Metal-Oxide Heterojunction: From Material Process to Neuromorphic Applications

Abstract

:1. Introduction

2. Metal-Oxide Heterojunction

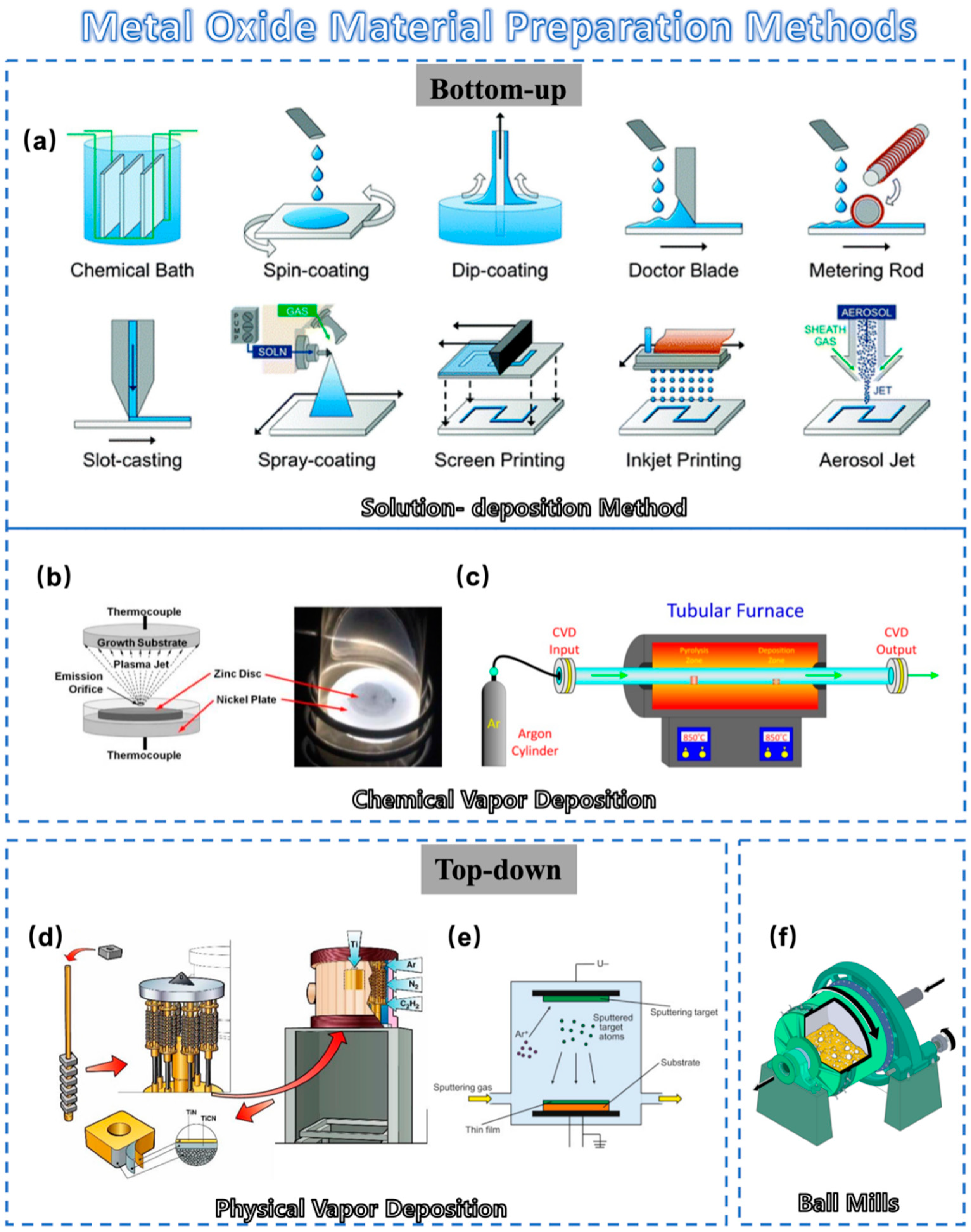

2.1. Preparation of Metal-Oxide Materials

2.1.1. Bottom-Up Approaches

- Solution-Deposition Method: Solution-deposition methods include a variety of methods (Figure 2a). Solution techniques allow for the deposition of films at atmospheric pressure with minimal equipment cost. Scalable deposition methods that allow for uniform, large-area coverage are important for high-throughput industrial applications [22]. We highlight the sol–gel method and inkjet printing method in this section. The latter method mainly involves transforming the desired precursor material into an inkjet state and then distributing it for printing in the same way as other solution-deposition methods. A new kind of fully inkjet-printed InP/ZnSe QD/SnO2 heterostructure thin film transistor (TFT) was fabricated with a bottom-gate, top-contact configuration by Liang et al. [27]. The fully printed device on a glass substrate exhibited a high optical transparency in the visible spectrum. This chemical method allows the formation of metal oxides using a colloidal solution (sol) approach. This method can well control composition and structure at the nanoscale. However, this process is always slow and often requires post-synthesis calcination [28].

- Chemical Vapor Deposition: Chemical vapor deposition is a process in which the substrate is exposed to one or more volatile precursors, and then reaction and decomposition are performed on the substrate surface to create the desired thin film. In typical CVD (Figure 2b), precursor gases are fed into the reaction chamber at ambient temperature. When they pass or come in contact with the heated substrate, they react or decompose to form a solid phase and then are deposited on the substrate. As shown in Figure 2c, the substrate temperature is very important and can affect the reactions that will take place. Compared to sol–gel methods, it typically offers a high degree of compositional and crystal structure control for precise material design. As a result, CVD has attracted growing interest in the semiconductor industry due to its large-area growth ability [29,30,31].

- Electrodeposition: Electrodeposition is a method for depositing ions from a solution onto an electrode’s surface through an electrochemical reaction [32]. For example, Yin et al. easily prepared Cu2O thin films using the electrodeposition method, thereby creating P-type Cu-based metal-oxide materials with excellent photoelectrochemical water splitting capability [32]. Unlike CVD, electrodeposition typically does not require high-temperature treatment or hazardous gases, making it environment-friendly. Moreover, it is a cost-effective way as it does not necessitate high-vacuum equipment or expensive precursors. These advantages make it an emerging favorite for the electronic materials [32,33].

2.1.2. Top-Down Approaches

- Mechanical Milling: Mechanical milling is a very traditional and simple method of making metal-oxide powders. In this approach, metal-oxide powders are directly generated by mechanically grinding the bulk materials using a ball mill, as shown in Figure 2f. The electrical properties of metal oxides can easily be altered by adding other materials such as metals in this traditional method, as reported by Mikio et al. [38]. Using this method, Ag particles were added to NaxCo2O4 thermoelectric oxide. A mechanical milling process was included for uniform dispersion of Ag particles in the NaxCo2O4 matrix phase. Mechanical milling is also effective in reducing grain size, which is expected to affect the electrical resistivity and thermal conductivity of the product. However, it often lacks the capability of precise control over particle size distribution [38].

- Physical Vapor Deposition: As one of the most common processes on the market (Figure 2d), PVD offers distinct advantages compared to other methods for preparing metal-oxide materials [36]. It excels in its precision at the micro- and nanoscale, resulting in high-quality, uniformly dense films (Figure 2e). Moreover, PVD operates at lower temperatures, reducing the risk of thermal stress [39]. PVD films are high-purity, environment-friendly, and compatible with most materials and substrates. These attributes render PVD highly sought after in electronic/optical coatings and material enhancement [40,41]. PVD methods for preparing metal-oxide materials encompass magnetron sputtering, laser deposition, ion beam deposition, molecular beam epitaxy, thermal evaporation, etc. These techniques play an important role in preparing metal-oxide films with desired structural properties [42,43,44,45,46,47].

