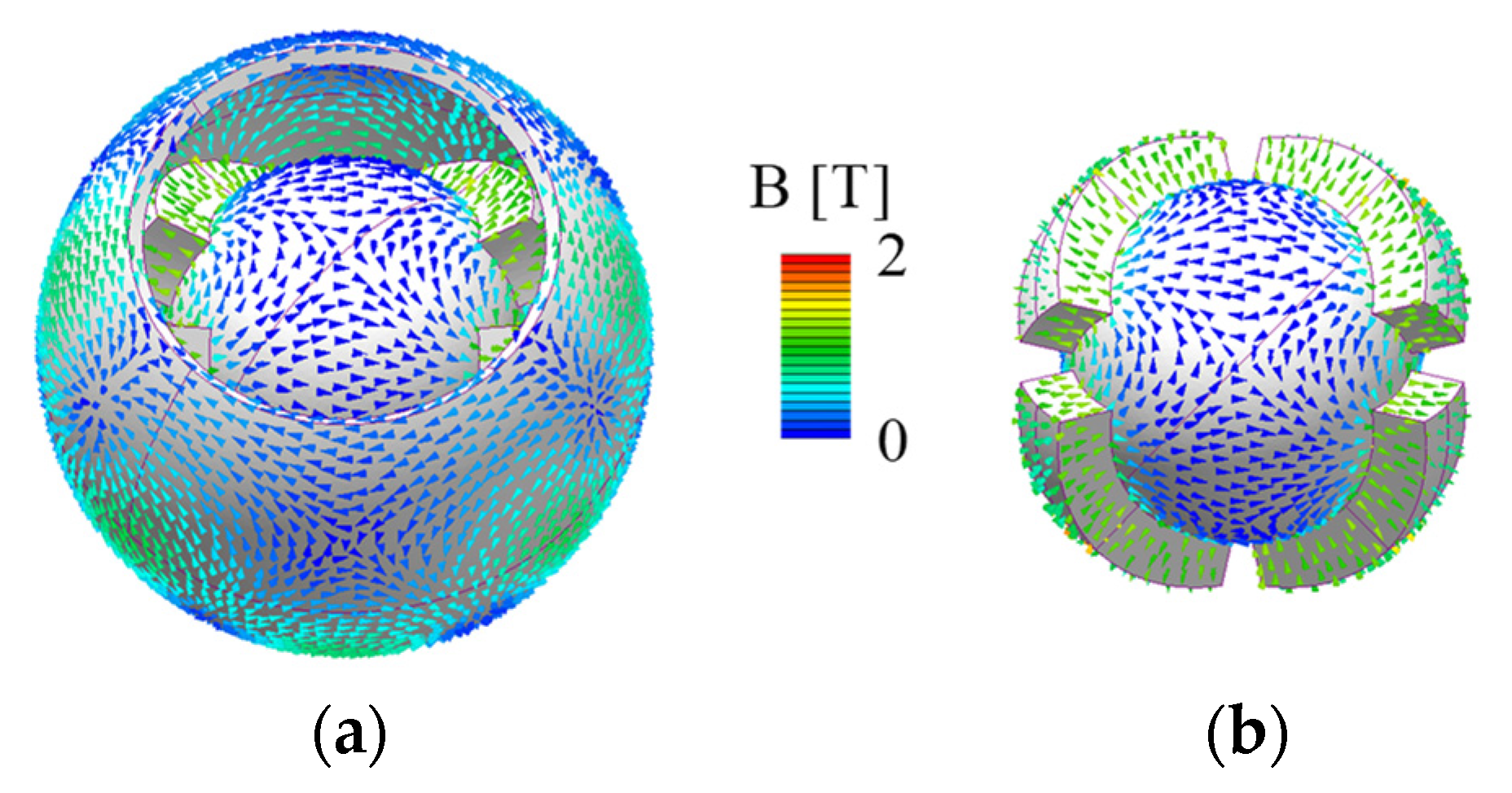

2.2. Operating Principle

3. Torque Characteristics

3.1. Analysis Conditions

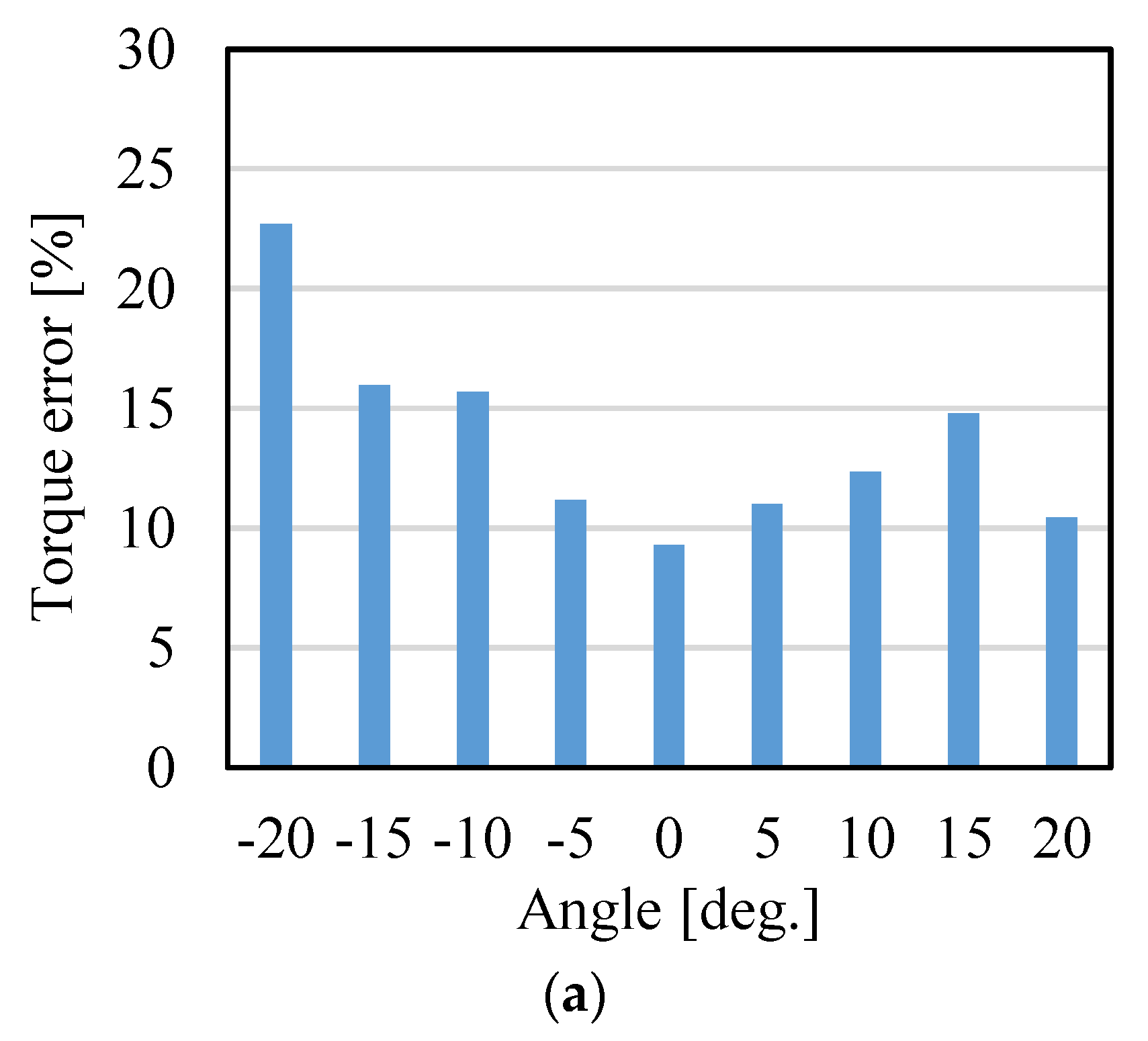

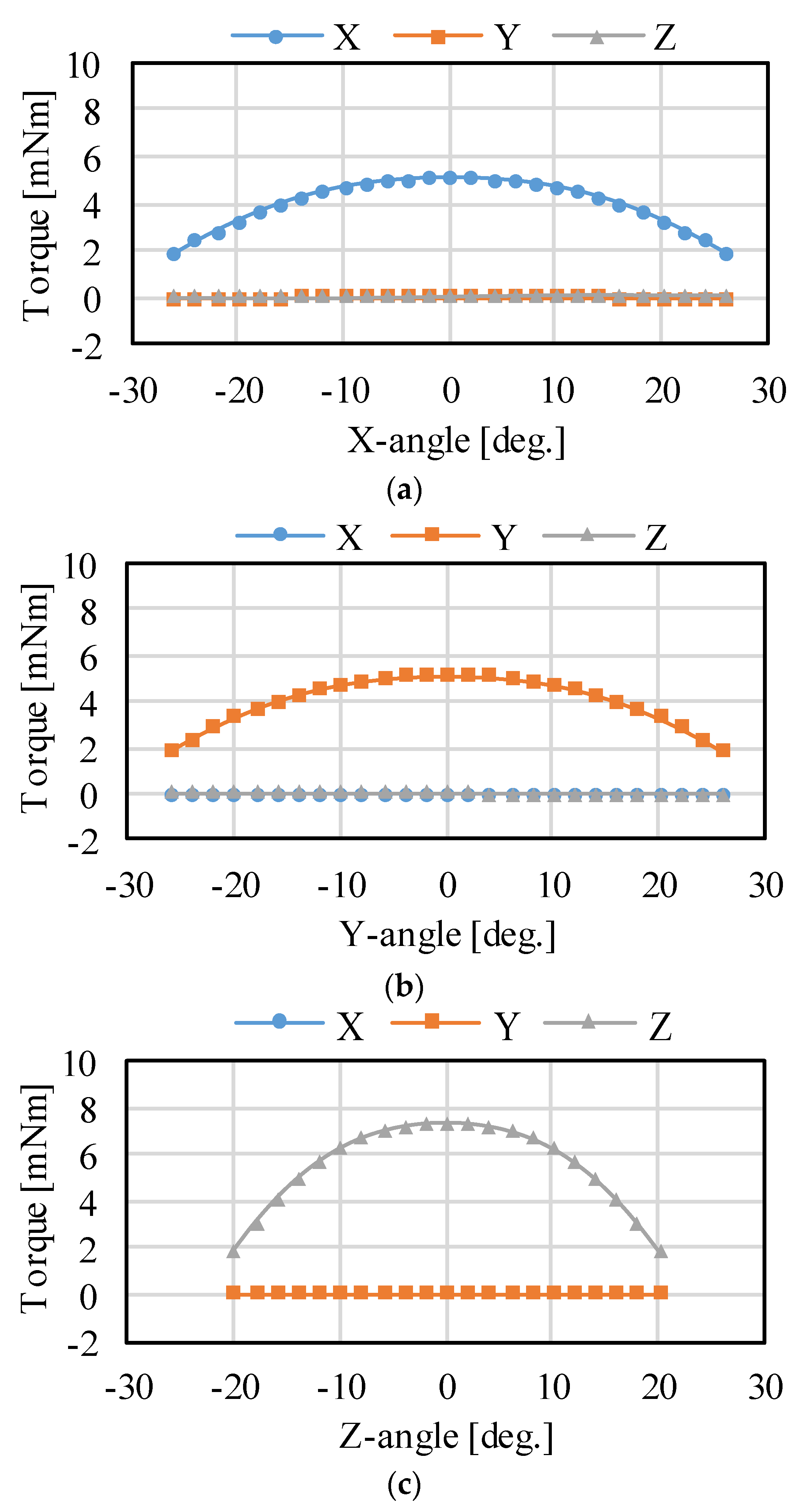

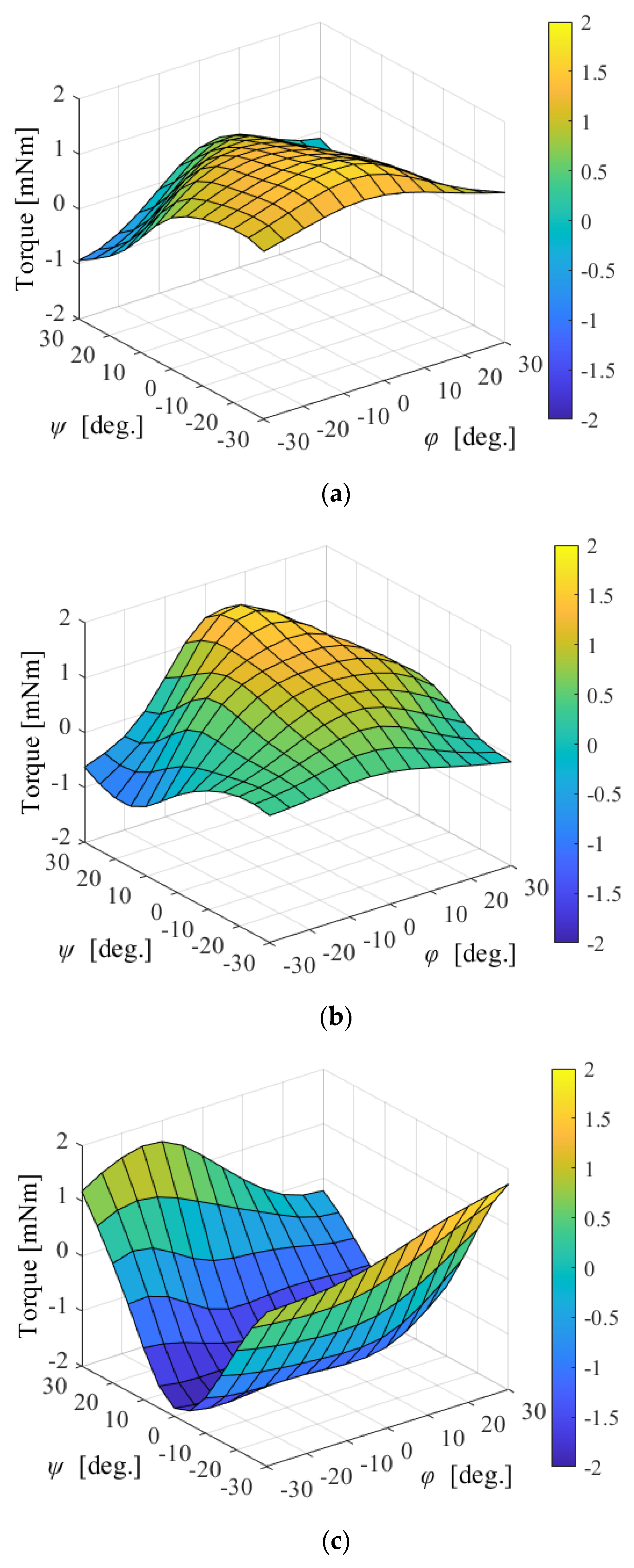

3.2. Results

3.3. Structural Comparison

4. Modeling and Control Method

4.1. Dynamic Modeling

