1. Introduction

Driven by the increasing concern for environment pollution caused by traditional energy sources, electrical power generation based on renewable energy has rapidly developed during past years. As the rapidest developing renewable energy, the development of wind power generation has been impressive in recent years. According to the latest statistical data from Global Wind Energy Council [

1], the global cumulative capacity of wind power has reached 486.7 GW in 2016, with a newly added capacity of 54.6 GW in 2016. It is anticipated that, in the America of 2030, more than 20% energy production will be provided by wind energy [

2]. Meanwhile, Chinese government makes an energy plan [

3] that non-fossil energy will rise to 15% and 20% in the national total primary energy consumption by 2020 and 2030, respectively. It is obvious that wind energy has become an important portion of energy. To further enhance its competitiveness, it is urgent to reduce the cost of wind power generation through utilizing modern technologies.

To ensure high performance while minimizing costs, optimal solutions have been developed constantly [

4]. On the one side, wind turbines (WTs) have grown considerably in size over the last several years; on the other side, advanced control algorithms have been intensively studied, among which maximum power-point tracking (MPPT) method gains the most attention [

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28]. The MPPT algorithm that is used to bring the turbine to the MPP over a full wind speed range aims to maximize the efficiency of a wind turbine (WT).

In a recent study [

8], MPPT algorithms were categorized into direct power controllers (DPC) and indirect power controllers (IPC). The former directly maximizes the output electrical power, while the latter maximizes the captured mechanical wind power. The DPC, which mainly refers to hill climbing search (HCS) [

9], does not require WT knowledge and tracks the MPP by analyzing the power variation based on a pre-obtained system curve. However, it always takes a long time to converge. Moreover, its robust performance may not be guaranteed, for instance, when there is an oscillation around the MPP. Under the IPC, there are three types of MPPT algorithms: power signal feedback (PSF) [

10], optimal torque (OT) algorithm [

11] and the tip-speed ratio (TSR) algorithm [

12]. The TSR algorithm depends on precise wind speed information that is hardly obtained in conventional WTs. Therefore, as alternative methods, the PSF and OT algorithms were developed and commonly used in current commercial WTs.

Principles of the PSF and OT algorithms are essentially the same and only differ in their implementation [

13]: the former calculates the optimum power based on a generator speed–power table enquiry method, whereas the latter produces the optimum torque based on a conventional control unit. Since there are only several points predefined in a generator speed–power table, the PSF algorithm may be slightly inferior to the OT algorithm. However, the OT algorithm is not optimal for exploiting energy production of a large-scale WT with a large inertia. To enhance the MPPT performance, improved techniques have been proposed, such as adding a feed-forward term to assist in acceleration or deceleration [

14], adopting estimation control methods to determine the accurate gain parameter [

15,

16] or readjusting the torque gain to match wind speed characteristics [

17,

18]. Nevertheless, as an alternative method, the OT algorithm is internally less accurate than the direct TSR method [

8]. Therefore, to maximize power extraction, the direct TSR method is necessary to be investigated.

As the development of technology, there are now two possible TSR methods: one is to use wind information measured by an advanced sensing device, such as lidar [

19,

20,

21], whereas the other is to use the estimated wind speed [

22,

23,

24,

25,

26]. Compared to the one based on measurement devices, the estimated wind-based TSR method almost requires no additional cost and therefore receives intense attention in recent years. A typical estimated wind-based TSR method consists of two parts: an effective wind speed estimator that provides an optimal speed reference and a speed controller that tracks the speed reference. Various wind speed estimation and speed tracking algorithms have been proposed in previous studies. Nevertheless, the previous studies mainly focused on algorithm development and overlooked the impact of WT’s inertia and wind speed characteristics on obtained performance. In a study conducted by Tang et al. [

27], it was shown that the power production performance of WTs under the OT algorithm was affected by both the turbine parameters and the wind speed characteristics. The study was only validated by simulation results on a 400 W WT, but the obtained result has been useful for optimizing the torque gain of the OT algorithm [

17,

18,

28]. In this regard, an investigation on performance of the estimated wind-based TSR method under different wind speed characteristics would be helpful to understand the capability and limitation of the control method, thus potential optimization rules for MPPT method can be sorted out.