2.2. The Advantages of Heterojunctions

2.2.1. Types of Heterojunctions

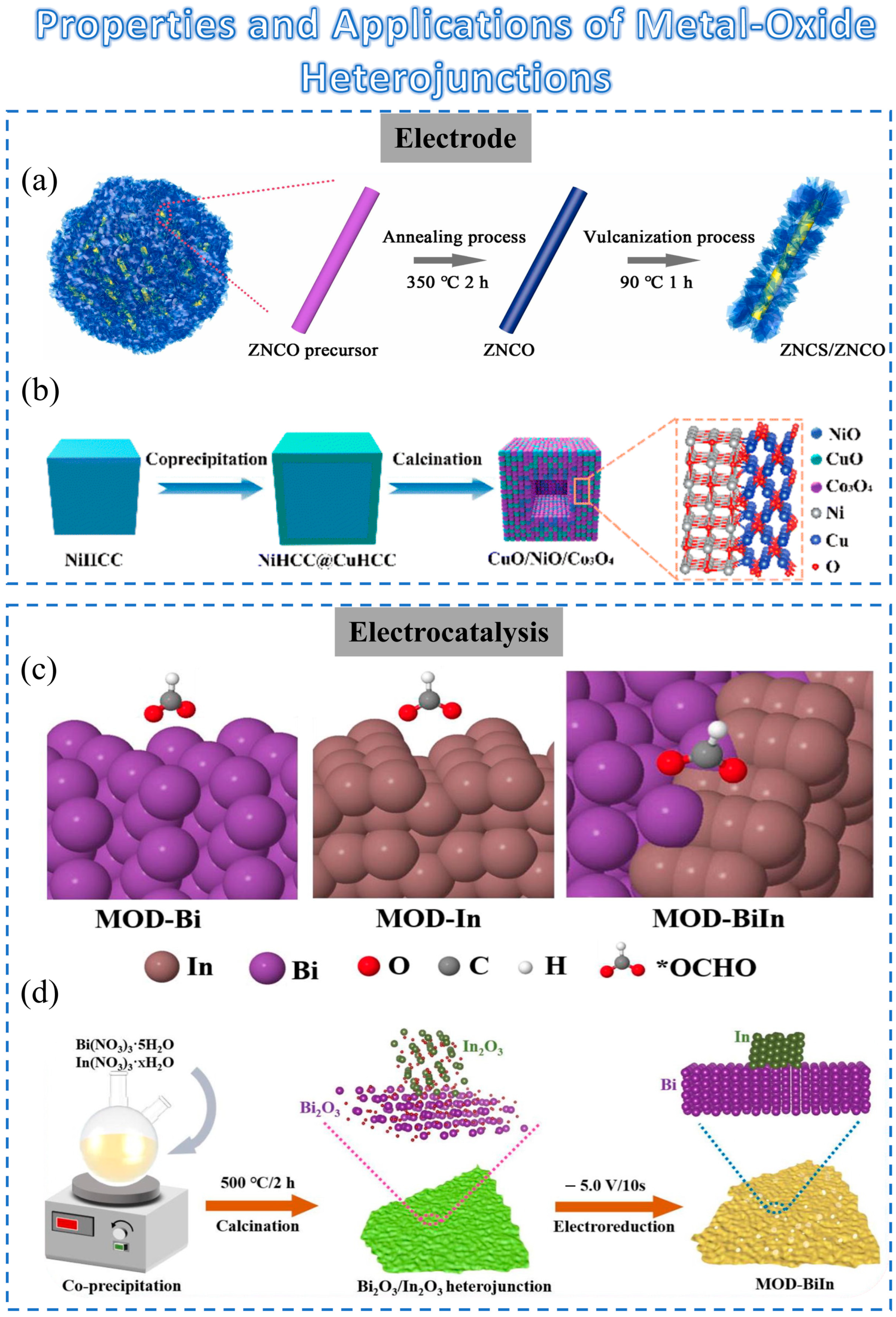

2.2.2. Applications of Heterojunctions

- Electrode materials for supercapacitors (SCs)

