Sodium Dodecyl Sulphate-Supported Nanocomposite as Drug Carrier System for Controlled Delivery of Ondansetron

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents and Instruments

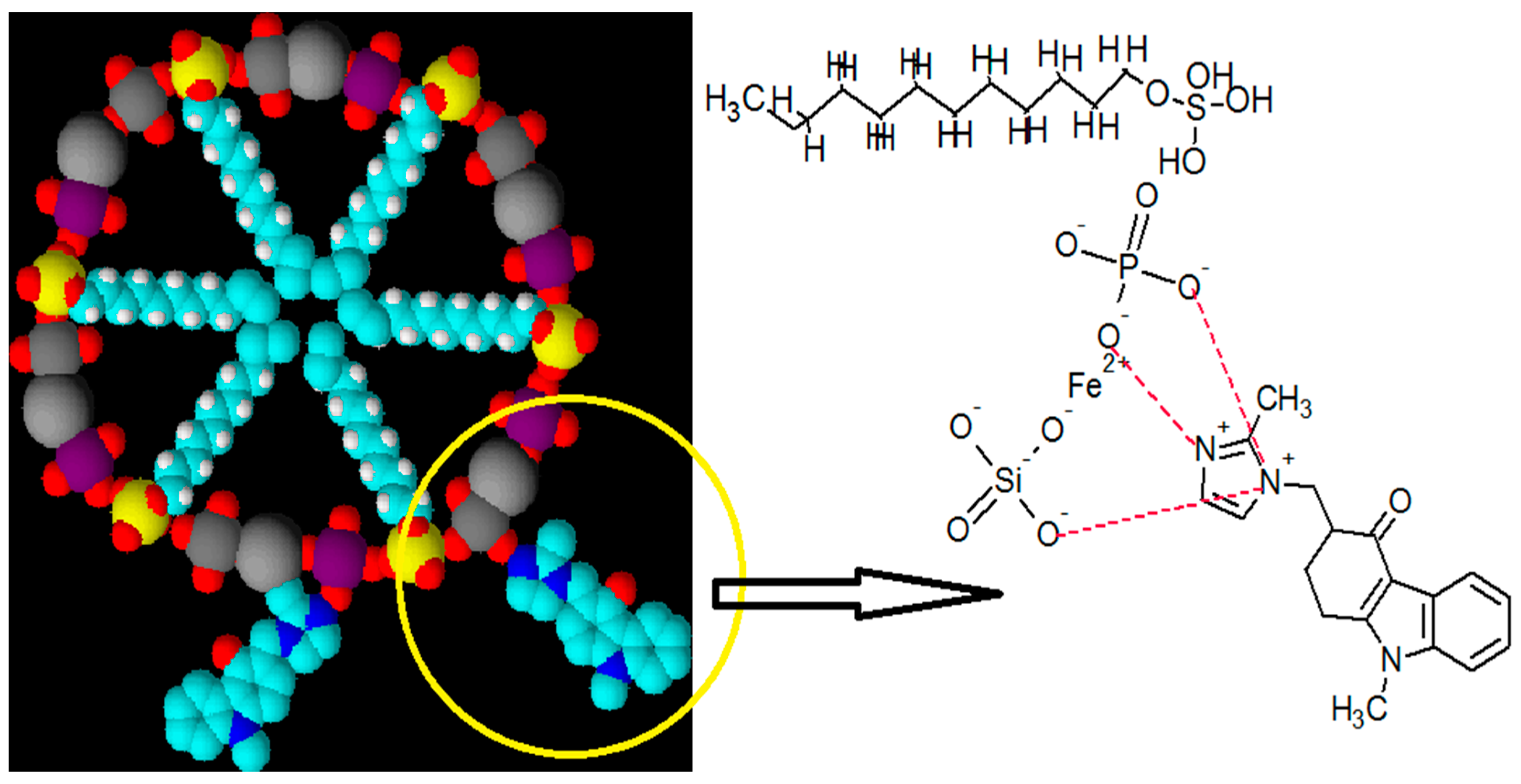

2.2. Synthesis of Sodiumdodecylsulphate Ironsilicophosphate Nanocomposite (SDS@FeSP)

2.3. Characterization Techniques

2.4. Measurement of Zeta Potential

2.5. Drug Delivery

2.5.1. Stock Solution

2.5.2. Determination of λmax

2.5.3. Preparation of Ondansetron Standard Calibration Curves

2.5.4. Ondansetron Loading on SDS-FeSP

2.5.5. Drug Release at Different Physiological Conditions

2.5.6. Cumulative Drug Release

2.6. Cytotoxicity Studies

2.6.1. Preparation and Cultivation of PBMC

2.6.2. Cell Viability and Cytotoxicity Assay

3. Results and Discussion

