Towards the Digital Twin (DT) of Narrow-Band Internet of Things (NBIoT) Wireless Communication in Industrial Indoor Environment

Abstract

:1. Introduction

2. Related Works

3. Technology Synopsis

3.1. Wireless Communication in Indoor Industrial Settings

3.1.1. Network Topologies and Designs

3.1.2. Types of Industrial Network Traffic

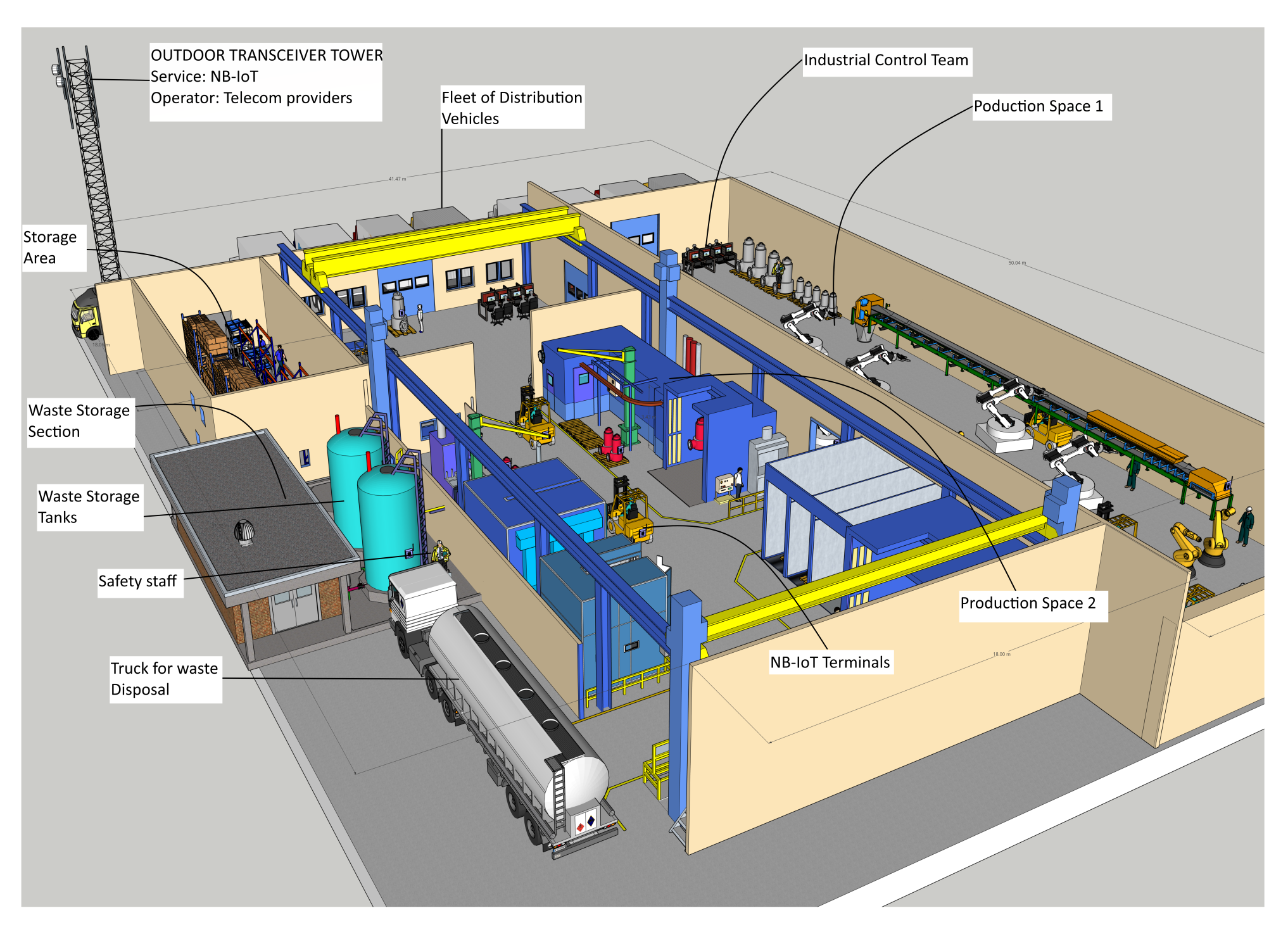

- Space for production: Finished goods are produced in the factory in this space through the processing of the raw materials. As part of the production process, raw materials are prepared, mixed, pre-processed, and post-processed, quality assurance is undertaken, product certification is obtained, packaging units are constructed, and assembly lines are installed. This section describes how NB-IoT applications gather and transmit four types of data. Monitor traffic (MT), non-critical alert traffic (NCAT), critical alert traffic (CAT), and critical control traffic (CCT) are included in this category. It is necessary to maintain medium-to-low latency and low reliability in this section due to the high data transmission rate ranging from seconds to hours.

