Environmental Assessment of Possible Future Waste Management Scenarios

Abstract

:1. Introduction

- To present the comprehensive LCA-model SWEA (Swedish Waste management Environmental Assessment). The model is unique in including most waste streams in Sweden except mining waste and hazardous waste.

- To present potential environmental impacts, as calculated with SWEA, of the different scenarios of Swedish waste management systems for the year 2030. These results can be a basis for a discussion on which are the most important environmental impacts in the Swedish waste management system and the most important processes from an environmental perspective.

- To present quantitative results on potential environmental impacts of policy instruments which were suggested to contribute to a more sustainable waste management [26].

2. Method

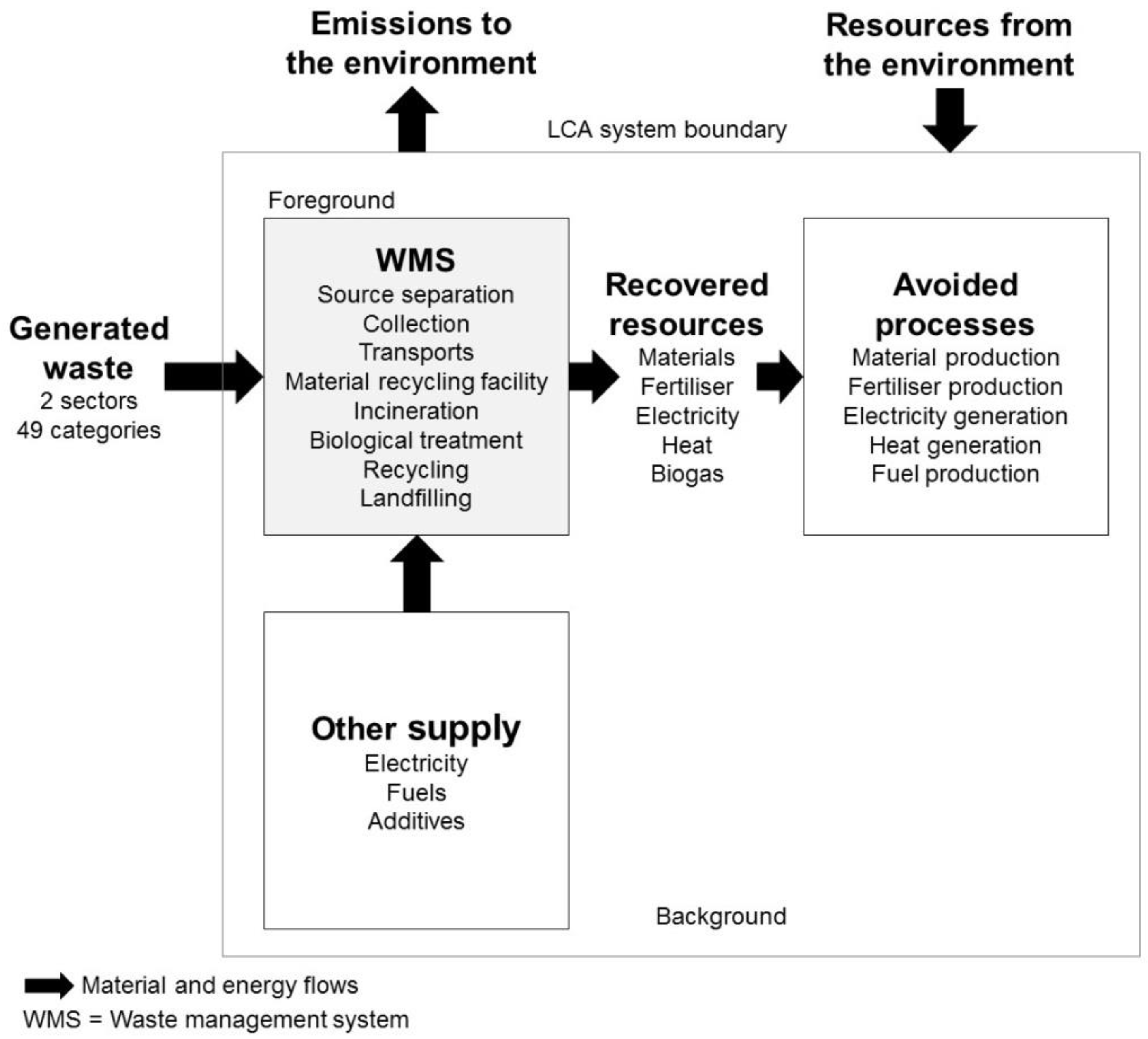

2.1. SWEA Model—Scope and General Outline

2.2. Data Inventory

2.2.1. Waste Flows

2.2.2. Foreground

2.2.3. Background

