Modeling and Control of Fluid Flow Networks with Application to a Nuclear-Solar Hybrid Plant

Abstract

:1. Introduction

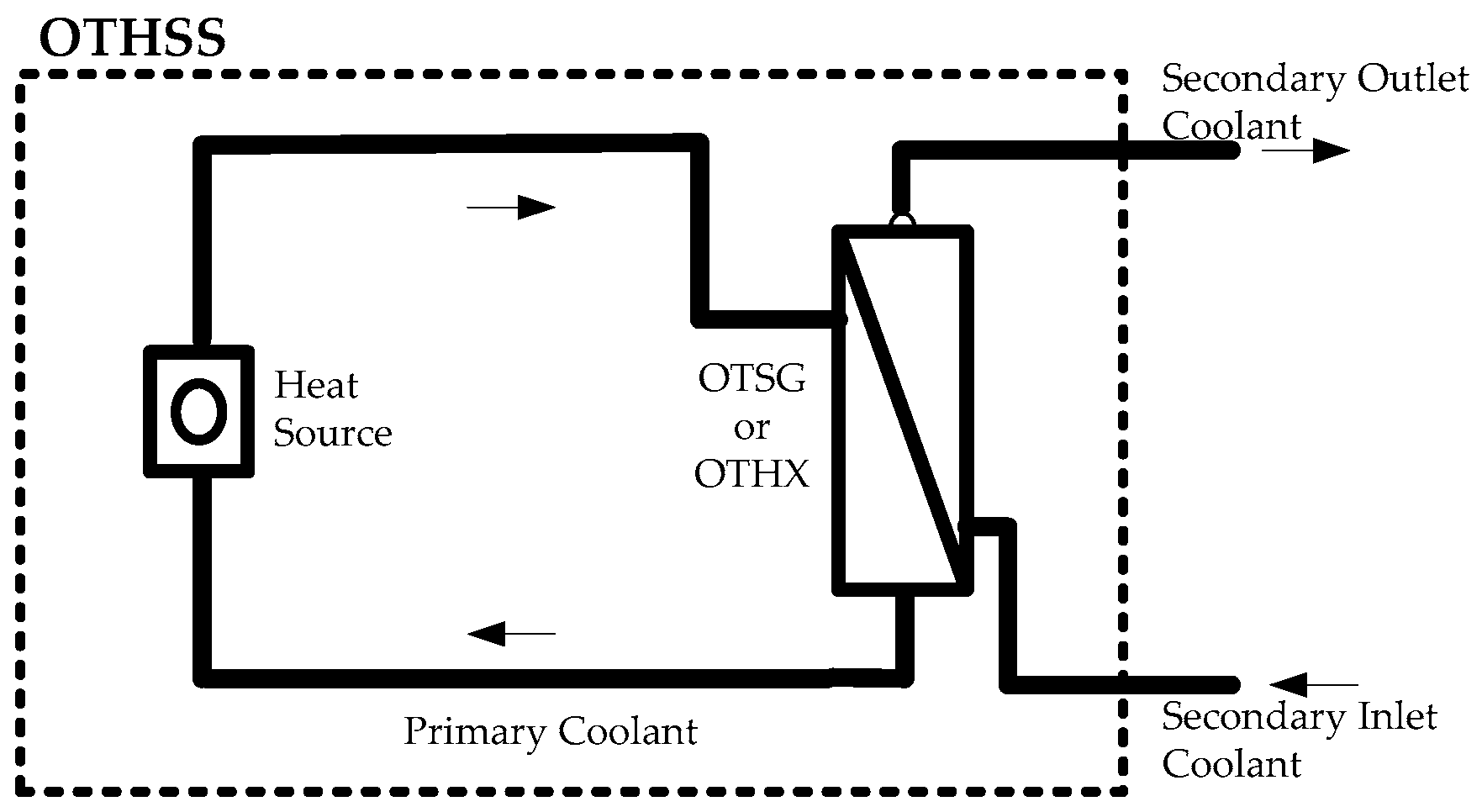

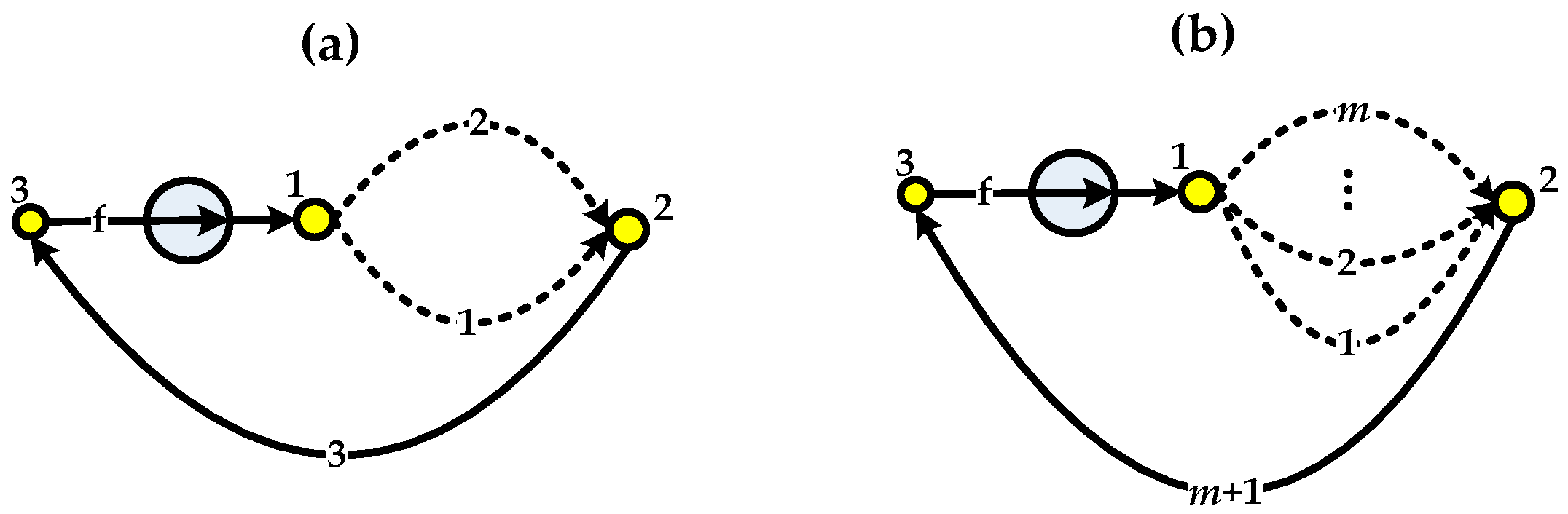

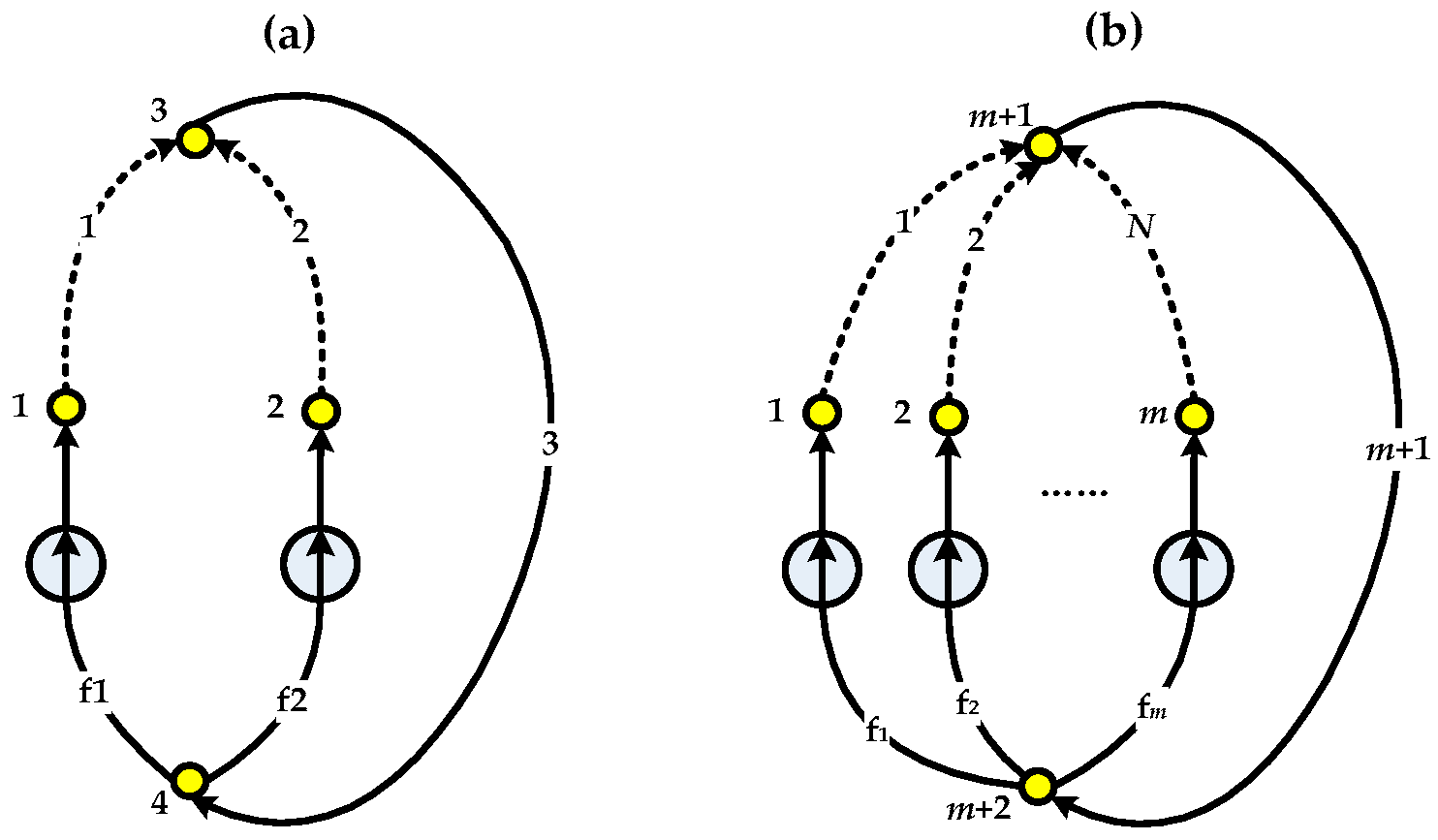

2. Nonlinear Differential-Algebraic Model