- Waste storage: By-products and waste generated during production are stored in this unit, which must be monitored as it involves toxic waste and poisonous gases that can endanger the safety of industrial employees and any occurrence must be immediately reported. It is therefore in this section that emergency traffic (ET) and medical traffic (MT) are transmitted. The system must be reliable and have minimal latency.

- Storage of finished products: This is the place where finished products are kept. Since NB-IoT technology provides adequate coverage for MT and NCAT traffic, NB-IoT is a well-suited technology for maintaining the count of the products, the state of the products, and the condition of the warehouse.

- Product distribution point: This unit is connected to the warehouse and assembles the finished products to be distributed. For smooth operation, this unit relies on MT.

- Coordination/control room: This is the factory’s observation room, which monitors all factory activities to ensure compliance with all standards, rules, and conditions required for smooth operation. It stores and transmits the information collected from various departments to the appropriate departments for action, including management, accounting, safety, and production, and thus collecting MT.

- Staff offices: This section includes the factory staff which are divided into departments. They receive MT on their handheld devices or dedicated computer systems so that they can act upon it.

3.1.3. Network Performance Metrics

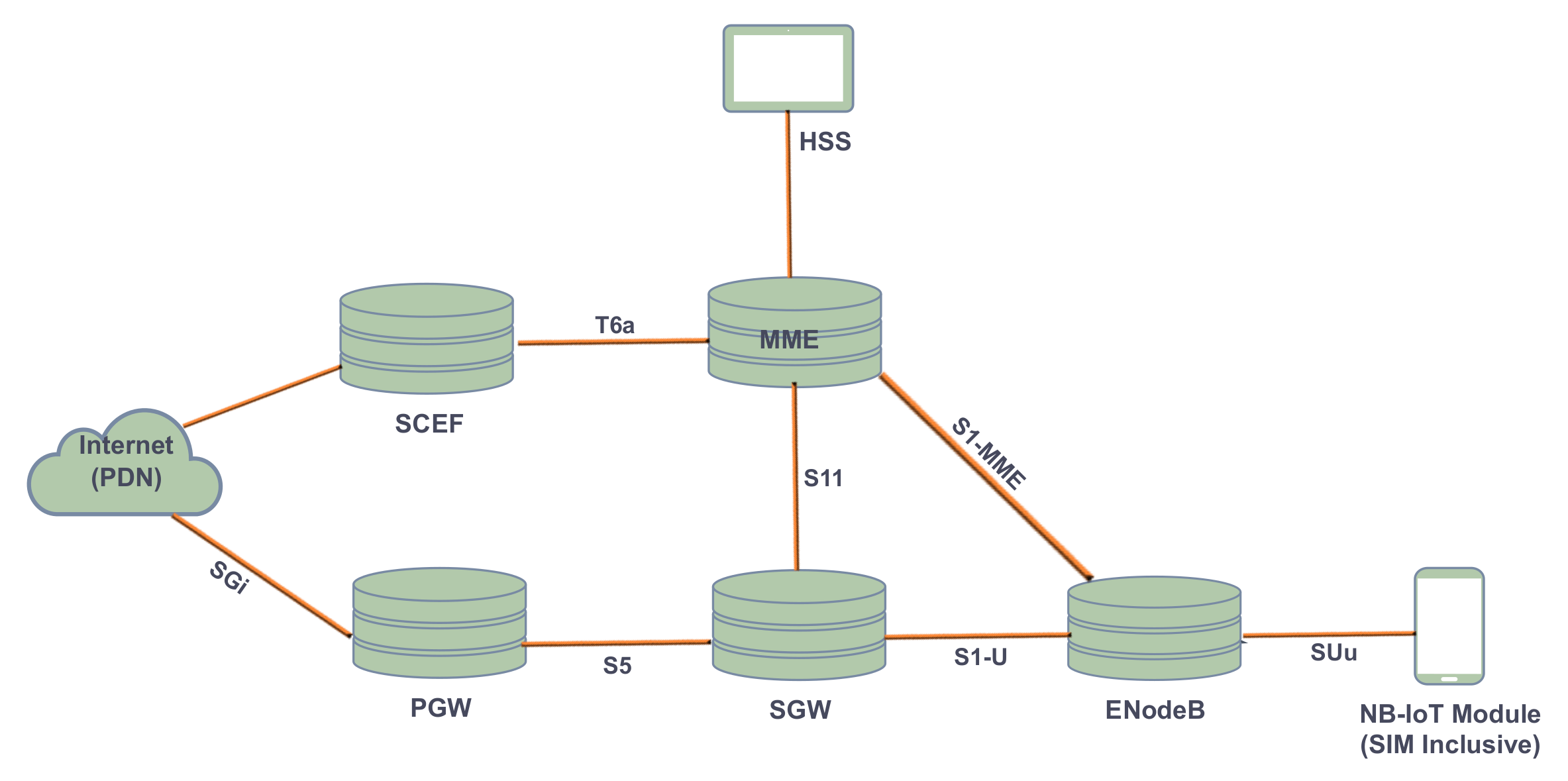

3.2. NB-IoT Configuration Boundaries and Topology in an Indoor Industries

- Bandwidth selection: For a 200 kHz bandwidth, the standalone deployment mode is required and for 180 kHz bandwidth, in-band or guardband will suffice.