4.2. Control Method

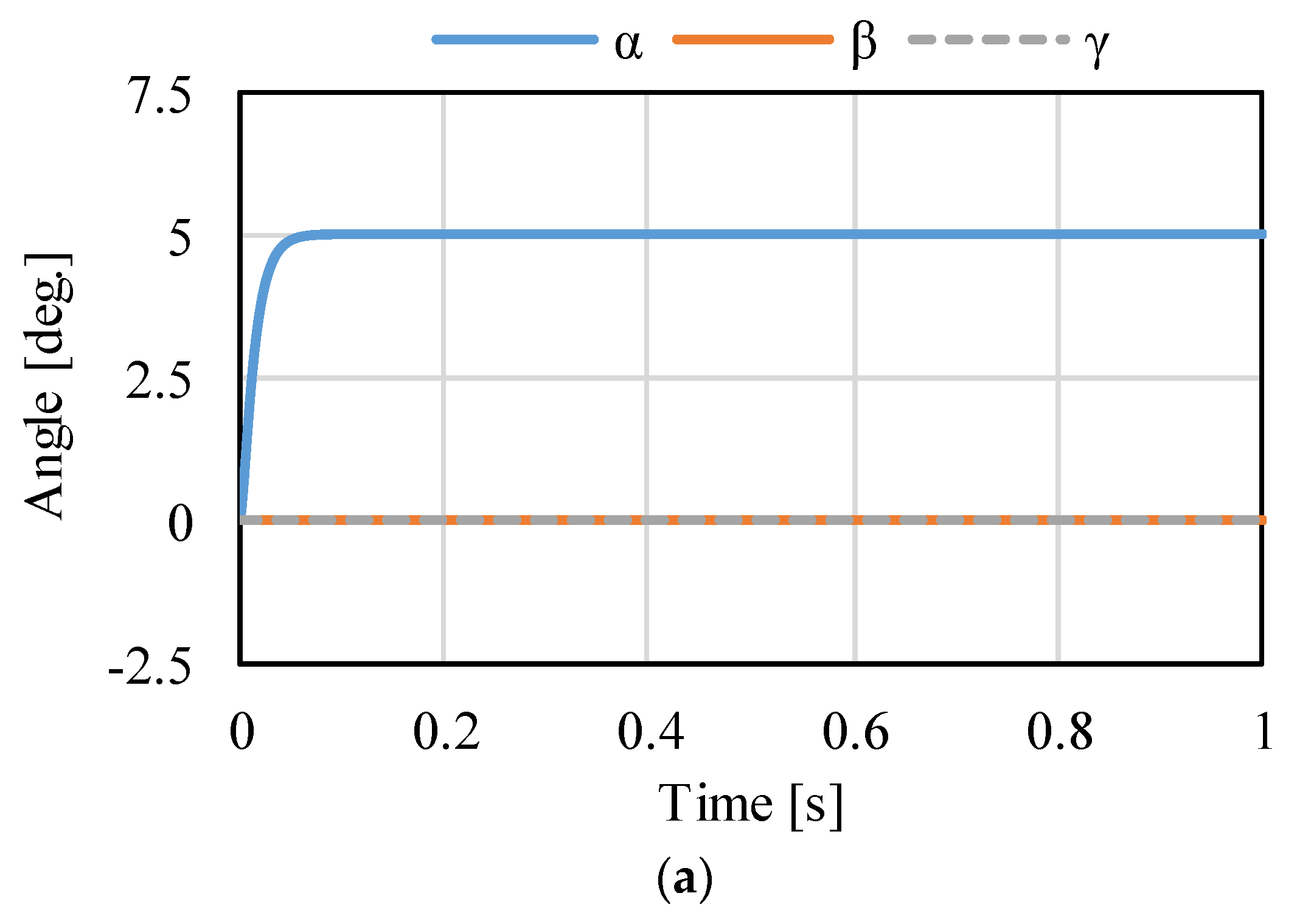

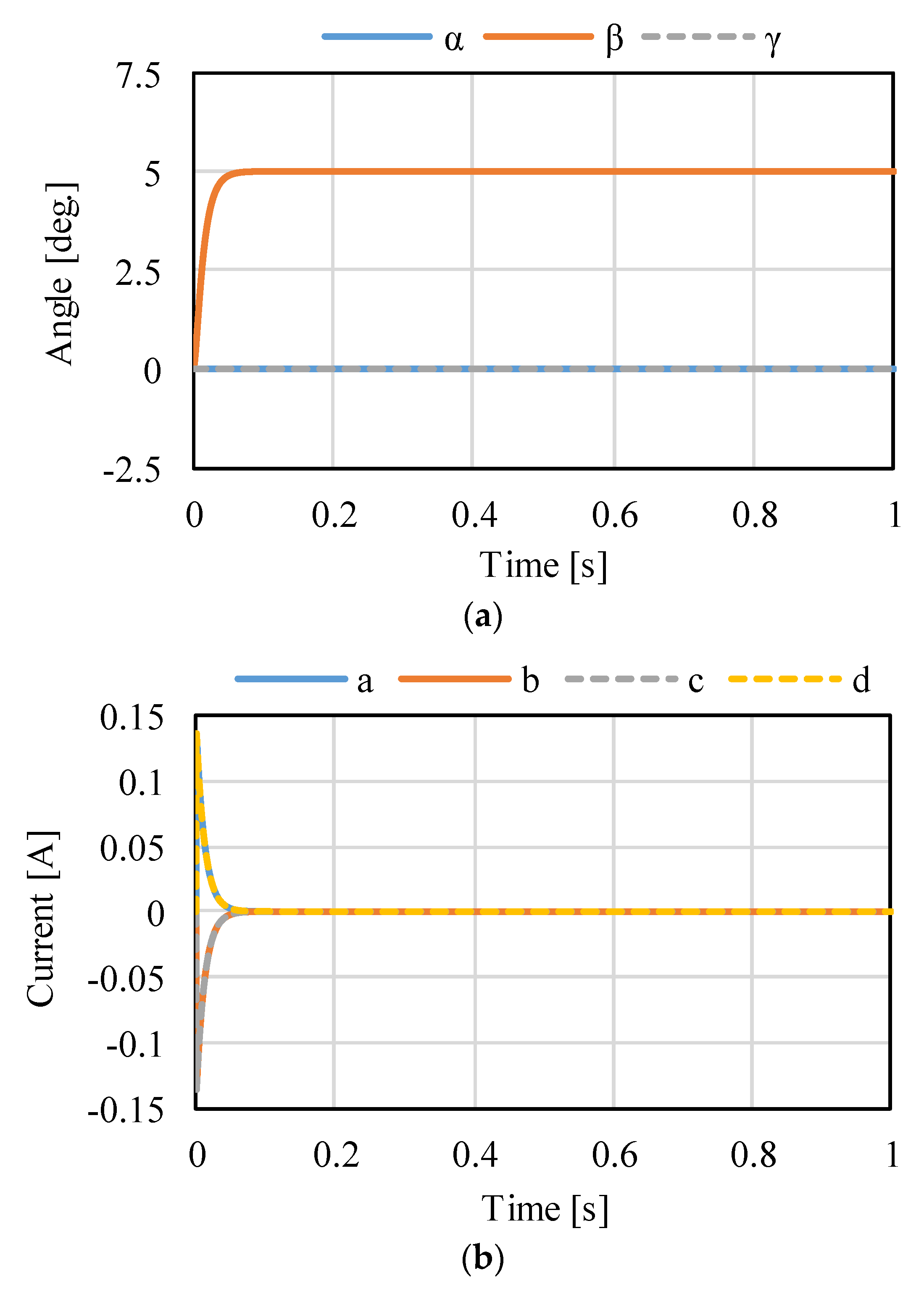

5. Dynamic Simulation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Kurazume, R.; Hirose, S. Development of image stabilization for remote operation of walking robots. In Proceedings of the IEEE International Conference