2.1. Branch Dynamics

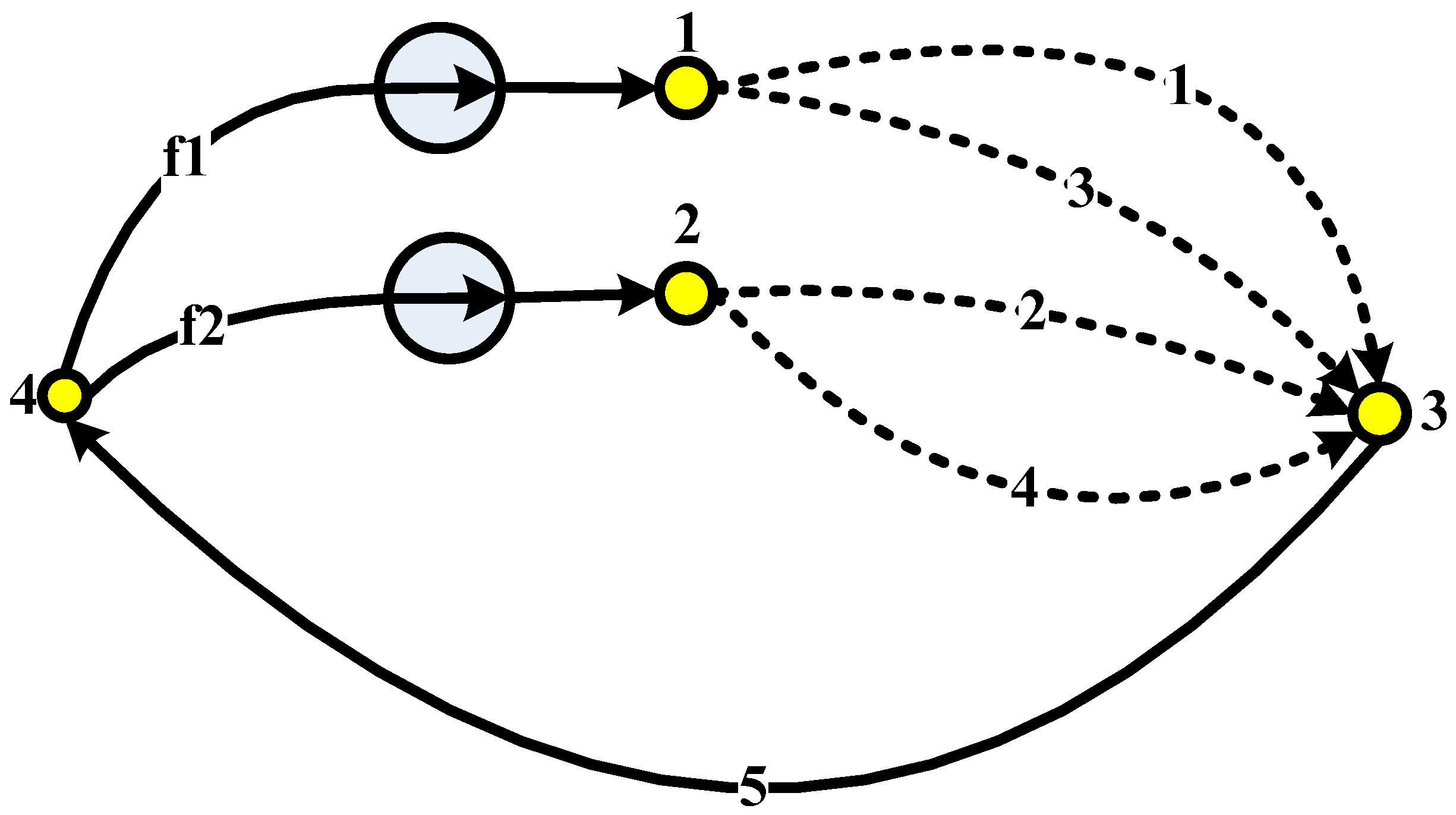

2.2. Graph Properties

2.3. Differential-Algebraic Network Model

- (A1)

- Branches 1 to l correspond to the links.

- (A2)

- Branches l + 1 to n + m correspond to tree-branches and all the fan branches are in the tree.