- Excellent properties for electrocatalysis

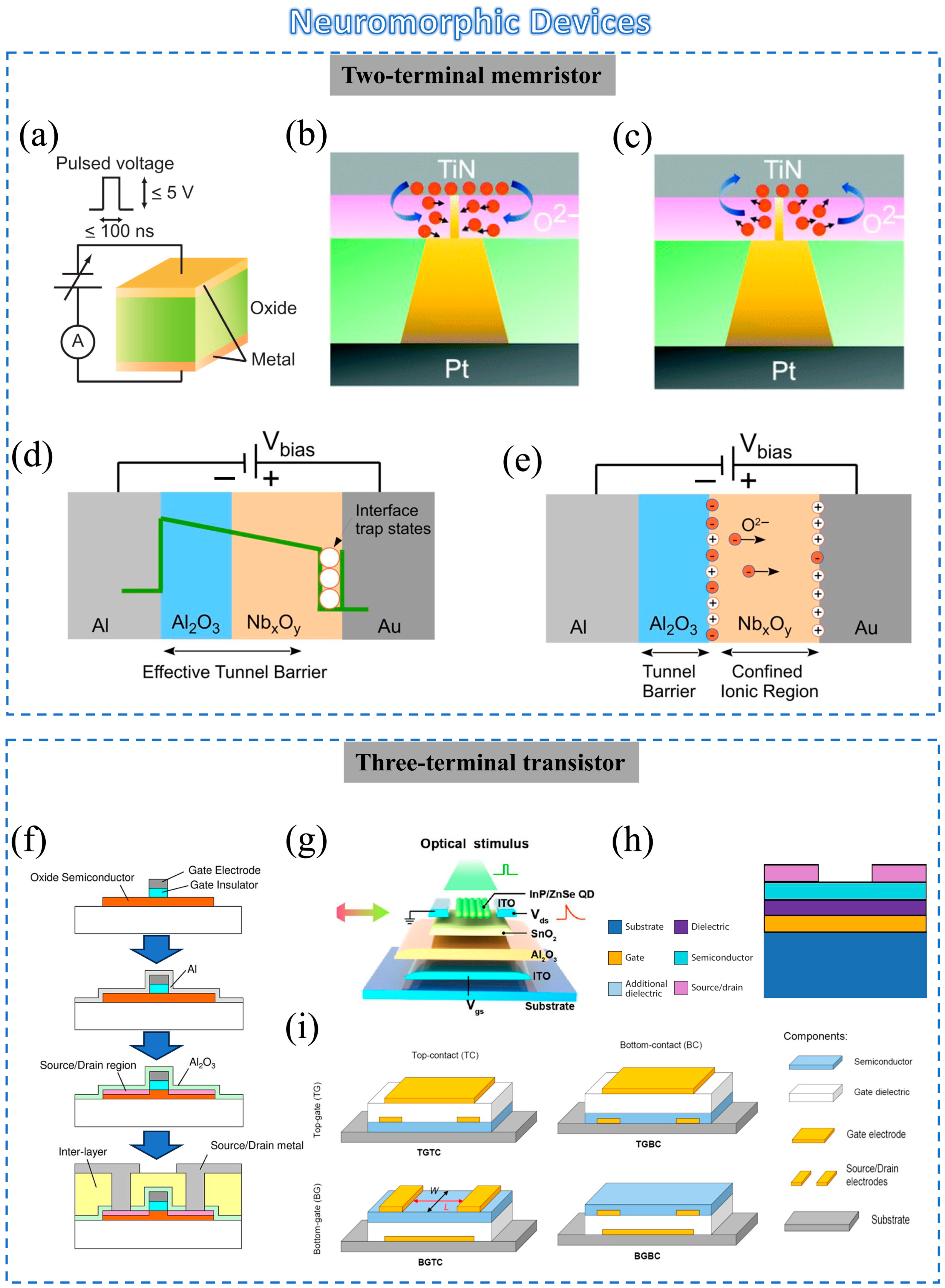

3. Neuromorphic Devices Based on Metal-Oxide Heterojunctions

3.1. Biological Synapses and Synaptic Plasticity

3.2. Two-Terminal Devices Based on Metal-Oxide Heterojunctions

- Forming conducting filaments

- Vacancy migration

3.3. Three-Terminal Devices Based on Metal-Oxide Heterojunctions

3.3.1. Bottom-Gate FETs

3.3.2. Top-Gate FETs

4. Neuromorphic Applications

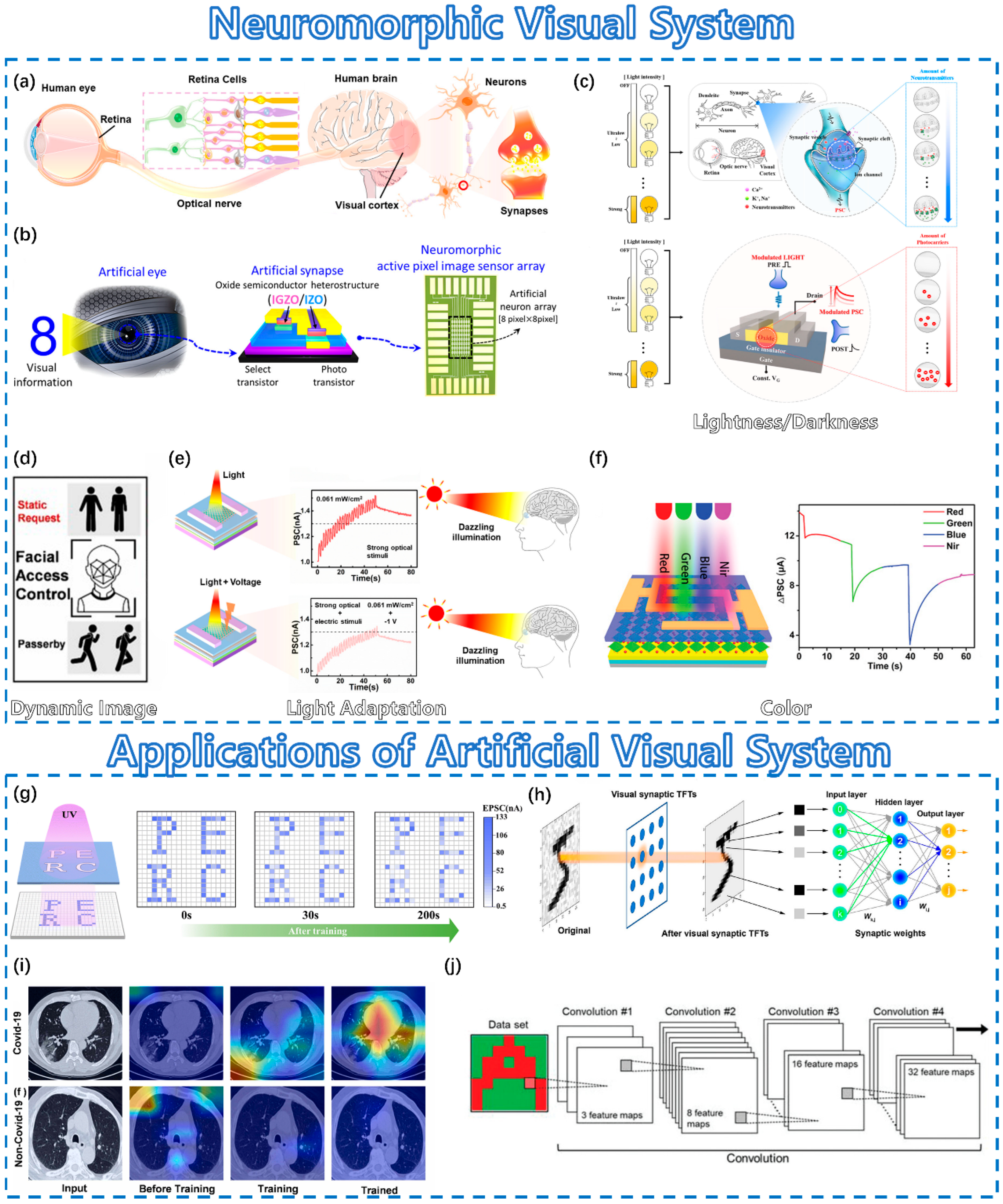

4.1. Neuromorphic Visual System

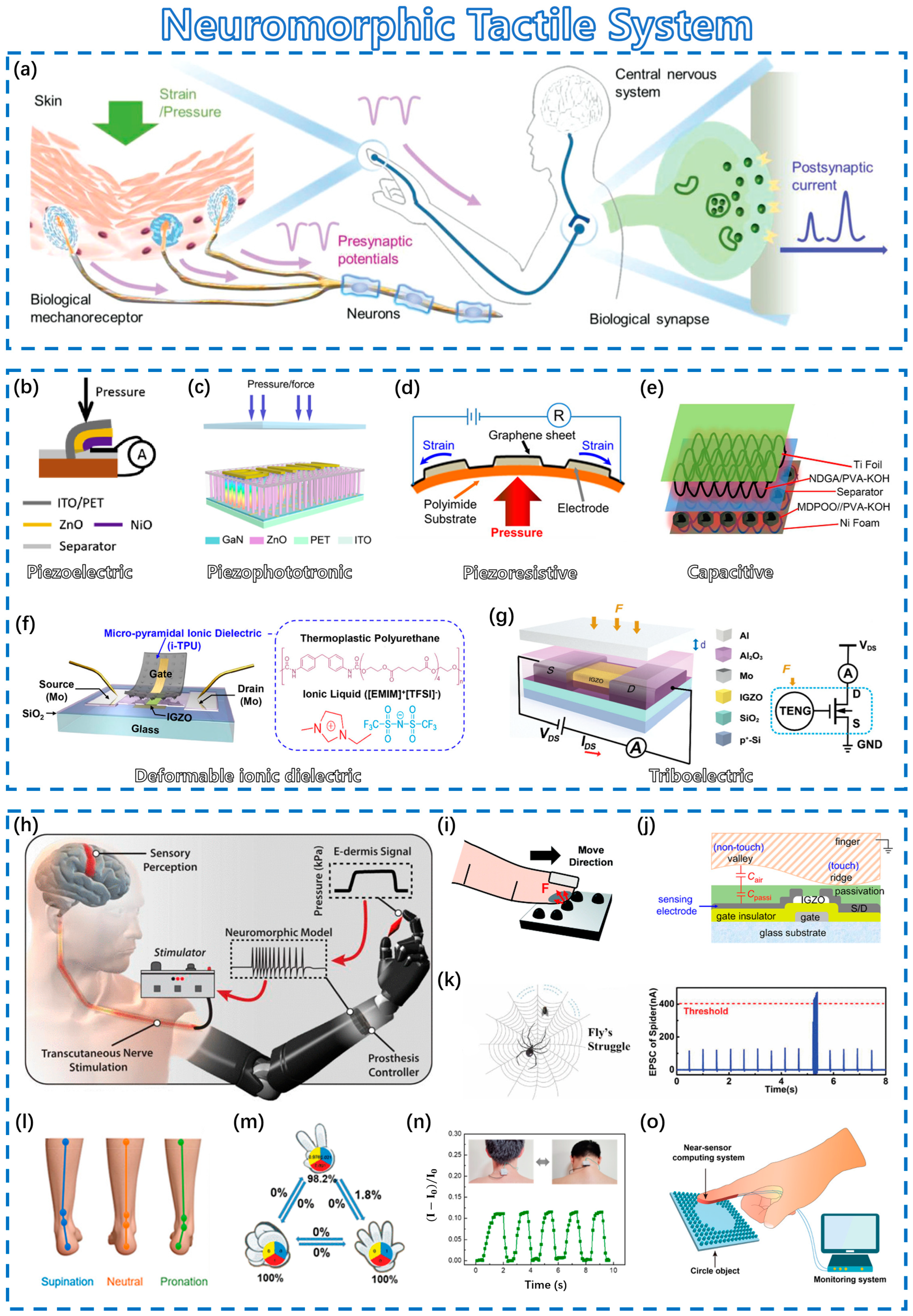

4.2. Neuromorphic Tactile System

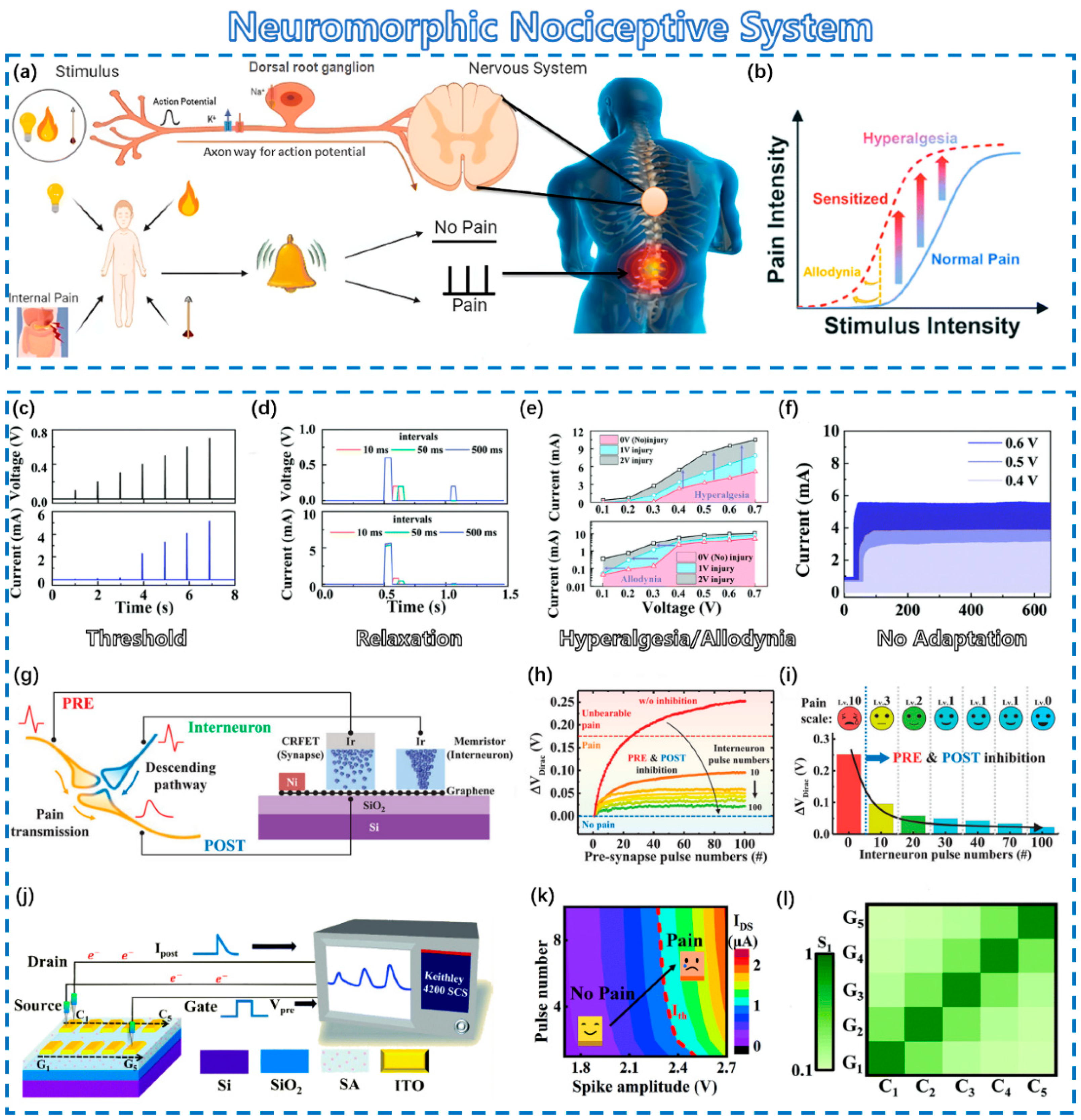

4.3. Neuromorphic Nociceptive System

5. Conclusions and Perspectives

Funding

Conflicts of Interest

References

- Marjani, M.; Nasaruddin, F.; Gani, A.; Karim, A.; Hashem, I.A.T.; Siddiqa, A.; Yaqoob, I. Big IoT Data Analytics: Architecture, Opportunities, and Open Research Challenges. IEEE Access 2017, 5, 5247–5261. [Google Scholar] [CrossRef]

- Gibney, E. Google AI Algorithm Masters Ancient Game of Go. Nature 2016, 529, 445–446. [Google Scholar] [CrossRef]

- Yu, S. Neuro-Inspired Computing with Emerging Nonvolatile Memorys. Proc. IEEE 2018, 106, 260–285. [Google Scholar] [CrossRef]

- Neumann, J. von First Draft of a Report on the EDVAC. IEEE Ann. Hist. Comput. 1993, 15, 27–75. [Google Scholar] [CrossRef]

- Najafabadi, M.M.; Villanustre, F.; Khoshgoftaar, T.M.; Seliya, N.; Wald, R.; Muharemagic, E. Deep Learning Applications and Challenges in Big Data Analytics. J. Big Data 2015, 2, 1. [Google Scholar] [CrossRef]

