Risk Field of Rock Instability using Microseismic Monitoringdata in Deep Mining

Abstract

:1. Introduction

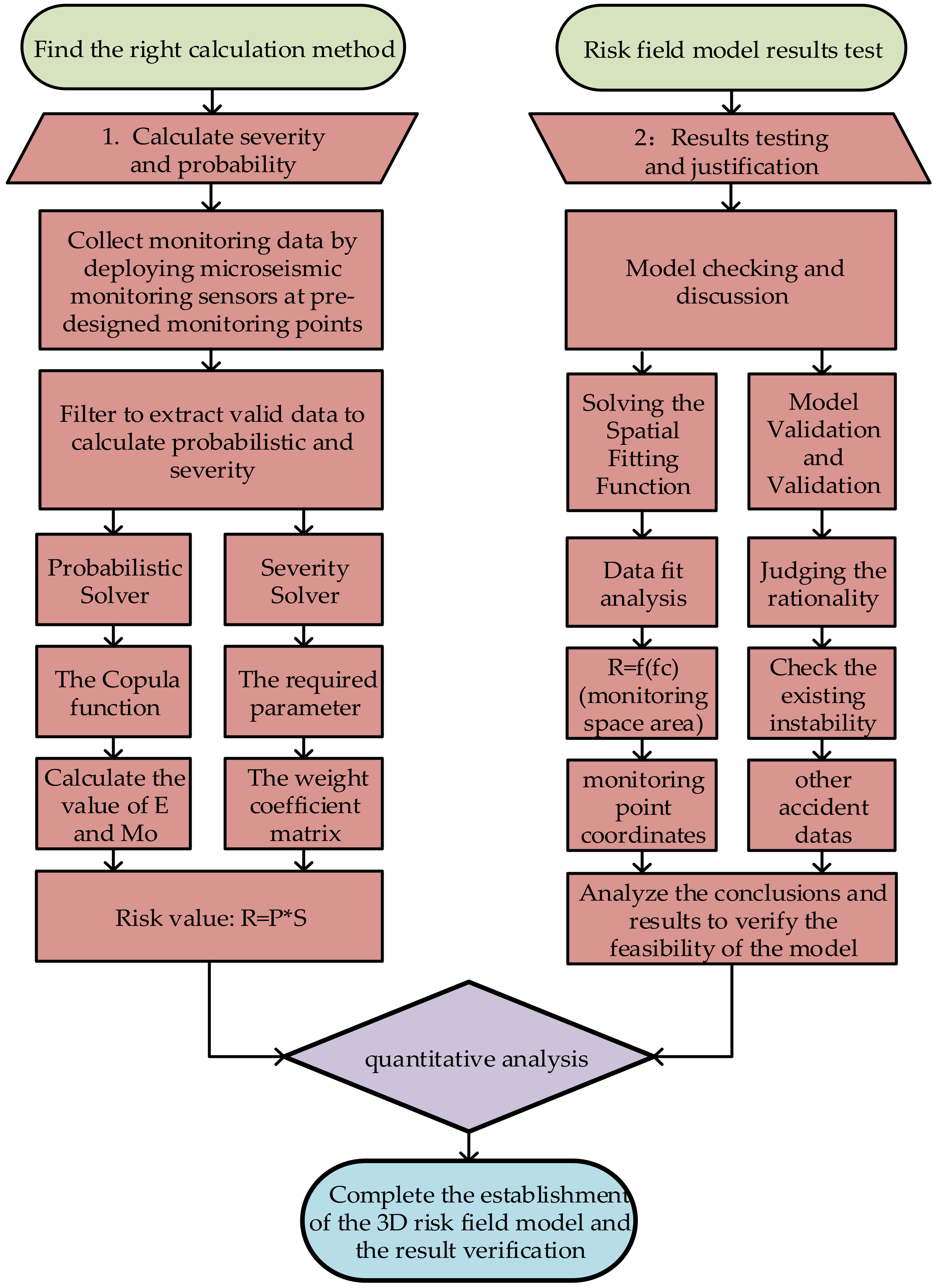

2. Materials and Methods

2.1. Risk Field

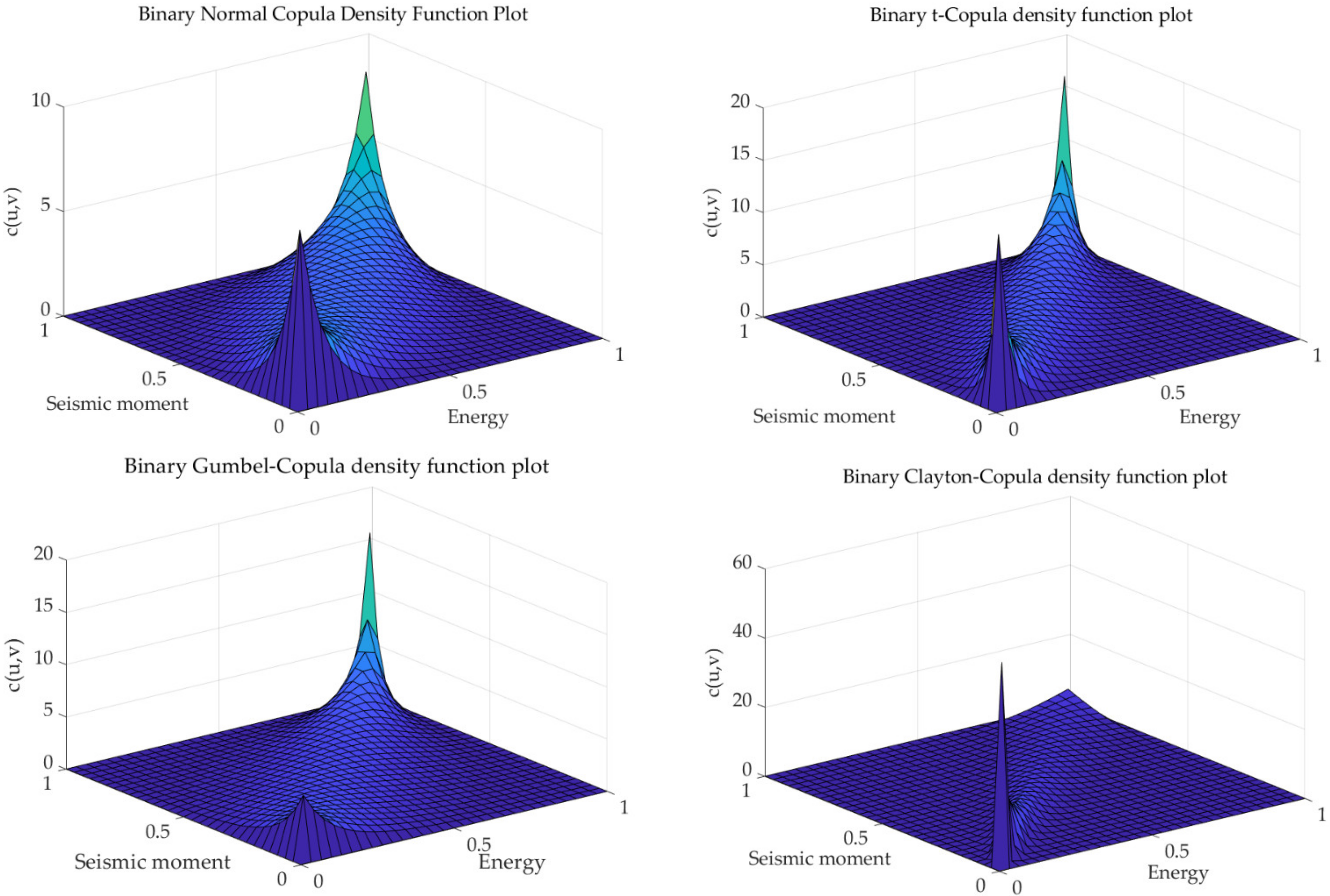

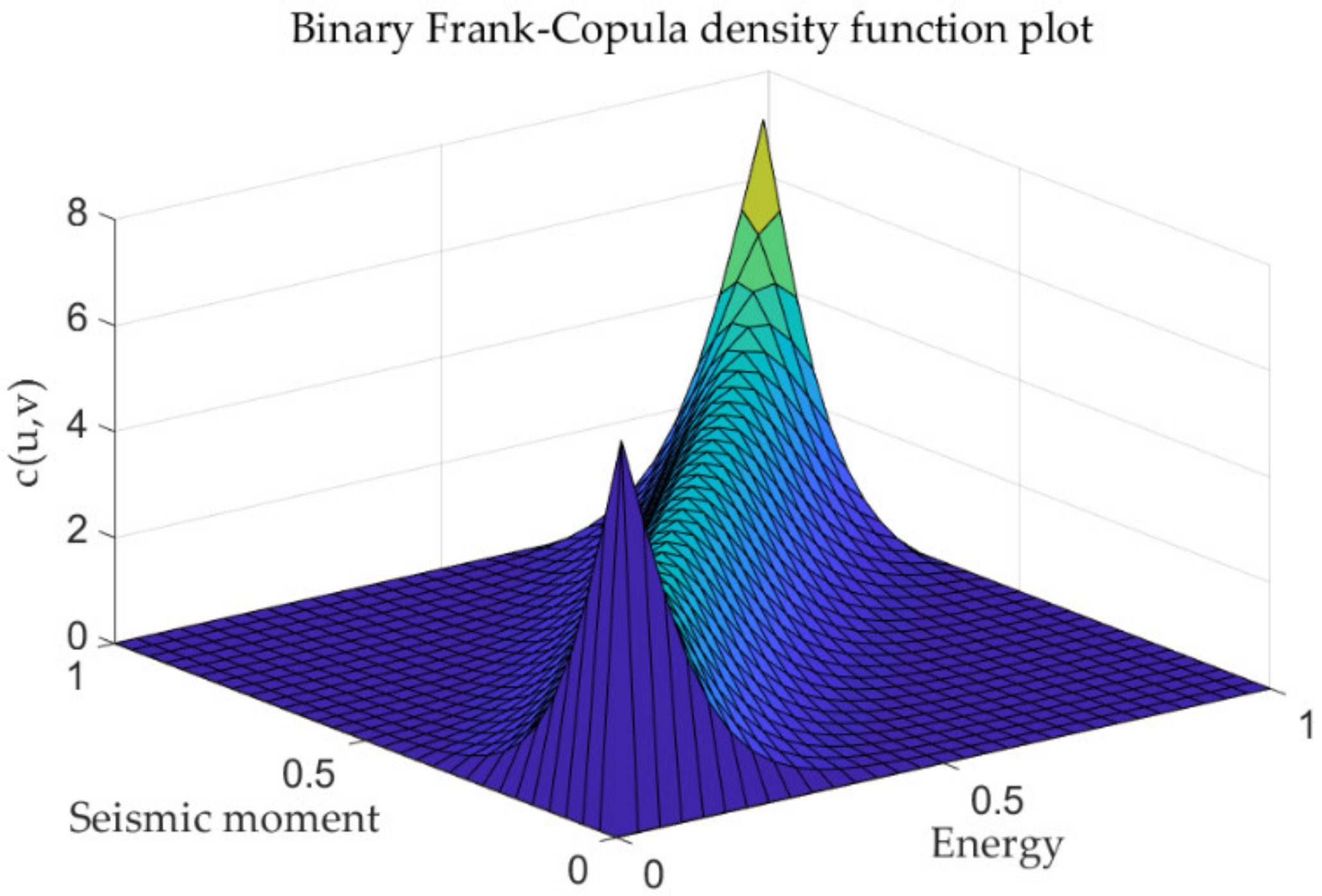

2.2. Probability

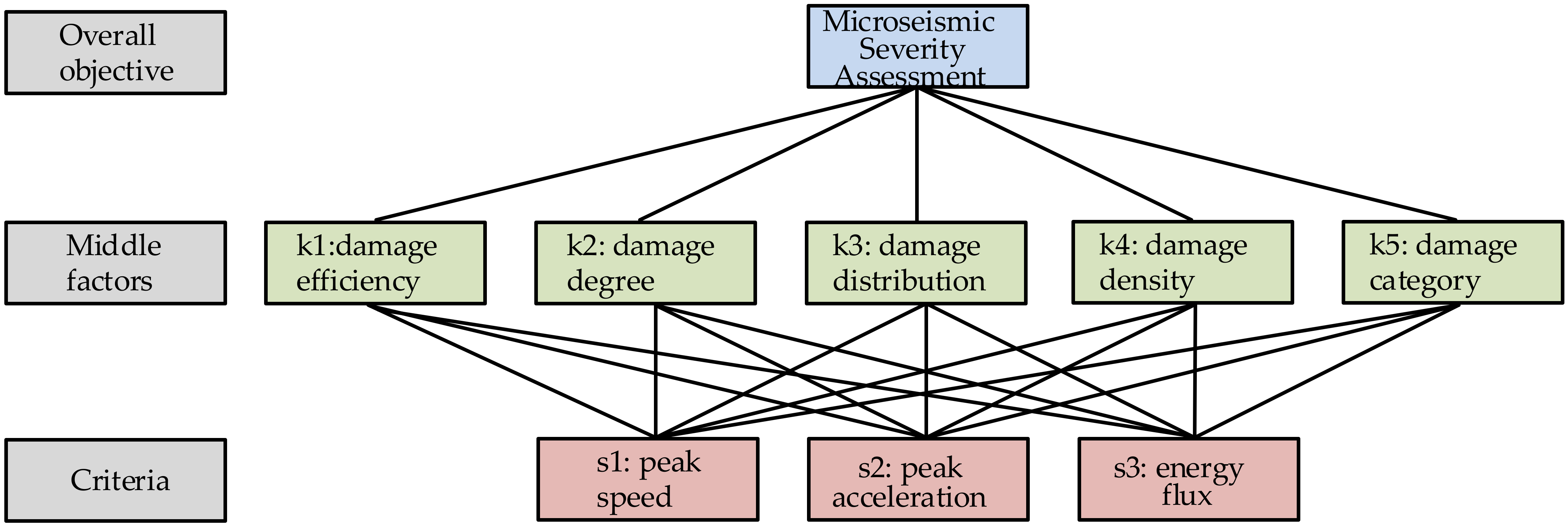

2.3. Evaluation of Severity

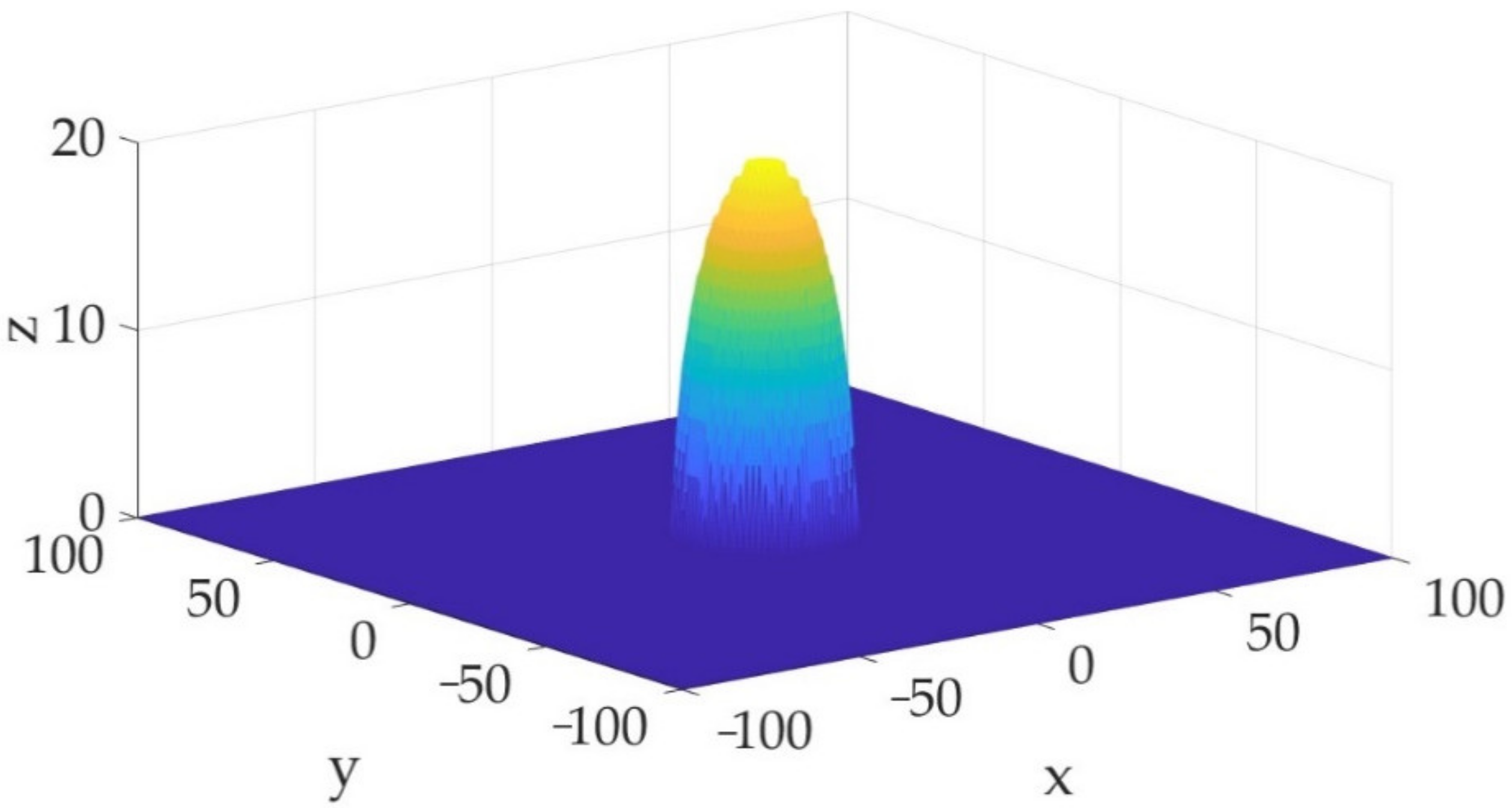

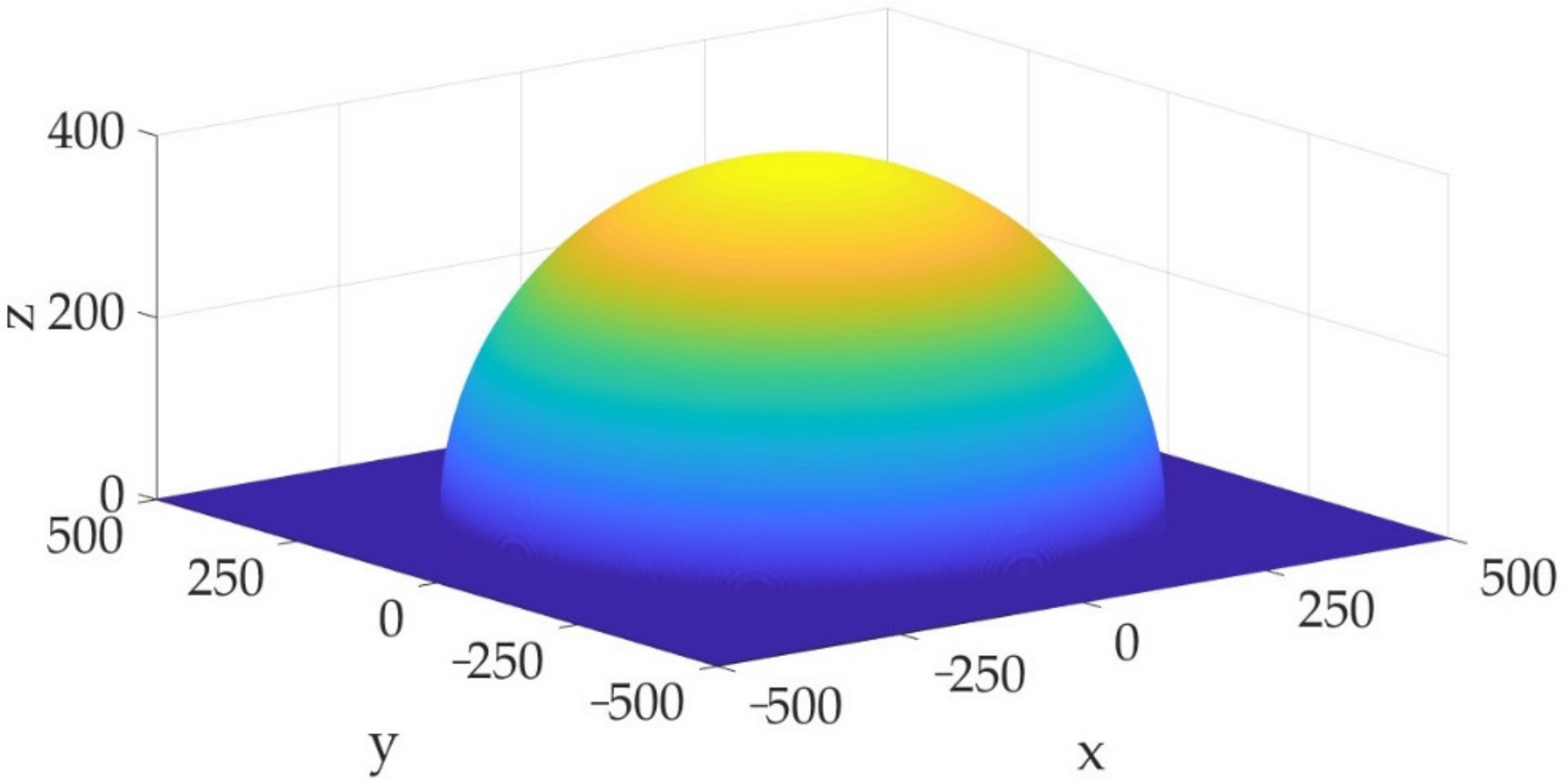

2.4. Risk Field Prediction Model

3. Results

3.1. Case Study

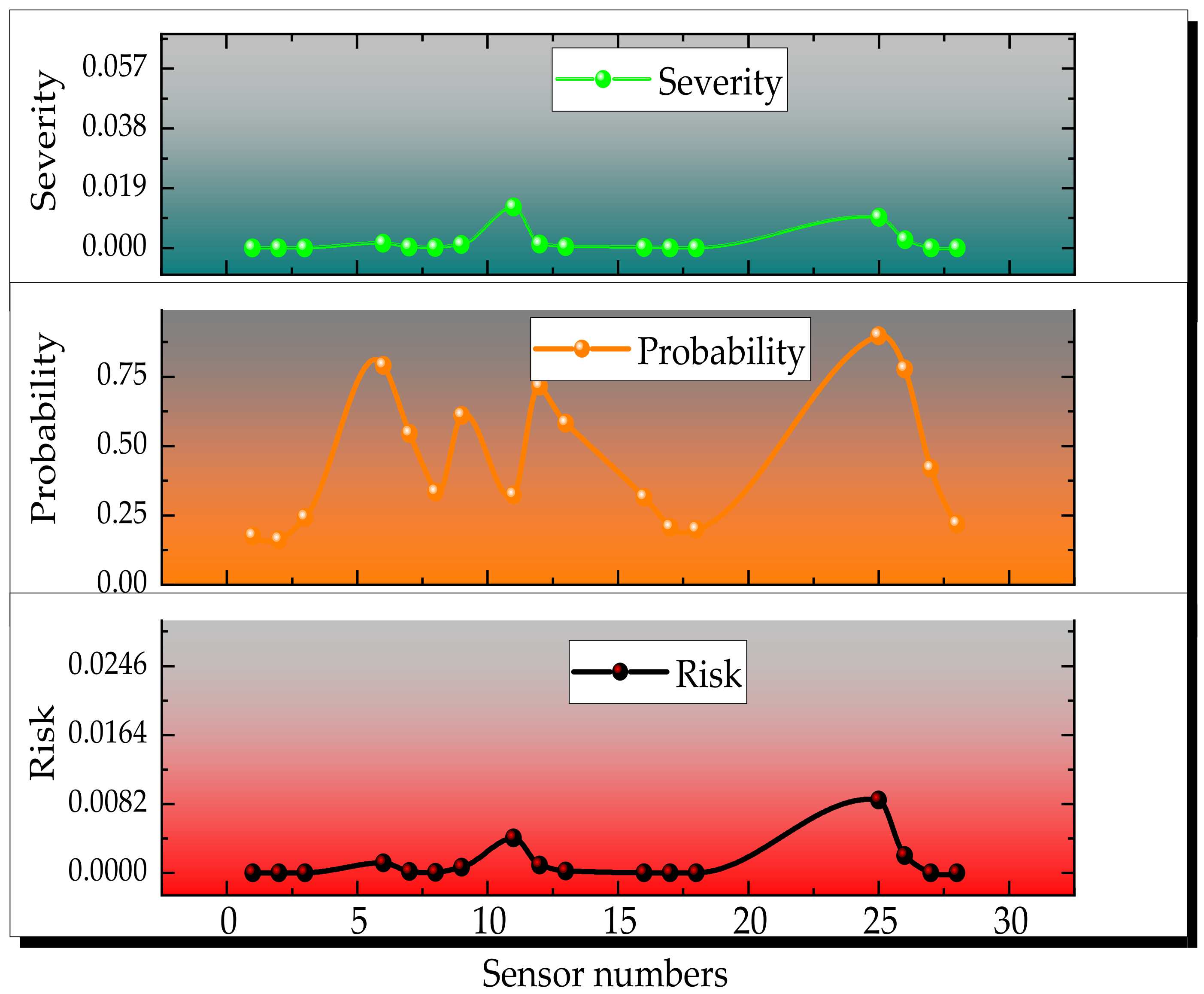

3.2. Severity Calculation

3.3. Probability Calculation

3.4. Rock Instability Risk Field