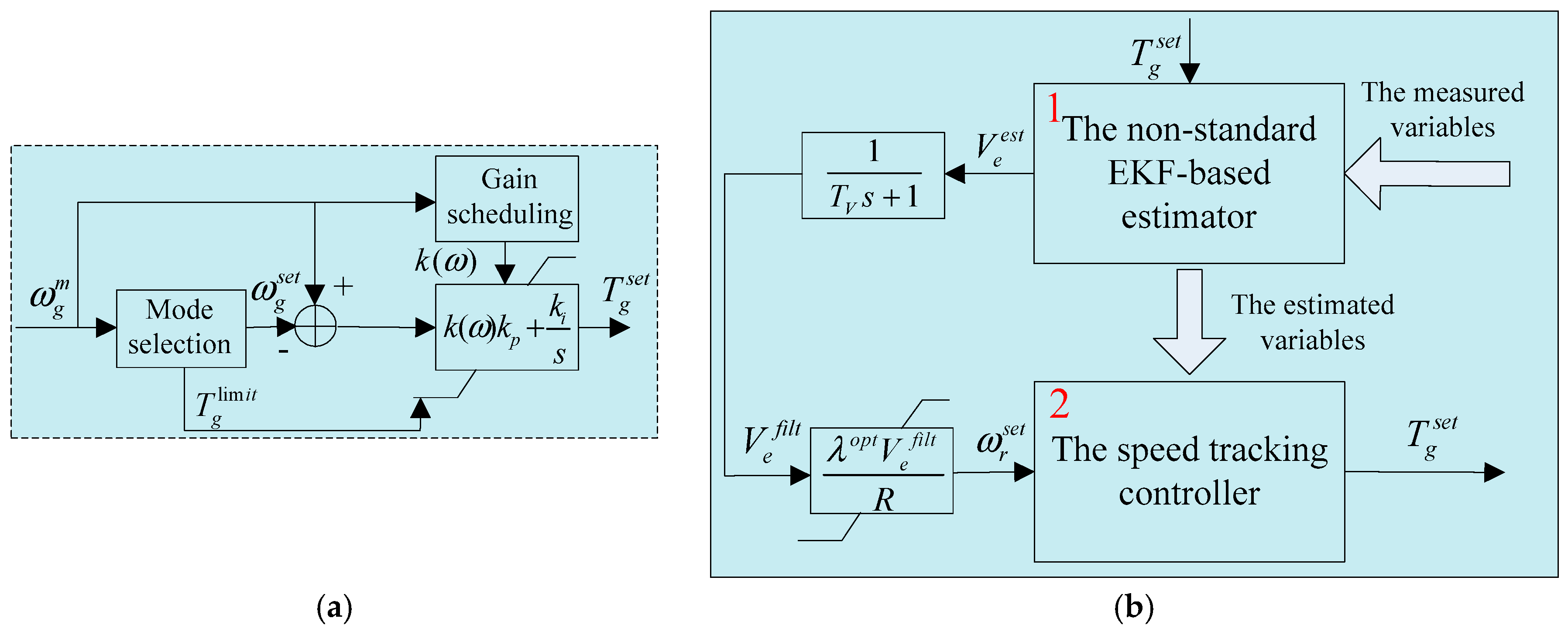

Motivated by the aforementioned observations, this paper carries out a comparison study on performance of an estimated wind-based TSR method and the OT method. The estimated wind-based TSR method tracks an optimal speed reference calculated by estimated variables from the non-standard extended Kalman filter (EKF) based wind estimation algorithm proposed in [

26], whereas the OT method adopts the standard PI-based one discussed in [

13]. Finally, the similarities and differences between the two methods under different wind speed characteristics are illustrated by some simulations. In addition, to provide a reliable result, a 1.5 MW variable speed WT manufactured by CMYWP (China Ming Yang Wind Power, Zhongshan, China) is used as the modeling subject and the industry-standard software for WT performance and load calculations, Garrad Hassan’s Bladed [

29,

30], is used to carry out simulations. Meanwhile, turbulent winds are employed to give different wind speed characteristics, thus the obtained results can be reliable and understandable.

The remainder of this work is organized as follows. The relevant WT and its modeling are introduced in

Section 2.

Section 3 describes the PI-based OT and the estimated wind-based TSR methods. This is followed by simulation tests and results discussions in

Section 4. Finally, conclusions are drawn in

Section 5.

4. Case Study

A comparison study between the PI-based OT method and the estimated wind-based TSR method is described in this section. In theory, the two MPPT methods are equivalent because they track the same optimal TSR. However, due to the large inertia of the WT, there exist differences between applying the OT method and the TSR method in terms of their dynamic performance. To illustrate these, five cases were investigated for the two methods. For each case, wind conditions were defined according to design load case 1.1 of IEC-standard [

35].

4.1. Simulation Settings

The two MPPT controllers were developed and tested on the concerned WT model using Bladed. Simulation tests were carried out through the predefined wind speeds. During the simulation tests, the two controllers were employed under same wind conditions.

4.1.1. Wind Speed Characteristics

Based on the normal turbulent model defined in [

35], wind speed characteristics was defined by the following equation:

where

is the turbulence standard deviation;

is the expected value of the turbulent intensity (TI) at 15 m/s;

is the hub height wind speed, and

b = 5.6 m/s; and

is the (TI).

