Fatigue and Recovery of Muscles for Pulling Tasks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experiment

2.2. Participants

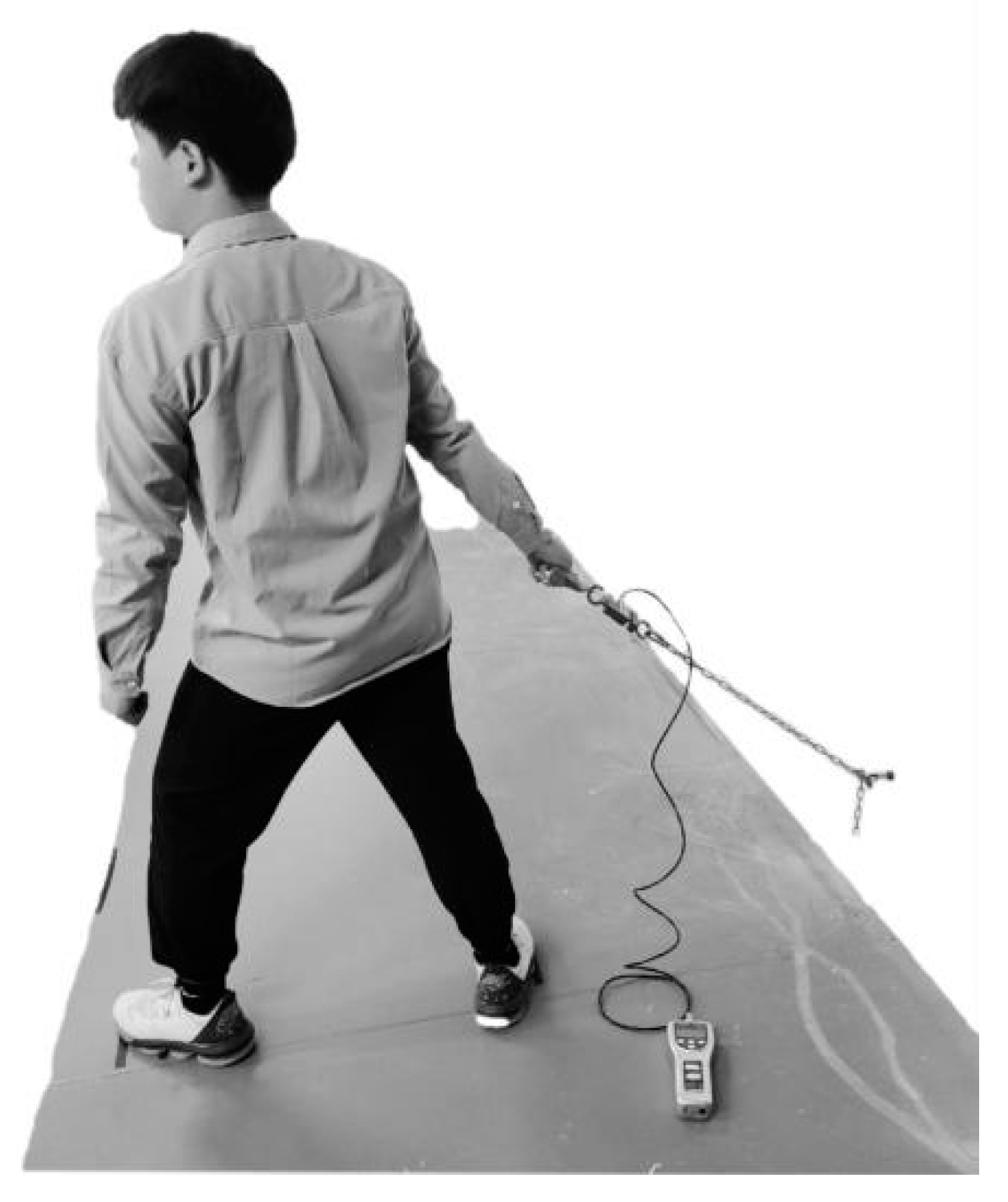

2.3. Apparatus and Tools

2.4. Experimental Design

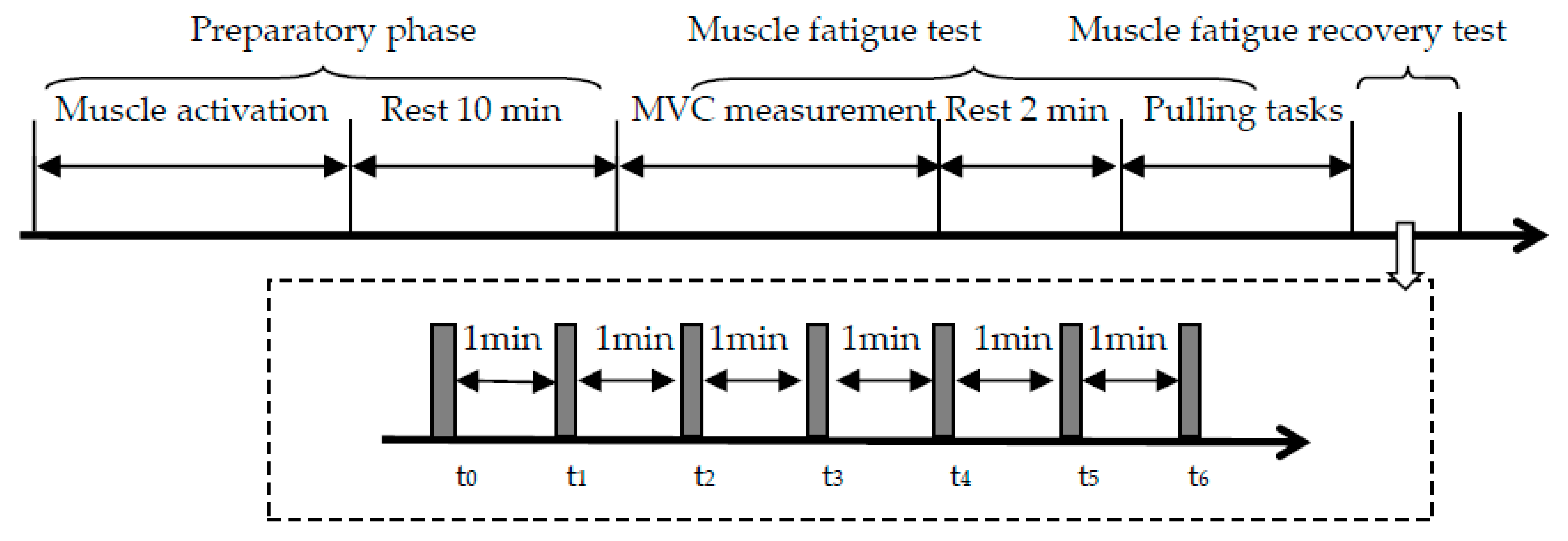

2.5. Procedures

2.6. Data Processing

3. Results

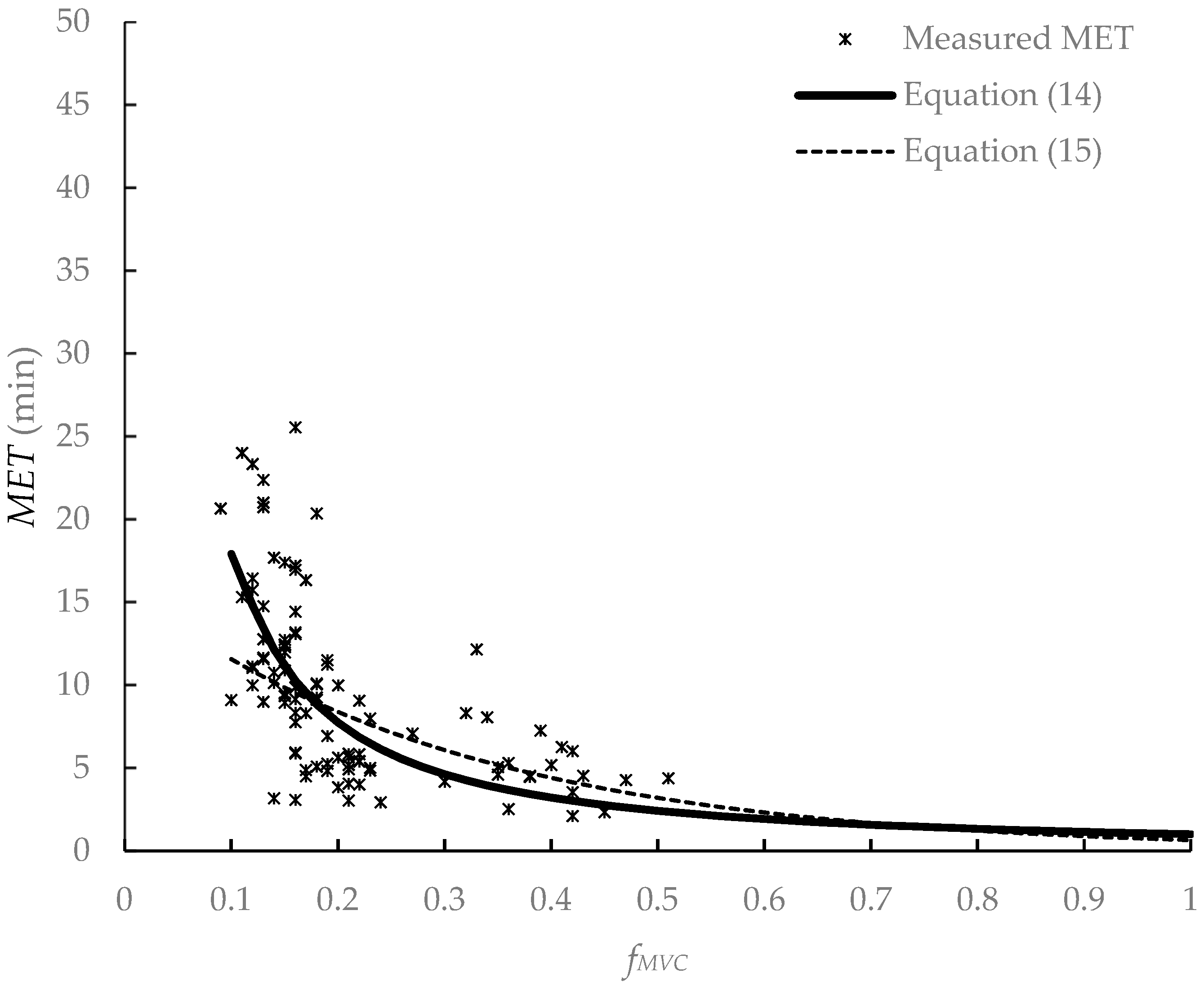

3.1. Muscle Fatigue for Pulling Tasks

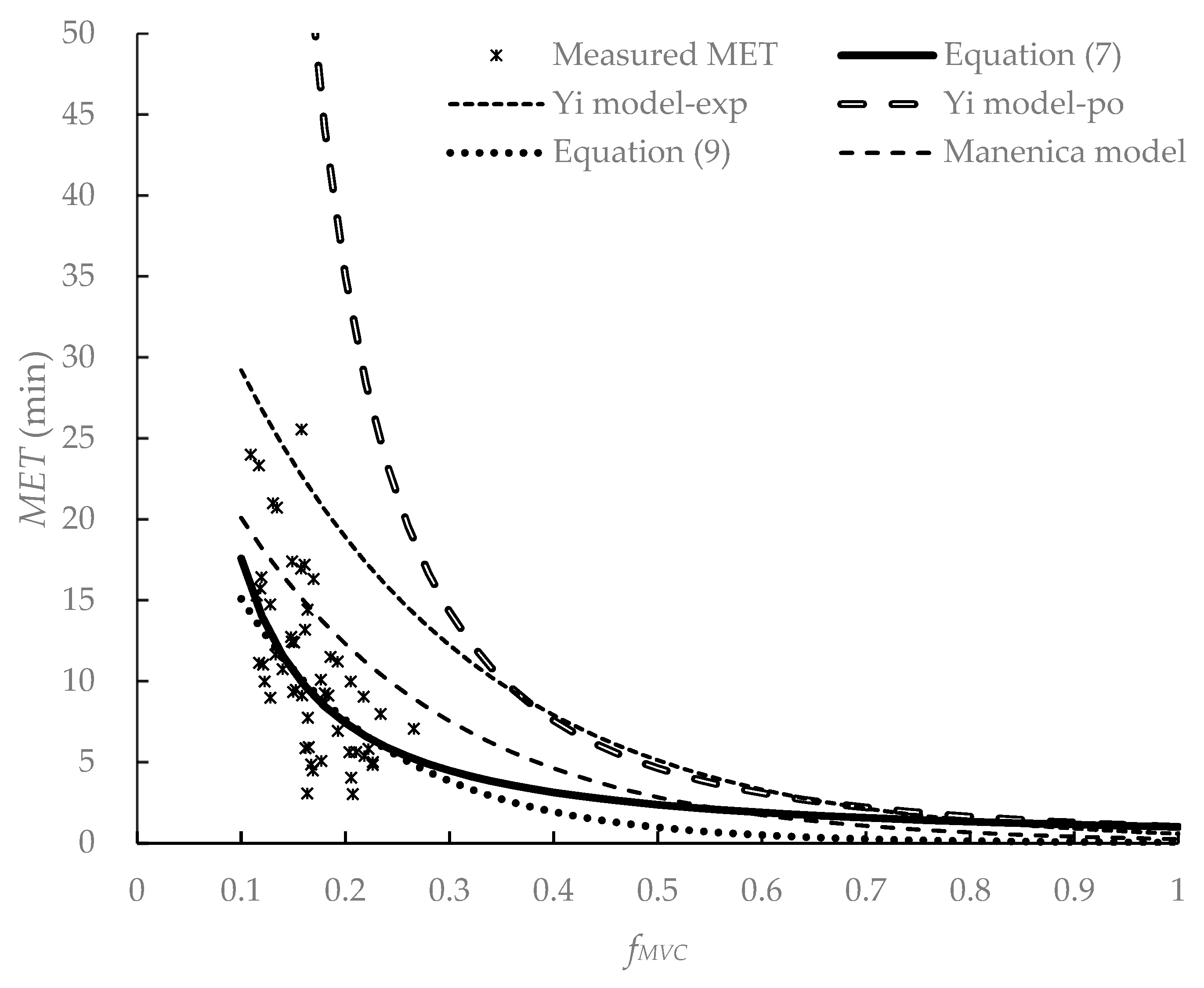

3.1.1. Models According to Static Force Exertion