4. Discussion

4.1. Verifying the Validity and Availability

4.2. Limitations and Prospects

- a.

- Effect of microseismic monitoring equipment performance and positioning accuracy.

- b.

- Calculation of probability values.

- c.

- Dynamic risk field model.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, L.; Wang, J.; Li, X.; Peng, K. Dynamic Stability Analysis of Rockmass: A Review. Adv. Civ. Eng. 2018, 2018, 4270187. [Google Scholar] [CrossRef] [Green Version]

- Dong, L.; Zhang, Y.; Bi, S.; Ma, J.; Yan, Y.; Cao, H. Uncertainty investigation for the classification of rock micro-fracture types using acoustic emission parameters. Int. J. Rock Mech. Min. Sci. 2023, 162, 105292. [Google Scholar] [CrossRef]

- Dong, L.; Chen, Y.; Sun, D.; Zhang, Y. Implications for rock instability precursors and principal stress direction from rock acoustic experiments. Int. J. Min. Sci. Technol. 2021, 31, 789–798. [Google Scholar] [CrossRef]

- Dong, L.-J.; Tang, Z.; Li, X.-B.; Chen, Y.-C.; Xue, J.-C. Discrimination of mining microseismic events and blasts using convolutional neural networks and original waveform. J. Cent. South Univ. 2020, 27, 3078–3089. [Google Scholar] [CrossRef]

