The Heat Transfer of Microencapsulated Phase Change Material Slurry and Its Thermal Energy Storage Performance of Combined Heat and Power Generating Units

Abstract

:1. Introduction

2. Thermal Physical Characteristics of the Selected MPCMS

3. Flow and Heat Transfer for MPCMS

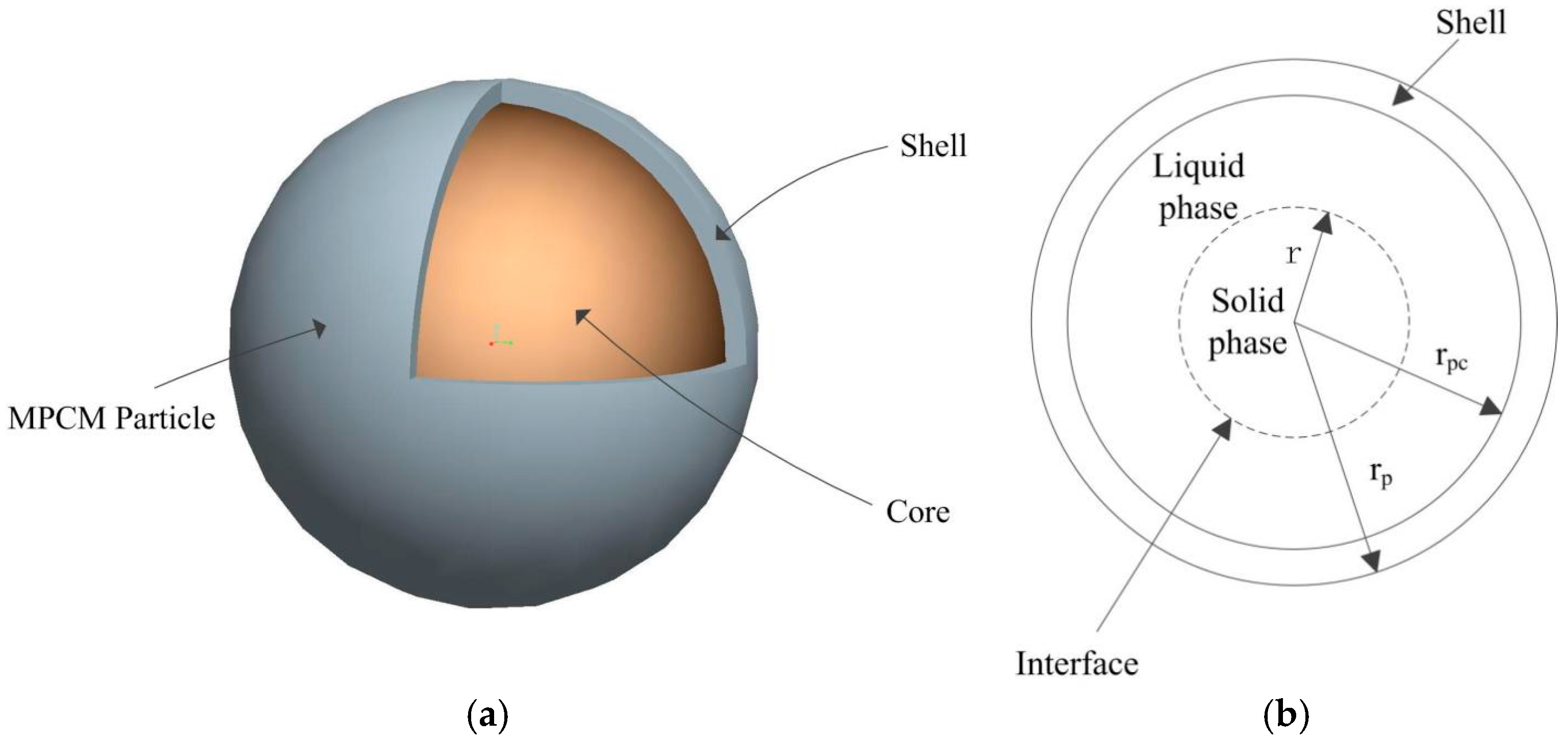

3.1. Simulation for Single MPCM Particle

3.2. Simulation for MPCMS

- (1)

- The fluid can be considered as a Newtonian fluid.