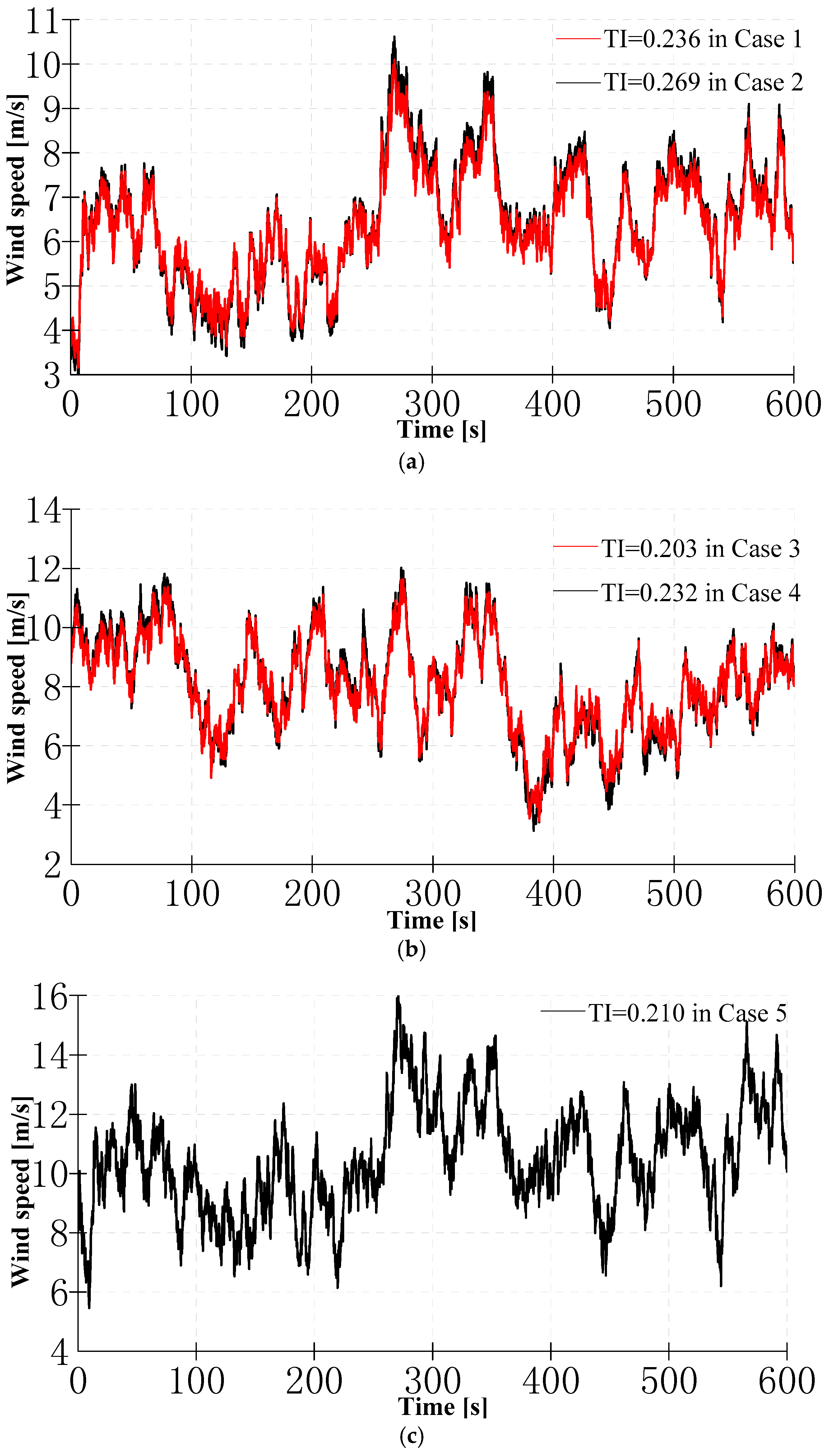

For the five simulation cases, the variables used in Equation (19) are summarized in

Table 3, and the wind speed curves are shown in

Figure 4.

4.1.2. Controller Parameters

For the OT controller, ; the PI gains are chosen by observation of the system response to step inputs: and ; and because the variation of the aerodynamic sensitivity is negligible.

For the TSR controller, the damping factor and crossover frequency are selected to guarantee qualified performance for a second-order system:

and

. The low pass filter time is set as

. For the wind speed estimator, the damping factor

is set to 1.2. The initial state covariance

, prediction covariance

, the process variance

and measurement covariance

are chosen as:

4.2. Simulation Results

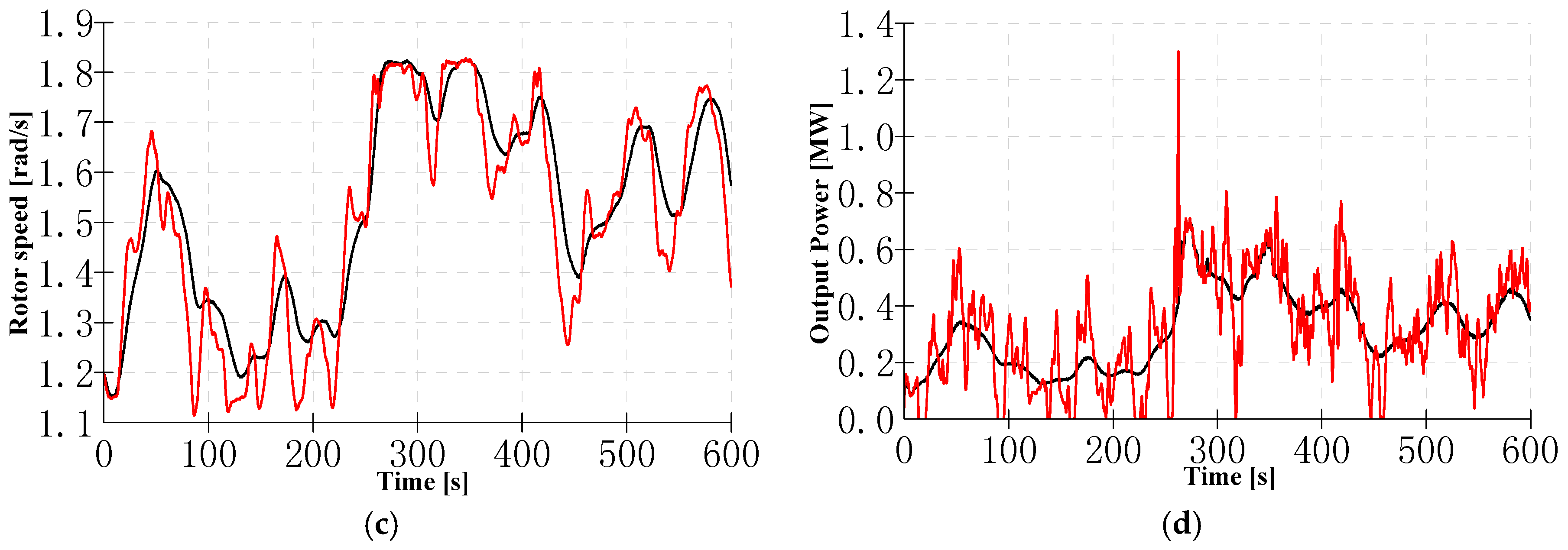

Since power production and component loads are determined by the WT operation, the rotor speed, output power, and the estimated TSR that are relevant to WT operation were measured. Meanwhile, the estimated wind speeds were also presented to check the effectiveness of the estimator. To clearly show the performance differences between the two controllers, their simulation results were together presented, where black curves and red curves are the OT controller and the TSR controller, respectively.

