Fabrication and Characterization of PZT Thick Films for Sensing and Actuation

Abstract

:1. Introduction

2. Fabrication

3. Characterization of PZT Thick Films

3.1 Physical Characterization

3.2 Observation of Morphology

3.3 Electrical Characterizations

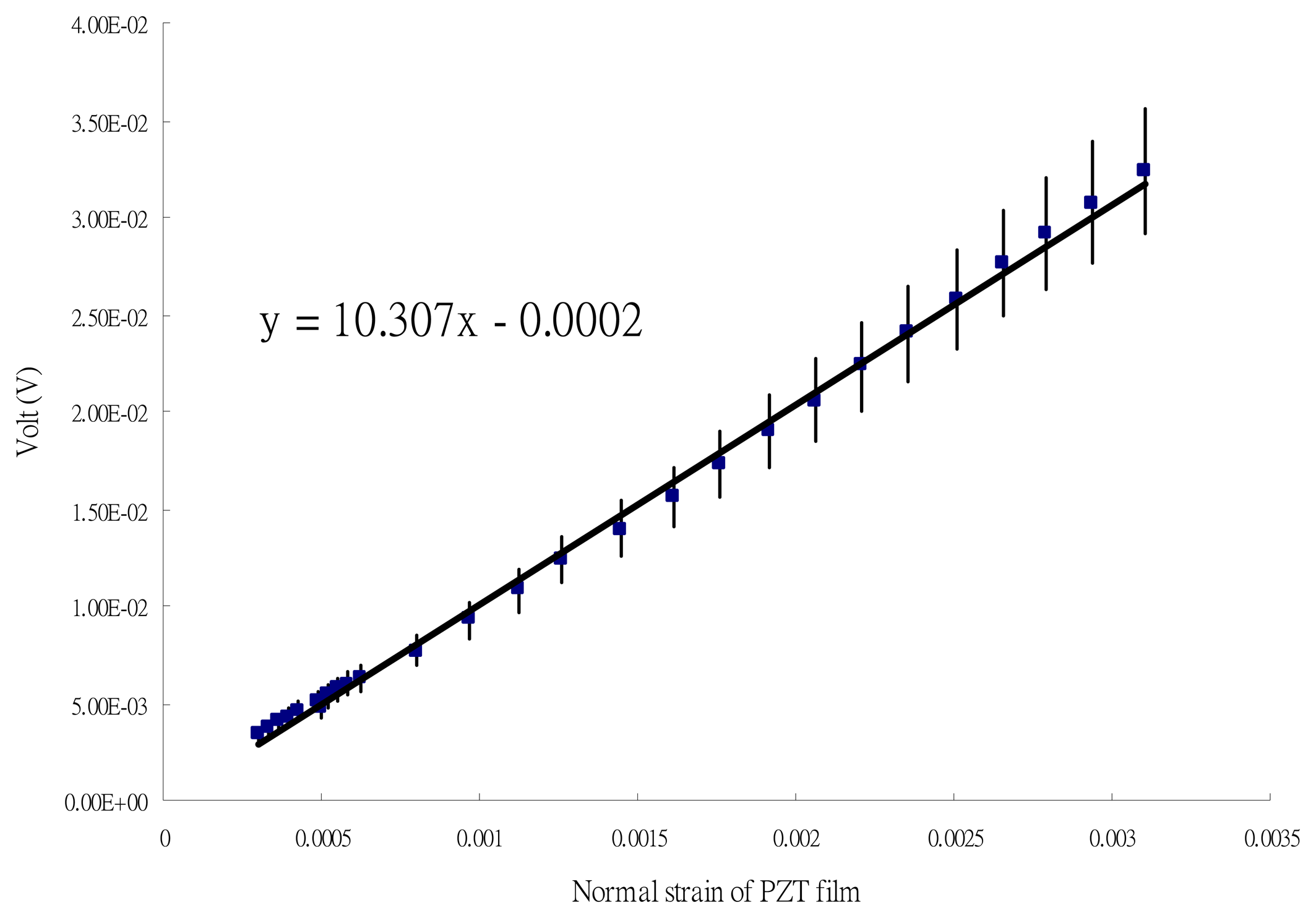

3.4 Dynamic Characterization

4. Conclusions

Acknowledgments

Appendix A. Recipe of PZT sol

- Dissolve 61.2 g Pb acetate in 38 ml acetic acid.

- Heat to 110 °C (5 min) and then cool to room temperature.