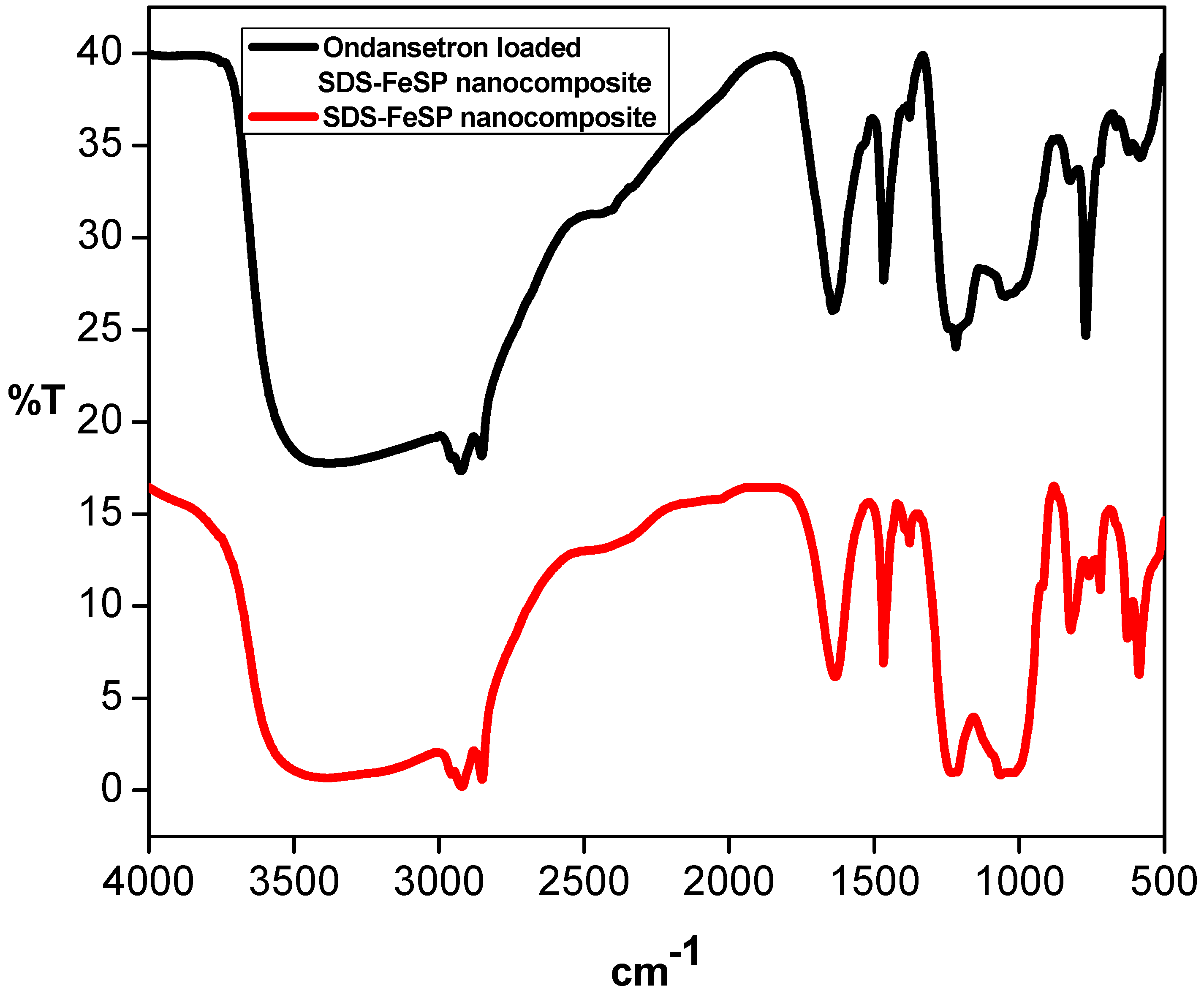

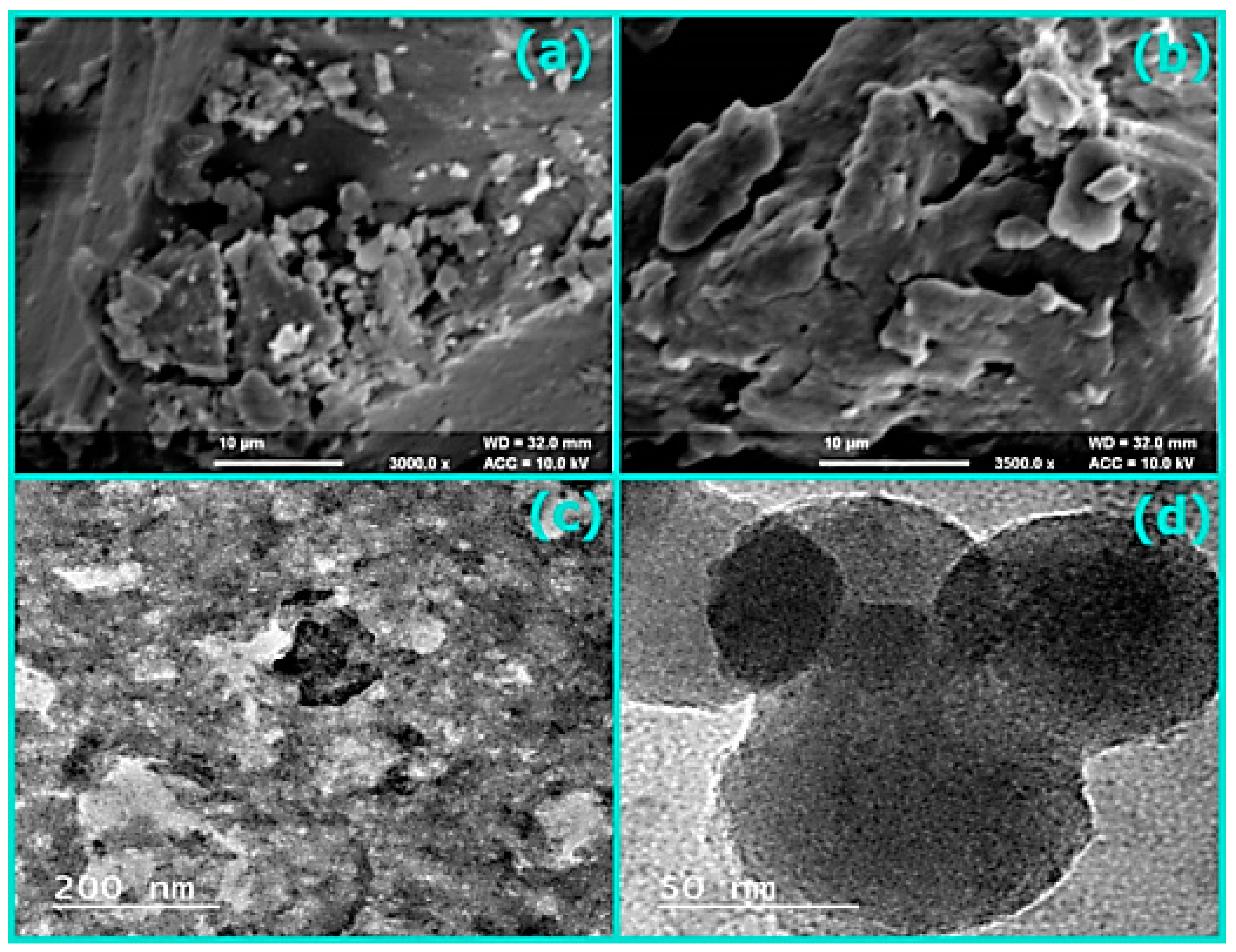

3.1. Characterization

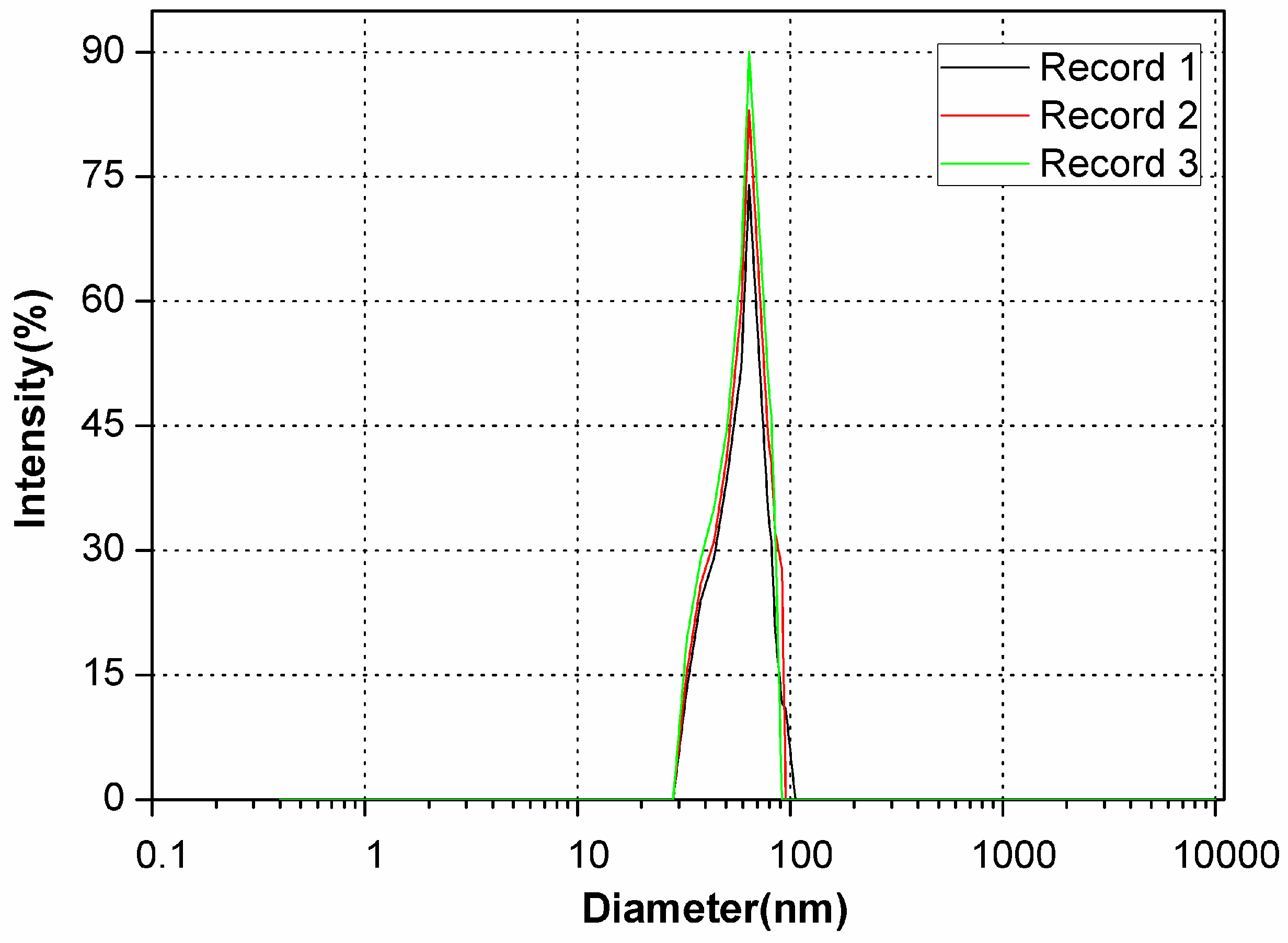

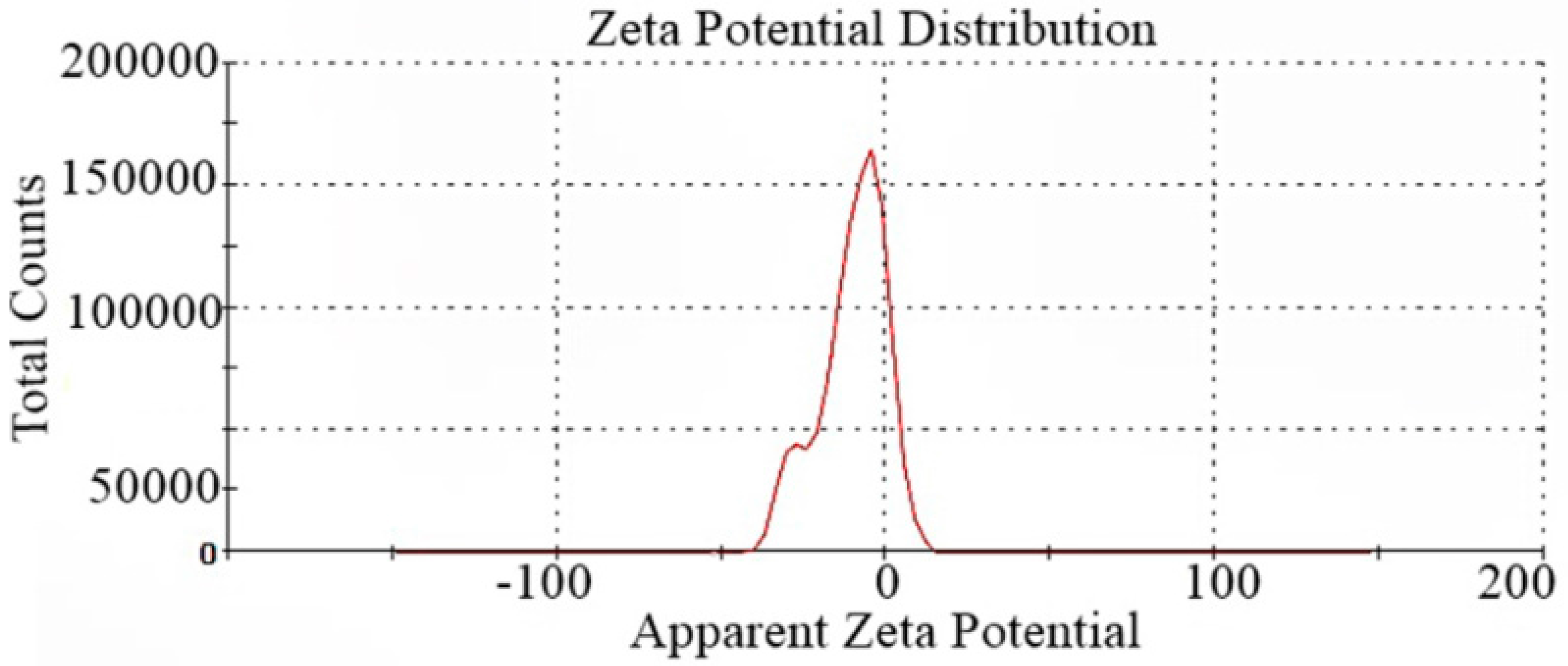

3.2. Measurement of Zeta Potential

3.3. Drug Delivery

3.3.1. Standard Calibration Curves

3.3.2. Drug Loading Efficiency (DLE)

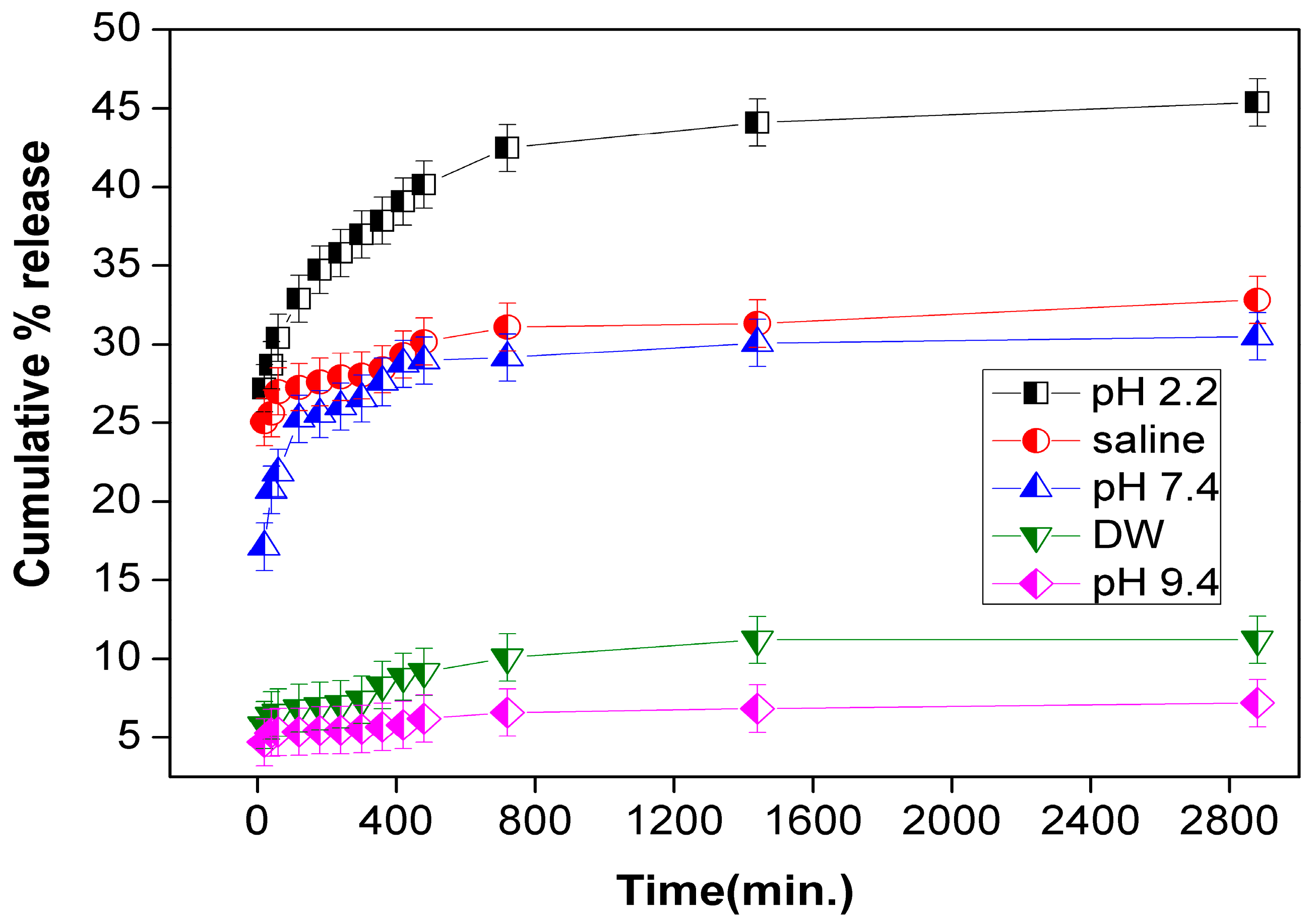

3.3.3. Drug Release

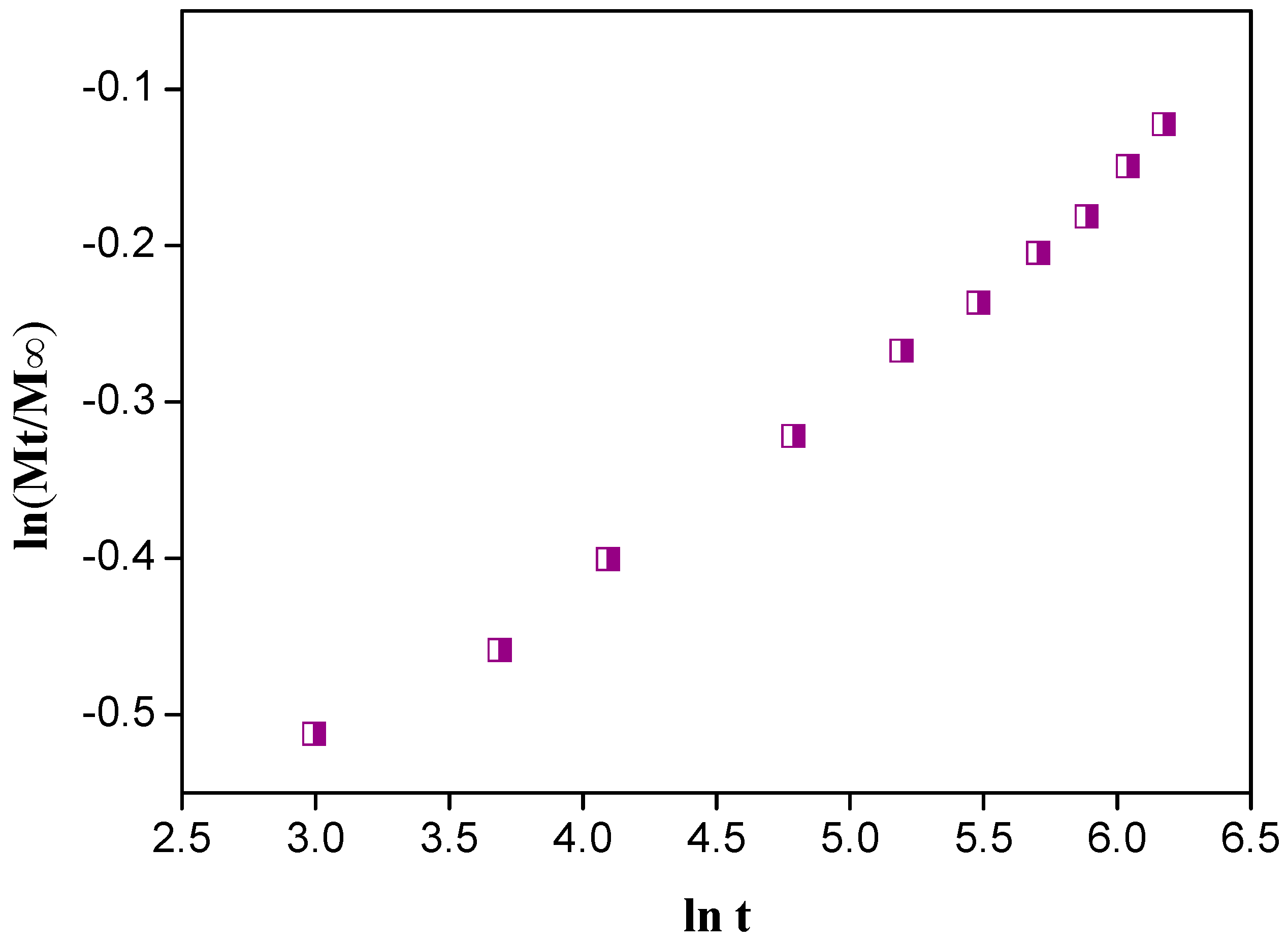

3.3.4. Mechanism of Drug Release

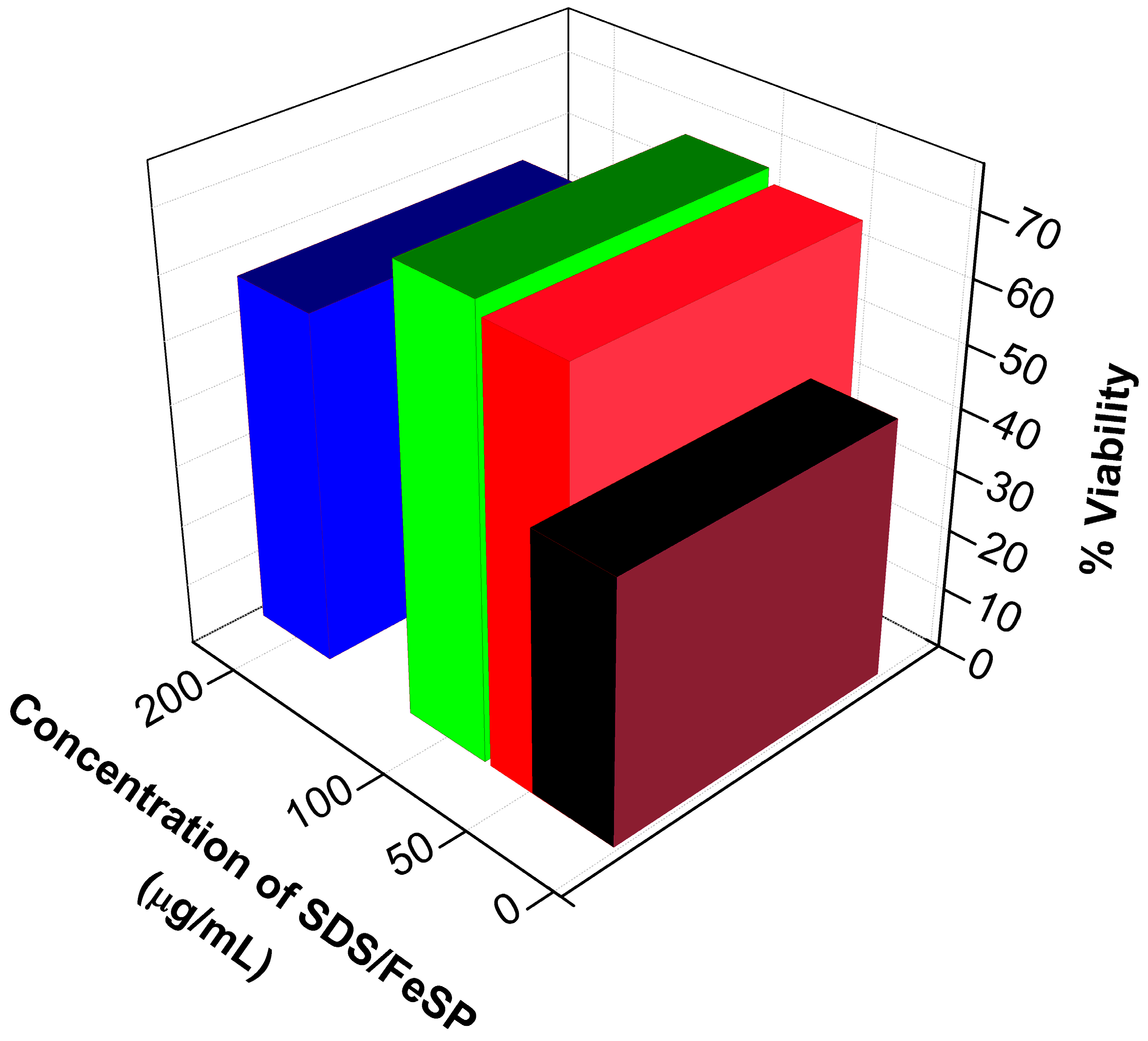

3.4. Cytotoxicity Studies

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bhattacharyya, S.; Kudgus, R.A.; Bhattacharya, R.; Mukherjee, P. Inorganic nanoparticles in cancer therapy. Pharm. Res. 2011, 28, 237–259. [Google Scholar] [CrossRef] [PubMed]