3.1.2. Models of Dynamic Force Exertion

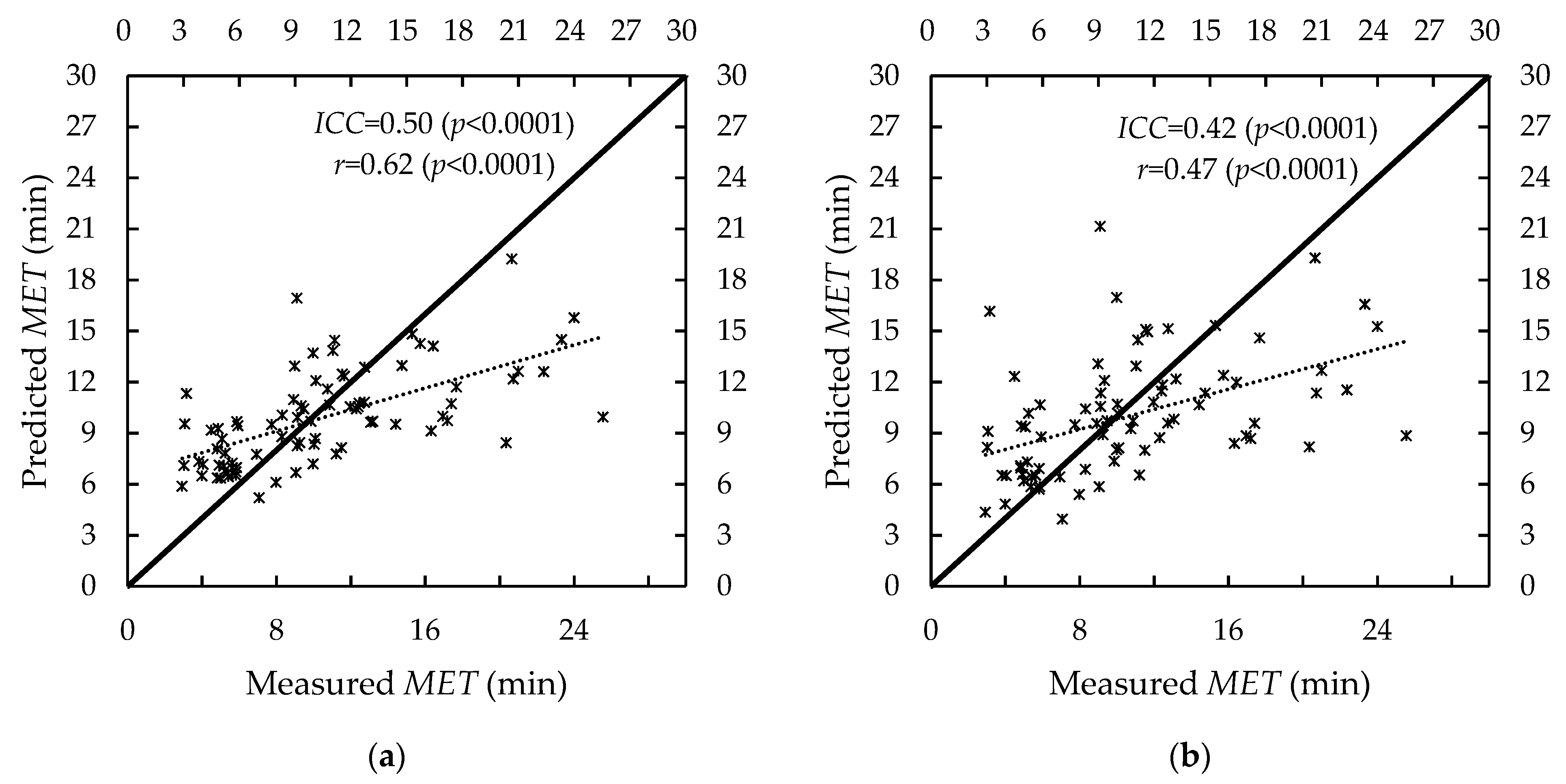

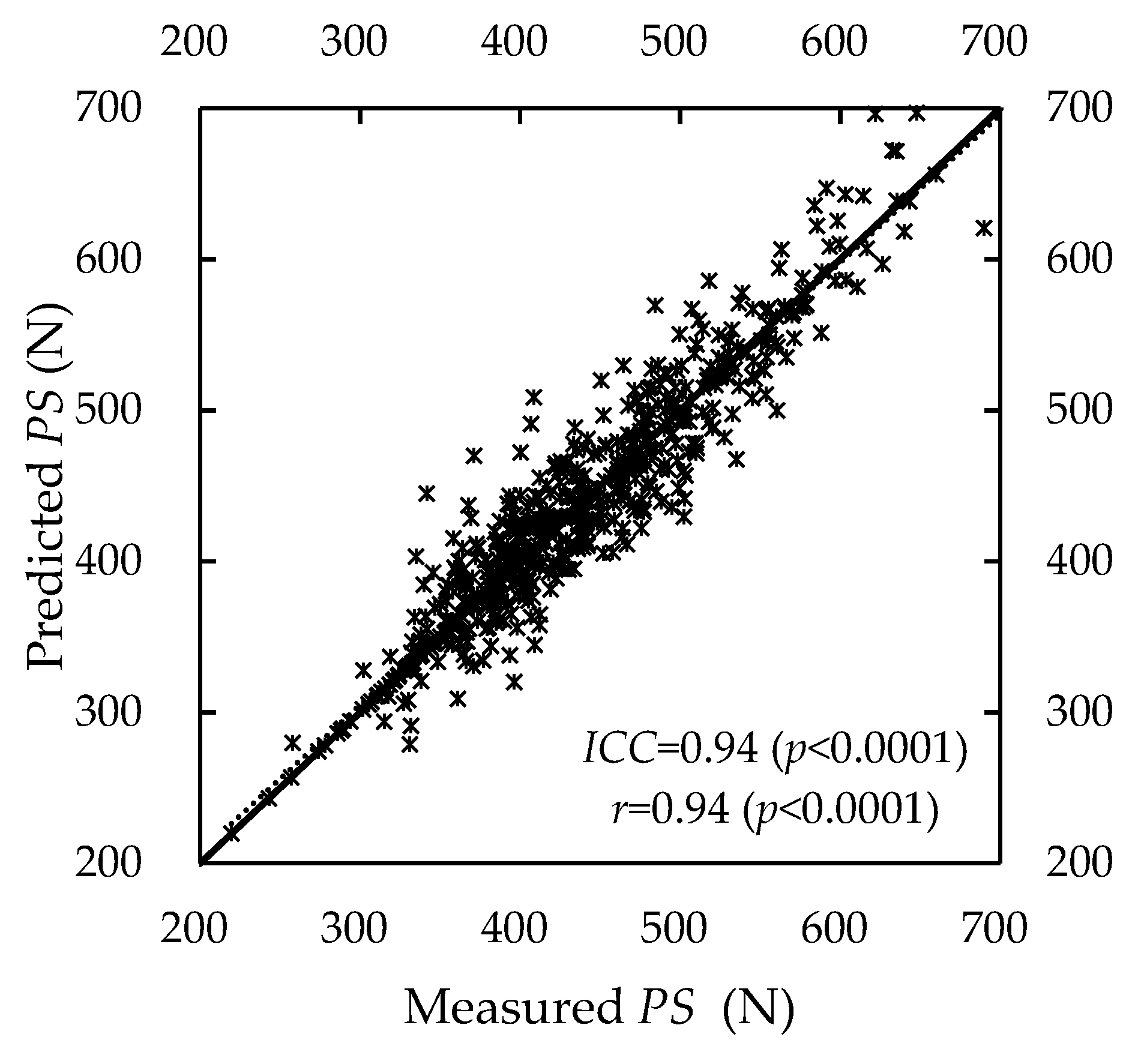

3.1.3. Model Comparison

3.2. Muscle Fatigue Recovery for Pulling Tasks

4. Discussion

4.1. Muscle Fatigue

4.2. Muscle Fatigue Recovery

4.3. Limitations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marras, W.S. Occupational low back disorder causation and control. Ergonomics 2000, 43, 880–902. [Google Scholar] [CrossRef] [PubMed]