- Mix 36.9 g Zr n-propoxide with 20.9 ml Ti-isopropoxide.

- Add to Pb solution the Zr + Ti mixture.

- Add 40 ml of deionized water.

- Add 8 ml lactic acid.

- Add 9 ml glycerol.

- Add 12 ml ethylene glycol.

References

- Muralt, P.; Kohli, M.; Maeder, T.; Kholkin, A.; Brooks, K.G.; Setter, N.; Luthier, R. Fabrication andcharacterization of PZT thin-film vibrators for micromotors. Sensors and Actuators A 1995, 48, 157–65. [Google Scholar]

- Willing, B.; Kohli, M.; Muralt, P.; Setter, N.; Oehler, O. Gas Spectrometry Based on Pyroelectric Thin Film Arrays Integrated on Silicon. Sensors and Actuators A 1998, 66, 109–113. [Google Scholar]

- Yang, Z.; Goto, H.; Matsumoto, M.; Maeda, R. Active micromixer for microfluidic systems using PZT-generated ultrasonic vibration. Electrophoresis 2000, 21, 116–119. [Google Scholar]

- Kueppers, H.; Leuerer, T.; Schnakenberg, U.; Mokwa, W.; Hoffmann, M.; Schneller, T.; Boettger, U.; Waser, R. PZT thin films for piezoelectric microactuator, applications. Sensors and Actuators A 2002, 97-98, 680–684. [Google Scholar]

- Defay, E.; Millon, C.; Malhaire, C.; Barbier, D. PZT thin films integration for the realisation of a high sensitivity pressure microsensor based on a vibrating membrane. Sensors and Actuators A 2002, 99, 64–67. [Google Scholar]

- Kanda, T.; Morita, T.; Kurosawa, M.; Higuchi, T. A Rod-shaped vibro touch sensor using PZT thin film. Proceedings of the IEEE Micro Electro Mechanical Systems (MEMS); 1998; pp. 378–383. [Google Scholar]

- Hunt, S.; Rudge, A.; Carey, M.; Parfitt, M.; Geoffrey, J.; Huntsman, I. Micro-electro-mechanical-systems direct fluid shear stress sensor arrays for flow control. Smart Materials and Structures 2002, 11(n 4), 617–621. [Google Scholar]

- Inoue, N.; Takeuchi, T.; Hayashi, Y. Compositional design of Pb(Zr,Ti)O3 for highly reliable ferroelectric memories. IEEE Transactions on Electron Devices 2002, 49(9), 1572–1579. [Google Scholar]

- Chang, R.-C.; Chu, S.-Y.; Chung, Y.-T. A study of Love wave devices in ZnO/Quartz and ZnO/LiTaO3 structures. Thin Solid Films 2006, 498, 146–151. [Google Scholar]

- Trolier-McKinstry, S.; Muralt, P. Piezoelectric Thin Films for MEMS. Integrated Ferroelectrics 1997, Vol. 17, p 297–307. [Google Scholar]

- Yao, K.; He, X.; Xu, Y.; Chen, M. Screen-printed piezoelectric ceramic thick films with sintering additives introduced through a liquid-phase approach. Sensors and Actuators A 2005, 118(2), 342–348. [Google Scholar]

- Yao, K.; He, X.; Xu, Y.; Chen, M. Piezoelectric ceramic thick films deposited on silicon substrates by screen-printing. Proceedings of SPIE - The International Society for Optical Engineering, Smart Structures and Materials - Smart Electronics, MEMS, BioMEMS, and Nanotechnology 2004, 5389, 108–113. [Google Scholar]

- Walter, V.; Delobelle, P.; Le Moal, P.; Joseph, E.; Collet, M. A piezo-mechanical characterization of PZT thick films screen-printed on alumina substrate. Sensors and Actuators, A 2002, 96(2-3), 157–166. [Google Scholar]

- Krupanidhi, S.B.; Maffei, N.; Sayer, M.; El-Assal, K.R.F. Magnetron sputtering of ferroelectric PZT films. Ferroelectrics 1983, 51(1-2), 93–98. [Google Scholar]

- Chang, W.L. Comparison of the microstructures and ferroelectric characteristics of sputter deposited PZT films with and without lead or lead oxide for compensation. Ceramics International 2005, 31(3), 461–468. [Google Scholar]