- Ma, J.; Dong, L.J.; Zhao, G.Y.; Li, X.B. Discrimination of seismic sources in an underground mine using full waveform inversion. Int. J. Rock Mech. Min. Sci. 2018, 106, 213–222. [Google Scholar] [CrossRef]

- Dong, L.; Wesseloo, J.; Potvin, Y.; Li, X. Discrimination of Mine Seismic Events and Blasts Using the Fisher Classifier, Naive Bayesian Classifier and Logistic Regression. Rock Mech. Rock Eng. 2016, 49, 183–211. [Google Scholar] [CrossRef]

- Ma, T.H.; Lin, D.Y.; Tang, C.A.; Yadav, K.P.; Feng, Z.Q.; Ma, K. Microseismic Monitoring, Positioning Principle, and Sensor Layout Strategy of Rock Mass Engineering. Geofluids 2020, 2020, 8810391. [Google Scholar] [CrossRef]

- Dong, L.; Yang, L.; Chen, Y. Acoustic Emission Location Accuracy and Spatial Evolution Characteristics of Granite Fracture in Complex Stress Conditions. Rock Mech. Rock Eng. 2022, 1–18. [Google Scholar] [CrossRef]

- Wang, H.Y.; Ma, J.; Wang, G.D.; Gao, H.; Cui, G.Y.; Li, X.S. Research on AE Source Location of Linear and Plane Rock Mass. Shock. Vib. 2020, 2020, 8846582. [Google Scholar] [CrossRef]

- Dong, L.J.; Zou, W.; Li, X.B.; Shu, W.W.; Wang, Z.W. Collaborative localization method using analytical and iterative solutions for microseismic/acoustic emission sources in the rockmass structure for underground mining. Eng. Fract. Mech. 2019, 210, 95–112. [Google Scholar] [CrossRef]