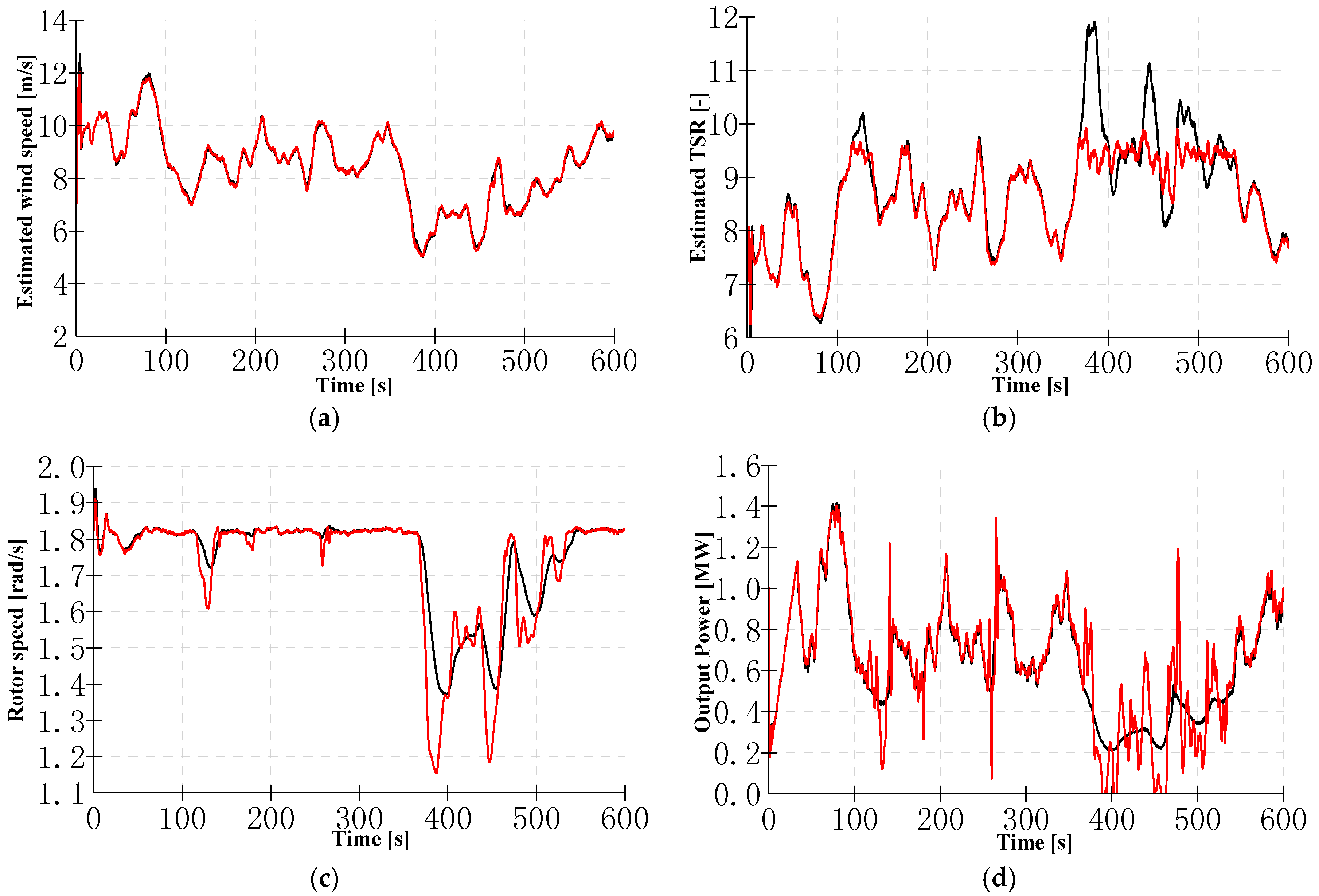

The simulation results for Cases 1 and 2 with mean wind speeds of 6 m/s and different TIs are shown in

Figure 5 and

Figure 6, respectively. It can be seen that, in these two cases, except the estimated winds, other three variables presented obvious differences between two controllers. The high similarities among the real wind speeds shown in

Figure 4a and the estimated wind speeds shown in

Figure 5a and

Figure 6a justified the effectiveness of the developed estimator. The differences among curves of rotor speed, the estimated TSR and output power are summarized as follows:

Following the variation of wind speed, the estimated TSR by the OT controller presented obvious fluctuations. By comparison, the estimated TSR by the TSR controller was maintained around the optimal value of 9.5.

The rotor speed by the TSR controller followed the variation of wind speed, whereas the rotor speed by the OT controller gave a loose follow. Meanwhile, it can be found that the rotor speeds lagged behind the wind speeds.

The output power by the OT controller was smooth, while the one by the other controller showed intensive variations.

When compared the results between

Figure 5 and

Figure 6, all curves presented high similarities, and there was only a slight difference that the curves of estimated TSR, rotor speed, and output power in

Figure 6 presented slight bigger variations than the ones in

Figure 5. Such a difference was induced by the increased TI.