- Wu, Y.; Feng, J. Development and Application of Artificial Neural Network. Wirel. Pers. Commun. 2018, 102, 1645–1656. [Google Scholar] [CrossRef]

- Moore, G.E. Cramming More Components onto Integrated Circuits, Reprinted from Electronics, Volume 38, Number 8, April 19, 1965, pp.114 ff. IEEE Solid-State Circuits Soc. Newsl. 2006, 11, 33–35. [Google Scholar] [CrossRef]

- Kandel, E.R.; Koester, J.D.; Mack, S.H.; Siegelbaum, S.A. Principles of Neural Science, 6th ed.; McGraw Hill: New York, NY, USA, 2021. [Google Scholar]

- Oh, C.; Jo, M.; Son, J. All-Solid-State Synaptic Transistors with High-Temperature Stability Using Proton Pump Gating of Strongly Correlated Materials. ACS Appl. Mater. Interfaces 2019, 11, 15733–15740. [Google Scholar] [CrossRef]

- He, Y.; Yang, Y.; Nie, S.; Liu, R.; Wan, Q. Electric-Double-Layer Transistors for Synaptic Devices and Neuromorphic Systems. J. Mater. Chem. C 2018, 6, 5336–5352. [Google Scholar] [CrossRef]

- Merolla, P.A.; Arthur, J.V.; Alvarez-Icaza, R.; Cassidy, A.S.; Sawada, J.; Akopyan, F.; Jackson, B.L.; Imam, N.; Guo, C.; Nakamura, Y.; et al. A Million Spiking-Neuron Integrated Circuit with a Scalable Communication Network and Interface. Science 2014, 345, 668–673. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Heo, J.-S.; Kim, T.-H.; Park, S.; Yoon, M.-H.; Kim, J.; Oh, M.S.; Yi, G.-R.; Noh, Y.-Y.; Park, S.K. Flexible Metal-Oxide Devices Made by Room-Temperature Photochemical Activation of Sol–Gel Films. Nature 2012, 489, 128–132. [Google Scholar] [CrossRef] [PubMed]

- Banger, K.K.; Yamashita, Y.; Mori, K.; Peterson, R.L.; Leedham, T.; Rickard, J.; Sirringhaus, H. Low-Temperature, High-Performance Solution-Processed Metal Oxide Thin-Film Transistors Formed by a ‘Sol–Gel on Chip’ Process. Nat. Mater. 2011, 10, 45–50. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Marks, T.J.; Facchetti, A. Metal Oxides for Optoelectronic Applications. Nat. Mater. 2016, 15, 383–396. [Google Scholar] [CrossRef]

- Gai, L.-Y.; Lai, R.-P.; Dong, X.-H.; Wu, X.; Luan, Q.-T.; Wang, J.; Lin, H.-F.; Ding, W.-H.; Wu, G.-L.; Xie, W.-F. Recent Advances in Ethanol Gas Sensors Based on Metal Oxide Semiconductor Heterojunctions. Rare Met. 2022, 41, 1818–1842. [Google Scholar] [CrossRef]

- Yao, Y.; Sang, D.; Duan, S.; Wang, Q.; Liu, C. Review on the Properties of Boron-Doped Diamond and One-Dimensional-Metal-Oxide Based P-N Heterojunction. Molecules 2021, 26, 71. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Jiang, R. Interfacial Engineering of Metal/Metal Oxide Heterojunctions toward Oxygen Reduction and Evolution Reactions. ChemPlusChem 2021, 86, 1586–1601. [Google Scholar] [CrossRef]

- Li, T.; Zeng, W.; Wang, Z. Quasi-One-Dimensional Metal-Oxide-Based Heterostructural Gas-Sensing Materials: A Review. Sens. Actuators B Chem. 2015, 221, 1570–1585. [Google Scholar] [CrossRef]

- Du, P.-F.; Feng, P.; Wan, X.; Yang, Y.; Wan, Q. Amorphous InGaZnO4 Neuron Transistors with Temporal and Spatial Summation Function. Chin. Phys. Lett. 2017, 34, 058502. [Google Scholar] [CrossRef]

- Zhu, Y.; He, Y.; Jiang, S.; Zhu, L.; Chen, C.; Wan, Q. Indium–Gallium–Zinc–Oxide Thin-Film Transistors: Materials, Devices, and Applications. J. Semicond. 2021, 42, 031101. [Google Scholar] [CrossRef]

- Guo, T.; Sun, B.; Ranjan, S.; Jiao, Y.; Wei, L.; Zhou, Y.N.; Wu, Y.A. From Memristive Materials to Neural Networks. ACS Appl. Mater. Interfaces 2020, 12, 54243–54265. [Google Scholar] [CrossRef]

- Pasquarelli, R.; Ginley, D.; O’Hayre, R. ChemInform Abstract: Solution Processing of Transparent Conductors: From Flask to Film. Chem. Soc. Rev. 2011, 40, 5406–5441. [Google Scholar] [CrossRef] [PubMed]

- Zakaria, S.N.F.; Aziz, H.A.; Hung, Y.-T.; Mojiri, A.; Glysson, E.A. Mechanical Volume Reduction. In Solid Waste Engineering and Management: Volume 1; Wang, L.K., Wang, M.-H.S., Hung, Y.-T., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 297–343. ISBN 978-3-030-84180-5. [Google Scholar]

- Chen, Y.; Gao, G.; Zhao, J.; Zhang, H.; Yu, J.; Yang, X.; Zhang, Q.; Zhang, W.; Xu, S.; Sun, J.; et al. Piezotronic Graphene Artificial Sensory Synapse. Adv. Funct. Mater. 2019, 29, 1900959. [Google Scholar] [CrossRef]

- Feng, G.; Jiang, J.; Zhao, Y.; Wang, S.; Liu, B.; Yin, K.; Niu, D.; Li, X.; Chen, Y.; Duan, H.; et al. A Sub-10 Nm Vertical Organic/Inorganic Hybrid Transistor for Pain-Perceptual and Sensitization-Regulated Nociceptor Emulation. Adv. Mater. 2020, 32, 1906171. [Google Scholar] [CrossRef] [PubMed]

- Xie, D.; Wei, L.; Xie, M.; Jiang, L.; Yang, J.; He, J.; Jiang, J. Photoelectric Visual Adaptation Based on 0D-CsPbBr3-Quantum-Dots/2D-MoS2 Mixed-Dimensional Heterojunction Transistor. Adv. Funct. Mater. 2021, 31, 2010655. [Google Scholar] [CrossRef]

- Liang, K.; Wang, R.; Huo, B.; Ren, H.; Li, D.; Wang, Y.; Tang, Y.; Chen, Y.; Song, C.; Li, F.; et al. Fully Printed Optoelectronic Synaptic Transistors Based on Quantum Dot–Metal Oxide Semiconductor Heterojunctions. ACS Nano 2022, 16, 8651–8661. [Google Scholar] [CrossRef]

- Sakka, S.; Kozuka, H.; Zhao, G. Sol-Gel Preparation of Metal Particle/Oxide Nanocomposites. In Proceedings of the Sol-Gel Optics III; SPIE: Bellingham, WA, USA, 1994; Volume 2288, pp. 108–119. [Google Scholar]

- Ou, N.C.; Su, X.; Bock, D.C.; McElwee-White, L. Precursors for Chemical Vapor Deposition of Tungsten Oxide and Molybdenum Oxide. Coord. Chem. Rev. 2020, 421, 213459. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhao, D.; Zhao, J.; Fei, L. The Song Dynasty Shipwreck Monitoring and Analysis Using Acoustic Emission Technique. Forests 2019, 10, 767. [Google Scholar] [CrossRef]

- Malandrino, G. Chemical Vapour Deposition. Precursors, Processes and Applications. Angew. Chem. Int. Ed. 2009, 48, 7478–7479. [Google Scholar] [CrossRef]

- Yin, T.-H.; Liu, B.-J.; Lin, Y.-W.; Li, Y.-S.; Lai, C.-W.; Lan, Y.-P.; Choi, C.; Chang, H.-C.; Choi, Y. Electrodeposition of Copper Oxides as Cost-Effective Heterojunction Photoelectrode Materials for Solar Water Splitting. Coatings 2022, 12, 1839. [Google Scholar] [CrossRef]

- Hu, R.; Liao, Y.; Qiao, H.; Li, J.; Wang, K.; Huang, Z.; Qi, X. Electrochemical Method Integrating Exfoliation and In-Situ Growth to Synthesize MoS2 Nanosheets/MnO2 Heterojunction for Performance-Enhanced Supercapacitor. Ceram. Int. 2022, 48, 23498–23503. [Google Scholar] [CrossRef]

- Pedersen, J.D.; Esposito, H.J.; Teh, K.S. Direct Synthesis and Characterization of Optically Transparent Conformal Zinc Oxide Nanocrystalline Thin Films by Rapid Thermal Plasma CVD. Nanoscale Res. Lett. 2011, 6, 568. [Google Scholar] [CrossRef]

- Kumeria, T.; Santos, A.; Losic, D. Nanoporous Anodic Alumina Platforms: Engineered Surface Chemistry and Structure for Optical Sensing Applications. Sensors 2014, 14, 11878–11918. [Google Scholar] [CrossRef]

- Reports, W.M. Physical Vapor Deposition Market Will Reach New Heights in the Upcoming Year 2022–2029. Oerlikon Balzers (Oerlikon Group), IHI Corporation, Silfex Inc. (Lam Research Corp.). Available online: https://www.openpr.com/news/2741878/physical-vapor-deposition-market-will-reach-new-heights-in (accessed on 27 October 2023).