- Dong, L.; Pei, Z.; Xie, X.; Zhang, Y.; Yan, X. Early identification of abnormal regions in rock-mass using traveltime tomography. Engineering 2022, in press. [Google Scholar] [CrossRef]

- Hlousek, F.; Hellwig, O.; Buske, S. Three-dimensional focused seismic imaging for geothermal exploration in crystalline rock near Schneeberg, Germany. Geophys. Prospect. 2015, 63, 999–1014. [Google Scholar] [CrossRef]

- Dong, L.; Tong, X.; Ma, J. Quantitative Investigation of Tomographic Effects in Abnormal Regions of Complex Structures. Engineering 2021, 7, 1011–1022. [Google Scholar] [CrossRef]

- Li, Z.L.; Wang, L.G.; Li, W.S. Mechanical Behavior and Fracture Characteristics of Rock with Prefabricated Crack under Different Triaxial Stress Conditions. Minerals 2022, 12, 673. [Google Scholar] [CrossRef]

- Zhao, J.S.; Jiang, Q.; Lu, J.F.; Chen, B.R.; Pei, S.F.; Wang, Z.L. Rock fracturing observation based on microseismic monitoring and borehole imaging: In situ investigation in a large underground cavern under high geostress. Tunn. Undergr. Space Technol. 2022, 126, 104549. [Google Scholar] [CrossRef]

- Dong, L.; Chen, Y.; Sun, D.; Zhang, Y.; Deng, S. Implications for identification of principal stress directions from acoustic emission characteristics of granite under biaxial compression experiments. J. Rock Mech. Geotech. Eng. 2022, in press. [Google Scholar] [CrossRef]

- Huang, L.; Xu, Y.C.; Liu, S.Q.; Gai, Q.K.; Miao, W.; Li, Y.B.; Zhao, L.S. Research on the Development Law of Pre-Mining Microseisms and Risk Assessment of Floor Water Inrush: A Case Study of the Wutongzhuang Coal Mine in China. Sustainability 2022, 14, 9774. [Google Scholar] [CrossRef]

- Gai, Q.K.; Gao, Y.B.; Huang, L.; Shen, X.Y.; Li, Y.B. Microseismic response difference and failure analysis of roof and floor strata under dynamic load impact. Eng. Fail. Anal. 2023, 143, 106874. [Google Scholar] [CrossRef]

- Ma, K.; Yuan, F.Z.; Wang, H.B.; Zhang, Z.H.; Sun, X.Y.; Peng, Y.L.; Wang, H.Y. Fracture mechanism of roof key strata in Dongjiahe coal mine using microseismic moment tensor. Geomat. Nat. Hazards Risk 2021, 12, 1467–1487. [Google Scholar] [CrossRef]

- Dong, L.; Deng, S.; Wang, F. Some developments and new insights for environmental sustainability and disaster control of tailings dam. J. Clean. Prod. 2020, 269, 122270. [Google Scholar] [CrossRef]

- He, H.; Dou, L.M.; Gong, S.Y.; He, J.; Zheng, Y.L.; Zhang, X. Microseismic and electromagnetic coupling method for coal bump risk assessment based on dynamic static energy principles. Saf. Sci. 2019, 114, 30–39. [Google Scholar] [CrossRef]

- Liu, J.P.; Xu, S.D.; Li, Y.H.; Lei, G. Analysis of Rock Mass Stability Based on Mining-Induced Seismicity: A Case Study at the Hongtoushan Copper Mine in China. Rock Mech. Rock Eng. 2019, 52, 265–276. [Google Scholar] [CrossRef]

- Huang, L.; Wan, W.; Li, F.; Li, B.; Yang, J.; Bi, J. A two-scale system to identify environmental risk of chemical industry clusters. J. Hazard. Mater. 2011, 186, 247–255. [Google Scholar] [CrossRef] [PubMed]

- Chen, I.C.; Ng, S.; Wang, G.-S.; Ma, H.-W. Application of receptor-specific risk distribution in the arsenic contaminated land management. J. Hazard. Mater. 2013, 262, 1080–1090. [Google Scholar] [CrossRef]

- Giubilato, E.; Zabeo, A.; Critto, A.; Giove, S.; Bierkens, J.; Den Hond, E.; Marcomini, A. A risk-based methodology for ranking environmental chemical stressors at the regional scale. Environ. Int. 2014, 65, 41–53. [Google Scholar] [CrossRef]

- Yan, F.; Dong, L.J.; Wang, B.; Ge, J.; Wang, B. Using risk meshing to improve three-dimensional risk assessment of chemical industry. Process Saf. Environ. Prot. 2022, 168, 1166–1178. [Google Scholar] [CrossRef]

- Gai, W.M.; Du, Y.; Deng, Y.F. Evacuation risk assessment of regional evacuation for major accidents and its application in emergency planning: A case study. Saf. Sci. 2018, 106, 203–218. [Google Scholar] [CrossRef]

- Christie, E.K.; Spencer, T.; Owen, D.; McLvor, A.L.; Moeller, I.; Viavattene, C. Regional coastal flood risk assessment for a tidally dominant, natural coastal setting: North Norfolk, southern North Sea. Coast. Eng. 2018, 134, 177–190. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Apel, D.B.; Dyczko, A.; Walentek, A.; Prusek, S.; Xu, H.W.; Wei, C. Investigation of the Rockburst Mechanism of Driving Roadways in Close-Distance Coal Seam Mining Using Numerical Modeling Method. Min. Metall. Explor. 2021, 38, 1899–1921. [Google Scholar] [CrossRef]

- Dong, L.; Tong, X.; Hu, Q.; Tao, Q. Empty region identification method and experimental verification for the two-dimensional complex structure. Int. J. Rock Mech. Min. Sci. 2021, 147, 104885. [Google Scholar] [CrossRef]