3. Results

3.1. Assessment of Scenarios

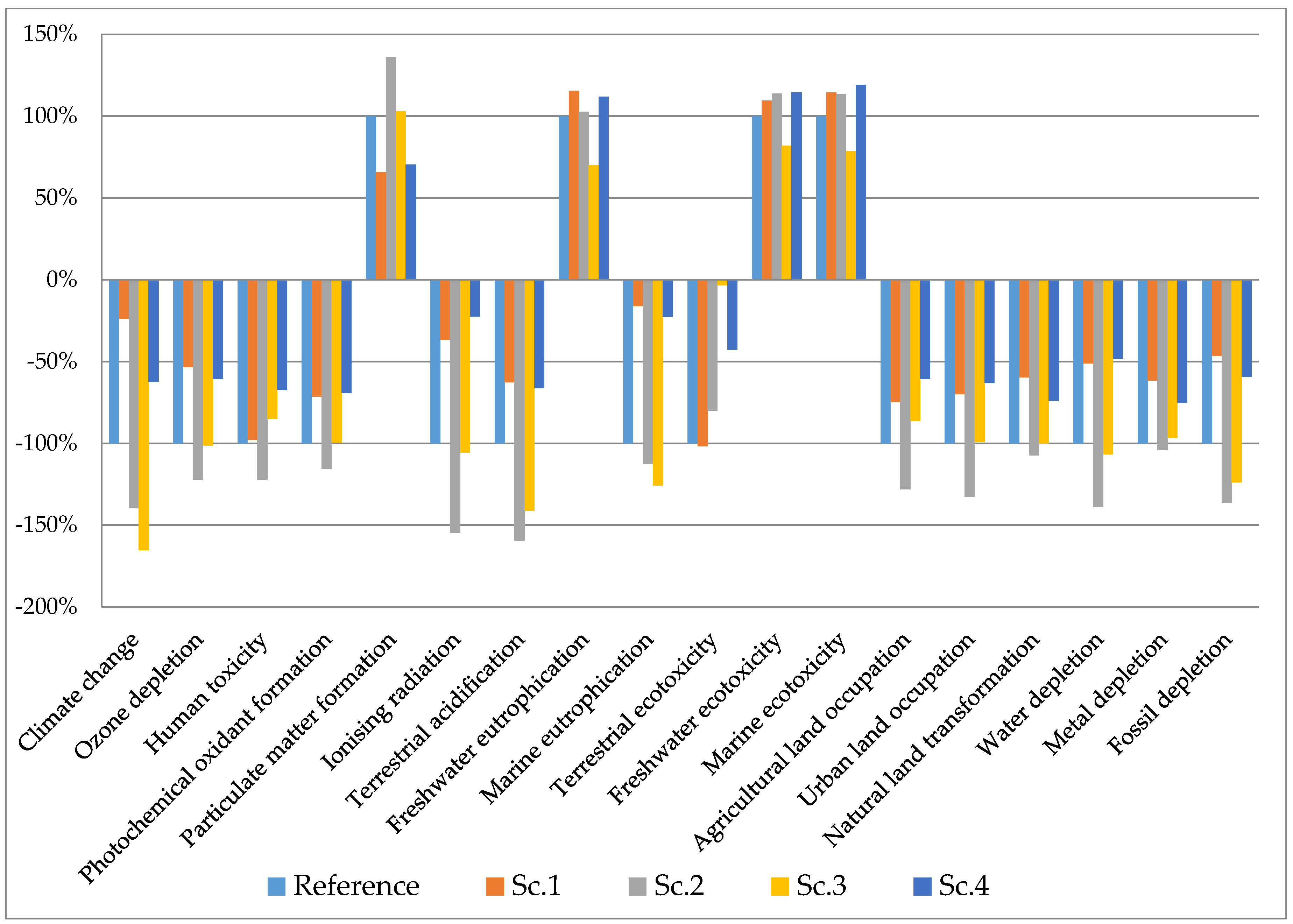

3.1.1. Potential Environmental Impacts

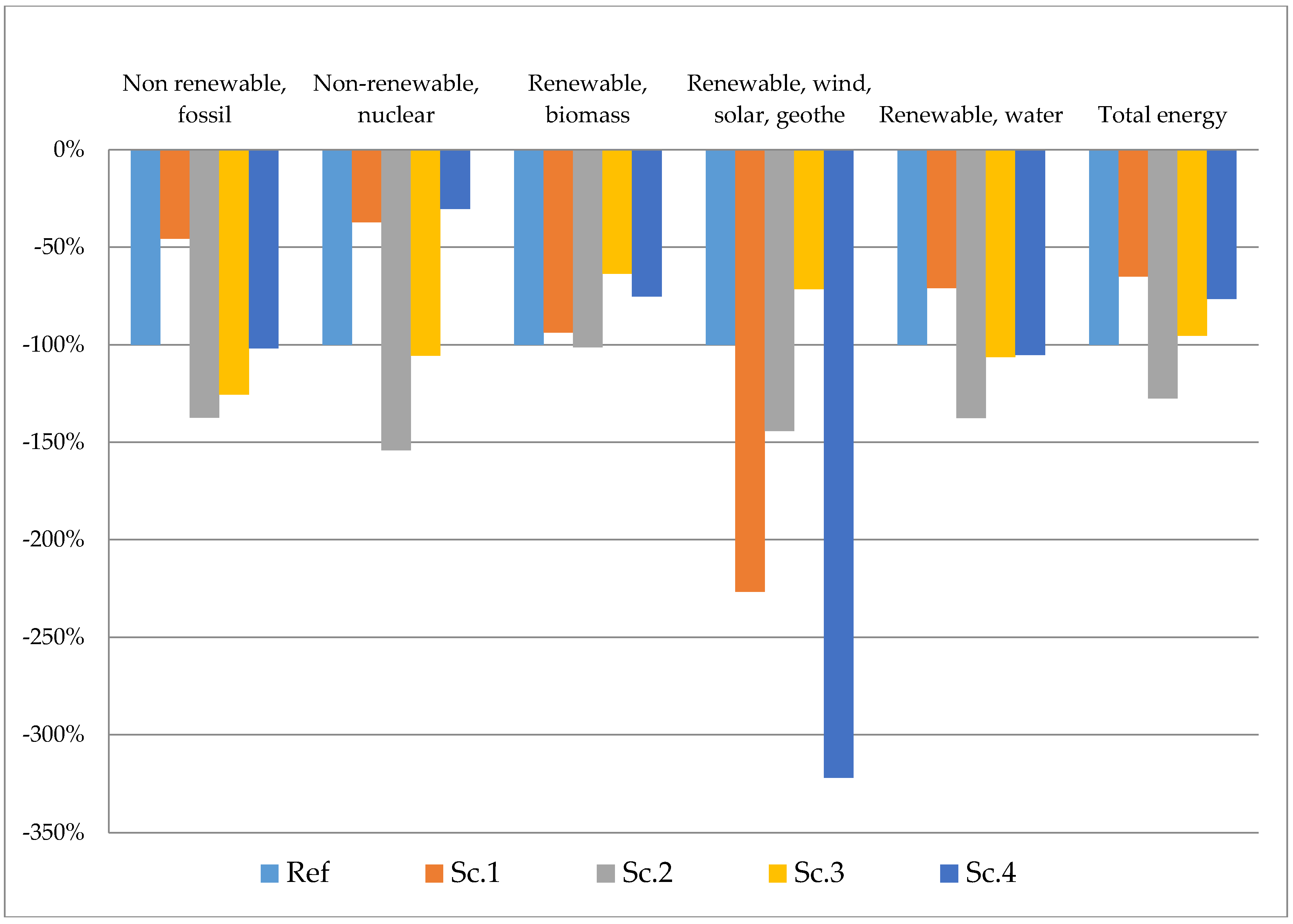

3.1.2. Cumulative Energy Demand

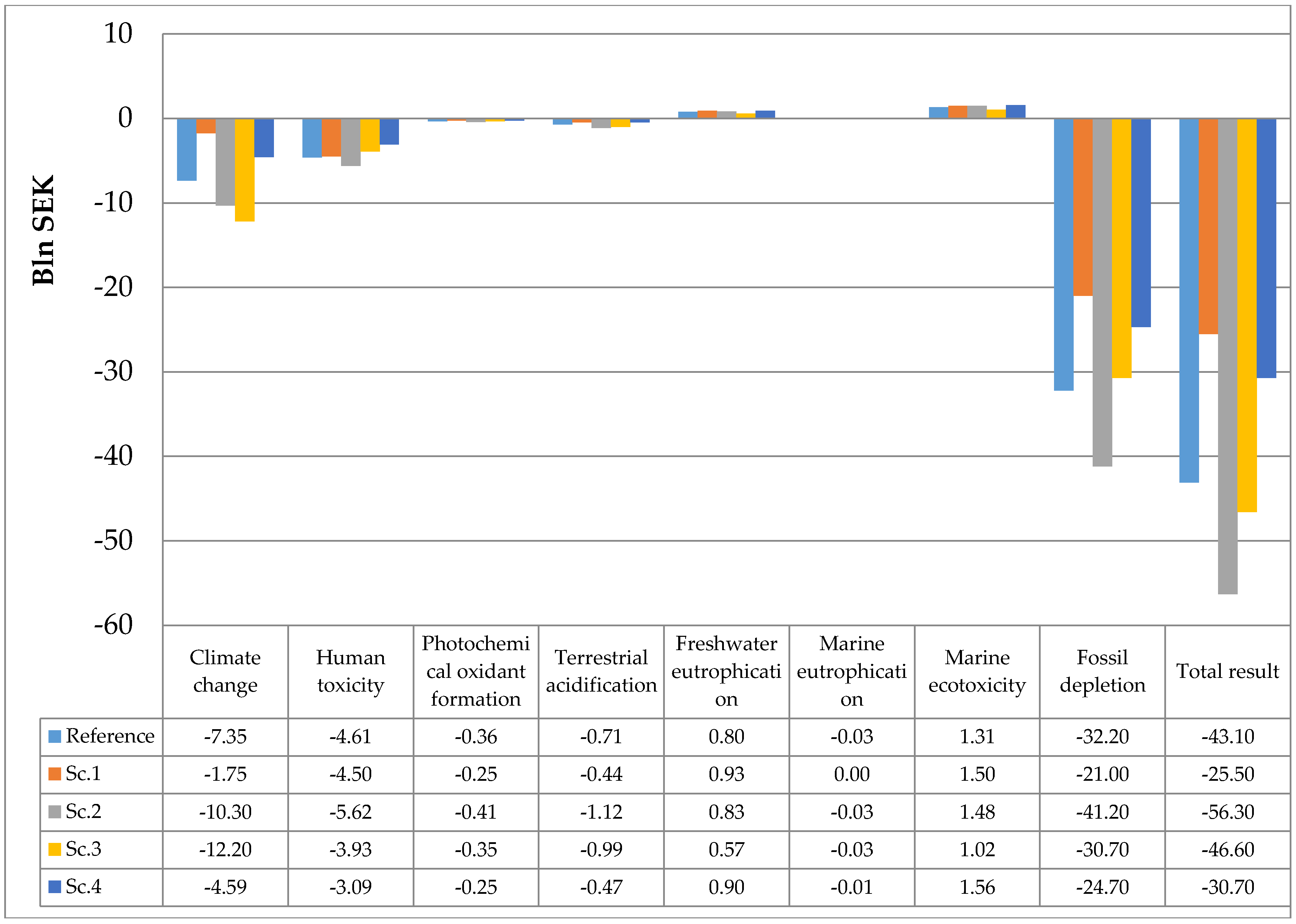

3.1.3. Monetary Assessment

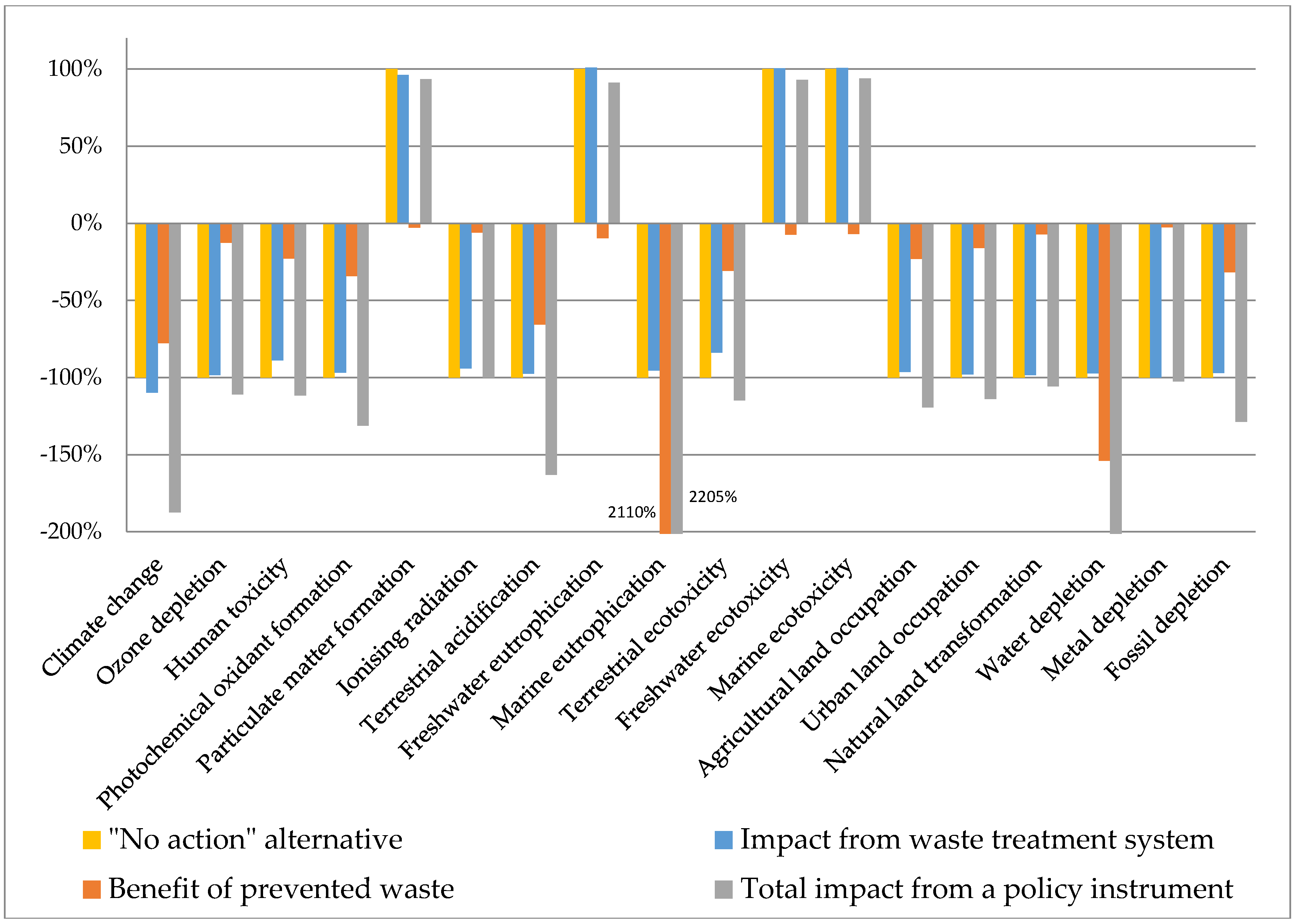

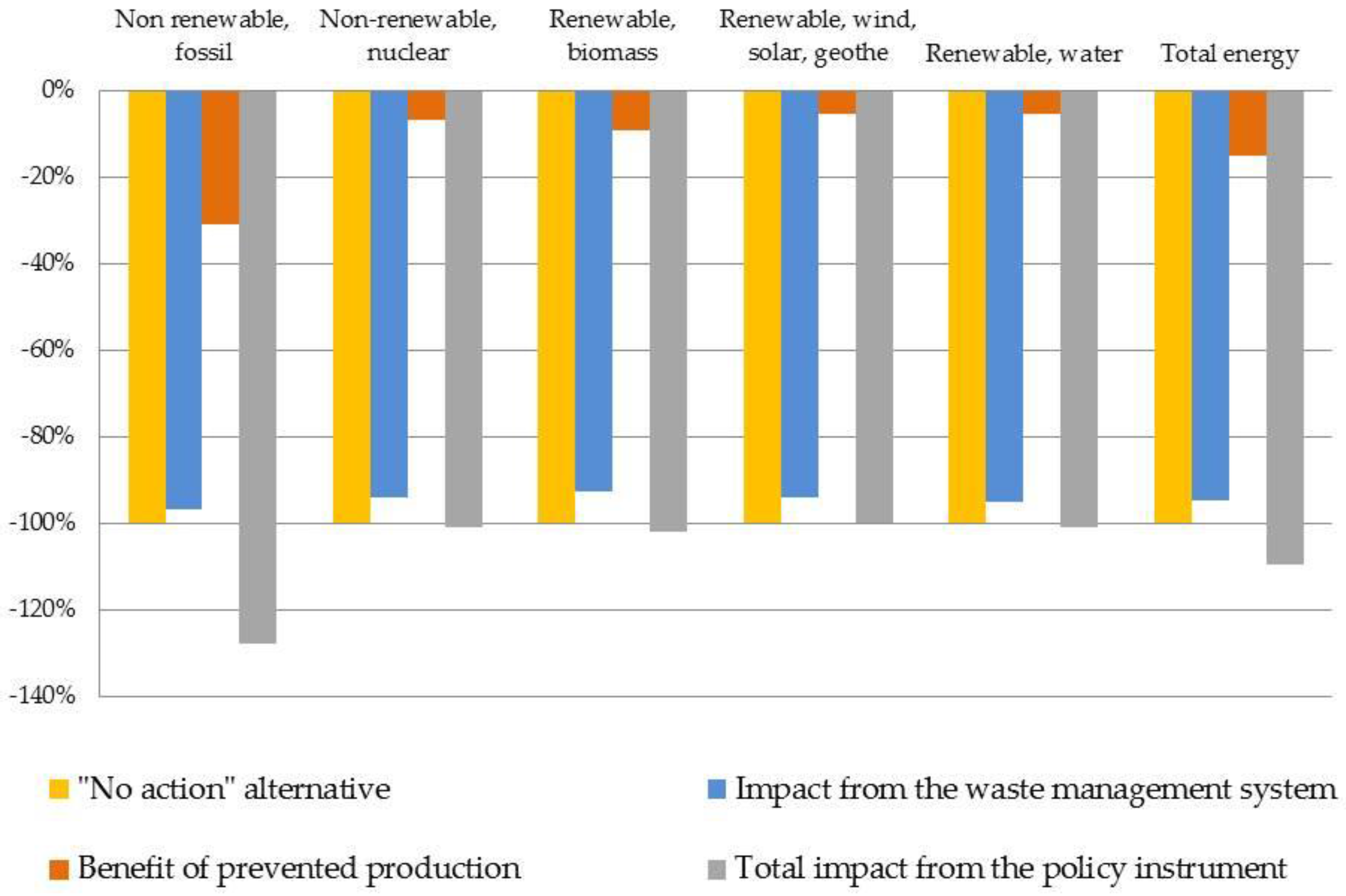

3.2. Assessment of Policy Instruments

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Overview of a Segment of the SWEA Model Structure