on Robotics and Automation, San Francisco, CA, USA, 24–28 April 2000; pp. 1856–1861. [Google Scholar]

- Hsu, S.-C.; Liang, S.-F.; Fan, K.-W.; Lin, C.-T. A Robust In-Car Digital Image Stabilization Technique. IEEE Trans. Syst. Man Cybern. C 2007, 37, 234–247. [Google Scholar]

- Anguilar, W.G.; Angulo, C. Real-time video stabilization without phantom movements for micro aerial vehicles. EURASIP J. Image Video Process. 2014, 2014, 46. [Google Scholar] [CrossRef]

- Behi, F. Kinematic analysis for a six-degree-of-freedom 3-PRPS parallel mechanism. IEEE J. Robot. Automat. 1988, 4, 561–565. [Google Scholar] [CrossRef]

- Geng, Z.; Haynes, L.S. Six-degree-of-freedom active vibration isolation using a stewart platform mechanism. J. Robot. Syst. 1993, 10, 725–744. [Google Scholar] [CrossRef]

- Abeywardena, S.; Chen, C. Inverse dynamic modelling of a three-legged six-degree-of-freedom parallel mechanism. Multibody Syst. Dyn. 2017, 41, 1–24. [Google Scholar] [CrossRef]

- Moldvan, L.; Gligor, A.; Grif, H.-S.; Moldvan, F. Dynamic Numerical Simulation of the 6-PGK Parallel Robot Manipulator. Proc. Rom. Acad. Ser. A 2019, 20, 67–75. [Google Scholar]

- Kahlen, K.; Voss, I.; Priebe, C.; Doncker, R.D. Torque Control of a Spherical Machine With Variable Pole Pitch. IEEE Trans. Power Electron. 2004, 19, 1628–1634. [Google Scholar] [CrossRef]