- Paging and random access on the non-anchor carrier, release assistance indication, NPRACH range enhancement.

- Connected mode mobility, wake-up signals, multicast transmission, and group messaging.

- Early data transmission (EDT), improved access control, small-cell control, cell re-selection.

- Coverage extension.

- Power saving mode (PSM), extended discontinues reception (eDRX), power class, new category NB2, battery efficiency security for low throughput (BEST).

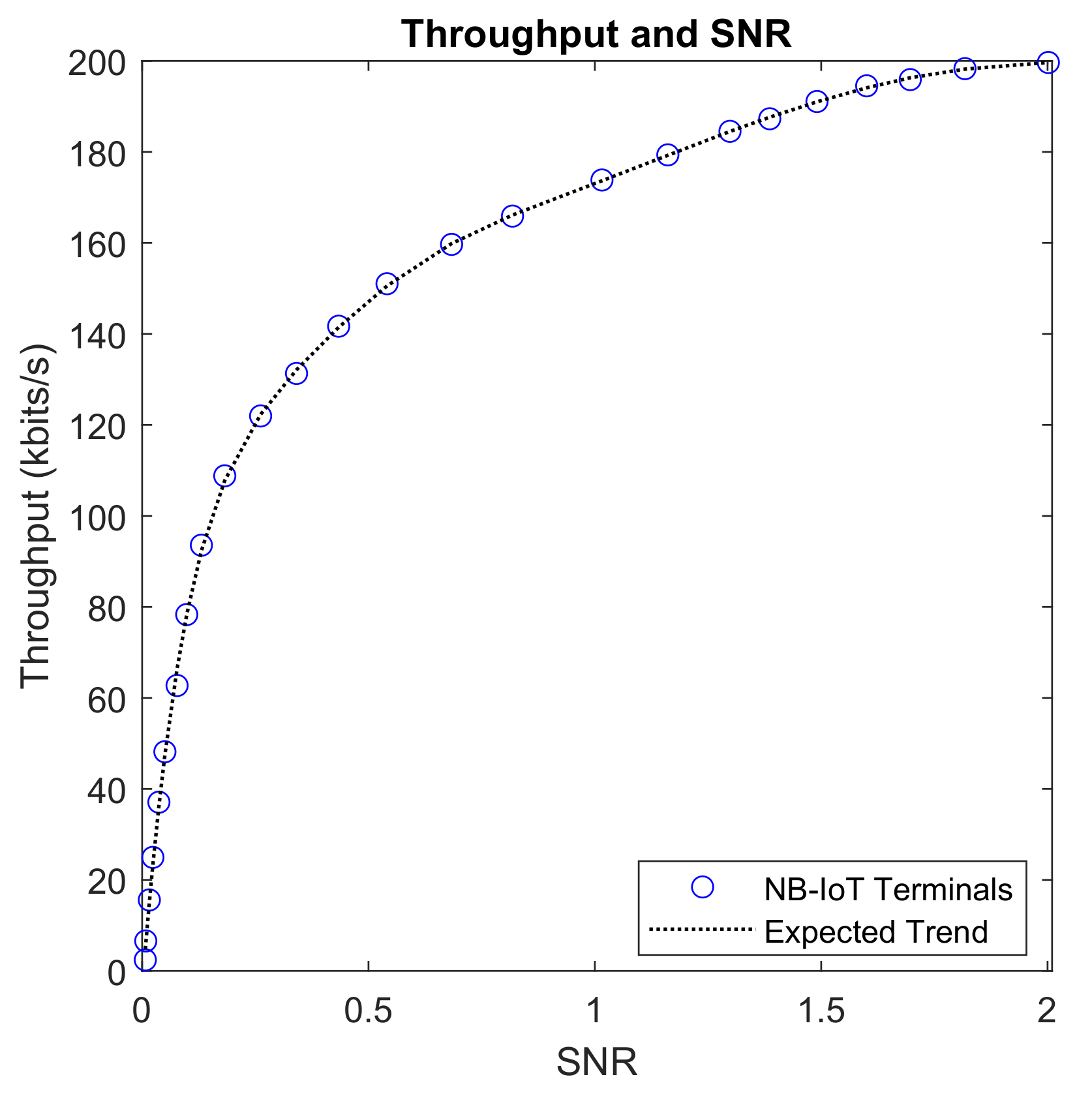

3.3. The Throughput of NB-IoT Terminals

- Overheads associated with the link layer and application layer protocols;

- Flow control and network contention;

- Congestion on the network and the number of users;

- Asymmetries between download and upload speeds;

- Conditions of the network channel;

- Incompatible hardware and software implementations that prevent optimal throughput.