Appendix B. Overview of Material Fractions and Processes

| Waste Categories and Material Fractions | Collection System | Treatment Technologies | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mixed Waste at P (H, I) | SS at P, Bags (H, I) | SS at P, Container (H, I) | SS Nearby P (H) | SS Nearby P (I) | SS at RS (H) | SS at RC (H) | SS at RC (I) | Sorting Facility | HOB | CHP | BIO | CKN | REC | WCP | RCP | ADG | LFL | |

| 1. Other chemical wastes and residues | x | x | 1 | 1 | 1 | 1 | ||||||||||||

| 1.1. Industrial sludge | ||||||||||||||||||

| chemical sludge and bio sludge | x | 1 | 1 | 1 | 1 | 1 | 2 | |||||||||||

| other industrial effluent sludge | x | 1 | 1 | 1 | 1 | |||||||||||||

| 1.2. Public sewage sludge | x | 1 | 1 | 1,2 | 1 | 2 | ||||||||||||

| 2. Metallic waste (mixed) | ||||||||||||||||||

| Aluminum | x | x | x | 1 | ||||||||||||||

| Ferrous metal | x | x | x | 1 | ||||||||||||||

| Stainless steel | x | x | x | 1 | ||||||||||||||

| Other metal | x | x | x | 1 | ||||||||||||||

| 3. Glass waste | ||||||||||||||||||

| glass container, clear | x | x | x | 1 | 1,2 | |||||||||||||

| glass container, colored | x | x | x | 1 | 1,2 | |||||||||||||

| 4. Paper and cardboard waste | ||||||||||||||||||

| 4.1. Mixed paper | 1,2 | 1,2 | ||||||||||||||||

| paper and cardboard containers | x | x | x | 1 | ||||||||||||||

| corrugated cardboard | x | x | x | 1 | ||||||||||||||

| Newsprint, journals, and catalogues | x | x | x | 1 | ||||||||||||||

| office paper | x | x | x | 1 | ||||||||||||||

| 4.2. Fibre reject | x | 1 | 1 | 1 | 1 | |||||||||||||

| 5. Rubber waste | x | x | 1,2 | 1,2 | 1,2 | 1 | ||||||||||||

| 6. Plastic waste | ||||||||||||||||||

| 6.1. Mixed plastic | 1,2 | 1,2 | 1,2 | |||||||||||||||

| PE | x | x | x | 1 | ||||||||||||||

| PP | x | x | x | 1 | ||||||||||||||

| PET | x | x | x | 1 | ||||||||||||||

| PS | x | x | x | 1 | ||||||||||||||

| PVC | x | x | x | 1 | ||||||||||||||

| PUR | x | x | x | 1 | ||||||||||||||

| PC | x | x | x | 1 | ||||||||||||||

| 6.2. Agricultural plastic | ||||||||||||||||||

| agricultural film | x | 1,2 | 1,2 | 1,2 | 1 | |||||||||||||

| cans (PE) | x | 1,2 | 1,2 | 1,2 | 1 | |||||||||||||

| other agricultural plastic | x | 1 | 1 | 1 | ||||||||||||||

| 7. Wood waste | x | 2 | 2 | 2 | 2 | 1 | ||||||||||||

| 8. Textile waste | x | 1 | 1 | |||||||||||||||

| 9. Discarded equipment | x | 1 | ||||||||||||||||

| 10. Animal and vegetal waste | ||||||||||||||||||

| manure | x | 1 | 1 | |||||||||||||||

| Animal waste from food preparation, non-hygienized | x | 1 | 1 | 1 | 1 | |||||||||||||

| Animal waste of food preparation, hygienized | x | 1 | 1 | 1 | 1 | |||||||||||||

| vegetal waste of food processing | x | 1 | 1 | 1 | 1 | |||||||||||||

| park and yard waste | x (Hh) | x (Hh) | x | x | x | 1 | 1 | 1 | ||||||||||

| food waste | x (Hh) | x (Hh) | x | 1 | 1 | 1 | 1 | |||||||||||

| 11. Household and similar waste | ||||||||||||||||||

| 11.1. Collected in bags and bins | ||||||||||||||||||

| food waste | x | x | x | 1 | 1,2 | 1,2 | 2 | 2 | ||||||||||

| park and yard waste | x | x | x | 1 | 1,2 | 1,2 | 2 | 2 | ||||||||||

| newsprint | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| corrugated cardboard | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| paper and cardboard containers | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| PE | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| PS | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| clear glass | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| colored glass | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| mixed metal | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| landfill residue | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| hazardous waste | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| WEEE | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| wood waste | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| textiles | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| other combustible waste | x | x | x | 1 | 1,2 | 1,2 | ||||||||||||

| 11.2. Bulky | ||||||||||||||||||

| 11.2.1. Combustible | ||||||||||||||||||

| paper and cardboard containers | x | x | x | 1 | 2,3 | 2,3 | 2,3 | 2 | ||||||||||

| mixed plastic | x | x | x | 1 | 2,3 | 2,3 | 2,3 | 2 | ||||||||||

| wood | x | x | x | 1 | 2,3 | 2,3 | 3 | 2,3 | 2 | |||||||||

| 11.2.2. Landfill residue | ||||||||||||||||||

| Plaster | x | x | x | 1 | 2 | 2,3 | ||||||||||||

| concrete, stone, bricks | x | x | x | 1 | 2 | 2,3 | ||||||||||||

| 12. Mixed and undifferentiated materials | ||||||||||||||||||

| 12.1. Combustible | ||||||||||||||||||

| paper and cardboard containers | x | x | 1 | 1,2,3 | 1,2,3 | 1, 2 | 2 | |||||||||||

| mixed plastic | x | x | 1 | 1,2,3 | 1,2,3 | 1, 2 | 2 | |||||||||||

| wood | x | x | 1 | 1,2,3 | 1,2,3 | 3 | 1, 2,3 | 2 | ||||||||||

| 12.2.Landfill residue | ||||||||||||||||||

| Plaster | x | x | 1 | 2 | 1,2,3 | |||||||||||||

| concrete, stone, bricks | x | x | 1 | 2 | 1,2,3 | |||||||||||||

| 12.3. Mixed waste | ||||||||||||||||||

| paper and cardboard containers | x | x | x | x | 1 | 1,2,3 | 1,2,3 | 2 | 2 | |||||||||

| mixed plastic | x | x | x | 1 | 1,2,3 | 1,2,3 | 2 | 2 | ||||||||||

| wood | x | x | x | 1 | 1,2,3 | 1,2,3 | 3 | 2,3 | 2 | |||||||||

| mixed metal | x | x | x | 1 | 1 | 1 | 2 | |||||||||||

| plaster | x | x | x | 1 | 1 | 1 | 2 | 2,3 | ||||||||||

| concrete, stone, bricks | x | x | x | 1 | 1 | 1 | 2 | 2,3 | ||||||||||

| 13. Sorting residues | ||||||||||||||||||

| fiber recycling reject | x | 1 | 1 | 1 | 1 | |||||||||||||

| sorting ashes | x | 1 | ||||||||||||||||

| 14. Mineral wastes | ||||||||||||||||||

| plaster | x | 1 | 1,2 | |||||||||||||||

| concrete, stone, bricks | x | 1 | 1,2 | |||||||||||||||

| asphalt | x | 1 | 1,2 | |||||||||||||||

| 15. Combustion wastes and wastes from thermal processes | ||||||||||||||||||

| steel slag, recyclable | x | 1 | 1 | |||||||||||||||

| steel slag, non-recyclable | x | 1 | 1 | |||||||||||||||

| wood fly ashes | x | 1 | 1 | |||||||||||||||

| other ashes | x | 1 | ||||||||||||||||

| bottom ash, MWC | x | 1 | 1 | |||||||||||||||

- H—household

- I—industrial

- P—premises (residential houses, offices, industrial facilities)

- SS—source separated

- RS—recycling station (packaging and newspapers)

- RC—recycling center (bulky, garden, electronic, hazardous waste)

- HOB—incineration at heat-only-boiler plant

- CHP—incineration at combined heat and power plant

- BIO—incineration in bio boiler

- CKN—incineration in cement kiln

- REC—recycling

- WCP—windrow composting

- RCP—reactor composting

- ADG—anaerobic digestion

- LFL—landfill

Appendix C. Process Data

Appendix C.1. Process Data for Incineration

- Incineration in a large scale plant for municipal solid waste—combined heat and power plant (CHP), and heat only boiler plant (HOB)

- Incineration in cement kiln (CKN)

- Incineration of sludge in a fluidized bed

Appendix C.1.1. Incineration, CHP and HOB

Appendix C.1.2. Incineration, CKN

Appendix C.1.3. Incineration of Sludge

Appendix C.2. Process Data for Landfilling

- For methane and VOC, which is not collected and combusted, 25% is oxidized (default 15%). Less methane generation, and better cover of landfills makes the oxidation in the cover more effective.

- The mobility of several metals is higher since the anaerobic phase is less developed. Leaching of heavy metals has increased with a factor 10.

- For landfill of digested sewage sludge, the sludge landfill sub model has been used.