- Roostaei, T.; Rahimpour, M.R.; Zhao, H.; Eisapour, M.; Chen, Z.; Hu, J. Recent Advances and Progress in Biotemplate Catalysts for Electrochemical Energy Storage and Conversion. Adv. Colloid Interface Sci. 2023, 318, 102958. [Google Scholar] [CrossRef]

- Ito, M.; Furumoto, D. Effects of Mechanical Milling and Ag Addition on Thermoelectric Properties of NaxCo2O4. Scr. Mater. 2006, 55, 533–536. [Google Scholar] [CrossRef]

- Campbell, S.A. The Science and Engineering of Microelectronic Fabrication; Oxford University Press: New York, NY, USA, 2001; ISBN 978-0-19-513605-0. [Google Scholar]

- O’Sullivan, J.; Burgess, S.; Rimmer, N. Metal Lift-off Using Physical Vapour Deposition. Microelectron. Eng. 2002, 64, 473–478. [Google Scholar] [CrossRef]

- Radulescu, F.; Miller, P.; Cunnane, L.; Harris, M.; Lam, H.; Bowers, C. Complete Sputtering Metallization for High-Volume Manufacturing. III-Vs Rev. 2002, 15, 42–45. [Google Scholar] [CrossRef]

- Wong, Y.H.; Cheong, K.Y. ZrO2 Thin Films on Si Substrate. J. Mater. Sci. Mater. Electron. 2010, 21, 980–993. [Google Scholar] [CrossRef]

- Chin, W.C.; Cheong, K.Y.; Hassan, Z. Sm2O3 Gate Dielectric on Si Substrate. Mater. Sci. Semicond. Process. 2010, 13, 303–314. [Google Scholar] [CrossRef]

- Nakazawa, H.; Sudoh, A.; Suemitsu, M.; Yasui, K.; Itoh, T.; Endoh, T.; Narita, Y.; Mashita, M. Mechanical and Tribological Properties of Boron, Nitrogen-Coincorporated Diamond-like Carbon Films Prepared by Reactive Radio-Frequency Magnetron Sputtering. Diam. Relat. Mater. 2010, 19, 503–506. [Google Scholar] [CrossRef]

- Wasa, K.; Kitabatake, M.; Adachi, H. 4—Sputtering Systems. In Thin Film Materials Technology; Wasa, K., Kitabatake, M., Adachi, H., Eds.; William Andrew Publishing: Norwich, NY, USA, 2004; pp. 115–189. ISBN 978-0-8155-1483-1. [Google Scholar]

- Wasa, K.; Kitabatake, M.; Adachi, H. 5—Deposition of Compound Thin Films. In Thin Film Materials Technology; Wasa, K., Kitabatake, M., Adachi, H., Eds.; William Andrew Publishing: Norwich, NY, USA, 2004; pp. 191–403. ISBN 978-0-8155-1483-1. [Google Scholar]

- Wasa, K.; Kitabatake, M.; Adachi, H. 6—Structural Control of Compound Thin Films: Perovskite and Nanometer Oxide Thin Films. In Thin Film Materials Technology; Wasa, K., Kitabatake, M., Adachi, H., Eds.; William Andrew Publishing: Norwich, NY, USA, 2004; pp. 405–463. ISBN 978-0-8155-1483-1. [Google Scholar]

- Ni, Y.; Liu, L.; Liu, J.; Xu, W. A High-Strength Neuromuscular System That Implements Reflexes as Controlled by a Multiquadrant Artificial Efferent Nerve. ACS Nano 2022, 16, 20294–20304. [Google Scholar] [CrossRef]

- Sassella, A.; Campione, M.; Raimondo, L.; Tavazzi, S.; Borghesi, A.; Goletti, C.; Bussetti, G.; Chiaradia, P. Epitaxial Growth of Organic Heterostructures: Morphology, Structure, and Growth Mode. Surf. Sci. 2007, 601, 2571–2575. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, Y.; Carvalho, W.S.P.; Fang, C.; Serpe, M.J. Microgel-Based Stretchable Reservoir Devices for Elongation Enhanced Small Molecule Release Rate. ACS Appl. Mater. Interfaces 2020, 12, 19062–19068. [Google Scholar] [CrossRef]

- Harhouz, A.; Hocini, A.; Tayoub, H. Ultracompact Gas-Sensor Based on a 2D Photonic Crystal Waveguide Incorporating with Tapered Microcavity. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1046, 012001. [Google Scholar] [CrossRef]

- Liu, Z.; Li, M.; Sun, Y.; Wang, H.; Chen, H.; Tian, Y.; Wang, H.; Ding, Y.; Chen, Z. Integrating Surface and Interface Engineering to Improve Optoelectronic Performance and Environmental Stability of MXene-Based Heterojunction towards Broadband Photodetection. Nano Res. 2023, 16, 10148–10155. [Google Scholar] [CrossRef]

- Shen, R.; Jiang, C.; Xiang, Q.; Xie, J.; Li, X. Surface and Interface Engineering of Hierarchical Photocatalysts. Appl. Surf. Sci. 2019, 471, 43–87. [Google Scholar] [CrossRef]

- Koretomo, D.; Hamada, S.; Magari, Y.; Furuta, M. Quantum Confinement Effect in Amorphous In–Ga–Zn–O Heterojunction Channels for Thin-Film Transistors. Materials 2020, 13, 1935. [Google Scholar] [CrossRef]

- Shi, J.; Starr, M.B.; Wang, X. Band Structure Engineering at Heterojunction Interfaces via the Piezotronic Effect. Adv. Mater. 2012, 24, 4683–4691. [Google Scholar] [CrossRef]

- Lu, L.; Xu, T.; Chen, W.; Lee, J.M.; Luo, Z.; Jung, I.H.; Park, H.I.; Kim, S.O.; Yu, L. The Role of N-Doped Multiwall Carbon Nanotubes in Achieving Highly Efficient Polymer Bulk Heterojunction Solar Cells. Nano Lett. 2013, 13, 2365–2369. [Google Scholar] [CrossRef]

- Lemmermann, T.; Becker, M.; Stehle, M.; Drache, M.; Beuermann, S.; Bogar, M.S.; Gohs, U.; Fittschen, U.E.A.; Turek, T.; Kunz, U. In Situ and in Operando Detection of Redox Reactions with Integrated Potential Probes during Vanadium Transport in Ion Exchange Membranes. J. Power Source 2022, 533, 231343. [Google Scholar] [CrossRef]

- Ge, Y.; Liu, Z.; Wu, Y.; Holze, R. On the Utilization of Supercapacitor Electrode Materials. Electrochim. Acta 2021, 366, 137390. [Google Scholar] [CrossRef]

- Lu, W.; Shen, J.; Zhang, P.; Zhong, Y.; Hu, Y.; Lou, X.W. Construction of CoO/Co-Cu-S Hierarchical Tubular Heterostructures for Hybrid Supercapacitors. Angew. Chem. 2019, 131, 15587–15593. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, L.; Lei, X.; Huang, H.; Guo, W.; Wang, S. Hierarchical Ternary Zn-Ni-Co Sulfide/Oxide Heterostructure for High Specific Energy Hybrid Supercapacitor. J. Alloys Compd. 2023, 962, 171201. [Google Scholar] [CrossRef]

- Ju, H.; Tang, Q.; Xu, Y.; Bai, X.; Pu, C.; Liu, T.; Liu, S.; Zhang, L. Prussian Blue Analogue-Derived Hollow Metal Oxide Heterostructure for High-Performance Supercapacitors. Dalton Trans. 2023, 52, 12948–12957. [Google Scholar] [CrossRef] [PubMed]

- Ye, R.; Zhu, J.; Tong, Y.; Feng, D.; Chen, P. Metal Oxides Heterojunction Derived Bi-In Hybrid Electrocatalyst for Robust Electroreduction of CO2 to Formate. J. Energy Chem. 2023, 83, 180–188. [Google Scholar] [CrossRef]

- Rajak, R.; Saraf, M.; Mobin, S.M. Robust Heterostructures of a Bimetallic Sodium–Zinc Metal–Organic Framework and Reduced Graphene Oxide for High-Performance Supercapacitors. J. Mater. Chem. A 2019, 7, 1725–1736. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, L.; Su, H.; Huang, W.; Dong, X. Binary Metal Oxide: Advanced Energy Storage Materials in Supercapacitors. J. Mater. Chem. A 2015, 3, 43–59. [Google Scholar] [CrossRef]

- Jia, J.; Hao, X.; Chang, Y.; Jia, M.; Wen, Z. Rational Design of Cu3PdN Nanocrystals for Selective Electroreduction of Carbon Dioxide to Formic Acid. J. Colloid Interface Sci. 2021, 586, 491–497. [Google Scholar] [CrossRef]

- Zhu, W.; Zhao, K.; Liu, S.; Liu, M.; Peng, F.; An, P.; Qin, B.; Zhou, H.; Li, H.; He, Z. Low-Overpotential Selective Reduction of CO2 to Ethanol on Electrodeposited CuxAuy Nanowire Arrays. J. Energy Chem. 2019, 37, 176–182. [Google Scholar] [CrossRef]

- Dai, W.; Long, J.; Yang, L.; Zhang, S.; Xu, Y.; Luo, X.; Zou, J.; Luo, S. Oxygen Migration Triggering Molybdenum Exposure in Oxygen Vacancy-Rich Ultra-Thin Bi2MoO6 Nanoflakes: Dual Binding Sites Governing Selective CO2 Reduction into Liquid Hydrocarbons. J. Energy Chem. 2021, 61, 281–289. [Google Scholar] [CrossRef]

