1. Introduction

The energy cost used in buildings for the developed countries in Europe was very high, up to 50% of which was due to air conditioning systems. On the other hand, water heating represented 13%, whilst lighting and electric appliances contributed to a further 12% in 2015 [

1,

2]. Air conditioning modules in buildings yield to heating/cooling tools, which can require also the regulation of advanced thermal comfort parameters represented by the air relative humidity and its temperature. The thermal unit (TU) module is fundamental in these systems, as it supplies the properly-treated air to the buildings. Therefore, the dynamic behaviour of TU modules represents the key point for decreasing the energy consumption and achieving the thermal comfort in buildings [

3].

The TU module can be described as a nonlinear time-invariant multivariable dynamic process, which is affected by disturbance and uncertainty terms when analysed for control applications [

4,

5]. Different control schemes exploited classic regulation approaches, such as on-off control laws and proportional, integral and differential (PID) standard compensators [

6,

7,

8]. These control schemes are simple with low-cost implementations, but sometimes unable to achieve accurate solutions. Moreover, the TU module can include nonlinear functions [

9], such as products between air temperature and mass flow rate, which can require advanced control strategies to achieve more complex thermal comfort indices and lower energy consumption. To overcome these problems, control strategies relying on artificial intelligence (AI) tools, namely artificial neural networks (ANN), fuzzy logic (FL), adaptive neuro-fuzzy inference systems (ANFIS) and model predictive controllers (MPC) have been proposed to obtain more advanced comfort issues in building applications [

10,

11,

12,

13]. As an example, an FL control scheme was proposed in [

14], where the heat, the humidity and the oxygen particle concentration represented the control variables, while the fresh air inflow and the fan circulation rate were the monitored outputs. It was shown that FL allowed for more accurate and straightforward results when compared to linear control schemes. A different FL controller to regulate the air conditioning system temperature was proposed in [

15], which was able to easily manage the system nonlinearity.

Other contributions considered different ANN tools that are able to enhance the design of suitable controllers used in air conditioning applications [

3,

12]. As an example, ANN controllers were proposed in [

12] for an air conditioning system and compared with a standard PID regulator. It was shown how these ANN controllers allowed one to achieve a controlled output with a shorter settling time and almost zero overshoot. The main advantage of ANN controllers is represented by their interesting features of automatic learning, easy adaptation and straightforward generalisation. However, more efficient solutions were proposed and based on the ANFIS tool [

15,

16,

17,

18]. In particular, in [

15], ANFIS was successfully exploited as an alternative control strategy with heating, ventilation and air conditioning (HVAC) systems to achieve accurate tracking errors.

Other works proposed MPC schemes for the temperature control of buildings [

2,

19,

20,

21]. As an example, in [

2], it was shown that the MPC scheme was able to achieve both thermal comfort and energy saving features. Similarly, [

19] suggested a more efficient control method when compared with traditional weather-compensated control schemes. Moreover, [

22] addressed an interesting overview of MPC methodologies for HVAC systems.

Note that recent studies considered the achievement of thermal comfort and energy efficiency issues using AI tools. However, the performances obtained by these AI-based methods were not analysed in detail and compared via extensive simulations as proposed in this paper using the Monte Carlo (MC) tool. Moreover, this work illustrates the design and the implementation of different control schemes with application to a nonlinear TU dynamic module proposed by the same authors in [

9]. Note also that the same authors presented some preliminary results in [

23,

24,

25], but the analysis of the achievable properties and the robustness features of the proposed solutions with their reliability characteristics have been described in detail in this paper.

Another key issue of the present study consists of illustrating the viable application of the suggested control schemes to real air conditioning systems. This point is fundamental for enhancing practitioners and HVAC young engineers to acquire the fundamentals and the basic design tools for effective HVAC controller development and application. To this aim, the suggested simulations have been synthesised in the MATLAB

® and Simulink

® environments and exploiting their standard toolboxes or free software tools. Note that some control strategies proposed in this work were already successfully applied to nonlinear models of energy conversion systems as shown, e.g., in [

26,

27,

28].

Finally, it is worth observing that several research papers have already dealt with this issue in the past (see, e.g., [

22,

29]), even if they are limited to MPC solutions. However, this work recalls, analyses and implement different control solutions when applied to the thermal unit model already developed by the authors in [

9]. Therefore, the key contribution of the work consists of investigating the viability and the reliability features of the proposed solutions with respect to the considered application example. The control performances achieved in simulation are verified and validated by means of the Monte Carlo tool. The proposed control strategies and the validation tools serve to highlight the potential application of the suggested methodologies to real dynamic processes, such as passive and active air conditioning systems.

The remainder of the paper is organised as follows.

Section 2 provides an overview of the TU module and its mathematical description.

Section 3 illustrates the suggested control schemes exploited in this study, whilst the obtained results are reported in

Section 4. The reliability and robustness characteristics of the proposed tools in simulation are discussed in

Section 4.1. Finally,

Section 5 ends the work by summarising the main achievements of the paper. Open problems and future issues that require further investigations are also suggested.

2. Thermal Unit Mathematical Description

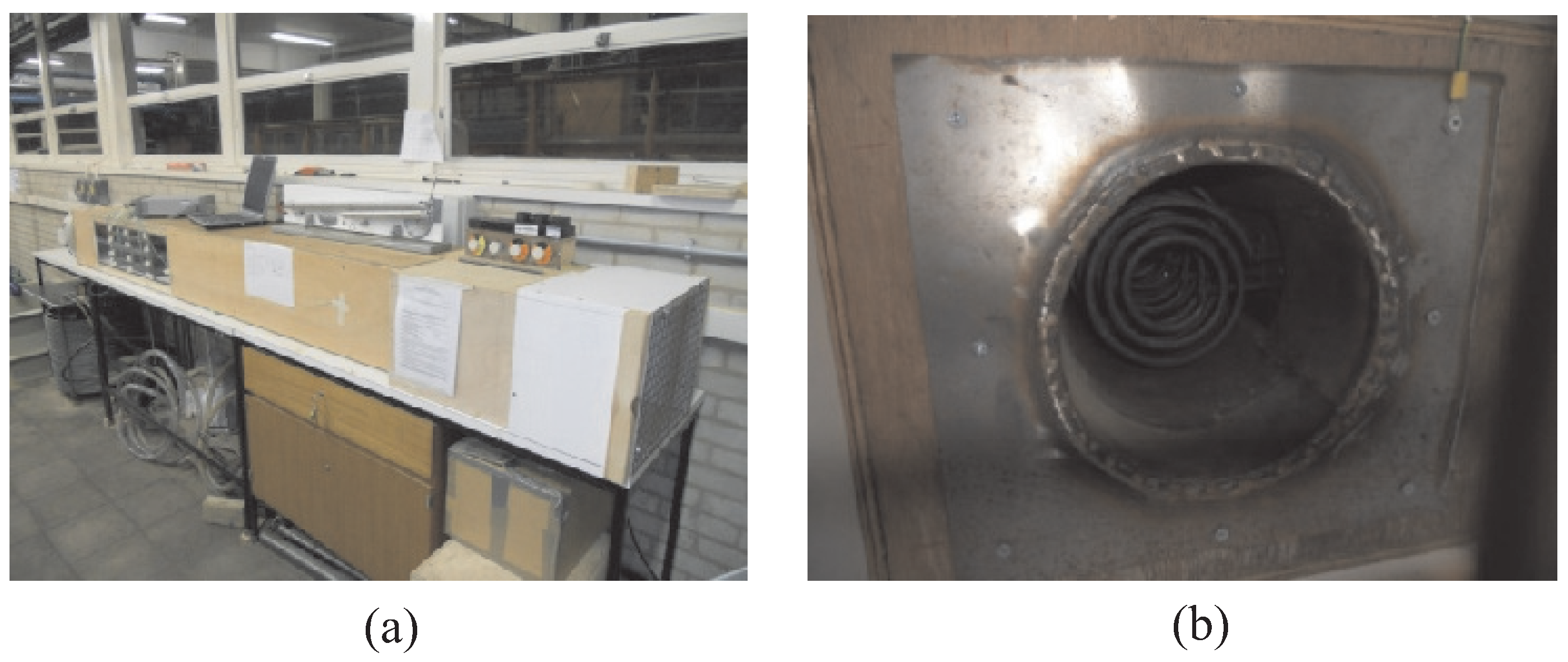

The TU module considered in this study consists of a fundamental block of the whole test-rig proposed for the description and the assessment of the dynamic behaviour of phase change material (PCM) systems used in passive air conditioning plants.