4. System Model

4.1. Simulation Setup

4.1.1. Industrial Structural Components and Plan

- The floor plan: A tiff format image of the floor plan was imported into the software using the Project–Open–Imagetabs. On the image property tab, the required entries are a short description of the image or floor plan, the coordinate for the orientation of the image, in this case, the Cartesian coordinate was chosen, top offset for image adjustment to the grid lines, and the pixel spacing for both x and y dimensions. This spacing allows for the scaling of the image to the appropriate size which is calculated as the ratio of the practical measurement of a portion of the floor plan and the pixel dimension of the image. To verify the correct size of the uploaded image, a measuring tool is used to measure part of the image.

- Floor plan geometry: On the Project–New–Feature–Floor plan tab, both the base and top heights (m) for the floor plan are specified. The floor plan editing window allows for other adjustable working tools such as the snap-to, grid spacing, and material modification tools. However, the floor cannot be created until the walls are first created as explained below.

- Barrier walls: The walls are created using the specified material types. These walls are repeatedly created using the New–walls tab.

- Windows and doors: The windows and doors are created using a similar step as the walls are created. However, values for width (m) and heights from the top and bottom of the windows and doors are required to be specified. Meanwhile, to simulate open doors or windows, a free space material is used, however, in this paper, all doors and windows are simulated in a closed state using the ITU 2.4 GHz wooden material.

- Ceilings or rooftops: the ceilings are also created using similar steps in the floor plan and following the floor geometry.

- NB-IoT waveform and antenna pattern: A sinusoidal waveform was used for this simulation through the waveform tab and the carrier frequency was also set at 900 MHz. An isotropic antenna pattern was also selected for wireless transmission and reception.