- Wang, S.; Kou, T.; Baker, S.E.; Duoss, E.B.; Li, Y. Recent Progress in Electrochemical Reduction of CO2 by Oxide-Derived Copper Catalysts. Mater. Today Nano 2020, 12, 100096. [Google Scholar] [CrossRef]

- Li, F.; Chen, L.; Xue, M.; Williams, T.; Zhang, Y.; MacFarlane, D.R.; Zhang, J. Towards a Better Sn: Efficient Electrocatalytic Reduction of CO2 to Formate by Sn/SnS2 Derived from SnS2 Nanosheets. Nano Energy 2017, 31, 270–277. [Google Scholar] [CrossRef]

- Tan, D.; Lee, W.; Kim, Y.E.; Ko, Y.N.; Youn, M.H.; Jeon, Y.E.; Hong, J.; Park, J.E.; Seo, J.; Jeong, S.K.; et al. In–Bi Electrocatalyst for the Reduction of CO2 to Formate in a Wide Potential Window. ACS Appl. Mater. Interfaces 2022, 14, 28890–28899. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Xiong, Y.; Hu, B.; Zhang, Z.; Wei, B.; Li, L.; Hao, J.; Shi, W. Indium Doped Bismuth Subcarbonate Nanosheets for Efficient Electrochemical Reduction of Carbon Dioxide to Formate in a Wide Potential Window. J. Colloid Interface Sci. 2022, 624, 261–269. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, X.; Zang, H.; Chen, F.; Wang, C.; Yu, N.; Geng, B. Metal–Organic Framework-Derived BiIn Bimetallic Oxide Nanoparticles Embedded in Carbon Networks for Efficient Electrochemical Reduction of CO2 to Formate. Inorg. Chem. 2022, 61, 12003–12011. [Google Scholar] [CrossRef]

- Purves, D.; Augustine, G.J.; Fitzpatrick, D.; Hall, W.; LaMantia, A.-S.; White, L. Neurosciences; De Boeck Supérieur: Paris, France, 2019; ISBN 2-8073-1492-9. [Google Scholar]

- Pakkenberg, B.; Pelvig, D.; Marner, L.; Bundgaard, M.J.; Gundersen, H.J.G.; Nyengaard, J.R.; Regeur, L. Aging and the Human Neocortex. Exp. Gerontol. 2003, 38, 95–99. [Google Scholar] [CrossRef] [PubMed]

- Goto, A. Synaptic Plasticity during Systems Memory Consolidation. Neurosci. Res. 2022, 183, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Trepel, C.; Racine, R.J. Long-Term Potentiation in the Neocortex of the Adult, Freely Moving Rat. Cereb. Cortex 1998, 8, 719–729. [Google Scholar] [CrossRef]

- Remondina, J.; Golubev, N.V.; Ignat’eva, E.S.; Sigaev, V.N.; Acciarri, M.; Paleari, A.; Lorenzi, R. Random Networks of Disconnected Nanoparticles in Dielectric Layers as a Source of Electric Responsivity. Mater. Des. 2023, 228, 111825. [Google Scholar] [CrossRef]

- Luo, L. Principles of Neurobiology; Garland Science, Taylor & Francis Group, LLC: New York, NY, USA, 2016. [Google Scholar]

- Liu, Q.; Yin, L.; Zhao, C.; Wu, Z.; Wang, J.; Yu, X.; Wang, Z.; Wei, W.; Liu, Y.; Mitrovic, I.Z.; et al. All-in-One Metal-Oxide Heterojunction Artificial Synapses for Visual Sensory and Neuromorphic Computing Systems. Nano Energy 2022, 97, 107171. [Google Scholar] [CrossRef]

- Li, J.; Jiang, D.; Yang, Y.; Zhou, Y.; Chen, Q.; Zhang, J. Li-Ion Doping as a Strategy to Modulate the Electrical-Double-Layer for Improved Memory and Learning Behavior of Synapse Transistor Based on Fully Aqueous-Solution-Processed In2O3/AlLiO Film. Adv. Electron. Mater. 2020, 6, 1901363. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, G.; Xin, Z.; Fu, C.; Wan, Q.; Shan, F. Solution-Processed, Electrolyte-Gated In2O3 Flexible Synaptic Transistors for Brain-Inspired Neuromorphic Applications. ACS Appl. Mater. Interfaces 2020, 12, 1061–1068. [Google Scholar] [CrossRef] [PubMed]

- Rolls, E.T.; Dempere-Marco, L.; Deco, G. Holding Multiple Items in Short Term Memory: A Neural Mechanism. PLoS ONE 2013, 8, e61078. [Google Scholar] [CrossRef]

- Lynch, M.A. Long-Term Potentiation and Memory. Physiol. Rev. 2004, 84, 87–136. [Google Scholar] [CrossRef]

- Sawa, A. Resistive Switching in Transition Metal Oxides. Mater. Today 2008, 11, 28–36. [Google Scholar] [CrossRef]

- Waser, R.; Aono, M. Nanoionics-Based Resistive Switching Memories. Nat. Mater. 2007, 6, 833–840. [Google Scholar] [CrossRef]

- Gao, B.; Sun, B.; Zhang, H.; Liu, L.; Liu, X.; Han, R.; Kang, J.; Yu, B. Unified Physical Model of Bipolar Oxide-Based Resistive Switching Memory. IEEE Electron Device Lett. 2009, 30, 1326–1328. [Google Scholar] [CrossRef]

- Waser, R.; Dittmann, R.; Staikov, G.; Szot, K. Redox-Based Resistive Switching Memories—Nanoionic Mechanisms, Prospects, and Challenges. Adv. Mater. 2009, 21, 2632–2663. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Kang, J.F.; Chen, Y.S.; Zhang, F.F.; Chen, B.; Huang, P.; Liu, L.F.; Liu, X.Y.; Wang, Y.Y.; Tran, X.A.; et al. Oxide-Based RRAM: Unified Microscopic Principle for Both Unipolar and Bipolar Switching. In Proceedings of the 2011 International Electron Devices Meeting, Washington, DC, USA, 5–7 December 2011; pp. 17.4.1–17.4.4. [Google Scholar]

- Wang, Z.; Yin, M.; Zhang, T.; Cai, Y.; Wang, Y.; Yang, Y.; Huang, R. Engineering Incremental Resistive Switching in TaOx Based Memristors for Brain-Inspired Computing. Nanoscale 2016, 8, 14015–14022. [Google Scholar] [CrossRef]

- Kim, S.G.; Han, J.S.; Kim, H.; Kim, S.Y.; Jang, H.W. Recent Advances in Memristive Materials for Artificial Synapses. Adv. Mater. Technol. 2018, 3, 1800457. [Google Scholar] [CrossRef]

- Pickett, M.D.; Strukov, D.B.; Borghetti, J.L.; Yang, J.J.; Snider, G.S.; Stewart, D.R.; Williams, R.S. Switching Dynamics in Titanium Dioxide Memristive Devices. J. Appl. Phys. 2009, 106, 074508. [Google Scholar] [CrossRef]

- Hansen, M.; Ziegler, M.; Kolberg, L.; Soni, R.; Dirkmann, S.; Mussenbrock, T.; Kohlstedt, H. A Double Barrier Memristive Device. Sci. Rep. 2015, 5, 13753. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, J.; Cao, J.; Lu, C.; Yang, G.; Shi, X.; Chuai, X.; Gong, Y.; Su, Y.; Zhao, Y.; et al. Photoelectric Plasticity in Oxide Thin Film Transistors with Tunable Synaptic Functions. Adv. Electron. Mater. 2018, 4, 1800556. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, J.; Yang, Y.; Chen, Q.; Zhang, J. Artificial Synapse Emulated through Fully Aqueous Solution-Processed Low-Voltage In2O3 Thin-Film Transistor with Gd2O3 Solid Electrolyte. ACS Appl. Mater. Interfaces 2020, 12, 980–988. [Google Scholar] [CrossRef] [PubMed]

- Dai, C.; Huo, C.; Qi, S.; Dai, M.; Webster, T.; Xiao, H. Flexible and Transparent Artificial Synapse Devices Based on Thin-Film Transistors with Nanometer Thickness. Int. J. Nanomed. 2020, 15, 8037–8043. [Google Scholar] [CrossRef] [PubMed]

- Beom, K.; Han, J.; Kim, H.-M.; Yoon, T.-S. Wide Range Modulation of Synaptic Weight in Thin-Film Transistors with Hafnium Oxide Gate Insulator and Indium-Zinc Oxide Channel Layer for Artificial Synapse Application. Nanoscale 2021, 13, 11370–11379. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.; Yim, S.; Rehman, S.; Ghafoor, F.; Kim, H.; Patil, H.; Khan, M.F.; Eom, J. Two-Dimensional Materials Memory Devices with Floating Metal Gate for Neuromorphic Applications. Mater. Today Adv. 2023, 20, 100438. [Google Scholar] [CrossRef]

- Morosawa, N.; Nishiyama, M.; Ohshima, Y.; Sato, A.; Terai, Y.; Tokunaga, K.; Iwasaki, J.; Akamatsu, K.; Kanitani, Y.; Tanaka, S.; et al. High-Mobility Self-Aligned Top-Gate Oxide TFT for High-Resolution AM-OLED: High-Mobility Self-Aligned Top-Gate Oxide TFT. J. Soc. Inf. Disp. 2013, 21, 467–473. [Google Scholar] [CrossRef]

- Allendorf, M.D.; Dong, R.; Feng, X.; Kaskel, S.; Matoga, D.; Stavila, V. Electronic Devices Using Open Framework Materials. Chem. Rev. 2020, 120, 8581–8640. [Google Scholar] [CrossRef]