- Government of Canada, Canadian Centre for Occupational Health and Safety. MMH Introduction: OSH Answers. Available online: https://www.ccohs.ca/oshanswers/ergonomics/mmh/mmhintro.html (accessed on 15 September 2022).

- National Institute for Occupational Safety and Health. Ergonomic Guidelines for Manual Material Handling. Available online: https://www.cdc.gov/niosh/docs/2007-131/pdfs/2007-131.pdf (accessed on 12 September 2022).

- HSE Work-Related Musculoskeletal Disorders Statistics in Great Britain. 2021. Available online: https://www.hse.gov.uk/statistics/causdis/msd.pdf (accessed on 11 September 2022).

- Ciriello, V.M.; McGorry, R.W.; Martin, S.E. Maximum acceptable horizontal and vertical forces of dynamic pushing on high and low coefficient of friction floors. Int. J. Ind. Ergon. 2001, 27, 1–8. [Google Scholar] [CrossRef]

- Bennett, A.I.; Todd, A.I.; Desai, S.D. Pushing and pulling, technique and load effects: An electromyographical study. Work-J. Prev. Assess. Rehabil. 2011, 38, 291–299. [Google Scholar] [CrossRef] [PubMed]

- Resnick, M.L.; Chaffin, D.B. An ergonomic evaluation of handle height and load in maximal and submaximal cart pushing. Appl. Ergon. 1995, 26, 173–178. [Google Scholar] [CrossRef]

- Das, B.; Black, N.L. Isometric pull and push strengths of paraplegics in the workspace: 1. Strength measurement profiles. Int. J. Occup. Saf. Ergon. 2000, 6, 47–65. [Google Scholar] [CrossRef]

- Bureau of Labor Statistics Census of Fatal Occupational Injuries. Available online: https://www.bls.gov/opub/hom/cfoi/pdf/cfoi.pdf. (accessed on 29 September 2022).