Figure 1 represents the complete PCM system facility considered in [

9], where the air flow speed and the temperature are the controlled variables that are exploited to perform the presented simulations and experiments. The heating element included into the PCM system is also sketched.

On the other hand,

Figure 2 illustrates how the inflow air is treated by means of the heating element (HE) of the TU. Moreover, the TU module is in a downstream series connection with a cooling unit, which is not reported in

Figure 2.

With reference to

Figure 2, the measured inlet air temperature,

(K), and the air velocity,

v (m/s), represent the system inputs considered in this study for describing the dynamic behaviour of the TU module. On the other hand, the system output is the outlet air temperature,

(K). The experimental data are acquired from the test-rig of

Figure 1, such that the HE sketched in

Figure 2 supplies a constant power

q (W), with an average value of

(W). As highlighted in

Figure 2, the signal measurements of

v,

and

are acquired from the cross-sectional area centre of the supply duct. Note that the input

is considered as a disturbance acting on the controlled system.

The mathematical expressions describing the energy balance of the TU module, its air control volume and the energy balance with respect to the adjacent duct walls have the following form:

where the variable

(J/K) indicates the heating element thermal capacity,

(J/K) is the thermal wall capacity (insulated plywood),

(J/kg·K) represents the air specific heat capacity,

(m

2) is the cross-sectional area of the duct,

(kg/m

3) denotes the air density,

represents the supplied constant heat gain, whilst

U (J/m

2·K) indicates the heat transfer coefficient. Note that in Equations (1)–(3), the term

(J/K) indicates the product of the heat transfer coefficient

U (J/m

2·K) with the efficient surface area,

A (m

2), through which the heat is transmitted and regarding the TU module. On the other hand,

(J/K) indicates the coefficient with reference to the inner duct wall, whilst

(J/K) denotes the same term regarding the outer duct wall.

The variables

(K),

(K) and

(K) denote the average heating element temperature, the wall temperature and outside air temperature, respectively. Note that the air surrounding the heating element is assumed to be perfectly mixed. Therefore, the outlet air temperature

is equal to the mean temperature of the whole control volume under the lumped parameter modelling approach (see Equation (

1)). Moreover, the thermal capacity of the air passing thought the TU element of

Figure 2 is assumed to be very small, so that the heat transfer between the heating element and the air is instantaneous. Under this assumption, the left side of Equation (2) is zero. Finally, in Equation (3), it is assumed that the heat loss occurs only through the walls of the duct.

A standard thermocouple type K has been used to measure the air temperatures. The accuracy is around 1

∘C for the whole measurement range. The airflow has been measured using a Hot Wire Thermo-Anemometer with a declared accuracy of

. For more details regarding the TU module, which is beyond the scope of this paper, the interested reader is referred to [

9].

The authors in [

9] showed that the complete dynamic behaviour of the TU module is described by a continuous-time time-invariant nonlinear model consisting of a product of two second-order continuous-time time-invariant transfer functions in the form of Equation (

4):

where

s denotes a differential operator. The parameters

,

,

and

of the model in the form of Equation (

4) were obtained by using a refined instrumental variable method described in [

9]. These values are reported in

Table 1.

The model is considered to be of low complexity yet achieves high simulation performance. The physical meaningfulness of the model provides enhanced insight into the performance and functionality of the system. In return, this information can be used during the system simulation and improved model-based and data-driven control designs for temperature regulation, as shown in the following sections.

4. Simulation Results

The control strategies summarised in

Section 3 were applied to the simulated TU process of Equation (

4). The achieved results shown in this section have been obtained in the MATLAB

® and Simulink

® environments using the most appropriate development tools. These control solutions will be compared in terms of a performance index represented by the mean sum of squared error (

) computed via Equation (

21):

where

N is the total number of samples.

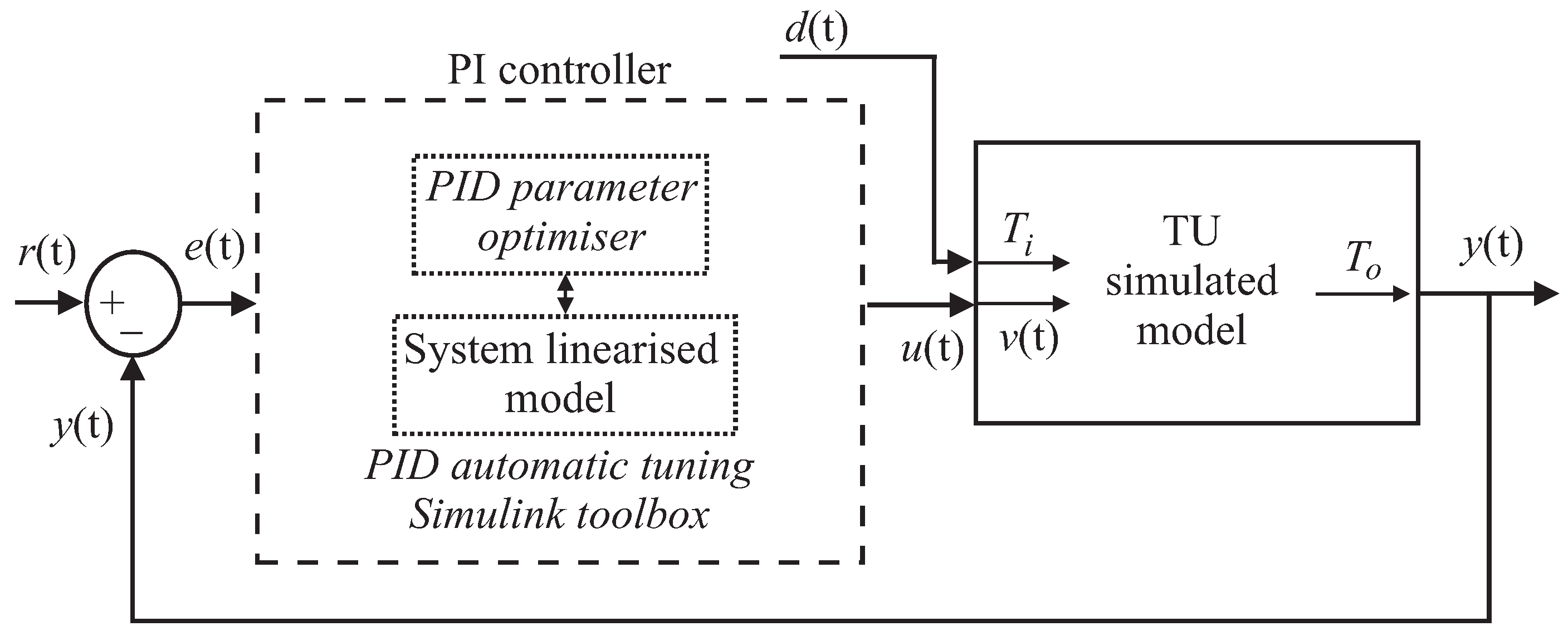

As already remarked, many HVAC systems are controlled via standard PID regulators. Therefore, the first results are achieved by exploiting a regulator in the form of Equation (