- Yan, F.; Xu, K.L.; Li, D.S.; Cui, Z.K. A novel hazard assessment method for biomass gasification stations based on extended set pair analysis. PLoS One 2017, 12, e0185006. [Google Scholar] [CrossRef] [Green Version]

- Smerzini, C.; Pitilakis, K. Seismic risk assessment at urban scale from 3D physics-based numerical modeling: The case of Thessaloniki. Bull. Earthq. Eng. 2018, 16, 2609–2631. [Google Scholar] [CrossRef]

- Szoke, I.; Louka, M.N.; Bryntesen, T.R.; Bratteli, J.; Edvardsen, S.T.; RoEitrheim, K.K.; Bodor, K. Real-time 3D radiation risk assessment supporting simulation of work in nuclear environments. J. Radiol. Prot. 2014, 34, 389–416. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suddle, S.; Ale, B. The third spatial dimension risk approach for individual risk and group risk in multiple use of space. J. Hazard. Mater. 2005, 123, 35–53. [Google Scholar] [CrossRef]

- Yet-Pole, I.; Cheng, T.L. The development of a 3D risk analysis method. J. Hazard. Mater. 2008, 153, 600–608. [Google Scholar]

- Grassi, L.; Tiboldo, F.; Destefanis, R.; Donath, T.; Winterboer, A.; Evans, L.; Janovsky, R.; Kempf, S.; Rudolph, M.; Schaefer, F.; et al. Satellite vulnerability to space debris–an improved 3D risk assessment methodology. Acta Astronaut. 2014, 99, 283–291. [Google Scholar] [CrossRef]

- Dong, L.J.; Shu, W.W.; Sun, D.Y.; Li, X.B.; Zhang, L.Y. Pre-Alarm System Based on Real-Time Monitoring and Numerical Simulation Using Internet of Things and Cloud Computing for Tailings Dam in Mines. IEEE Access 2017, 5, 21080–21089. [Google Scholar] [CrossRef]

- Lai, X.P.; Jia, C.; Cui, F.; Chen, J.Q.; Zhou, Y.P.; Feng, G.G.; Gao, Y.J. Microseismic energy distribution and impact risk analysis of complex heterogeneous spatial evolution of extra-thick layered strata. Sci. Rep. 2022, 12, 10832. [Google Scholar] [CrossRef]

- Schefzik, R.; Thorarinsdottir, T.L.; Gneiting, T. Uncertainty Quantification in Complex Simulation Models Using Ensemble Copula Coupling. Stat. Sci. 2013, 28, 616–640. [Google Scholar] [CrossRef]

- Gu, Y.-K.; Fan, C.-J.; Liang, L.-Q.; Zhang, J. Reliability calculation method based on the Copula function for mechanical systems with dependent failure. Ann. Oper. Res. 2022, 311, 99–116. [Google Scholar] [CrossRef]

- Jiang, F.F.; Zhou, H.; Sheng, J.; Li, X.D.; Hu, Y.; Zhou, Y.L. Evaluation of safety and deformation characteristics of cemented tailings backfill mining disturbed area near shafts: A case study in China. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 6, 1–12. [Google Scholar] [CrossRef]

- Li, X.B.; Dong, L.J.; Zhao, G.Y.; Huang, M.; Liu, A.H.; Zeng, L.F.; Dong, L.; Chen, G.H. Stability analysis and comprehen-sive treatment methods of landslides under complex mining environment-A case study of Dahu landslide from Linbao Henan in China. Saf. Sci. 2012, 50, 695–704. [Google Scholar] [CrossRef]

- Zhu, W.Q.; Mousavi, S.M.; Beroza, G.C. Seismic Signal Denoising and Decomposition Using Deep Neural Networks. IEEE Trans. Geosci. Remote Sens. 2019, 57, 9476–9488. [Google Scholar] [CrossRef] [Green Version]

- Long, Y.; Lin, J.; Huang, X.G.; da Silva, N.V.; Hu, Y.; Chen, Z.B. Automatic Microseismic Event Detection with Variance Fractal Dimension via Multitrace Envelope Energy Stacking. IEEE Trans. Geosci. Remote Sens. 2022, 60, 1–15. [Google Scholar] [CrossRef]

- Vrieze, S.I. Model Selection and Psychological Theory: A Discussion of the Differences Between the Akaike Information Criterion (AIC) and the Bayesian Information Criterion (BIC). Psychol. Methods 2012, 17, 228–243. [Google Scholar] [CrossRef] [Green Version]

- Yan, F.; Jin, C.; Li, Z.J.; Cao, R.H.; Xu, K.L. Research and development of field theory-based three-dimensional risk assessment. Part I: Optimization of risk reduction. Saf. Sci. 2019, 120, 312–322. [Google Scholar] [CrossRef]