4.1.2. Industrial Equipment

4.1.3. Configuration and Placement of NB-IoT Terminals

4.2. Simulation of Scenario

Data Collection

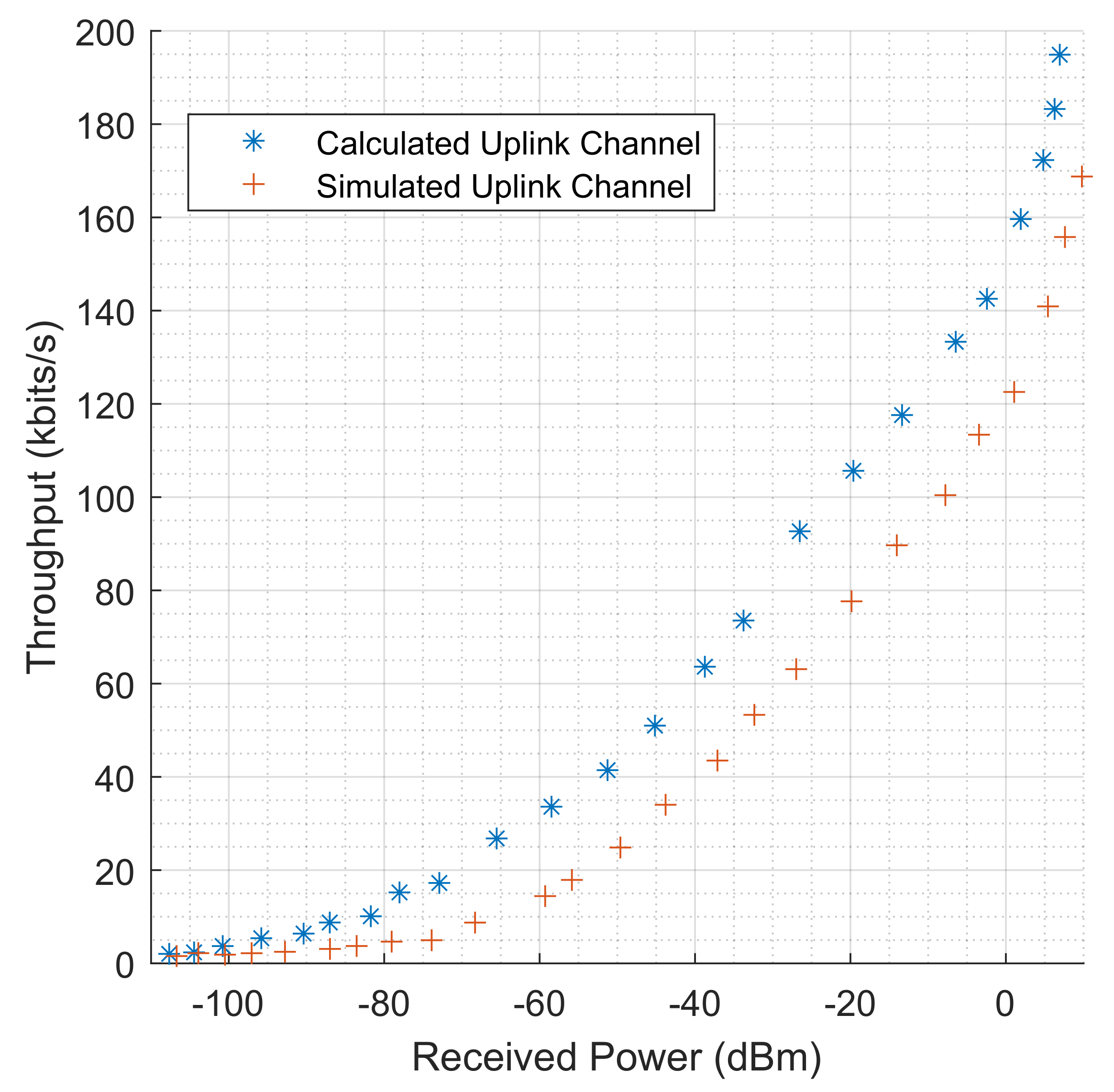

5. Simulation Results

5.1. Throughput Levels Based on Received Power

5.2. Reliance of Throughput on NB-IoT Distance from Transceiver

5.3. The Effect of Signal-to-Noise (SNR) on Throughput

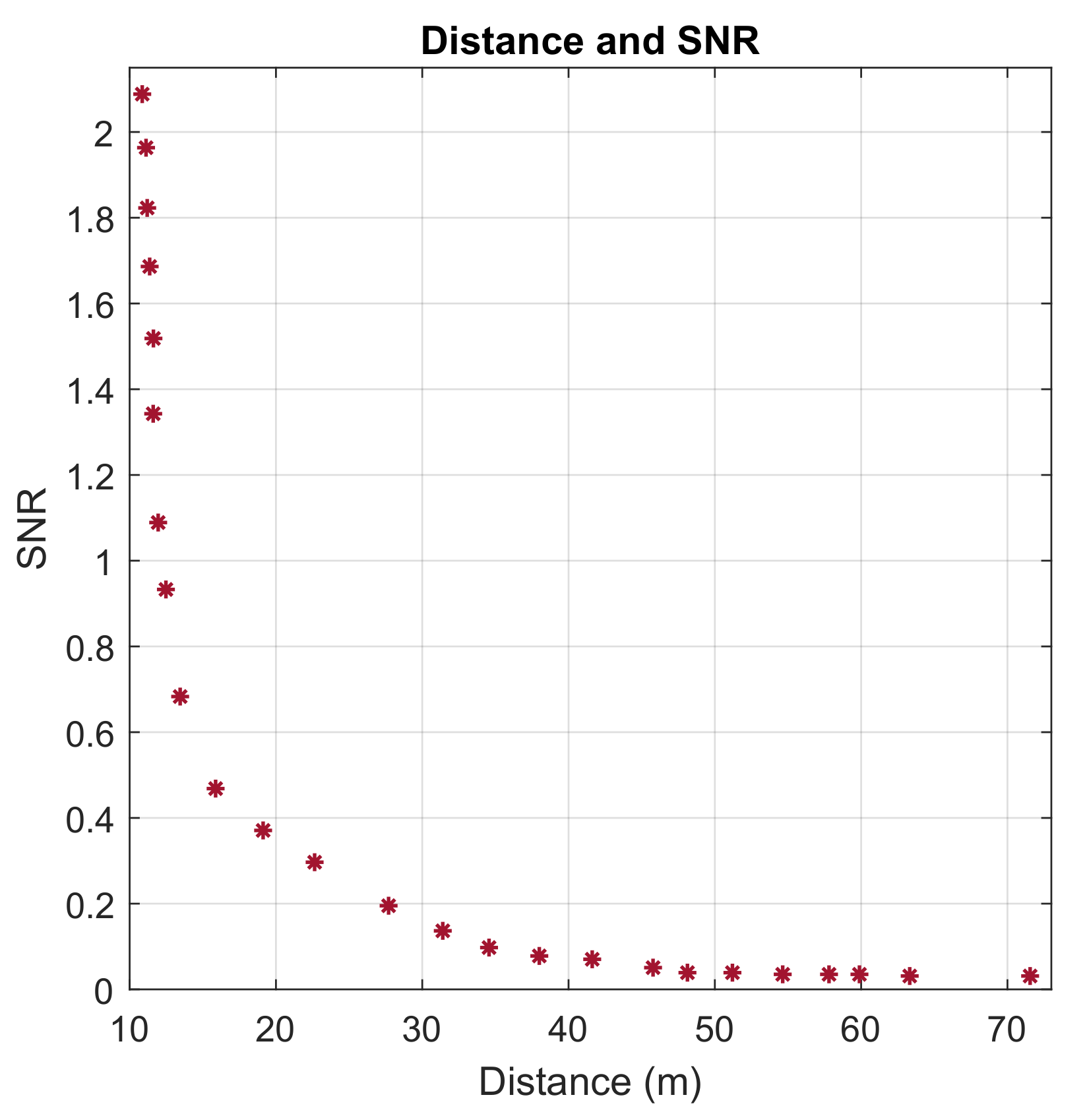

5.4. Evaluating Distance and SNR

5.5. Received Power Dependency on Distance

6. Challenges and Future Works

- Energy-harvesting techniques: Maintaining the low consumption rate of energy as specified by 3GPP (through its PSM and eDRx schemes) by NB-IoT is becoming challenging. This is because of the re-transmission mechanism used to achieve coverage and reliability as the energy saved is depleted in this aspect. Therefore, an energy-harvesting mechanism that incorporates the sourcing of energy from the surrounding environment such as vibration from industrial machines would add more life to this technology.