Appendix C.3. Process Data for Composting

- Reactor (CPR)

- Open windrow (CPW)

Appendix C.4. Process Data for Anaerobic Digestion

Appendix C.5. Process Data for Recycling

| Material Recycled | Name of the Process in Original Dataset | References | Comment on Modifications Made |

|---|---|---|---|

| Aluminum | Aluminum, secondary, from old scrap, at plant/kg/RER U | [32] | Added avoided virgin production (97% substitution), but removed aluminum scrap input. Direct use of electricity has been replaced by the Swedish electricity used in different scenarios. |

| Cardboard | Corrugated board, recycling fiber, single wall, at plant/RER U | [68] | Added avoided virgin production (90% substitution), but removed paper waste input in Wellenstoff and Testliner production. Direct use of electricity has been replaced by the Swedish electricity used in different scenarios. |

| Corrugated board | Corrugated board, recycling fiber, single wall, at plant/RER U | [68] | Added avoided virgin production (90% substitution), but removed paper waste input in Wellenstoff and Testliner production. Direct use of electricity has been replaced by the Swedish electricity used in different scenarios. |

| Ferrous metals | Steel, electric, un- and low-alloyed, at plant/RER U | [32] | Added avoided virgin production (90% substitution), removed steel scrap input. Direct use of electricity has been replaced by the Swedish electricity used in different scenarios. |

| Glass (clear and color) | [69,70] | Dataset created based on collected data. Avoided virgin production 100%. | |

| Inert material mix | [71] | Due to the lack of data it was decided to approximate it to the landfilling process. The process is a copy of a LFL (InMix) but with adding avoided gravel (100% substitution). | |

| Metal | Mix of Aluminum, Ferrous metals, Stainless metals, and Other metals | [72] | Dataset created based on collected data |

| Newsprint | Paper, recycling, with deinking/RER U | [68] | Added avoided production (85% substitution), but removed waste paper input. Direct use of electricity has been replaced by the Swedish electricity used in different scenarios. |

| Office paper | Paper, recycling, with deinking/RER U | [68] | Added avoided production (85% substitution), but removed waste paper input. Direct use of electricity has been replaced by the Swedish electricity used in different scenarios. |

| Other metal | Copper, secondary, at refinery/RER U | [32] | Added avoided virgin production (76% substitution), but removed metal scrap input. Direct use of electricity has been replaced by the Swedish electricity used in different scenarios. |

| PC, PE, PET, PP, PS, PUR, PVC, Plastics | Rigid plastics to fine sorting and recycling | [73] | Avoided virgin production with 77% substitution. |

| Plaster | [74] | Dataset created based on collected data. Avoided virgin production with 93% substitution. | |

| Rubber | [75] | Dataset created based on collected data. Tires cutting and granulation (whole tires). Avoided virgin production with 100% substitution. | |

| Stainless metal | Steel, electric, chromium steel 18/8, at plant/RER U | [32] | Added avoided primary steel production (52% substitution), but removed metal scrap input. Direct use of electricity has been replaced by the Swedish electricity used in different scenarios. |

Appendix D. Waste Composition

| Waste Fraction | Comment on Assumptions | References |

|---|---|---|

| OtherAshes | [76] | |

| PE | Soft plastic packaging (6%) | [36] |

| PS | Styrofoam | [36] |

| Metal mixed | Excluding by-product (metal waste from metal industry) | |

| Vegetal | [77] | |

| Food waste, household | [36] | |

| Park, low HHV | From households | [77] |

| Animal | No difference between hygienized and non hygienized animal waste | [77] |

| Wood | Excluding by-products from sawmills and secondary wood waste from recycling | [77] |

| Newsprint | Collected separately from start | [36,77] |

| GlassClear | Excluding returnable bottles | [77] |

| GlassColor | Excluding returnable bottles. | [77] |

| Textiles | [77] | |

| CorrBoard | Collected as a separate fractions from start | [36] |

| SewSludge | Drained sewage sludge, wet weight. Excluding sludge from drinking water purification and from households. | [78] |

| Plaster | [79] | |

| SlagRecyc | Different types of waste from steel industry that can be recycled. Assumed to mainly consist of blast furnace slag. | [76,80] |

| SlagNRecyc | Different types of waste from steel industry that can be recycled, other than blast furnace slag. | [76,80] |

| Equip_h | [79] | |

| Cardboard | Collected separately from the start. Assumption: 100% fiber reject from pulp production. | [36] |

| HA Chemical | Modeled as green liquor slam | [76] |

| IndSlOrg | Drained sludge, wet weight, 50% chemical sludge, 50% bio sludge | [76] |

| IndSlNOrg | Drained sludge, wet weight. | [76] |

| FibreRej | Collected separately from start. Only from pulp and paper industry, TS 50%. | [76,81] |

| PC | [76] | |

| Haz_h | Hazardous waste found in waste bags | [76] |

| RecFibRej | Returnable fiber reject | [76] |

| WoodFlyAsh | [76] |

Appendix E. Energy Mixes Assumed for Scenarios

| Electricity Source | Reference Scenario | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

|---|---|---|---|---|---|

| Nuclear power | 42.1% | 18.9% | 44.7% | 41.5% | 8.4% |

| Hydropower | 39.5% | 44.1% | 39.1% | 40.5% | 58.4% |

| Wind power | 3.9% | 6.9% | 2.9% | 2.0% | 10.0% |

| Solar power | 0.0% | 6.9% | 1.0% | 0.5% | 10.0% |

| CHP *, oil | 0.0% | 0.0% | 1.0% | 2.0% | 0.0% |

| CHP, natural gas | 3.8% | 0.0% | 2.1% | 2.2% | 0.0% |

| CHP, coal | 0.4% | 0.0% | 4.1% | 8.1% | 0.0% |

| CHP, biofuel | 4.6% | 23.3% | 5.1% | 3.0% | 13.0% |

| CHP, peat | 0.1% | 0.0% | 0.0% | 0.0% | 0.0% |

| CHP, blast furnace gas | 0.9% | 0.0% | 0.0% | 0.0% | 0.0% |

| Oil back pressure | 0.2% | 0.0% | 0.0% | 0.0% | 0.0% |

| Blast furnace back pressure | 0.4% | 0.0% | 0.0% | 0.0% | 0.0% |

| Biofuel back pressure | 3.6% | 0.0% | 0.0% | 0.0% | 0.0% |

| Gas back pressure | 0.5% | 0.0% | 0.0% | 0.0% | 0.0% |

| Total | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% |

| Fuel Supply | Reference Scenario | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

|---|---|---|---|---|---|

| Coal | 3.3% | 0.0% | 14.3% | 19.7% | 0.0% |

| Biofuels | 65.7% | 82.4% | 35.7% | 30.3% | 80.0% |

| Heavy fuel oils (Eo2-5) | 1.5% | 0.0% | 8.6% | 10.5% | 0.0% |

| Petroleum gas | 0.4% | 0.0% | 0.0% | 0.0% | 0.0% |

| Natural gas | 15.8% | 0.0% | 7.1% | 6.6% | 4.7% |

| Blast furnace gas | 2.7% | 2.4% | 5.7% | 3.9% | 2.4% |

| Electricity to electric boiler | 0.0% | 0.0% | 1.4% | 0.0% | 0.0% |

| Electricity to heat pump | 0.0% | 0.0% | 15.7% | 5.3% | 0.0% |

| Steam/hot water to heat pump | 10.6% | 9.4% | 0.0% | 10.5% | 7.1% |

| Excess heat | 0.0% | 5.9% | 11.4% | 13.2% | 5.9% |

| Total | 100.0% | 100.0% | 100.0% | 100.0% | 100.0% |

| Fuel | Reference Scenario, Scenarios 2 and 3 | Scenarios 1 and 4 |

|---|---|---|

| Diesel | 90% | 79% |

| FAME * | 7% | 15% |

| Ethanol | 3% | 6% |

| Fuel | Reference Scenario, Scenario 2 and 3 | Scenario 1 and 4 |

|---|---|---|

| Diesel | 50% | 17% |

| Ethanol | 50% | 17% |

| Biodiesel | 0% | 66% |

| Fuel | Reference Scenario, Scenario 2 and 3 | Scenario 1 and 4 |

|---|---|---|

| Petrol | 60% | 10% |

| Ethanol | 10% | 30% |

| Electricity | 20% | 30% |

| Diesel | 10% | 30% |

Appendix F. Environmental Impact Assessment Results

| Impact Category | Unit | Reference Scenario | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

|---|---|---|---|---|---|---|

| Climate change | kg CO2 eq | −2.58 × 109 | −6.13 × 108 | −3.60 × 109 | −4.27 × 109 | −1.61 × 109 |

| Ozone depletion | kg CFC-11 eq | −1.25 × 103 | −6.62 × 102 | −1.52 × 103 | −1.26 × 103 | −7.57 × 102 |