- Wang, W.; Wang, J.; Jewel, G.W.; Howe, D. Design and Control of a Novel Spherical Permanent Magnet Actuator with Three Degrees of Freedom. IEEE/ASME Trans. Mechatron. 2003, 8, 457–468. [Google Scholar] [CrossRef]

- Nishiura, Y.; Hirata, K.; Sakaidani, Y. 3-DOF Outer Rotor Electromagnetic Spherical Actuator. Int. J. Auto. Tech. 2016, 10, 591–598. [Google Scholar] [CrossRef]

- Chirikijian, G.S.; Stein, D. Kinematic Design and Commutation of a Spherical Stepper Motor. IEEE/ASME Trans. Mechatron. 1999, 4, 342–353. [Google Scholar] [CrossRef]

- Kasashima, N.; Ashida, K.; Yano, T.; Gofuku, A.; Shibata, M. Torque Control Method of an Electromagnetic Spherical Motor Using Torque Map. IEEE/ASME Trans. Mechatron. 2016, 21, 2050–2060. [Google Scholar] [CrossRef]

- Kumagai, M.; Hollis, R.L. Development and Control of a Three DOF Spherical Induction Motor. In Proceedings of the IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 1528–1533. [Google Scholar]

- Heya, A.; Hirata, K. Proposal of Novel Multiple-Degree-of-Freedom Voice Coil Actuator. In Proceedings of the IEEE International Magnetics Conference, Lyon, France, 26–30 April 2021; p. BD-09. [Google Scholar]

- Webb, J.P.; Forghani, B. A T-Ω method using hierarchal edge elements. IEE Proc. Sci. Meas. Tech. 1995, 142, 133–141. [Google Scholar] [CrossRef]

- Webb, J.P.; Forghani, B. DC Current Distributions and Magnetic Fields using the T-Ω Edge-Element Method. IEEE Trans. Magn. 1995, 31, 1444–1447. [Google Scholar] [CrossRef]

- Heya, A.; Hirata, K. Experimental Verification of Three-Degree-of-Freedom Electromagnetic Actuator for Image Stabilization. Sensors 2020, 20, 2485. [Google Scholar] [CrossRef] [PubMed]

| Symbol | Description | Value |

|---|---|---|

| roy | Outer radius of the outer yoke | 15.0 mm |

| riy | Outer radius of the inner yoke | 9.0 mm |

| toy | Thickness of the outer yoke | 1.0 mm |

| tc | Thickness of the coil | 1.2 mm |

| tpm | Thickness of the PM | 3.0 mm |

| wpm | Width of the PM | 4.0 mm |

| θpm | Angle of the PM | 85.0° |

| θci | Inner angle of the coil | 34.0° |

| θco | Outer angle of the coil | 56.0° |

| g | Air gap length | 2.0 mm |

| Opening angle of the outer yoke | 90.0° |

| Torque | Coil a | Coil b | Coil c | Coil d |

|---|---|---|---|---|

| τx | 1 | 1 | −1 | −1 |

| τy | 1 | −1 | −1 | 1 |

| τz | −1 | 1 | −1 | 1 |

| Variable | Description | Value |

|---|---|---|

| Ixx (=Iyy) | Inertia of moment [10−7 × kgm2] | 3.6 |

| Izz | 6.0 | |

| R | Resistance [Ω] | 0.31 |

| L | Inductance [mH] | 0.0349 |

| M | Mutual inductance [mH] | 0 |

| D | Viscous friction coefficient [Nms/rad] | 0.0001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heya, A.; Hirata, K. Three-Degree-of-Freedom Voice Coil Actuator Driven by a Four-Phase Current. Sensors 2022, 22, 6926. https://doi.org/10.3390/s22186926

Heya A, Hirata K. Three-Degree-of-Freedom Voice Coil Actuator Driven by a Four-Phase Current. Sensors. 2022; 22(18):6926. https://doi.org/10.3390/s22186926

Chicago/Turabian StyleHeya, Akira, and Katsuhiro Hirata. 2022. "Three-Degree-of-Freedom Voice Coil Actuator Driven by a Four-Phase Current" Sensors 22, no. 18: 6926. https://doi.org/10.3390/s22186926