- Bilas, R.; Sriram, K.; Maheswari, P.U.; Sheriffa Begum, K.M. Highly biocompatible chitosan with super paramagnetic calcium ferrite (CaFe2O4) nanoparticle for the release of ampicillin. Int. J. Biol. Macromol. 2017, 97, 513–525. [Google Scholar] [CrossRef] [PubMed]

- Champeau, M.; Thomassin, J.M.; Tassaing, T.; Jerome, C. Drug loading of polymer implants by supercritical CO2 assisted impregnation: A review. J. Control. Release 2015, 209, 248–259. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, B.; Colilla, M.; Diez, J.; Pedraza, D.; Guembe, M.; Izquierdo-Barba, I.; Vallet-Regí, M. Mesoporous silica nanoparticles decorated with polycationic dendrimers for infection treatment. Acta Biomater. 2018, 68, 261–271. [Google Scholar] [CrossRef] [PubMed]

- Sharma, G.; Kumar, D.; Kumar, A.; Al-Muhtaseb, A.H.; Pathania, D.; Naushad, M.; Mola, G.T. Revolution from monometallic to trimetallic nanoparticle composites, various synthesis methods and their applications: A review. Mater. Sci. Eng. C 2017, 71, 1216–1230. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Zhang, Z.; Ma, X.; Jing, K.; Shen, M.; Yu, N.; Tang, J.; Dionysiou, D.D. Preparation of N,F-codoped TiO2 nanoparticles by three different methods and comparison of visible-light photocatalytic performances. Sep. Purif. Technol. 2017, 175, 305–313. [Google Scholar] [CrossRef]

- Pathania, D.; Katwal, R.; Sharma, G.; Naushad, M.; Khan, M.R.; Al-Muhtaseb, A.H. Novel guar gum/Al2O3 nanocomposite as an effective photocatalyst for the degradation of malachite green dye. Int. J. Biol. Macromol. 2016, 87, 366–374. [Google Scholar] [CrossRef] [PubMed]