- (2)

- The MPCM particles are uniformly distributed in the slurry.

- (3)

- The viscous dissipation and axial heat conduction can be ignored.

- (4)

- The no-slip condition is considered.

- (5)

- The interfacial thermal resistance for MPCM particles is too small to be neglected.

4. Results with Discussions

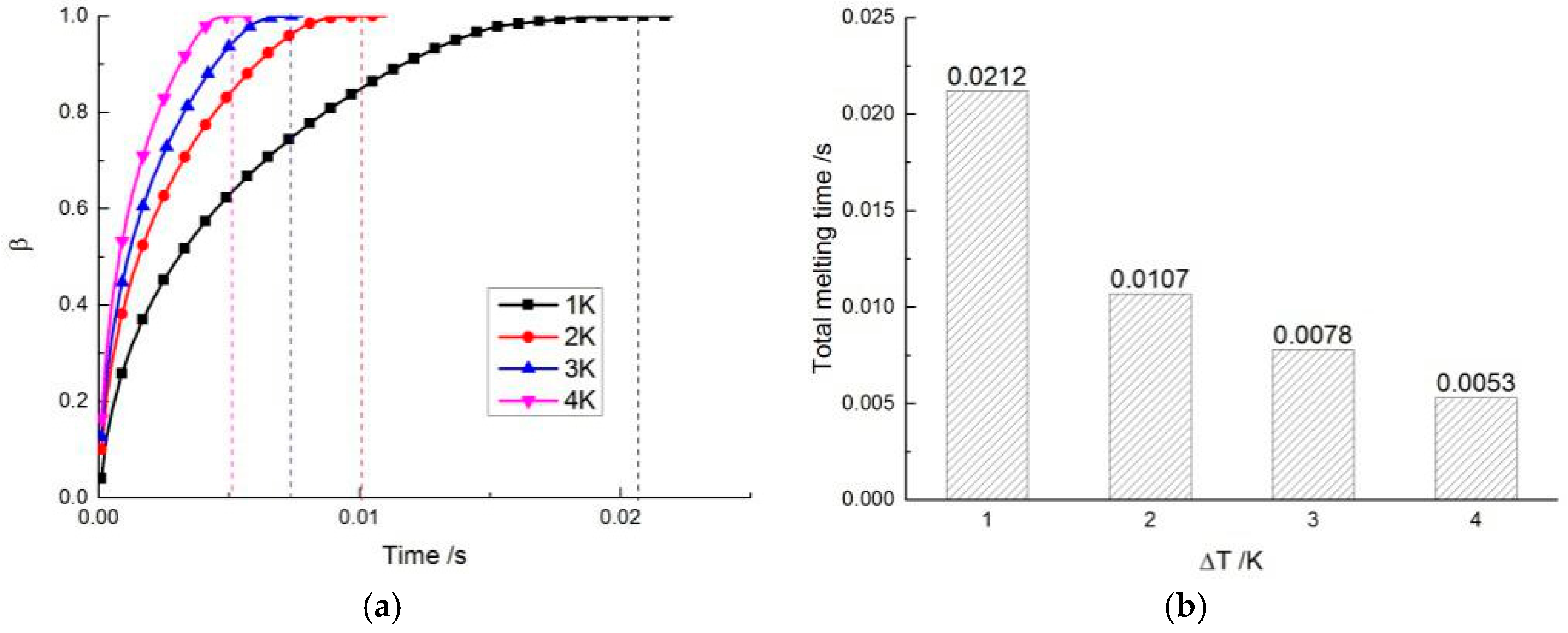

4.1. The Melting Process of a Single MPCM Particle

4.2. MPCMS Heat Transfer in Circular Tube

4.3. A 300 MW CHP Unit Case Study

5. Conclusions

- (1)

- The MPCM particle’s total melting time is very short, which indicates that the thermal resistance between the carrier fluid and the MPCM particle is very small. This proves that the equivalent specific heat model used in heat transfer simulations is effective.