- Big data and NB-IoT capacity: The design capacity of NB-IoT to handle and transmit data periodically and the rate of big data generated in the industrial environment coupled with other variables that need to be considered for the implementation of DT needs reconciliation. In this regard, the implementation of ML has become paramount to overcoming this challenge.

- ML and wireless prediction: The use of ML techniques to predict the wireless communication of NB-IoT terminals in an industrial indoor environment while focusing on the communication parameters and set of environmental conditions gathered in the study. This is aimed to provide a mechanism that would allow for the extrapolation of the study to other industrial facilities that share some common features.

- ML and Link Adaptation Mechanism: According to some researchers, a hybrid link adaptation strategy can be used to study how coverage enhancement features affect network reliability and latency. In this strategy, latency and coverage were optimized. In order to achieve this, they formulated and solved an optimization problem in which the optimal value of repetitions, bandwidth, and modulation and coding scheme (MCS) was found so that latency is minimized and reliability is maintained. It is, therefore, necessary to apply machine learning in the link adaptation selection process for better optimization since the hybrid link adaptation method achieves lower latency and higher coverage than any other coverage enhancement technique [42].

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dangana, M.; Ansari, S.; Abbasi, Q.H.; Hussain, S.; Imran, M.A. Suitability of NB-IoT for Indoor Industrial Environment: A Survey and Insights. Sensors 2021, 21, 5284. [Google Scholar] [CrossRef] [PubMed]

- Asad, S.M.; Tahir, A.; Rais, R.N.B.; Ansari, S.; Abubakar, A.I.; Hussain, S.; Abbasi, Q.H.; Imran, M.A. Edge Intelligence in Private Mobile Networks for Next-Generation Railway Systems. Front. Commun. Netw. 2021, 2, 769299. [Google Scholar] [CrossRef]

- Goswami, S.A.; Padhya, B.P.; Patel, K.D. Internet of Things: Applications, Challenges and Research Issues. In Proceedings of the 2019 Third International conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud) (I-SMAC), Palladam, India, 12–14 December 2019; pp. 47–50. [Google Scholar] [CrossRef]

- Liao, Y.; de Freitas Rocha Loures, E.; Deschamps, F. Industrial Internet of Things: A Systematic Literature Review and Insights. IEEE Internet Things J. 2018, 5, 4515–4525. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Shen, H. Design of Greenhouse Environment Monitoring System based on NB-IoT Furthermore, Edge Computing. In Proceedings of the 2021 IEEE 5th Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 March 2021; Volume 5, pp. 1319–1324. [Google Scholar] [CrossRef]

- Mumtaz, S.; Alsohaily, A.; Pang, Z.; Rayes, A.; Tsang, K.F.; Rodriguez, J. Massive Internet of Things for Industrial Applications: Addressing Wireless IIoT Connectivity Challenges and Ecosystem Fragmentation. IEEE Ind. Electron. Mag. 2017, 11, 28–33. [Google Scholar] [CrossRef]

- Chen, M.; Miao, Y.; Hao, Y.; Hwang, K. Narrow Band Internet of Things. IEEE Access 2017, 5, 20557–20577. [Google Scholar] [CrossRef]

- Hwang, Y.; Kang, S.; Shin, J. A study of Efficient Small Data Transmission in Industry IoT based 3GPP NB-IoT System. In Proceedings of the 2020 International Conference on Information and Communication Technology Convergence (ICTC), Jeju Island, Korea, 21–23 October 2020; pp. 1848–1850. [Google Scholar] [CrossRef]

- Li, T.; Hou, P. Application of NB-IoT in Intelligent Fire Protection System. In Proceedings of the 2019 International Conference on Virtual Reality and Intelligent Systems (ICVRIS), Jishou, China, 14–15 September 2019; pp. 203–206. [Google Scholar] [CrossRef]

- Stusek, M.; Stepanov, N.; Moltchanov, D.; Masek, P.; Mozny, R.; Turlikov, A.; Hosek, J. Optimizing NB-IoT Communication Patterns for Permanently Connected mMTC Devices. In Proceedings of the 2022 IEEE Wireless Communications and Networking Conference (WCNC), Austin, TX, USA, 10–13 April 2022; pp. 1413–1418. [Google Scholar] [CrossRef]

- Malik, H.; Khan, S.Z.; Leonel Redondo Sarmiento, J.; Kuusik, A.; Alam, M.M.; Le Moullec, Y.; Pärand, S. NB-IoT Network Field Trial: Indoor, Outdoor and Underground Coverage Campaign. In Proceedings of the 2019 15th International Wireless Communications and Mobile Computing Conference (IWCMC), Tangier, Morocco, 24–28 June 2019; pp. 537–542. [Google Scholar] [CrossRef]