- Bagal-Kestwal, D.R.; Kestwal, R.M.; Hsieh, W.T.; Chiang, B.H. Chitosan-guar gum-silver nanoparticles hybrid matrix with immobilized enzymes for fabrication of beta-glucan and glucose sensing photometric flow injection system. J. Pharm. Biomed. Anal. 2014, 88, 571–578. [Google Scholar] [CrossRef] [PubMed]

- Sharma, G.; Naushad, M.; Kumar, A.; Rana, S.; Sharma, S.; Bhatnagar, A.J.; Stadler, F.; Ghfar, A.A.; Khan, M.R. Efficient removal of coomassie brilliant blue R-250 dye using starch/poly(alginic acid- cl-acrylamide) nanohydrogel. Process Saf. Environ. Protect. 2017, 109, 301–310. [Google Scholar] [CrossRef]

- Pathania, D.; Sharma, G.; Naushad, M.; Kumar, A. Synthesis and characterization of a new nanocomposite cation exchanger polyacrylamide Ce(IV) silicophosphate: Photocatalytic and antimicrobial applications. J. Ind. Eng. Chem. 2014, 20, 3596–3603. [Google Scholar] [CrossRef]

- Zazakowny, K.; Lewandowska-Lancucka, J.; Mastalska-Poplawska, J.; Kaminski, K.; Kusior, A.; Radecka, M.; Nowakowska, M. Biopolymeric hydrogels—Nanostructured TiO2 hybrid materials as potential injectable scaffolds for bone regeneration. Colloids Surf. B Biointerfaces 2016, 148, 607–614. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Naushad, M.; Rana, A.; Sharma, G.; Ghfar, A.A.; Stadler, F.J.; Khan, M.R. ZnSe-WO3 nano-hetero-assembly stacked on Gum ghatti for photo-degradative removal of Bisphenol A: Symbiose of adsorption and photocatalysis. Int. J. Biol. Macromol. 2017, 104, 1172–1184. [Google Scholar] [CrossRef] [PubMed]