3. Flowrate-Pressure Control Design

3.1. State-Space Model

3.2. Globally Asymptotic Control Design

3.3. Adaptive Control Design

4. Application to a Nuclear-Solar Hybrid Plant

4.1. Feasibility of HES Based on MHTGR and STP

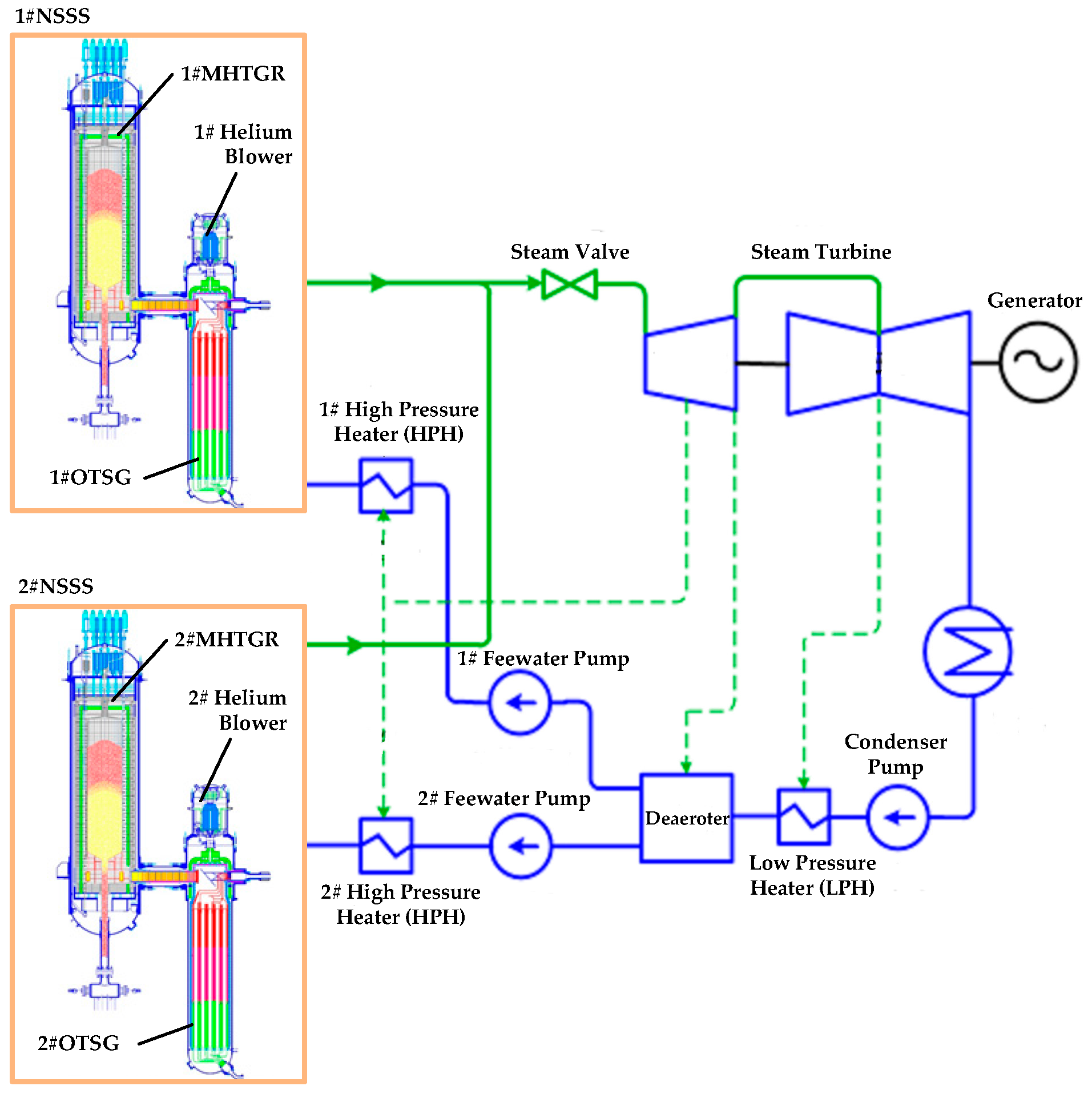

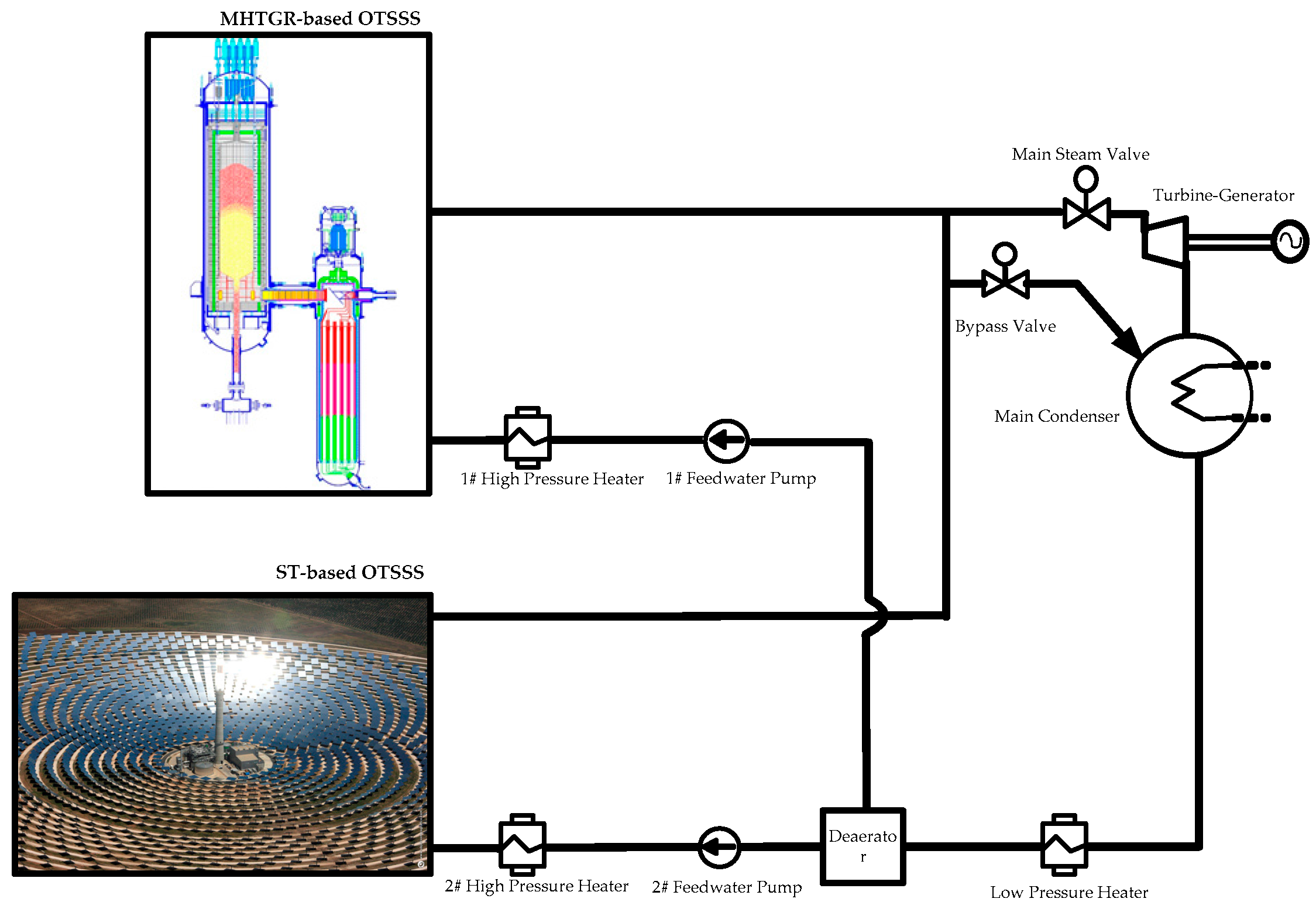

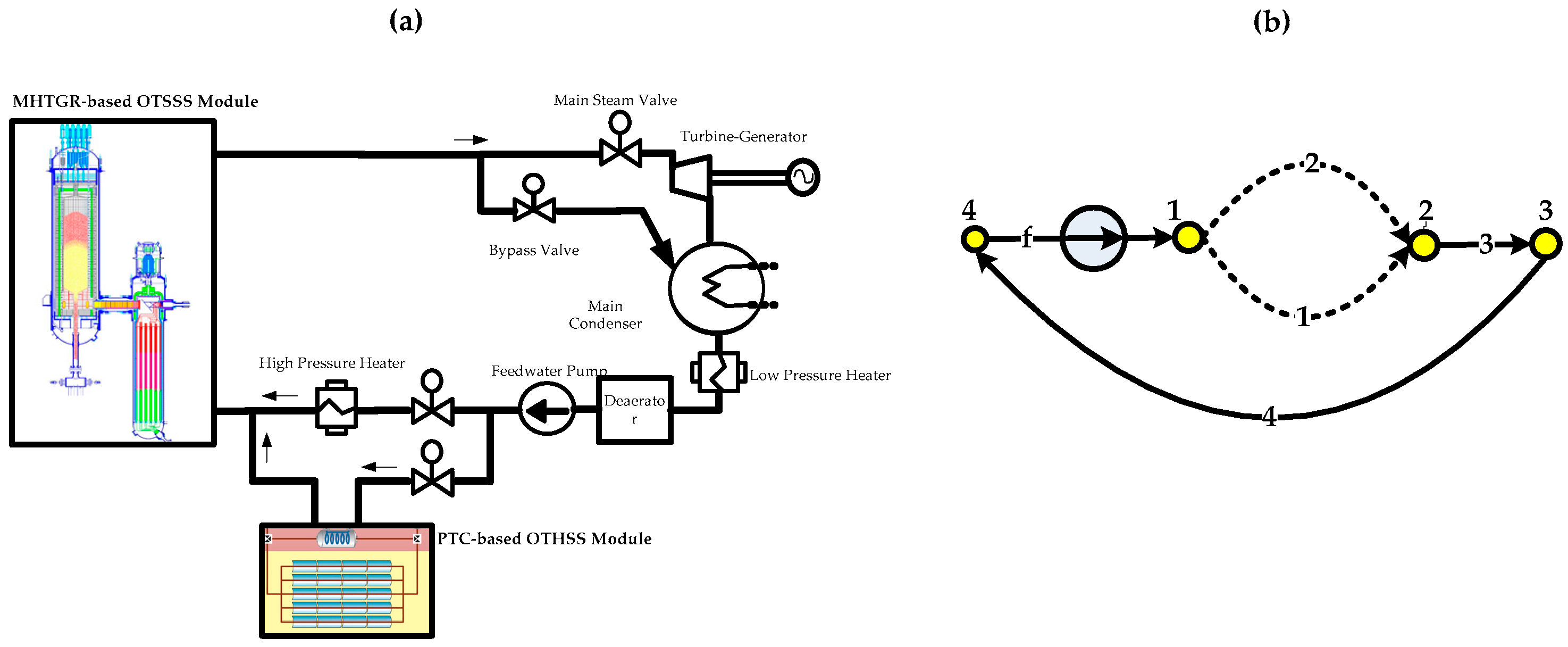

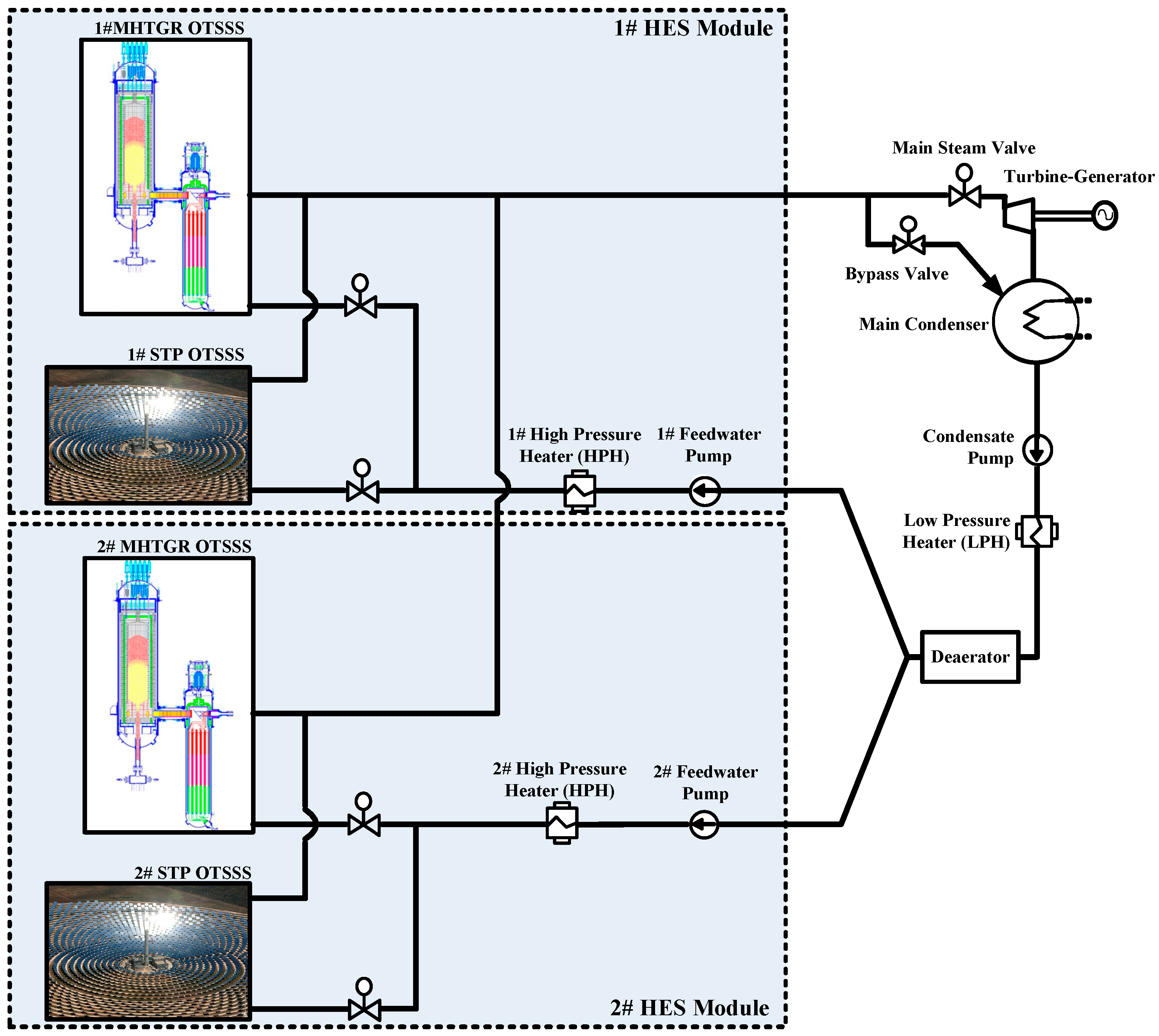

4.2. A MHTGR-STP Coupled HES

4.2.1. Schematic Diagram and Design Parameters

4.2.2. Secondary FFN and Control Strategy

4.3. Simulation Results with Discussions

4.3.1. Controller Parameters

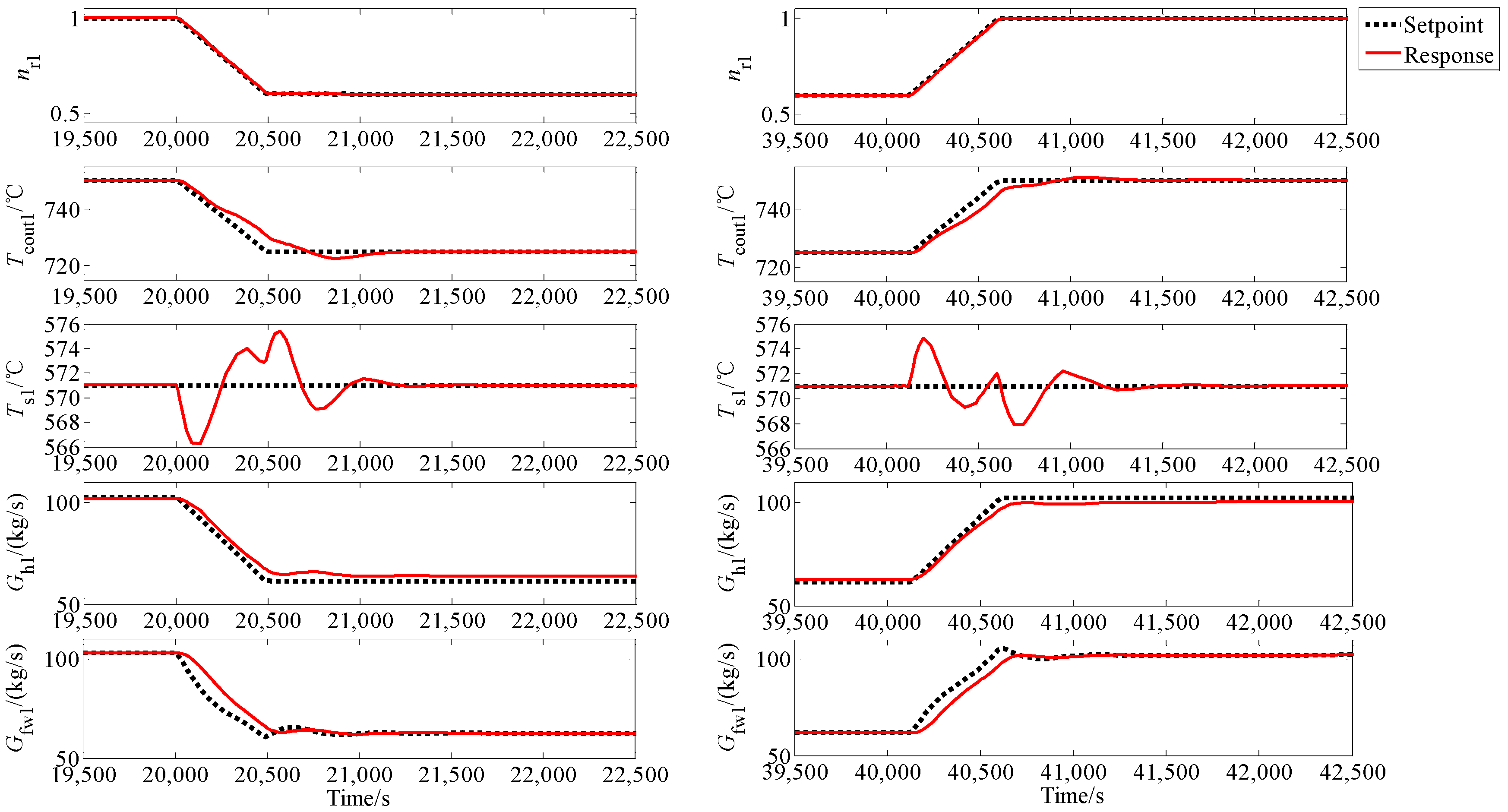