- Kumar, S. Upper body push-pull strength of normal young adults in sagittal plane at three heights. Int. J. Ind. Ergon. 1995, 15, 427–436. [Google Scholar] [CrossRef]

- Baril-Gingras, G.; Lortie, M. The handling of objects other than boxes: Univariate analysis of handling techniques in a large transport company. Ergonomics 1995, 38, 905–925. [Google Scholar] [CrossRef]

- Hoozemans, M.J.M.; Kuijer, P.P.F.M.; Kingma, I.; van Dieën, J.H.; de Vries, W.H.K.; van der Woude, L.H.V.; Veeger, D.J.H.E.J.; van der Beek, A.J.; Frings-Dresen, M.H.W. Mechanical loading of the low back and shoulders during pushing and pulling activities. Ergonomics 2004, 47, 1–18. [Google Scholar] [CrossRef]

- Harris-Adamson, C.; Lin, J.-H. Effect of handle design on pallet jack operations. Hum. Factors Ergon. Soc. 2013, 21, 15–21. [Google Scholar] [CrossRef]

- Hoozemans, M.J.M.; van der Beek, A.J.; Fringsdresen, M.H.W.; Van Dijk, F.J.H.; Van Der Woude, L.H.V. Pushing and pulling in relation to musculoskeletal disorders: A review of risk factors. Ergonomics 1998, 41, 757–781. [Google Scholar] [CrossRef]

- Hoozemans, M.J.M.; Knelange, E.B.; Frings-Dresen, M.H.W.; Veeger, H.E.J.; Kuijer, P.P.F.M. Are pushing and pulling work-related risk factors for upper extremity symptoms? A systematic review of observational studies. Occup. Environ. Med. 2014, 71, 788–795. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rohmert, W.; Wangenheim, M.; Mainzer, J.; Zipp, P.; Lesser, W. A study stressing the need for a static postural force model for work analysis. Ergonomics 1986, 29, 1235–1249. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.-H.; McGorry, R.W.; Maynard, W. One-handed standing pull strength in different postures: Normative data. Appl. Ergon. 2013, 44, 603–608. [Google Scholar] [CrossRef] [PubMed]

- Yi, C.; Tang, F.; Li, K.W. Muscular strength decrease and maximum endurance time assessment for a simulated truck pulling task. J. Ind. Prod. Eng. 2017, 34, 486–493. [Google Scholar] [CrossRef]

- Yi, C.; Tang, F.; Peng, L.; Li, K.W.; Ma, L.; Hu, H. Modeling of maximum endurance time for static pulling tasks. Work- J. Prev. Assess. Rehabil. 2018, 60, 455–463. [Google Scholar] [CrossRef]

- Yi, C.; Li, K.W.; Tang, F.; Zuo, H.; Ma, L.; Hu, H. Pulling strength, muscular fatigue, and prediction of maximum endurance time for simulated pulling tasks. PLoS ONE 2018, 13, e0207283. [Google Scholar] [CrossRef]

- Li, K.W.; Yi, C.; Liu, M. Maximum endurance time modeling for push and pull tasks considering gender and handle height. Hum. Factors Ergon. Manuf. Serv. Ind. 2021, 31, 3–12. [Google Scholar] [CrossRef]

- Yi, C.; Tang, F.; Li, K.; Hu, H.; Zuo, H.; Zhao, C. Effects of pause design on the decline in pulling effort and the evaluation of perceived effort in pulling tasks. Appl. Sci. 2021, 11, 12022. [Google Scholar] [CrossRef]

- Ohnishi, A.; Takanokura, M.; Sugama, A. Evaluation of interhandle distance during pushing and pulling of a four-caster cart for upper limb exertion. Saf. Health Work 2016, 7, 237–243. [Google Scholar] [CrossRef] [Green Version]

- Al-Eisawi, K.W.; Kerk, C.J.; Congleton, J.J.; Amendola, A.A.; Jenkins, O.C.; Gaines, W.G. The effect of handle height and cart load on the initial hand forces in cart pushing and pulling. Ergonomics 1999, 42, 1099–1113. [Google Scholar] [CrossRef]

- Kao, H.C.; Lin, C.J.; Lee, Y.H.; Chen, S.H. The effects of direction of exertion, path, and load placement in nursing cart pushing and pulling tasks: An electromyographical study. PLoS ONE 2015, 10, e0140792. [Google Scholar] [CrossRef] [PubMed]

- Calé-Benzoor, M.; Dickstein, R.; Arnon, M.; Ayalon, M. Dynamic push–pull characteristics at three hand-reach envelopes: Applications for the workplace. Appl. Ergon. 2016, 52, 216–221. [Google Scholar] [CrossRef] [PubMed]