- Qiagedeer, A.; Maira, B.; Strauss, R.; Zhao, Y.; Chammingkwan, P.; Mizutani, G.; Taniike, T. Preparation and characterization of polypropylene/noble metal nanocomposites based on reactor granule technology. Polymer 2017, 127, 251–258. [Google Scholar] [CrossRef]

- Bayón, B.; Bucalá, V.; Castro, G.R. Development of antimicrobial hybrid mesoporous silver phosphate-pectin microspheres for control release of levofloxacin. Microporous Mesoporous Mater. 2016, 226, 71–78. [Google Scholar] [CrossRef]

- Song, M.-M.; Xu, H.-L.; Liang, J.-X.; Xiang, H.-H.; Liu, R.; Shen, Y.-X. Lactoferrin modified graphene oxide iron oxide nanocomposite for glioma-targeted drug delivery. Mater. Sci. Eng. C 2017, 77, 904–911. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wang, Y.; Yao, J.; Gao, L.; Li, D.-S.; Liu, Y. Highly magnetic sensitivity of polymer nanocomposite hydrogels based on magnetic nanoparticles. Compos. Sci. Technol. 2017, 141, 40–47. [Google Scholar] [CrossRef]

- Čampelj, S.; Makovec, D.; Drofenik, M. Functionalization of magnetic nanoparticles with 3-aminopropyl silane. J. Magn. Magn. Mater. 2009, 321, 1346–1350. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, D.; Fu, Y.; Du, H. Recent advances of superhard nanocomposite coatings: A review. Surf. Coat. Technol. 2003, 167, 113–119. [Google Scholar] [CrossRef]

- Iijima, M.; Yonemochi, Y.; Tsukada, M.; Kamiya, H. Microstructure control of iron hydroxide nanoparticles using surfactants with different molecular structures. J. Colloid Interface Sci. 2006, 298, 202–208. [Google Scholar] [CrossRef] [PubMed]

- Malisetty, S.C.; Allena, R.; Sandina, S.; Gangadharappa, H. Formulation and evaluation of modified-release effervescent floating tablets of ofloxacin. Int. J. Health Allied Sci. 2013, 2, 99–107. [Google Scholar] [CrossRef]

- Chueh, H.R.; Zia, H.; Rhodes, C.T. Optimization of Sotalol Floating and Bioadhesive Extended Release Tablet Formulations. Drug Dev. Ind. Pharm. 1995, 21, 1725–1747. [Google Scholar] [CrossRef]

- Iannuccelli, V.; Coppi, G.; Bernabei, M.T.; Cameroni, R. Air compartment multiple-unit system for prolonged gastric residence. Part I. Formulation study. Int. J. Pharm. 1998, 174, 47–54. [Google Scholar] [CrossRef]

- Gröning, R.; Heun, G. Oral Dosage Forms with Controlled Gastrointestinal Transit. Drug Dev. Ind. Pharm. 1984, 10, 527–539. [Google Scholar] [CrossRef]

- Sellers, E.M.; Toneatto, T.; Romach, M.K.; Somer, G.R.; Sobell, L.C.; Sobell, M.B. Clinical Efficacy of the 5-HT3 Antagonist Ondansetron in Alcohol Abuse and Dependence. Alcohol. Clin. Exp. Res. 1994, 18, 879–885. [Google Scholar] [CrossRef]

- Sharma, G.; Thakur, B.; Naushad, M.; Al-Muhtaseb, A.H.; Kumar, A.; Sillanpaa, M.; Mola, G.T. Fabrication and characterization of sodium dodecyl sulphate@ironsilicophosphate nanocomposite: Ion exchange properties and selectivity for binary metal ions. Mater. Chem. Phys. 2017, 193, 129–139. [Google Scholar] [CrossRef]

- Alothman, Z.A.; Alam, M.M.; Naushad, M. Heavy toxic metal ion exchange kinetics: Validation of ion exchange process of composite cation exchanger nylon 6,6 Zr(IV) phosphate. J. Ind. Eng. Chem. 2013, 19, 956–960. [Google Scholar] [CrossRef]

- Alothman, Z.A.; Naushad, M. Adsorption thermodynamics of trichloroacetic acid herbicide on polypyrrole Th(IV) phosphate composite cation-exchanger. Chem. Eng. J. 2011, 169, 38–42. [Google Scholar] [CrossRef]

- Nabi, S.A.; Bushra, R.; Naushad, M.; Khan, A. Synthesis, Characterization and Ion Exchange Behavior of Composite Material, Poly-o-toluidine Stannic molybdate and its use in the separation of Toxic Metal Ions. Chem. Eng. J. 2010, 165, 529–536. [Google Scholar] [CrossRef]

- Anirudhan, T.S.; Divya, P.L.; Nima, J. Synthesis and characterization of silane coated magnetic nanoparticles/glycidylmethacrylate-grafted-maleated cyclodextrin composite hydrogel as a drug carrier for the controlled delivery of 5-fluorouracil. Mater. Sci. Eng. C 2015, 55, 471–481. [Google Scholar] [CrossRef] [PubMed]

- Negi, P.; Aggarwal, M.; Sharma, G.; Rathore, C.; Sharma, G.; Singh, B.; Katare, O.P. Niosome-based hydrogel of resveratrol for topical applications: An effective therapy for pain related disorder(s). Biomed. Pharmacother. 2017, 88, 480–487. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Xiao, L.; Deng, H.; Shi, X.; Cao, Q. Remote controlled drug release from multi-functional Fe3O4/GO/Chitosan microspheres fabricated by an electrospray method. Colloids Surf. B Biointerfaces 2017, 151, 354–362. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Feng, S.S. The drug encapsulation efficiency, in vitro drug release, cellular uptake and cytotoxicity of paclitaxel-loaded poly(lactide)-tocopheryl polyethylene glycol succinate nanoparticles. Biomaterials 2006, 27, 4025–4033. [Google Scholar] [CrossRef] [PubMed]