| Human toxicity | kg 1.4-DB eq | −1.64 × 109 | −1.60 × 109 | −2.00 × 109 | −1.40 × 109 | −1.10 × 109 |

| Photochemical oxidant formation | kg NMVOC | −2.22 × 107 | −1.58 × 107 | −2.57 × 107 | −2.21 × 107 | −1.54 × 107 |

| Particulate matter formation | kg PM10 eq | 1.45 × 108 | 9.57 × 107 | 1.97 × 108 | 1.49 × 108 | 1.02 × 108 |

| Ionizing radiation | kg U235 eq | −5.89 × 109 | −2.16 × 109 | −9.11 × 109 | −6.22 × 109 | −1.32 × 109 |

| Terrestrial acidification | kg SO2 eq | −2.35 × 107 | −1.47 × 107 | −3.74 × 107 | −3.31 × 107 | −1.55 × 107 |

| Freshwater eutrophication | kg P eq | 3.74 × 106 | 4.32 × 106 | 3.84 × 106 | 2.63 × 106 | 4.18 × 106 |

| Marine eutrophication | kg N eq | −4.10 × 105 | −6.61 × 104 | −4.61 × 105 | −5.15 × 105 | −9.28 × 104 |

| Terrestrial ecotoxicity | kg 1.4-DB eq | −5.90 × 106 | −6.01 × 106 | −4.72 × 106 | −2.01 × 105 | −2.52 × 106 |

| Freshwater ecotoxicity | kg 1.4-DB eq | 1.42 × 108 | 1.56 × 108 | 1.62 × 108 | 1.16 × 108 | 1.63 × 108 |

| Marine ecotoxicity | kg 1.4-DB eq | 1.09 × 108 | 1.25 × 108 | 1.23 × 108 | 8.54 × 107 | 1.30 × 108 |

| Agricultural land occupation | m2a | −9.54 × 109 | −7.12 × 109 | −1.22 × 1010 | −8.25 × 109 | −5.77 × 109 |

| Urban land occupation | m2a | −1.84 × 108 | −1.29 × 108 | −2.45 × 108 | −1.82 × 108 | −1.16 × 108 |

| Natural land transformation | m2 | −3.60 × 106 | −2.15 × 106 | −3.87 × 106 | −3.61 × 106 | −2.66 × 106 |

| Water depletion | m3 | −8.52 × 107 | −4.35 × 107 | −1.18 × 108 | −9.09 × 107 | −4.13 × 107 |

| Metal depletion | kg Fe eq | −7.64 × 109 | −4.70 × 109 | −7.9 × 109 | −7.39 × 109 | −5.74 × 109 |

| Fossil depletion | kg oil eq | −1.89 × 109 | −8.74 × 108 | −2.57 × 109 | −2.34 × 109 | −1.12 × 109 |

| Impact Category | Unit | Reference Scenario | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

|---|---|---|---|---|---|---|

| Nonrenewable: fossil | MJ eq. | −8.13 × 1010 | −3.71 × 1010 | −1.12 × 1011 | −1.02 × 1011 | −8.28 × 1010 |

| Non-renewable: nuclear | MJ eq. | −6.25 × 1010 | −2.33 × 1010 | −9.63 × 1010 | −6.60 × 1010 | −1.90 × 1010 |

| Renewable: biomass | MJ eq. | −1.02 × 1011 | −9.61 × 1010 | −1.04 × 1011 | −6.51 × 1010 | −7.71 × 1010 |

| Renewable: wind, solar, geothermal | MJ eq. | −1.51 × 109 | −3.42 × 109 | −2.17 × 109 | −1.08 × 109 | −4.86 × 109 |

| Renewable: water | MJ eq. | −2.07 × 1010 | −1.47 × 1010 | −2.85 × 1010 | −2.20× 1010 | −2.18 × 1010 |

| Total energy | MJ eq | −2.68 × 1011 | −1.75 × 1011 | −3.43 × 1011 | −2.56 × 1011 | −2.06 × 1011 |

References

- State Environment Policy Act (SEPA). Från Avfallshantering till Resurshushållning. Sveriges Avfallsplan 2012–2017; Naturvårdsverket: Stockholm, Sweden, 2012. (In Svenska)

- European Commission (EC). Closing the Loop—An EU Action Plan for the Circular Economy; Com/2015/0614 Final; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Ekvall, T.; Hirschnitz-Garbers, M.; Eboli, F.; Śniegocki, A. A systemic and systematic approach to the development of a policy mix for material resource efficiency. Sustainability 2016, 8, 373. [Google Scholar] [CrossRef]

- Finnveden, G.; Bisaillon, M.; Noring, M.; Stenmarck, Å.; Sundberg, J.; Sundqvist, J.-O.; Tyskeng, S. Developing and evaluating new policy instruments for sustainable waste management. Int. J. Environ. Sustain. Dev. 2012, 11, 19–31. [Google Scholar] [CrossRef]

- Watkins, E.; ten Brink, P.; Schweitzer, J.-P.; Rogissart, L.; Nesbit, M. Policy mixes to achieve absolute decoupling: An ex ante assessment. Sustainability 2016, 8, 528. [Google Scholar] [CrossRef]

- Münster, M.; Finnveden, G.; Wenzel, H. Future waste treatment and energy systems-examples of joint scenarios. Waste Manag. 2013, 33, 2457–2464. [Google Scholar] [CrossRef] [PubMed]

- Börjeson, L.; Höjer, M.; Dreborg, K.-H.; Ekvall, T.; Finnveden, G. Scenario types and techniques: Towards a user’s guide. Futures 2006, 38, 723–739. [Google Scholar] [CrossRef]

- Höjer, M.; Ahlroth, S.; Dreborg, K.-H.; Ekvall, T.; Finnveden, G.; Hjelm, O.; Hochschorner, E.; Nilsson, M.; Palm, V. Scenarios in selected tools for environmental systems analysis. J. Clean. Prod. 2008, 16, 1958–1970. [Google Scholar] [CrossRef]

- International Organisation for Standardization (ISO). ISO 14040 international standard. In Environmental Management—Life Cycle Assessment—Principles and Framework; International Organisation for Standardization: Geneva, Switzerland, 2006; Volume SFS-EN ISO 14040. [Google Scholar]

- Björklund, A.; Finnveden, G.; Roth, L. Application of LCA to waste management. In Solid Waste Technology and Management; Christensen, T.H., Ed.; Wiley: Chichester, UK, 2011; Volume 1, pp. 137–160. [Google Scholar]

- Lazarevic, D.; Buclet, N.; Brandt, N. The application of life cycle thinking in the context of European waste policy. J. Clean. Prod. 2012, 29, 199–207. [Google Scholar] [CrossRef]

- Gentil, E.C.; Damgaard, A.; Hauschild, M.; Finnveden, G.; Eriksson, O.; Thorneloe, S.; Kaplan, P.O.; Barlaz, M.; Muller, O.; Matsui, Y. Models for waste life cycle assessment: Review of technical assumptions. Waste Manag. 2010, 30, 2636–2648. [Google Scholar] [CrossRef] [PubMed]

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Life cycle assessment of thermal waste-to-energy technologies: Review and recommendations. Waste Manag. 2015, 37, 104–115. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schott, A.B.S.; Wenzel, H.; la Cour Jansen, J. Identification of decisive factors for greenhouse gas emissions in comparative life cycle assessments of food waste management—An analytical review. J. Clean. Prod. 2016, 119, 13–24. [Google Scholar] [CrossRef]

- Björklund, A.; Finnveden, G. Recycling revisited—Life cycle comparisons of global warming impact and total energy use of waste management strategies. Resour. Conserv. Recycl. 2005, 44, 309–317. [Google Scholar] [CrossRef]

- Laurent, A.; Bakas, I.; Clavreul, J.; Bernstad, A.; Niero, M.; Gentil, E.; Hauschild, M.Z.; Christensen, T.H. Review of lca studies of solid waste management systems–part i: Lessons learned and perspectives. Waste Manag. 2014, 34, 573–588. [Google Scholar] [CrossRef] [PubMed]

- Laurent, A.; Clavreul, J.; Bernstad, A.; Bakas, I.; Niero, M.; Gentil, E.; Christensen, T.H.; Hauschild, M.Z. Review of lca studies of solid waste management systems–part ii: Methodological guidance for a better practice. Waste Manag. 2014, 34, 589–606. [Google Scholar] [CrossRef] [PubMed]