- (2)

- Both the wall temperature and the ball diameter are important factors for the MPCM particle melting process. A ball with a small diameter is ideal in MPCMS. Raising ∆T cannot always achieve obvious improvement when ∆T is high enough. So the wall temperature is recommended to choose in a small range higher than the melting point.

- (3)

- It was found that the heat transfer characteristics of MPCMS are different depending on whether the heat transfer is in a laminar and a turbulent flow. Only in a turbulent flow condition will there be an isothermal process along the tube. The heat transfer characteristics in a turbulent flow are much greater than those in a laminar flow.

- (4)

- The research also indicates that thermal storage system increases the peak shaving capacity of cogeneration units. For a 300 MW CHP unit, the peak shaving capacity increases from 52.2 to 92.19 MW, which is an improvement of 81.4%.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Global Wind Energy Council (GWEC). Global Wind Report 2016-Annual Market Update. 2016. Available online: http://www.gwec.net/publications/global-wind-report-2/global-wind-report-2016-annual-market-update (accessed on 10 September 2017).

- Hu, Y.; Huang, W.; Wang, J.; Chen, S.; Zhang, J. Current status, challenges, and perspectives of Sichuan’s renewable energy development in Southwest China. Renew. Sustain. Energy Rev. 2016, 57, 1373–1385. [Google Scholar] [CrossRef]

- Luo, G.; Li, Y.; Tang, W.; Wei, X. Wind curtailment of China’s wind power operation: Evolution, causes and solutions. Renew. Sustain. Energy Rev. 2016, 53, 1190–1201. [Google Scholar] [CrossRef]

- Fan, X.; Wang, W.; Shi, R.; Li, F. Analysis and countermeasures of wind power curtailment in China. Renew. Sustain. Energy Rev. 2015, 52, 1429–1436. [Google Scholar] [CrossRef]

- Delgado, M.; Lázaro, A.; Mazo, J.; Zalba, B. Review on phase change material emulsions and microencapsulated phase change material slurries: Materials, heat transfer studies and applications. Renew. Sustain. Energy Rev. 2012, 16, 253–273. [Google Scholar] [CrossRef]

- Stamatiou, E.; Kawaji, M. Thermal and flow behavior of ice slurries in a vertical rectangular channel. Part I: Local distribution measurements in adiabatic flow. Int. J. Heat Mass Transf. 2005, 48, 3527–3543. [Google Scholar] [CrossRef]

- Royon, L.; Guiffant, G. Forced convection heat transfer with slurry of phase change material in circular ducts: A phenomenological approach. Energy Convers. Manag. 2008, 49, 928–932. [Google Scholar] [CrossRef]

- HE, B.; Martin, V.; Setterwall, F. Phase transition temperature ranges and storage density of paraffin wax phase change materials. Energy 2004, 29, 1785–1804. [Google Scholar] [CrossRef]

- Sohn, C.; Chen, M. Microconvective Thermal Conductivity in Disperse Two-Phase Mixtures as Observed in a Low Velocity Couette Flow Experiment. J. Heat Transf. 1981, 103, 47–51. [Google Scholar] [CrossRef]

- Charunyakorn, P.; Sengupta, S.; Roy, S. Forced convection heat transfer in microencapsulated phase change material slurries: Flow in circular ducts. Int. J. Heat Mass Transf. 1991, 34, 819–833. [Google Scholar] [CrossRef]