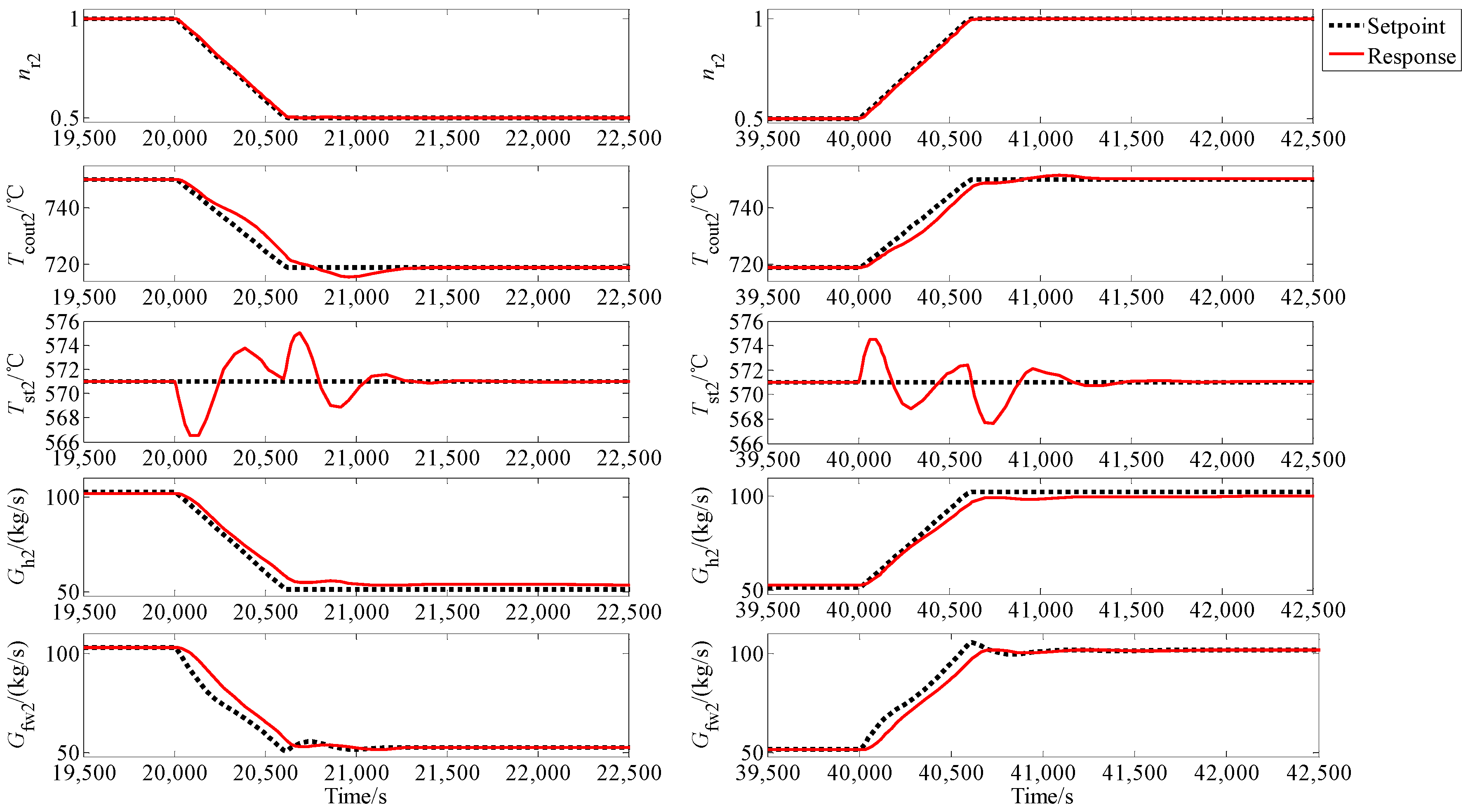

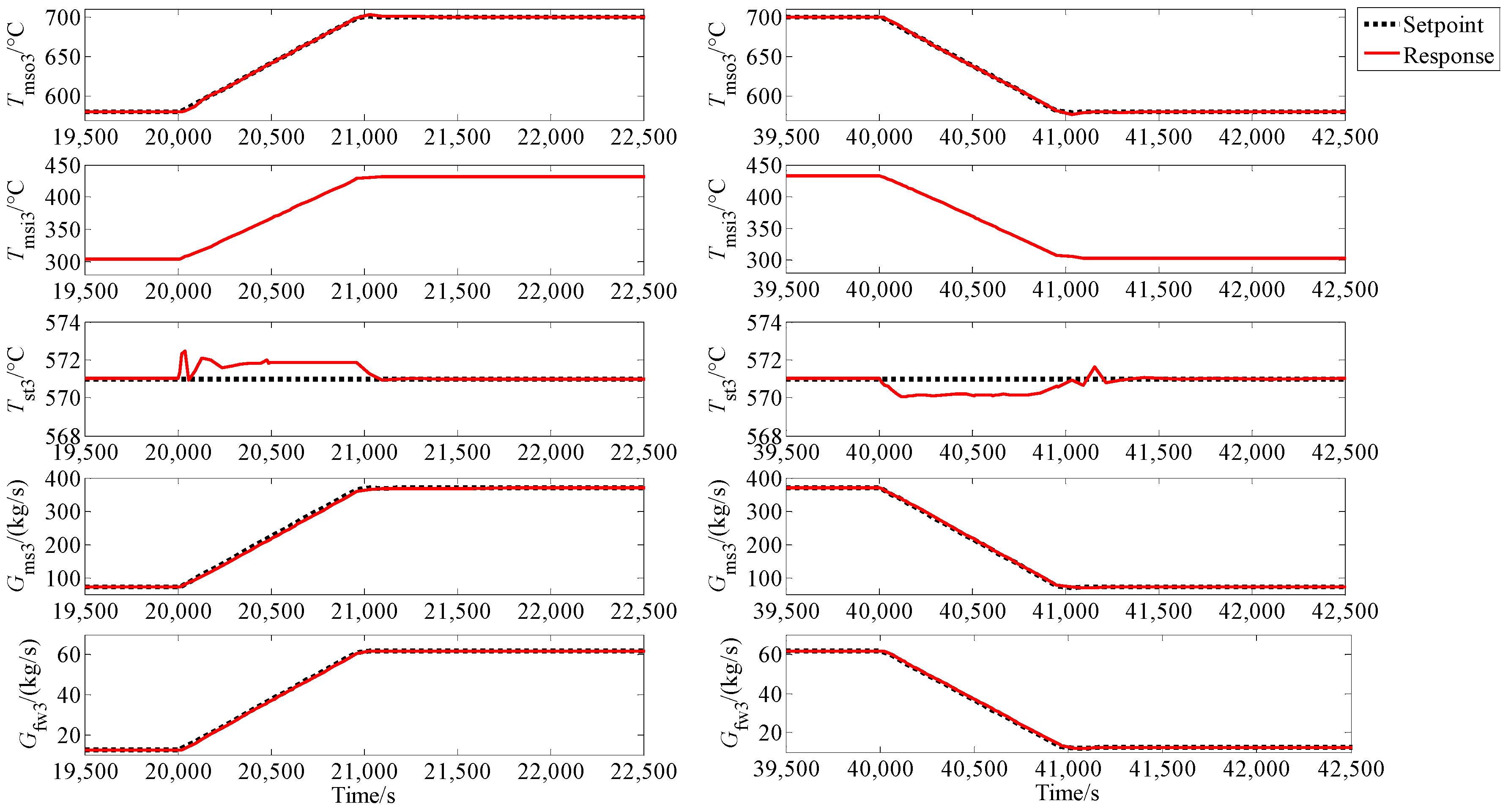

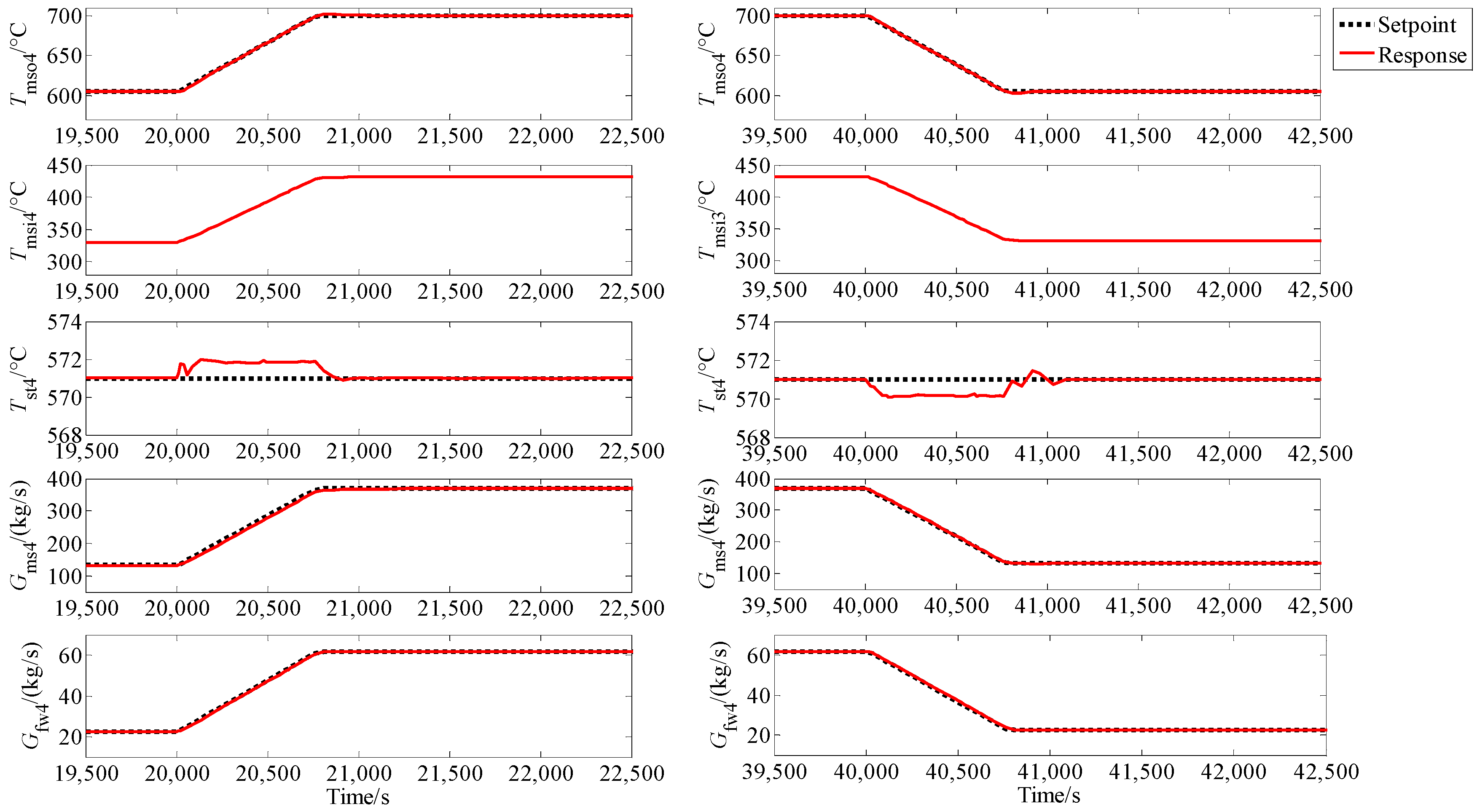

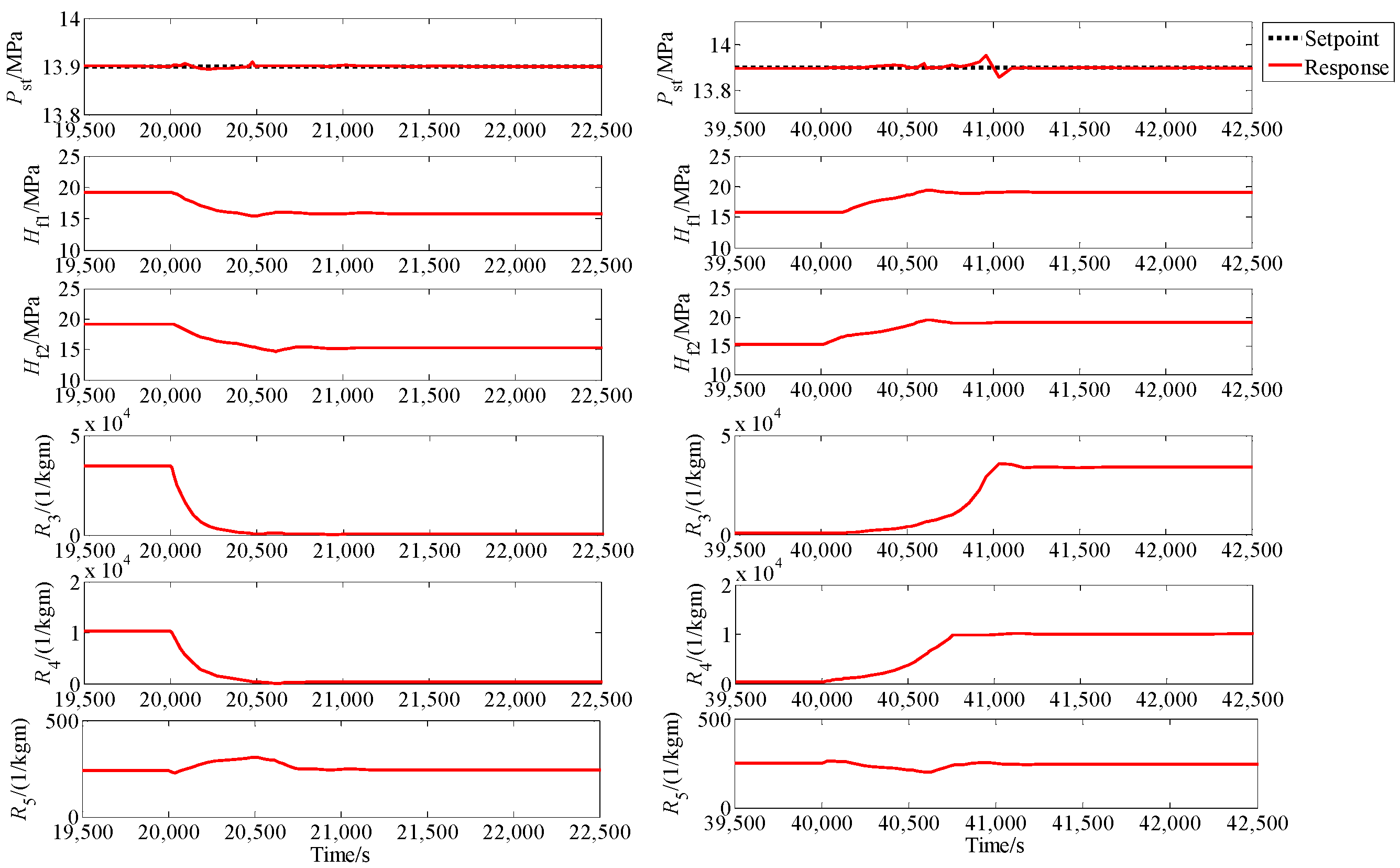

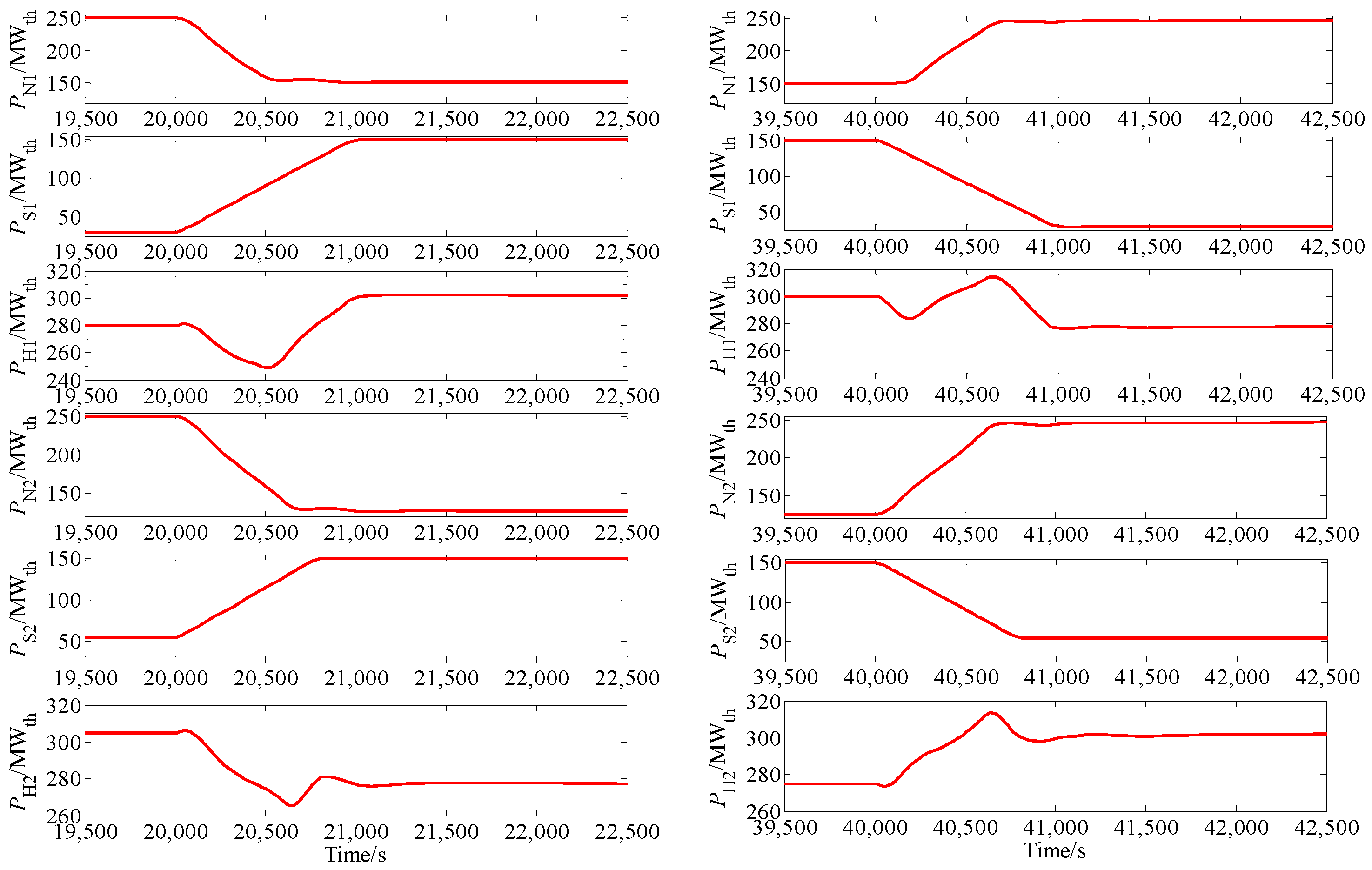

4.3.2. Simulation Cases and Results

4.3.3. Discussions

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ruth, M.F.; Zinaman, O.R.; Antkowiak, M.; Boardman, R.D.; Cherry, R.S.; Bazilian, M.D. Nuclear-renewable hybrid energy systems: Opportunities, interconnections and needs. Energy Convers. Manag. 2014, 78, 684–694. [Google Scholar] [CrossRef]