- Cheng, J.; Li, N.; Cross, L.E.; Meng, Z. Self-poling effects in sol-gel derived Pb(Zr1-xTix)O3 thin films. Materials Research Society Symposium – Proceedings 2003, 748, 179–185. [Google Scholar]

- Cheng, J.; Meng, Z. Thickness-dependent microstructures and electrical properties of PZT films derived from sol-gel process. Thin Solid Films 2001, 385(1-2), 5–10. [Google Scholar]

- Gerlach, G.; Suchaneck, G.; Koehler, R.; Sandner, T.; Padmini, P.; Krawietz, R.; Pompe, W.; Frey, J.; Jost, O.S. Properties of sputter and sol-gel deposited PZT thin films for sensor and actuator applications: preparation, stress and space charge distribution, self poling. Ferroelectrics 1999, 230(n 1-4), pt 2. 411/109–416/114. [Google Scholar]

- Hsu, Y.-C.; Wu, C.-C.; Lee, C.-C.; Caoc, G.Z.; Shen, I.Y. Demonstration and characterization of PZT thin-film sensors and actuators for meso- and micro-structures. Sensors and Actuators A 2004, 116, 369–377. [Google Scholar]

- Kwon, Y.T.; Lee, W.I.; Kim, C.J.; Yoo, I.K. Novel silicon carbide/polypyrrole composites; preparation and physicochemical properties. Mater. Res. Bull. 1999, 34(5), 749. [Google Scholar]

- Chen, Z.; Yang, C.; Wang, S.; Yang, B. The effects of the PbO content and seeding layers upon the microstructure and orientation of sol-gel derived PZT films. J. Mater. Sci.: Mater. Electron. 2006, 17(1), 51. [Google Scholar]

- Li, J.; Zhang, L.; Yao, X.; Wang, J. A new and rapid heat-treatment process for fabricating lead zirconate titanate thin film. Ceram. Int. 2004, 30(7), 509. [Google Scholar]

- Xie, J.; Hub, M.; Ling, S.-F.; Du, H. Fabrication and characterization of piezoelectric cantilever for micro transducers. Sensors and Actuators A 2006, 126, 182–186. [Google Scholar]

| Frequency [KHz] | Capacitance [nF] | Dielectric constant | Frequency [KHz] | Capacitance [nF] | Dielectric constant | ||||

|---|---|---|---|---|---|---|---|---|---|

| 2.19 µm | Pad 1 | 1 | 9.633 | 148.984 | 7.29 µm | Pad 1 | 1 | 3.065 | 156.645 |

| 10 | 9.157 | 141.623 | 10 | 2.951 | 148.072 | ||||

| Pad 2 | 1 | 9.232 | 142.783 | Pad 2 | 1 | 3.005 | 156.713 | ||

| 10 | 8.877 | 137.292 | 10 | 2.896 | 150.884 | ||||

| Pad 3 | 1 | 9.577 | 148.119 | Pad 3 | 1 | 3.178 | 162.49 | ||

| 10 | 9.184 | 142.04 | 10 | 3.05 | 155.946 | ||||

| Actuator (excitation voltage into PZT film, Vpp= 196 V) | Sensor (excitation voltage into shaker, Vpp = 99 V) | Theory | ||||||

|---|---|---|---|---|---|---|---|---|

| Mode | Tip center | Corner | Frequency | Amplitude | Signal* | Frequency | ||

| Frequency | Amplitude | Frequency | Amplitude | |||||

| 1st bending | 346 | 2.4 | 345.8 | 2.2 | 347 | 7.8 | 60 | 364.39 |

| 2nd bending | 2300 | 0.96 | 2303 | 0.66 | - | - | - | 2283.3 |

© 2007 by MDPI ( http://www.mdpi.org). Reproduction is permitted for noncommercial purposes.

Share and Cite

Jang, L.-S.; Kuo, K.-C. Fabrication and Characterization of PZT Thick Films for Sensing and Actuation. Sensors 2007, 7, 493-507. https://doi.org/10.3390/s7040493

Jang L-S, Kuo K-C. Fabrication and Characterization of PZT Thick Films for Sensing and Actuation. Sensors. 2007; 7(4):493-507. https://doi.org/10.3390/s7040493

Chicago/Turabian StyleJang, Ling-Sheng, and Kuo-Ching Kuo. 2007. "Fabrication and Characterization of PZT Thick Films for Sensing and Actuation" Sensors 7, no. 4: 493-507. https://doi.org/10.3390/s7040493