- Rehman, S.; Khan, M.F.; Rahmani, M.K.; Kim, H.; Patil, H.; Khan, S.A.; Kang, M.H.; Kim, D. Neuro-Transistor Based on UV-Treated Charge Trapping in MoTe2 for Artificial Synaptic Features. Nanomaterials 2020, 10, 2326. [Google Scholar] [CrossRef]

- Weimer, P.K. The TFT A New Thin-Film Transistor. Proc. IRE 1962, 50, 1462–1469. [Google Scholar] [CrossRef]

- Kuo, Y. Thin Film Transistor Technology—Past, Present, and Future. Electrochem. Soc. Interface 2013, 22, 55. [Google Scholar] [CrossRef]

- Klasens, H.A.; Koelmans, H. A Tin Oxide Field-Effect Transistor. Solid-State Electron. 1964, 7, 701–702. [Google Scholar] [CrossRef]

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-Temperature Fabrication of Transparent Flexible Thin-Film Transistors Using Amorphous Oxide Semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Rim, Y.S. Review of Metal Oxide Semiconductors-Based Thin-Film Transistors for Point-of-Care Sensor Applications. J. Inf. Disp. 2020, 21, 203–210. [Google Scholar] [CrossRef]

- Mirshojaeian Hosseini, M.J.; Nawrocki, R.A. A Review of the Progress of Thin-Film Transistors and Their Technologies for Flexible Electronics. Micromachines 2021, 12, 655. [Google Scholar] [CrossRef] [PubMed]

- Duan, N.; Li, Y.; Chiang, H.-C.; Chen, J.; Pan, W.-Q.; Zhou, Y.-X.; Chien, Y.-C.; He, Y.-H.; Xue, K.-H.; Liu, G.; et al. An Electro-Photo-Sensitive Synaptic Transistor for Edge Neuromorphic Visual Systems. Nanoscale 2019, 11, 17590–17599. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Liu, S. Visual Information Computing and Processing Model Based on Artificial Neural Network. Comput. Intell. Neurosci. 2022, 2022, 4713311. [Google Scholar] [CrossRef] [PubMed]

- Meng, J.; Wang, T.; Zhu, H.; Ji, L.; Bao, W.; Zhou, P.; Chen, L.; Sun, Q.-Q.; Zhang, D.W. Integrated In-Sensor Computing Optoelectronic Device for Environment-Adaptable Artificial Retina Perception Application. Nano Lett. 2022, 22, 81–89. [Google Scholar] [CrossRef]

- Jiang, Z.; Jiang, Y.; Chen, N.; Chen, X. Artificial Visual Electronics for Closed-Loop Sensation/Action Systems. Adv. Intell. Syst. 2021, 3, 2100071. [Google Scholar] [CrossRef]

- Pei, Y.; Yan, L.; Wu, Z.; Lu, J.; Zhao, J.; Chen, J.; Liu, Q.; Yan, X. Artificial Visual Perception Nervous System Based on Low-Dimensional Material Photoelectric Memristors. ACS Nano 2021, 15, 17319–17326. [Google Scholar] [CrossRef]

- Hong, S.; Cho, H.; Kang, B.H.; Park, K.; Akinwande, D.; Kim, H.J.; Kim, S. Neuromorphic Active Pixel Image Sensor Array for Visual Memory. ACS Nano 2021, 15, 15362–15370. [Google Scholar] [CrossRef]

- Yang, J.S.; Jung, S.H.; Kim, D.S.; Choi, J.H.; Suh, H.W.; Lee, H.H.; Lee, K.W.; Cho, H.K. Design of Functionally Stacked Channels of Oxide Thin-Film Transistors to Mimic Precise Ultralow-Light-Irradiated Synaptic Weight Modulation. Micromachines 2022, 13, 526. [Google Scholar] [CrossRef]

- Liu, Q.; Yin, L.; Zhao, C.; Wang, J.; Wu, Z.; Lei, H.; Liu, Y.; Tian, B.; Zhang, Z.; Zhao, Z.; et al. Hybrid Mixed-Dimensional Perovskite/Metal-Oxide Heterojunction for All-in-One Opto-Electric Artificial Synapse and Retinal-Neuromorphic System. Nano Energy 2022, 102, 107686. [Google Scholar] [CrossRef]

- Huang, X.; Li, Q.; Shi, W.; Liu, K.; Zhang, Y.; Liu, Y.; Wei, X.; Zhao, Z.; Guo, Y.; Liu, Y. Dual-Mode Learning of Ambipolar Synaptic Phototransistor Based on 2D Perovskite/Organic Heterojunction for Flexible Color Recognizable Visual System. Small 2021, 17, 2102820. [Google Scholar] [CrossRef] [PubMed]

- Jo, C.; Kim, J.; Kwak, J.Y.; Kwon, S.M.; Park, J.B.; Kim, J.; Park, G.-S.; Kim, M.-G.; Kim, Y.-H.; Park, S.K. Retina-Inspired Color-Cognitive Learning via Chromatically Controllable Mixed Quantum Dot Synaptic Transistor Arrays. Adv. Mater. 2022, 34, 2108979. [Google Scholar] [CrossRef] [PubMed]

- Shao, S.; Wang, S.; Li, M.; Xie, T.; Fang, Y.; Guo, P.; Chen, Z.; Zhao, J. 75 Kbit Printed Indium Oxide (IO)/Indium Gallium Zinc Oxide (IGZO) Heterojunction Photoelectric Synaptic Transistor Arrays for an Artificial Visual Memory System. J. Mater. Chem. C 2023, 11, 7019–7029. [Google Scholar] [CrossRef]

- Kwon, S.M.; Cho, S.W.; Kim, M.; Heo, J.S.; Kim, Y.-H.; Park, S.K. Environment-Adaptable Artificial Visual Perception Behaviors Using a Light-Adjustable Optoelectronic Neuromorphic Device Array. Adv. Mater. 2019, 31, 1906433. [Google Scholar] [CrossRef]

- Jin, C.; Liu, W.; Xu, Y.; Huang, Y.; Nie, Y.; Shi, X.; Zhang, G.; He, P.; Zhang, J.; Cao, H.; et al. Artificial Vision Adaption Mimicked by an Optoelectrical In2O3 Transistor Array. Nano Lett. 2022, 22, 3372–3379. [Google Scholar] [CrossRef]

- Xie, S.; Wang, L.; Mao, X.; Cong, J.; Zhao, Y.; Chen, H. Brain Inspired Color Feature Selection Chip. IEEE Photonics J. 2022, 14, 1–9. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, B.; Han, Z.; Shi, X.; Zhang, N.; Miao, T.; Lin, D.; Jiang, Z.; Liu, M.; Guo, H.; et al. Bidirectional Photoresponse in a Mixed-Dimensional MoS2/Ge Heterostructure and Its Optic-Neural Synaptic Behavior for Colored Pattern Recognition. ACS Photonics 2023, 10, 1575–1582. [Google Scholar] [CrossRef]

- Li, D.; Li, C.; Ilyas, N.; Jiang, X.; Liu, F.; Gu, D.; Xu, M.; Jiang, Y.; Li, W. Color-Recognizing Si-Based Photonic Synapse for Artificial Visual System. Adv. Intell. Syst. 2020, 2, 2000107. [Google Scholar] [CrossRef]

- Dahiya, R.S.; Cattin, D.; Adami, A.; Collini, C.; Barboni, L.; Valle, M.; Lorenzelli, L.; Oboe, R.; Metta, G.; Brunetti, F. Towards Tactile Sensing System on Chip for Robotic Applications. IEEE Sens. J. 2011, 11, 3216–3226. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wu, W. Piezotronics and Piezo-Phototronics: Fundamentals and Applications. Natl. Sci. Rev. 2013, 1, 62–90. [Google Scholar] [CrossRef]

- Kumar, M.; Singh, R.; Kang, H.; Kim, S.; Seo, H. An Artificial Piezotronic Synapse for Tactile Perception. Nano Energy 2020, 73, 104756. [Google Scholar] [CrossRef]

- Xie, W.; Peng, W.; Wang, Y.; Li, F.; He, Y. On the Piezophototronic Effect in Heterojunction Photodiode with Type-II Energy Band: Theoretical Model for Anisotype Heterojunction. Phys. Status Solidi RRL Rapid Res. Lett. 2023, 17, 2300034. [Google Scholar] [CrossRef]

- Peng, Y.; Que, M.; Lee, H.E.; Bao, R.; Wang, X.; Lu, J.; Yuan, Z.; Li, X.; Tao, J.; Sun, J.; et al. Achieving High-Resolution Pressure Mapping via Flexible GaN/ ZnO Nanowire LEDs Array by Piezo-Phototronic Effect. Nano Energy 2019, 58, 633–640. [Google Scholar] [CrossRef]

- Wang, C.; Gong, D.; Feng, P.; Cheng, Y.; Cheng, X.; Jiang, Y.; Zhang, D.; Cai, J. Ultra-Sensitive and Wide Sensing-Range Flexible Pressure Sensors Based on the Carbon Nanotube Film/Stress-Induced Square Frustum Structure. ACS Appl. Mater. Interfaces 2023, 15, 8546–8554. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Cai, J.; Xu, J.; Gong, D. High-Performance Strain Sensors Based on Au/Graphene Composite Films with Hierarchical Cracks for Wide Linear-Range Motion Monitoring. ACS Appl. Mater. Interfaces 2022, 14, 39230–39239. [Google Scholar] [CrossRef]