6) applied to the TU simulated model as represented in

Figure 3. Note that in the scheme of

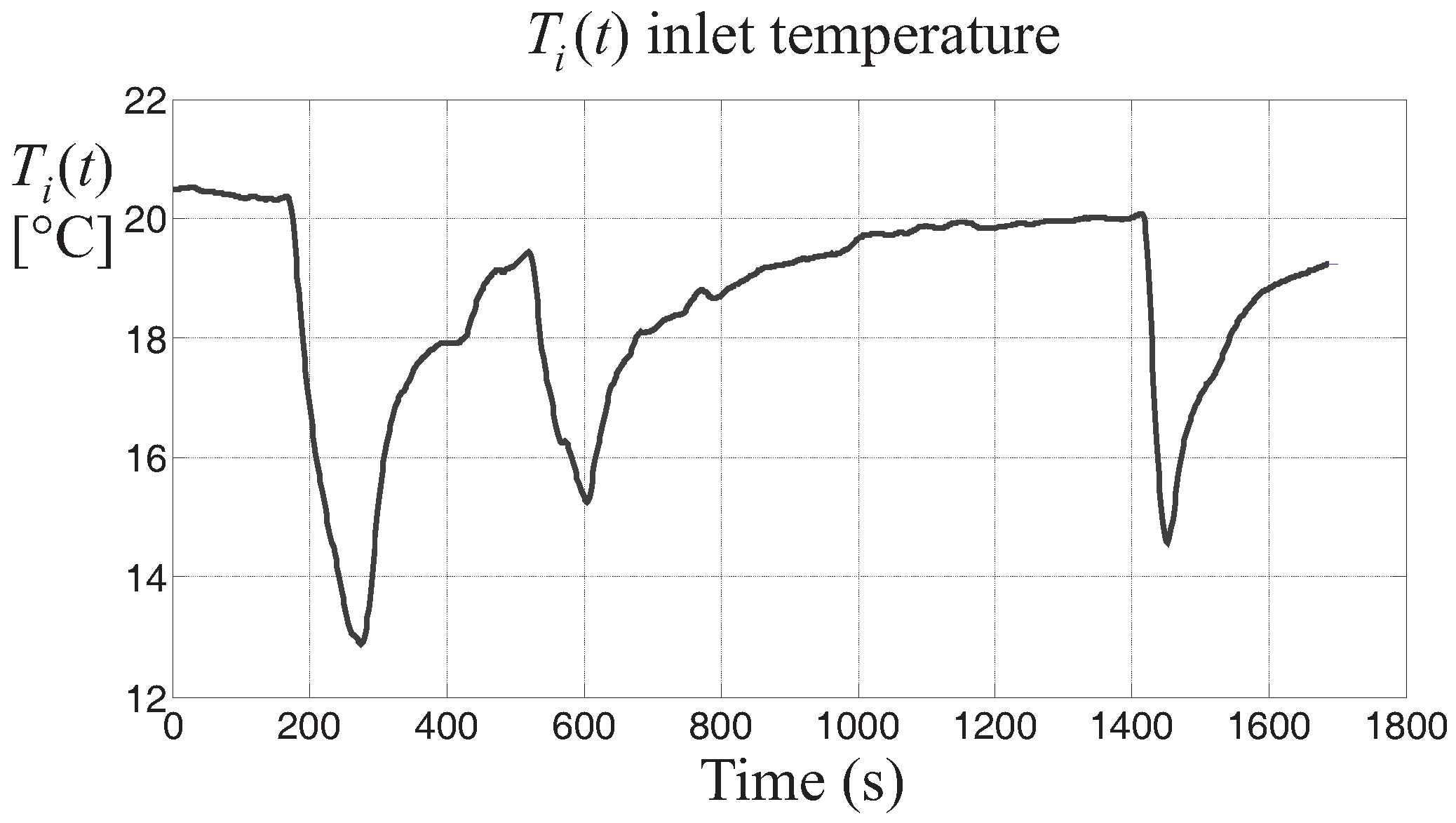

Figure 3, the control input

is the inlet air speed

, whilst the inlet air temperature

is considered as measurable disturbance

, which is shown in

Figure 4.

With reference to this control strategy, the optimal controller gains are computed using the automatic PID tuning procedure from the PID Simulink® block. The proportional, integral and derivative gains have been determined as , and , respectively. The derivative filter time–constant has been estimated as .

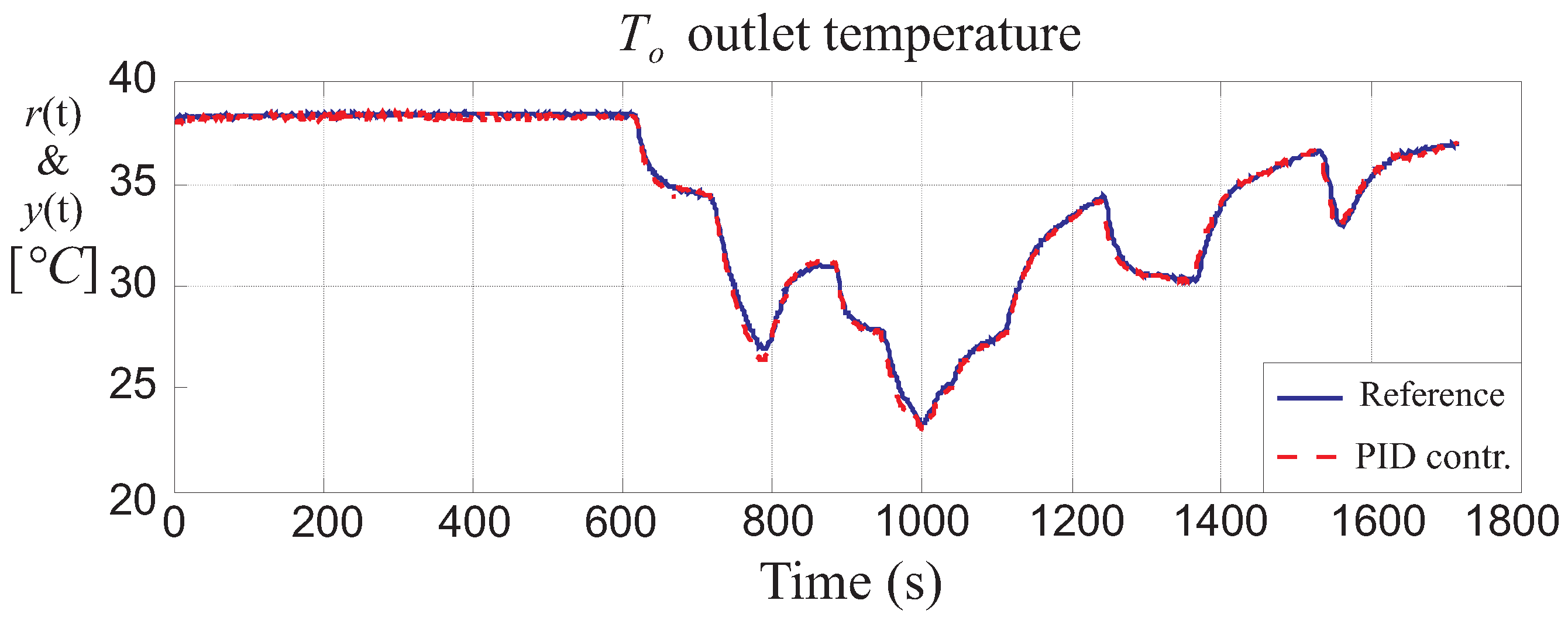

Figure 5 represents the set-point

(blue continuous line) and the TU measured output

(red dashed line) regulated via the PID standard controller. With this methodology, the PID regulator is able to guarantee a response with settling time

s and maximum overshoot

. These values are derived by applying a step change in the reference signal

from 39 °C to 40 °C. The tracking error evaluated via Equation (

21) is

.

Note that the reference signal

considered for control purpose, i.e., the outlet air temperature

represented also one of the excitation signals exploited for the identification of the TU model described in [

9]. Moreover, the authors have exploited this reference signal since it guarantees the correct working conditions and the validity of the identified model of Equation (

4).

It is worth observing that PID standard controllers can provide sufficient robustness properties after a straightforward tuning phase, thus representing interesting and easy to use solutions with simple and viable implementation. However, despite these features, the achieved control laws might not be sufficiently efficient in terms, e.g., of energy consumption and maintenance costs, when applied to HVAC systems. Due to these possible limitations, the paper has investigated alternative control strategies for achieving improved performances. To this aim, the PID regulator obtained via the auto-tuning procedure is regarded as a reference controller for the computation of advanced and alternative control strategies.