- Montes, M.J.; Rovira, A.; Muñoz, M.; Martínez-Val, J.M. Performance analysis of an integrated solar combined cycle using direct steam generation in parabolic through collectors. Appl. Energy 2011, 88, 3228–3238. [Google Scholar] [CrossRef]

- Ingersoll, D.T. Deliberately small reactors and the second nuclear era. Prog. Nucl. Energy 2009, 51, 589–603. [Google Scholar] [CrossRef]

- Vujić, J.; Bergmann, R.M.; Škoda, R.; Miletić, M. Small modular reactors: Simpler, safer, cheaper? Energy 2012, 45, 288–295. [Google Scholar] [CrossRef]

- Rowinski, M.K.; White, T.J.; Zhao, J. Small and medium sized reactors (SMR): A review of technology. Renew. Sustain. Energy Rev. 2015, 44, 643–656. [Google Scholar] [CrossRef]

- Ingersoll, D.T.; Houghton, Z.J.; Bromm, R.; Desportes, C. Nuscale small modular reactor for co-generation of electricity and water. Desalination 2014, 340, 84–93. [Google Scholar] [CrossRef]

- Reutler, H.; Lohnert, G.H. The modular high-temperature reactor. Nucl. Technol. 1983, 62, 22–30. [Google Scholar] [CrossRef]

- Reutler, H.; Lohnert, G.H. Advantages of going modular. Nucl. Eng. Des. 1984, 78, 129–136. [Google Scholar] [CrossRef]

- Lohnert, G.H. Technical design features and essential safety-related properties of the HTR-MODULE. Nucl. Eng. Des. 1990, 121, 259–275. [Google Scholar] [CrossRef]

- Lanning, D.D. Modularized high-temperature gas-cooled reactor systems. Nucl. Technol. 1989, 88, 139–156. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, Y. Economic potential of modular reactor nuclear power plants based on the Chinese HTR-PM project. Nucl. Eng. Des. 2007, 237, 2265–2274. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Z.; Wang, D.; Xu, Y.; Sun, Y.; Li, F.; Dong, Y. Current status and technical description of Chinese 2 × 250 MWth HTR-PM demonstration plant. Nucl. Eng. Des. 2009, 239, 1212–1219. [Google Scholar] [CrossRef]