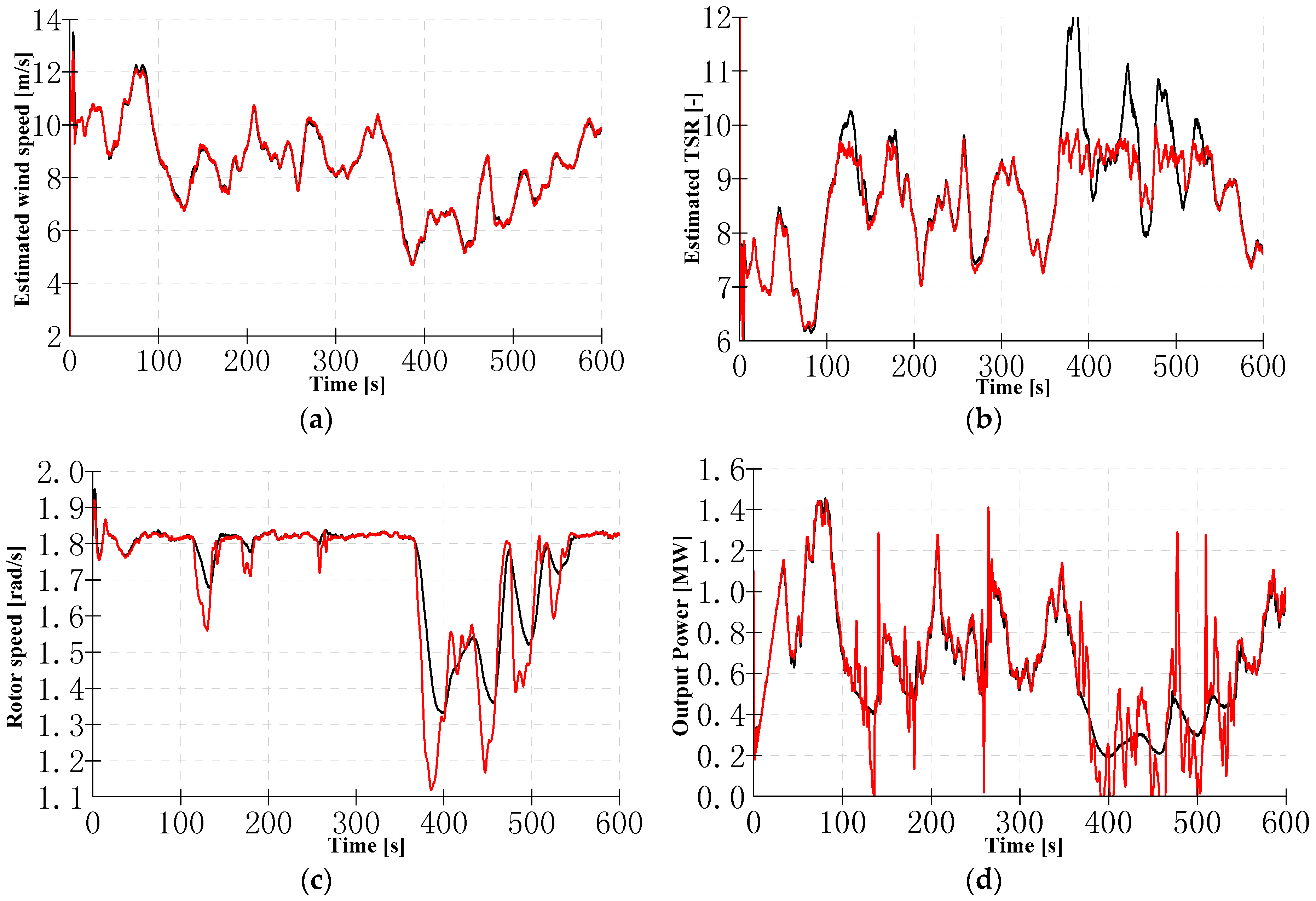

The simulation results for Cases 3 and 4 with mean wind speeds of 8 m/s and different TIs are shown in

Figure 7 and

Figure 8, respectively. From results in these two cases, similar trends as the ones in Cases 1 and 2 can be found: the rotor speed and output power by the TSR controller varied intensively, while the ones by the OT controller gave smooth results. Comparing to the results in

Figure 5 and

Figure 6, there was less difference between the estimated TSRs of two controllers. The reason is that the rotor speed reached the rated value of 1.824 rad/s when wind speeds increased up to a certain value. Under this circumstance, the two controllers were used to maintain the rated speed rather than tracking the optimal TSR.