- Tyskeng, S.; Finnveden, G. Comparing energy use and environmental impacts of recycling and waste incineration. J. Environ. Eng. 2010, 136, 744–748. [Google Scholar] [CrossRef]

- Ljunggren Söderman, M.; Eriksson, O.; Björklund, A.; Östblom, G.; Ekvall, T.; Finnveden, G.; Arushanyan, Y.; Sundqvist, J.-O. Integrated economic and environmental assessment of waste policy instruments. Sustainability 2016, 8, 411. [Google Scholar] [CrossRef]

- Dreborg, K.H.; Tyskeng, S. Framtida Förutsättningar för en Hållbar Avfallshantering: Övergripande Omvärldsscenarier Samt Referensscenario; Miljöstrategisk Analys-fms, Kungliga Tekniska Högskolan: Stockholm, Sweden, 2008. [Google Scholar]

- Östblom, G.; Söderman, M.L.; Sjöström, M. Analysing Future Solid Waste Generation-Soft Linking a Model of Waste Management with a CGE-Model for Sweden; National Institute of Economic Research: Stockholm, Sweden, 2010. [Google Scholar]

- Östblom, G.; Berg, C. The EMEC Model: Version 2.0; National Institute of Economic Research: Stockholm, Sweden, 2006. [Google Scholar]

- Sjöström, M.; Östblom, G. Future Waste Scenarios for Sweden Based on a CGE-Model; National Institute of Economic Research: Stockholm, Sweden, 2009. [Google Scholar]

- Ljunggren, M. Modelling national solid waste management. Waste Manag. Res. 2000, 18, 525–537. [Google Scholar] [CrossRef]

- Ljunggren Söderman, M. Ekonomisk Analys av nya Styrmedel för Hanteringen av Svenskt Avfall; Report C229; IVL Swedish Environmental Research Institute: Göteborg, Sweden, 2017. [Google Scholar]

- Finnveden, G.; Ekvall, T.; Arushanyan, Y.; Bisaillon, M.; Henriksson, G.; Gunnarsson Östling, U.; Söderman, M.; Sahlin, J.; Stenmarck, Å.; Sundberg, J.; et al. Policy instruments towards a sustainable waste management. Sustainability 2013, 5, 841–881. [Google Scholar] [CrossRef]

- Eriksson, O.; Frostell, B.; Björklund, A.; Assefa, G.; Sundqvist, J.-O.; Granath, J.; Carlsson, M.; Baky, A.; Thyselius, L. Orware—A simulation tool for waste management. Resour. Conserv. Recycl. 2002, 36, 287–307. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Clift, R.; Doig, A.; Finnveden, G. The application of life cycle assessment to integrated solid waste management: Part 1—methodology. Process Saf. Environ. Prot. 2000, 78, 279–287. [Google Scholar] [CrossRef]

- PRé. About Simapro. Available online: https://simapro.com/about/ (accessed on 11 February 2017).

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; De Schryver, A.; Struijs, J.; van Zelm, R. Recipe 2008. In A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; Ruimte en Milieu: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Althaus, H.-J.; Hischier, R.; Doka, G.; Bauer, C.; Dones, R.; Nemecek, T.; Hellweg, S.; Humbert, S.; Margni, M.; Koellner, T.; et al. Implementation of Life Cycle Impact Assessment Methods; Data v20 (2007), No 3 (INIS-CH--10091); EcoInvent Center: Dübendorf, Switzerland, 2007. [Google Scholar]

- Finnveden, G.; Håkansson, C.; Noring, M. A new set of valuation factors for LCA and LCC based on damage costs: Ecovalue 2012. In Proceedings of the 6th International Conference on Life Cycle Management in Gothenburg, Gothenburg, Sweden, 25–28 August 2013; pp. 197–200.

- Ahlroth, S.; Finnveden, G. Ecovalue08—A new valuation set for environmental systems analysis tools. J. Clean. Prod. 2011, 19, 1994–2003. [Google Scholar] [CrossRef]

- Björklund, A.E.; Finnveden, G. Life cycle assessment of a national policy proposal—The case of a Swedish waste incineration tax. Waste Manag. 2007, 27, 1046–1058. [Google Scholar] [CrossRef] [PubMed]

- Finnveden, G.; Johansson, J.; Lind, P.; Moberg, Å. Life cycle assessment of energy from solid waste—Part 1: General methodology and results. J. Clean. Prod. 2005, 13, 213–229. [Google Scholar] [CrossRef]

- Eriksson, O.; Bisaillon, M.; Haraldsson, M.; Sundberg, J. Integrated waste management as a mean to promote renewable energy. Renew. Energy 2014, 61, 38–42. [Google Scholar] [CrossRef]

- Eriksson, O.; Reich, M.C.; Frostell, B.; Björklund, A.; Assefa, G.; Sundqvist, J.-O.; Granath, J.; Baky, A.; Thyselius, L. Municipal solid waste management from a systems perspective. J. Clean. Prod. 2005, 13, 241–252. [Google Scholar] [CrossRef]

- Bisaillon, M.; Sundberg, J.; Haraldsson, M.; Eriksson, O. Systemstudie Avfall i Göteborg; Technical Report, Project Report WR 21; SP Sveriges Tekniska Forskningsinstitut: Boras, Sweden, 2010. [Google Scholar]

- CPM LCA Database. LCI Dataset “Waste Treatment—Incineration in Heat Only Boiler Plant (SWEA HOB)”. Available online: http://cpmdatabase.cpm.chalmers.se/ (accessed on 11 February 2017).

- CPM LCA Database. LCI Dataset “Waste Treatment—Incineration for Heat in Cement Kiln (SWEA CKN)”. Available online: http://cpmdatabase.cpm.chalmers.se/ (accessed on 11 February 2017).

- CPM LCA Database. LCI Dataset “Waste Treatment—Incineration in Combined Heat and Power Plant (SWEA CHP)”. Available online: http://cpmdatabase.cpm.chalmers.se/ (accessed on 11 February 2017).

- CPM LCA Database. LCI Dataset “Waste Treatment—Landfill (SWEA LFL)”. Available online: http://cpmdatabase.cpm.chalmers.se/ (accessed on 11 February 2017).

- CPM LCA Database. LCI Dataset “Waste Treatment—Reactor Composting (SWEA CPR)”. Available online: http://cpmdatabase.cpm.chalmers.se/ (accessed on 11 February 2017).

- CPM LCA Database. LCI Dataset “Waste Treatment—Windrow Composting (SWEA CPW)”. Available online: http://cpmdatabase.cpm.chalmers.se/ (accessed on 11 February 2017).

- Larsen, A.W.; Vrogd, M.; Christensen, T. Diesel consumption in waste collection and transport and its environmental significance. Waste Manag. Res. 2009, 27, 738–745. [Google Scholar] [CrossRef] [PubMed]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Hischier, R.; Hellweg, S.; Nemecek, T.; Rebitzer, G.; Spielman, M. Overview and Methodology; Final Report Ecoinvent Data v 2.0, No. 1; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Tillman, A.-M. Significance of decision-making for lca methodology. Environ. Impact Assess. Rev. 2000, 20, 113–123. [Google Scholar] [CrossRef]

- Swedish Energy Agency. Långsiktsprognos 2008; Swedish Energy Agency: Stockholm, Sweden, 2009. [Google Scholar]

- Björklund, A. Life cycle assessment as an analytical tool in strategic environmental assessment. Lessons learned from a case study on municipal energy planning in Sweden. Environ. Impact Assess. Rev. 2012, 32, 82–87. [Google Scholar] [CrossRef]

- Herngren, E.; Morales, C.L. Fjärrvärmen 2030 (Heating 2030); Svensk Fjärrvärme AB (Swedish Heating): Stockholm, Sweden, 2013. [Google Scholar]

- Finnveden, G. On the limitations of life cycle assessment and environmental systems analysis tools in general. Int. J. Life Cycle Assess. 2000, 5, 229–238. [Google Scholar] [CrossRef]

- Alvarenga, R.A.; Lins, I.d.O.; Almeida Neto, J.A.d. Evaluation of abiotic resource LCIA methods. Resources 2016, 5, 13. [Google Scholar] [CrossRef]

- Finnveden, G.; Arushanyan, Y.; Brandão, M. Exergy as a measure of resource use in life cycle assessment and other sustainability assessment tools. Resources 2016, 5, 23. [Google Scholar] [CrossRef]