- Masek, P.; Stusek, M.; Zeman, K.; Hosek, J.; Mikhaylov, K.; Andreev, S.; Koucheryavy, Y.; Zeman, O.; Votapek, J.; Roubicek, M. Tailoring NB-IoT for Mass Market Applications: A Mobile Operator’s Perspective. In Proceedings of the 2018 IEEE Globecom Workshops (GC Wkshps), Abu Dhabi, United Arab Emirates, 9–13 December 2018; pp. 1–7. [Google Scholar] [CrossRef] [Green Version]

- Wan, L.; Zhang, Z.; Huang, Y.; Yan, Y.; Wang, J. Performance Analysis of NB-IoT Technology for Indoor IoT Applications. In Proceedings of the 2017 International Conference on Computer Technology, Electronics and Communication (ICCTEC), Dalian, China, 18–20 December 2017; pp. 1365–1369. [Google Scholar] [CrossRef]

- Malarski, K.M.; Thrane, J.; Bech, M.G.; Macheta, K.; Christiansen, H.L.; Petersen, M.N.; Ruepp, S. Investigation of Deep Indoor NB-IoT Propagation Attenuation. In Proceedings of the 2019 IEEE 90th Vehicular Technology Conference (VTC2019-Fall), Honolulu, HI, USA, 22–25 September 2019; pp. 1–5. [Google Scholar] [CrossRef] [Green Version]

- Huang, W.; Zhang, Y.; Zeng, W. Development and application of digital twin technology for integrated regional energy systems in smart cities. Sustain. Comput. Inform. Syst. 2022, 36, 100781. [Google Scholar] [CrossRef]

- He, Y.; Guo, J.; Zheng, X. From Surveillance to Digital Twin: Challenges and Recent Advances of Signal Processing for Industrial Internet of Things. IEEE Signal Process. Mag. 2018, 35, 120–129. [Google Scholar] [CrossRef]

- Jeong, D.Y.; Baek, M.S.; Lim, T.B.; Kim, Y.W.; Kim, S.H.; Lee, Y.T.; Jung, W.S.; Lee, I.B. Digital Twin: Technology Evolution Stages and Implementation Layers With Technology Elements. IEEE Access 2022, 10, 52609–52620. [Google Scholar] [CrossRef]

- Haw, J.; Sing, S.L.; Liu, Z.H. Digital twins in design for additive manufacturing. Mater. Today Proc. 2022, in press. [CrossRef]

- Vitturi, S.; Zunino, C.; Sauter, T. Industrial Communication Systems and Their Future Challenges: Next-Generation Ethernet, IIoT, and 5G. Proc. IEEE 2019, 107, 944–961. [Google Scholar] [CrossRef]

- Drivers, Automation–Innovation. Guest Editorial Special Section on Communications in Automation–Innovation Drivers and New Trends. IEEE Trans. Ind. Inform. 2017, 13, 841–845. [Google Scholar] [CrossRef]

- Sauter, T.; Soucek, S.; Kastner, W.; Dietrich, D. The Evolution of Factory and Building Automation. IEEE Ind. Electron. Mag. 2011, 5, 35–48. [Google Scholar] [CrossRef]

- Johnson, A. Wireless Concepts. In Pearson Education; Cisco Press: Indianapolis, IN, USA, 2020. [Google Scholar]

- Zhao, G. Wireless Sensor Networks for Industrial Process Monitoring and Control: A Survey. Netw. Protoc. Algoritm. 2011, 3, 46–63. [Google Scholar] [CrossRef]

- Hong, S. Bandwidth allocation scheme for cyclic-service field-bus networks. IEEE/ASME Trans. Mechatron. 2001, 6, 197–204. [Google Scholar] [CrossRef]

- Bernat, G.; Burns, A.; Liamosi, A. Weakly hard real-time systems. IEEE Trans. Comput. 2001, 50, 308–321. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Jiang, J. Comparative Examination on Architecture and Protocol of Industrial Wireless Sensor Network Standards. IEEE Commun. Surv. Tutor. 2016, 18, 2197–2219. [Google Scholar] [CrossRef]

- Celebi, H.B.; Pitarokoilis, A.; Skoglund, M. Wireless Communication for the Industrial IoT. In Industrial IoT: Challenges, Design Principles, Applications, and Security; Springer International Publishing: Cham, Switzerland, 2020; Volume 8, pp. 57–94. [Google Scholar]

- Dangana, M.; Ansari, S.; Hussain, S.; Imran, M.A. NB-IoT Performance Analysis and Evaluation in Indoor Industrial Environment. In Proceedings of the 2022 IEEE 95th Vehicular Technology Conference: (VTC2022-Spring), Helsinki, Finland, 19–22 June 2022; pp. 1–7. [Google Scholar] [CrossRef]

- Trivedi, K.S.; Ramani, S.; Fricks, R.I. Recent advances in modeling response-time distributions in real-time systems. Proc IEEE 2020, 91, 1023–1037. [Google Scholar] [CrossRef]