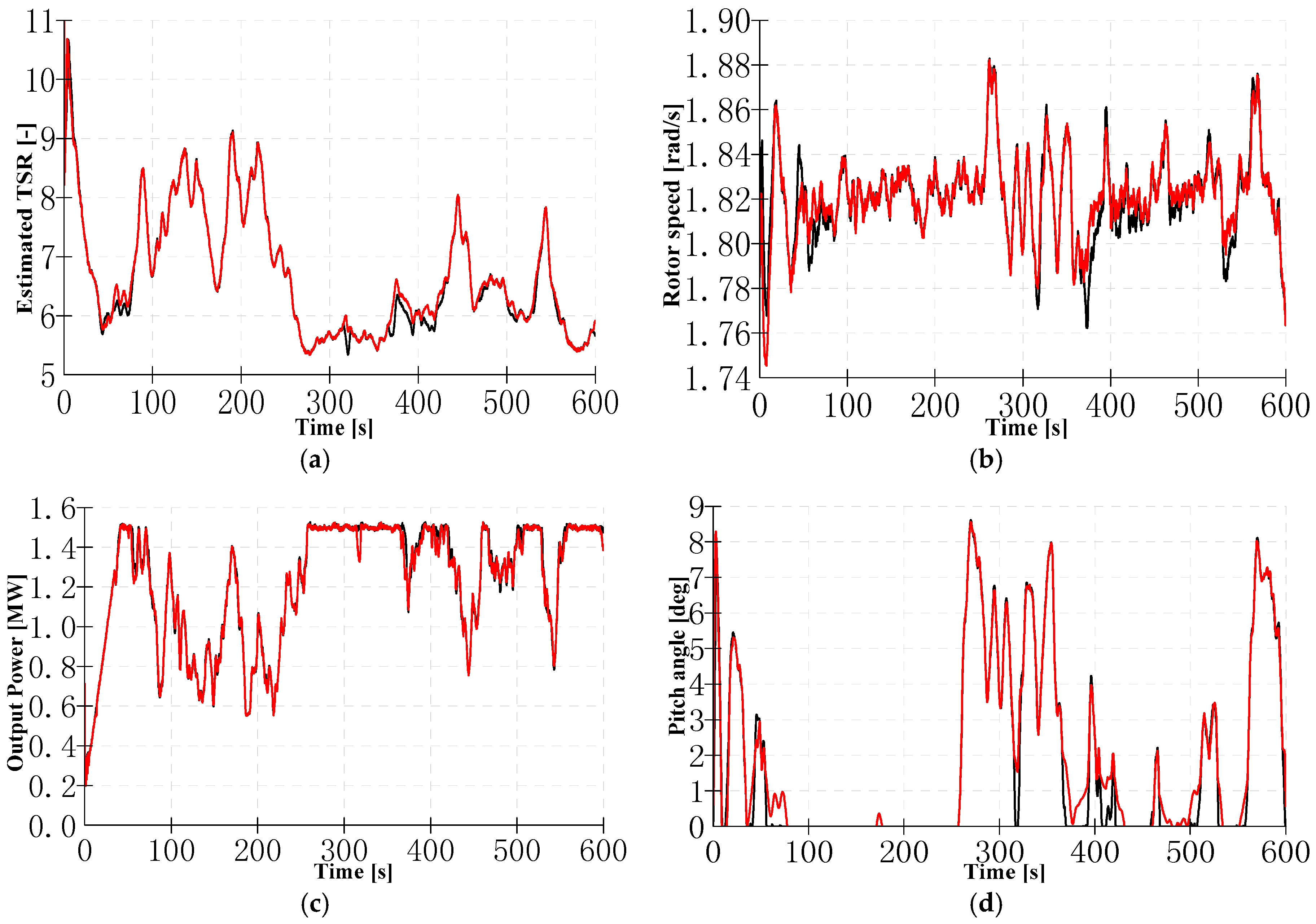

The simulation results for Case 5 with mean wind speed of 10 m/s and TI of 0.210 are shown in

Figure 9. From results in this case, different trends from the ones in Cases 1–4 are found: the curves of estimated TSR, rotor speed and output power under two controllers were similar to each other. The reason is that both of the TSR and OT controllers controlled the rotor speeds around the rated value when wind speed was close to the rated wind speed of 10.8 m/s, whereas the pitch controllers were activated to maintain the rotor speed at the rated value when the wind speed was higher than its rated value. Nevertheless, there were still small differences for results of the two controllers: during the time range of 380–500 s, the rotor speed by the TSR controller was well held around the rated value and gave less variation than the one by the OT controller. Accordingly, the pitch controller operated in parallel with the TSR controller gave less pitch action than the one with the OT controller. Therefore, it can be concluded that through cooperating with the pitch controller, both of the two controllers offered a successful transition between partial and full load operation. Meanwhile, the TSR controller gave a slightly smoother transition than its counterpart.

From above observations, it can be known that the TSR controller outperformed the OT controller in terms of optimal TSR tracking, but the payback was noticeable variations of rotor speed and output power. Meanwhile, their performance was affected by the wind characteristics. Consequently, these two controllers may have different performance in terms of power production and load performance, which will be discussed in the next section.