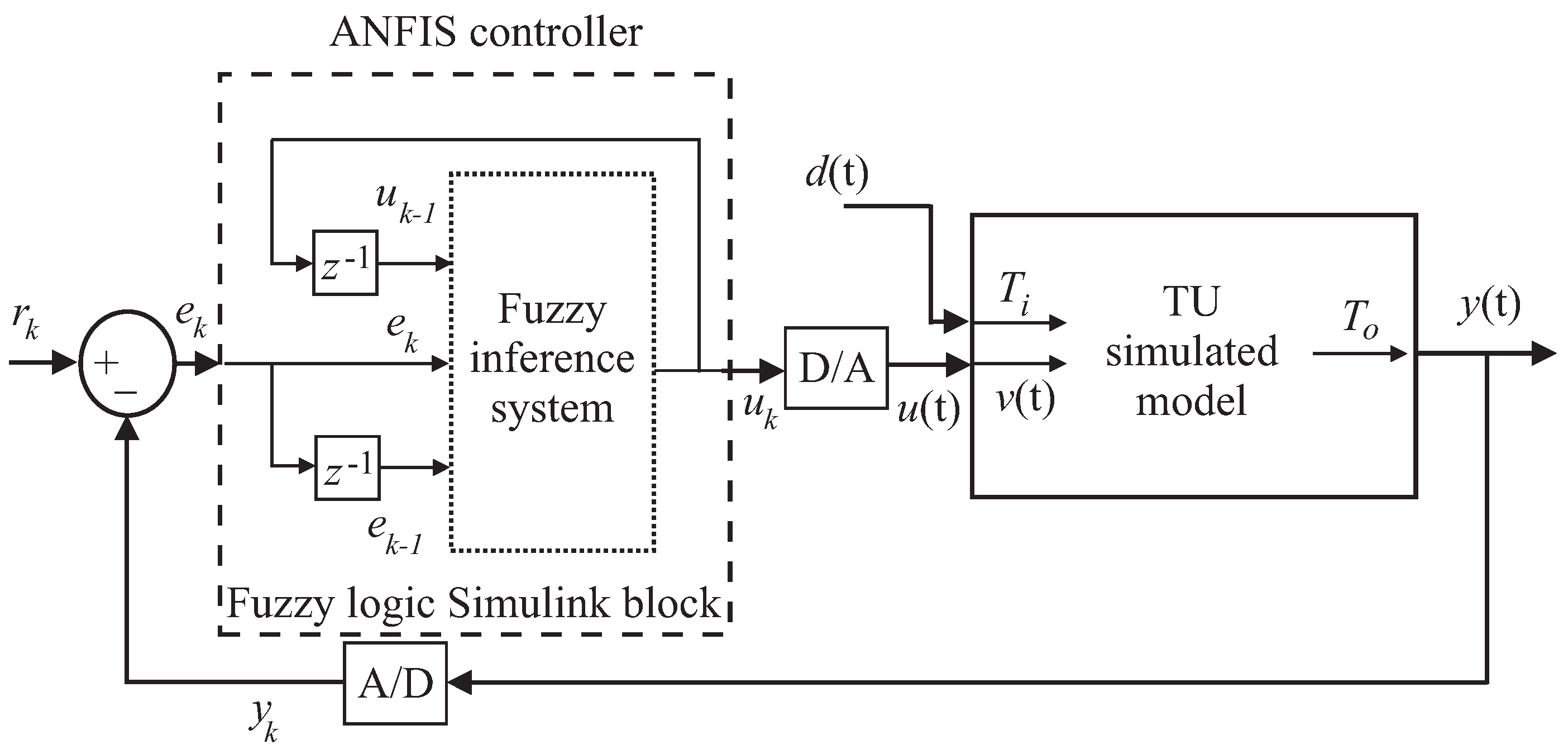

First, a TS fuzzy model of the controller has been derived using the fuzzy identification method recalled in

Section 3.2. The procedure exploited the so-called model reference control (MRC) approach described, e.g., in [

49]. In this way, the TS fuzzy controller is derived via the ANFIS tool, with a sampling interval

s.

Figure 6 reports the diagram of this control solution, where this fuzzy regulator uses

Gaussian membership functions and a number of delayed input and output samples

.

Figure 6 highlights also that the antecedent vector of the ANFIS tool is

.

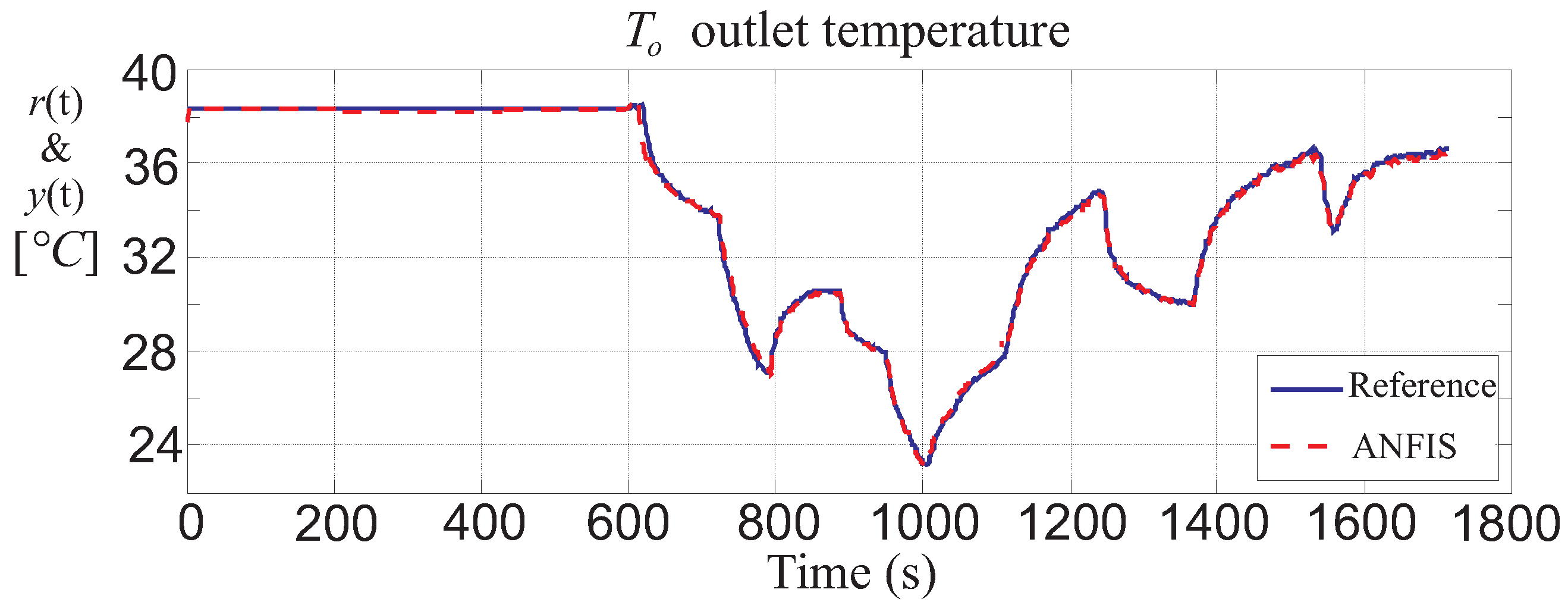

On the other hand,

Figure 7 reports the achieved performance of the regulator obtained with the ANFIS tool by comparing the reference

(continuous blue line) and controlled output

(red dashed line). In this case, the settling time is

, with a maximum overshoot

and

.

This work also proposes the derivation of a fuzzy controller in the form of Equation (

11), whose structure and parameter estimation relies on the FMID tool. This tool is able also to provide the estimation of the fuzzy membership functions

in Equation (

11).