| Parameter | Index | Weight |

|---|---|---|

| PGV | ϑ1 | 0.245 |

| PGA | ϑ2 | 0.299 |

| Energy flux | ϑ3 | 0.455 |

| Sensor Serial Number | S1 | S2 | S3 | Severity |

|---|---|---|---|---|

| 1 | 8.10 × 10−8 | 5.04 × 10−5 | 2.92 × 10−9 | 1.51 × 10−5 |

| 2 | 8.27 × 10−8 | 8.26 × 10−6 | 3.20 × 10−9 | 2.49 × 10−6 |

| 3 | 4.90 × 10−7 | 1.60 × 10−4 | 7.88 × 10−8 | 4.79 × 10−5 |

| 6 | 3.45 × 10−5 | 4.60 × 10−3 | 3.21 × 10−4 | 1.53 × 10−3 |

| 7 | 2.46 × 10−6 | 9.47 × 10−4 | 3.26 × 10−6 | 2.85 × 10−4 |

| 8 | 2.37 × 10−6 | 3.76 × 10−4 | 8.45 × 10−7 | 1.13 × 10−4 |

| 9 | 1.50 × 10−5 | 3.58 × 10−3 | 1.83 × 10−5 | 1.08 × 10−3 |

| 11 | 2.07 × 10−4 | 4.11 × 10−4 | 2.80 × 10−2 | 1.29 × 10−2 |

| 12 | 1.34 × 10−5 | 4.08 × 10−3 | 1.09 × 10−4 | 1.27 × 10−3 |

| 13 | 7.56 × 10−6 | 1.22 × 10−3 | 1.29 × 10−5 | 3.72 × 10−4 |

| 16 | 5.16 × 10−7 | 2.32 × 10−4 | 2.40 × 10−7 | 6.97 × 10−5 |

| 17 | 4.65 × 10−7 | 1.23 × 10−4 | 5.63 × 10−8 | 3.71 × 10−5 |

| 18 | 4.17 × 10−7 | 1.09 × 10−4 | 4.38 × 10−8 | 3.26 × 10−5 |

| 25 | 4.38 × 10−5 | 3.04 × 10−2 | 1.25 × 10−3 | 9.66 × 10−3 |

| 26 | 1.65 × 10−5 | 8.60 × 10−3 | 9.55 × 10−5 | 2.62 × 10−3 |

| 27 | 1.77 × 10−7 | 1.24 × 10−4 | 1.67 × 10−7 | 3.72 × 10−5 |

| 28 | 2.32 × 10−7 | 1.34 × 10−4 | 3.44 × 10−8 | 4.01 × 10−5 |

| Copula Function | AIC | BIC |

|---|---|---|

| Gaussian | −18.4695 | −17.6363 |

| t-Copula | −20.3901 | −19.5569 |

| Gumbel | −13.6901 | −12.8569 |

| Clayton | −34.407 | −33.5738 |

| Frank | −22.888 | −22.0547 |

| Sensor Number | Severity | Probability | Risk |

|---|---|---|---|

| 1 | 1.51 × 10−5 | 0.18 | 2.65 × 10−6 |

| 2 | 2.49 × 10−6 | 0.16 | 4.01 × 10−7 |

| 3 | 4.79 × 10−5 | 0.24 | 1.16 × 10−5 |

| 6 | 1.53 × 10−3 | 0.79 | 1.21 × 10−3 |

| 7 | 2.85 × 10−4 | 0.55 | 1.55 × 10−4 |

| 8 | 1.13 × 10−4 | 0.33 | 3.78 × 10−5 |

| 9 | 1.08 × 10−3 | 0.61 | 6.61 × 10−4 |

| 11 | 1.29 × 10−2 | 0.32 | 4.17 × 10−3 |

| 12 | 1.27 × 10−3 | 0.72 | 9.11 × 10−4 |

| 13 | 3.72 × 10−4 | 0.58 | 2.17 × 10−4 |

| 16 | 6.97 × 10−5 | 0.31 | 2.20 × 10−5 |

| 17 | 3.71 × 10−5 | 0.21 | 7.65 × 10−6 |

| 18 | 3.26 × 10−5 | 0.20 | 6.45 × 10−6 |

| 25 | 9.66 × 10−3 | 0.90 | 8.67 × 10−3 |

| 26 | 2.62 × 10−3 | 0.78 | 2.03 × 10−3 |

| 27 | 3.72 × 10−5 | 0.42 | 1.56 × 10−5 |

| 28 | 4.01 × 10−5 | 0.22 | 8.75 × 10−6 |

| Data Comparison Group | Sensor Serial Number | Risk Value without Disturbance | Risk Value with Disturbance | Ratio of Risk Value |

|---|---|---|---|---|

| Comparison of group data at time T1 and t1 | 12 | 2.11 × 10−6 | 3.14 × 10−5 | 14.90 |

| 13 | 1.60 × 10−6 | 8.02 × 10−5 | 50.05 | |

| 6 | 3.40 × 10−6 | 6.24 × 10−3 | 1838.85 | |

| 18 | 1.45 × 10−6 | 8.67 × 10−7 | 0.60 | |

| 27 | 2.97 × 10−7 | 2.58 × 10−6 | 8.71 | |

| Comparison of group data at time T2 and t2 | 22 | 3.40 × 10−8 | 1.04 × 10−7 | 3.04 |

| 21 | 2.75 × 10−7 | 1.10 × 10−5 | 39.95 | |

| 2 | 7.32 × 10−7 | 2.47 × 10−6 | 3.37 | |

| 20 | 1.57 × 10−6 | 5.08 × 10−5 | 32.40 | |

| 18 | 3.01 × 10−5 | 2.03 × 10−5 | 0.68 | |

| 19 | 6.27 × 10−6 | 4.73 × 10−5 | 7.54 | |

| Comparison of group data at time T3 and t3 | 18 | 7.98 × 10−7 | 4.30 × 10−5 | 53.85 |

| 3 | 5.13 × 10−6 | 1.02 × 10−4 | 20.00 | |

| 17 | 6.39 × 10−6 | 1.52 × 10−5 | 2.39 | |

| 16 | 9.06 × 10−7 | 2.00 × 10−6 | 2.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, L.; Zhu, H.; Yan, F.; Bi, S. Risk Field of Rock Instability using Microseismic Monitoringdata in Deep Mining. Sensors 2023, 23, 1300. https://doi.org/10.3390/s23031300

Dong L, Zhu H, Yan F, Bi S. Risk Field of Rock Instability using Microseismic Monitoringdata in Deep Mining. Sensors. 2023; 23(3):1300. https://doi.org/10.3390/s23031300

Chicago/Turabian StyleDong, Longjun, Huanyu Zhu, Fang Yan, and Shuijin Bi. 2023. "Risk Field of Rock Instability using Microseismic Monitoringdata in Deep Mining" Sensors 23, no. 3: 1300. https://doi.org/10.3390/s23031300