4.3. Peformance Comparisons Based on Statistical Data

4.3.1. Power Production Comparisons

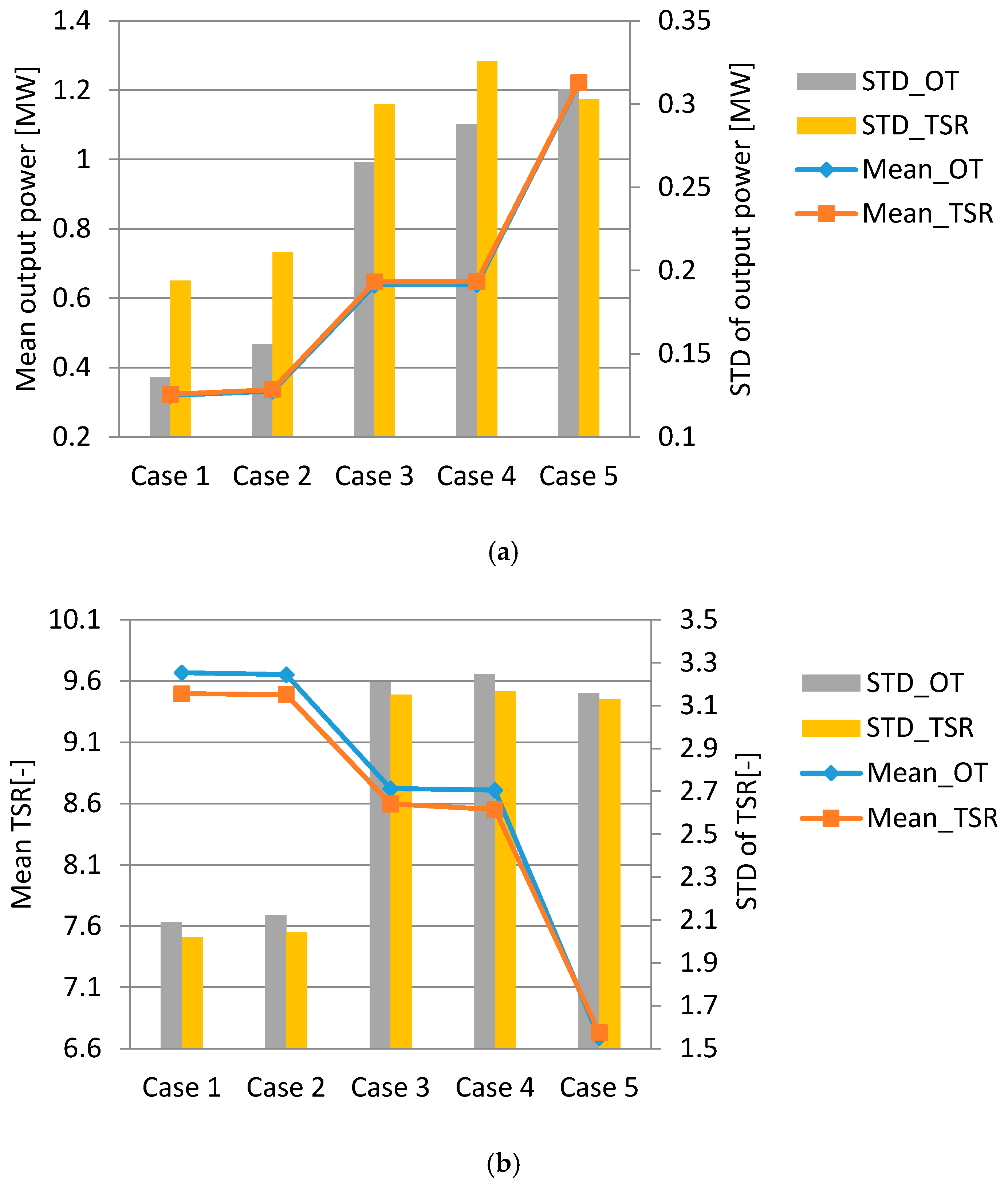

To evaluate the power production performance of the two controllers, the averaged value and the standard deviation of the output power and the TSR were calculated and compared.

Figure 10a,b shows results of the output power and the TSR for the two controllers under different wind speed characteristics, respectively. The results in

Figure 10a reveal the fact that both the mean value and standard deviation of the output power under the two controllers were gradually increased from Case 1 to Case 4, which means that the two controllers produced more power when the mean value or the TI of wind speed increased. At Case 5, the two controllers produced nearly same output power. To further clarify the feature of the two controllers under different wind speed characteristics, the power reduction

were calculated and illustrated in

Table 4. The power reduction was calculated by:

where

is the theoretical maximum

with a value of 0.483.

In

Table 4, it can be obviously seen that power reduction was reduced when the TI was increased for two controllers. Among Cases 3–5, there were significant power reductions that were caused by the fact that rotor speeds were maintained at rated value rather than optimal speed.

In

Figure 10a, it can be also seen that the output power obtained by the TSR controller was more than the one by the OT controller. In comparison to the results of the OT controller, the TSR controller increased output power about 0.96%, 1.2%, 1.4%, 1.1% and 0.1% for Cases 1, 2, 3, 4 and 5, respectively. The reason can be found from the results in

Figure 10b, which is that the TSR controller had a better optimal TSR tracking capability in comparison with the OT controller. Nevertheless, the payback of the increased energy capture was a significant increment of output power variation, which will bring about high component loads that are presented in the following section. By comparison to the results of the OT controller, the TSR controller increased power variation about 42.7%, 35.5%, 13.3%, 13.2% and −1.9% for the five cases, respectively.