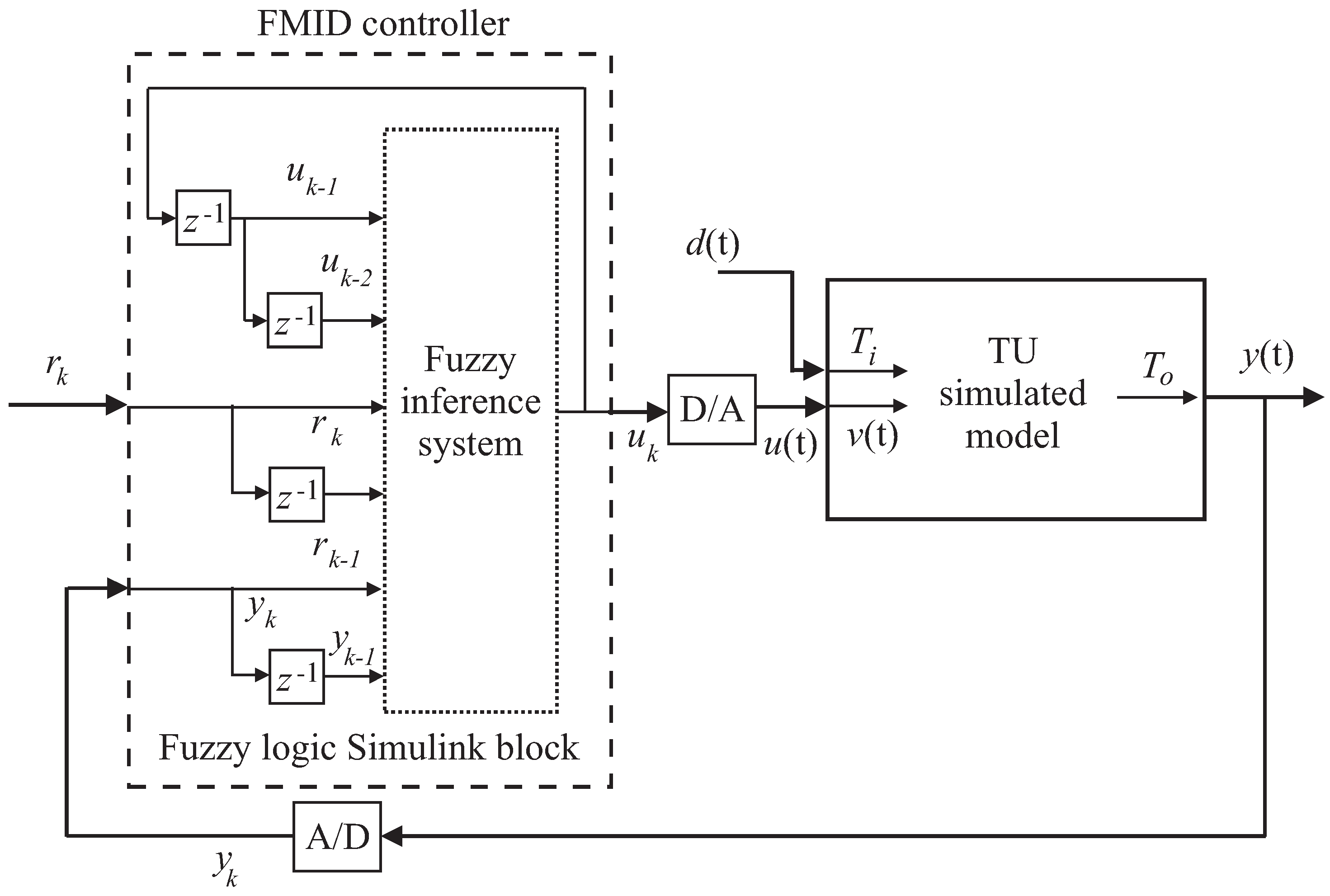

Once the structure of this TS fuzzy regulator has been achieved, the obtained regulator is sketched in

Figure 8, for an optimal number of clusters

and delays

. For this fuzzy system, the antecedent vector is defined as

.

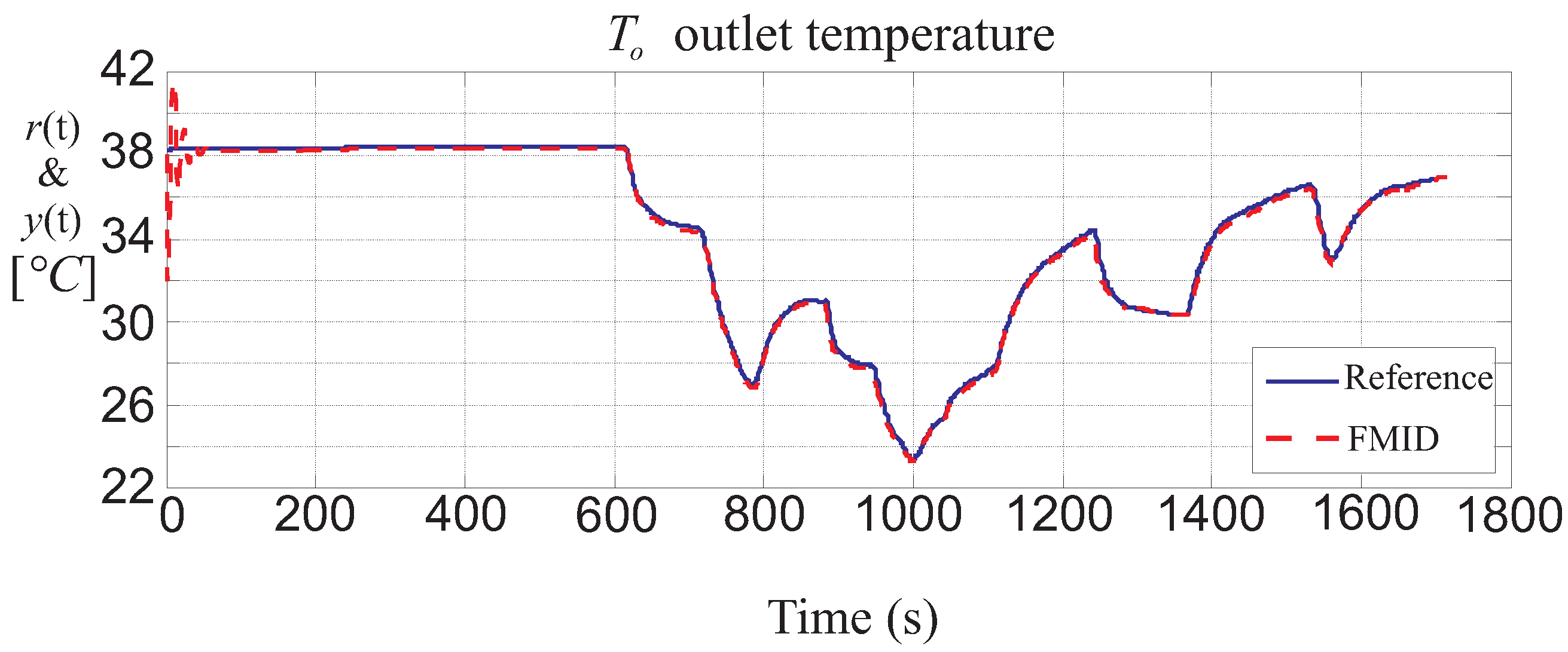

The results achieved by this TS fuzzy regulator obtained via the FMID library of the MATLAB

® environment are summarised in

Figure 9. In this situation, the set-point

(blue continuous line) is tracked with an

. On the other hand, the step transient response presents a settling time

s and a maximum overshoot

. Finally, it is worth nothing that the high overshoot at the beginning of the simulation in

Figure 9 is due to the initial conditions of the delay blocks of the fuzzy controller represented in

Figure 9 that are zero.