- Klinglmair, M.; Sala, S.; Brandão, M. Assessing resource depletion in LCA: A review of methods and methodological issues. Int. J. Life Cycle Assess. 2014, 19, 580–592. [Google Scholar] [CrossRef]

- Dahlén, L.; Lagerkvist, A. Pay as you throw: Strengths and weaknesses of weight-based billing in household waste collection systems in sweden. Waste Manag. 2010, 30, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Montevecchi, F. Policy mixes to achieve absolute decoupling: A case study of municipal waste management. Sustainability 2016, 8, 442. [Google Scholar] [CrossRef]

- Antosiewicz, M.; Lewandowski, P.; Witajewski-Baltvilks, J. Input vs. Output taxation—A DSGE approach to modelling resource decoupling. Sustainability 2016, 8, 352. [Google Scholar] [CrossRef]

- Bicket, M.; Vanner, R. Designing policy mixes for resource efficiency: The role of public acceptability. Sustainability 2016, 8, 366. [Google Scholar] [CrossRef]

- Eriksson, O.; Finnveden, G. Plastic waste as a fuel—CO2-neutral or not? Energy Environ. Sci. 2009, 2, 907–914. [Google Scholar] [CrossRef]

- Björklund, A. Environmental Systems Analysis Waste Management. Master’s Thesis, KTH, Stockholm, Sweden, 1998. [Google Scholar]

- AvfallSverige. Energy Report (Status 2006) Results of Specific Data for Energy, Efficiency Rates, Plant Efficiency Factors, ncv and Determination of the Main Energy Results of 20 Investigated Swedish w-t-e Plants; Report F2008:06; AvfallSverige (Waste Management Sweden): Malmö, Sweden, 2008. [Google Scholar]

- Rahmberg, M. Utvärdering och Modellering av Återvinningsprocesser i ORWARE. Master’s Thesis, Uppsala University, Uppsala, Sweden, 2001. [Google Scholar]

- Sundqvist, J.-O.; Baky, A.; Carlsson Reich, M.; Eriksson, O.; Granath, J. Hur Skall Hushållsavfallet tas om Hand? Utvärdering av Olika Behandlingsmetoder; Report B1462; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2002. [Google Scholar]

- Carlström, A. Kompostering av Organiskt Avfall Från Gästrikeregionen–Miljöpåverkan av Olika Behandlingsalternativ. Master’s Thesis, Uppsala University, Uppsala, Sweden, 2006. [Google Scholar]

- Baky, A.; Eriksson, O. Systems Analysis of Organic Waste Management in Denmark; Danish Ministry of the Environment, Danish Environmental Protection Agency: København, Denmark, 2003.

- Dalemo, M. Environmental Systems Analysis of Organic Waste Management: The Orware Model and the Sewage Plant and Anaerobic Digestion Submodels; Swedish University of Agricultural Sciences: Uppsala, Sweden, 1999. [Google Scholar]

- Hischier, R. Life Cycle Inventories of Packaging and Graphical Paper; Ecoinvent Report No 11; Swiss Centre for Life Cycle Inventories: Duebendorf, Switzerland, 2007. [Google Scholar]

- Tillman, A.-M.; Baumann, H.; Eriksson, E.; Rydberg, T. Life-Cycle Analyses of Selected Packaging Materials: Quantification of Environmental Loadings; Chalmers Industriteknik: Goteborg, Sweden, 1991. [Google Scholar]

- Nyström, E.; Svensk glasåtervinning AB, Hammar, Sweden. Personal communication, 2008.

- Finnveden, G.; KTH, Stockholm, Sweden. Personal communication, 2011.

- Forsgren, C.; Stenametall, Göteborg, Sweden. Personal communication, 2008.

- Pilz, H.; Schlager, R.; Ekvall, T.; Ljunggren Söderman, M.; Rydberg, T.; Roos, S. Strategies for Sensible Recovery of Domestic Plastic Packaging Waste in Sweden; GUA Gesellschaft für Umfassende Analysen GmbH and IVL Swedish Environmental Research Institute AB on Behalf of Plastkretsen AB: Stockholm, Sweden, 2006. [Google Scholar]

- Waste and Resources Action Programme (WRAP). Life Cycle Assessment of Plasterboard: Quantifying the Environmental Impacts Throughout the Product Life Cycle, Building the Evidence Base in Sustainable Construction; WRAP: Banbury, UK, 2007. [Google Scholar]

- Hallberg, L.; Strömberg, K.; Eriksson, E.; Rydberg, T. Comparative Life Cycle Assessment of the Utilization of Used Tires. On Behalf of Svensk Däckåtervinning; CIT Ekologik AB: Göteborg, Sweden, 2004. [Google Scholar]

- Sundqvist, J.-O.; IVL Swedish Environmental Research Institute, Stockholm, Sweden. Personal communication, 2008.

- Damgaard, A. Easewaste Database; DTU Environment: Kgs Lyngby, Denmark, 2008. [Google Scholar]

- Fredriksson, O.; Gryaab, Gothenburg, Sweden. Personal communication, 2008.

- Sundberg, J. SEA Database (sammansättning och egenskaper för avfall); Profu AB: Mölndal, Sweden, 2008. [Google Scholar]

- Jansson, Å. Riktlinjer för Slagganvändning. Available online: http://www.jernkontoret.se/sv/publicerat/forskning/oppna-rapporter-serie-d/d-781/ (accessed on 5 November 2014).

- Strömberg, B. Handbook of Fuels; Värmeforsk: Stockholm, Sweden, 2005. [Google Scholar]

| Sector | Waste Fraction | Reference Scenario | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

|---|---|---|---|---|---|---|

| Household | Recyclable | 1.83 | 1.13 | 2.95 | 2.01 | 0.86 |

| Bulky | 1.09 | 0.67 | 1.76 | 1.20 | 0.51 | |

| Food | 0.43 | 0.27 | 0.69 | 0.47 | 0.20 | |

| Garden/park | 0.53 | 0.33 | 0.85 | 0.58 | 0.25 | |

| Household mix | 3.84 | 2.38 | 6.23 | 4.23 | 1.82 | |

| Sewage sludge | 0.84 | 0.92 | 1.07 | 0.92 | 0.97 | |

| Industry | Bulky | 0.21 | 0.17 | 0.32 | 0.22 | 0.16 |

| Inert | 4.05 | 3.03 | 4.02 | 3.68 | 3.56 | |

| Animal waste (n.h.) | 0.02 | 0.01 | 0.01 | 0.02 | 0.01 | |

| Recyclable | 8.02 | 5.51 | 7.76 | 7.33 | 7.10 | |

| Combustible | 1.01 | 0.68 | 1.23 | 1.02 | 0.79 | |

| Non combustible | 0.25 | 0.17 | 0.31 | 0.25 | 0.20 | |

| Mix | 1.27 | 0.85 | 1.54 | 1.27 | 0.99 | |

| Non organic sludge | 0.13 | 0.13 | 0.19 | 0.14 | 0.13 | |

| Food | 0.60 | 0.38 | 0.52 | 0.55 | 0.48 | |

| Animal waste (h.) | 0.16 | 0.10 | 0.13 | 0.14 | 0.13 | |

| Park/garden | 0.02 | 0.01 | 0.02 | 0.02 | 0.01 | |

| Household mix | 0.71 | 0.61 | 1.17 | 0.77 | 0.56 | |

| Sewage sludge | 2.72 | 2.71 | 3.74 | 2.48 | 2.57 | |

| Total | 27.74 | 20.08 | 34.52 | 27.31 | 21.30 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arushanyan, Y.; Björklund, A.; Eriksson, O.; Finnveden, G.; Ljunggren Söderman, M.; Sundqvist, J.-O.; Stenmarck, Å. Environmental Assessment of Possible Future Waste Management Scenarios. Energies 2017, 10, 247. https://doi.org/10.3390/en10020247

Arushanyan Y, Björklund A, Eriksson O, Finnveden G, Ljunggren Söderman M, Sundqvist J-O, Stenmarck Å. Environmental Assessment of Possible Future Waste Management Scenarios. Energies. 2017; 10(2):247. https://doi.org/10.3390/en10020247

Chicago/Turabian StyleArushanyan, Yevgeniya, Anna Björklund, Ola Eriksson, Göran Finnveden, Maria Ljunggren Söderman, Jan-Olov Sundqvist, and Åsa Stenmarck. 2017. "Environmental Assessment of Possible Future Waste Management Scenarios" Energies 10, no. 2: 247. https://doi.org/10.3390/en10020247