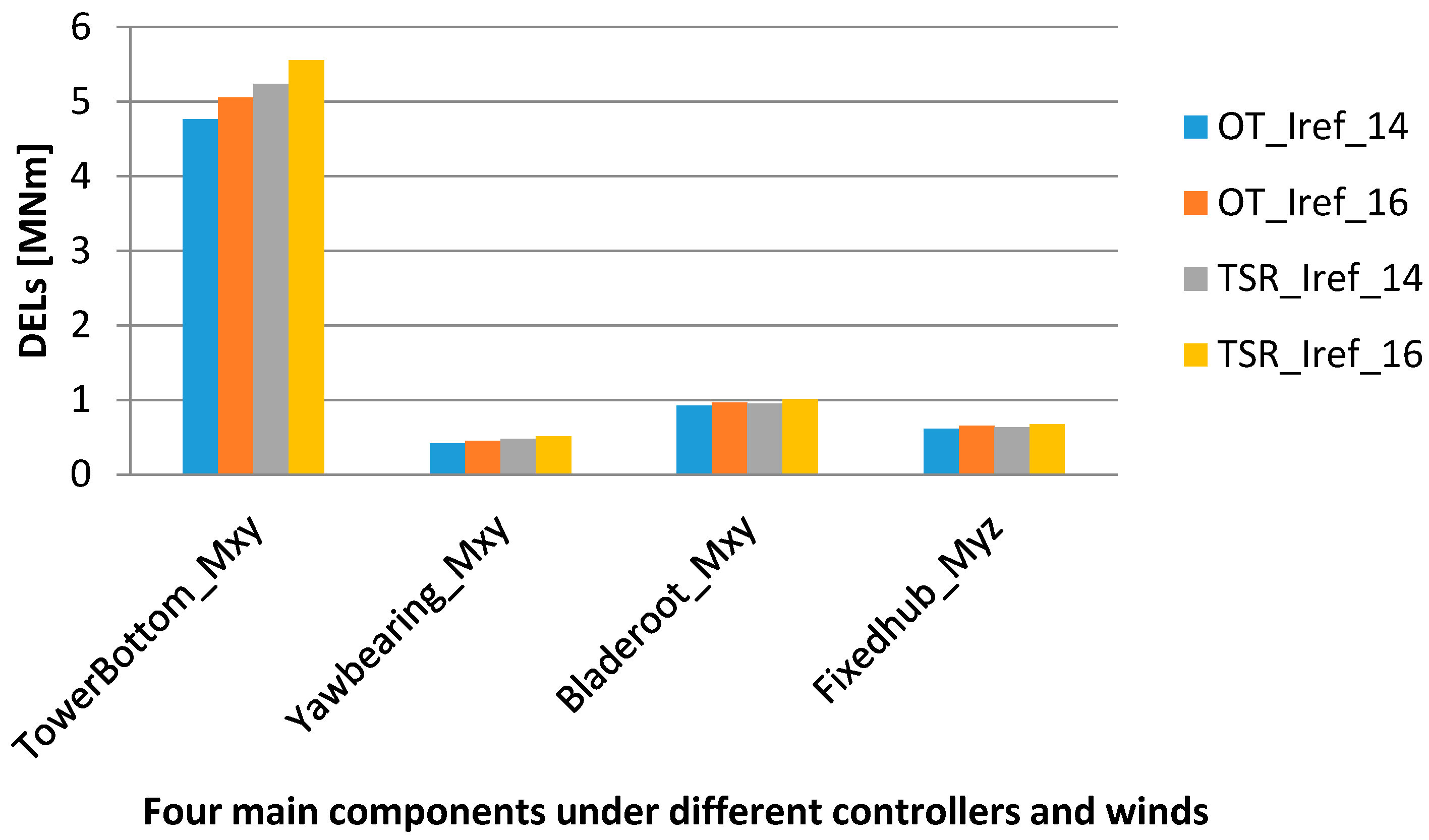

4.3.2. Component Loads Comparisons

To evaluate load performance of the WT under the two controllers, we further carried out other simulations at below rated winds considering two wind conditions defined in Equation (19):

and

. Based on simulation results of these simulation cases, damage equivalent loads (DELs) were calculated based on the assumption that the WT lifetime is 20 years and the press cycle time is 1.0 × 10

8. By using a Wohler exponent of 4 for steel, the DELs of four main components (including tower bottom, yaw bearing, fixed hub and blade root) were computed. According to the coordinate systems defined in Bladed, component loads can be calculated in three directions. In this paper, only the dominative DELs were provided to show for the sake of simplicity. For tower bottom, yaw bearing, and blade root, their DELs of Mxy were used, whereas, for the hub, the DEL of Myz was used. Their results are shown in

Figure 11.

The results in

Figure 11 show a similar trend that all component loads under two controllers were increased in a degree when the TI of wind speed increases. For the TSR controller, comparing to the results at TI of

, the DELs at TI of

were increased about 6.2%, 9.2%, 4.5% and 6.5% for tower bottom Mxy, yaw bearing Mxy, blade root Mxy and fixed hub Myz, respectively, while for the OT controller, comparing to the results at TI of

, the DELs at TI of

were increased about 6.1%, 9.2%, 6.2% and 5.9% for the same four components, respectively.

Meanwhile, it can be obviously seen that the component loads by the TSR controller were larger than the ones by the OT controller under same TIs. At TI of , by comparison to the results of the OT controller, DELs of the TSR controller were increased about 9.9%, 14.4%, 2.6% and 3.2% for tower bottom, yaw bearing, blade root and fixed hub, respectively. At TI of , by comparison to the results of the OT controller, DELs of the TSR controller were increased about 9.8%, 12.6%, 4.2% and 2.6% for the four components, respectively. The comparison results well fitted the fact that bigger variation of output power was caused by the TSR controller than its counterpart.

4.4. Result Discussions

It appears that over a wide range of the wind speed, the TSR controller outperformed the OT controller in terms of power production performance, but it had a power variation that induced large loads for WT’s components. Comparing results for dominative loads of four main components illustrated that the TSR controller gave a payback of load increments for its power production enhancement. Since fatigue loads and energy production performance are two indexes for evaluating a control algorithm, it can be seen that, for a large WT, the two MPPT controllers have different advantages.

Meanwhile, it is obvious that both controllers suffered from power reduction and power variation to a degree that is relevant to the mean value and TI of the wind speed: the power reduction is increased by the increased TI, whereas the power variation is increased by both the increased TI and the increased mean wind speed. The power reduction reason was revealed by the fact that the rotor speeds lagged behind the wind speeds and the TSR presented variations around the optimal value. Comparing to the OT method, the TSR method offers a fast response. However, both methods have the limitation that it is infeasible to further optimize wind energy capture performance for a large WT. To tackle this problem, a feasible way may be to apply wind speed prediction technology in a more advanced controller.

5. Conclusions

MPPT algorithm is indispensable for enhancing energy capture performance of WTs. It is important to understand capability of the MPPT control method before applying it. Meanwhile, it is also necessary to investigate the limitation of the existing MPPT control methods before researching new methods. In this paper, we compared two MPPT control methods: the OT method is the standard MPPT method, whereas the TSR method is the one under study. Most of the previous works have considered only the algorithm design, regardless of the fact that the control performance may be affected by the inertia of a large WT and the wind speed characteristics. We carried out simulations to investigate the performance of the two control methods in the presences of different wind speed characteristics.

To clearly show the investigation results, we provided different simulation results under five cases: Cases 1 and 2 were with a wind speed of mean value 6 m/s; Cases 3 and 4 were with a wind speed of mean value 8 m/s; and Case 5 was with a wind speed of mean value 10 m/s. Meanwhile, different turbulence intensities were used for each case. From the comparison results of the two controllers under different winds, we demonstrate that the TSR method outperforms the OT method in terms of power production, whereas the OT method is preferable in terms of component fatigue loads. The results can be used as a reference by wind turbine designers to determine the control algorithm depending on their preference, whether to maximize power output or optimize component loads. Besides, we find out that the two methods suffer from power reduction that is caused by a delayed response due to a large inertia. The delayed response issue is the main burden of further optimizing wind energy capture performance for a large WT, thus a feasible way may be to address advanced control methods that can take advantage of wind speed prediction information. Furthermore, it is worthy noting that when the parameters of a WT are unknown or uncertain, an adaptive method will be required to track the real MPP.