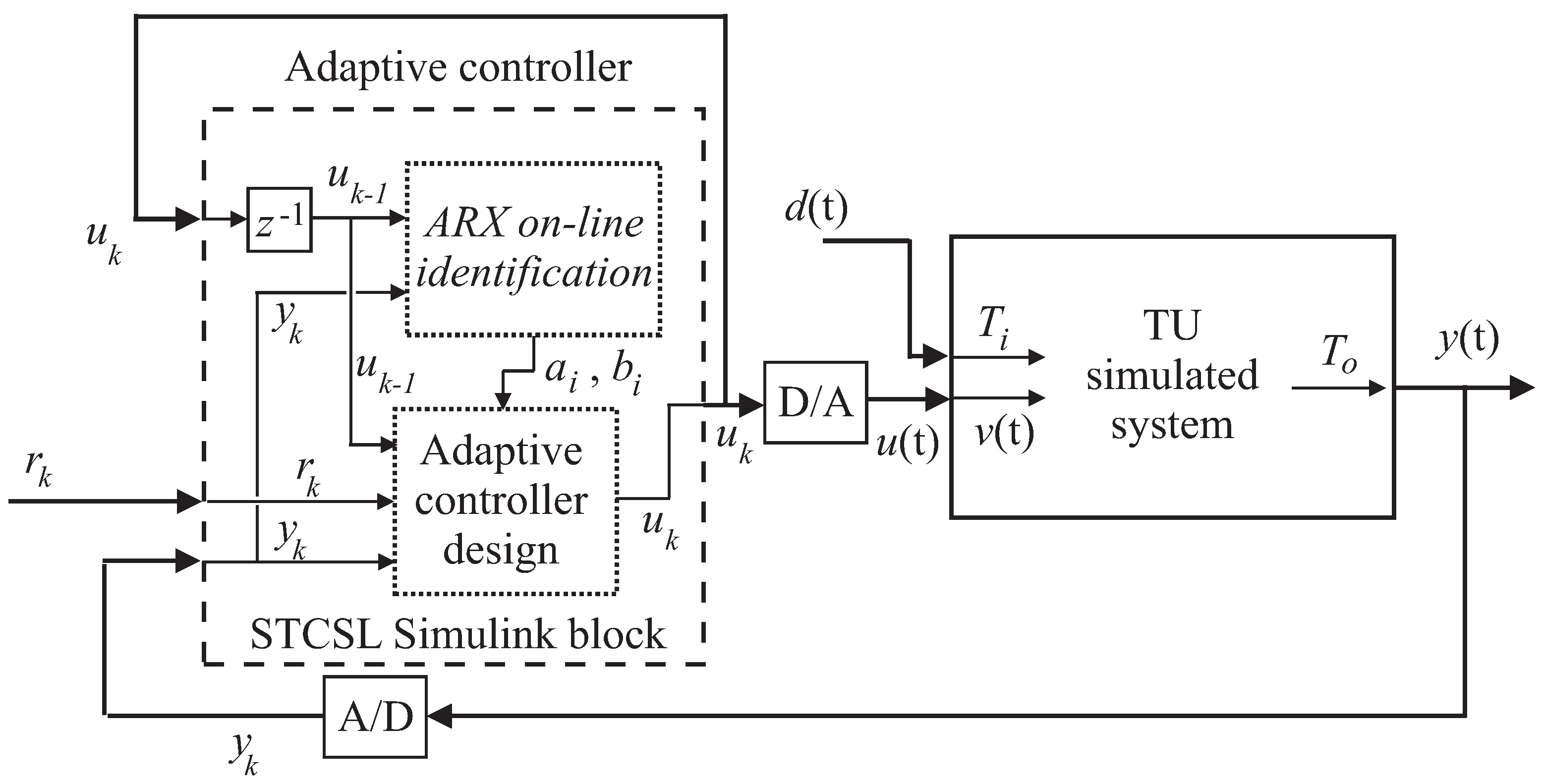

A further class of regulators has been considered in this work, and an adaptive controller has been developed according to the strategy recalled in

Section 3.3.

The diagram of the adaptive compensator in the form of Equation (

13) is shown in

Figure 10, which is applied to the TU simulated model. The time-varying parameters of the difference model of Equation (

12) have been recursively estimated by considering appropriate values of

δ and

in the polynomial

of Equation (

16), which represent the damping factor and the natural resonance frequency of the closed-loop controlled system.

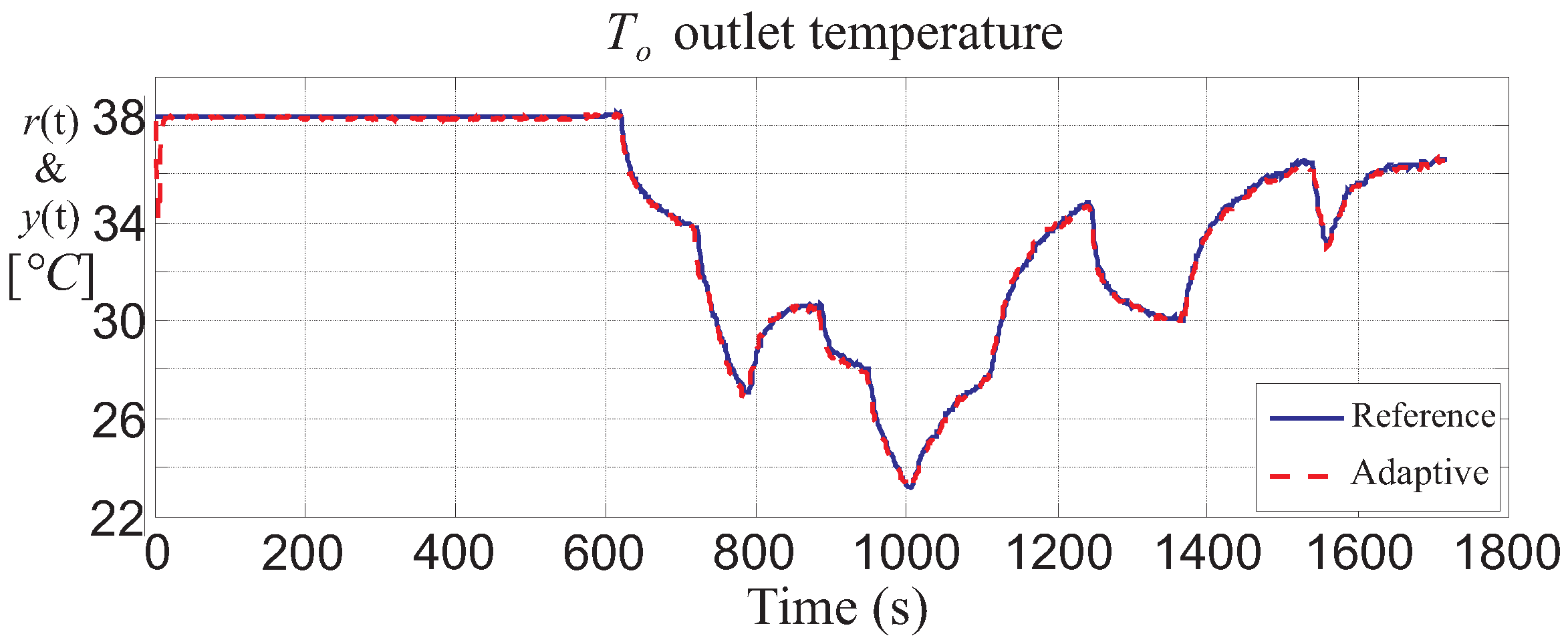

The tracking performances of the designed adaptive controller are summarised

Figure 11. In particular, the settling time of the step transient response is

s with a maximum overshoot

, whilst the achieved tracking error corresponds to an

.