- Tang, F.; Yi, C.; Li, K.W.; Zuo, H.; Yin, L.; Li, W. Modeling effect of walking speed and load on muscular fatigue for dynamic tension work. China Saf. Sci. J. 2021, 31, 191–196. [Google Scholar]

- Vøllestad, N.K. Measurement of human muscle fatigue. J. Neurosci. Methods 1997, 74, 219–227. [Google Scholar] [CrossRef]

- Rohmert, W. Problems in determining rest allowances: Part 1: Use of modern methods to evaluate stress and strain in static muscular work. Appl. Ergon. 1973, 4, 91–95. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, W.; Wu, S.; Zhang, Z. A new simple local muscle recovery model and its theoretical and experimental validation. Int. J. Occup. Saf. Ergon. 2015, 21, 86–93. [Google Scholar] [CrossRef]

- Duong, B.; Low, M.; Moseley, A.M.; Lee, R.Y.W.; Herbert, R.D. Time course of stress relaxation and recovery in human ankles. Clin. Biomech. 2001, 16, 601–607. [Google Scholar] [CrossRef]

- Fulco, C.S.; Rock, P.B.; Muza, S.R.; Lammi, E.; Cymerman, A.; Butterfield, G.; Moore, L.G.; Braun, B.; Lewis, S.F. Slower fatigue and faster recovery of the adductor pollicis muscle in women matched for strength with men. Acta Physiol. Scand. 1999, 167, 233–239. [Google Scholar] [CrossRef]

- Yi, C.; Tang, F.; Li, K.; Hu, H.; Zuo, H.; Zhao, C. Modeling and validation of fatigue and recovery of muscles for manual demolition tasks. Int. J. Environ. Res. Public Health 2022, 19, 930. [Google Scholar] [CrossRef]

- Li, K.W.; Chiu, W. Isometric arm strength and subjective rating of upper limb fatigue in two-handed carrying tasks. PLoS ONE 2015, 10, e0119550. [Google Scholar] [CrossRef]

- Hu, H.; Yi, C.; Li, K.W.; Tang, F.; Zuo, H.; Pi, K. Study on models for evaluating muscular fatigue of upper extremity for pulling task. China Saf. Sci. J. 2018, 28, 61–67. [Google Scholar]

- Hu, H.; Yi, C.; Li, K.W.; Tang, F.; Zuo, H.; Chen, C. Evaluation model of muscular fatigue for force exertion task. China Saf. Sci. J. 2018, 28, 79–85. [Google Scholar]

- Zhou, Q.; Chen, Y.; Ma, C.; Zheng, X. Evaluation model for muscle fatigue of upper limb based on sEMG analysis. Sci. China Life Sci. 2011, 41, 608–614. [Google Scholar]

- Borg, G. Psychophysical scaling with applications in physical work and the perception of exertion. Scand. J. Work. Environ. Health 1990, 16, 55–58. [Google Scholar] [CrossRef]

- Ma, L.; Chablat, D.; Bennis, F.; Zhang, W.; Hu, B.; Guillaume, F. A novel approach for determining fatigue resistances of different muscle groups in static cases. Int. J. Ind. Ergon. 2011, 41, 10–18. [Google Scholar] [CrossRef] [Green Version]

- Li, K.W.; Wang, C.W.; Yu, R. Modeling of predictive muscular strength for sustained one-handed carrying task. Work 2015, 52, 911–919. [Google Scholar] [CrossRef]

- Spielholz, P. Calibrating Borg scale ratings of hand force exertion. Appl. Ergon. 2006, 37, 615–618. [Google Scholar] [CrossRef]

- Erik Mathiassen, S.; Åhsberg, E. Prediction of shoulder flexion endurance from personal factors. Int. J. Ind. Ergon. 1999, 24, 315–329. [Google Scholar] [CrossRef]

- Bao, Z.; Ma, P.; Tong, J.; Wang, C. Research on the velocity characteristics of human walking. Res. Explor. Lab. 2006, 19, 43–46. [Google Scholar]

- Liu, K.; Su, P.; Zhao, W. Stochastic U-line balancing with operators’ walking time considered. Ind. Eng. J. 2012, 15, 124–130. [Google Scholar] [CrossRef]

- Li, K.W.; Chu, J.C.; Chen, C.C. Strength decrease, perceived physical exertion and endurance time for backpacking tasks. Int. J. Environ. Res. Public Health 2019, 16, 1296. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, Z. Video Measurement Technology of Human Walking Parameters. Master’s Thesis, Southeast University, Nanjing, China, 2021. [Google Scholar]

- POPSUGAR Fitness 40 Minute Full Body Workout|Beginner Strength Training|Class FitSugar. Available online: https://www.youtube.com/watch?v=istOU9nxhm8 (accessed on 17 December 2021).