- Commission, I.E. Industrial communication networks—Profiles—Part 2: Additional fieldbus profiles for real-time networks based on ISO/IEC 8802-3. Ind. Electrotech. Comm. 2014, 4, 103–286. [Google Scholar]

- IoT, D.T. NB-IoT, LoRaWAN, Sigfox: An up-to-Date Comparison; Deutsche Telekom AG: Bonn, Germany, 2021; Volume 222. [Google Scholar]

- GSMA. NB-IOT Deployment Guide—GSMA. Internet Things 2022, 1, 19–45. [Google Scholar]

- Hassan, M.B.; Ali, E.S.; Mokhtar, R.A.; Saeed, R.A.; Chaudhari, B.S. NB-IoT: Concepts, applications, and deployment challenges. In LPWAN Technologies for IoT and M2M Applications; Chaudhari, B.S., Zennaro, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 119–144. [Google Scholar] [CrossRef]

- Bull, D.R.; Zhang, F. Chapter 1—Introduction. In Intelligent Image and Video Compression, 2nd ed.; Bull, D.R., Zhang, F., Eds.; Academic Press: Oxford, UK, 2021; pp. 1–16. [Google Scholar] [CrossRef]

- Wang, Y.P.E.; Lin, X.; Adhikary, A.; Grovlen, A.; Sui, Y.; Blankenship, Y.; Bergman, J.; Razaghi, H.S. A Primer on 3GPP Narrowband Internet of Things. IEEE Commun. Mag. 2017, 55, 117–123. [Google Scholar] [CrossRef]

- Michael, P. Error Correction Coding, Newnes, New South Wales, Australia, 2017; 129–147.

- Kumar, A.; Manjunath, D.; Kuri, J. Chapter 2—Wireless Communication: Concepts, Techniques, Models. In Wireless Networking; Kumar, A., Manjunath, D., Kuri, J., Eds.; The Morgan Kaufmann Series in Networking; Morgan Kaufmann; Burlington: Singapore, 2008; pp. 15–51. [Google Scholar] [CrossRef]

- Temcom, E. Determining Peak Data Rates for NB-IoT. In Narrow Band IoT; Temcom Electronics, Test and Measurements; Temcom Electronics: Paris, France, 2019; pp. 221–234. [Google Scholar]

- Remcom, I. Indoor Propagation. In 3D Wireless Prediction; Remcom: State College, PA, USA, 2020; pp. 321–423. [Google Scholar]

- Government, U.K. The Building Regulations. In The Merged Approved Documents; Govt. of UK: London, UK, 2021. [Google Scholar]

- 3GPP. Cellular System Support for Ultra-Low Complexity and Low Throughput Internet of Things (CIoT); Tech. Rep. 45.820, v13. 1.0; European Telecommunications Standards Institute: Sophia Antipolis, France, 2015. [Google Scholar]

- Ravi, S.; Zand, P.; El Soussi, M.; Nabi, M. Evaluation, Modeling and Optimization of Coverage Enhancement Methods of NB-IoT. In Proceedings of the 2019 IEEE 30th Annual International Symposium on Personal, Indoor and Mobile Radio Communications (PIMRC), Istanbul, Turkey, 8–11 September 2019; pp. 1–7. [Google Scholar] [CrossRef]

| Property Type | Setting |

|---|---|

| Transceiver antenna | Omnidirectional |

| Antenna gain | 3.5 |

| Antenna waveform | Sinusoidal |

| NB-IoT max. Tx power | 14 dBm |

| Bandwidth | 180 kHz |

| Deployment mode | In-band |

| Frequency | 900 MHz |

| Modulation | QPSK |

| Max. propagation paths | 25 |

| Propagation model | X3D |

| Number of reflections | 6 |

| Number of transmissions | 4 |

| Number of diffractions | 1 |

| Receiver threshold (dBm) | −250 |

| Ray tracing acceleration | Octree |

| Ray spacing | 0.2500 |

| Polarization | Vertical |

| Tx/Rx coordinate system | Cartesian |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dangana, M.; Ansari, S.; Asad, S.M.; Hussain, S.; Imran, M.A. Towards the Digital Twin (DT) of Narrow-Band Internet of Things (NBIoT) Wireless Communication in Industrial Indoor Environment. Sensors 2022, 22, 9039. https://doi.org/10.3390/s22239039

Dangana M, Ansari S, Asad SM, Hussain S, Imran MA. Towards the Digital Twin (DT) of Narrow-Band Internet of Things (NBIoT) Wireless Communication in Industrial Indoor Environment. Sensors. 2022; 22(23):9039. https://doi.org/10.3390/s22239039

Chicago/Turabian StyleDangana, Muhammad, Shuja Ansari, Syed Muhammad Asad, Sajjad Hussain, and Muhammad Ali Imran. 2022. "Towards the Digital Twin (DT) of Narrow-Band Internet of Things (NBIoT) Wireless Communication in Industrial Indoor Environment" Sensors 22, no. 23: 9039. https://doi.org/10.3390/s22239039