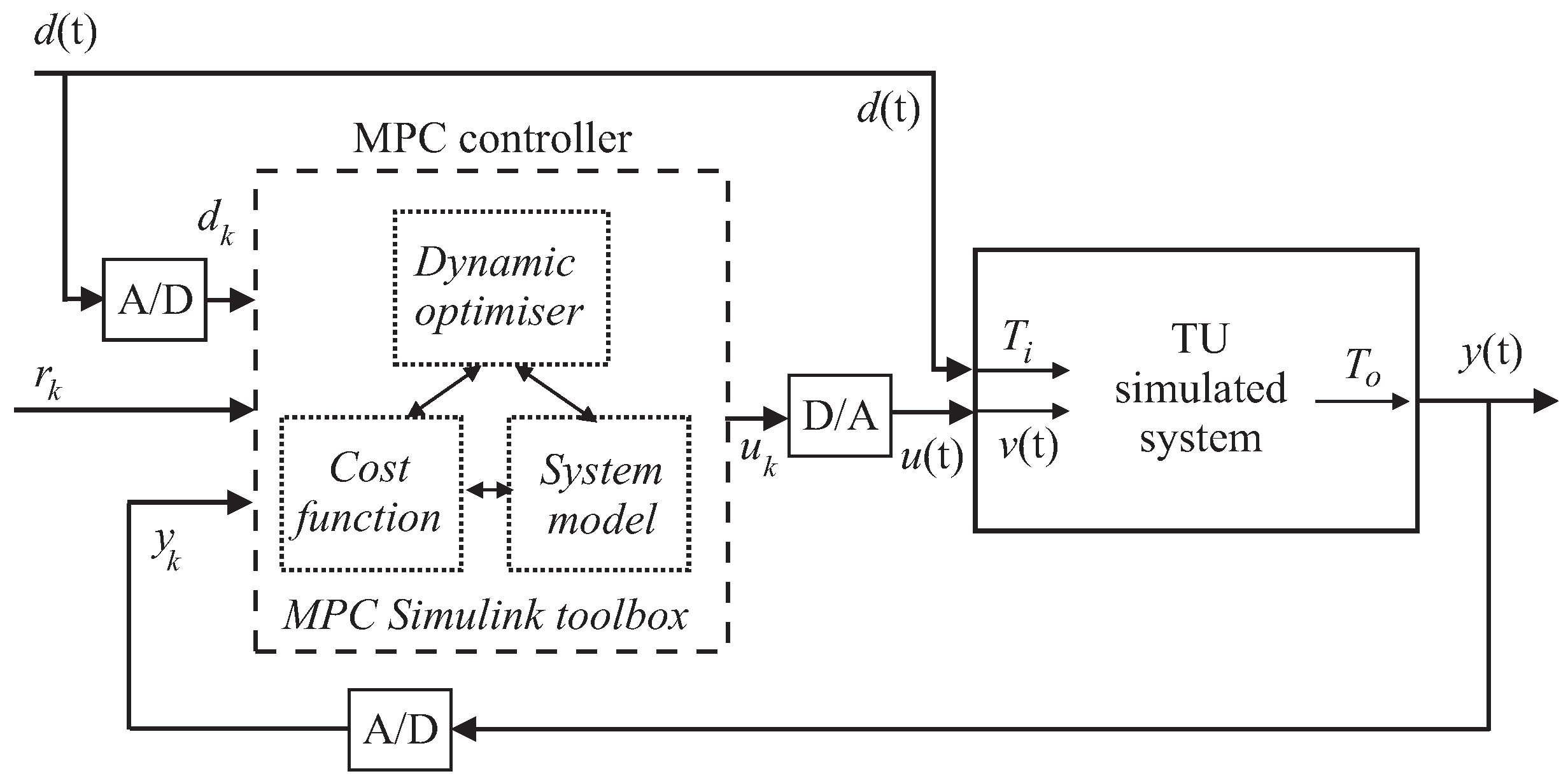

Finally, with reference to the MPC strategy summarised in

Section 3.4,

Figure 12 reports the block diagram of the MPC applied to the TU module via the D/A and A/D devices. The scheme of

Figure 12 assumes that the disturbance signal

can be measured and exploited by the MPC block.

It is worth noting that in this case, the MPC design exploits a prediction horizon of

and a control horizon of

for the minimisation of the cost function

J of Equation (

17). Moreover, the weighting coefficients of this cost function

J are settled to

and

in order to minimise possible abrupt changes of the control input

that would increase the energy consumption and the controlled system efficiency.

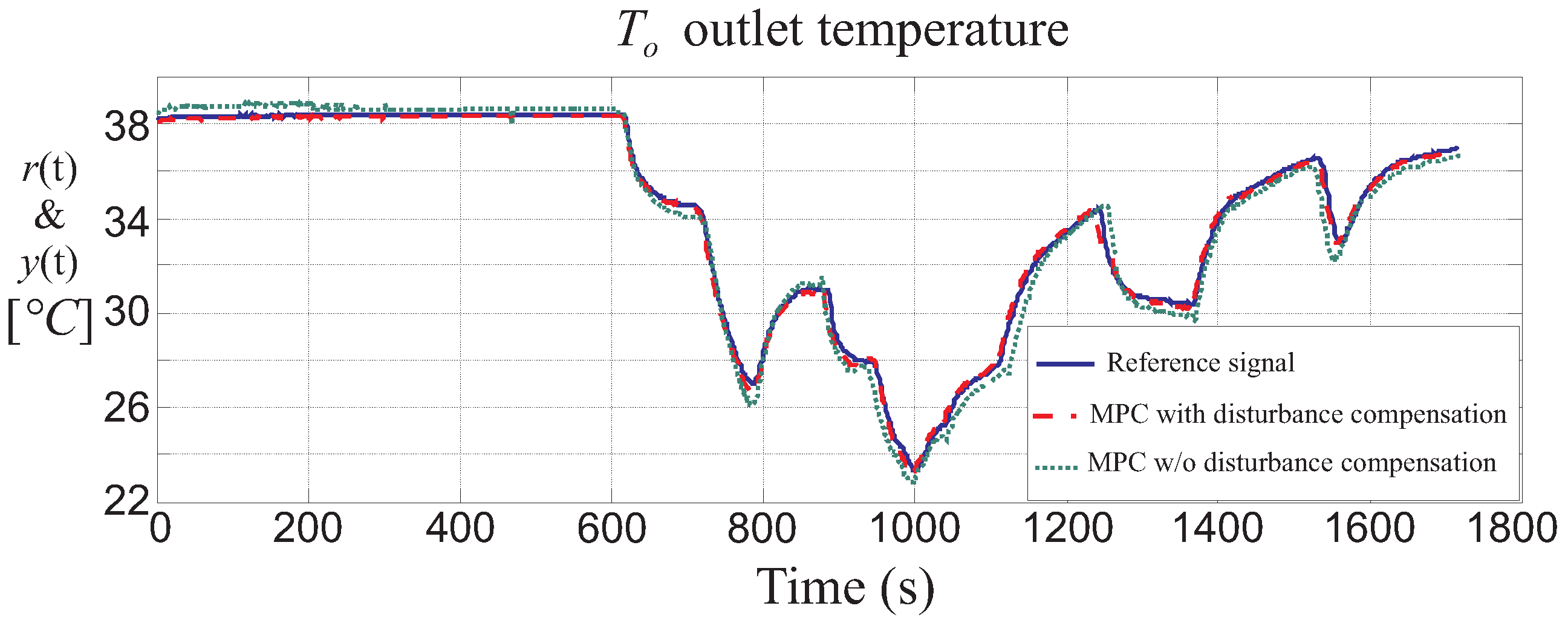

In this situation, as shown in

Figure 13, the step transient response of the controlled TU module presents a settling time

s and a maximum overshoot

, with a tracking error

.

Figure 13 shows also the results obtained with the MPC control using the linearised state-space model of Equation (

19), when the disturbance

does not feed the MPC block of

Figure 12.

Figure 13 highlights that the knowledge of the measured disturbance

that is exploited by the MPC block of

Figure 12 improves the performance of the linear MPC strategy.