- Clayberger, C.; Finn, M.W.; Wang, T.; Saini, R.; Wilson, C.; Barr, V.A.; Sabatino, M.; Castiello, L.; Stroncek, D.; Krensky, A.M. 15 kDa Granulysin Causes Differentiation of Monocytes to Dendritic Cells but Lacks Cytotoxic Activity. J. Immunol. 2012, 188, 6119–6126. [Google Scholar] [CrossRef] [PubMed]

- Pooja, D.; Kulhari, H.; Tunki, L.; Chinde, S.; Kuncha, M.; Grover, P.; Rachamalla, S.S.; Sistla, R. Nanomedicines for targeted delivery of etoposide to non-small cell lung cancer using transferrin functionalized nanoparticles. RSC Adv. 2015, 5, 49122–49131. [Google Scholar] [CrossRef]

- Moreira, J.N.; Ishida, T.; Gaspar, R.; Allen, T.M. Use of the Post-Insertion Technique to Insert Peptide Ligands into Pre-Formed Stealth Liposomes with Retention of Binding Activity and Cytotoxicity. Pharm. Res. 2002, 19, 265–269. [Google Scholar] [CrossRef] [PubMed]

- Dhiman, P.; Naushad, M.; Batoo, K.M.; Kumar, A.; Sharma, G.; Ghfar, A.A.; Kumar, G.; Singh, M. Nano FexZn1−xO as a tuneable and efficient photocatalyst for solar powered degradation of bisphenol A from aqueous environment. J. Clean. Prod. 2017, 165, 1542–1556. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, G.; Naushad, M.; Kumar, A.; Kalia, S.; Guo, C.; Mola, G.T. Facile hetero-assembly of superparamagnetic Fe3O4/BiVO4 stacked on biochar for solar photo-degradation of methyl paraben and pesticide removal from soil. J. Photochem. Photobiol. A 2017, 337, 118–131. [Google Scholar] [CrossRef]

- Sharma, G.; Pathania, D.; Naushad, M. Preparation, characterization and antimicrobial activity of biopolymer based nanocomposite ion exchanger pectin zirconium(IV) selenotungstophosphate: Application for removal of toxic metals. J. Ind. Eng. Chem. 2014, 20, 4482–4490. [Google Scholar] [CrossRef]

- Sharma, G.; Naushad, M.; Al-Muhtaseb, A.H.; Kumar, A.; Khan, M.R.; Kalia, S.; Bala, M.; Sharma, A. Fabrication and characterization of chitosan-crosslinked-poly(alginic acid) nanohydrogel for adsorptive removal of Cr(VI) metal ion from aqueous medium. Int. J. Biol. Macromol. 2017, 95, 484–493. [Google Scholar] [CrossRef] [PubMed]

- An, J.; Zhang, X.; Guo, Q.; Zhao, Y.; Wu, Z.; Li, C. Glycopolymer modified magnetic mesoporous silica nanoparticles for MR imaging and targeted drug delivery. Colloids Surf. A 2015, 482, 98–108. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, X.; Zheng, C.; Wu, Z.; Li, C. A pH Gated, Glucose-Sensitive Nanoparticle Based on Worm-Like Mesoporous Silica for Controlled Insulin Release. J. Phys. Chem. B 2013, 117, 3852–3860. [Google Scholar] [CrossRef] [PubMed]

- Pathania, D.; Gupta, D.; Kothiyal, N.C.; Sharma, G.; Eldesoky, G.E.; Naushad, M. Preparation of a novel chitosan-g-poly(acrylamide)/Zn nanocomposite hydrogel and its applications for controlled drug delivery of ofloxacin. Int. J. Biol. Macromol. 2016, 84, 340–348. [Google Scholar] [CrossRef] [PubMed]

- Perez, E.; Fernandez, A.; Olmo, R.; Teijon, J.M.; Blanco, M.D. pH and Glutathion-responsive hydrogel for localized delivery of paclitaxel. Colloids Surf. B Biointerfaces 2014, 116, 247–256. [Google Scholar] [CrossRef] [PubMed]

- Soltan-Dallal, M.M.; Validi, M.; Douraghi, M.; Fallah-Mehrabadi, M.; Lormohammadi, L. Evaluation the cytotoxic effect of cytotoxin-producing Klebsiella oxytoca isolates on the HEp-2 cell line by MTT assay. Microb. Pathog. 2017, 113, 416–420. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharma, G.; Naushad, M.; Thakur, B.; Kumar, A.; Negi, P.; Saini, R.; Chahal, A.; Kumar, A.; Stadler, F.J.; Aqil, U.M.H. Sodium Dodecyl Sulphate-Supported Nanocomposite as Drug Carrier System for Controlled Delivery of Ondansetron. Int. J. Environ. Res. Public Health 2018, 15, 414. https://doi.org/10.3390/ijerph15030414

Sharma G, Naushad M, Thakur B, Kumar A, Negi P, Saini R, Chahal A, Kumar A, Stadler FJ, Aqil UMH. Sodium Dodecyl Sulphate-Supported Nanocomposite as Drug Carrier System for Controlled Delivery of Ondansetron. International Journal of Environmental Research and Public Health. 2018; 15(3):414. https://doi.org/10.3390/ijerph15030414

Chicago/Turabian StyleSharma, Gaurav, Mu. Naushad, Bharti Thakur, Amit Kumar, Poonam Negi, Reena Saini, Anterpreet Chahal, Ashok Kumar, Florian J. Stadler, and U.M.H. Aqil. 2018. "Sodium Dodecyl Sulphate-Supported Nanocomposite as Drug Carrier System for Controlled Delivery of Ondansetron" International Journal of Environmental Research and Public Health 15, no. 3: 414. https://doi.org/10.3390/ijerph15030414