- Goel, M.; Roy, S.; Sengupta, S. Laminar forced convection heat transfer in microcapsulated phase change material suspensions. Int. J. Heat Mass Transf. 1994, 37, 593–604. [Google Scholar] [CrossRef]

- Yamagishi, Y.; Takeuchi, H.; Pyatenko, A.; Kayukawa, N. Characteristics of microencapsulated PCM slurry as a heat-transfer fluid. AIChE J. 1999, 45, 696–707. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, Y. Novel insight and numerical analysis of convective heat transfer enhancement with microencapsulated phase change material slurries: Laminar flow in a circular tube with constant heat flux. Int. J. Heat Mass Transf. 2002, 45, 3163–3172. [Google Scholar] [CrossRef]

- Wang, X.; Niu, J. Performance of cooled-ceiling operating with MPCM slurry. Energy Convers. Manag. 2009, 50, 583–591. [Google Scholar] [CrossRef]

- Qiu, Z.; Zhao, X.; Li, P.; Zhang, X.; Ali, S.; Tan, J. Theoretical investigation of the energy performance of a novel MPCM (Microencapsulated Phase Change Material) slurry based PV/T module. Energy 2015, 87, 686–698. [Google Scholar] [CrossRef]

- Griffiths, P.; Eames, P. Performance of chilled ceiling panels using phase change material slurries as the heat transport medium. Appl. Therm. Eng. 2007, 27, 1756–1760. [Google Scholar] [CrossRef]

- Wang, X.; Niu, J.; van Paassen, A. Raising evaporative cooling potentials using combined cooled ceiling and MPCM slurry storage. Energy Build. 2008, 40, 1691–1698. [Google Scholar] [CrossRef]

- Huang, M.; Eames, P.; McCormack, S.; Griffiths, P.; Hewitt, N. Microencapsulated phase change slurries for thermal energy storage in a residential solar energy system. Renew. Energy 2011, 36, 2932–2939. [Google Scholar] [CrossRef]

- Vand, V. Theory of Viscosity of Concentrated Suspensions. Nature 1945, 155, 364–365. [Google Scholar] [CrossRef]

- Tian, C.; Lv, X.; Li, D.; Dong, T.; Han, X. Analysis on Thermal Economy and Peak-Shaving Capability for Combined Heat and Power (CHP) Unit in Varying Operating Conditions. Appl. Mech. Mater. 2014, 521, 508–515. [Google Scholar] [CrossRef]

| Parameters | Carrier Fluid | Core Material | Wall Material |

|---|---|---|---|

| Material | Water | Hentetracontane | Urea resin |

| Density/(kg/m3) | 998 | 870 | 1420 |

| Specific heat/(J/kg·K) | 4180 | 2200 | 1672 |

| Melting point/(°C) | - | 84.1 | - |

| Latent heat/(J/g) | - | 262.1 | - |

| conductivity/(W/m·K) | 0.67 | 0.21 | 0.56 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Zhang, X.; Yang, L.; Xu, C.; Du, X. The Heat Transfer of Microencapsulated Phase Change Material Slurry and Its Thermal Energy Storage Performance of Combined Heat and Power Generating Units. Energies 2017, 10, 1662. https://doi.org/10.3390/en10101662

Guo Y, Zhang X, Yang L, Xu C, Du X. The Heat Transfer of Microencapsulated Phase Change Material Slurry and Its Thermal Energy Storage Performance of Combined Heat and Power Generating Units. Energies. 2017; 10(10):1662. https://doi.org/10.3390/en10101662

Chicago/Turabian StyleGuo, Yonghong, Xinglong Zhang, Lijun Yang, Chao Xu, and Xiaoze Du. 2017. "The Heat Transfer of Microencapsulated Phase Change Material Slurry and Its Thermal Energy Storage Performance of Combined Heat and Power Generating Units" Energies 10, no. 10: 1662. https://doi.org/10.3390/en10101662