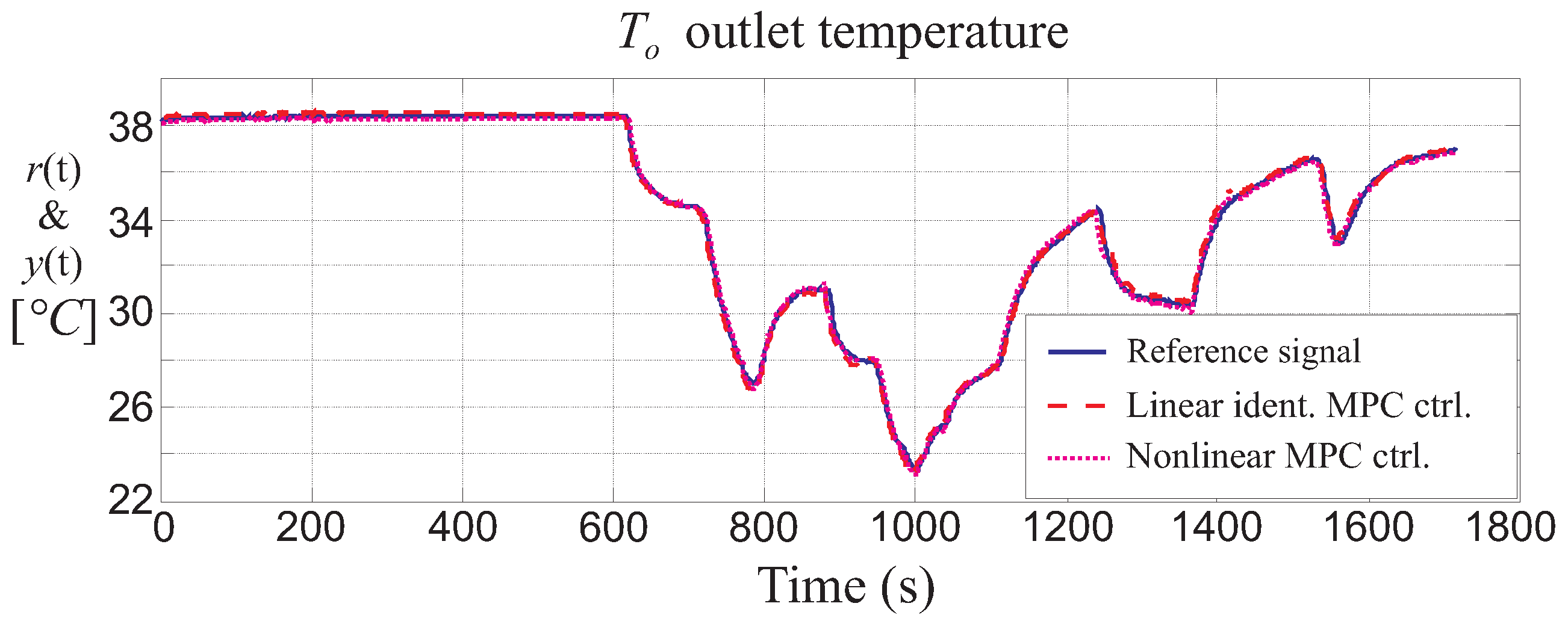

On the other hand,

Figure 14 shows the comparison between the MPC design performed using the identified state-space model of Equation (

20) and the nonlinear dynamic MPC scheme relying on a neural model of the controlled process sketched in

Section 3.4.

Figure 14 highlights that the nonlinear MPC leads to slightly better results with respect to the linear MPC with the identified state-space model of Equation (

20).

In order to analyse the obtained performance and compare the results achieved with the application of the control strategies proposed in this work,

Table 2 summarises the features of these regulators in terms of step response settling time

, maximum overshoot

and tracking error

.

With reference to

Table 2, the MPC schemes allow one to achieve the best performances with respect to the proposed indices. The superior results obtained by this control scheme seem to derive from the ability of the MPC methodology to anticipate future events, thus being able to take control actions accordingly. Moreover, the benefits of exploiting both an identified state-space model and a nonlinear prototype of the controlled process in connection with the knowledge of the measured disturbance

seem quite clear from the results reported in

Table 2.

On the other hand, also the TS fuzzy controller derived via the ANFIS toolbox in connection with the MRC principle seems to present interesting features in terms of step response settling time, maximum overshoot and tracking error when compared to the other methodologies. This property can be due to the ANFIS strategy that relies on a fuzzy inference system. In fact, the ANFIS scheme includes the capabilities of both the neural network and the fuzzy logic tools, with the advantage of integrating their benefits in one whole structure. Moreover, as already observed, the proposed fuzzy approach that integrates learning capability is able to approximate the process nonlinear behaviour with an error depending on the required accuracy level. The adaptation strategy implemented in ANFIS presents interesting computationally-efficient features since it relies on genetic algorithms used to estimate the best model structure and its parameters [

49].

Note, however, that the standard PID regulator leads to achieving the second best step response settling time since it exploits the auto-tuning scheme implemented in the Simulink® PID block in order to optimise its parameters. This feature can represent an important aspect when a good trade-off between control performance and implementation simplicity is required. In general, the standard PID control law is usually based on the process controlled variable and not on the knowledge of the underlying process behaviour. However, on the one hand, an automatic tuning of its parameters allows the PID controller to manage general control requirements, also in terms of step response rise time, closed-loop bandwidth, maximum overshoot and system oscillation amplitude. On the other hand, PID controllers cannot guarantee any control optimality and, in some situations, the overall system stability, but provides a viable and easy-to-use tool for providing a simple control law with acceptable performance.

4.1. Control Solution Sensitivity Evaluation

This study has considered further simulations that are useful for analysing the reliability and robustness characteristics of the considered control solutions with respect to possible parameter variations. This approach represents a way for analysing the well-known model-reality mismatch issue that can represent a limitation of the achievable performance of the proposed controller designs.

To this aim, the Monte Carlo (MC) tool is the key point since the controller behaviour and the design strategy depend on this model-reality mismatch, which can derive, e.g., from the model nonlinearity and its approximation, the uncertainty and disturbance terms, as well as input and output measurement errors. Therefore, the MC analysis simulates the behaviour of the controlled TU model when its parameters are described as Gaussian variables with mean values equal to the nominal ones and standard deviations of of the corresponding parameter values.

Under these assumptions, the analysis of the closed-loop control schemes has been performed by computing the best, average and the worst values of the

index of Equation (

21) evaluated over 500 MC runs. These values are summarised in

Table 3.

On the basis of the results of

Table 3, it seems clear that the MPC designs lead to the best performance when the modelling of the controlled system and the measured disturbance

is taken into account. On the one hand, the MPC design can rely on the knowledge of a state-space model in the form of Equation (

18), derived from both a linearisation procedure or an identification experiment. On the other hand, the MPC design can use an identified nonlinear model of the process, as remarked at the end of

Section 3.4. The overall methodology is based on the optimisation of the cost function of Equation (

17). However, once the description of the controlled process has been available as a linear or nonlinear dynamic model, the MPC design is quite simple and straightforward.

The control schemes relying on the ANFIS and the FMID tools can lead to interesting control performance, but with a learning phase that can be computationally heavy and time consuming, especially when the numbers of rules K, the antecedents and the model delays n are high.

Similar considerations hold for the adaptive controllers, which can track possible variations of the controlled model parameters, but with possibly complex design procedures required for computing the controller coefficients.

Standard PID regulators require simple design and simple implementation, but in general, they lead to limited performance, which can imply lower efficiency when applied, e.g., to HVAC systems. The same remarks are valid for the fuzzy controllers relying on AI tools, whose parameters can be easily estimated from the input-output data acquired from the controlled process. However, a further optimisation stage can be required, which sometimes is time consuming, but these fuzzy solutions can enhance the achievement of advanced performance indices.

It is worth observing that the MC methodology proposed in this work seems to represent the key point for the validation and the verification of the proposed control solutions when applied to the TU module in the presence of modelling and measurement errors, uncertainty and disturbance terms.

Note finally that the control methodologies followed by the analysis procedures shown in

Section 3 and

Section 4 are developed using the MATLAB

® and Simulink

® software tools, in order to automate the overall design and simulation phases. These feasibility and reliability studies are of paramount importance for real application of control strategies once implemented for future air conditioning system installations.