- Mahmud, M.A.P.; Tat, T.; Xiao, X.; Adhikary, P.; Chen, J. Advances in 4D-Printed Physiological Monitoring Sensors. Exploration 2021, 1, 20210033. [Google Scholar] [CrossRef]

- Aygun, L.E.; Kumar, P.; Zheng, Z.; Chen, T.S.; Wagner, S.; Sturm, J.C.; Verma, N. Hybrid LAE-CMOS Force-Sensing System Employing TFT-Based Compressed Sensing for Scalability of Tactile Sensing Skins. IEEE Trans. Biomed. Circuits Syst. 2019, 13, 1264–1276. [Google Scholar] [CrossRef]

- Qiao, Y.; Jian, J.; Tang, H.; Ji, S.; Liu, Y.; Liu, H.; Li, Y.; Li, X.; Han, F.; Liu, Z.; et al. An Intelligent Nanomesh-Reinforced Graphene Pressure Sensor with an Ultra Large Linear Range. J. Mater. Chem. A 2022, 10, 4858–4869. [Google Scholar] [CrossRef]

- Kang, I.H.; Hong, M.T.; Bae, B.S. Capacitive Sensor Pixel Circuit with Single Transistor for Touch-Fingerprint Recognition Sensor. Electron. Lett. 2018, 54, 1212–1214. [Google Scholar] [CrossRef]

- Zhang, C.; Li, S.; He, Y.; Chen, C.; Jiang, S.; Yang, X.; Wang, X.; Pan, L.; Wan, Q. Oxide Synaptic Transistors Coupled With Triboelectric Nanogenerators for Bio-Inspired Tactile Sensing Application. IEEE Electron Device Lett. 2020, 41, 617–620. [Google Scholar] [CrossRef]

- Pang, Y.; Zhang, K.; Yang, Z.; Jiang, S.; Ju, Z.; Li, Y.; Wang, X.; Wang, D.; Jian, M.; Zhang, Y.; et al. Epidermis Microstructure Inspired Graphene Pressure Sensor with Random Distributed Spinosum for High Sensitivity and Large Linearity. ACS Nano 2018, 12, 2346–2354. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Liu, Z.; Luo, Z.; Wu, X.; Qiao, F.; Wang, X.; Li, G.; Wu, J.; Zhang, J.; Liu, Z.; et al. Dual-Mode Sensor and Actuator to Learn Human-Hand Tracking and Grasping. IEEE Trans. Electron Devices 2019, 66, 5407–5410. [Google Scholar] [CrossRef]

- Yu, T.; Tao, Y.; Wu, Y.; Zhang, D.; Yang, J.; Liu, X. Self-Encapsulated Breathable Reduced Oxide Graphene-Coated Melamine Foam for Stress Sensing. ACS Appl. Electron. Mater. 2023, 5, 4624–4634. [Google Scholar] [CrossRef]

- Jia, M.; Guo, P.; Wang, W.; Yu, A.; Zhang, Y.; Wang, Z.; Zhai, J. Tactile Tribotronic Reconfigurable P-n Junctions for Artificial Synapses. Sci. Bull. 2022, 67, 803–812. [Google Scholar] [CrossRef]

- Khan, R.; Rehman, N.U.; Ilyas, N.; Sfina, N.; Barhoumi, M.; Khan, A.; Althubeiti, K.; Otaibi, S.A.; Iqbal, S.; Rahman, N.; et al. Threshold Switching in Nickel-Doped Zinc Oxide Based Memristor for Artificial Sensory Applications. Nanoscale 2023, 15, 1900–1913. [Google Scholar] [CrossRef] [PubMed]

- Gong, G.; Gao, S.; Xie, Z.; Ye, X.; Lu, Y.; Yang, H.; Zhu, X.; Li, R.-W. A Visible Light-Triggered Artificial Photonic Nociceptor with Adaptive Tunability of Threshold. Nanoscale 2021, 13, 1029–1037. [Google Scholar] [CrossRef]

- Yang, J.-H.; Mao, S.-C.; Chen, K.-T.; Chen, J.-S. Emulating Nociceptive Receptor and LIF Neuron Behavior via ZrOx-Based Threshold Switching Memristor. Adv. Electron. Mater. 2023, 9, 2201006. [Google Scholar] [CrossRef]

- Kim, Y.; Kwon, Y.J.; Kwon, D.E.; Yoon, K.J.; Yoon, J.H.; Yoo, S.; Kim, H.J.; Park, T.H.; Han, J.-W.; Kim, K.M.; et al. Nociceptive Memristor. Adv. Mater. 2018, 30, 1704320. [Google Scholar] [CrossRef]

- Shrivastava, S.; Pratik, S.; Lin, A.S.; Tseng, T.Y. Emulating Synaptic and Nociceptive Behavior via Negative Photoconductivity of a Memristor. IEEE Trans. Electron Devices 2023, 70, 3530–3535. [Google Scholar] [CrossRef]

- Bousoulas, P.; Tsioustas, C.; Tsoukalas, D. Emulating Low Power Nociceptive Functionalities with a Forming-Free SiO2/VOx Conductive Bridge Memory with Pt Nanoparticles. Appl. Phys. Lett. 2022, 120, 253509. [Google Scholar] [CrossRef]

- Xu, X.; Cho, E.J.; Bekker, L.; Talin, A.A.; Lee, E.; Pascall, A.J.; Worsley, M.A.; Zhou, J.; Cook, C.C.; Kuntz, J.D.; et al. A Bioinspired Artificial Injury Response System Based on a Robust Polymer Memristor to Mimic a Sense of Pain, Sign of Injury, and Healing. Adv. Sci. 2022, 9, 2200629. [Google Scholar] [CrossRef] [PubMed]

- Xia, Q.; Qin, Y.; Qiu, P.; Zheng, A.; Zhang, X. A Bio-Inspired Tactile Nociceptor Constructed by Integrating Wearable Sensing Paper and a VO2 Threshold Switching Memristor. J. Mater. Chem. B 2022, 10, 1991–2000. [Google Scholar] [CrossRef]

- Niu, H.; Gao, S.; Yue, W.; Li, Y.; Zhou, W.; Liu, H. Highly Morphology-Controllable and Highly Sensitive Capacitive Tactile Sensor Based on Epidermis-Dermis-Inspired Interlocked Asymmetric-Nanocone Arrays for Detection of Tiny Pressure. Small 2020, 16, 1904774. [Google Scholar] [CrossRef]

- Jang, S.; Jee, E.; Choi, D.; Kim, W.; Kim, J.S.; Amoli, V.; Sung, T.; Choi, D.; Kim, D.H.; Kwon, J.-Y. Ultrasensitive, Low-Power Oxide Transistor-Based Mechanotransducer with Microstructured, Deformable Ionic Dielectrics. ACS Appl. Mater. Interfaces 2018, 10, 31472–31479. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Bu, T.; Fang, C.; Zhang, C.; Huang, X.; Zhang, C. High-Resolution Monolithic Integrated Tribotronic InGaZnO Thin-Film Transistor Array for Tactile Detection. Adv. Funct. Mater. 2020, 30, 2002613. [Google Scholar] [CrossRef]

- Haniff, M.A.S.M.; Hafiz, S.M.; Huang, N.M.; Rahman, S.A.; Wahid, K.A.A.; Syono, M.I.; Azid, I.A. Piezoresistive Effect in Plasma-Doping of Graphene Sheet for High-Performance Flexible Pressure Sensing Application. ACS Appl. Mater. Interfaces 2017, 9, 15192–15201. [Google Scholar] [CrossRef]

- Wang, M.; Tu, J.; Huang, Z.; Wang, T.; Liu, Z.; Zhang, F.; Li, W.; He, K.; Pan, L.; Zhang, X.; et al. Tactile Near-Sensor Analogue Computing for Ultrafast Responsive Artificial Skin. Adv. Mater. 2022, 34, 2201962. [Google Scholar] [CrossRef]

- Fu, Y.; Chan, Y.-T.; Jiang, Y.-P.; Chang, K.-H.; Wu, H.-C.; Lai, C.-S.; Wang, J.-C. Polarity-Differentiated Dielectric Materials in Monolayer Graphene Charge-Regulated Field-Effect Transistors for an Artificial Reflex Arc and Pain-Modulation System of the Spinal Cord. Adv. Mater. 2022, 34, 2202059. [Google Scholar] [CrossRef]

- Li, Y.; Yin, K.; Diao, Y.; Fang, M.; Yang, J.; Zhang, J.; Cao, H.; Liu, X.; Jiang, J. A Biopolymer-Gated Ionotronic Junctionless Oxide Transistor Array for Spatiotemporal Pain-Perception Emulation in Nociceptor Network. Nanoscale 2022, 14, 2316–2326. [Google Scholar] [CrossRef]

- Tian, C.; Wei, L.; Jiang, J. MoS2-Based Multiterminal Ionic Transistor with Orientation-Dependent STDP Learning Rules. Solid-State Electron. 2022, 194, 108386. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diao, Y.; Zhang, Y.; Li, Y.; Jiang, J. Metal-Oxide Heterojunction: From Material Process to Neuromorphic Applications. Sensors 2023, 23, 9779. https://doi.org/10.3390/s23249779

Diao Y, Zhang Y, Li Y, Jiang J. Metal-Oxide Heterojunction: From Material Process to Neuromorphic Applications. Sensors. 2023; 23(24):9779. https://doi.org/10.3390/s23249779

Chicago/Turabian StyleDiao, Yu, Yaoxuan Zhang, Yanran Li, and Jie Jiang. 2023. "Metal-Oxide Heterojunction: From Material Process to Neuromorphic Applications" Sensors 23, no. 24: 9779. https://doi.org/10.3390/s23249779