- Liu, B.; Ma, L.; Chen, C.; Zhang, Z. Experimental validation of a subject-specific maximum endurance time model. Ergonomics 2018, 61, 806–817. [Google Scholar] [CrossRef] [PubMed]

- El Ahrache, K.; Imbeau, D.; Farbos, B. Percentile values for determining maximum endurance times for static muscular work. Int. J. Ind. Ergon. 2006, 36, 99–108. [Google Scholar] [CrossRef]

- Hagberg, M. Muscular endurance and surface electromyogram in isometric and dynamic exercise. J. Appl. Physiol. 1981, 51, 1–7. [Google Scholar] [CrossRef]

- Li, K.W.; Peng, L.; Yi, C. Modeling of maximum endurance time for one-handed carrying tasks. Hum. Factors Ergon. Manuf. Serv. Ind. 2019, 29, 319–326. [Google Scholar] [CrossRef]

- Sato, H.; Ohashi, J.; Iwanaga, K.; Yoshitake, R.; Shimada, K. Endurance time and fatigue in static contractions. J. Hum. Ergol. 1984, 13, 147–154. [Google Scholar]

- Manenica, I. A technique for postural load assessment. In The Ergonomics of Working Postures; Taylor & Francis: London, UK, 1986; pp. 270–277. [Google Scholar]

- Ma, R.; Chablat, D.; Bennis, F.; Ma, L. Human muscle fatigue model in dynamic motions. In Proceedings of the Latest Advances in Robot Kinematics; Springer: Innsbruck, Austria, 2012; pp. 349–356. [Google Scholar]

- Ma, L.; Chablat, D.; Bennis, F.; Zhang, W. A new simple dynamic muscle fatigue model and its validation. Int. J. Ind. Ergon. 2009, 39, 211–220. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Zhou, A. Study on the Effect of Different Muscle Fatigue Recovery Methods on Muscle Stiffness Recovery; Atlantic Press: Paris, France, 2017; pp. 497–500. [Google Scholar]

- Jonsson, B. The static load component in muscle work. Eur. J. Appl. Physiol. 1988, 57, 305–310. [Google Scholar] [CrossRef]

- Liu, B.; Ma, L.; Zhang, W.; Zhang, Z. Subject-specific hand grip fatigability indicator determined using parameter identification technique. Hum. Factors Ergon. Manuf. Serv. Ind. 2019, 29, 86–94. [Google Scholar] [CrossRef] [Green Version]

- Wiktorin, C.; Selin, K.; Ekenvall, L.; Kilbom, Å.; Alfredsson, L. Evaluation of perceived and self-reported manual forces exerted in occupational materials handling. Appl. Ergon. 1996, 27, 231–239. [Google Scholar] [CrossRef]

- Gamberale, F. Perception of effort in manual materials handling. Scand. J. Work. Environ. Health 1990, 16 (Suppl. S1), 59–66. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, K.W.; Yu, R.; Zhang, W. Perception of hand force in power grip for females. Hum. Factors Ergon. Manuf. Serv. Ind. 2013, 23, 77–84. [Google Scholar] [CrossRef]

| t (min) | PS (N) | CR-10 |

|---|---|---|

| 0 | 370.3 ± 69.2 A | 7.9 ± 0.9 a |

| 1 | 408.3 ± 68.7 B | 6.1 ± 1.2 b |

| 2 | 426.2 ± 66.4 BC | 5.0 ± 1.2 c |

| 3 | 442.1 ± 68.6 CD | 4.2 ± 1.4 d |

| 4 | 458.0 ± 73.1 DE | 3.5 ± 1.4 e |

| 5 | 472.1 ± 73.0 EF | 3.1 ± 1.4 f |

| 6 | 491.4 ± 74.3 F | 2.7 ± 1.2 g |

| Models | MAD (min) | ||

|---|---|---|---|

| Body pull model [53] | Manenica | 5.47 (±2.70) | |

| Dynamic pull model [27] | Tang et al. | 4.82 (±3.42) | |

| Static pull model [19] | Exponential model | 11.67 (±4.22) | |

| Power model | 50.52 (±32.07) | ||

| Current study | Equation (7) | Group A data | 3.28 (±2.99) |

| Group B data | 3.22 (±2.88) | ||

| Equation (9) | Group A data | 3.57 (±3.08) | |

| Group B data | 3.70 (±3.74) | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, C.; Zuo, H.; Zhao, C.; Li, K.-W.; Hu, H.; Tang, F.; Long, T. Fatigue and Recovery of Muscles for Pulling Tasks. Int. J. Environ. Res. Public Health 2022, 19, 15159. https://doi.org/10.3390/ijerph192215159

Yi C, Zuo H, Zhao C, Li K-W, Hu H, Tang F, Long T. Fatigue and Recovery of Muscles for Pulling Tasks. International Journal of Environmental Research and Public Health. 2022; 19(22):15159. https://doi.org/10.3390/ijerph192215159

Chicago/Turabian StyleYi, Cannan, Huali Zuo, Caijun Zhao, Kai-Way Li, Hong Hu, Fan Tang, and Tong Long. 2022. "Fatigue and Recovery of Muscles for Pulling Tasks" International Journal of Environmental Research and Public Health 19, no. 22: 15159. https://doi.org/10.3390/ijerph192215159