- Zhang, Z.; Dong, Y.; Li, F.; Zhang, Z.; Wang, H.; Huang, X.; Li, H.; Liu, B.; Wu, X.; Wang, H.; et al. The shandong shidao bay 200 MWe high-temperature-gas-cooled reactor pebble-bed module (HTR-PM) demonstration power plant: An engineering and technological innovation. Engineering 2016, 2, 112–118. [Google Scholar] [CrossRef]

- Flueckiger, S.M.; Iverson, B.D.; Garimella, S.V.; Pacheco, J.E. System-level simulation of a solar power tower plant with thermocline thermal energy storage. Appl. Energy 2014, 113, 86–96. [Google Scholar] [CrossRef]

- Peng, S.; Hong, H.; Wang, Y.; Wang, Z.; Jin, H. Off-design thermodynamic performances on typical days of a 330MW solar aided coal-fired power plant in China. Appl. Energy 2014, 130, 500–509. [Google Scholar] [CrossRef]

- Kim, K.K.; Bernard, J.A. Considerations in the control of PWR-type multimodular reactor plants. IEEE Trans. Nucl. Sci. 1994, 41, 2686–2697. [Google Scholar]

- Garcia, H.E.; Chen, J.; Kim, J.S.; Vilim, R.B.; Binder, W.R.; Sitton, S.M.B.; Boardman, R.D.; McKellar, M.G.; Paredis, C.J.J. Dynamic performance analysis of two regional nuclear hybrid energy systems. Energy 2016, 107, 234–258. [Google Scholar] [CrossRef]

- Lykidi, M.; Gourdel, P. How to manage flexible nuclear power plants in a deregulated electricity market from the point of view of social welfare? Energy 2015, 85, 167–180. [Google Scholar] [CrossRef]

- Perillo, S.R.P.; Upadhyaya, B.R.; Li, F. Control and instrumentation strategies for multi-modular integral nuclear reactor systems. IEEE Trans. Nucl. Sci. 2011, 58, 2442–2451. [Google Scholar] [CrossRef]

- Dong, Z.; Song, M.; Huang, X.; Zhang, Z.; Wu, Z. Module coordination control of MHTGR-based multi-modular nuclear plants. IEEE Trans. Nucl. Sci. 2016, 63, 1889–1900. [Google Scholar] [CrossRef]

- Zhang, H.L.; Baeyens, J.; Degrѐve, J.; Cacѐres, G. Concentrated solar power plants: Review and design methodology. Renew. Sustain. Energy Rev. 2013, 22, 466–481. [Google Scholar] [CrossRef]

- Mahdi, A.A.; McPherson, M.J. An introduction to automatic control of mine ventilation systems. Min. Technol. 1971, 53, 5–10. [Google Scholar]

- DeMoyer, R.J. System modeling and simulation for water distribution control. Model. Simul. 1974, 5, 185. [Google Scholar]

- Rao, H.S. Modeling of water distribution systems. In Proceedings of the 16th IEEE Conference on Decision and Control, New York, NY, USA, 7–9 December 1977; pp. 653–658. [Google Scholar]

- Kocić, D.D. On the autonomy of local systems in ventilation control. In Proceedings of the 2nd Mine Ventilation Congress, Reno, NV, USA, 4–8 November 1979. [Google Scholar]

- Hu, Y.; Koroleva, O.I.; Kristić, M. Nonlinear control of mine ventilation networks. Syst. Control Lett. 2003, 49, 239–254. [Google Scholar] [CrossRef]

- Dong, Z. Dissipation analysis and adaptive control of fluid networks. In Proceedings of the American Control Conference, Chicago, IL, USA, 1–3 July 2015; pp. 671–676. [Google Scholar]

- Dong, Z.; Song, M.; Huang, X.; Zhang, Z.; Wu, Z. Coordination control of SMR-based NSSS modules integrated by feedwater distribution. IEEE Trans. Nucl. Sci. 2016, 63, 2682–2690. [Google Scholar] [CrossRef]

- Ward-Smith, A.J. Internal Fluid Flow—The Fluid Dynamics of Flow in Pipes and Ducts; Clarendon Press: Oxford, UK, 1980. [Google Scholar]

- Desoer, C.A.; Kuh, E.S. Basic Circuit Theory; McGraw-Hill: New York, NY, USA, 1969. [Google Scholar]

- Reddy, V.S.; Kaushik, S.C.; Ranjan, K.R.; Tyagi, S.K. State-of-the-art of solar thermal power plants—A review. Renew. Sustain. Energy Rev. 2013, 27, 258–273. [Google Scholar] [CrossRef]

- Li, X.; Kong, W.; Wang, Z.; Chang, C.; Bai, F. Thermal model and thermodynamic performance of molten salt cavity receiver. Renew. Energy 2010, 35, 981–988. [Google Scholar] [CrossRef]

- Benammar, S.; Khellaf, A.; Mohammedi, K. Contribution to the modeling and simulation of solar power tower plants using energy analysis. Energy Convers. Manag. 2014, 78, 923–930. [Google Scholar] [CrossRef]

- Dong, Z.; Pan, Y.; Zhang, Z.; Dong, Y.; Huang, X. Model-free adaptive control law for nuclear superheated-steam supply systems. Energy 2017, 135, 53–67. [Google Scholar] [CrossRef]

- Camacho, E.F.; Rubio, F.R.; Berenguel, M.; Valenzuela, L. A survey on control schemes for distributed solar collector fields. Part I: Modeling and basic control approaches. Sol. Energy 2007, 81, 1240–1251. [Google Scholar] [CrossRef]

- Cirre, C.M.; Berenguel, M.; Valenzuela, L.; Camacho, E.F. Feedback linearization control for a distributed solar collector field. Control Eng. Pract. 2007, 15, 1533–1544. [Google Scholar] [CrossRef]

| Parameter | Unit | Value | |

|---|---|---|---|

| Plant | Maximal Plant thermal power | MWt | 800 |

| Maximal Plant electrical power | MWe | 320 | |

| Number of modules | 2 | ||

| Main steam temperature | °C | 571 | |

| Main steam pressure | MPa | 13.9 | |

| MHTGR-Based OTSSS | Rated thermal power | MWth | 250 |

| Average core power density | MW/m3 | 3.22 | |

| Active core diameter/height | m | 3/11 | |

| Primary helium pressure | MPa | 7 | |

| Helium temperature at reactor inlet/outlet | °C | 277/750 | |

| Helium flowrate | kg/s | 102 | |

| Feedwater temperature | °C | 250 | |

| Feedwater flowrate | kg/s | 103 | |

| STP-Based OTSSS | Rated thermal power | MWth | 150 |

| Heat transfer fluid (HTF) | Molten nitrate salt mixture (60 wt % NaNO3, 40 wt % KNO3) | ||

| HTF temperature at cold/hot leg | °C | 432/700 | |

| HTF flowrate | kg/s | 368 | |

| Feedwater temperature | °C | 250 | |

| Feedwater flowrate | kg/s | 61 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Z.; Pan, Y.; Zhang, Z.; Dong, Y.; Huang, X. Modeling and Control of Fluid Flow Networks with Application to a Nuclear-Solar Hybrid Plant. Energies 2017, 10, 1912. https://doi.org/10.3390/en10111912

Dong Z, Pan Y, Zhang Z, Dong Y, Huang X. Modeling and Control of Fluid Flow Networks with Application to a Nuclear-Solar Hybrid Plant. Energies. 2017; 10(11):1912. https://doi.org/10.3390/en10111912

Chicago/Turabian StyleDong, Zhe, Yifei Pan, Zuoyi Zhang, Yujie Dong, and Xiaojin Huang. 2017. "Modeling and Control of Fluid Flow Networks with Application to a Nuclear-Solar Hybrid Plant" Energies 10, no. 11: 1912. https://doi.org/10.3390/en10111912